Mechanical, Flame-Retardant and Dielectric Properties of Intumescent Flame Retardant/Glass Fiber-Reinforced Polypropylene through a Novel Dispersed Distribution Mode

Abstract

:1. Introduction

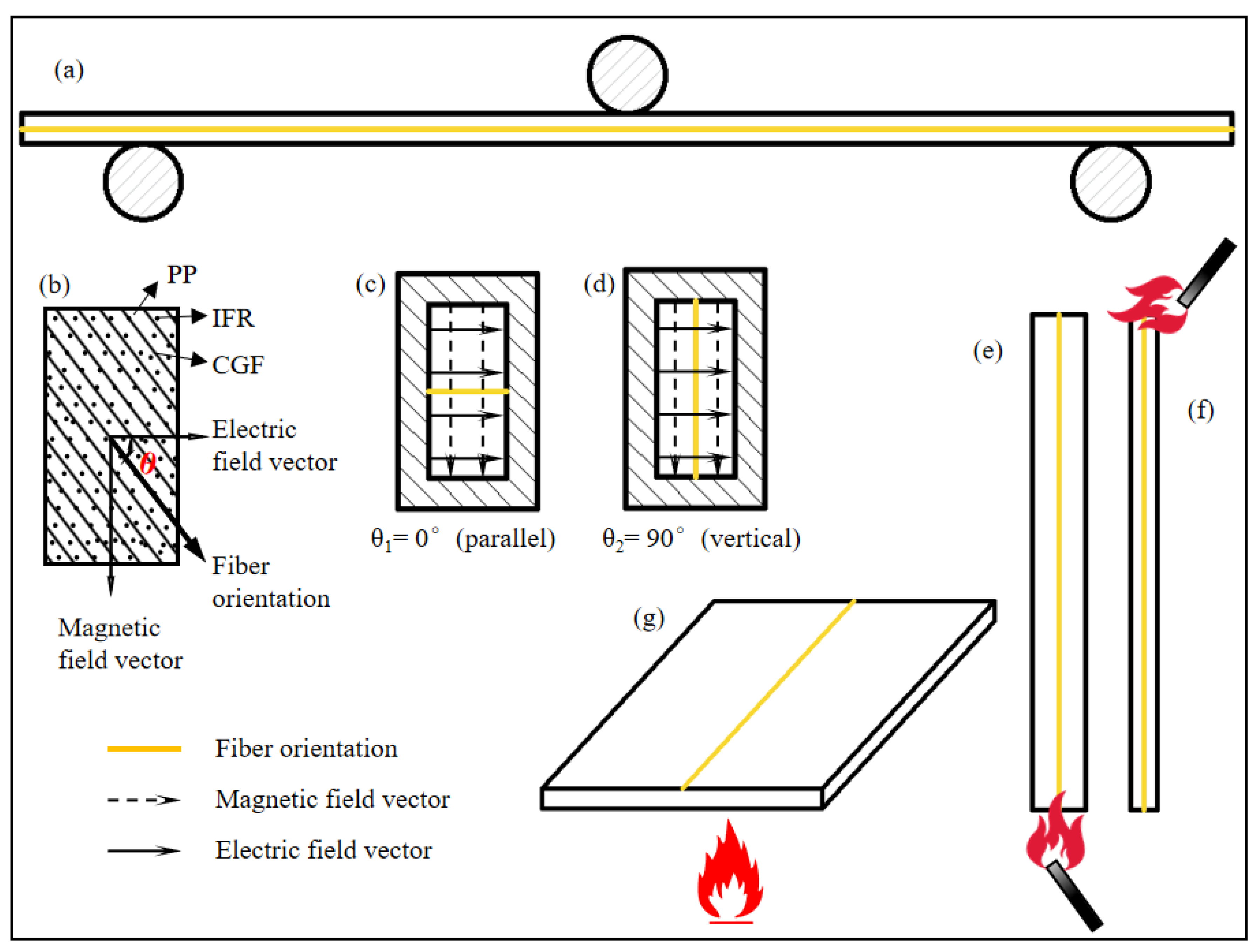

2. Materials and Methods

2.1. Materials

2.2. Preparation of IFR/PP

2.3. Preparation of IFR/GF/PP Prepregs

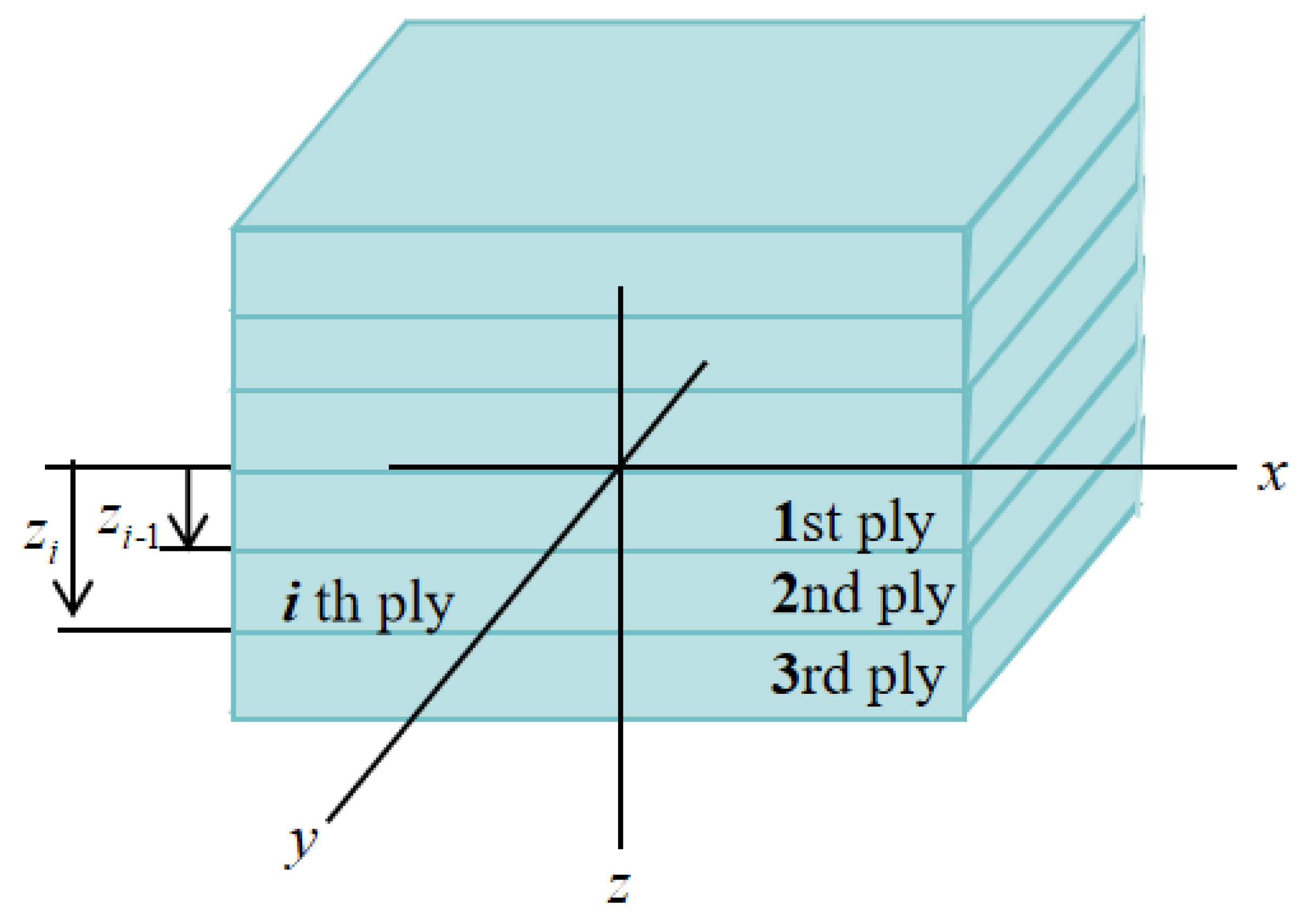

2.4. Preparation of IFR/GF/PP Laminates

