Assessing the Sound and Heat Insulation Characteristics of Layered Nonwoven Composite Structures Composed of Meltblown and Recycled Thermo-Bonded Layers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Manufacturing of Nonwoven Layers and Layered Nonwoven Composite Structures

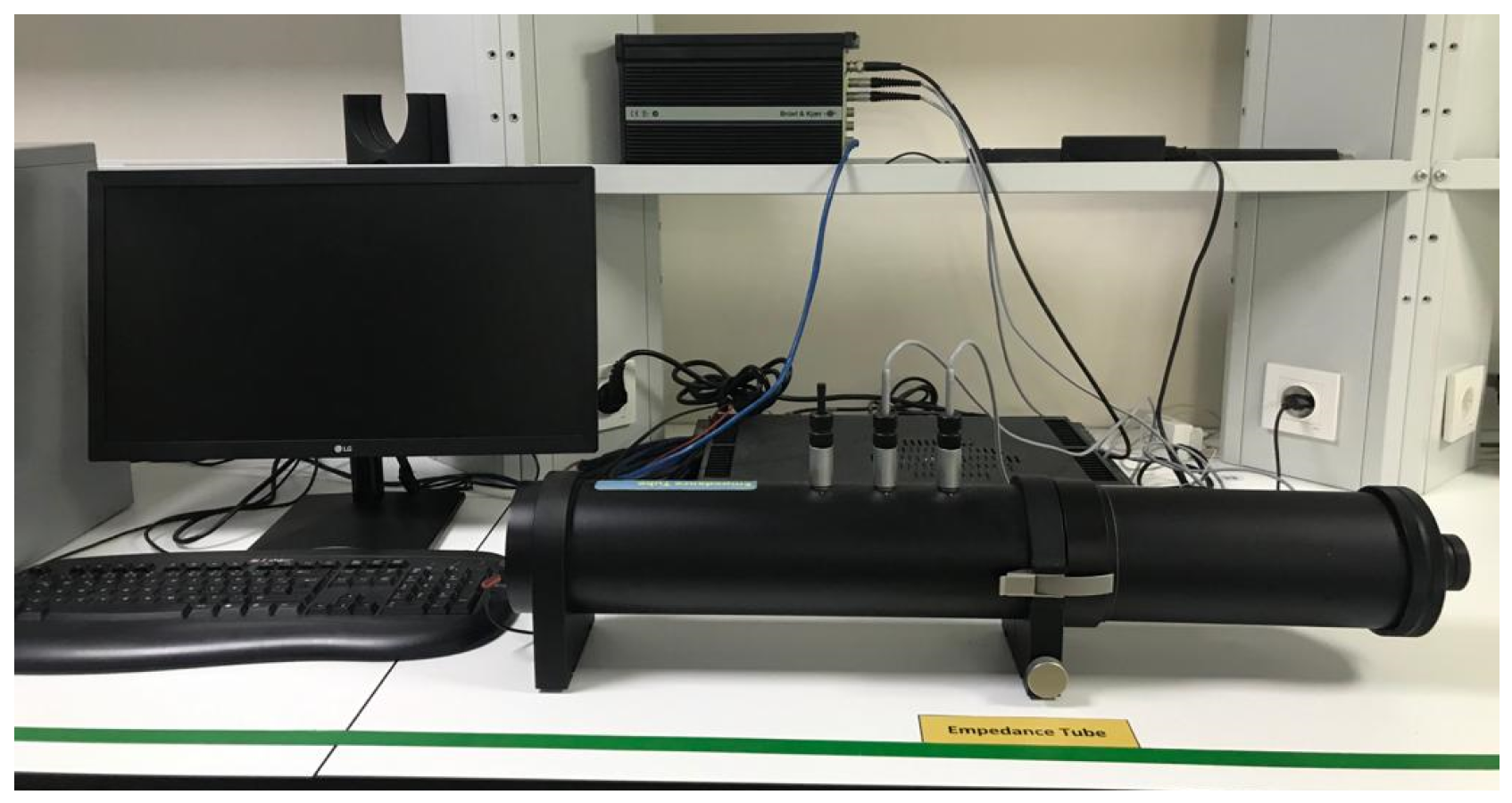

2.2.2. Testing of Nonwoven Layers and Layered Nonwoven Composite Structure

3. Results and Discussion

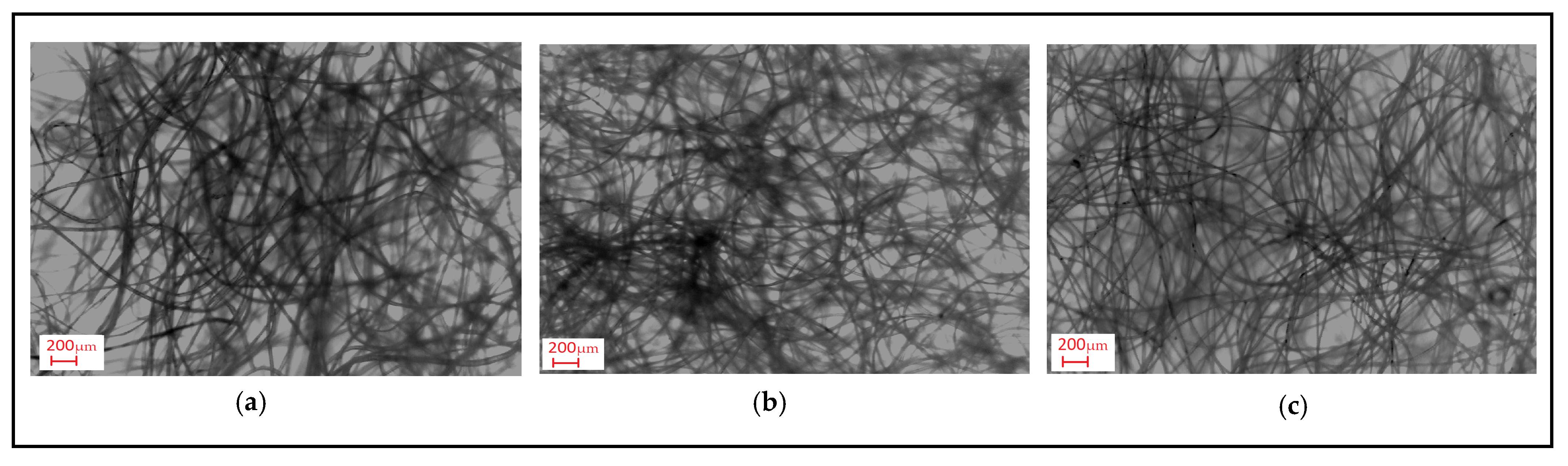

