TCAD Device Simulation of All-Polymer Solar Cells for Indoor Applications: Potential for Tandem vs. Single Junction Cells

Abstract

:1. Introduction

2. Materials and Methods

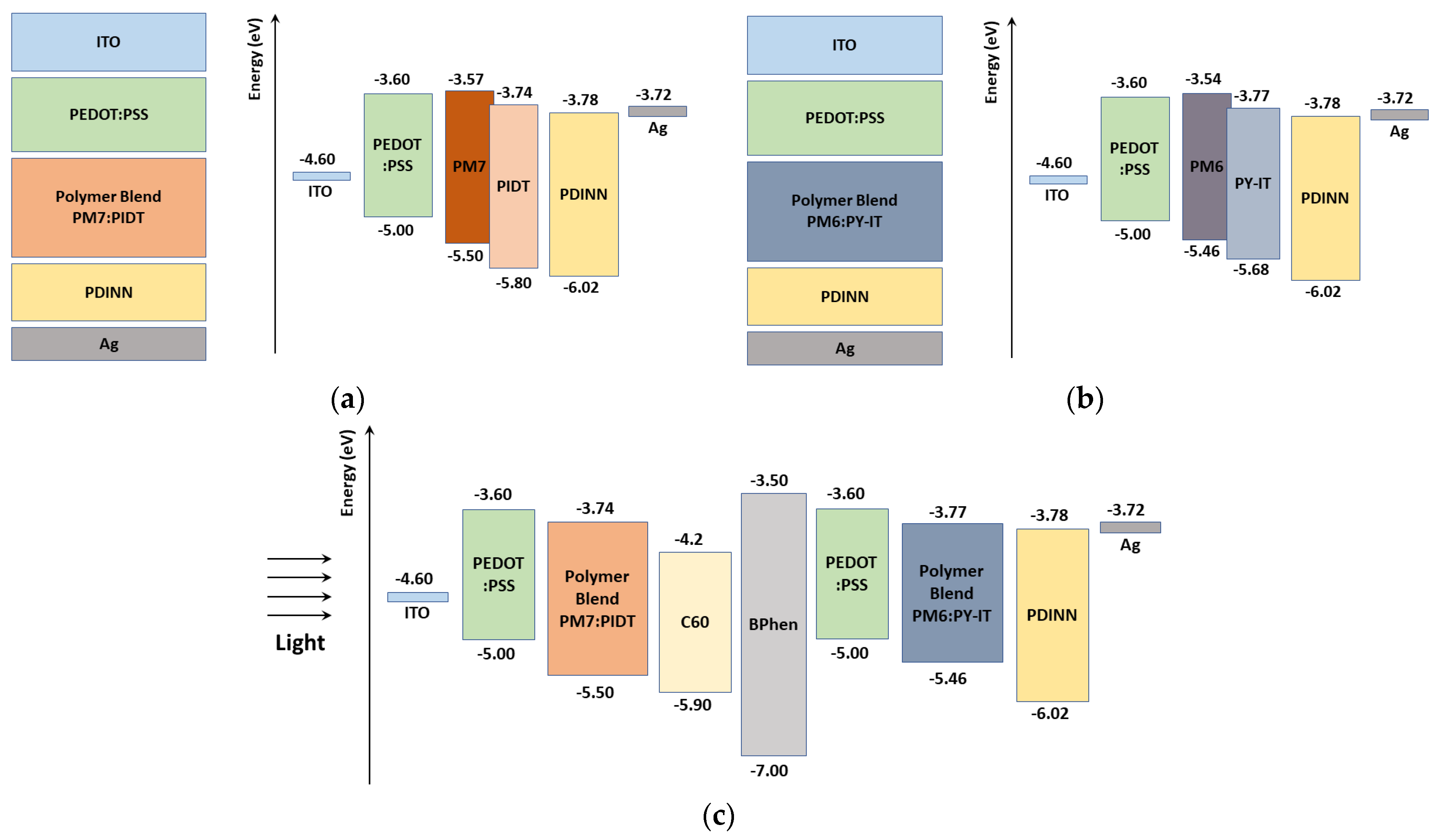

2.1. Solar Cell Configurations and Material Parameters

2.2. Simulation Methodology

2.3. Calibration of Standalone and Tandem Cells

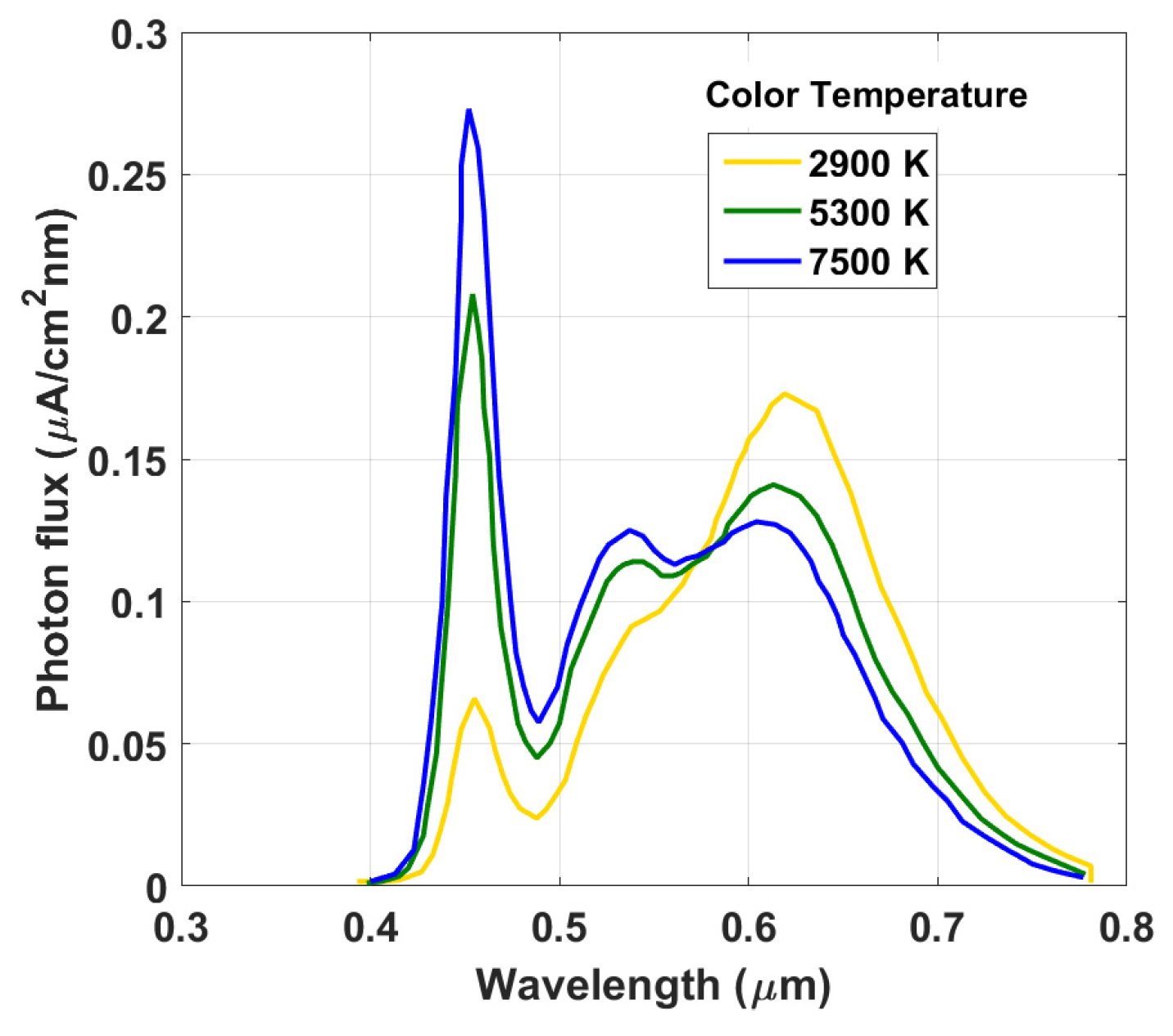

2.4. Indoor Light LED Characteristics

