Application of Atmospheric-Pressure Plasma Treatment in Anti-Hairfalling of Polyester–Cotton Fleece Knitted Fabrics

Abstract

:1. Introduction

2. Experimental

2.1. Materials

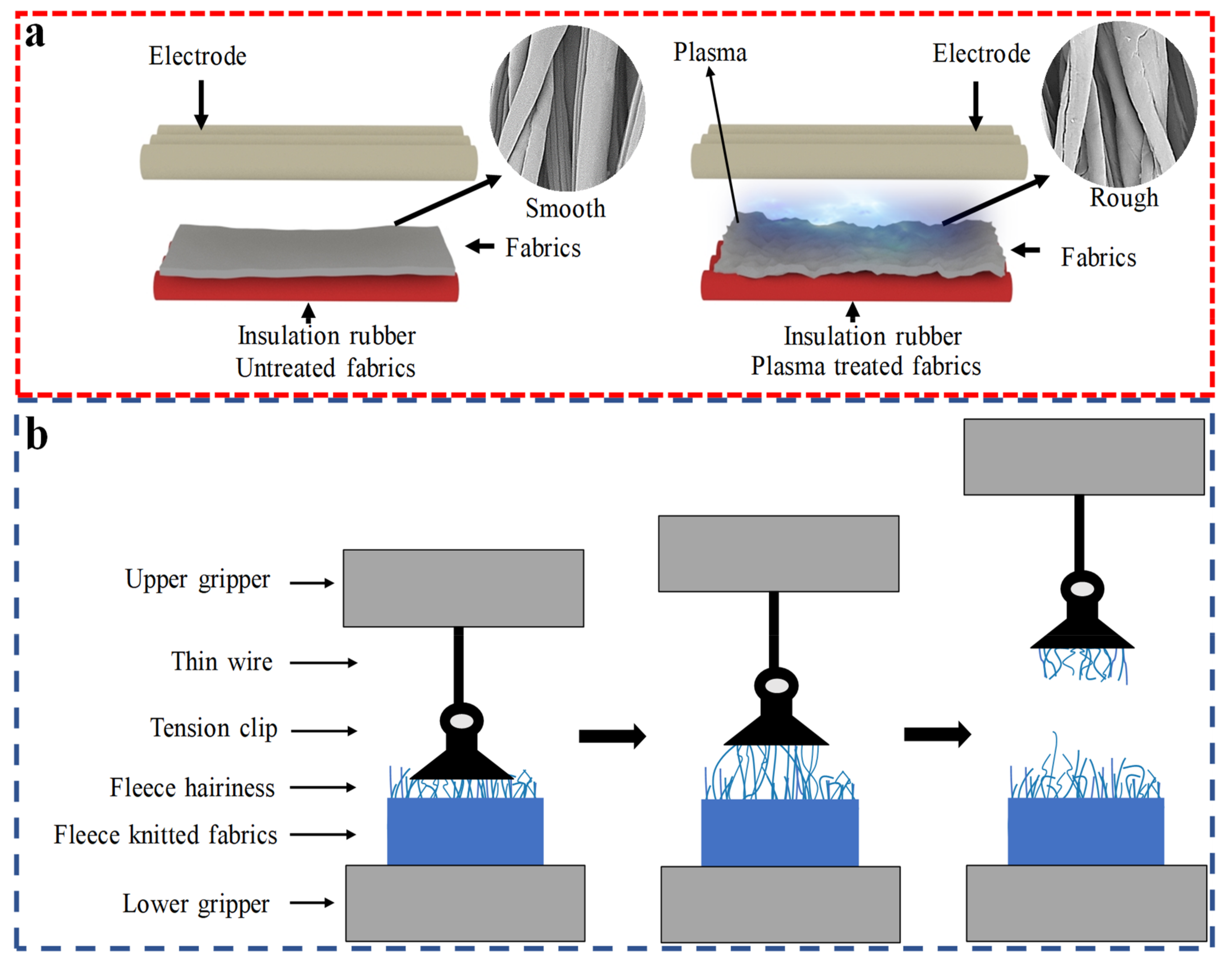

2.2. APP Treatment