3.1. Properties of Individual Layers Forming the Composite Structures

3.2. Properties of the Nonwoven Composite Structures

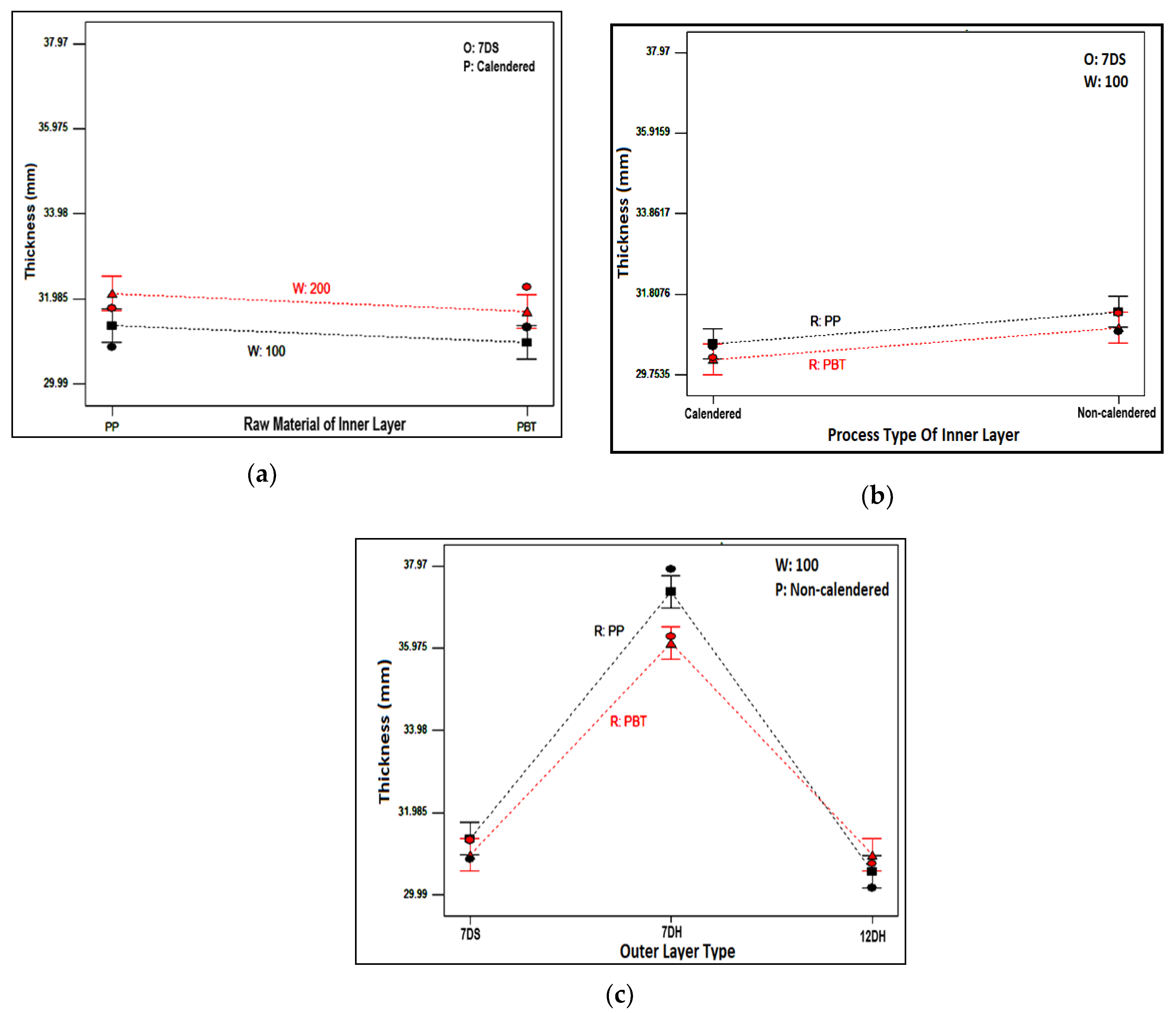

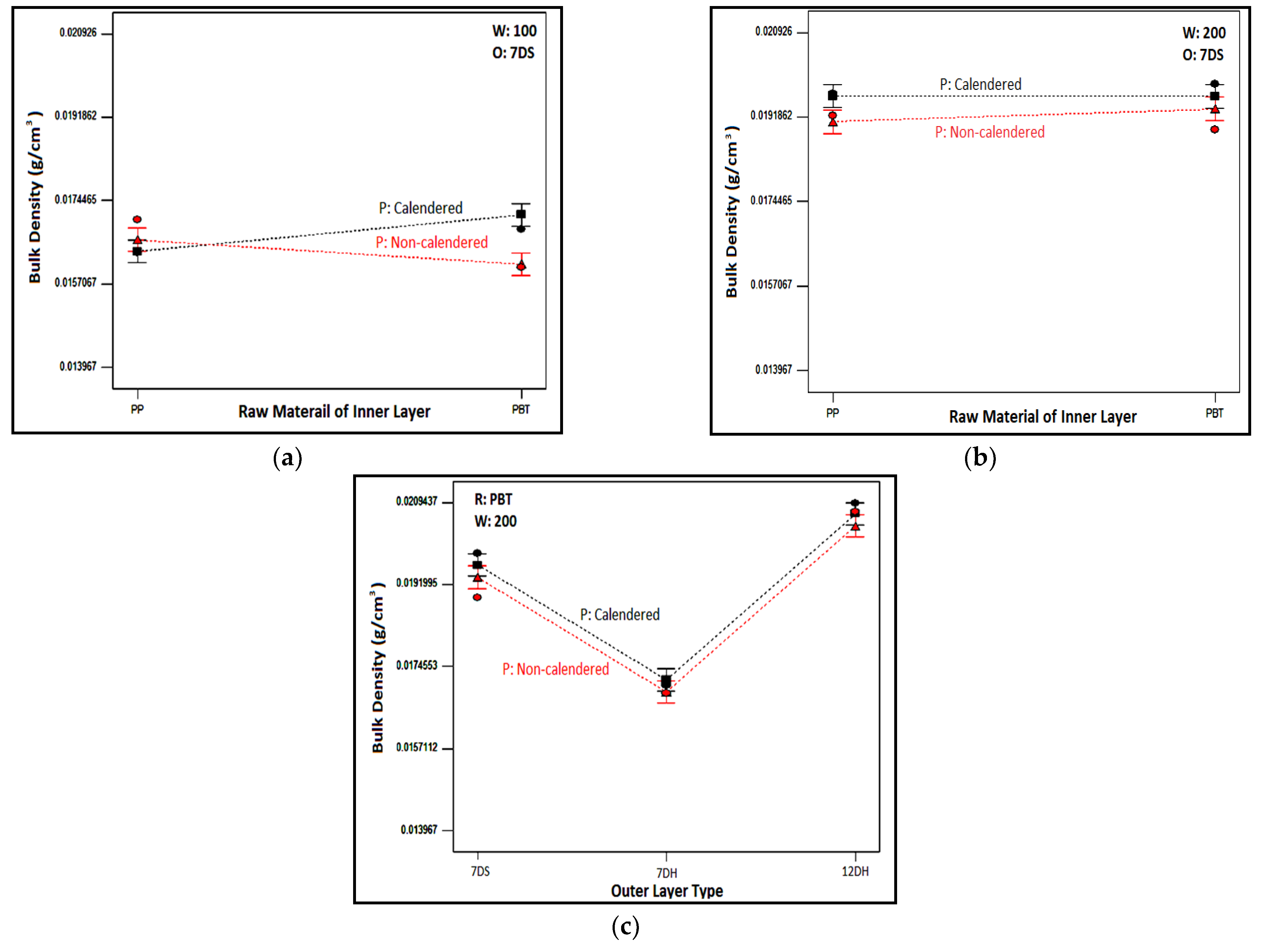

3.2.1. Thickness and Bulk Density

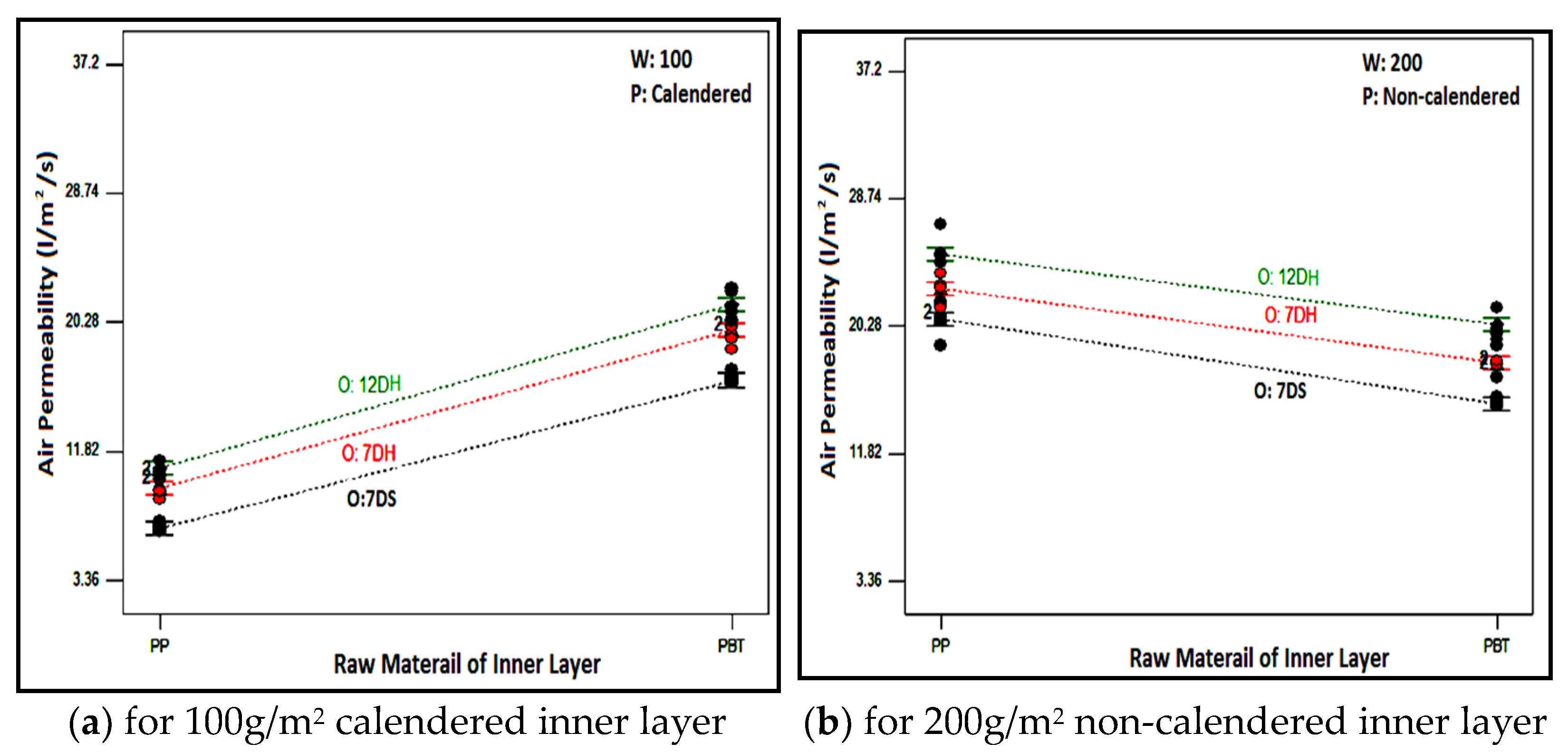

3.2.2. Air Permeability

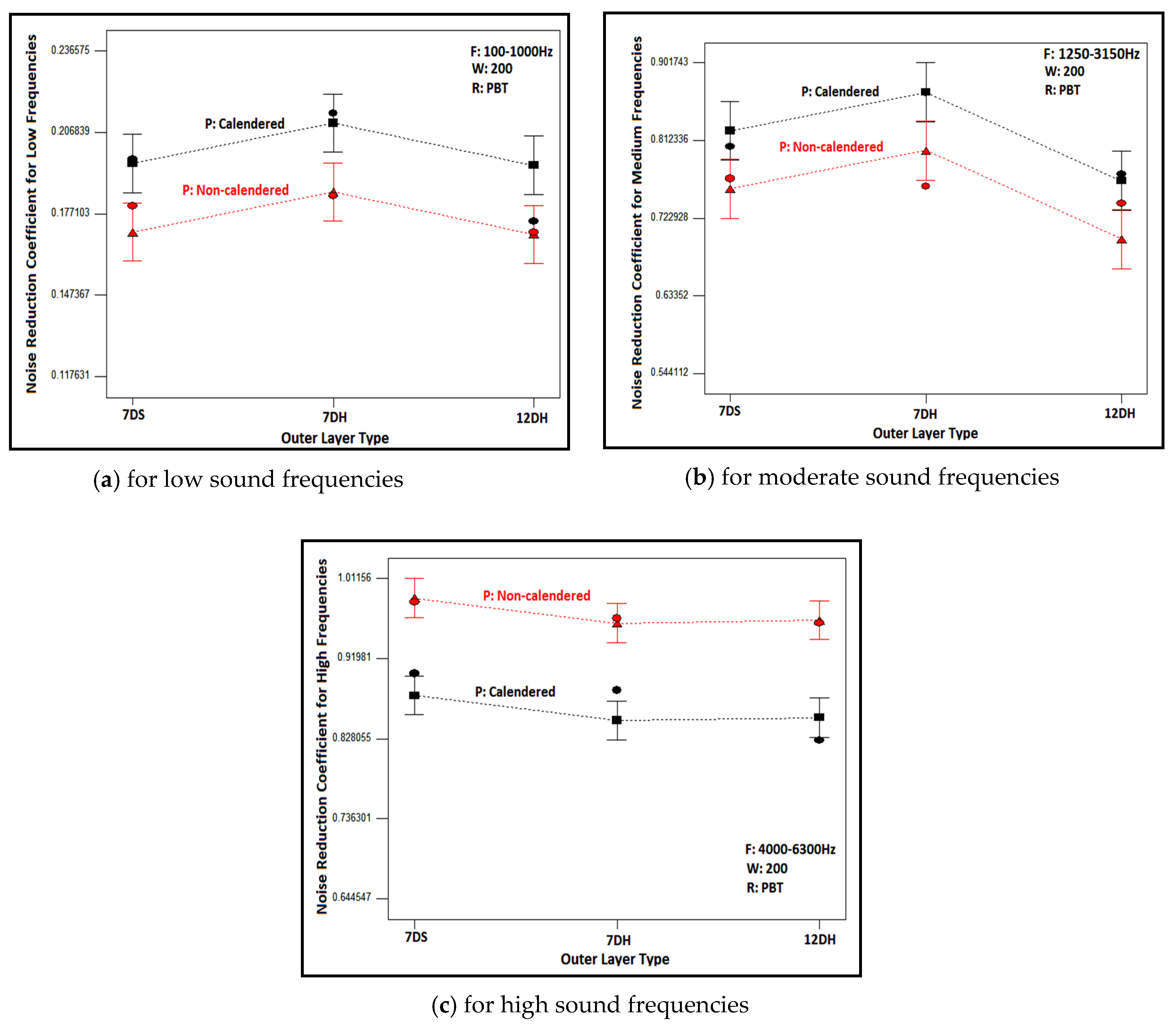

3.2.3. Sound Absorption Coefficient

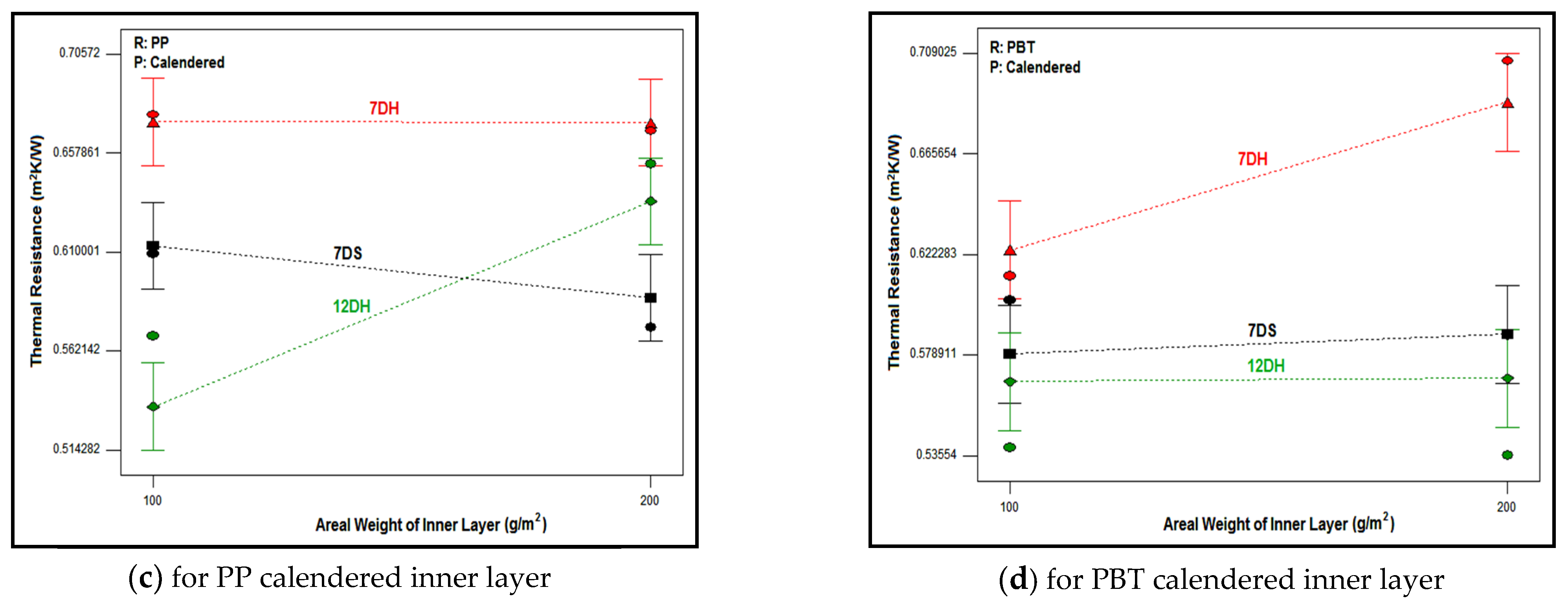

3.2.4. Thermal Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Padhye, R.; Nayak, R. Acoustic textiles: An introduction. In Acoustic Textiles, 1st ed.; Padhye, R., Nayak, R., Eds.; Springer: Singapore, 2016; pp. 1–32. ISBN 978-981-10-1476-5. [Google Scholar]

- Jayaraman, K.A. Acoustical Absorptive Properties of Nonwovens. Master’s Thesis, The Graduate Faculty of North Carolina State University, Raleigh, NC, USA, 2005; 138p. Available online: https://fitfibers.com/wp-content/uploads/2018/06.0/4dg-acoustic-absorption.pdf (accessed on 1 February 2024).