3. Results and Discussions

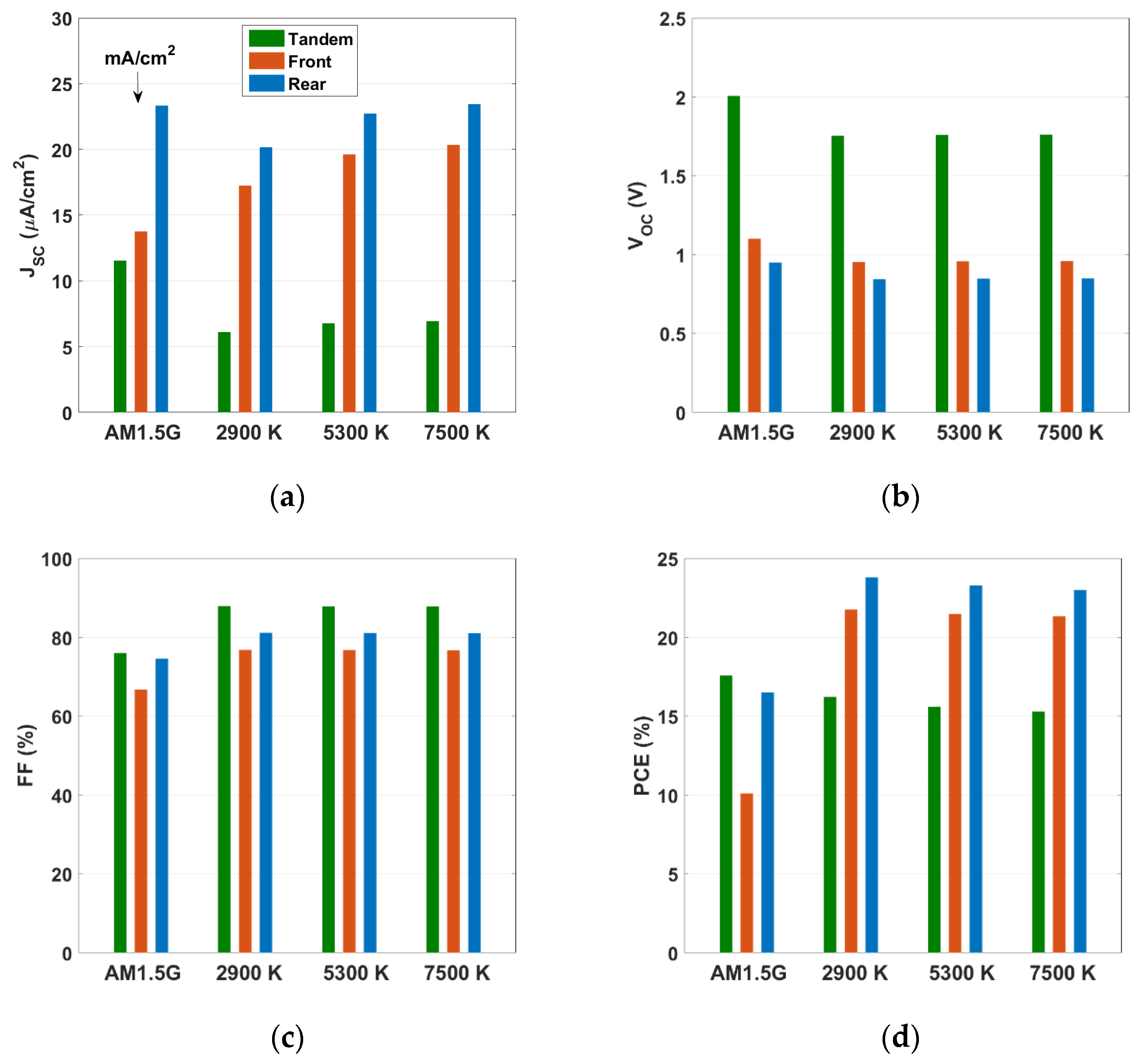

3.1. Impact of LED Color Temperature

3.2. Impact of LED Intensity

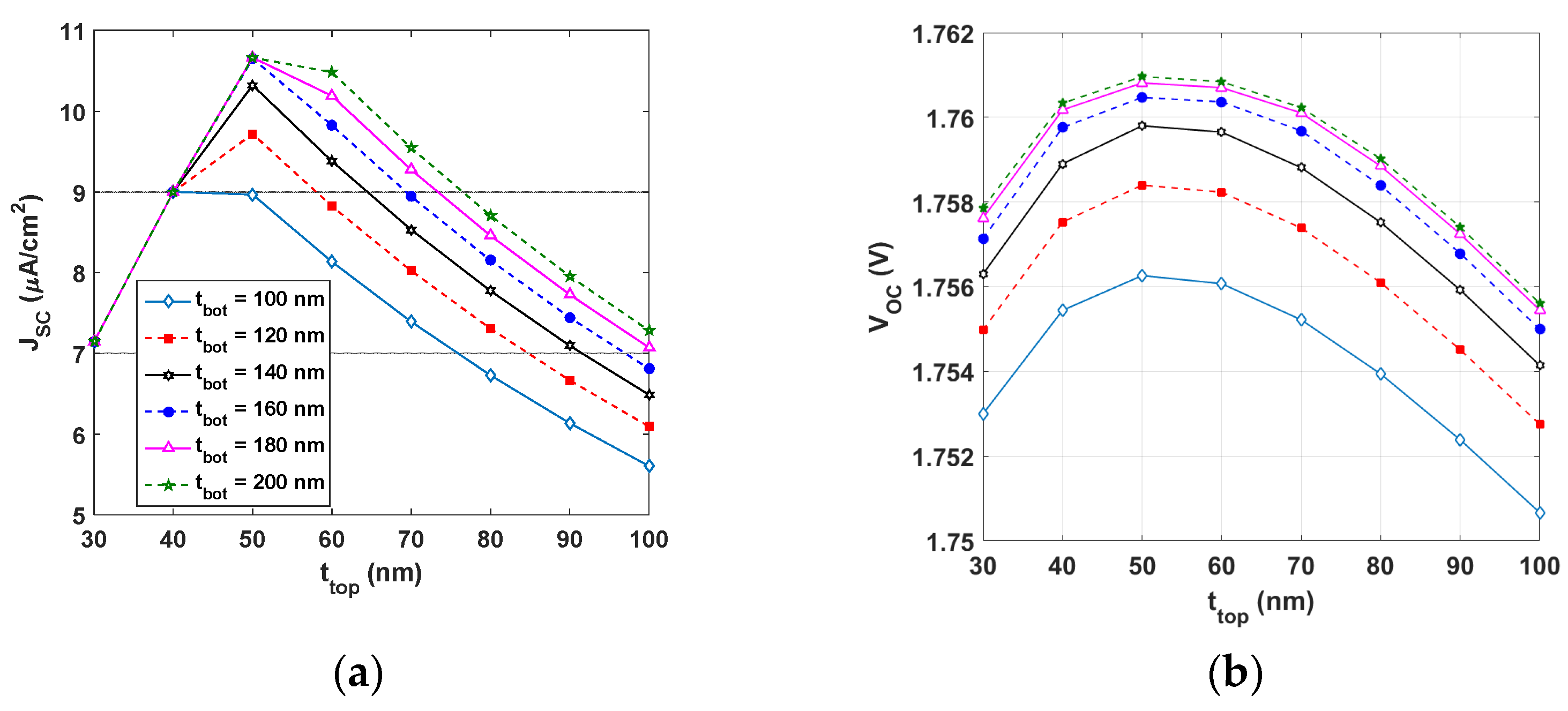

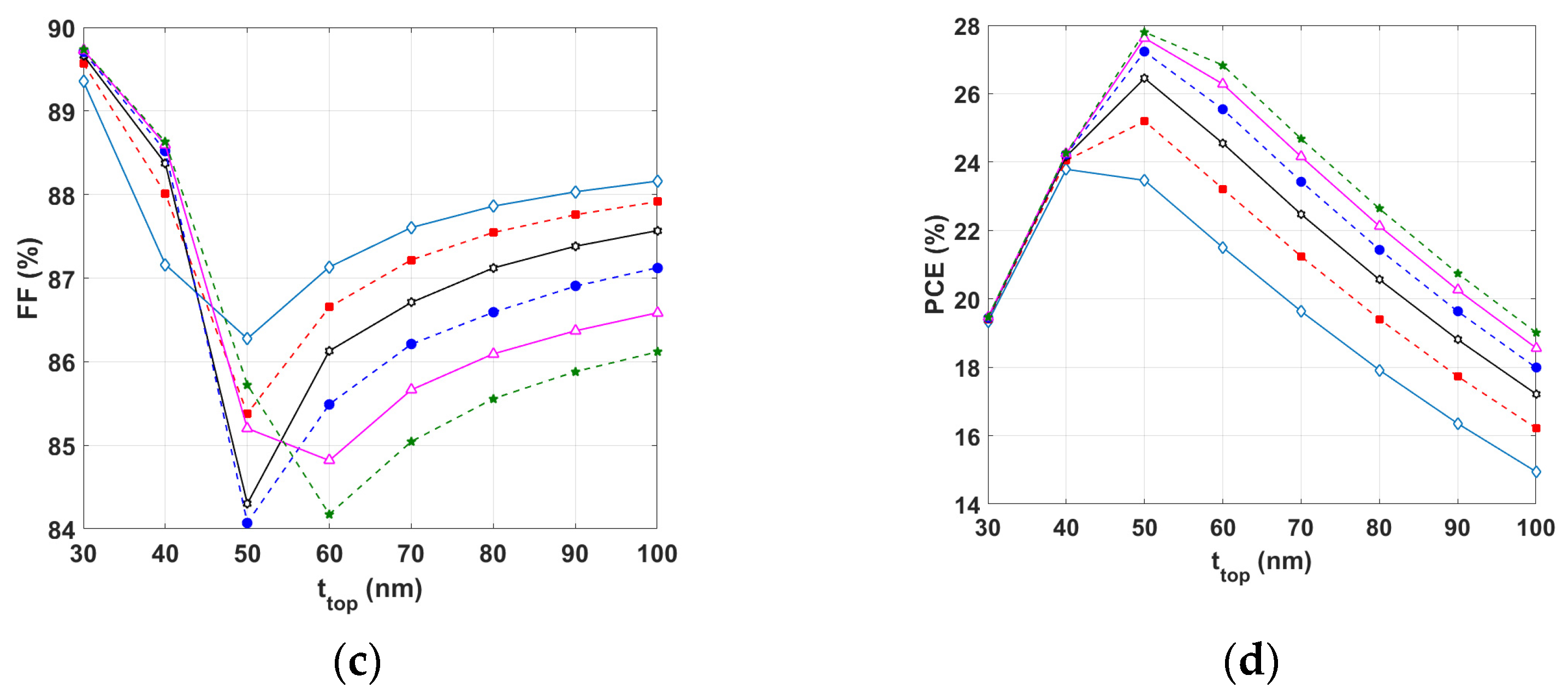

3.3. Optimization of Tandem Cells for an Indoor Environment

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zekry, A. A road map for transformation from conventional to