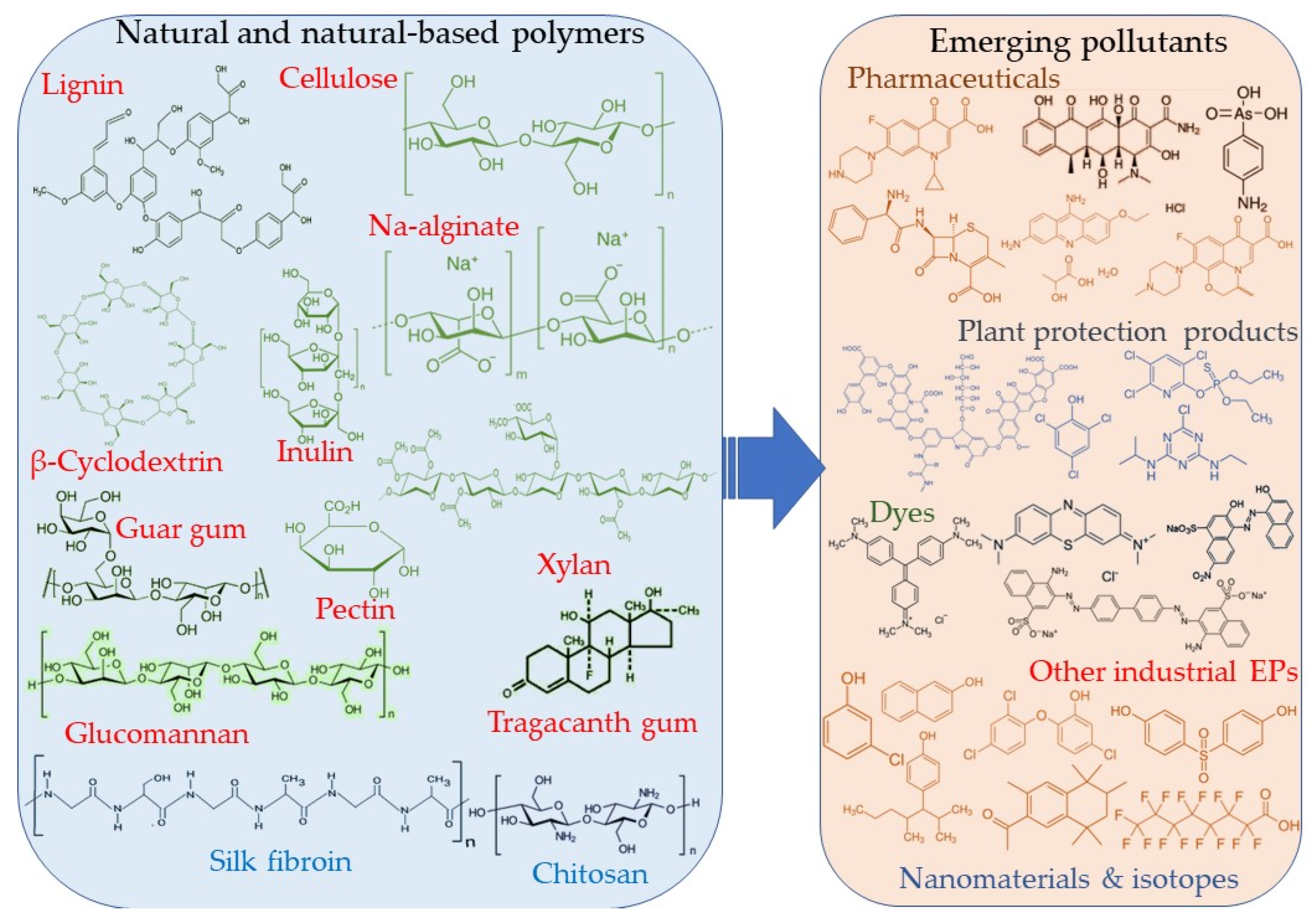

Natural and Natural-Based Polymers: Recent Developments in Management of Emerging Pollutants

Abstract

:1. Introduction

2. Emerging Pollutants—A New Threat to the Environment with Natural Solutions?

3. Methodology

- -

- Research articles published from 2012 to the present, full text;

- -

- Articles published or available in English;

- -

- Removal of emerging pollutants—for the automatic screening, only the term “pollutant” was used;

- -

- Evaluation of natural polymers’ application in the management of emerging pollutants (as defined in Section 2)—manual screening;

- -

- Relevance to the review topic (new information provided).

- -

- Articles published before 2012;

- -

- Book chapters or book;

- -

- Review or systematic review articles;

- -

- Conference papers, notes, letters, short surveys, errata or conference reviews;

- -

- Articles published in languages other than English;

- -

- Articles presenting the removal of pollutants monitored in routine studies (such as commonly encountered heavy metals).

4. Results

5. Natural Polymers for the Management of Emerging Pollutants

5.1. Management of Pharmaceuticals Using Natural Polymers

5.2. Management of Plant Protection Product Pollutants Using Natural Polymers

5.3. Management of Industrial Dyes and Dye Models Using Natural Polymers

5.4. Management of Other Types of Industrial Emerging Pollutants Using Natural Polymers

5.5. Management of Other Hazardous Emerging Pollutants Using Natural Polymers

6. Concluding Remarks and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Bolisetty, S.; Peydayesh, M.; Mezzenga, R. Sustainable technologies for water purification from heavy metals: Review and analysis. Chem. Soc. Rev. 2019, 48, 463–487. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, R.K.; Shetti, N.P.; Reddy, K.R.; Nadagouda, M.N.; Badawi, M.; Bonilla-Petriciolet, A.; Aminabhavi, T.M. Valorization of biowastes for clean energy production, environmental depollution and soil fertility. J. Environ. Manag. 2023, 332, 117410. [Google Scholar] [CrossRef] [PubMed]

- Subash, A.; Naebe, M.; Wang, X.; Kandasubramanian, B. Biopolymer—A sustainable and efficacious material system for effluent removal. J. Hazard. Mater. 2023, 443, 130168. [Google Scholar] [CrossRef] [PubMed]

- Pandi, K.; Prabhu, S.M.; Ahn, Y.; Park, C.M.; Choi, J. Design and synthesis of biopolymer-derived porous graphitic carbon covered iron-organic frameworks for depollution of arsenic from waters. Chemosphere 2020, 254, 126769. [Google Scholar] [CrossRef] [PubMed]

- Köse, K.; Mavlan, M.; Youngblood, J.P. Applications and impact of nanocellulose based adsorbents. Cellulose 2020, 27, 2967–2990. [Google Scholar] [CrossRef]

- Mallakpour, S.; Naghadi, M. Design and identification of poly(vinyl chloride)/layered double hydroxide@MnO2 nanocomposite films and evaluation of the methyl orange uptake: Linear and non-linear isotherm and kinetic adsorption models. New J. Chem. 2020, 44, 6510–6523. [Google Scholar] [CrossRef]

- Dai, K.; Liu, G.; Xu, W.; Deng, Z.; Wu, Y.; Zhao, C.; Zhang, Z. Judicious fabrication of bifunctionalized graphene oxide/MnFe2O4 magnetic nanohybrids for enhanced removal of Pb(II) from water. J. Colloid Interface Sci. 2020, 579, 815–822. [Google Scholar] [CrossRef] [PubMed]

- Morin-Crini, N.; Lichtfouse, E.; Fourmentin, M.; Ribeiro, A.R.L.; Noutsopoulos, C.; Mapelli, F.; Fenyvesi, É.; Vieira, M.G.A.; Picos-Corrales, L.A.; Moreno-Piraján, J.C.; et al. Remediation of emerging contaminants. In Environmental Chemistry for a Sustainable World; Emerging Contaminants; Morin-Crini, N., Lichtfouse, E., Crini, G., Eds.; Springer International Publishing: Cham, Switzerland, 2021; Volume 2, pp. 1–106. [Google Scholar]

- Rahaman, H.; Islam, A.; Islam, M.; Rahman, A.; Nur Alam, S.M. Biodegradable composite adsorbent of modified cellulose and chitosan to remove heavy metal ions from aqueous solution. Curr. Res. Green Sustain. Chem. 2021, 4, 100119. [Google Scholar] [CrossRef]

- Mudhoo, A.; Sharma, G.; Mohan, D.; Pittman, C.U., Jr.; Sillanpää, M. Can ‘biodegradability’ of adsorbents constitute an ‘Achilles’ heel’ in real-world water purification? Perspectives and opportunities. J. Environ. Chem. Eng. 2022, 10, 107321. [Google Scholar] [CrossRef]