- Hassanzadeh, S.; Hasani, H.; Zarrebini, M. Analysis and prediction of the noise reduction coefficient of lightly-needled estabragh/polypropylene nonwovens using simplex lattice design. J. Text. Inst. 2014, 105, 256–263. [Google Scholar] [CrossRef]

- Lee, Y.E.; Joo, C.W. Sound absorption parameters of recycled polyester fibrous assembly absorbers. Autex Res. J. 2003, 3, 78–84. [Google Scholar] [CrossRef]

- Bharanitharan, R.; Thangamani, K.; Sundaresan, S. Development of highloft nonwoven materials for health care acoustics. Int. Res. J. Pharm. 2017, 8, 112–117. [Google Scholar] [CrossRef]

- Hajimohammadi, M.; Soltani, P.; Semnani, D.; Taban, E.; Fashandi, H. Nonwoven fabric coated with core-shell and hollow nanofiber membranes for efficient sound absorption in buildings. Built Environ. 2022, 213, 108887. [Google Scholar] [CrossRef]

- Çelikel, D.C.; Babaarslan, O. Effect of bicomponent fibers on sound absorption properties of multilayer nonwovens. J. Eng. Fibers Fabr. 2017, 12, 15–25. [Google Scholar] [CrossRef]

- Shahani, F.; Soltani, P.; Zarrebini, M. The analysis of acoustic characteristics and sound absorption coefficient of needle punched nonwoven fabrics. J. Eng. Fibers Fabr. 2014, 9, 84–92. [Google Scholar] [CrossRef]

- Kadam, V.V.; Nayak, R. Basics of Acoustic Science. In Acoustic Textiles, 1st ed.; Padhye, R., Nayak, R., Eds.; Springer: Singapore, 2016; pp. 1–32. ISBN 978-981-10-1476-5. [Google Scholar]

- Paşayev, N.; Kocatepe, S.; Maraş, N. Investigation of sound absorption properties of nonwoven webs produced from chicken feather fibers. J. Ind. Text. 2019, 48, 1616–1635. [Google Scholar] [CrossRef]

- Bhat, G.; Messiry, M.E. Effect of microfiber layers on acoustical absorptive properties of nonwoven fabrics. J. Ind. Text. 2020, 50, 312–332. [Google Scholar] [CrossRef]

- Qiu, X. Principles of sound absorbers. In Acoustic Textiles, 1st ed.; Padhye, R., Nayak, R., Eds.; Springer: Singapore, 2016; pp. 43–72. [Google Scholar] [CrossRef]

- Küçük, M.; Korkmaz, Y. The effect of physical parameters on sound absorption properties of natural fiber mixed nonwoven composites. Text. Res. J. 2012, 82, 2043–2053. [Google Scholar] [CrossRef]

- Seddeq, H.S. Factors Influencing acoustic performance of sound absorptive materials. AusJBAS 2009, 3, 4610–4617. [Google Scholar]

- Singh, V.; Mukhopadhyay, S. Manufacturing methods for acoustic textiles. In Acoustic Textiles, 1st ed.; Padhye, R., Nayak, R., Eds.; Springer: Singapore, 2016; pp. 1–32. ISBN 978-981-10-1476-5. [Google Scholar]

- Patnaik, A. Materials used for acoustic textiles. In Acoustic Textiles, 1st ed.; Padhye, R., Nayak, R., Eds.; Springer: Singapore, 2016; pp. 1–32. ISBN 978-981-10-1476-5. [Google Scholar]

- Suvari, F.; Ulcay, Y.; Pourdeyhimi, B. Sound absorption analysis of thermally bonded high-loft nonwovens. Text. Res. J. 2016, 86, 837–847. [Google Scholar] [CrossRef]

- Fages, E.; Cano, M.; Gironés, S.; Boronat, T.; Fenollar, O.; Balart, R. The use of wet-laid techniques to obtain flax nonwovens with different thermoplastic binding fibers for technical insulation applications. Text. Res. J. 2013, 83, 426–437. [Google Scholar] [CrossRef]

- Parikh, D.V.; Chen, Y.; Sun, L. Reducing automotive interior noise with natural fibre nonwoven floor covering systems. Text. Res. J. 2006, 76, 813–820. [Google Scholar] [CrossRef]

- Basu, G.; Datta, M.; Sengupta, S.; Nath, D.; Debnath, S. Jute felt for noise reduction: Understanding effect of pore size distribution. J. Nat. Fibers. 2022, 19, 6482–6496. [Google Scholar] [CrossRef]

- Liu, X.; Yan, X.; Zhang, H. Effects of pore structure on sound absorption of kapok-based fiber nonwoven fabrics at low frequency. Text. Res. J. 2016, 86, 755–764. [Google Scholar] [CrossRef]

- Sengupta, S. Sound reduction by needle-punched nonwoven fabrics. Indian J. Fibre Text. Res. 2010, 35, 237–242. [Google Scholar]

- Veerakumar, A.; Selvakumara, N. A preliminary investigation on kapok/polypropylene nonwoven composite for sound absorption. Indian J. Fibre Text. Res. 2012, 37, 385–388. [Google Scholar]

- Thilagavathi, G.; Pradeep, E.; Kannaian, T.; Sasikala, L. Development of natural fibre nonwovens for application as car interiors noise control. J. Ind. Text. 2010, 39, 267–278. [Google Scholar] [CrossRef]

- Koizumi, T.; Tsujiuchi, N.; Adachi, A. The development of sound absorbing materials using natural bamboo fibers. Built Environ. High Perform. Struct. Compos. 2002, 59, 157–166. [Google Scholar] [CrossRef]

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R.D. Thermal and sound insulation materials from waste wool and recycled polyester fibres and their biodegradation studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

- Kalebek, N.A. Sound absorbing polyester recycled nonwovens for the automotive industry. Fibres Text East Eur. 2016, 1, 107–113. [Google Scholar] [CrossRef]

- Sakthivel, S.; Kumar, S.; Melese, B.; Mekonnen, S.; Solomon, E.; Edae, A.; Abedom, F.; Gedilu, M. Development of nonwoven composites from recycled cotton/polyester apparel waste materials for sound absorbing and insulating properties. Appl. Acoust. 2021, 180, 108126. [Google Scholar] [CrossRef]

- Sakthivel, S.; Senthil Kumar, B. Studies on influence of bonding methods on sound absorption characteristic of polyester/cotton recycled nonwoven fabric. Appl. Acoust. 2021, 174, 107749. [Google Scholar] [CrossRef]

- Sakthivel, S.; Senthil Kumar, S.; Mekonnen, S.; Solomon, E. Thermal and sound insulation properties ofrecycled cotton/polyester chemical bonded nonwovens. J. Eng. Fibers Fabr. 2020, 15, 155892502096881. [Google Scholar] [CrossRef]

- Bogalea, M.; Sakthivela, S.; Senthil Kumar, S.; Senthil Kumar, B. Sound absorbing and thermal insulating properties of recycled cotton/polyesterselvedge waste chemical bonded nonwovens. J. Text. Inst. 2023, 114, 134–141. [Google Scholar] [CrossRef]

- Jiang, N.; Chen, J.Y.; Parikh, D.V. Acoustical evaluation of carbonized and activated cotton nonwovens. Bioresour. Technol. 2009, 100, 6533–6536. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, N. Carbonized and activated non-wovens as high-performance acoustic materials: Part ı noise absorption. Text. Res. J. 2007, 77, 785–791. [Google Scholar] [CrossRef]

- Seddeq, H.M.; Aly, N.M.; Marwa, A.A.; Elshakankery, M.H. Investigation on sound absorption properties for recycled fibrous materials. J. Ind. Text. 2013, 43, 56–73. [Google Scholar] [CrossRef]

- Manning, J.; Panneton, R. Acoustical model for shoddy-based fibre sound absorbers. Text. Res. J. 2013, 83, 1356–1370. [Google Scholar] [CrossRef]

- Suvari, F.; Ulcay, Y.; Maze, B.; Pourdeyhimi, B. Acoustical absorptive properties of spunbonded nonwovens made from ıslands-ın-the-sea bicomponent filaments. J. Text. Inst. 2013, 104, 438–445. [Google Scholar] [CrossRef]

- Mahmoud, A.; El-Shenawy, G.; Ramadan, E. Using nonwoven hollow fibers to improve cars interior acoustic properties. Res. J. Text. Appar. 2012, 16, 49–56. [Google Scholar] [CrossRef]

- Tascan, M.; Vaughn, E.A. Effects of total surface area and fabric density on the acoustical behavior of needlepunched nonwoven fabrics. Text. Res. J. 2008, 78, 289–296. [Google Scholar] [CrossRef]