photovoltaic energy generation and its challenges. J. King Saud Univ.-Eng. Sci. 2020, 32, 407–410. [Google Scholar] [CrossRef]

- Okil, M.; Salem, M.S.; Abdolkader, T.M.; Shaker, A. From Crystalline to Low-cost Silicon-based Solar Cells: A Review. Silicon 2021, 14, 1895–1911. [Google Scholar] [CrossRef]

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H.; et al. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Salem, M.S.; Zekry, A.; Shaker, A.; Abouelatta, M. Design and simulation of proposed low cost solar cell structures based on heavily doped silicon wafers. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Z.; Zhang, W.; Ma, Q.; Jiang, Z.; Ma, D. High performance hybrid silicon micropillar solar cell based on light trapping characteristics of Cu nanoparticles. AIP Adv. 2018, 8, 055309. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, H. Nanowires for High-Efficiency, Low-Cost Solar Photovoltaics. Crystals 2019, 9, 87. [Google Scholar] [CrossRef]

- Salem, M.S.; Alzahrani, A.J.; Ramadan, R.A.; Alanazi, A.; Shaker, A.; Abouelatta, M.; Zekry, A. Physically based analytical model of heavily doped silicon wafers based proposed solar cell microstructure. IEEE Access 2020, 8, 138898–138906. [Google Scholar] [CrossRef]