- Udayakumar, G.P.; Muthusamy, S.; Selvaganesh, B.; Sivarajasekar, N.; Rambabu, K.; Sivamani, S.; Sivakumar, N.; Maran, J.P.; Hosseini-Bandegharaei, A. Ecofriendly biopolymers and composites: Preparation and their applications in water-treatment. Biotechnol. Adv. 2021, 52, 107815. [Google Scholar] [CrossRef]

- Deyris, P.A.; Pelissier, F.; Grison, C.M.; Hesemann, P.; Petit, E.; Grison, C. Efficient removal of persistent and emerging organic pollutants by biosorption using abundant biomass wastes. Chemosphere 2023, 313, 137307. [Google Scholar] [CrossRef] [PubMed]

- Joseph, L.; Jun, B.M.; Flora, J.R.V.; Park, C.M.; Yoon, Y. Removal of heavy metals from water sources in the developing world using low-cost materials: A review. Chemosphere 2019, 229, 142–159. [Google Scholar] [CrossRef]

- Liu, D.; Gu, W.; Zhou, L.; Wang, L.; Zhang, J.; Liu, Y.; Lei, J. Recent advances in MOF-derived carbon-based nanomaterials for environmental applications in adsorption and catalytic degradation. Chem. Eng. J. 2022, 427, 131503. [Google Scholar] [CrossRef]

- Geissen, V.; Mol, H.; Klumpp, E.; Umlauf, G.; Nadal, M.; van der Ploeg, M.; van de Zee, S.E.A.T.M.; Ritsema, C.J. Emerging pollutants in the environment: A challenge for water resource management. Int. Soil Water Conserv. Res. 2015, 3, 57–65. [Google Scholar] [CrossRef]

- NORMAN Network. Available online: https://www.norman-network.com/nds/susdat/susdatSearchShow.php# (accessed on 21 March 2023).

- Deblonde, T.; Cossu-Leguille, C.; Hartemann, P. Emerging pollutants in wastewater: A review of the literature. Int. J. Hyg. Environ. Health 2011, 214, 442–448. [Google Scholar] [CrossRef] [PubMed]

- Gavrilescu, M.; Demnerová, K.; Aamand, J.; Agathos, S.; Fava, F. Emerging pollutants in the environment: Present and future challenges in biomonitoring, ecological risks and bioremediation. New Biotechnol. 2015, 25, 147–156. [Google Scholar] [CrossRef]

- Tang, Y.; Yin, M.; Yang, W.; Li, H.; Zhong, Y.; Mo, L.; Liang, Y.; Ma, X.; Sun, X. Emerging pollutants in water environment: Occurrence, monitoring, fate, and risk assessment. Water Environ. Res. 2019, 91, 984–991. [Google Scholar] [CrossRef] [Green Version]

- Peña-Guzmán, C.; Ulloa-Sánchez, S.; Mora, K.; Helena-Bustos, R.; Lopez-Barrera, E.; Alvarez, J.; Rodriguez-Pinzón, M. Emerging pollutants in the urban water cycle in Latin America: A review of the current literature. J. Environ. Manag. 2019, 237, 408–423. [Google Scholar] [CrossRef]

- Arman, N.Z.; Salmiati, S.; Aris, A.; Salim, M.R.; Nazifa, T.H.; Muhamad, M.S.; Marpongahtun, M. A Review on Emerging Pollutants in the Water Environment: Existences, Health Effects and Treatment Processes. Water 2021, 13, 3258. [Google Scholar] [CrossRef]

- Krishnakumar, S.; Singh, D.S.H.; Godson, P.S.; Thanga, S.G. Emerging pollutants: Impact on environment, management, and challenges. Environ. Sci. Pollut. Res. 2022, 29, 72309–72311. [Google Scholar] [CrossRef]

- Dalu, T.; Tavengwa, N. Emerging Freshwater Pollutants. Analysis, Fate and Regulations; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–6. [Google Scholar]

- Desidery, L.; Lanotte, M. Polymers and plastics: Types, properties, and manufacturing. In Plastic Waste for Sustainable Asphalt Roads; Giustozzi, F., Nizamuddin, S., Eds.; Woodhead Publishing: Cambridge, MS, USA, 2022; pp. 3–28. [Google Scholar]

- Doppalapudi, S.; Katiyar, S.; Domb, A.J.; Khan, W. Biodegradable natural polymers. In Advanced Polymers in Medicine; Puoci, F., Ed.; Springer Cham: Cham, Switzerland, 2015; pp. 33–66. [Google Scholar]

- Guidance for Monomers and Polymers. Available online: Echa.europa.eu/guidance-documents/guidance-on-reach (accessed on 29 March 2023).

- Ravve, A. Naturally Occurring Polymers. Principles of Polymer Chemistry; Springer: New York, NY, USA, 2000; pp. 449–475. [Google Scholar]

- Olatunji, O. Classification of Natural Polymers. In Natural Polymers; Olatunji, O., Ed.; Springer: Cham, Switzerland, 2016; pp. 1–17. [Google Scholar]

- Manaila-Maximean, D.; Danila, O.; Almeida, P.L.; Ganea, C.P. Electrical properties of a liquid crystal dispersed in an electrospun cellulose acetate network. Beilstein J. Nanotechnol. 2018, 9, 155–163. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manaila-Maximean, D.; Danila, O.; Ganea, C.P.; Almeida, P.L. Filling in the voids of electrospun hydroxypropyl cellulose network: Dielectric investigations. Europ. Phys. J. Plus 2018, 133, 159. [Google Scholar] [CrossRef]

- Rosu, C.; Manaila-Maximean, D.; Kundu, S.; Almeida, P.L.; Danila, O. Perspectives on the electrically induced properties of electrospun cellulose/liquid crystal devices. J. Electrostat. 2011, 69, 623–630. [Google Scholar] [CrossRef]

- Dumitriu, S. Polysaccharides: Structural Diversity and Functional Versatility, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Ogawa, K.; Yui, T. X-Ray Diffraction Study of Polysaccharides; Marcel Dekker: New York, NY, USA, 1998; pp. 101–130. [Google Scholar]

- Talebi, N.; Lopes, D.; Lopes, J.; Macário-Soares, A.; Dan, A.K.; Ghanbari, R.; Kahkesh, K.H.; Peixoto, D.; Giram, P.S.; Raza, F.; et al. Natural polymeric nanofibers in transdermal drug delivery. Appl. Mater. Today 2023, 30, 101726. [Google Scholar] [CrossRef]

- Jiménez-Gómez, C.P.; Cecilia, J.A. Chitosan: A Natural Biopolymer with a Wide and Varied Range of Applications. Molecules 2020, 25, 3981. [Google Scholar] [CrossRef]

- Lee, M.; Chen, B.-Y.; Den, W. Chitosan as a Natural Polymer for Heterogeneous Catalysts Support: A Short Review on Its Applications. Appl. Sci. 2015, 5, 1272–1283. [Google Scholar] [CrossRef] [Green Version]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The Prisma 2020 statement: An updated guideline for reporting systematic reviews. PLoS Med. 2021, 18, e1003583. [Google Scholar] [CrossRef]

- Paut Kusturica, M.; Jevtic, M.; Ristovski, J.T. Minimizing the environmental impact of unused pharmaceuticals: Review focused on prevention. Front. Environ. Sci. 2022, 10, 1077974. [Google Scholar] [CrossRef]

- Nippes, R.P.; Macruz, P.D.; da Silva, G.N.; Neves Olsen Scaliante, M.H. A critical review on environmental presence of pharmaceutical drugs tested for the COVID-19 treatment. Process Saf. Environ. Prot. 2021, 152, 568–582. [Google Scholar] [CrossRef]

- Global Chemicals Outlook II, from Legacies to Innovative Solutions: Implementing the 2030 Agenda for Sustainable Development—Synthesis Report. Copyright © United Nations Environment Programme. 2019. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/27651/GCOII_synth.pdf?sequence=1&isAllowed=y (accessed on 10 March 2023).