2.5. Characterization

2.5.1. Mechanical Properties

2.5.2. Dielectric Properties

2.5.3. Limiting Oxygen Index (LOI)

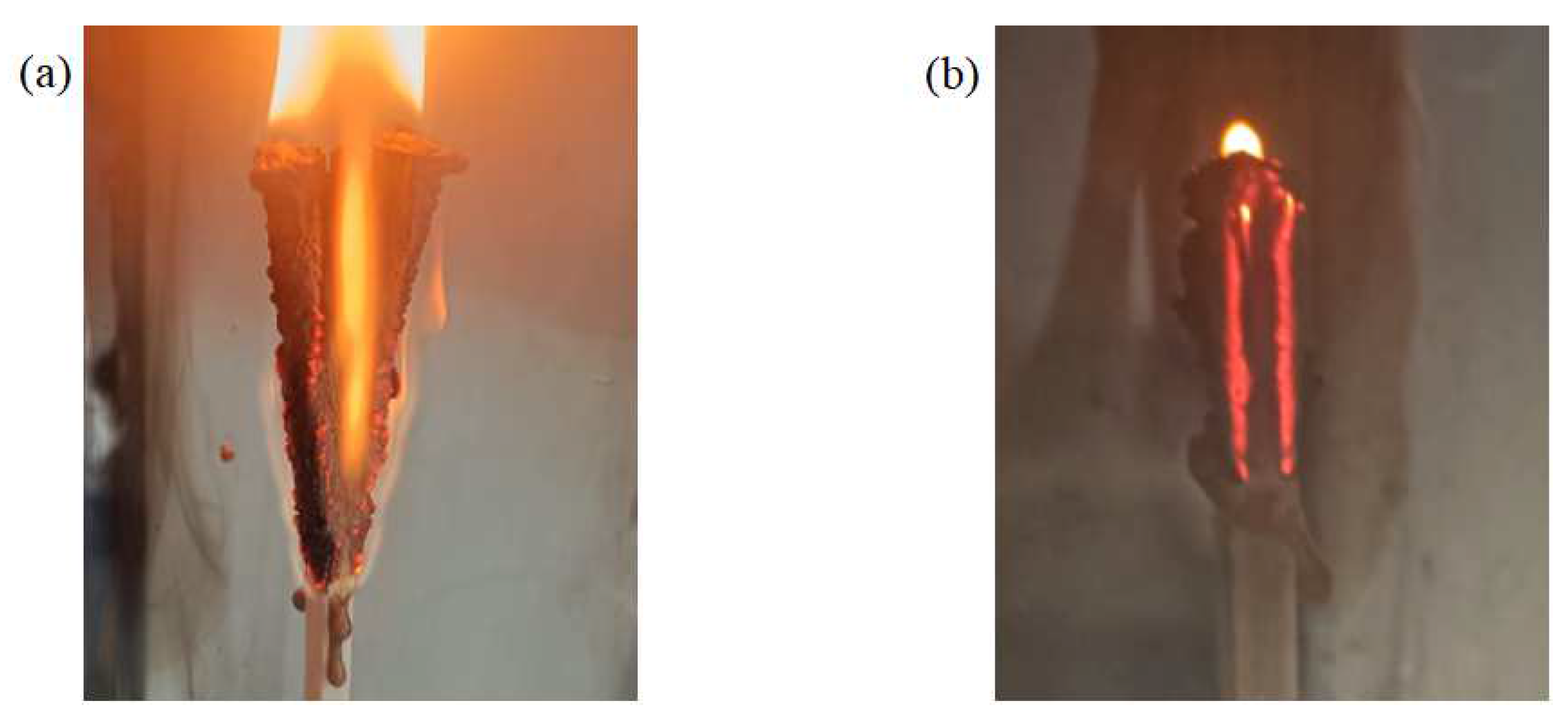

2.5.4. Vertical Burning Test

2.5.5. Cone Calorimeter Test (CCT)

3. Results and Discussion

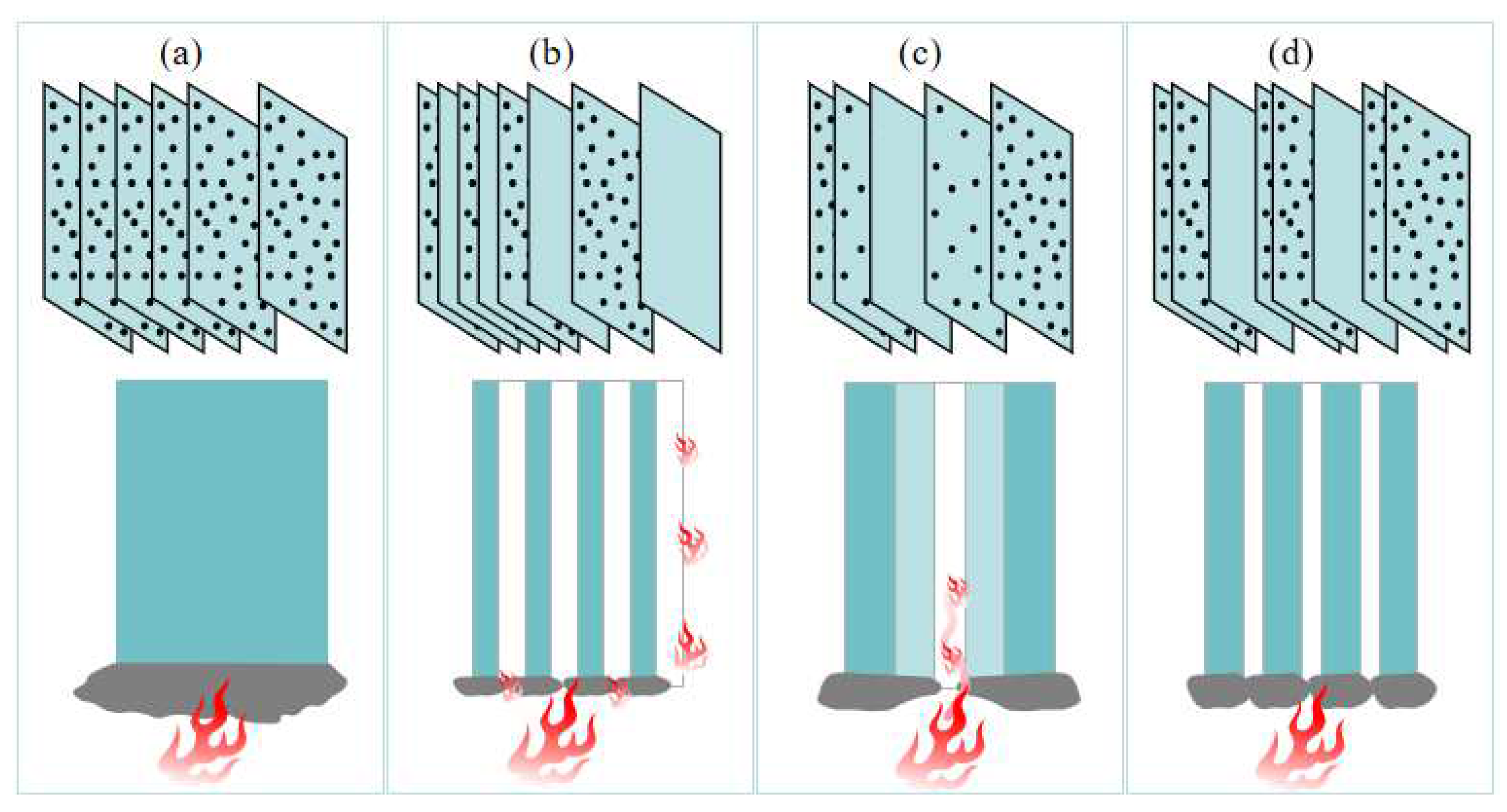

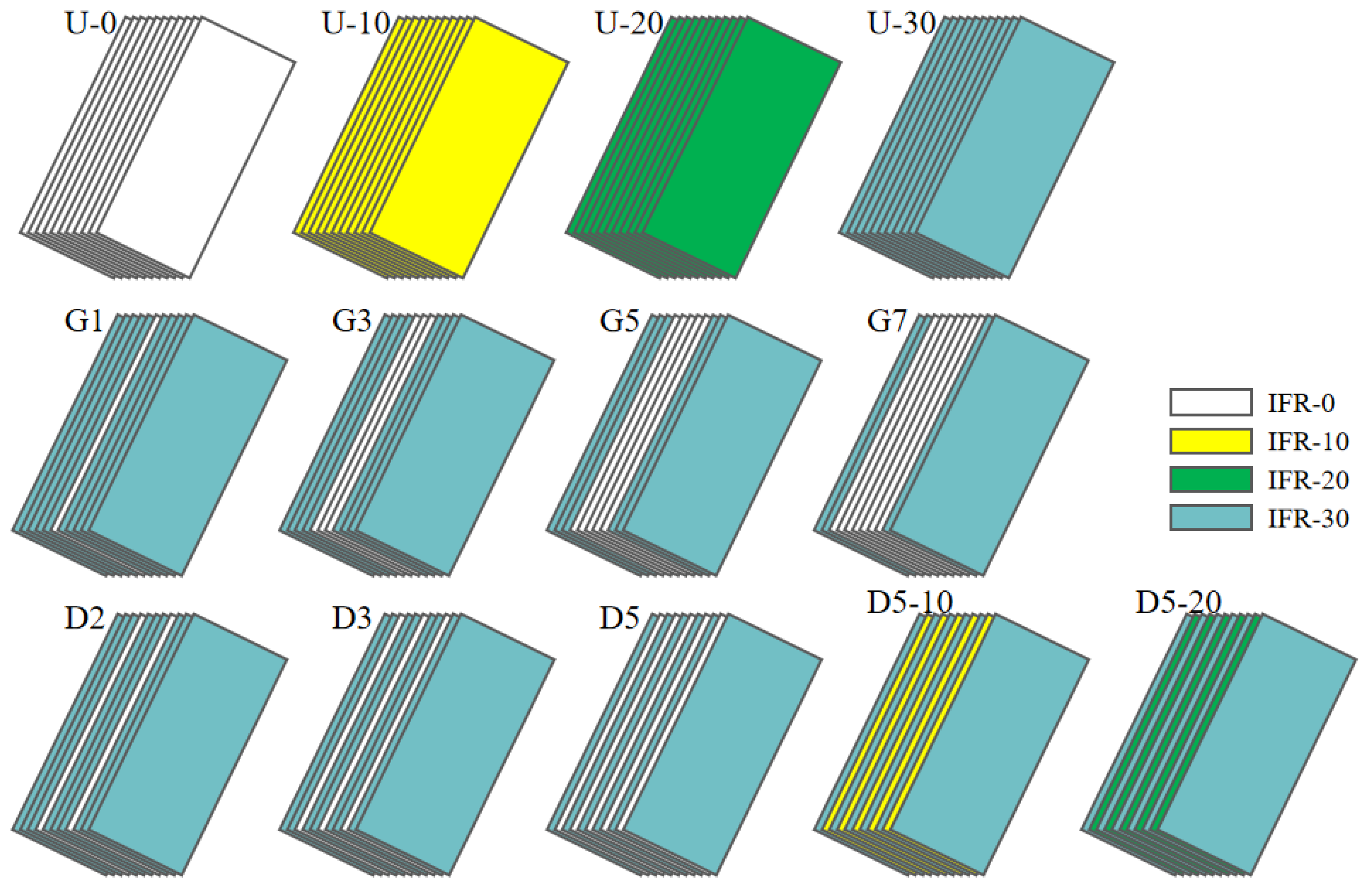

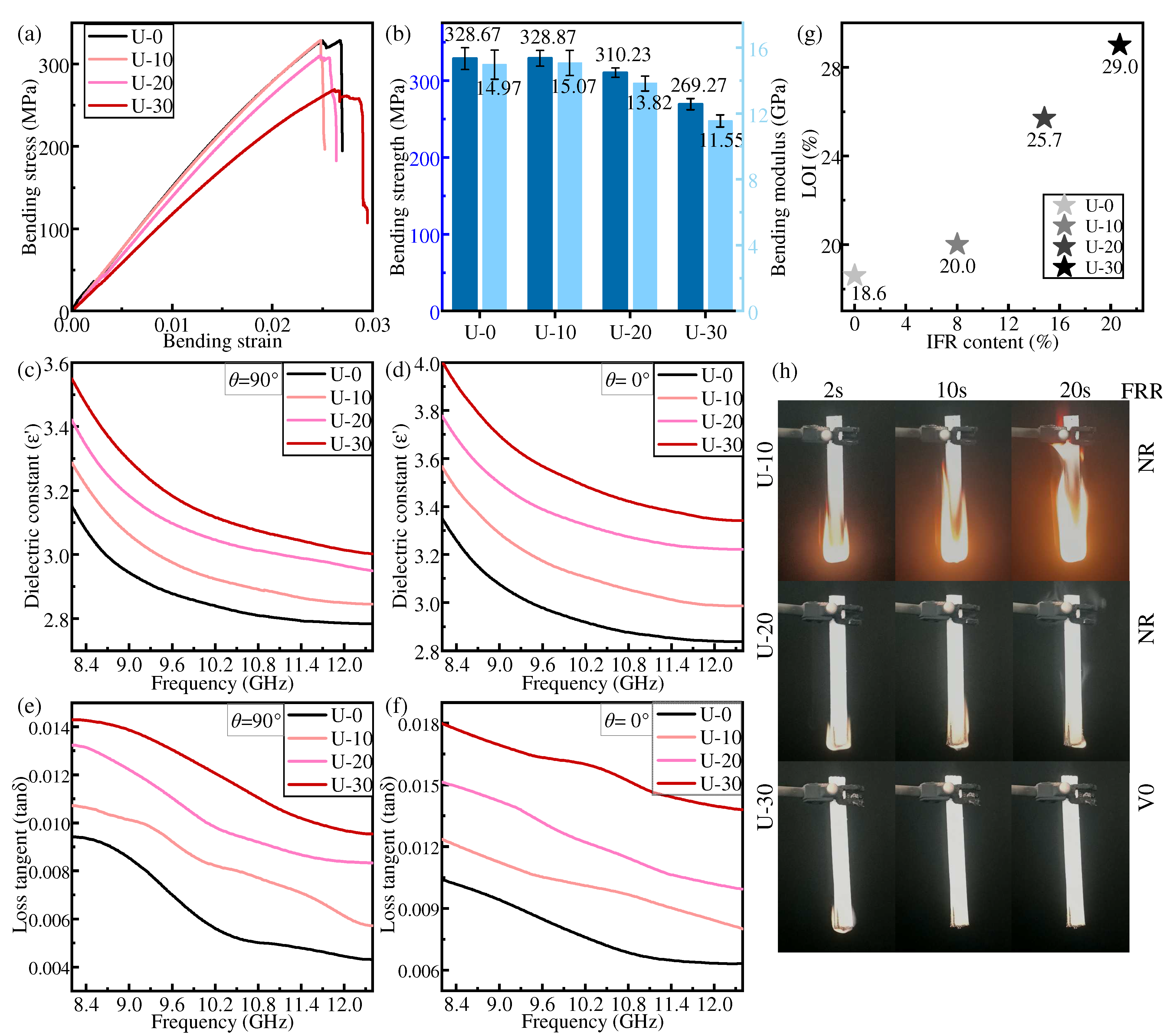