- Al Busaidi, H.; Suhail, A.; Jenkins, D.; Pan, G. Developed graphene/Si Schottky junction solar cells based on the top-window structure. Carbon Trends 2023, 10, 100247. [Google Scholar] [CrossRef]

- Alanazi, T.I.; Eid, O.I. Simulation of Triple-Cation Perovskite Solar Cells: Key Design Factors for Efficiency Promotion. Energies 2023, 16, 2717. [Google Scholar] [CrossRef]

- Salem, M.S.; Shaker, A.; Zekry, A.; Abouelatta, M.; Alanazi, A.; Alshammari, M.T.; Gontand, C. Analysis of hybrid hetero-homo junction lead-free perovskite solar cells by SCAPS simulator. Energies 2021, 14, 5741. [Google Scholar] [CrossRef]

- Kim, S.; Choi, H.; Lee, M.; Jung, H.; Shin, Y.; Lee, S.; Kim, K.; Kim, M.H.; Kwak, K.; Kim, B. Critical Role of Non-Halogenated Solvent Additives in Eco-Friendly and Efficient All-Polymer Solar Cells. Polymers 2023, 15, 1354. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, L.; Zhao, C.; Wang, Y.; Hu, R.; Che, J.; He, S.; Chen, W.; Cao, L.; Luo, Z.; et al. Efficient All-Polymer Solar Cells Enabled by Interface Engineering. Polymers 2022, 14, 3835. [Google Scholar] [CrossRef] [PubMed]

- Salem, M.S.; Shaker, A.; Salah, M.M. Device Modeling of Efficient PBDB-T:PZT-Based All-Polymer Solar Cell: Role of Band Alignment. Polymers 2023, 15, 869. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Yang, T.; Ma, R.; Zhan, L.; Luo, Z.; Zhang, G.; Li, Y.; Gao, K.; Xiao, Y.; Yu, J.; et al. 16% efficiency all-polymer organic solar cells enabled by a finely tuned morphology via the design of ternary blend. Joule 2021, 5, 914–930. [Google Scholar] [CrossRef]

- Wang, J.; Cui, Y.; Xu, Y.; Xian, K.; Bi, P.; Chen, Z.; Zhou, K.; Ma, L.; Zhang, T.; Yang, Y.; et al. A New Polymer Donor Enables Binary All-Polymer Organic Photovoltaic Cells with 18% Efficiency and Excellent Mechanical Robustness. Adv. Mater. 2022, 34, 2205009. [Google Scholar] [CrossRef]

- Ma, Q.; Jia, Z.; Meng, L.; Yang, H.; Zhang, J.; Lai, W.; Guo, J.; Jiang, X.; Cui, C.; Li, Y. 17.87% Efficiency All-Polymer Tandem Solar Cell Enabled by Complementary Absorbing Polymer Acceptors. Adv. Funct. Mater. 2023, 33, 2210733. [Google Scholar] [CrossRef]

- Jacobsson, T.J.; Hultqvist, A.; Svanström, S.; Riekehr, L.; Cappel, U.B.; Unger, E.; Rensmo, H.; Johansson, E.M.; Edoff, M.; Boschloo, G. 2-Terminal CIGS-perovskite tandem cells: A layer by layer exploration. Sol. Energy 2020, 207, 270–288. [Google Scholar] [CrossRef]

- Boukortt, N.E.I.; Patanè, S.; AlAmri, A.M.; AlAjmi, D.; Bulayyan, K.; AlMutairi, N. Numerical Investigation of Perovskite and u-CIGS Based Tandem Solar Cells Using Silvaco TCAD Simulation. Silicon 2023, 15, 293–303. [Google Scholar] [CrossRef]

- Yuan, J.; Gu, J.; Shi, G.; Sun, J.; Wang, H.Q.; Ma, W. High efficiency all-polymer tandem solar cells. Sci. Rep. 2016, 6, 26459. [Google Scholar] [CrossRef]

- Zhang, K.; Xia, R.; Fan, B.; Liu, X.; Wang, Z.; Dong, S.; Yip, H.L.; Ying, L.; Huang, F.; Cao, Y. 11.2% All-polymer tandem solar cells with simultaneously improved efficiency and stability. Adv. Mater. 2018, 30, 1803166. [Google Scholar] [CrossRef]