2.3. Morphologies

2.4. Anti-Hairfalling Property

2.5. Wettability

2.6. Tensile Test

3. Results and Discussion

3.1. Surface Characteristic

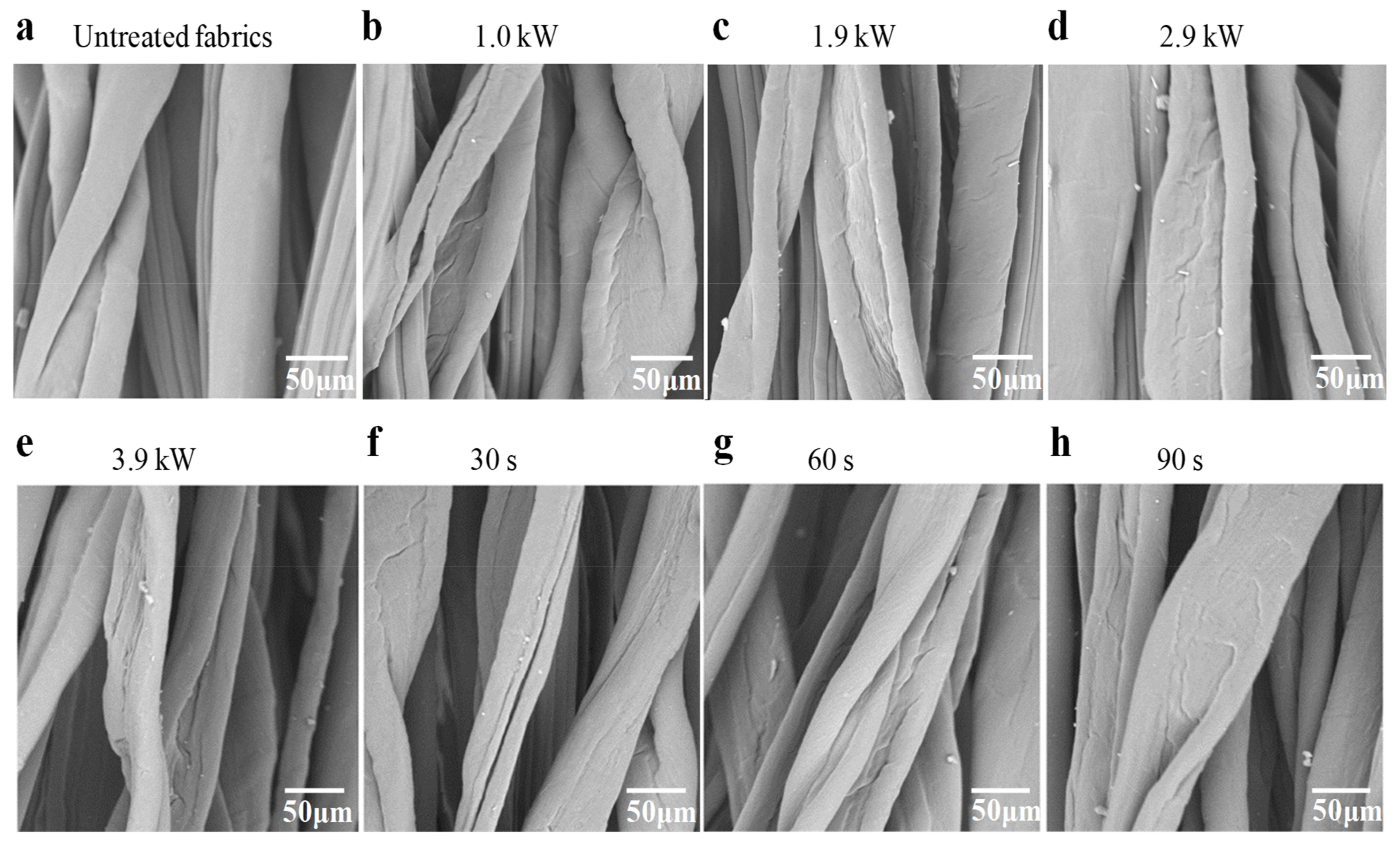

3.1.1. Morphology

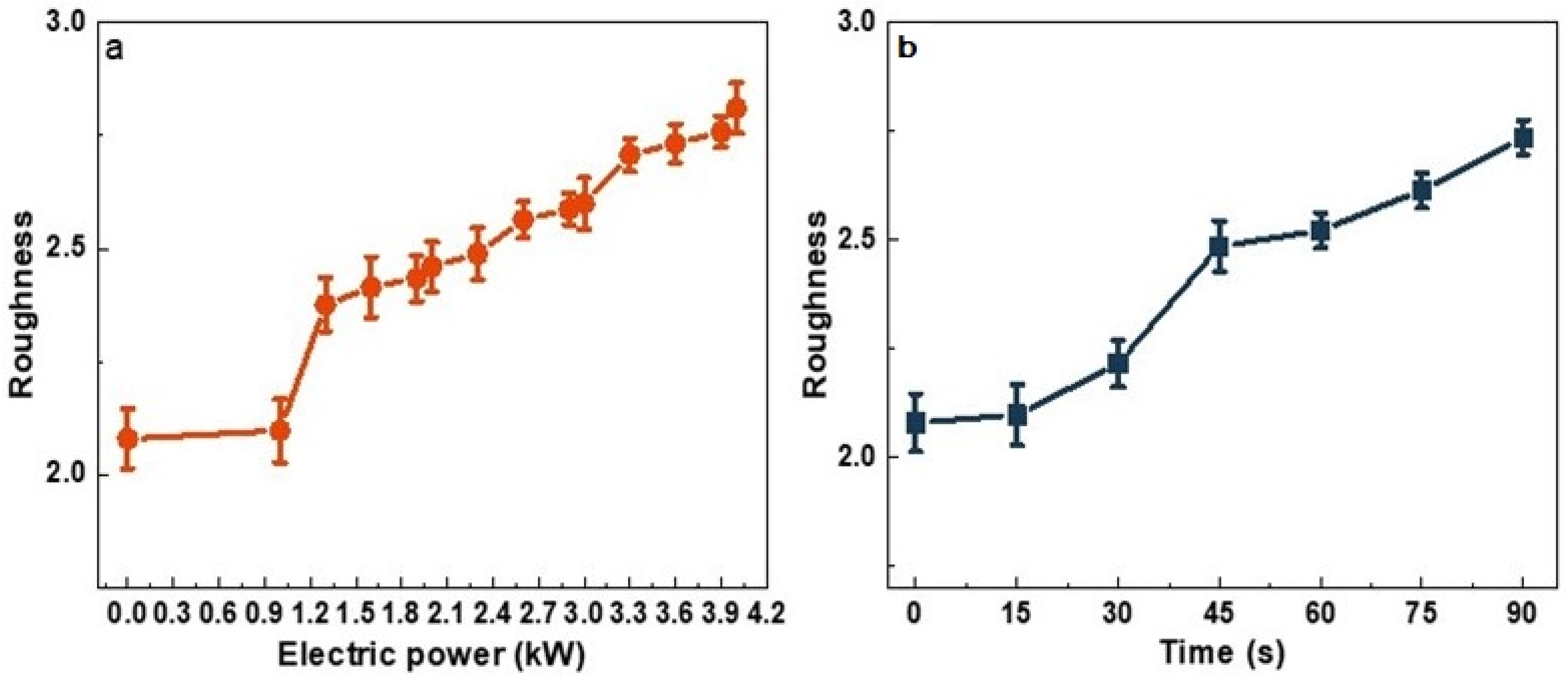

