Flexural Behaviour of GFRP-Softwood Sandwich Panels for Prefabricated Building Construction

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

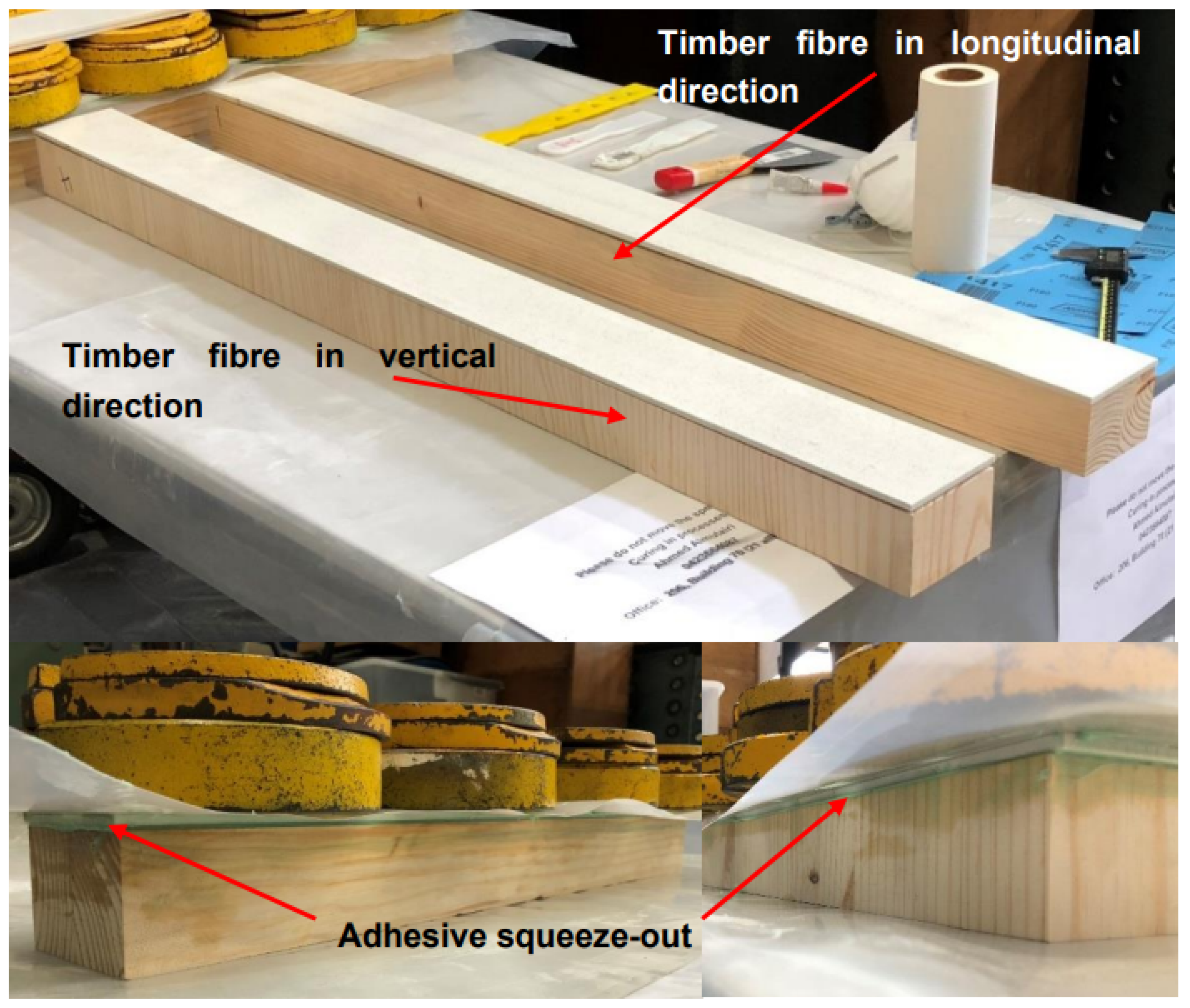

2.2. Specimen Details and Preparation

2.3. Experimental Setup and Instrumentation

3. FE Modelling

4. Results and Discussion

4.1. Failure Modes

4.2. Load–Displacement Behaviour

4.3. Load–Strain Behaviour and Composite Action

4.4. Effect of Shear-Span-to-Depth Ratio and Timber Fibre Direction of Core

5. Conclusions

- All tested GFRP-softwood sandwich specimens, with the core configurations of either longitudinal or vertical timber fibre direction, exhibited similar load–deflection behaviours, which were approximately linear until the first failure occurred. The increase in moment capacity was similar for the specimens with a shear-span-to-depth ratio a/d of 4 (L4 and V4) by around 60% in comparison to L2 and V2 (a/d of 2). However, there was a different improvement in moment capacity for L6.5 (95%) and V6.5 (68%) in comparison to L2 and V2, respectively.

- The results showed that timber with longitudinal fibre and shear-span-to-depth ratios a/d of 2 and 4 showed different drop patterns due to progressive failure, while that with a shear-span-to-depth ratio a/d of 6.5 showed sudden drop at the ultimate load due to brittle failure. In contrast, the timber core with vertical fibres exhibited sudden failure at the ultimate load for specimens with a/d ratios of 2, 4, and 6.5.

- The strain results showed that the adhesive bonding used in this study was able to provide a full composite action between the GFRP panels and softwood core during the loading process up to failure for all tested specimens. Furthermore, a gradual and stable deformation was observed along the span and depth of each GFRP-softwood sandwich specimen. It can be therefore identified that excellent bonding quality and full composite action were maintained at different load levels along the span.