- Wei, F.; Yao, L.; Lan, F.; Li, G.; Liu, L. Tandem polymer solar cells: Simulation and optimization through a multiscale scheme. Beilstein J. Nanotechnol. 2017, 8, 123–133. [Google Scholar] [CrossRef]

- Biswas, S.; Kim, H. Solar Cells for Indoor Applications: Progress and Development. Polymers 2020, 12, 1338. [Google Scholar] [CrossRef] [PubMed]

- Águas, H.; Mateus, T.; Vicente, A.; Gaspar, D.; Mendes, M.J.; Schmidt, W.A.; Pereira, L.; Fortunato, E.; Martins, R. Thin film silicon photovoltaic cells on paper for flexible indoor applications. Adv. Funct. Mater. 2015, 25, 3592–3598. [Google Scholar] [CrossRef]

- Shin, S.C.; Koh, C.W.; Vincent, P.; Goo, J.S.; Bae, J.H.; Lee, J.J.; Shin, C.; Kim, H.; Woo, H.Y.; Shim, J.W. Ultra-thick semi-crystalline photoactive donor polymer for efficient indoor organic photovoltaics. Nano Energy 2019, 58, 466–475. [Google Scholar] [CrossRef]

- Hwang, S.; Yasuda, T. Indoor photovoltaic energy harvesting based on semiconducting π-conjugated polymers and oligomeric materials toward future IoT applications. Polym. J. 2022, 55, 297–316. [Google Scholar] [CrossRef]

- Bouclé, J.; Ribeiro Dos Santos, D.; Julien-Vergonjanne, A. Doing More with Ambient Light: Harvesting Indoor Energy and Data Using Emerging Solar Cells. Solar 2023, 3, 161–183. [Google Scholar] [CrossRef]

- Lucarelli, G.; Di Giacomo, F.; Zardetto, V.; Creatore, M.; Brown, T.M. Efficient light harvesting from flexible perovskite solar cells under indoor white light-emitting diode illumination. Nano Res. 2017, 10, 2130–2145. [Google Scholar] [CrossRef]

- Biswas, S.; You, Y.J.; Vincent, P.; Bae, J.H.; Shim, J.W.; Kim, H. Organic tandem solar cells under indoor light illumination. Prog. Photovolt. Res. Appl. 2020, 28, 946–955. [Google Scholar] [CrossRef]

- Abdelaziz, W.; Shaker, A.; Abouelatta, M.; Zekry, A. Possible efficiency boosting of non-fullerene acceptor solar cell using device simulation. Opt. Mater. 2019, 91, 239–245. [Google Scholar] [CrossRef]

- Yao, J.; Qiu, B.; Zhang, Z.G.; Xue, L.; Wang, R.; Zhang, C.; Chen, S.; Zhou, Q.; Sun, C.; Yang, C.; et al. Cathode engineering with perylene-diimide interlayer enabling over 17% efficiency single-junction organic solar cells. Nat. Commun. 2020, 11, 2726. [Google Scholar] [CrossRef]

- Salem, M.S.; Shaker, A.; Abouelatta, M.; Saeed, A. Full Optoelectronic Simulation of Lead-Free Perovskite/Organic Tandem Solar Cells. Polymers 2023, 15, 784. [Google Scholar] [CrossRef]

- ATLAS. Atlas User’s Manual; Silvaco Inc.: Santa Clara, CA, USA, 2016; Available online: https://silvaco.com/products/tcad/device_simulation/atlas/atlas.html (accessed on 10 March 2023).