3.1.2. Surface Roughness

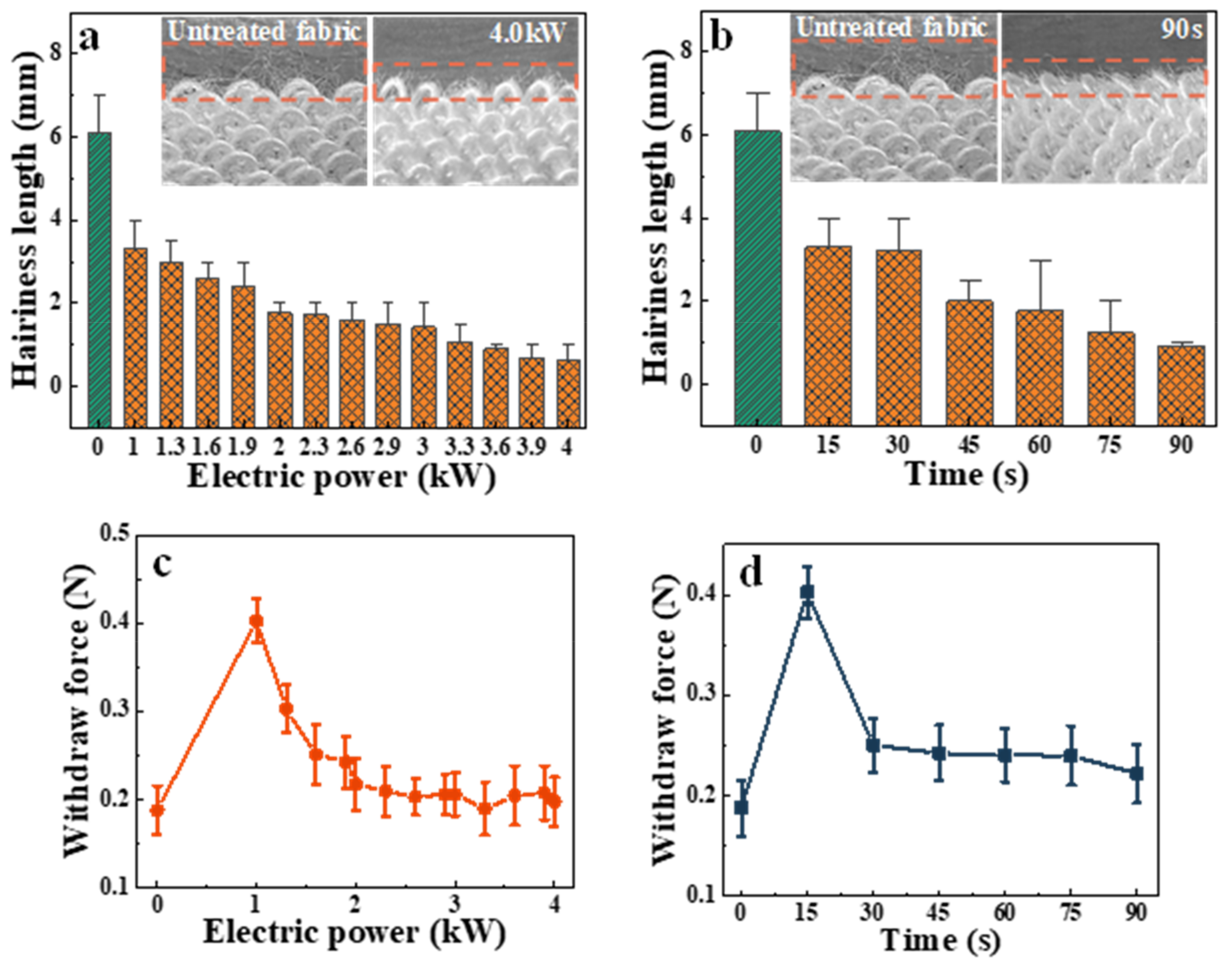

3.1.3. Hairiness Length and Withdraw Force

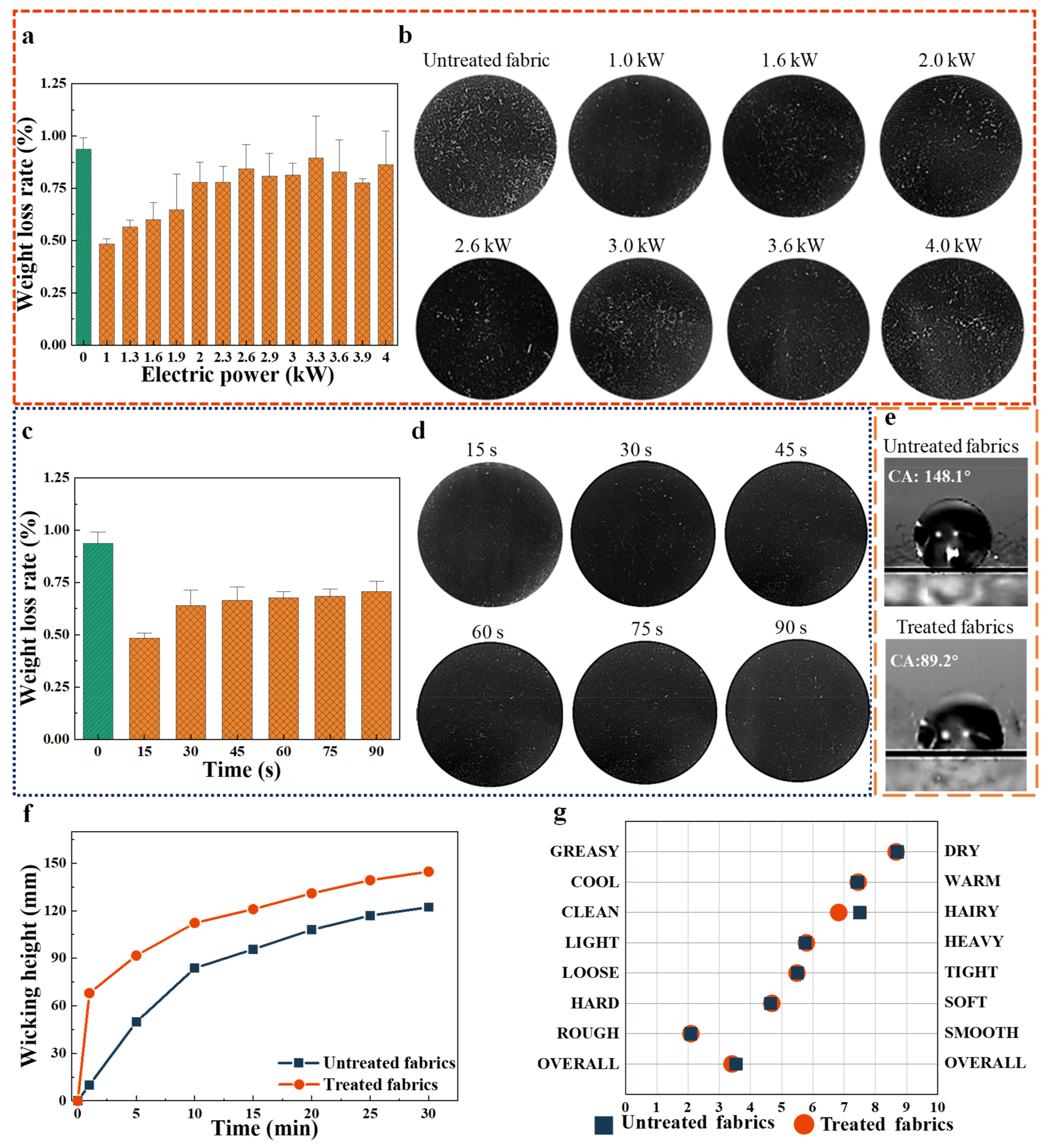

3.2. Anti-Hairfalling Results

3.3. The Property of the Fabrics after APP Treatment