3.1. Uniform Distribution

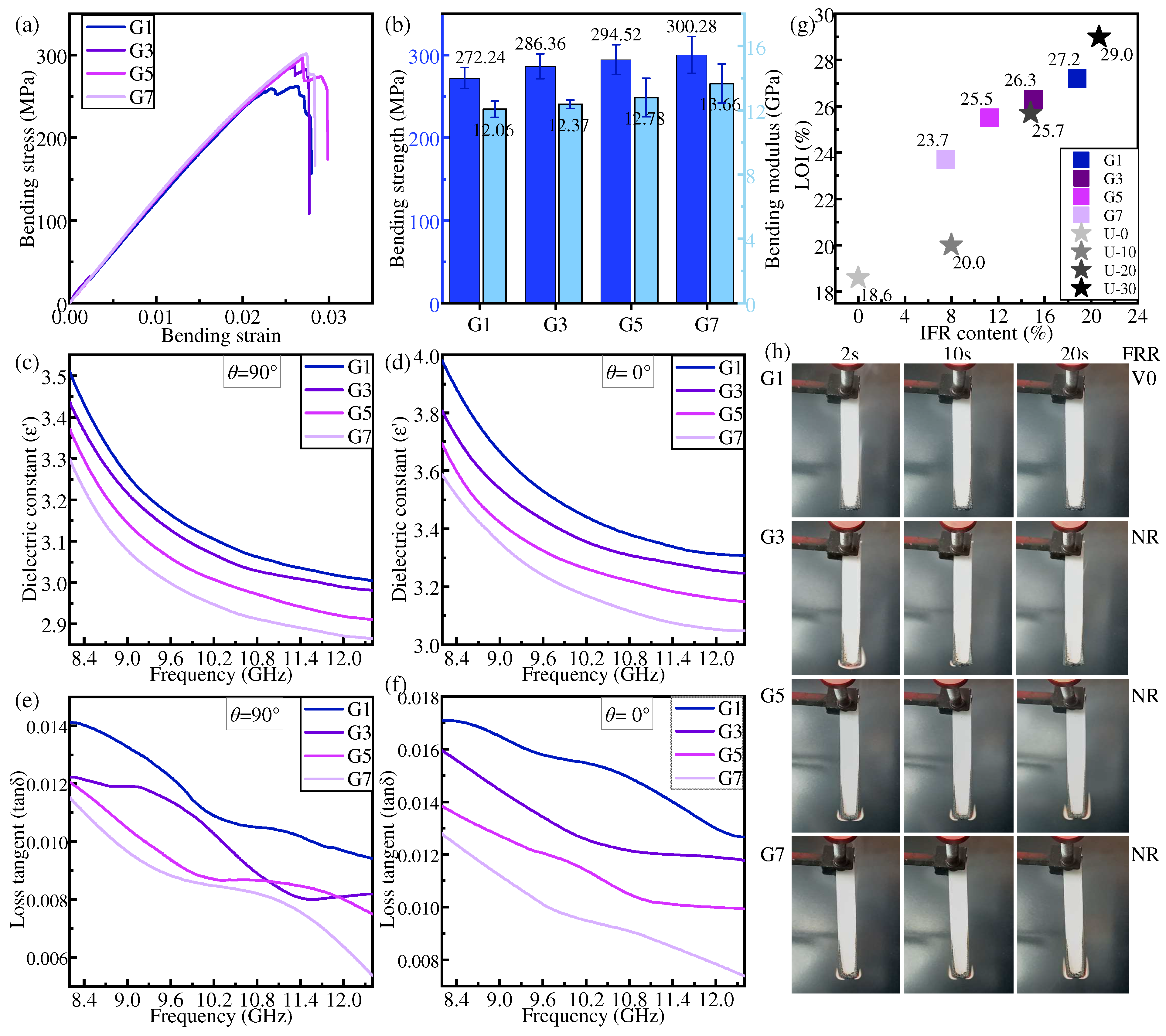

3.2. Gradient Distribution

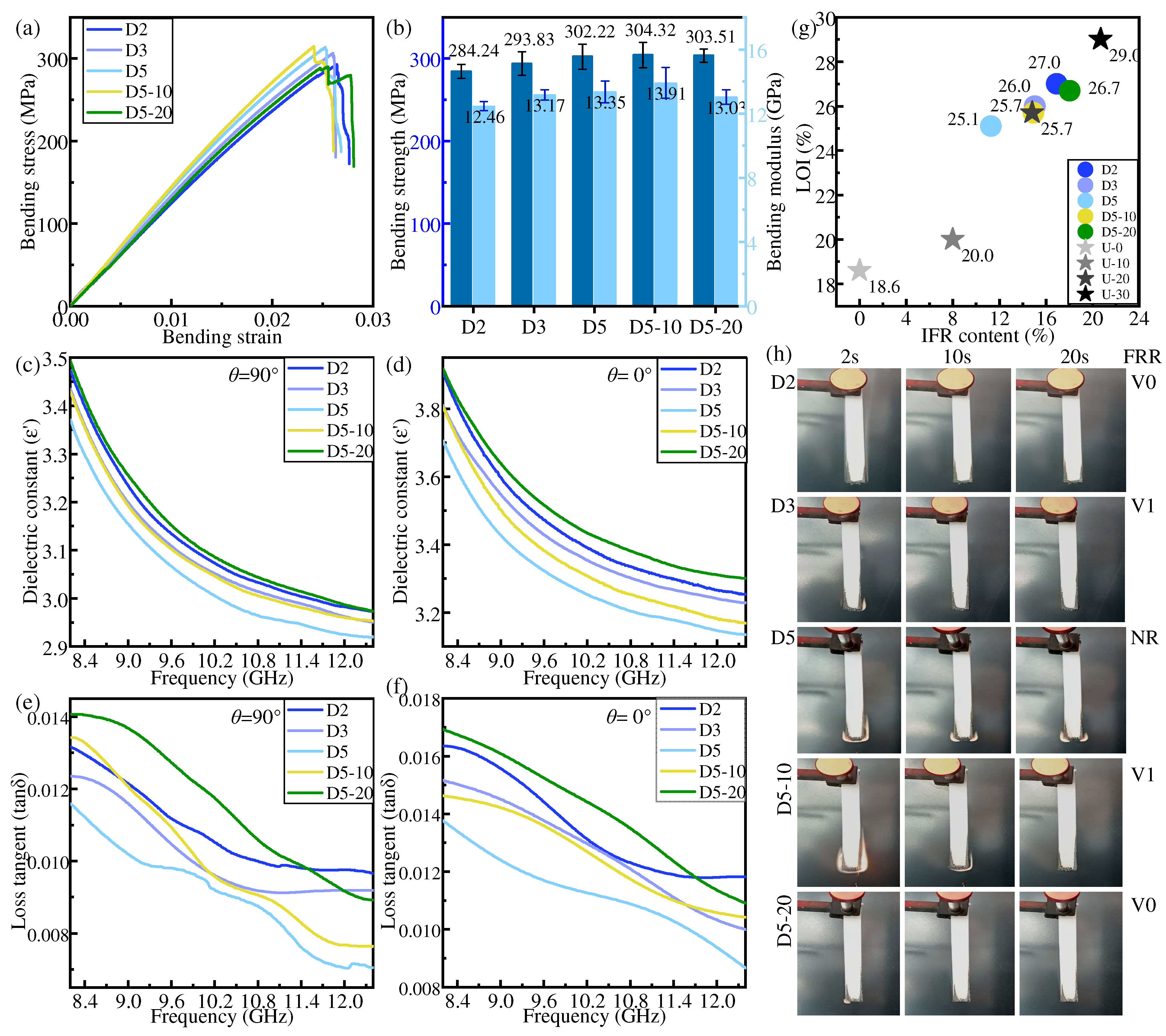

3.3. Dispersed Distribution

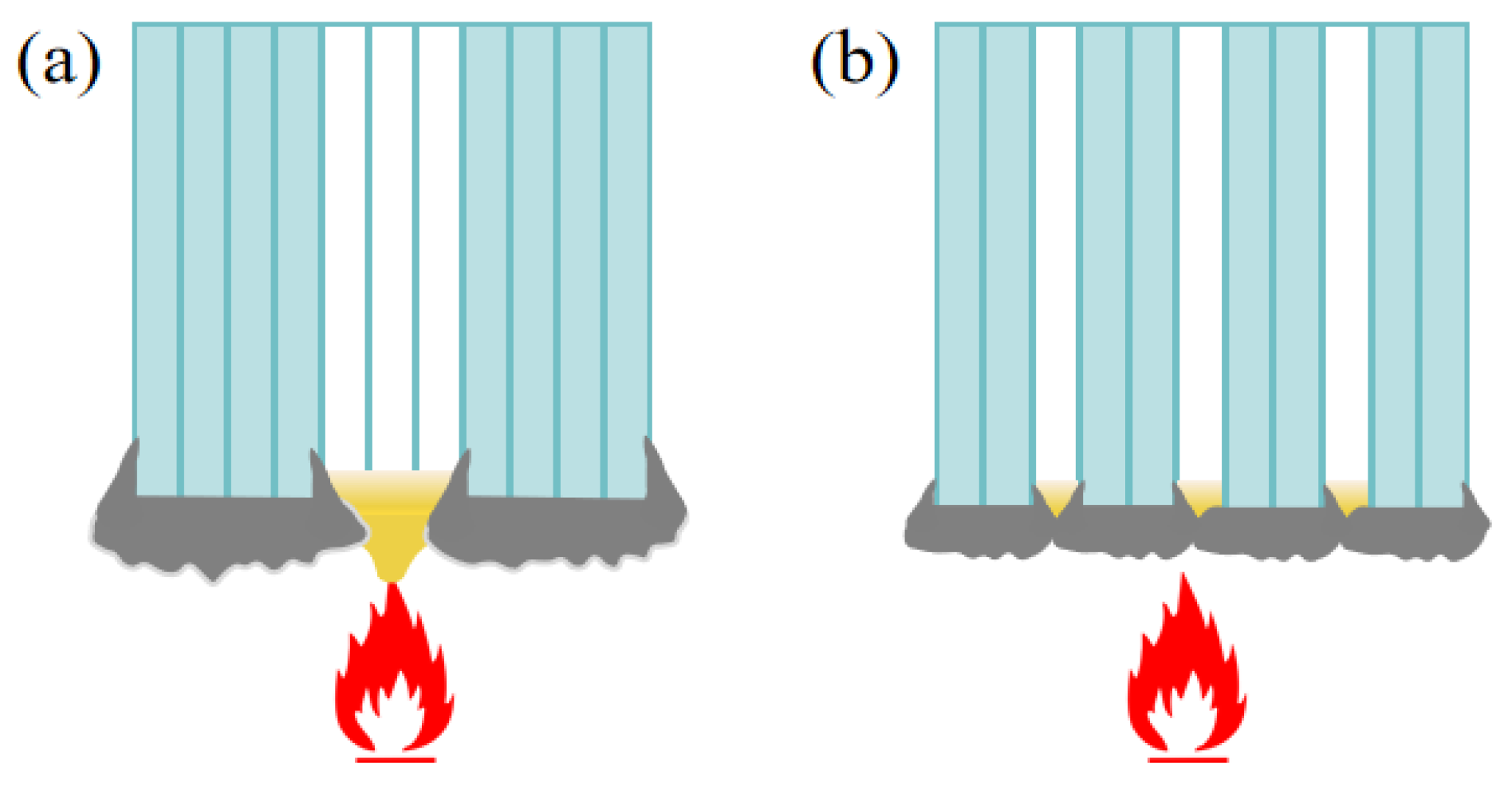

3.4. Performance Comparison by Distribution Mode

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part B Eng. 2021, 224, 109143. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef] [PubMed]