- The timber fibre direction of the softwood cores used in this study affected the bending stiffness EI of the GFRP-softwood sandwich beams. The specimens with longitudinal-timber-fibre-direction cores had greater bending stiffness in comparison to the specimens with vertical-timber-fibre-direction cores. It was also found that the shear deformability was more pronounced for the sandwich beams that had a smaller shear-span-to-depth ratio, where specimens with a shear-span-to-depth ratio of 2 showed about 38.3% to 54.3% shear deformability.

- The FE modelling approach used in this study for the proposed GFRP-softwood sandwich beams showed results in satisfactory agreement with the experimental results with a maximum deviation of 16.1%. Furthermore, the FE results well described the failure modes and composite action.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced Polymer Composites for Construction-State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Bank, L.C. Progressive Failure and Ductility of FRP Composites for Construction: Review. J. Compos. Constr. 2013, 17, 406–419. [Google Scholar] [CrossRef]

- Saafi, M.; Asa, E. Extending the Service Life of Electric Distribution and Transmission Wooden Poles Using a Wet Layup FRP Composite Strengthening System. J. Perform. Constr. Facil. 2010, 24, 409–416. [Google Scholar] [CrossRef]

- Polyzois, D.; Kell, J.A. Repair and rehabilitation of wood utility poles with fibre-reinforced polymers. Can. J. Civ. Eng. 2007, 34, 116–119. [Google Scholar] [CrossRef]

- Ferdous, W.; Almutairi, A.D.; Huang, Y.; Bai, Y. Short-term flexural behaviour of concrete filled pultruded GFRP cellular and tubular sections with pin-eye connections for modular retaining wall construction. Compos. Struct. 2018, 206, 1–10. [Google Scholar] [CrossRef]

- Hou, M.; Wang, Q.Y.; Zhu, Y.M.; Yuan, S.C. Square Short Wood Columns Strengthened with FRP Sheets under Compressive Load. Appl. Mech. Mater. 2012, 256–259, 1008–1011. [Google Scholar]

- Fang, H.; Bai, Y.; Liu, W.; Qi, Y.; Wang, J. Connections and structural applications of fibre reinforced polymer composites for civil infrastructure in aggressive environments. Compos. Part B Eng. 2019, 164, 129–143. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T. Behaviour of glued fibre composite sandwich structure in flexure: Experiment and Fibre Model Analysis. Mater. Eng. 2012, 39, 458–468. [Google Scholar] [CrossRef]