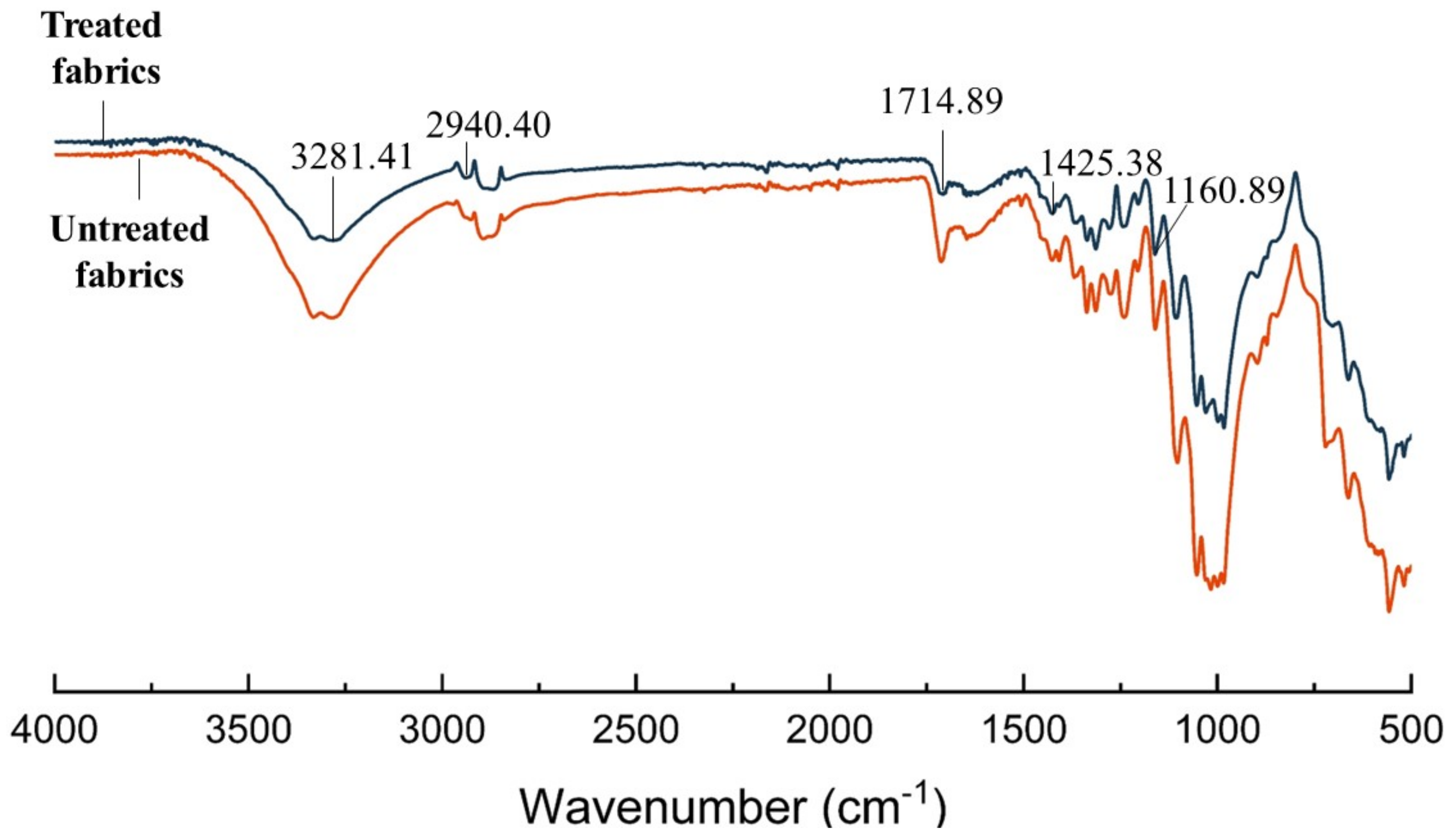

3.3.1. Chemical Characterization

3.3.2. The Effects of APP Activation on Wettability

3.3.3. Handle

3.3.4. Tensile Property

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, D.; Di, Z.; Feng, K.; Zhang, X.; Liu, D.; Yang, S. The cold and atmospheric-pressure air surface barrier discharge plasma for large-area sterilization applications. Appl. Phys. Lett. 2011, 98, 1. [Google Scholar] [CrossRef]