- Qiao, Y.; Fring, L.D.; Pallaka, M.R.; Simmons, K.L. A review of the fabrication methods and mechanical behavior of continuous thermoplastic polymer fiber–thermoplastic polymer matrix composites. Polym. Compos. 2023, 44, 694–733. [Google Scholar] [CrossRef]

- Gibson, A.G.; Torres, M.E.O.; Browne, T.N.A.; Feih, S.; Mouritz, A.P. High temperature and fire behaviour of continuous glass fibre/polypropylene laminates. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1219–1231. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Y.; Han, Y.; Liu, Y.; Wang, Q. Interfacial charring method to overcome the wicking action in glass fiber-reinforced polypropylene composite. Compos. Sci. Technol. 2015, 121, 9–15. [Google Scholar] [CrossRef]

- Zhao, W.; Kumar Kundu, C.; Li, Z.; Li, X.; Zhang, Z. Flame retardant treatments for polypropylene: Strategies and recent advances. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106382. [Google Scholar] [CrossRef]

- Wang, H.; Qiao, H.; Guo, J.; Sun, J.; Li, H.; Zhang, S.; Gu, X. Preparation of cobalt-based metal organic framework and its application as synergistic flame retardant in thermoplastic polyurethane (TPU). Compos. Part B Eng. 2020, 182, 107498. [Google Scholar] [CrossRef]