- Keller, T.; Gürtler, H. Composite Action and Adhesive Bond between Fiber-Reinforced Polymer Bridge Decks and Main Girders. J. Compos. Constr. 2005, 9, 360–368. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Zhao, X.-L.; Al-Mahaidi, R. Effects of ultraviolet radiation and associated elevated temperature on mechanical performance of steel/CFRP double strap joints. Compos. Struct. 2012, 94, 3563–3573. [Google Scholar] [CrossRef]

- Ramôa Correia, J. Pultrusion of Advanced Fibre-Reinforced Polymer (FRP) Composites; Woodhead Publishing: Sawston, UK, 2013; pp. 207–251. [Google Scholar]

- Satasivam, S.; Bai, Y. Mechanical performance of bolted modular GFRP composite sandwich structures using standard and blind bolts. Compos. Struct. 2014, 117, 59–70. [Google Scholar] [CrossRef]

- Shi, H.; Liu, W.; Fang, H.; Bai, Y.; Hui, D. Flexural responses and pseudo-ductile performance of lattice-web reinforced GFRP-wood sandwich beams. Compos. Part B Eng. 2017, 108, 364–376. [Google Scholar] [CrossRef]

- Zhu, D.; Shi, H.; Fang, H.; Liu, W.; Qi, Y.; Bai, Y. Fiber reinforced composites sandwich panels with web reinforced wood core for building floor applications. Compos. Part B Eng. 2018, 150, 196–211. [Google Scholar] [CrossRef]

- Satasivam, S.S. Modular FRP Sandwich Structures for Building Floor Construction; Monash University: Clayton, Australia, 2017. [Google Scholar]

- Almutairi, A.D.; Bai, Y.; Zhao, X.-L.; Ferdous, W. Full Scale Evaluation of GFRP Confined Softwood after Long-Term Exposure to High Humidity Environment. Forests 2023, 14, 343. [Google Scholar] [CrossRef]

- Bai, Y.; Satasivam, S.; Yang, X.; Almutairi, A.; Christofer, H.I.; Ding, C. Large Scale Structural Applications. In Composites for Building Assembly; Springer: Berlin/Heidelberg, Germany, 2023; pp. 357–384. [Google Scholar]

- Almutairi, A.D.; Bai, Y.; Wang, Y.; Jeske, J. Mechanical performance of fibre reinforced polymer confined softwood timber for pole applications. Compos. Struct. 2020, 235, 111807. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Almutairi, A.D.; Satasivam, S.; Jeske, J. Modular assembly of water-retaining walls using GFRP hollow profiles: Components and connection performance. Compos. Struct. 2018, 194, 1–11. [Google Scholar] [CrossRef]

- Qiao, P.; Yang, M. Impact analysis of fiber reinforced polymer honeycomb composite sandwich beams. Compos. Part B Eng. 2007, 38, 739–750. [Google Scholar] [CrossRef]

- Allen, H.G. Analysis and Design of Structural Sandwich Panels; Elsevier: Amsterdam, The Netherlands, 1969. [Google Scholar]

- Manalo, A.C.; Aravinthan, T.; Karunasena, W. Flexural behaviour of glue-laminated fibre composite sandwich beams. Compos. Struct. 2010, 92, 2703–2711. [Google Scholar] [CrossRef]

- Fam, A.; Sharaf, T. Flexural performance of sandwich panels comprising polyurethane core and GFRP skins and ribs of various configurations. Compos. Struct. 2010, 92, 2927–2935. [Google Scholar] [CrossRef]

- Fang, H.; Sun, H.; Liu, W.; Wang, L.; Bai, Y.; Hui, D. Mechanical performance of innovative GFRP-bamboo-wood sandwich beams: Experimental and modelling investigation. Compos. Part B Eng. 2015, 79, 182–196. [Google Scholar] [CrossRef]