- Balachandramohan, J.; Sivasankar, T. Ultrasound assisted synthesis of guar gum-zero valent iron nanocomposites as a novel catalyst for the treatment of pollutants. Carbohydr. Polym. 2018, 199, 41–50. [Google Scholar] [CrossRef]

- Kong, Y.; Wang, L.; Ge, Y.; Su, H.; Li, Z. Lignin xanthate resin–bentonite clay composite as a highly effective and low-cost adsorbent for the removal of doxycycline hydrochloride antibiotic and mercury ions in water. J. Hazard. Mater. 2019, 368, 33–41. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Chen, L.; Liu, S.; Hu, L.; Zhang, J.; Wang, A.; Yu, X.; Yan, Z. Insights into the interfacial interaction mechanisms of p-arsanilic acid adsorption on ionic liquid modified porous cellulose. J. Environ. Chem. Eng. 2021, 9, 105225. [Google Scholar] [CrossRef]

- Rusu, L.; Grigoraș, C.-G.; Simion, A.-I.; Suceveanu, E.M.; Șuteu, D.; Harja, M. Application of Saccharomyces cerevisiae/Calcium Alginate Composite Beads for Cephalexin Antibiotic Biosorption from Aqueous Solutions. Materials 2021, 14, 4728. [Google Scholar] [CrossRef]

- Shokri, M.; Mojtabavi, S.; Jafari-Nodoushan, H.; Vojdanitalab, K.; Golshani, S.; Jahandar, H.; Faramarzi, M.A. Laccase-loaded magnetic dialdehyde inulin nanoparticles as an efficient heterogeneous natural polymer-based biocatalyst for removal and detoxification of ofloxacin. Biodegradation 2022, 33, 489–508. [Google Scholar] [CrossRef] [PubMed]

- Şahin, M.; Arslan, Y.; Tomul, F. Removal of naproxen and diclofenac using magnetic nanoparticles/nanocomposites. Res. Chem. Intermed. 2022, 48, 5209–5226. [Google Scholar] [CrossRef]

- Rusu, L.; Grigoraș, C.-G.; Simion, A.-I.; Suceveanu, E.-M.; Blaga, A.-C.; Harja, M. Encapsulation of Saccharomyces pastorianus Residual Biomass in Calcium Alginate Matrix with Insights in Ethacridine Lactate Biosorption. Polymers 2022, 14, 170. [Google Scholar] [CrossRef] [PubMed]

- Rusu, L.; Grigoraș, C.-G.; Simion, A.-I.; Suceveanu, E.-M.; Dediu Botezatu, A.V.; Harja, M. Biosorptive Removal of Ethacridine Lactate from Aqueous Solutions by Saccharomyces pastorianus Residual Biomass/Calcium Alginate Composite Beads: Fixed-Bed Column Study. Materials 2022, 15, 4657. [Google Scholar] [CrossRef]

- Tang, F.H.M.; Lenzen, M.; McBratney, A.; Maggi, F. Risk of pesticide pollution at the global scale. Nat. Geosci. 2021, 14, 206–210. [Google Scholar] [CrossRef]

- Mie, A.; Rudén, C. What you don’t know can still hurt you-underreporting in EU pesticide regulation. Environ. Health 2022, 21, 79. [Google Scholar] [CrossRef]

- du Jardin, P. Plant biostimulants: Definition, concept, main categories and regulation. Sci. Hortic. 2015, 196, 3–14. [Google Scholar] [CrossRef] [Green Version]

- European Parliament. Regulation (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 Laying down Rules on the Making Available on the Market of EU Fertilising Products and Amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and Repealing Regulation (EC) No 2003/2003. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02019R1009-20230316 (accessed on 21 March 2023).

- Sehaqui, H.; de Larraya, U.P.; Tingaut, P.; Zimmermann, T. Humic acid adsorption onto cationic cellulose nanofibers for bioinspired removal of copper(II) and a positively charged dye. Soft Matter 2015, 11, 5294–5300. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Zhou, S. Removal of humic acid from aqueous solution using polyacrylamide/chitosan semi-IPN hydrogel. Water Sci. Technol. 2018, 2017, 16–26. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Kim, S.B.; Lee, S.H.; Choi, J.W. Laboratory and pilot-scale field experiments for application of iron oxide nanoparticle-loaded chitosan composites to phosphate removal from natural water. Environ. Technol. 2018, 39, 770–779. [Google Scholar] [CrossRef]

- Hossain, M.E.; Ritt, C.L.; Almeelbi, T.B.; Bezbaruah, A.N. Biopolymer Beads for Aqueous Phosphate Removal: Possible Applications in Eutrophic Lakes. J. Environ. Eng. 2018, 144, 04018030. [Google Scholar] [CrossRef]

- Hu, X.; Xu, G.; Zhang, H.; Li, M.; Tu, Y.; Xie, X.; Zhu, Y.; Jiang, L.; Zhu, X.; Ji, X.; et al. Multifunctional β-Cyclodextrin Polymer for Simultaneous Removal of Natural Organic Matter and Organic Micropollutants and Detrimental Microorganisms from Water. ACS Appl. Mater. Interfaces 2020, 12, 12165–12175. [Google Scholar] [CrossRef]

- Attallah, O.A.; Wafa, M.M.A.; Al-Ghobashy, M.A.; Nebsen, M.; Monir, H.H. Adsorptive removal of pesticides from aqueous solutions using chitosan/gelatin polymeric composite: Process monitoring and optimization. Int. J. Environ. Sci. Technol. 2022, 19, 8183–8194. [Google Scholar] [CrossRef]

- Merlo, F.; Profumo, A.; Fontàs, C.; Anticó, E. Preparation of new polymeric phases for thin-film liquid phase microextraction (TF-LPME) of selected organic pollutants. Microchem. J. 2022, 175, 107120. [Google Scholar] [CrossRef]

- Sun, L.; Xu, G.; Tu, Y.; Zhang, W.; Hu, X.; Yang, P.; Wu, D.; Liang, Y.; Wei, D.; Li, A.; et al. Multifunctional porous β-cyclodextrin polymer for water purification. Water Res. 2022, 222, 118917. [Google Scholar] [CrossRef]

- Lellis, B.; Fávaro-Polonio, C.Z.; Pamphile, J.A.; Polonio, J.C. Effects of textile dyes on health and the environment and bioremediation potential of living organisms. Biotechnol. Res. Innov. 2019, 3, 275–290. [Google Scholar] [CrossRef]

- Khan, S.; Naushad, M.; Govarthanan, M.; Iqbal, J.; Alfadul, S.M. Emerging contaminants of high concern for the environment: Current trends and future research. Environ. Res. 2022, 207, 112609. [Google Scholar] [CrossRef]

- Singh, J.; Gupta, P.; Das, A. Dyes from Textile Industry Wastewater as Emerging Contaminants in Agricultural Fields. In Sustainable Agriculture Reviews 50; Kumar Singh, V., Singh, R., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2021; Volume 50, pp. 109–129. [Google Scholar]

- Khan, I.; Saeed, K.; Zekker, I.; Zhang, B.; Hendi, A.H.; Ahmad, A.; Ahmad, S.; Zada, N.; Ahmad, H.; Shah, L.A.; et al. Review on Methylene Blue: Its Properties, Uses, Toxicity and Photodegradation. Water 2022, 14, 242. [Google Scholar] [CrossRef]

- Geetha, D.; Kavitha, S.; Ramesh, P.S. A novel bio-degradable polymer stabilized Ag/TiO2 nanocomposites and their catalytic activity on reduction of methylene blue under natural sun light. Ecotoxicol. Environ. Saf. 2015, 121, 126–134. [Google Scholar] [CrossRef]

- Sun, X.F.; Liu, B.; Jing, Z.; Wang, H. Preparation and adsorption property of xylan/poly(acrylic acid) magnetic nanocomposite hydrogel adsorbent. Carbohydr. Polym. 2015, 118, 16–23. [Google Scholar] [CrossRef]

- Li, M.; Wang, Z.; Li, B. Adsorption behaviour of congo red by cellulose/chitosan hydrogel beads regenerated from ionic liquid. Desalin. Water Treat. 2016, 57, 16970–16980. [Google Scholar] [CrossRef]

- Ling, S.; Jin, K.; Kaplan, D.L.; Buehler, M.J. Ultrathin Free-Standing Bombyx mori Silk Nanofibril Membranes. Nano Lett. 2016, 16, 3795–3800. [Google Scholar] [CrossRef]

- Sultana, S.; Ahmad, N.; Faisal, S.M.; Owais, M.; Sabir, S. Synthesis, characterisation and potential applications of polyaniline/chitosan-Ag-nanobiocomposite. IET Nanobiotechnol. 2017, 11, 835–842. [Google Scholar] [CrossRef]

- Cui, G.; Wang, X.; Xun, J.; Lou, T. Microwave assisted synthesis and characterization of a ternary flocculant from chitosan, acrylamide and lignin. Int. Biodeter. Biodegrad. 2017, 123, 269–275. [Google Scholar] [CrossRef]