- Liu, W.; Chen, X.; Lei, X.; Bian, H.; Wang, Y. Surface Processing of Polyester Canvas using Atmospheric Pressure Air Glow Discharge Plasma. Plasma Chem. Plasma Process. 2016, 37, 465–474. [Google Scholar] [CrossRef]

- Gorjanc, M.; Mozeti, M. Modification of Fibrous Polymers by Gaseous Plasma; Principles, Techniques and Applications; LAP Lambert Academic Publishing: Saarland, Germany, 2014; ISBN 978-3-659-61460-6. [Google Scholar]

- Kan, C.W.; Cheung, H.F.; Chan, Q. A study of plasma-induced ozone treatment on the colour fading of dyed cotton. J. Clean. Prod. 2016, 112, 3514–3524. [Google Scholar] [CrossRef]

- Kumari, N.; Jassal, M.; Agrawal, A.K. A facile method for the phosphorylation of cellulosic fabric via atmospheric pressure plasma. Carbohydr. Polym. 2021, 256, 117531. [Google Scholar] [CrossRef]

- Wang, L.; Xiang, Z.Q.; Bai, Y.L.; Long, J.J. A plasma aided process for grey cotton fabric pretreatment. J. Clean. Prod. 2013, 54, 323–331. [Google Scholar] [CrossRef]

- Pappas, D. Status and potential of atmospheric plasma processing of materials. J. Vac. Sci. Technol. A Vac. Surf. Film. 2011, 29, 020801. [Google Scholar] [CrossRef]

- Chang, J.S. Recent development of plasma pollution control technology: A critical review. Sci. Technol. Adv. Mater. 2001, 2, 571–576. [Google Scholar] [CrossRef]

- Matsui, K.; Ikenaga, N.; Sakudo, N. Effect of Sterilization Process Using Plasma-Excited Neutral Gas on Materials of Medical Instruments. IEEJ Trans. Sens. Micromach. 2016, 136, 6–11. [Google Scholar] [CrossRef]

- Boeuf, J.P. Topical Review: Plasma display panels: Physics, recent developments and key issues. J. Phys. D Appl. Phys. 2003, 36, R53. [Google Scholar] [CrossRef]

- Rahardian, A.; Masfufah, M.; Maftuhah, S.; Yulianto, E.; Nur, M. Effective medical ozone production using mesh electrodes in double dielectric barrier type plasma generators. In Proceedings of the 2nd International Conference on Chemical Process and Product Engineering (ICCPPE) 2019, Semarang, Indonesia, 25–26 September 2019. [Google Scholar]

- Shishoo, R. Plasma Technologies for Textiles; Woodhead Publishing: Cambridge, UK; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Cech, V.; Prikryl, R.; Balkova, R.; Grycova, A.; Vanek, J. Plasma surface treatment and modification of glass fibers. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1367–1372. [Google Scholar] [CrossRef]

- Moosburger-Will, J.; Lachner, E.; Löffler, M.; Kunzmann, C.; Greisel, M.; Ruhland, K.; Horn, S. Adhesion of carbon fibers to amine hardened epoxy resin: Influence of ammonia plasma functionalization of carbon fibers. Appl. Surf. Sci. 2018, 453, 141–152. [Google Scholar] [CrossRef]

- Khelifa, F.; Ershov, S.; Habibi, Y.; Snyders, R.; Dubois, P. Free-Radical-Induced Grafting from Plasma Polymer Surfaces. Chem. Rev. 2016, 116, 3975–4005. [Google Scholar] [CrossRef] [PubMed]

- Narushima, K.; Yamashita, N.; Fukuoka, M.; Inagaki, N.; Isono, Y.; Islam, M.R. Surface Modifications of Polyester Films by Ammonia Plasma. Jpn. J. Appl. Phys. 2007, 46, 4238–4245. [Google Scholar] [CrossRef]

- Jie, S.; Lan, Y.; Gao, Z.; Peng, S.; Wang, C.; Qiu, Y. Surface modification of PET films by atmospheric pressure plasma-induced acrylic acid inverse emulsion graft polymerization. Surf. Coat. Technol. 2010, 204, 4101–4106. [Google Scholar]