- Manalo, A.C.; Aravinthan, T.; Karunasena, W.; Islam, M.M. Flexural behaviour of structural fibre composite sandwich beams in flatwise and edgewise positions. Compos. Struct. 2010, 92, 984–995. [Google Scholar] [CrossRef]

- Lombardi, N.J.; Liu, J. Glass fiber-reinforced polymer/steel hybrid honeycomb sandwich concept for bridge deck applications. Compos. Struct. 2011, 93, 1275–1283. [Google Scholar] [CrossRef]

- Liu, Z.; Majumdar, P.K.; Cousins, T.E.; Lesko, J.J. Development and Evaluation of an Adhesively Bonded Panel-to-Panel Joint for a FRP Bridge Deck System. J. Compos. Constr. 2008, 12, 224–233. [Google Scholar] [CrossRef]

- Keller, T.; Rothe, J.; de Castro, J.; Osei-Antwi, M. GFRP-Balsa Sandwich Bridge Deck: Concept, Design, and Experimental Validation. J. Compos. Constr. 2014, 18, 4013043. [Google Scholar] [CrossRef]

- Dey, T.K.; Srivastava, I.; Khandelwal, R.P.; Sharma, U.K.; Chakrabarti, A. Optimum design of FRP rib core bridge deck. Compos. Part B Eng. 2013, 45, 930–938. [Google Scholar] [CrossRef]

- Keller, T.; Schollmayer, M. Plate bending behavior of a pultruded GFRP bridge deck system. Compos. Struct. 2004, 64, 285–295. [Google Scholar] [CrossRef]

- Satasivam, S.; Bai, Y.; Zhao, X.-L. Adhesively bonded modular GFRP web–flange sandwich for building floor construction. Compos. Struct. 2014, 111, 381–392. [Google Scholar] [CrossRef]

- Zi, G.; Kim, B.M.; Hwang, Y.K.; Lee, Y.H. An experimental study on static behavior of a GFRP bridge deck filled with a polyurethane foam. Compos. Struct. 2008, 82, 257–268. [Google Scholar] [CrossRef]

- Satasivam, S.; Bai, Y.; Yang, Y.; Zhu, L.; Zhao, X.-L. Mechanical performance of two-way modular FRP sandwich slabs. Compos. Struct. 2018, 184, 904–916. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007; Volume 2. [Google Scholar]

- Osei-Antwi, M.; de Castro, J.; Vassilopoulos, A.P.; Keller, T. Structural limits of FRP-balsa sandwich decks in bridge construction. Compos. Part B Eng. 2014, 63, 77–84. [Google Scholar] [CrossRef]

- Galos, J.; Das, R.; Sutcliffe, M.P.; Mouritz, A.P. Review of balsa core sandwich composite structures. Mater. Des. 2022, 221, 111013. [Google Scholar] [CrossRef]

- Labans, E.; Kalnins, K.; Bisagni, C. Flexural behavior of sandwich panels with cellular wood, plywood stiffener/foam and thermoplastic composite core. J. Sandw. Struct. Mater. 2019, 21, 784–805. [Google Scholar] [CrossRef]

- Peliński, K.; Smardzewski, J. Static response of synclastic sandwich panel with auxetic wood-based honeycomb cores subject to compression. Thin-Walled Struct. 2022, 179, 109559. [Google Scholar] [CrossRef]

- Shalbafan, A.; Luedtke, J.; Welling, J.; Thoemen, H. Comparison of foam core materials in innovative lightweight wood-based panels. Eur. J. Wood Wood Prod. 2012, 70, 287–292. [Google Scholar] [CrossRef]

- Vahedi, N.; Correia, J.R.; Vassilopoulos, A.P.; Keller, T. Effects of core air gaps and steel inserts on thermomechanical response of GFRP-balsa sandwich panels subjected to fire. Compos. Struct. 2023, 313, 116924. [Google Scholar] [CrossRef]