- Huang, W.; Hu, Y.; Li, Y.; Zhou, Y.; Niu, D.; Lei, Z.; Zhang, Z. Citric acid-crosslinked β-cyclodextrin for simultaneous removal of bisphenol A, methylene blue and copper: The roles of cavity and surface functional groups. J. Taiwan Inst. Chem. Eng. 2018, 82, 189–197. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Peresin, M.S.; Tamminen, T.; Rodríguez, A.; Larrañeta, E.; Jääskeläinen, A.S. Lignin-based hydrogels with “super-swelling” capacities for dye removal. Int. J. Biol. Macromol. 2018, 115, 1249–1259. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, L.L.; Jiang, L.N.; Wang, S.Y.; Sun, M.M.; Li, D.Q.; Du, G.M. Pectin microgel particles as high adsorption rate material for methylene blue: Performance, equilibrium, kinetic, mechanism and regeneration studies. Int. J. Biol. Macromol. 2018, 112, 383–389. [Google Scholar] [CrossRef] [PubMed]

- El-Aassar, M.R.; Fakhry, H.; Elzain, A.A.; Farouk, H.; Hafez, E.E. Rhizofiltration system consists of chitosan and natural Arundo donax L. for removal of basic red dye. Int. J. Biol. Macromol. 2018, 120, 1508–1514. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Shi, P.; Zhang, J.; Li, Y.; Duan, T.; Dai, L.; Wang, L.; Yu, X.; Zhu, W. Natural polymer konjac glucomannan mediated assembly of graphene oxide as versatile sponges for water pollution control. Carbohydr. Polym. 2018, 202, 425–433. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, S.K.; Hegazy, S.H.; Abdelwahab, N.A.; Ramadan, A.M. Coupled adsorption-photocatalytic degradation of crystal violet under sunlight using chemically synthesized grafted sodium alginate/ZnO/graphene oxide composite. Int. J. Biol. Macromol. 2018, 108, 1185–1198. [Google Scholar] [CrossRef] [PubMed]

- Mallakpour, S.; Tabesh, F. Tragacanth gum based hydrogel nanocomposites for the adsorption of methylene blue: Comparison of linear and non-linear forms of different adsorption isotherm and kinetics models. Int. J. Biol. Macromol. 2019, 133, 754–766. [Google Scholar] [CrossRef] [PubMed]

- Lou, T.; Yan, X.; Wang, X. Chitosan coated polyacrylonitrile nanofibrous mat for dye adsorption. Int. J. Biol. Macromol. 2019, 135, 919–925. [Google Scholar] [CrossRef]

- Ernawati, L.; Wahyuono, R.A.; Halim, A.; Noorain, R.; Widiyastuti, W.; Dewi, R.T.; Enomae, T. Hierarchically 3-D Porous Structure of Silk Fibroin-Based Biocomposite Adsorbent for Water Pollutant Removal. Environments 2021, 8, 127. [Google Scholar] [CrossRef]

- Hong, G.-B.; Yu, T.-J.; Lee, H.-C.; Ma, C.-M. Using Rice Bran Hydrogel Beads to Remove Dye from Aqueous Solutions. Sustainability 2021, 13, 5640. [Google Scholar] [CrossRef]

- Mallakpour, S.; Azadi, E.; Dinari, M. Novel mesoporous cupric oxide-based biomaterial: An efficient nanocatalyst toward catalytic reduction of emerging contaminants in the wastewater. J. Clean. Prod. 2022, 378, 134527. [Google Scholar] [CrossRef]

- El Sayed, A.A.; Ali, M.M.S.; Helal, A.A. Synthesis of chitosan hydrogel polymer for removal of radioactive organic research waste prior to treatment. Int. J. Environ. Analyt. Chem. 2023, 103, 454–468. [Google Scholar] [CrossRef]

- Ma, S.; Shi, W.; Li, H.; Zhang, Y. Biomimetic mineralization of nacre-inspired multiple crosslinked PVA/CaAlg/SiO2 membrane with simultaneously enhanced mechanical and separation properties. Int. J. Biol. Macromol. 2023, 234, 123650. [Google Scholar] [CrossRef]

- Alshahrani, A.A.; Alorabi, A.Q.; Hassan, M.S.; Amna, T.; Azizi, M. Chitosan-Functionalized Hydroxyapatite-Cerium Oxide Heterostructure: An Efficient Adsorbent for Dyes Removal and Antimicrobial Agent. Nanomaterials 2022, 12, 2713. [Google Scholar] [CrossRef]

- Robati, D. Pseudo-second-order kinetic equations for modeling adsorption systems for removal of lead ions using multi-walled carbon nanotube. J. Nanostructure Chem. 2013, 3, 55. [Google Scholar] [CrossRef] [Green Version]

- Paneysar, J.S.; Barton, S.; Chandra, S.; Ambre, P.; Coutinho, E. Novel thermoresponsive assemblies of co-grafted natural and synthetic polymers for water purification. Water Sci. Technol. 2017, 75, 1084–1097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Z.; Ren, K.; Guibal, E.; Jia, S.; Shen, J.; Zhang, X.; Yang, W. Removal of trace nonylphenol from water in the coexistence of suspended inorganic particles and NOMs by using a cellulose-based flocculant. Chemosphere 2016, 161, 482–490. [Google Scholar] [CrossRef]

- Xiao, L.; Ling, Y.; Alsbaiee, A.; Li, C.; Helbling, D.E.; Dichtel, W.R. β-Cyclodextrin Polymer Network Sequesters Perfluorooctanoic Acid at Environmentally Relevant Concentrations. J. Am. Chem. Soc. 2017, 139, 7689–7692, correction to J. Am. Chem. Soc. 2017, 139, 10585. [Google Scholar] [CrossRef] [Green Version]

- Ge, L.; Zhang, M.; Wang, R.; Li, N.; Zhang, L.; Liu, S.; Jiao, T. Fabrication of CS/GA/RGO/Pd composite hydrogels for highly efficient catalytic reduction of organic pollutants. RSC Adv. 2020, 10, 15091–15097. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Xue, P.; Jia, F.; Qiu, D.; Shi, K.; Zhang, W. Tailoring polymeric composite gel beads-encapsulated microorganism for efficient degradation of phenolic compounds. Chinese J. Chem. Eng. 2021, 32, 301–306. [Google Scholar] [CrossRef]

- Balram, D.; Lian, K.Y.; Sebastian, N.; Al-Mubaddel, F.S.; Noman, M.T. Bi-functional renewable biopolymer wrapped CNFs/Ag doped spinel cobalt oxide as a sensitive platform for highly toxic nitroaromatic compound detection and degradation. Chemosphere 2022, 291, 132998. [Google Scholar] [CrossRef]

- Mallakpour, S.; Amini, Z. Green synthesis of Ag ultra-fine nano-catalyst supported on layered double oxide and chitosan: Accelerated reduction of 4-nitrophenol to 4-aminophenol. J. Clean. Prod. 2022, 381, 135154. [Google Scholar] [CrossRef]

- Ling, Y.; Klemes, M.J.; Xiao, L.; Alsbaiee, A.; Dichtel, W.R.; Helbling, D.E. Benchmarking Micropollutant Removal by Activated Carbon and Porous β-Cyclodextrin Polymers under Environmentally Relevant Scenarios. Environ. Sci. Technol. 2017, 51, 7590–7598. [Google Scholar] [CrossRef] [Green Version]

- Topuz, F.; Holtzl, T.; Szekely, G. Scavenging organic micropollutants from water with nanofibrous hypercrosslinked cyclodextrin membranes derived from green resources. Chem. Eng. J. 2021, 419, 129443. [Google Scholar] [CrossRef]

- Ebele, A.J.; Abdallah, M.A.E.; Harrad, S. Pharmaceuticals and personal care products (PPCPs) in the freshwater aquatic environment. Emerg. Contam. 2017, 3, 1–16. [Google Scholar] [CrossRef]

- Patel, A.B.; Shaikh, S.; Jain, K.R.; Desai, C.; Madamwar, D. Polycyclic Aromatic Hydrocarbons: Sources, Toxicity, and Remediation Approaches. Front. Microbiol. 2020, 11, 562813. [Google Scholar] [CrossRef]

- Låg, M.; Øvrevik, J.; Refsnes, M.; Holme, J.A. Potential role of polycyclic aromatic hydrocarbons in air pollution-induced non-malignant respiratory diseases. Respir. Res 2020, 21, 299. [Google Scholar] [CrossRef]

- Honda, M.; Suzuki, N. Toxicities of Polycyclic Aromatic Hydrocarbons for Aquatic Animals. Int. J. Environ. Res. Public Health 2020, 17, 1363. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arteta, S.M.; Vera, R.; Pérez, L.D. Hydrophobic cellulose fibers via ATRP and their performance in the removal of pyrene from water. J. Appl. Polym. Sci. 2017, 134, 44482. [Google Scholar] [CrossRef]