- Chen, H.; Wang, J.; Ni, A.; Ding, A.; Sun, Z.; Han, X. Effect of novel intumescent flame retardant on mechanical and flame retardant properties of continuous glass fibre reinforced polypropylene composites. Compos. Struct. 2018, 203, 894–902. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Liu, Q.; Sun, J.; Li, H.; Gu, X.; Jiang, S.; Zhang, S. Constructing cross-functional intumescent flame retardants with UV resistance for polypropylene composites. Mater. Today Chem. 2022, 26, 101048. [Google Scholar] [CrossRef]

- Wang, S.; Lim, Q.F.; Toh, J.P.W.; Tan, M.Y.; Zhu, Q.; Thitsartarn, W.; He, C.; Liu, S.; Kong, J. A versatile, highly effective intumescent flame-retardant synergist for polypropylene and polyamide 6 composites. Compos. Commun. 2023, 42, 101699. [Google Scholar] [CrossRef]

- Tao, M.; Qian, L.; Wang, J.; Zhu, H.; Tang, W.; Chen, Y.; Xi, W.; Qiu, Y. From physical mixtures to block copolymer: Impose outstandingly toughening and flame retardant effect to polypropylene. Compos. Part B Eng. 2023, 253, 110538. [Google Scholar] [CrossRef]

- Cheng, Z.; Liao, D.; Hu, X.; Li, W.; Xie, C.; Zhang, H.; Yang, W. Synergistic fire retardant effect between expandable graphite and ferrocene-based non-phosphorus polymer on polypropylene. Polym. Degrad. Stab. 2020, 178, 109201. [Google Scholar] [CrossRef]

- Yuan, G.; Yang, B.; Chen, Y.; Jia, Y. Synthesis of a novel multi-structure synergistic POSS-GO-DOPO ternary graft flame retardant and its application in polypropylene. Compos. Part A Appl. Sci. Manuf. 2019, 117, 345–356. [Google Scholar] [CrossRef]

- Ding, S.; Liu, P.; Zhang, S.; Gao, C.; Wang, F.; Ding, Y.; Yang, M. Crosslinking of β-cyclodextrin and combining with ammonium polyphosphate for flame-retardant polypropylene. J. Appl. Polym. Sci. 2020, 137, 48320. [Google Scholar] [CrossRef]

- Laachachi, A.; Ball, V.; Apaydin, K.; Toniazzo, V.; Ruch, D. Diffusion of Polyphosphates into (Poly(allylamine)-montmorillonite) Multilayer Films: Flame Retardant-Intumescent Films with Improved Oxygen Barrier. Langmuir 2011, 27, 13879–13887. [Google Scholar] [CrossRef] [PubMed]

- Qin, S.; Pour, M.G.; Lazar, S.; Köklükaya, O.; Gerringer, J.; Song, Y.; Wågberg, L.; Grunlan, J.C. Super Gas Barrier and Fire Resistance of Nanoplatelet/Nanofibril Multilayer Thin Films. Adv. Mater. Interfaces 2019, 6, 1801424. [Google Scholar] [CrossRef]

- Choi, K.; Kim, J.; Kwon, T.; Kang, S.; Song, J.; Park, Y. Mechanically Sustainable Starch-Based Flame-Retardant Coatings on Polyurethane Foams. Polymers 2021, 13, 1286. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wu, J.; Mei, C.; Yang, R.; He, W.; Li, X.; Cai, L.; Guo, M.; Li, J.; Xia, C. Thermal and flame-retardant properties of multilayered composites prepared through novel multilayering approach. Environ. Res. 2022, 213, 113724. [Google Scholar] [CrossRef]

- Ji, X.; Chen, D.; Shen, J.; Guo, S. Flexible and flame-retarding thermoplastic polyurethane-based electromagnetic interference shielding composites. Chem. Eng. J. 2019, 370, 1341–1349. [Google Scholar] [CrossRef]

- Chen, B.; Gao, W.; Shen, J.; Guo, S. The multilayered distribution of intumescent flame retardants and its influence on the fire and mechanical properties of polypropylene. Compos. Sci. Technol. 2014, 93, 54–60. [Google Scholar] [CrossRef]

- Luo, S.; Zheng, Y.; Zheng, Z.; Wu, H.; Shen, J.; Guo, S. Competitive growth of α- and β-transcrystallinity in isotactic polypropylene induced by the multilayered distribution of α-nucleating agents: Toward high mechanical performances. Chem. Eng. J. 2019, 355, 710–720. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, M.; Zhang, Y.; Yang, W.; Jiao, Z.; Yang, L. EG/TPU composites with enhanced flame retardancy and mechanical properties prepared by microlayer coextrusion technology. RSC Adv. 2019, 9, 23944–23956. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Yang, M.; Yang, S.; Wu, H.; Guo, S.; Wang, Y. Ordered multilayer film of (graphene oxide/polymer and boron nitride/polymer) nanocomposites: An ideal EMI shielding material with excellent electrical insulation and high thermal conductivity. Compos. Sci. Technol. 2016, 136, 104–110. [Google Scholar] [CrossRef]

- He, L.; Shi, Y.; Wang, Q.; Chen, D.; Shen, J.; Guo, S. Strategy for constructing electromagnetic interference shielding and flame retarding synergistic network in poly (butylene succinate) and thermoplastic polyurethane multilayered composites. Compos. Sci. Technol. 2020, 199, 108324. [Google Scholar] [CrossRef]

- Ji, X.; Chen, D.; Zheng, Y.; Shen, J.; Guo, S.; Harkin-Jones, E. Multilayered assembly of poly(vinylidene fluoride) and poly(methyl methacrylate) for achieving multi-shape memory effects. Chem. Eng. J. 2019, 362, 190–198. [Google Scholar] [CrossRef]

- Zheng, Y.; Ji, X.; Wang, Q.; Shen, J.; Guo, S. Structural design of polyurethane/poly(butylene succinate)/polycaprolactone compounds via a multilayer-assembled strategy: Achieving tunable triple-shape memory performances. RSC Adv. 2018, 8, 42337–42345. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Dong, R.; Shen, J.; Guo, S. Tunable Shape Memory Performances via Multilayer Assembly of Thermoplastic Polyurethane and Polycaprolactone. ACS Appl. Mater. Interfaces 2016, 8, 1371–1380. [Google Scholar] [CrossRef]