- Truxel, A.; Aviles, F.; Carlsson, L.; Grenestedt, J.; Millay, K. Influence of face/core interface on debond toughness of foam and balsa cored sandwich. J. Sandw. Struct. Mater. 2006, 8, 237–258. [Google Scholar] [CrossRef]

- Zanuttini, R.; Negro, F. Wood-Based Composites: Innovation towards a Sustainable Future; Multidisciplinary Digital Publishing Institute: Basel, Switzerland, 2021; p. 1717. [Google Scholar]

- Shir Mohammadi, M.; Nairn, J.A. Balsa sandwich composite fracture study: Comparison of laminated to solid balsa core materials and debonding from thick balsa core materials. Compos. Part B Eng. 2017, 122, 165–172. [Google Scholar] [CrossRef]

- ASTM D143–94; Standard Test Methods for Small Clear Specimens of Timber. ASTM: West Conshohocken, PA, USA, 2000.

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2000.

- Lee, S.; Munro, M.; Scott, R.F. Evaluation of three in-plane shear test methods for advanced composite materials. Composites 1990, 21, 495–502. [Google Scholar] [CrossRef]

- ASTM D2344; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM: West Conshohocken, PA, USA, 2000.

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2010.

- Clarke, J.L. European Structural Polymeric Composites, G, ProQuest. In Structural Design of Polymer Composites: Eurocomp Design Code and Handbook; E and FN Spon: London, UK, 1996. [Google Scholar]

- ASTMC393-00; Standard Test Method for Flexural Properties of Sandwich Constructions. ASTM: West Conshohocken, PA, USA, 2000.

- Bai, Y.; Qiu, C. Load-Dependent Composite Action for Beam Nonlinear and Ductile Behavior. J. Struct. Eng. 2020, 146, 04020028. [Google Scholar] [CrossRef]

- Timoshenko, S.; Goodier, J.N. Theory of Elasticity, 3rd ed.; McGraw-Hill: New York, NY, USA, 1969. [Google Scholar]

| Parameters | Magnitude | Unit |

|---|---|---|

| Tensile strength parallel to wood grain direction | 58.4 | MPa |

| Tensile strength perpendicular to wood grain direction | 4.6 | MPa |

| Compressive strength parallel to wood grain direction | 50.4 | MPa |

| Compressive strength perpendicular to wood grain direction | 10.6 | MPa |

| Shear strength parallel to wood grain direction | 16.5 | MPa |

| Tensile modulus of elasticity parallel to wood grain direction | 11.8 | GPa |

| Tensile modulus of elasticity perpendicular to wood grain direction | 1.6 | GPa |

| Compressive modulus of elasticity parallel to wood grain direction | 10.4 | GPa |

| Compressive modulus of elasticity perpendicular to wood grain direction | 1.6 | GPa |

| Shear modulus of elasticity parallel to wood grain direction | 1.5 | GPa |

| Shear modulus of elasticity perpendicular to wood grain direction | 0.8 | GPa |

| Density of the softwood | 523 | kg/m3 |

| Adhesive modulus of elasticity | 4.6 | GPa |

| Adhesive shear modulus | 1.5 | GPa |

| Adhesive tensile strength | 40.2 | MPa |

| Tensile strength in longitudinal direction of GFRP | 393 | MPa |

| Tensile strength in transverse direction of GFRP | 23 | MPa |

| Tensile modulus of elasticity in longitudinal direction of GFRP | 32.2 | GPa |

| Tensile modulus of elasticity in transverse direction of GFRP | 5.2 | GPa |

| Shear modulus of GFRP | 3.5 | GPa |

| Shear strength of GFRP | 20.2 | MPa |

| Poisson ratio | 0.3 |

| Specimens 1 | a/d | L | b | d | a |

|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | ||

| L2 | 2 | 495 | 90 | 74 | 165 |

| V2 | 2 | 495 | 90 | 74 | 165 |

| L4 | 4 | 945 | 90 | 74 | 315 |

| V4 | 4 | 945 | 90 | 74 | 315 |

| L6.5 | 6.5 | 1440 | 90 | 74 | 480 |

| V6.5 | 6.5 | 1440 | 90 | 74 | 480 |

| Specimens | (P/δ)exp | Experimental Bending Stiffness EIexp | Shear Deformability | Ultimate Failure Load Pu | Mid-Span Bending Moment Mb |