- Mehmandost, N.; Soriano, M.L.; Lucena, R.; Goudarzi, N.; Chamjangali, M.A.; Cardenas, S. Recycled polystyrene-cotton composites, giving a second life to plastic residues for environmental remediation. J. Environ. Chem. Eng. 2019, 7, 103424. [Google Scholar] [CrossRef]

- Fu, Z.; Zhou, S.; Xia, L.; Mao, Y.; Zhu, L.; Cheng, Y.; Wang, A.; Zhang, C.; Xu, W. Juncus effusus fiber-based cellulose cigarette filter with 3D hierarchically porous structure for removal of PAHs from mainstream smoke. Carbohydr. Polym. 2020, 241, 116308. [Google Scholar] [CrossRef] [PubMed]

- Batool, A.; Valiyaveettil, S. Surface functionalized cellulose fibers—A renewable adsorbent for removal of plastic nanoparticles from water. J. Hazard. Mater. 2021, 413, 125301. [Google Scholar] [CrossRef] [PubMed]

- Gomez-Maldonado, D.; Reynolds, A.M.; Johansson, L.S.; Burnett, D.J.; Ramapuram, J.B.; Waters, M.N.; Erramuspe, I.B.V.; Peresin, M.S. Fabrication of aerogels from cellulose nanofibril grafted with β-cyclodextrin for capture of water pollutants. J. Porous Mater. 2021, 28, 1725–1736. [Google Scholar] [CrossRef]

- Hassan (El-Moushy), R.M. Novel synthesis of natural cation exchange resin by crosslinking the sodium alginate as a natural polymer with 1,6-hexamethylene diisocyanate in inert solvents: Characteristics and applications. Int. J. Biol. Macromol. 2021, 184, 926–935. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Jia, W.; Yan, Y.; Zhao, S. Coagulation removal and recycling strategy of TiO2 nanoparticles based on Enteromorpha prolifera polysaccharide application. J. Water Proc. Eng. 2022, 49, 103083. [Google Scholar] [CrossRef]

- Campo, J.; Picó, Y. Emerging contaminants and toxins. In Chemical Analysis of Food. Techniques and Applications, 2nd ed.; Pico, Y., Ed.; Academic Press: London, UK, 2020; pp. 729–758. [Google Scholar]

- Lambert, S.; Wagner, M. Microplastics Are Contaminants of Emerging Concern in Freshwater Environments: An Overview. In Freshwater Microplastics. The Handbook of Environmental Chemistry; Wagner, M., Lambert, S., Eds.; Springer: Cham, Switzerland, 2018; Volume 58, pp. 1–23. [Google Scholar]

- Bhuyan, M.S. Effects of Microplastics on Fish and in Human Health. Front. Environ. Sci. 2022, 10, 827289. [Google Scholar] [CrossRef]

- González-Pleiter, M.; Cirés, S.; Wörmer, L.; Agha, R.; Pulido-Reyes, G.; Martín-Betancor, K.; Rico, A.; Leganés, F.; Quesada, A.; Fernández-Piñas, F. Ecotoxicity assessment of microcystins from freshwater samples using a bioluminescent cyanobacterial bioassay. Chemosphere 2020, 240, 124966. [Google Scholar] [CrossRef]

- Lad, A.; Breidenbach, J.D.; Su, R.C.; Murray, J.; Kuang, R.; Mascarenhas, A.; Najjar, J.; Patel, S.; Hegde, P.; Youssef, M.; et al. As We Drink and Breathe: Adverse Health Effects of Microcystins and Other Harmful Algal Bloom Toxins in the Liver, Gut, Lungs and Beyond. Life 2022, 12, 418. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 231/2012 of 9 March 2012 Laying down Specifications for Food Additives Listed in Annexes II and III to Regulation (EC) No 1333/2008 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32012R0231 (accessed on 1 April 2023).

- Przybyla, M.A.; Yilmaza, G.; Becer, C.R. Natural cyclodextrins and their derivatives for polymer synthesis. Polym. Chem. 2020, 11, 7582–7602. [Google Scholar] [CrossRef]

- Kunwar, B.; Mondal, S.; Saini, V.K.; Bahukhandi, K.D.; Kumar, A. Utilization of barks of Araucaria columnaris: Preparation of activated carbon/clay composite beads and adsorptive treatment of phenolic wastewater. Ind. Crop. Prod. 2023, 197, 116534. [Google Scholar] [CrossRef]

- Hussain, O.A.; Hathout, A.S.; Abdel-Mobdy, Y.E.; Rashed, M.M.; Abdel Rahim, E.A.; Fouzy, A.S.M. Preparation and characterization of activated carbon from agricultural wastes and their ability to remove chlorpyrifos from water. Toxicol. Rep. 2023, 10, 146–154. [Google Scholar] [CrossRef]

| P (Problem) | Presence of emerging pollutants in water streams |

| I (Intervention) | Application of innovative, natural polymeric materials for emerging pollutants’ removal |

| C (Comparison) | Materials with known properties in environment protection or singular components, in the case of composite materials |

| O (Outcome) | Improvement of pollutant uptake and the use of natural polymers |

| Natural Polymer | Targeted Application | Application Form | Obtained Results | Process Parameters | Ref. |

|---|---|---|---|---|---|

| Guar gum | Ciprofloxacin (fluoroquinolone antibiotic) adsorption, 15 mg/L | Zerovalent iron-guar gum nanocomposite, spherical, particle size of ∼60–70 nm (0.5 g/L) | 94% removal after 60 min | Superior adsorption at pH 4, compared with pH 2.6 (41%), superior to zerovalent ion by itself (69%); removal efficiency over 85% after 2 recycling cycles | [41] |

| Lignin | Adsorption of doxycycline hydrochloride (tetracycline antibiotic), 30 mg/L | Lignin xanthate resin–bentonite clay composite, porous structure | Adsorption capacity 438.75 mg/g | Superior to bentonite (119.93 mg/g); isotherm—Langmuir model (monolayer and uniform adsorption); kinetics—pseudo-second-order model (multilayer adsorption on heterogeneous surfaces, adsorption through electrostatic interaction, hydrogen bonding and π–π interactions—chemisorption) | [42] |

| Cellulose | p-arsanilic acid (veterinary use) | Ionic liquid-modified cellulose | Adsorption capacity 216.9 mg/g | Comparable results with other works, fast adsorption rate 3.21 × 10−3 g/(mg × min), process conformed to Freundlich (multi-layer adsorption on heterogenous surfaces) and pseudo-second-order kinetics model; 77% of initial capacity after six recycling cycles | [43] |

| Sodium alginate | Cephalexin (beta-lactam antibiotic), 30 mg/L | Saccharomyces cerevisiae/calcium alginate composite beads, 3.32 mm diameter | Adsorption capacity 94.34 mg/g | Superior to literature biosorbents; isotherm—Langmuir model; kinetics—pseudo-second-order model | [44] |

| Inulin | Adsorption and heterogenous catalysis of ofloxacin (fluoroquinolone-type antibiotic), 25 mM | Immobilization of laccase onto dialdehyde inulin -coated silica-capped magnetite nanoparticles, 90% of the particles with diameters 1–10 nm | 63% removal capacity | Superior results to laccase alone. Ofloxacin removal—through adsorption and biodegradation mechanisms; kinetics—pseudo-second-order model; 50% of initial activity after 6 reuse cycles | [45] |

| Chitosan, sodium alginate | Adsorption and catalytic oxidation of naproxen, diclofenac (nonsteroidal anti-inflammatory drugs—NSAID), 25 mg/L, individually or simultaneously | Magnetite or Fe/Cu nanoparticles, on alginate or chitosan beads | 84/92% removal of naproxen/diclofenac, using Fe/Cu on alginate or chitosan, respectively, after 9 min | Good removal capacity in short reaction time (9 min); kinetics—pseudo-first-order model (reaction more inclined towards physisorption); slight decrease in removal efficiencies after three recycling cycles | [46] |

| Sodium alginate | Biosorption of ethacridine lactate (aromatic organic compound, antiseptic, trade name Rivanol), 50 mg/L | Encapsulation of Saccharomyces pastorianus residual biomass in calcium alginate, irregular and elongated shape, 1.89 mm diameter | Maximum capacity 21.39 mg/g, batch study | Kinetics—pseudo-second-order and intraparticle diffusion (adsorption controlled by one of the following: film diffusion/adsorbate diffusion into the pores/ surface adsorption); equilibrium isotherms—Freundlich and Dubinin–Radushkevich (adsorption is related to pores volume filling). | [47] |