- Tascan, M.; Vaughn, E.A. Effects of fiber denier. fiber cross-sectional shape and fabric density on acoustical behavior of vertically lapped nonwoven fabrics. J. Eng. Fibers Fabr. 2008, 3, 32–38. [Google Scholar] [CrossRef]

- Kino, N.; Ueno, T. Evaluation of acoustical and non-acoustical properties of sound absorbing materials made of polyester fibres of various cross-sectional shapes. Appl. Acoust. 2008, 69, 575–582. [Google Scholar] [CrossRef]

- Palak, H.; Kayaoğlu, B.K. Analysis of the effect of fiber cross section and different bonding methods on sound absorption performance of PET fiber based nonwovens using Taguchi method. J. Text. Inst. 2020, 111, 575–585. [Google Scholar] [CrossRef]

- Data, M.; Nandi, S.; Nath, D.; Debnath, S.; Basu, G. Fiber Cross Sectional Shape: A Persuadable Feature for Assessment of Acoustic Noise Control Property of Some Natural Fibers and Its Geometrical Modeling. J. Nat. Fibers. 2022, 19, 15600–15613. [Google Scholar] [CrossRef]

- Ramanathan, B.; Thangamani, K.; Sundaresan, S. Ecological potential of highloft textiles from jute blended nonwovens for sound and thermal insulation. Ecol. Environ. Conserv. 2018, 24, 1691–1696. [Google Scholar]

- Yang, T.; Xiong, X.; Mishra, R.; Novák, J.; Militký, J. Acoustic evaluation of Struto nonwovens and their relationship with thermal properties. Text. Res. J. 2018, 88, 426–437. [Google Scholar] [CrossRef]

- Yang, T.; Xiong, X.; Mishra, R.; Novák, J.; Chaloupek, J.; Sanetrnik, F.; Militký, J. Investigation on acoustic behavior and air permeability of struto nonwovens. Fibers Polym. 2016, 17, 2078–2084. [Google Scholar] [CrossRef]

- Yang, T.; Saati, F.; Horoshenkov, K.V.; Xiong, X.; Yang, K.; Mishra, R.; Marburg, S.; Militky, J. Study on the sound absorption behavior of multi-component polyester nonwovens: Experimental and numerical methods. Text. Res. J. 2019, 89, 3342–3361. [Google Scholar] [CrossRef]

- Messiry, M.E.; Bhat, G.; Eloufy, A.; Latif, S.A.; Ayman, Y. Acoustical absorptive properties of meltblown nonwovens for textile machinery. Text. Res. J. 2021, 91, 1341–1353. [Google Scholar] [CrossRef]

- Liu, X.; Liu, J.; Su, X. Simulation model for the absorption coefficients of double layered nonwovens. Fibres Text East Eur. 2012, 4, 102–107. [Google Scholar]

- Tai, K.C.; Chen, P.; Lin, C.W.; Lou, C.W.; Tan, H.M.; Lin, J.H. Evaluation on the sound absorption and mechanical property of the multi-layer needlepunching nonwoven. Adv. Mat. Res. 2010, 123, 475–478. [Google Scholar] [CrossRef]

- Yilmaz, N.D.; Michielsen, S.; Banks-Lee, P.; Powell, N.B. Effects of material and treatment parameters on noise-control performance of compressed three-layered multifiber needle-punched nonwovens. J. Appl. Polym. Sci. 2012, 123, 2095–2106. [Google Scholar] [CrossRef]

- Yılmaz, N.D.; Powell, N.B.; Banks-Lee, P.; Michielsen, S. Multi-fiber needle-punched nonwoven composites: Effects of heat treatment on sound absorption performance. J. Ind. Text. 2013, 43, 231–246. [Google Scholar] [CrossRef]

- Yılmaz, N.D.; Banks-Lee, P.; Powell, N.B.; Michielsen, S. Effects of Porosity. Fiber Size. and Layering Sequence on Sound Absorption Performance of Needle-Punched Nonwovens. J. Appl. Polym. Sci. 2011, 121, 3056–3069. [Google Scholar] [CrossRef]

- Broda, J.; Bączek, M. Acoustic Properties of Multi-Layer Wool Nonwoven Structures. J. Nat. Fibers. 2020, 17, 1567–1581. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Xu, Y.; Bao, W. The acoustic characteristics of dual-layered porous nonwovens: A theoretical and experimental analysis. J. Text. Inst. 2014, 105, 1076–1088. [Google Scholar] [CrossRef]

- Coates, M.; Kierzkowski, M. Acoustic textiles—lighter, thinner and more absorbent. Text. Technol. Int. 2002, 11, 15–18. [Google Scholar]

- Mohrova, J.; Kalinova, K. Different Structures of PVA Nanofibrous Membrane for Sound Absorption Application. J. Nanomater. 2012, 2012, 643043. [Google Scholar] [CrossRef]

- Küçükali-Öztürk, M.; Nergis, B.; Candan, C.; Kalinova, K. Effect of fiber diameter and air gap on acoustic performance of nanofibrous membrane. JCCE 2015, 9, 45–50. [Google Scholar] [CrossRef]

- Küçükali-Öztürk, M.; Nergis, B.; Candan, C. Design of layered structure with nanofibrous resonant membrane for acoustic applications. J. Ind. Text. 2018, 47, 1739–1756. [Google Scholar] [CrossRef]

- Bihola, D.V.; Amin, H.N.; Shah, V.D. Application of nano material to enhance acoustic properties. J. Eng. Sci. Futur. Technol. 2015, 1, 001–009. [Google Scholar]

- Kalinova, K. Nanofibrous resonant membrane for acoustic applications. J. Nanomater. 2011, 1, 265720. [Google Scholar] [CrossRef]

- Kalinova, K.; Ozturk, M.K.; Komarek, M. Open and closed tube method for determination of resonance frequencies of nanofibrous membrane. J. Text. Inst. 2016, 107, 1068–1078. [Google Scholar] [CrossRef]

- Elkasaby, M.A.; Utkarsh, F.; Syed, N.A.; Rizvi, G.; Mohany, A.; Pop-Iliev, R. Evaluation of electro-spun polymeric nanofibers for sound absorption applications. In Proceedings of the 35th International Conference of the Polymer Processing Society (PPS-35), Cesme-Izmir, Turkey, 26–30 May 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Gao, B.; Zuo, L.; Zuo, B. Sound absorption properties of spiral vane electrospun PVA/nano particle nanofiber membrane and non-woven composite material. Fibers Polym. 2016, 17, 1090–1096. [Google Scholar] [CrossRef]

- Xiang, H.F.; Tan, S.X.; Yu, X.L.; Long, Y.H.; Zhang, X.L.; Zhao, N.; Xu, J. Sound absorption behavior of electrospun polyacrylonitrile nanofibrous membranes. Chin. J. Polym. Sci. 2011, 29, 650–657. [Google Scholar] [CrossRef]

- Bahrambeygi, H.; Sabetzadeh, N.; Rabbi, A.; Nasouri, K.; Shoushtari, A.M.; Babaei, M.R. Nanofibers (PU and PAN) and nanoparticles (Nanoclay and MWNTs) simultaneous effects on polyurethane foam sound absorption. J. Polym. Res. 2013, 20, 72. [Google Scholar] [CrossRef]

- Rabbi, A.; Bahrambeygi, H.; Shoushtari, A.M.; Nasouri, K. Manufacturing of PAN or PU nanofiber layers/PET nonwoven composite as highly effective sound absorbers. Adv. Polym. Technol. 2014, 33, 21425. [Google Scholar] [CrossRef]

- Öztürk, M.K.; Kalinova, K.; Nergis, B.; Candan, C. Comparison of Resonance Frequency of a Nanofibrous Membrane and a Homogeneous Membrane structure. Text. Res. J. 2013, 83, 2204–2210. [Google Scholar] [CrossRef]

- Özturk, M.K.; Yenigun, E.; Nergis, B.; Candan, C. Nanofiber-enhanced lightweight composite textiles for acoustic applications. J. Ind. Text. 2017, 46, 1498–1510. [Google Scholar] [CrossRef]

- Küçükali Öztürk, M.; Nergis, F.B.; Candan, C. Design of electrospun polyacrylonitrile nanofiber-coated nonwoven structure for sound absorption. Polym. Adv. Technol. 2018, 29, 1255–1260. [Google Scholar] [CrossRef]

- Rabbi, A.; Bahrambeygi, H.; Shoushtari, A.M.; Nasouri, K. Incorporation of nanofiber layers in nonwoven materials for improving their acoustic properties. J. Eng. Fibers Fabr. 2013, 8, 36–41. [Google Scholar] [CrossRef]