- Cui, Y.; Wang, Y.; Bergqvist, J.; Yao, H.; Xu, Y.; Gao, B.; Yang, C.; Zhang, S.; Inganäs, O.; Gao, F.; et al. Wide-gap non-fullerene acceptor enabling high-performance organic photovoltaic cells for indoor applications. Nat. Energy 2019, 4, 768–775. [Google Scholar] [CrossRef]

- Shaker, A.; Salem, M.S.; Jayan, K.D. Analysis and design of pn homojunction Sb2Se3 solar cells by numerical simulation. Sol. Energy 2022, 242, 276–286. [Google Scholar] [CrossRef]

- Saloux, E.; Teyssedou, A.; Sorin, M. Explicit model of photovoltaic panels to determine voltages and currents at the maximum power point. Sol. Energy 2011, 85, 713–722. [Google Scholar] [CrossRef]

- Cui, Y.; Hong, L.; Zhang, T.; Meng, H.; Yan, H.; Gao, F.; Hou, J. Accurate photovoltaic measurement of organic cells for indoor applications. Joule 2021, 5, 1016–1023. [Google Scholar] [CrossRef]

- Kyaw, A.K.K.; Wang, D.H.; Gupta, V.; Leong, W.L.; Ke, L.; Bazan, G.C.; Heeger, A.J. Intensity dependence of current–voltage characteristics and recombination in high-efficiency solution-processed small-molecule solar cells. ACS Nano 2013, 7, 4569–4577. [Google Scholar] [CrossRef]

| Parameters | PEDOT:PSS [29] | PM7:PIDT [16] | PM6:PYIT [16] | PDINN [30] | C60 [31] |

|---|---|---|---|---|---|

| t (nm) | 30 | 100 | 100 | 30 | 20 |

| ELUMO (eV) | 3.40 | 3.74 | 3.77 | 3.78 | 4.2 |

| EHOMO (eV) | 5.00 | 5.50 | 5.46 | 6.02 | 5.9 |

| εr | 3.0 | 3.0 | 3.0 | 5.0 | 5.0 |

| µn (cm2/V·s) | 4.5 × 10−4 | 2.89 × 10−4 | 1.97 × 10−4 | 2 × 10−6 | 0.08 |

| µp (cm2/V·s) | 9.9 × 10−5 | 2.89 × 10−4 | 1.97 × 10−4 | 1 × 10−3 | 0.0035 |

| Nc (cm−3) | 1 × 1022 | 1 × 1021 | 1 × 1021 | 1 × 1019 | 2.2 × 1018 |

| Nv (cm−3) | 1 × 1022 | 1 × 1021 | 1 × 1021 | 1 × 1019 | 1.8 × 1019 |

| ND (cm−3) | - | - | - | 1 × 1019 | 1 × 1017 |

| NA (cm−3) | 5 × 1019 | - | - | - | - |

| PV Parameters | JSC (mA/cm2) | VOC (V) | FF (%) | η (%) | |

|---|---|---|---|---|---|

| Front subcell | Exp. | 14.0 ± 0.3 | 1.10 ± 0.01 | 65.3 ± 1.2 | 10.1 ± 1.3 |

| TCAD | 13.764 | 1.101 | 66.768 | 10.110 | |

| Rear subcell | Exp. | 23.2 ± 0.6 | 0.94 ± 0.01 | 72.6 ± 1.5 | 16.0 ± 0.4 |

| TCAD | 23.330 | 0.949 | 74.584 | 16.504 | |

| Tandem cell | Exp. | 11.5 ± 0.2 | 2.00 ± 0.01 | 75.0 ± 1.2 | 17.6 ± 0.2 |

| TCAD | 11.543 | 2.005 | 75.975 | 17.578 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alanazi, T.I. TCAD Device Simulation of All-Polymer Solar Cells for Indoor Applications: Potential for Tandem vs. Single Junction Cells. Polymers 2023, 15, 2217. https://doi.org/10.3390/polym15092217

Alanazi TI. TCAD Device Simulation of All-Polymer Solar Cells for Indoor Applications: Potential for Tandem vs. Single Junction Cells. Polymers. 2023; 15(9):2217. https://doi.org/10.3390/polym15092217

Chicago/Turabian StyleAlanazi, Tarek I. 2023. "TCAD Device Simulation of All-Polymer Solar Cells for Indoor Applications: Potential for Tandem vs. Single Junction Cells" Polymers 15, no. 9: 2217. https://doi.org/10.3390/polym15092217

APA StyleAlanazi, T. I. (2023). TCAD Device Simulation of All-Polymer Solar Cells for Indoor Applications: Potential for Tandem vs. Single Junction Cells. Polymers, 15(9), 2217. https://doi.org/10.3390/polym15092217