| Sodium alginate | Biosorption of ethacridine lactate (aromatic organic compound, antiseptic, trade name Rivanol), 20/40 mg/L | Encapsulation of Saccharomyces pastorianus residual biomass in calcium alginate; spherical, whitish beads, 3.218 mm diameter | Biosorption capacity 138.584 mg/g, fixed-bed column study | Biosorption capacity variable with bed height, pollutant concentration and flow rate. Experimental data best fit the Yoon–Nelson (premise—decreasing adsorption rate directly proportional to adsorbate adsorption), Clark (premise—adsorption is mass-transfer concept combined with Freundlich isotherm, piston type behavior of flow in column), and, to a lesser extent, Yan model (dose–response model) | [48] |

| Natural Polymer | Pollutant | Pollutant Class | Application Form | Obtained Results | Process Parameters | Ref. |

|---|---|---|---|---|---|---|

| Cellulose | Humic acid, 1 g/L | Biostimulant | Cellulose nanofibers obtained by addition of epoxypropyl trimethyl ammonium chloride at 65 °C, 8 h | Adsorption rate 184 × 10−3 min−1 | Composite (1 mL, 0.2–0.4 wt%) added to different amounts of humic acid solution, shaken for 2 days; best results at pH 4.5; at pH = 6.2, adsorption rate = 49 × 10−3 min−1; isotherms—Langmuir model | [53] |

| Chitosan | Humic acid | Biostimulant | Polyacrylamide/chitosan semi-interpenetrating network hydrogels | Maximum adsorption 166.30 mg/g | 0.025 g of composite dispersed in 50 mL of 60 mg/mL pollutant; pH = 3 to 11; results superior to other organic and inorganic adsorbents in literature; isotherm—Sips model (multilayer adsorption on heterogeneous surfaces at low concentrations and monolayer adsorption at higher pollutant concentrations) | [54] |

| Chitosan | Phosphate | Fungicide | Iron oxide nanoparticle-loaded chitosan composites | Removal capacity of 0.059 mgP/g | Pilot plant: adsorption tower (height = 100 cm, inner diameter = 45 cm, flow rate = 7.05 ± 0.18 L/min), composite volume = 80 L, composite weight = 85.74 kg; constant adsorption capacity after six recycling cycles | [55] |

| Sodium alginate | Phosphate | Fungicide | Iron crosslinked alginate beads | Maximum adsorption capacity 79 mg/g | Experiments conducted with synthetic water; kinetics—pseudo-second-order model, isotherm—Freundlich model; experiments with real eutrophic lake water—81–100% removal in 24 h (11–69 μg/L initial concentration). | [56] |

| β-Cyclodextrin | Humic acid, 10 mg/L | Biostimulant | β-cyclodextrin polymer synthesized in the aqueous phase using tetrafluoroterephthalonitrile as a rigid crosslinker, epichlorohydrin as a flexible crosslinker and 2,3- epoxypropyltrimethylammonium chloride as a quaternization reagent | Maximum adsorption 40 mg/g | Solid/liquid ratio = 1 mg/mL; adsorption superior to commercial materials; kinetics—pseudo-second-order model and Elovich model (solute adsorption rate decreases with the increase of adsorbed solute); isotherm—Freundlich model; no significant adsorption decrease after five recycling cycles | [57] |

| β-Cyclodextrin | Fluvic acid, 30 mg/L | Biostimulant | Maximum adsorption 166 mg/g | |||

| β-Cyclodextrin | 2,4,6-trichlorophenol, 0.1 mmol/L | Fungicide, herbicide, insecticide | Maximum adsorption 108 mg/g | |||

| Chitosan, gelatin | Atrazine (20 mg/L), fenitrothion (20 mg/L) | Pesticides | Polymeric composite prepared by inotropic gelation at room temperature | Adsorption capacity 75.19 mg/g (atrazine), 36.23 mg/g (fenitrothion) | Composite (0.3 g/L) added to 50 mL pollutant solution; adsorption time 180 min. Isotherm—Langmuir model | [58] |

| Cellulose | Chlorpyrifos, 100 μg/L | Insecticide | Polymeric films developed by incorporating dibutyl sebacate, bis(2-ethylhexyl) sebacate, bis(2-ethylhexyl) phthalate, bis(1-butylpentyl) adipate, 2-nitrophenyl octyl ether or 2-fluorophenyl 2-nitrophenyl ether in cellulose triacetate, by solvent casting | Extraction efficiency from synthetic water 71–87% (after 8 h) | Best results obtained for composite with bis(2-ethylhexyl) sebacate; water samples maintained in contact with the film having area of 2.89 cm2, under orbital agitation | [59] |

| β-cyclodextrin | Humic acid | Biostimulant | Friedel–Crafts alkylation reaction between modified β-cyclodextrin and 4,4′ -bis(chloromethyl)-1,1′—biphenyl in a homogeneous ionic liquid system | Maximum adsorption 142 mg/g | 0.015 g of composite dispersed in 15 mL of 20 mg/L pollutant; results superior to activated carbon; isotherm—Freundlich model; over 90% efficiency after six recycling cycles | [60] |

| Natural Polymer | Targeted Application | Application Form | Obtained Results | Process Parameters | Ref. |

|---|---|---|---|---|---|

| Cellulose | Adsorption of crystal violet (dye with practical applications), 11.1 mg/L | Freeze-dried foams consisting of cellulose nanofibers (obtained by addition of epoxypropyl trimethyl ammonium chloride at 65 °C, 8 h) with adsorbed humic acid | 55% adsorption | Porous foam with density of 25 kg/m3, porosity 98% (20 mg) added to 45 mL of dye solution | [53] |

| Chitosan | Reduction of methylene blue (model dye), 10 ppm | Silver nitrate mixed with chitosan/polyethylene glycol solution, various concentrations of TiO2 added at 80 °C | 63.48% degradation | Direct sunlight photocatalysis; Langmuir–Hinshelwood mechanism | [65] |

| Xylan | Adsorption of methylene blue (model dye), 400 mg/L | Xylan/poly(acrylic acid) magnetite nanoparticles nanocomposite hydrogel | Maximum adsorption capacity—438.60 mg/g | Removal rate >90% for 3 g/L adsorbent; isotherm—Langmuir model; kinetics—pseudo-second-order model | [66] |

| Cellulose and chitosan | Adsorption of Congo red (histological staining agent), 30 mg/L | Cellulose/chitosan hydrogel prepared by extruding and regenerating from ionic liquid 1-ethyl-3-methylimidazolium acetate in ethanol | Maximum adsorption capacity—40 mg/g | For adsorbent dosage of 2.0 g/L, equilibrium was reached within 115 min, removal rate was 89.6%; isotherms—Langmuir model; kinetics—pseudo-second-order model | [67] |

| Silk | Filtration of dyes with industrial and biotechnology applications | Membranes prepared by vacuum filtration of exfoliated degummed Bombyx mori silk fibers | >90% rejection | Vacuum filtration device, best results obtained for Alcian Blue 8GX (100%, initial concentration 185 µM), Brilliant Blue G (100%, initial concentration 398 µM), Rhodamine B (91%, initial concentration 5 mM) | [68] |

| Chitosan | Photodegradation of Ponceau BS (staining agent) | Polyaniline-grafted chitosan prepared by chemical using ammonium per sulfate; Ag nanoparticles incorporated into the polymer matrix | Complete degradation after 40 min | Photodegradation under visible light; kinetic—pseudo-first-order model | [69] |

| Chitosan, lignin | Removal of acid black-172 (dye with industrial applications), 100 mg/L | Ternary graft copolymer (chitosan–acrylamide–lignin), synthesized using microwave irradiation and chemical-free radical initiator technique | Removal efficiency—97.1% | Dosage 200 mg/L; possible mechanisms—charge neutralization, bridging and sweeping effects | [70] |

| Guar gum | Catalytic oxidation of methyl orange (100 ppm) | Zerovalent iron–guar gum nanocomposite, spherical, particle size of ∼60–70 nm (0.5 g/L) | 99% after 60 min, pH 7 | Superior oxidation to zerovalent ion by itself (39%) | [41] |

| β-cyclodextrin | Adsorption of methylene blue (model dye), 100 mg/L | Citric acid-crosslinked β-cyclodextrin | Maximum adsorption capacity—0.9229 mmol/g | 0.4 g in 200 mL pollutant, pH = 1–10; kinetics—pseudo-second-order model; isotherm—Sips model; no decrease in performance after five recycling cycles | [71] |