- Kan, C.; Lam, C. Atmospheric Pressure Plasma Treatment for Grey Cotton Knitted Fabric. Polymers 2018, 10, 53. [Google Scholar] [CrossRef]

- Huang, H.C.; Ye, D.Q.; Huang, B.C. Nitrogen plasma modification of viscose-based activated carbon fibers. Surf. Coat. Technol. 2007, 201, 9533–9540. [Google Scholar] [CrossRef]

- Wang, G.J.; Liu, Y.W.; Guo, Y.J.; Zhang, Z.X.; Yang, Z.X. Surface modification and characterizations of basalt fibers with non-thermal plasma. Surf. Coat. Technol. 2007, 201, 6565–6568. [Google Scholar] [CrossRef]

- Liu, Y.C.; Xiong, Y.; Lu, D.N. Surface characteristics and antistatic mechanism of plasma-treated acrylic fibers. Appl. Surf. Sci. 2006, 252, 2960–2966. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, L.; Yu, M.; Qu, L.; Men, Y.; Zhang, X. Surface processing and ageing behavior of silk fabrics treated with atmospheric-pressure plasma for pigment-based ink-jet printing. Appl. Surf. Sci. 2018, 434, 198–203. [Google Scholar] [CrossRef]

- Chan, C.-M.; Ko, T.-M.; Hiraoka, H. Polymer surface modification by plasmas and photons. Surf. Sci. Rep. 1996, 24, 1–54. [Google Scholar] [CrossRef]

- Egitto, F.D.; Matienzo, L.J. Plasma modification of polymer surfaces for adhesion improvement. Ibm J. Res. Dev. 1994, 38, 423–439. [Google Scholar] [CrossRef]

- Mrsic, I.; Buerle, T.; Ulitzsch, S.; Lorenz, G.; Chassé, T. Oxygen plasma surface treatment of polymer films-Pellethane 55DE and EPR-g-VTMS. Appl. Surf. Sci. 2021, 536, 147782. [Google Scholar] [CrossRef]

- Lin, F.; Li, W.; Tang, Y.; Shao, H.; Su, C.; Jiang, J.; Chen, N. High-Performance Polyimide Filaments and Composites Improved by O2 Plasma Treatment. Polymers 2018, 10, 695. [Google Scholar] [CrossRef] [PubMed]

- Muzammil, I.; Li, Y.; Lei, M. Tunable wettability and pH-responsiveness of plasma copolymers of acrylic acid and octafluorocyclobutane. Plasma Process. Polym. 2017, 14, 1700053. [Google Scholar] [CrossRef]

- Leng, C. A Study on the Plasma Surface Modification of Rabbit Hair. J. Chang. Univ. Technol. 1992, Z1, 179–184. [Google Scholar]

- Lin, L. Researches on Plasma Surface Modification of Rabbit Hair. J. Text. Res. 1999, 1, 29, 46–49. [Google Scholar]

- Wu, J.; Liu, X.; Niu, A.; Peng, S.; Wang, T. A study on the plasma treated Angora rabbit hair in light of the scale field-angle. Int. J. Adhes. Adhes. 1999, 19, 381–385. [Google Scholar]

- Danish, N.; Garg, M.K.; Rane, R.S.; Jhala, P.B.; Nema, S.K. Surface modification of Angora rabbit fibers using dielectric barrier discharge. Appl. Surf. Sci. 2007, 253, 6915–6921. [Google Scholar] [CrossRef]

- Kuo, Y.L.; Chang, K.H.; Hung, T.S.; Chen, K.S.; Inagaki, N. Atmospheric-pressure plasma treatment on polystyrene for the photo-induced grafting polymerization of N-isopropylacrylamide. Thin Solid Film. 2010, 518, 7568–7573. [Google Scholar] [CrossRef]

- Poletti, G.; Orsini, F.; Raffaele-Addamo, A.; Riccardi, C.; Selli, E. Cold plasma treatment of PET fabrics: AFM surface morphology characterisation. Appl. Surf. Sci. 2003, 219, 311–316. [Google Scholar] [CrossRef]

- Ma, C.; Wang, L.; Nikiforov, A.; Onyshchenko, Y.; Morent, R. Atmospheric-pressure plasma assisted engineering of polymer surfaces: From high hydrophobicity to superhydrophilicity. Appl. Surf. Sci. 2020, 535, 147032. [Google Scholar] [CrossRef]

- Badr, A.A.; El-Nahrawy, A. Moisture properties of raised 3-thread fleece fabric knitted with different face and fleecy yarns. Alex. Eng. J. 2016, 55, 2881–2892. [Google Scholar] [CrossRef]