- Özkal, A.; Çallıoglu, F.C. Effect of nanofiber spinning duration on the sound absorption capacity of nonwovens produced from recycled polyethylene terephthalate fibers. Appl. Acoust. 2020, 169, 107468. [Google Scholar] [CrossRef]

- Özkal, A.; Cengiz Çallıoglu, F.; Akduman, Ç. Development of a new nanofibrous composite material from recycled nonwovens to improve sound absorption ability. J. Text. Inst. 2020, 111, 189–201. [Google Scholar] [CrossRef]

- Asmatulu, R.; Khan, W.; Yıldırım, M.B. Acoustical properties of electrospun nanofibers for aircraft interior noise reduction. In Proceedings of the ASME 2009 International Mechanical Engineering Congress & Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009; pp. 223–227. [Google Scholar] [CrossRef]

- Khan, W.S.; Asmatulu, R.; Yildirim, M.B. Acoustical Properties of Electrospun Fibers for Aircraft Interior Noise Reduction. J. Aerosp. Eng. 2012, 25, 376–382. [Google Scholar] [CrossRef]

- Del Sorbo, G.; Truda, G.; Bifulco, A.; Passaro, J.; Petrone, G.; Vitolo, B.; Ausanio, G.; Vergara, A.; Marulo, F.; Branda, F. Non monotonous effects of noncovalently functionalized graphene addition on the structure and sound absorption properties of polyvinylpyrrolidone (1300 kda) electrospun mats. Materials 2019, 12, 108. [Google Scholar] [CrossRef] [PubMed]

- Avossa, J.; Branda, F.; Marulo, F.; Petrone, G.; Guido, S.; Tomaiuolo, G.; Costantini, A. Light electrospun polyvinylpyrrolidone blanket for low frequencies sound absorption. Chin. J. Polym. Sci. 2018, 36, 1368–1374. [Google Scholar] [CrossRef]

- Na, Y.; Agnhage, T.; Cho, G. Sound absorption of multiple layers of nanofiber webs and the comparison of measuring methods for sound absorption coefficients. Fibers Polym. 2012, 13, 1348–1352. [Google Scholar] [CrossRef]

- Trematerra, A.; Iannace, G.; Nesti, S.; Fatarella, E.; Peruzzi, F. Acoustic properties of nanofibers. In Proceedings of the Seventh Forum Acusticum Conference, Krakow, Poland, 7–12 September 2014; pp. 1–5. [Google Scholar]

- Liu, H.; Zuo, B. Sound absorption property of PVA/PEO/GO nanofiber membrane and non-woven composite material. J. Ind. Text. 2020, 50, 512–525. [Google Scholar] [CrossRef]

- Aydemir, H. Using Pet and r-Pet Polymers in Electrospinning to Develop Enhanced Sound Absorbing Properties of Nanofibrous Nonwovens. Ph.D. Thesis, Erciyes University, Graduate School of Natural and Applied Sciences, Kayseri, Turkey, July 2021; 174p. [Google Scholar]

- Geus, H.G. Developments in manufacturing techniques for technical nonwovens. In Advances in Technical Nonwovens, 1st ed.; Kellie, G., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 133–153. [Google Scholar] [CrossRef]

- Sivri, Ç.; Haji, A. Surface Coating of Needle-Punched Nonwovens with Meltblown Nonwovens to Improve Acoustic Properties. Coatings 2022, 12, 1092. [Google Scholar] [CrossRef]

- Lee, B.O.; Ko, J.A.; Han, S.W. Characteristics of PP/PET Bicomponent Melt Blown Nonwovens as Sound Absorbing Material. Adv. Mater. Res. 2010, 23–125, 935–938. [Google Scholar] [CrossRef]

- Cerkez, I.; Kocer, H.B.; Broughton, R.M. Airlaid nonwoven panels for use as structural thermal insulation. J. Text. Inst. 2018, 109, 17–23. [Google Scholar] [CrossRef]

- Barker, R.L.; Heniford, R.C. Factors affecting the thermal insulation and abrasion resistance of heat resistant hydro-entangled nonwoven batting materials for use in firefighter turnout suit thermal liner systems. J. Eng. Fibers Fabr. 2011, 6, 1–10. [Google Scholar] [CrossRef]

- Gnanauthayan, G.; Rengasamy, R.S.; Kothari, V.K. Heat insulation characteristics of high bulk nonwovens. J. Text. Inst. 2017, 108, 2173–2179. [Google Scholar] [CrossRef]

- Debnath, S.; Madhusoothanan, M. Thermal insulation. compression and air permeability of polyester needle-punched nonwoven. Indian J. Fibre Text. Res. 2010, 35, 38–44. [Google Scholar]

- Saleh, S.S. Performance of Needle-Punching Lining Nonwoven Fabrics and their Thermal Insulation Properties. J. Basic Appl. Sci. Res. 2011, 1, 3513–3524. [Google Scholar]

- Sakthivel, S.; Ramachandran, T.; Sakthivel, M.S.; Ramachandran, D.T. Thermal conductivity of non-woven materials using reclaimed fibres. Int. J. Eng. Res. Appl. 2012, 2, 2983–2987. [Google Scholar]

- Jirsak, O.; Sadıkoğlu, T.G.; Özipek, B.; Pan, N. Thermo-Insulating properties of perpendicular-laid versus cross-laid lofty nonwoven fabrics. Text. Res. J. 2000, 70, 121–128. [Google Scholar] [CrossRef]

- Gibson, P.W.; Lee, C.; Ko, F.; Reneker, D. Application of nanofiber technology to nonwoven thermal insulation. J. Eng. Fibers Fabr. 2007, 2, 32–40. [Google Scholar] [CrossRef]

- Ladgaonkar, H.; Mhetre, S.B. Factors affecting thermal comfort of nonwoven. Int. J. Sci. Res. Eng. Res. 2012, 3, 1–4. [Google Scholar]

- Obendorf, S.K.; Smith, J.P. Heat Transfer Characteristics of Nonwoven Insulating Materials. Text. Res. J. 1986, 56, 691–696. [Google Scholar] [CrossRef]

- Rahimzadeh, H.; Bafekrpoor, H.; Jeddi, A.A. Influence of Punch Density and Fiber Blends on Thermal Conductivity on Nonwoven. Open Text. J. 2011, 4, 1–6. [Google Scholar] [CrossRef]

- Yachmenev, V.; Negulescu, I.; Yan, C. Thermal insulation properties of cellulosic-based nonwoven composites. J. Ind. Text. 2006, 36, 73–87. [Google Scholar] [CrossRef]

- ISO 139; Textiles—Standard Atmospheres for Conditioning and Testing. ISO (International Organization for Standardization): Geneva, Switzerland, 2005.

- NWSP 130.1; Nonwovens Standard Procedures-Standard Test Method for Determining Mass per Unit Area of Nonwoven Fabrics. INDA&EDANA Worldwide Strategic Partners: Brussels, Belgium, 2012.

- NWSP 120.1; Nonwovens Standard Procedures-Standard Test Method for Determining Thickness of Nonwoven Fabrics. INDA&EDANA Worldwide Strategic Partners: Brussels, Belgium, 2012.

- Koç, E.; Çinçik, E. An analysis on abrasion resistance of polyester-/viscose-blended needle-punched nonwovens. J. Text. Inst. 2013, 104, 852–860. [Google Scholar] [CrossRef]

- Abbasi, M.; Reza, M.; Mojtahedi, M.; Kotek, R. Effect of melt spinning variables on the structural changes of recycled and bottle grade filament yarn pet. J. Text. Polym. 2018, 6, 67–75. [Google Scholar]

- Wang, W.; Zeng, Y. Polypropylene—Polymerization and Characterization of Mechanical and Thermal Properties; IntechOpen: London, UK, 2020; pp. 1–122. [Google Scholar] [CrossRef]

- Krishnan, P.S.G.; Kulkarni, S.T. Polyester Resins. In Polyester and Polyamids, 1st ed.; Deopuno, B.L., Alogirusamy, R., Joshi, M., Gupto, B., Eds.; CRC Press Woodhead Publishing: Cambridge, UK, 2008; pp. 3–40. ISBN 978-1-84569-298-8. [Google Scholar]

- Lepoittevin, B.; Roger, P. Poly(ethylene terephthalate). In Handbook of Engineering and Specialty Thermoplastics: Polyethers and Polyesters, 1st ed.; Thomas, S., Visakh, P.M., Eds.; Wiley Online Library: Montreal, QC, Canada, 2011; pp. 97–126. ISBN 9780470639269. [Google Scholar]

- Antić, V.V.; Pergal, M.V. Poly(butylene terephthalate)—Synthesis, Properties, Application. In Handbook of Engineering and Specialty Thermoplastics: Polyethers and Polyesters, 1st ed.; Thomas, S., Visakh, P.M., Eds.; Wiley Online Library: Montreal, QC, Canada, 2011; pp. 127–180. ISBN 9780470639269. [Google Scholar]

- ASTM E1294; Standard Test Method for Pore Size Characteristics of Membrane Filters Using Automated Liquid Porosimeter. ASTM: West Conshohocken, PA, USA, 1999.