| Lignin | Adsorption of methylene blue (model dye), 1 mg/mL | Hydrogels obtained by crosslinking poly(methyl vinyl ether co-maleic acid) and lignin in ammonium and sodium hydroxide solutions | Adsorption capacity—629 mg/g | Dry hydrogels (20–30 mg) placed in 20 mL pollutant solution, stirred for 48 h at room temperature; maximum removal efficiency—96%, superior results to control hydrogels (without lignin) | [72] |

| Pectin | Adsorption of methylene blue (model dye), 100–1000 mg/L | Pectin microgel particles | Adsorption capacity—284.09 mg/g | Different uptake times (2–310 min), pH 1–7; isotherm—Langmuir model; kinetics—pseudo-second-order model; recovery efficiency higher than 80% after three cycles | [73] |

| Chitosan | Adsorption of CI Basic Red 14 (dye with industrial applications), 100 ppm | Polymeric beads containing chitosan, Arundo donax L. cells, gelatin and poly(vinyl)pyrrolidone | Maximum adsorption capacity—41.322 mg/g | Removal efficiency of 92.2% (at 2 g. adsorbent); isotherms—Langmuir model; kinetics—pseudo-first-order model | [74] |

| (Konjac) glucomannan | Adsorption of malachite green (common dye with industrial applications) | Konjac glucomannan/graphene oxide sponges prepared by ice template method | Maximum adsorption capacity—189.96 mg/g | Isotherms—Langmuir model; kinetics—pseudo-first-order model; adsorption capacity relatively high after five recycling cycles | [75] |

| Sodium alginate | Adsorption and photocatalytic degradation of crystal violet (dye with practical applications) | Grafted sodium alginate/ZnO/graphene oxide composite | Maximum adsorption capacity—13.85 mg/g | Maximum capacity at pH = 5; isotherm—Freundlich model; kinetics—pseudo-second-order model; photocatalytic degradation enhanced the removal efficiency by 10% | [76] |

| Tragacanth gum | Adsorption of methylene blue (model dye) | Hydrogel nanocomposite composed of tragacanth gum and modified CaCO3 nanoparticles | Maximum adsorption capacity—476 mg/g | Isotherm—Langmuir model; kinetics—pseudo-first-order model; film diffusion—main mechanism of adsorption | [77] |

| Chitosan | Adsorption of Acid Blue-113 (industrial dye) | Chitosan-coated polyacrylonitrile nanofibrous mat | Maximum adsorption capacity—1708 mg/g | Superior results compared with control (without chitosan); superior capacity than commercial activated carbon; isotherm—Langmuir model; kinetics—pseudo-second-order model; film diffusion—main mechanism of adsorption; slight decrease in adsorption after four cycles | [78] |

| Silk | Adsorption of crystal violet (dye with practical applications) | 3D porous network in a freeze-dried silk fibroin/ soursop seed polymer composite | Maximum adsorption capacity—83.31 mg/g | Isotherms—Freundlich model; kinetics—pseudo-first-order model. | [79] |

| Sodium alginate, | Adsorption of crystal violet (cationic dye with practical applications), 200 mg/L | Hydrogel beads from rice bran combined with sodium alginate | Maximum adsorption capacity—454.55 mg/g | Isotherms—Freundlich model; kinetics—pseudo-second-order model; no adsorption decrease after five regeneration cycles | [80] |

| Chitosan | Adsorption of reactive blue 4 (anionic dye with practical applications), 200 mg/L | Hydrogel beads from rice bran combined with chitosan | Maximum adsorption capacity—212.77 mg/g | Isotherms—Langmuir model; kinetics—pseudo-first-order model; satisfactory adsorption (20% decrease) after five recycling cycles | |

| Sodium alginate | Degradation of methylene blue (model dye) | Ca-alginate/CuO beads | 92% degradation in 8 min | 100 mg composite added to 5 mL methylene blue solution in the presence of 1 mL NaBH4 (0.08 mol/L); kinetics—pseudo-first-order model; degradation reduced when using recycled composites; slow decrease in degradation after ten recycling cycles | [81] |

| Chitosan | Adsorption of Arsenazo-III (staining, analytical reagent), 100 mg/L | Chitosan hydrogel polymer, initiator potassium persulphate | Maximum adsorption capacity—99.9 mg/g | pH = 6, shaking time of 120 min, polymer dose of 0.01 g, room temperature | [82] |

| Chitosan | Alizarin Red S (staining, analytical reagent), 100 mg/L | Maximum adsorption capacity—62.5 mg/g | |||

| Sodium alginate | Separation of Congo red (histological staining agent), 0.1 mg/L | Nacre-inspired multiple crosslinked polyvinyl alcohol/ calcium alginate/SiO2 membrane | Rejection efficiency—99.5% | Long-term separation properties demonstrated by the membrane; over 99% of initial efficiency retained after three recycling cycles | [83] |

| Separation of Alizarin red (staining, analytical reagent), 0.1 mg/L | Rejection efficiency—99.1% | ||||

| Separation of Sunset yellow (dye for food and beverage industry), 0.1 mg/L | Rejection efficiency—98.3% |

| Natural Polymer | Targeted Application | Pollutant Class | Application Form | Obtained Results | Process Parameters | Ref. |

|---|---|---|---|---|---|---|

| Chitosan | Adsorption of chlorophenol (50 mg/kg) and phthalic anhydride (70 mg/kg) | industrial precursor/plasticizer | Poly(N,N-diethylacrylamide), poly(N-isopropylacrylamide) and poly(N-vinylcaprolactum) grafted on chitosan/derivatives | 100% removal of organic impurities | Best results obtained for poly(N-isopropylacrylamide) graft carboxymethylchitosan at 6 mg/mL; materials can be used for at least 5 cycles | [86] |

| Cellulose | Flocculation of nonylphenol, 100 μg/L | Precursor for antioxidants, lubricating oil additives, laundry, dish detergents, emulsifiers, solubilizers, surfactants | (poly N-isopropyl acrylamide)-co-(poly diallyl dimethyl ammonium chloride) grafted on carboxymethylcellulose | Flocculation, nonylphenol removal = 79% | Optimized conditions: pH = 4; T = 35 °C; dosage = 40 mg/L | [87] |

| β-cyclodextrin | Adsorption of perfluorooctanoic acid | surfactant, industrial importance | β-cyclodextrin decafluorobiphenyl polymer (DFB-CDP, 1:β-CD feed ratio = 3) | Adsorption capacity = 34 mg/g, superior to sieved coconut shell-activated carbon | Freundlich model best fit the adsorption isotherm; no significant differences after four recycling cycles | [88] |

| β-cyclodextrin | Adsorption of bisphenol A, 100 mg/L | Plastics industry | Citric acid-crosslinked β-cyclodextrin | Maximum adsorption capacity = 0.3636 mmol/g | 0.4 g in 200 mL pollutant, pH = 1–10; kinetics—pseudo-second-order model; isotherm—Langmuir model; 80% adsorption capacity after five recycling cycles | [71] |

| β-Cyclodextrin | Adsorption of 2-naphthol, 0.1 mmol/L | Intermediate in dyes production | β-cyclodextrin polymer synthesized in the aqueous phase using tetrafluoroterephthalonitrile as a rigid crosslinker, epichlorohydrin as a flexible crosslinker and 2,3- epoxypropyltrimethylammonium chloride as a quaternization reagent | Maximum adsorption = 74 mg/g | Solid/liquid ratio = 1 mg/mL; adsorption superior to commercial materials; kinetics—pseudo-second-order and Elovich (solute adsorption rate decreases with the increase of adsorbed solute) models; isotherm—Freundlich model | [57] |

| β-Cyclodextrin | Adsorption of 3-phenylphenol, 0.1 mmol/L | Colorimetric reagent | Maximum adsorption = 101 mg/g | |||

| β-Cyclodextrin | Adsorption of bisphenol A, 0.1 mmol/L | Plastics industry | Maximum adsorption = 103 mg/g | |||

| β-Cyclodextrin | Adsorption of bisphenol S, 0.1 mmol/L | Industrial application in epoxy resins | Maximum adsorption = 117 mg/g | |||

| Chitosan | Catalytic reduction of p-nitrophenol, 5 mM | Industrial intermediate | Chitosan/reduced graphene oxide-based composite hydrogel, with glutaraldehyde crosslinking agent, loaded with Pd nanoparticles | Catalytic reduction, rate constant = 0.0348 min−1 | Hydrogel mixed with 1 mL pollutant solution, added 10 mL NaBH4 solution (0.01 M); results superior to literature data, better for 2-nitroaniline | [89] |