- Zhang, J.; Li, B.; Wang, Y. The Effect of Gradient Distribution of IFR on Flame Retarded Properties and Mechanic Properties of Flame Retarded EVA. Chem. Adhes. 2011, 33, 4–8. [Google Scholar]

- Zuo, L.; Ao, J.; Zhao, T.; Sun, W.; Zhang, W.; Zhao, G.; Chen, B. Influences of Layered Flame Retardant Structure on Properties of PBT/IFR Composites. Eng. Plast. Appl. 2016, 44, 26–30. [Google Scholar]

- Liao, H.; Liu, Y.; Jiang, J.; Liu, Y.; Wang, Q. Flame-retardant, glass-fabric-reinforced epoxy resin laminates fabricated through a gradient distribution mode. J. Appl. Polym. Sci. 2017, 134, 44369. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, H.; Wang, Y.; Ma, Y.; Zhu, Z.; Lin, X. A novel highly efficient intumescent flame-retardant polypropylene: Thermal degradation, flame retardance and mechanism. J. Polym. Res. 2022, 29, 205. [Google Scholar] [CrossRef]

- Lim, K.S.; Bee, S.T.; Sin, L.T.; Tee, T.T.; Ratnam, C.T.; Hui, D.; Rahmat, A.R. A review of application of ammonium polyphosphate as intumescent flame retardant in thermoplastic composites. Compos. Part B Eng. 2016, 84, 155–174. [Google Scholar] [CrossRef]

- ASTM D7264; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM D2863; Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index). American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ISO 5660; Reaction-to-Fire Tests Heat Release, Smoke Production and Mass Loss Rate. International Organization for Standardization: Geneva, Switzerland, 2015.

- Chin, W.S.; Lee, D.G. Binary mixture rule for predicting the dielectric properties of unidirectional E-glass/epoxy composite. Compos. Struct. 2006, 74, 153–162. [Google Scholar] [CrossRef]

| Samples | PP (phr) | MAPP (phr) | PP-MF650X (phr) | IFR (phr) | IFR Content (wt%) |

|---|---|---|---|---|---|

| IFR-0 | 100 | 5 | 10 | 0 | 0 |

| IFR-10 | 100 | 5 | 10 | 10 | 8.00 |

| IFR-20 | 100 | 5 | 10 | 20 | 14.81 |

| IFR-30 | 100 | 5 | 10 | 30 | 20.69 |

| Samples | Resin Matrix Composition and Distribution in Each Prepreg Layer | IFR Content (wt%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | 0 |

| U-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | IFR-10 | 8.00 |

| U-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | IFR-20 | 14.81 |

| U-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | 20.69 |

| G1 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-0 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | 18.81 |

| G3 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | IFR-0 | IFR-0 | IFR-0 | IFR-30 | IFR-30 | IFR-30 | IFR-30 | 15.05 |

| G5 | IFR-30 | IFR-30 | IFR-30 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-30 | IFR-30 | IFR-30 | 11.29 |

| G7 | IFR-30 | IFR-30 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-0 | IFR-30 | IFR-30 | 7.52 |

| D2 | IFR-30 | IFR-30 | IFR-30 | IFR-0 | IFR-30 | IFR-30 | IFR-30 | IFR-0 | IFR-30 | IFR-30 | IFR-30 | 16.93 |

| D3 | IFR-30 | IFR-30 | IFR-0 | IFR-30 | IFR-30 | IFR-0 | IFR-30 | IFR-30 | IFR-0 | IFR-30 | IFR-30 | 15.05 |

| D5 | IFR-30 | IFR-0 | IFR-30 | IFR-0 | IFR-30 | IFR-0 | IFR-30 | IFR-0 | IFR-30 | IFR-0 | IFR-30 | 11.29 |

| D5-10 | IFR-30 | IFR-10 | IFR-30 | IFR-10 | IFR-30 | IFR-10 | IFR-30 | IFR-10 | IFR-30 | IFR-10 | IFR-30 | 14.92 |

| D5-20 | IFR-30 | IFR-20 | IFR-30 | IFR-20 | IFR-30 | IFR-20 | IFR-30 | IFR-20 | IFR-30 | IFR-20 | IFR-30 | 18.02 |

| Samples | IFR Content (wt%) | TTI (s) | TPHRR (s) | PHRR (kw/m2) | THR (MJ/m2) | FPI (s.m2/kW) |

|---|---|---|---|---|---|---|

| G1 | 18.81 | 28 | 74 | 121.64 | 88.23 | 0.2466 |

| D2 | 16.93 | 30 | 49 | 137.15 | 140.82 | 0.2187 |

| D5-20 | 18.02 | 30 | 57 | 130.58 | 116.08 | 0.2297 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Sun, Y.; Zhang, B.; Qi, G. Mechanical, Flame-Retardant and Dielectric Properties of Intumescent Flame Retardant/Glass Fiber-Reinforced Polypropylene through a Novel Dispersed Distribution Mode. Polymers 2024, 16, 1341. https://doi.org/10.3390/polym16101341

Li J, Sun Y, Zhang B, Qi G. Mechanical, Flame-Retardant and Dielectric Properties of Intumescent Flame Retardant/Glass Fiber-Reinforced Polypropylene through a Novel Dispersed Distribution Mode. Polymers. 2024; 16(10):1341. https://doi.org/10.3390/polym16101341

Chicago/Turabian StyleLi, Jingwen, Yiliang Sun, Boming Zhang, and Guocheng Qi. 2024. "Mechanical, Flame-Retardant and Dielectric Properties of Intumescent Flame Retardant/Glass Fiber-Reinforced Polypropylene through a Novel Dispersed Distribution Mode" Polymers 16, no. 10: 1341. https://doi.org/10.3390/polym16101341

APA StyleLi, J., Sun, Y., Zhang, B., & Qi, G. (2024). Mechanical, Flame-Retardant and Dielectric Properties of Intumescent Flame Retardant/Glass Fiber-Reinforced Polypropylene through a Novel Dispersed Distribution Mode. Polymers, 16(10), 1341. https://doi.org/10.3390/polym16101341