|---|---|---|---|---|---|

| (kN·mm2) × 108 | % | kN | kN·m | ||

| L2 | 18.18 | 1.24 | 38.29 | 101.74 | 8.39 |

| V2 | 12.59 | 1.17 | 54.26 | 64.30 | 5.30 |

| L4 | 4.07 | 1.48 | 16.89 | 85.98 | 13.54 |

| V4 | 2.58 | 0.98 | 20.20 | 53.93 | 8.49 |

| L6.5 | 1.13 | 1.31 | 7.24 | 68.25 | 16.38 |

| V6.5 | 0.72 | 0.84 | 9.18 | 37.09 | 8.90 |

| Specimens | % Strain at Mid-Span Top | % Strain at Mid-Span Bottom | % Strain at Shear-Span | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Exp. | FE | % D | Exp. | FE | % D | Exp. | FE | % D | |

| L2 | −0.39 | −0.46 | −15.22 | 0.42 | 0.45 | −6.67 | 1.26 | 1.13 | 11.5 |

| V2 | −0.48 | −0.49 | −2.04 | 0.49 | 0.50 | −2 | 0.91 | 0.85 | 7.06 |

| L4 | −0.76 | −0.81 | −6.17 | 0.72 | 0.81 | −11.11 | 1.01 | 0.87 | 16.09 |

| V4 | −0.72 | −0.75 | −4 | 0.83 | 0.75 | 10.67 | 0.74 | 0.79 | −6.33 |

| L6.5 | −1.02 | −1.01 | 0.99 | 0.98 | 1.01 | −2.97 | 0.71 | 0.67 | 5.97 |

| V6.5 | −0.78 | −0.80 | −2.56 | 0.76 | 0.86 | −11.62 | 0.50 | 0.58 | −13.8 |

| Specimens | FE Bending Stiffness | Failure Load (kN) | ||||

|---|---|---|---|---|---|---|

| (P/δ)FE | EIFE (kN·mm2) × 108 | % D (EIexp/EIFE) | Exp. | FE | % D | |

| L2 | 19.11 | 1.33 | −4.51 | 101.7 | 107.6 | −5.48 |

| V2 | 13.42 | 1.28 | −8.59 | 64.3 | 73.2 | −12.15 |

| L4 | 3.91 | 1.38 | 7.24 | 86 | 95.8 | −10.23 |

| V4 | 2.66 | 1.01 | −2.97 | 53.9 | 61.4 | −12.21 |

| L6.5 | 1.16 | 1.32 | −0.76 | 68.2 | 75.5 | −9.67 |

| V6.5 | 0.69 | 0.80 | 5 | 37.1 | 41.0 | −9.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almutairi, A.D.; Bai, Y.; Ferdous, W. Flexural Behaviour of GFRP-Softwood Sandwich Panels for Prefabricated Building Construction. Polymers 2023, 15, 2102. https://doi.org/10.3390/polym15092102

Almutairi AD, Bai Y, Ferdous W. Flexural Behaviour of GFRP-Softwood Sandwich Panels for Prefabricated Building Construction. Polymers. 2023; 15(9):2102. https://doi.org/10.3390/polym15092102

Chicago/Turabian StyleAlmutairi, Ahmed D., Yu Bai, and Wahid Ferdous. 2023. "Flexural Behaviour of GFRP-Softwood Sandwich Panels for Prefabricated Building Construction" Polymers 15, no. 9: 2102. https://doi.org/10.3390/polym15092102

APA StyleAlmutairi, A. D., Bai, Y., & Ferdous, W. (2023). Flexural Behaviour of GFRP-Softwood Sandwich Panels for Prefabricated Building Construction. Polymers, 15(9), 2102. https://doi.org/10.3390/polym15092102