| Chitosan | Catalytic reduction 2-nitroaniline, 5 mM | Industrial intermediate | Catalytic reduction, rate constant = 0.125 min−1 | |||

| Chitosan | Degradation of phenol, 100 mg/L | Industrial intermediate | Recombination of chitosan and polyvinyl alcohol, with microorganisms added | Biodegradation, 99%, degradation rate increasing after several uses | Best results obtained at 30 °C, pH = 7, higher compared with microorganism alone; over 95% degradation rates after 90 recycling cycles | [90] |

| Chitosan | Degradation of p-cresol, 100 mg/L | Industrial intermediate | Degradation in the presence of 1600 mg/L phenol, concentration decreased to 0.4 mg/L | |||

| Chitosan | Degradation of catechol, 100 mg/L | Industrial intermediate | Degradation in the presence of 1600 mg/L phenol, concentration decreased to 0.6 mg/L | |||

| Chitosan | Degradation of 2-aminophenol, 100 mg/L | Industrial intermediate | Degradation in the presence of 1600 mg/L phenol, concentration decreased to 4.7 mg/L | |||

| Chitosan | Degradation of p-nitrophenol, 10 mg/L | Industrial intermediate | Bi-functional ternary nanocomposite constructed using chitosan-wrapped carbon nanofibers, embedded with Ag-doped Co3O4 | Degradation constant = 0.0186 min−1; degradation efficiency = 97.39% for 40 mg catalyst | 10–40 mg catalyst immersed in 100 mL pollutant solution; solution irradiated with visible light; degradation rate higher than carbon nanofibers and metal oxide alone; over 90% degradation after five recycling cycles | [91] |

| β-cyclodextrin | Adsorption of bisphenol A, 20 mg/L | Plastics industry | Friedel–Crafts alkylation reaction between modified β-cyclodextrin and 4,4′-bis(chloromethyl)-1,1′-biphenyl in a homogeneous ionic liquid system | Maximum adsorption = 257.75 mg/g | 0.015 g of composite dispersed in 15 mL pollutant; results superior to activated carbon; isotherm—Freundlich model; over 90% efficiency after six recycling cycles | [60] |

| Sodium alginate | Degradation of p-nitrophenol, 10−4 M | Industrial intermediate | Ca-alginate/CuO beads | Degradation constant = 0.202 min−1; degradation efficiency = 97–98% | 100 mg of composite, in the presence of 0.08 mol/L NaBH4. Degradation efficiency higher than Ca-alginate alone; kinetics—pseudo-first-order model; 75% reduction after 60 min, after 10 recycling cycles | [81] |

| Chitosan | Degradation of p-nitrophenol, 20 mg/L | Industrial intermediate | Chitosan/Ag nanoparticles/layered double-hydroxide nanocatalyst | Apparent rate constant = 1.65 × 10−2 s−1 | 20 mg nanocatalyst added to 4 mL NaBH4 (0.54 g/L) and 6 mL of pollutant solution; kinetics—pseudo-first-order model; performance unchanged by 5 recycling cycles | [92] |

| Cellulose | Extraction of triclosan, tonalide, 100 μg/L | Personal care products | Polymeric films developed by incorporating dibutyl sebacate, bis(2-ethylhexyl) sebacate, bis(2-ethylhexyl) phthalate, bis(1-butylpentyl) adipate, 2-nitrophenyl octyl ether or 2-fluorophenyl 2-nitrophenyl ether in cellulose triacetate, by solvent casting | Extraction efficiency from synthetic water = 68–93%/44–94% (after 8 h) | Best results for composite with 2-nitrophenyl octyl ether/dibutyl sebacate; water samples maintained in contact with the film having area of 2.89 cm2, under orbital agitation | [59] |

| Natural Polymer | Targeted Application | Pollutant Class | Application Form | Obtained Results | Process Parameters | Ref. |

|---|---|---|---|---|---|---|

| Silk | Filtration of gold nanoparticles, 5 nm, 5.5 × 1013 unit per mL | Nanoparticles | Membranes prepared by vacuum filtration of exfoliated degummed Bombyx mori silk fibers | Rejection 99% | Vacuum filtration device | [68] |

| CdSeS/ZnS quantum dots, 6 nm, 1 mg/mL | Rejection 100% | |||||

| Cellulose | Removal of pyrene (25, 100 ppb) from water | Polycyclic aromatic hydrocarbon | Cellulose fibers grafted with poly(lauryl acrylate) and poly(octadecyl acrylate | Adsorption capacity 38 mg/g | Higher capacity for octadecyl acrylate grafted cellulose | [99] |

| (Konjac) glucomannan | Adsorption of U (VI) | Radionuclides | Konjac glucomannan/graphene oxide sponges prepared by ice template method | Maximum adsorption capacity—266.97 mg/g | Selectivity in multi-ions system; isotherms—Langmuir model; kinetics—pseudo-first-order model; adsorption capacity relatively high after five recycling cycles | [75] |

| Cellulose | Removal of fluorene, 20 µg/L | Polycyclic aromatic hydrocarbon | Polystyrene–cotton composites, obtained by dipping pretreated cotton in 2% polystyrene solution in chloroform | Extraction recovery after two elution = 65% | Recovery increased at the second elution | [100] |

| Removal of anthracene, 20 µg/L | Extraction recovery after two elution = 71% | |||||

| Removal of fluoranthene, 20 µg/L | Extraction recovery after two elution = 85% | |||||

| Removal of pyrene, 20 µg/L | Extraction recovery after two elution = 93% | |||||

| Cellulose | Removal of polycyclic aromatic hydrocarbons from mainstream cigarette smoke | Polycyclic aromatic hydrocarbon | Cellulose cigarette filter with porous structure, pore size controlled by polyvinylpyrrolidone using a dip–dry method | Removal efficiency 61.79% | Higher than conventional cellulose acetate filter (39.22% removal) | [101] |

| Cellulose | Plastic micro/nanoparticles stained with neutral red dye | Microplastic particles from commercial body scrub | Cellulose surface functionalized with polyethylenimine | Maximum adsorption efficiency of 97%, 98% and 99% for polymethyl methacrylate, polyvinyl chloride and polyvinyl acetate nanoparticles | Kinetics—pseudo-second-order model | [102] |

| Cellulose, β-cyclodextrin | Adsorption of microcystin-LR, 1.5, 0.8 µg/mL | Cyanotoxin | Aerogels from cellulose nanofibril grafted with β-cyclodextrin | Adsorption capacity 0.078 mg/g | Aerogels placed in 20 mL of toxin solutions at room temperature and constant stirring; kinetics—pseudo-second-order model | [103] |

| Sodium alginate | Adsorption of U (VI), 5 mmol/L | Radionuclides | Granulated resin obtained by crosslinking sodium alginate with 1,6-hexamethylene diisocyanate in benzene | Maximum adsorption capacity—269.80 mg/g | Replacement of Na+ ions by H+ (using dilute mineral acids); replacement of hydrogen ions with metal ions by ion exchange. Higher capacity for U ions compared to other metals | [104] |

| Polysaccharides | Coagulation and removal of TiO2 nanoparticles in the form of TiO2–humic acid complex | Nanoparticles | Enteromorpha prolifera polysaccharide together with poly aluminum chloride | Removal efficiency 87.12% | Highest efficiency for 1 mg/L polysaccharides; in the presence of poly aluminum chloride 95.68%; isotherm—Langmuir model; faster growing, larger and stronger flocs | [105] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fierascu, R.C.; Fierascu, I.; Matei, R.I.; Manaila-Maximean, D. Natural and Natural-Based Polymers: Recent Developments in Management of Emerging Pollutants. Polymers 2023, 15, 2063. https://doi.org/10.3390/polym15092063

Fierascu RC, Fierascu I, Matei RI, Manaila-Maximean D. Natural and Natural-Based Polymers: Recent Developments in Management of Emerging Pollutants. Polymers. 2023; 15(9):2063. https://doi.org/10.3390/polym15092063

Chicago/Turabian StyleFierascu, Radu Claudiu, Irina Fierascu, Roxana Ioana Matei (Brazdis), and Doina Manaila-Maximean. 2023. "Natural and Natural-Based Polymers: Recent Developments in Management of Emerging Pollutants" Polymers 15, no. 9: 2063. https://doi.org/10.3390/polym15092063

APA StyleFierascu, R. C., Fierascu, I., Matei, R. I., & Manaila-Maximean, D. (2023). Natural and Natural-Based Polymers: Recent Developments in Management of Emerging Pollutants. Polymers, 15(9), 2063. https://doi.org/10.3390/polym15092063