- NWSP 070.1; Nonwovens Standard Procedures-Standard Test Method for Determining Air Permeability of Nonwoven Materials. INDA&EDANA Worldwide Strategic Partners: Brussels, Belgium, 2012.

- ISO 10534-2; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method. ISO: Geneva, Switzerland, 1998.

- ASTM E1050–08; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Micro-phones and a Digital Frequency Analysis System. ASTM International: West Conshohocken, PA, USA, 2008.

- Demiryürek, O.; Aydemir, H. Sound absorbing properties of roller blind curtain fabrics. J. Ind. Text. 2017, 47, 3–19. [Google Scholar] [CrossRef]

- Barron, R.F. Industrial Noise Control and Acoustic; Marcel Dekker Inc.: New York, NY, USA, 2003; pp. 1–534. ISBN 0-8247-0701-X. [Google Scholar]

- Marmarali, A.; Dönmez Kretzschmar, S.; Özdil, N.; Gülsevin Oğlakcioğlu, N. Parameters that affect thermal comfort of garment. Text. Appar. 2006, 16, 241–246. [Google Scholar]

- Li, Y. The Science of Clothing Comfort. Text. Prog. 2001, 31, 1–135. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, D. Thermal Conductivity of Polypropylene-Based Materials; IntechOpen: London, UK, 2019; pp. 1–20. [Google Scholar] [CrossRef]

- Hu, J.; Lu, J.; Zhu, Y. New developments in elastic fibers. Polym. Rev. 2008, 48, 275–301. [Google Scholar] [CrossRef]

- Physical Properties of PBT Polymers. Available online: https://polymerdatabase.com/Commercial%20Polymers/PBT.html (accessed on 26 February 2023).

- TS 825; Thermal Insulation Requirements for Buildings. Turkish Standards Institution: Ankara, Türkiye, 2013.

- Özlüsoylu, I.; Istek, A. The Effect of Hybrid Resin Usage on Thermal Conductivity in Ecological Insulation Panel Production. In Proceedings of the 4th International Conference on Engineering Technology and Applied Sciences (Icetas), Kiev, Ukraine, 24–28 April 2019; pp. 292–296. [Google Scholar]

- Kecebas, A.; Kayfeci, M. Effect on optimum insulation thickness, cost and saving of storage design temperature in cold storage in Turkey. Energy Educ. Sci. Tech. Part A Energy Sci. Res. 2010, 25, 117–127. [Google Scholar]

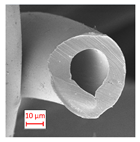

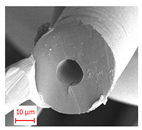

| Fiber Type | Linear Density (denier) | Length (mm) | Strength (g/denier) | Elongation (%) | Crimp (Crimps/cm) | Cross Section (1000×) |

|---|---|---|---|---|---|---|

| 7D Solid r-Pet (7DS) | 6.8 (2.8) | 64.4 (1.3) | 3.6 (2.2) | 63 (2.5) | 3.2 (0.7) |  |

| 7D Hollow r-Pet (7DH) | 7.3 (4.1) | 64.5 (0.9) | 4.01 (2.6) | 42 (2.4) | - |  |

| 12D Hollow r-Pet (12DH) | 12.2 (3.3) | 64.3 (0.7) | 3.55 (3.8) | 60.3 (3.7) | 5.1 (0.5) |  |

| 4D Bicomponent Polyester | 4.2 (2.7) | 51.1 (1.2) | 3.68 (4.1) | 54.15 (3.9) | 2.75 (0.8) |  |

| Outer Web Layer | Content |

|---|---|

| 7DS | 80%–7D Solid r-PET and 20% 4D Bicomponent PET |

| 7DH | 80%–7D-Hollow r-PET and 20% 4 D Bicomponent PET |

| 12DH | 80%–12D Hollow r-PET and 20% 4 D Bicomponent PET |

| Layer Code | Raw Material | Manufacturing Process | Target Areal Weight (g/m2) |

|---|---|---|---|

| PP-NC-100 | Polypropylene | Produced with meltblown technology and non-calendared | 100 |

| PP-NC-200 | Polypropylene | Produced with meltblown technology and non-calendared | 200 |

| PP-C-100 | Polypropylene | Produced with meltblown technology and calendared | 100 |

| PP-C-200 | Polypropylene | Produced with meltblown technology and calendared | 200 |

| PBT-NC-100 | Polybutylene Terephthalate | Produced with meltblown technology and non-calendared | 100 |

| PBT-NC-200 | Polybutylene Terephthalate | Produced with meltblown technology and non-calendared | 200 |

| PBT-C-100 | Polybutylene Terephthalate | Produced with meltblown technology and calendared | 100 |

| PBT-C-200 | Polybutylene Terephthalate | Produced with meltblown technology and calendared | 200 |

| N | Polyamide | Electrospun | 8 |

| Outer Web Layer | Content | Areal Weight (g/m2) | Thickness (mm) | Calculated Bulk Density (g/cm3) | Calculated Porosity (%) | Air Permeability (L/m2/s) |

|---|---|---|---|---|---|---|

| 7DS | 80%–7D Solid r-PET 20% 4D Bicomponent PET | 200.99 (0.68) | 12.74 (4.57) | 0.0158 | 98.83 | 216.60 (4.5) |

| 7DH | 80%–7D-Hollow r-PET 20% 4 D Bicomponent PET | 201.12 (0.55) | 14.72 (4.16) | 0.0137 | 98.99 | 238.00 (4.1) |

| 12DH | 80%–12D Hollow r-PET 20% 4 D Bicomponent PET | 201.81 (0.50) | 11.68 (3.86) | 0.0173 | 98.72 | 279.40 (3.3) |

| Sample Code | Fiber Fineness (µm) | Areal Weight (g/m2) | Thickness (mm) | Strength in MD (N) | Elongation in MD (%) | Strength in CD (N) | Elongation in CD (%) | Calculated Bulk Density (g/cm3) | Calculated Porosity (%) | Pore Size (ìm) | Air Permeability (L/m2/s) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PP-C-100 | 3.87 (7.8) | 102.1 (3.9) | 0.72 (2.3) | 42 (3.5) | 30 (1.9) | 44 (1.2) | 35 (1.8) | 0.159 | 82.344 | 16.5 (5.3) | 4.64 (6.0) |

| PP-C-200 | 4.33 (9.3) | 208.4 (3.6) | 0.87 (2.5) | 110 (2.8) | 30 (2.3) | 60 (3.1) | 40 (2.2) | 0.241 | 73.260 | 15.0 (4.8) | 1.27 (12.6) |

| PP-NC-100 | 6.46 (8.7) | 108.95 (4.3) | 1.24 (4.4) | 18.94 (5.1) | 10.55 (3.8) | 33.83 (4.2) | 28.56 (4.7) | 0.088 | 90.243 | 33.5 (6.2) | 30.08 (5.4) |

| PP-NC-200 | 5.04 (10.3) | 210.43 (5.9) | 2.36 (3.8) | 27.23 (4.9) | 10.32 (4.2) | 61.33 (3.9) | 34.6 (4.1) | 0.089 | 90.093 | 31.5 (5.2) | 21.06 (5.9) |

| PBT-C-100 | 4.97 (8.6) | 99.08 (3.9) | 0.57 (1.9) | 41.30 (2.4) | 50.99 (3.3) | 34.02 (2.9) | 52.94 (2.3) | 0.175 | 87.033 | 23.2 (4.8) | 15.24 (6.6) |

| PBT-C-200 | 7.69 (11.2) | 204.39 (2.3) | 0.80 (2.4) | 74.69 (2.6) | 37.07 (2.8) | 66.10 (2.5) | 45.15 (2.4) | 0.255 | 81.123 | 20.6 (4.4) | 6.07 (12.3) |

| PBT-NC-100 | 4.97 (7.9) | 103.97 (3.9) | 0.63 (3.3) | 9.20 (4.1) | 43.79 (4.9) | 22.59 (4.2) | 38.86 (4.3) | 0.164 | 87.853 | 26.2 (6.3) | 30.62 (5.8) |

| PBT-NC-200 | 6.11 (8.4) | 218.22 (2.9) | 1.26 (2.8) | 20.11 (4.7) | 18.2 (3.9) | 63.39 (3.8) | 68.70 (3.7) | 0.174 | 87.144 | 22.7 (5.9) | 13.06 (9.8) |