- Zhao, Z.; Hurren, C.; Zhou, L.; Sun, L.; Wu, J. Effects of gallic acid grafted chitosan on improving light fastness of cotton fabric dyed with gardenia yellow. J. Text. Inst. 2020, 112, 1954–1964. [Google Scholar] [CrossRef]

- Podgorski, L.; Bousta, C.; Schambourg, F.; Maguin, J.; Chevet, B. Surface modification of wood by plasma polymerisation. Pigment. Resin Technol. 2002, 31, 33–40. [Google Scholar] [CrossRef]

- Radetić, M.; Lj-Petrović, Z. Application of plasma technology for the modification of polymer and textile materials. Hem. Ind. 2004, 58, 55–63. [Google Scholar] [CrossRef]

- Kamlangkla, K.; Paosawatyanyong, B.; Pavarajarn, V.; Hodak, J.H.; Hodak, S.K. Mechanical strength and hydrophobicity of cotton fabric after SF6 plasma treatment. Appl. Surf. Sci. 2010, 256, 5888–5897. [Google Scholar] [CrossRef]

- Teli, M.D.; Pandit, P.; Samanta, K.K.; Basak, S.; Gayatri, T.N. Salt-free and low temperature colouration of silk using He-N2 nonthermal plasma irradiation. J. Clean. Prod. 2021, 296, 126576. [Google Scholar] [CrossRef]

- Lin, F.; Li, W.; Du, X.; Chen, N.; Jiang, J. Electrically conductive silver/polyimide fabric composites fabricated by spray-assisted electroless plating. Appl. Surf. Sci. 2019, 493, 1–8. [Google Scholar] [CrossRef]

- Morent, R.; De Geyter, N.; Verschuren, J.; De Clerck, K.; Kiekens, P.; Leys, C. Non-thermal plasma treatment of textiles. Surf. Coat. Technol. 2008, 202, 3427–3449. [Google Scholar] [CrossRef]

| Untreated Fabric | 1.0 Kw | 1.3 Kw | 1.6 Kw | 1.9 Kw | 2.0 Kw | 2.3 Kw | 2.6 Kw | 2.9 Kw | 3.0 Kw | 3.3 Kw | 3.6 Kw | 3.9 Kw | 4.0 Kw |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2.08 | 2.10 | 2.37 | 2.41 | 2.43 | 2.46 | 2.49 | 2.56 | 2.59 | 2.60 | 2.71 | 2.73 | 2.75 | 2.81 |

| Untreated Fabric | 15 s | 30 s | 45 s | 60 s | 75 s | 90 s |

|---|---|---|---|---|---|---|

| 2.08 | 2.10 | 2.22 | 2.49 | 2.52 | 2.61 | 2.74 |

| Handle Index | Grey Fabrics | Treated Fabrics |

|---|---|---|

| OVERALL | 3.53 | 3.41 |

| ROUGH/SMOOTH | 2.08 | 2.10 |

| HARD/SOFT | 4.64 | 4.68 |

| LOOSE/TIGHT | 5.50 | 5.49 |

| LIGHT/HEAVY | 5.75 | 5.79 |

| CLEAN/HAIRY | 7.50 | 6.82 |

| COOL/WARM | 7.42 | 7.45 |

| GREASY/DRY | 8.70 | 8.66 |

| Fabric Type | Breaking Strength/ N | Breaking Elongation/ mm |

|---|---|---|

| Untreated fabrics | 153 | 72.8 |

| Treated fabrics | 150 | 64.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Zhao, Z.; Wu, J. Application of Atmospheric-Pressure Plasma Treatment in Anti-Hairfalling of Polyester–Cotton Fleece Knitted Fabrics. Polymers 2023, 15, 2097. https://doi.org/10.3390/polym15092097

Chen Z, Zhao Z, Wu J. Application of Atmospheric-Pressure Plasma Treatment in Anti-Hairfalling of Polyester–Cotton Fleece Knitted Fabrics. Polymers. 2023; 15(9):2097. https://doi.org/10.3390/polym15092097

Chicago/Turabian StyleChen, Zhipeng, Zhong Zhao, and Jihong Wu. 2023. "Application of Atmospheric-Pressure Plasma Treatment in Anti-Hairfalling of Polyester–Cotton Fleece Knitted Fabrics" Polymers 15, no. 9: 2097. https://doi.org/10.3390/polym15092097

APA StyleChen, Z., Zhao, Z., & Wu, J. (2023). Application of Atmospheric-Pressure Plasma Treatment in Anti-Hairfalling of Polyester–Cotton Fleece Knitted Fabrics. Polymers, 15(9), 2097. https://doi.org/10.3390/polym15092097