| N | 0.19 (10.9) | 8.3 (3.3) | - | - | - | - | - | - | - | 0.38 (10.2) | - |

| ANOVA for Thickness | ANOVA for Bulk Density | ||||||

|---|---|---|---|---|---|---|---|

| Source | F-Value | p-Values | Contribution (%) | Source | F-Value | p-Values | Contribution (%) |

| Model | 130.079 | <0.0001 | R2 = 98.28 | Model | 19.01 | <0.0001 | R2 = 98.82 |

| R | 4.866 | 0.0424 | 0.53 | R | 1.29 | 0.2725 | 0.095 |

| W | 16.138 | 0.0010 | 1.74 | W | 633.85 | <0.0001 | 46.60 |

| O | 428.750 | <0.0001 | 92.55 | O | 340.14 | <0.0001 | 50.02 |

| P | 18.992 | 0.0005 | 2.05 | P | 12.17 | 0.0030 | 0.89 |

| RWO | 6.529 | 0.0085 | 1.41 | RP | 4.90 | 0.0416 | 0.36 |

| Residual | 1.72 | RWP | 11.60 | 0.0036 | 0.85 | ||

| Cor Total | 100 | Residual | 1.18 | ||||

| Cor Total | 100 | ||||||

| Source | Sum of Squares | Degrees of Freedom | Contribution (%) | Mean Square | F Value | P > F | Significance |

|---|---|---|---|---|---|---|---|

| Model | 10,790.99 | 15 | R2 = 99.29 | 719.40 | 966.21 | <0.0001 | Significant |

| R | 277.10 | 1 | 2.55 | 277.10 | 372.16 | <0.0001 | Significant |

| W | 2277.93 | 1 | 20.96 | 2277.93 | 3059.44 | <0.0001 | Significant |

| O | 430.25 | 2 | 3.96 | 215.12 | 288.93 | <0.0001 | Significant |

| P | 6700.44 | 1 | 61.65 | 6700.44 | 8999.23 | <0.0001 | Significant |

| RW | 275.76 | 1 | 2.54 | 275.76 | 370.37 | <0.0001 | Significant |

| RO | 4.64 | 2 | 0.04 | 2.32 | 3.12 | 0.0486 | Significant |

| RP | 640.10 | 1 | 5.89 | 640.10 | 859.71 | <0.0001 | Significant |

| WO | 8.01 | 2 | 0.07 | 4.00 | 5.38 | 0.0060 | Significant |

| WP | 161.40 | 1 | 1.49 | 161.40 | 216.78 | <0.0001 | Significant |

| OP | 9.35 | 2 | 0.09 | 4.67 | 6.28 | 0.0027 | Significant |

| RWP | 6.03 | 1 | 0.06 | 6.03 | 8.09 | 0.0054 | Significant |

| Residual | 77.43 | 104 | 0.71 | 0.75 | - | - | |

| Cor Total | 10,868.43 | 119 | 100 | - | - |

| Source | Sum of Squares | Degrees of Freedom | Contribution (%) | Mean Square | F Value | P > F | Significance |

|---|---|---|---|---|---|---|---|

| Model | 54.01 | 10 | R2 = 94.79 | 5.40 | 803.6 | <0.0001 | Significant |

| R | 0.0007 | 1 | 0.001 | 0.0007 | 0.1 | 0.7474 | Not significant |

| W | 0.16 | 1 | 0.28 | 0.16 | 23.6 | <0.0001 | Significant |

| P | 0.03 | 1 | 0.05 | 0.03 | 4.3 | 0.0384 | Significant |

| O | 0.07 | 2 | 0.13 | 0.035 | 5.4 | 0.0050 | Significant |

| F | 42.45 | 1 | 74.50 | 42.45 | 6315.4 | <0.0001 | Significant |

| F2 | 11.20 | 1 | 19.66 | 11.20 | 1666.2 | <0.0001 | Significant |

| RF | 0.05 | 1 | 0.08 | 0.05 | 6.8 | 0.0094 | Significant |

| WF | 0.09 | 1 | 0.15 | 0.09 | 12.7 | 0.0004 | Significant |

| PF | 0.19 | 1 | 0.34 | 0.19 | 28.6 | <0.0001 | Significant |

| Residual | 2.97 | 442 | 5.21 | 0.007 | - | - | - |

| Cor Total | 56.98 | 456 | 100 | - | - | - | - |

| NRC for Low Frequencies (100–1000 Hz) | NRC for Medium Frequencies (1250–3000 Hz) | NRC for High Frequencies (4000–6300 Hz) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | F Value | P > F | Contribution (%) | Source | F Value | P > F | Contribution (%) | Source | F Value | P > F | Contribution (%) |

| Model | 21.47 | <0.0001 | R2 = 93.25 | Model | 16.06 | <0.0001 | R2 = 95.43 | Model | 47.25 | <0.0001 | R2 = 95.39 |

| R | 3.37 | 0.0879 | 1.63 | R | 8.33 | 0.0162 | 3.81 | R | 37.98 | <0.0001 | 10.95 |

| W | 109.47 | <0.0001 | 52.82 | W | 58.33 | <0.0001 | 26.66 | W | 33.93 | <0.0001 | 9.78 |

| P | 34.04 | <0.0001 | 16.42 | P | 63.16 | <0.0001 | 28.87 | P | 147.00 | <0.0001 | 42.39 |

| O | 9.79 | 0.0022 | 9.44 | O | 16.52 | 0.0007 | 15.10 | O | 2.98 | 0.0792 | 1.72 |

| RP | 10.30 | 0.0063 | 4.97 | RW | 9.40 | 0.0119 | 4.29 | RP | 63.76 | <0.0001 | 18.39 |

| WP | 9.223 | 0.0089 | 4.45 | RO | 7.59 | 0.0099 | 6.94 | WP | 42.14 | <0.0001 | 12.15 |

| WO | 3.64 | 0.0533 | 3.51 | WP | 5.54 | 0.0404 | 2.53 | Residual | - | - | 4.61 |

| Residual | 6.75 | WO | 3.17 | 0.0858 | 2.89 | Cor Total | - | - | 100 | ||

| Cor Total | 100 | WPO | 4.74 | 0.0356 | 4.33 | - | - | - | - | ||

| - | - | - | - | Residual | - | - | 4.57 | - | - | - | - |

| - | - | - | - | Cor Total | - | - | 100 | - | - | - | - |

| Source | Sum of Squares | Degrees of Freedom | Contribution (%) | Mean Square | F Value | P > F | Significance |

|---|---|---|---|---|---|---|---|

| Model | 0.052 | 9 | R2 = 88.94 | 0.006 | 12.51 | <0.0001 | Significant |

| R | 0.002 | 1 | 2.87 | 0.002 | 3.64 | 0.0772 | Not significant |

| W | 0.004 | 1 | 6.16 | 0.004 | 7.80 | 0.0144 | Significant |

| O | 0.035 | 2 | 60.13 | 0.0175 | 38.06 | <0.0001 | Significant |

| P | 0.0006 | 1 | 0.98 | 0.0006 | 1.23 | 0.2853 | Not significant |

| RWO | 0.007 | 2 | 12.65 | 0.0035 | 8.02 | 0.0048 | Significant |

| WOP | 0.004 | 2 | 6.15 | 0.002 | 3.89 | 0.0454 | Significant |

| Residual | 0.007 | 14 | 11.16 | 0.0005 | - | - | - |

| Cor Total | 0.059 | 23 | 100 | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Çinçik, E.; Aslan, E. Assessing the Sound and Heat Insulation Characteristics of Layered Nonwoven Composite Structures Composed of Meltblown and Recycled Thermo-Bonded Layers. Polymers 2024, 16, 1391. https://doi.org/10.3390/polym16101391

Çinçik E, Aslan E. Assessing the Sound and Heat Insulation Characteristics of Layered Nonwoven Composite Structures Composed of Meltblown and Recycled Thermo-Bonded Layers. Polymers. 2024; 16(10):1391. https://doi.org/10.3390/polym16101391

Chicago/Turabian StyleÇinçik, Emel, and Eda Aslan. 2024. "Assessing the Sound and Heat Insulation Characteristics of Layered Nonwoven Composite Structures Composed of Meltblown and Recycled Thermo-Bonded Layers" Polymers 16, no. 10: 1391. https://doi.org/10.3390/polym16101391

APA StyleÇinçik, E., & Aslan, E. (2024). Assessing the Sound and Heat Insulation Characteristics of Layered Nonwoven Composite Structures Composed of Meltblown and Recycled Thermo-Bonded Layers. Polymers, 16(10), 1391. https://doi.org/10.3390/polym16101391