The Effects of Aging on Microstructures and Rheological Properties of Modified Asphalt with GO/SBS Composite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of GO/SBS Composites and GO/SBS-MA

2.3. Aging Tests

2.3.1. PAV Test

2.3.2. UV Aging Test

2.4. Microstructure Tests

2.4.1. SEM (Scanning Electron Microscopy) Test

2.4.2. FTIR (Fourier-Transform Infrared Spectroscopy) Test

2.4.3. AFM (Atomic Force Microscope) Test

2.5. Rheological Property Tests

2.5.1. BROOKFIELD Viscosity Test

2.5.2. DSR (Dynamic Shear Rheometer) Test

2.5.3. BBR (Bending Beam Rheometer) Test

3. Results

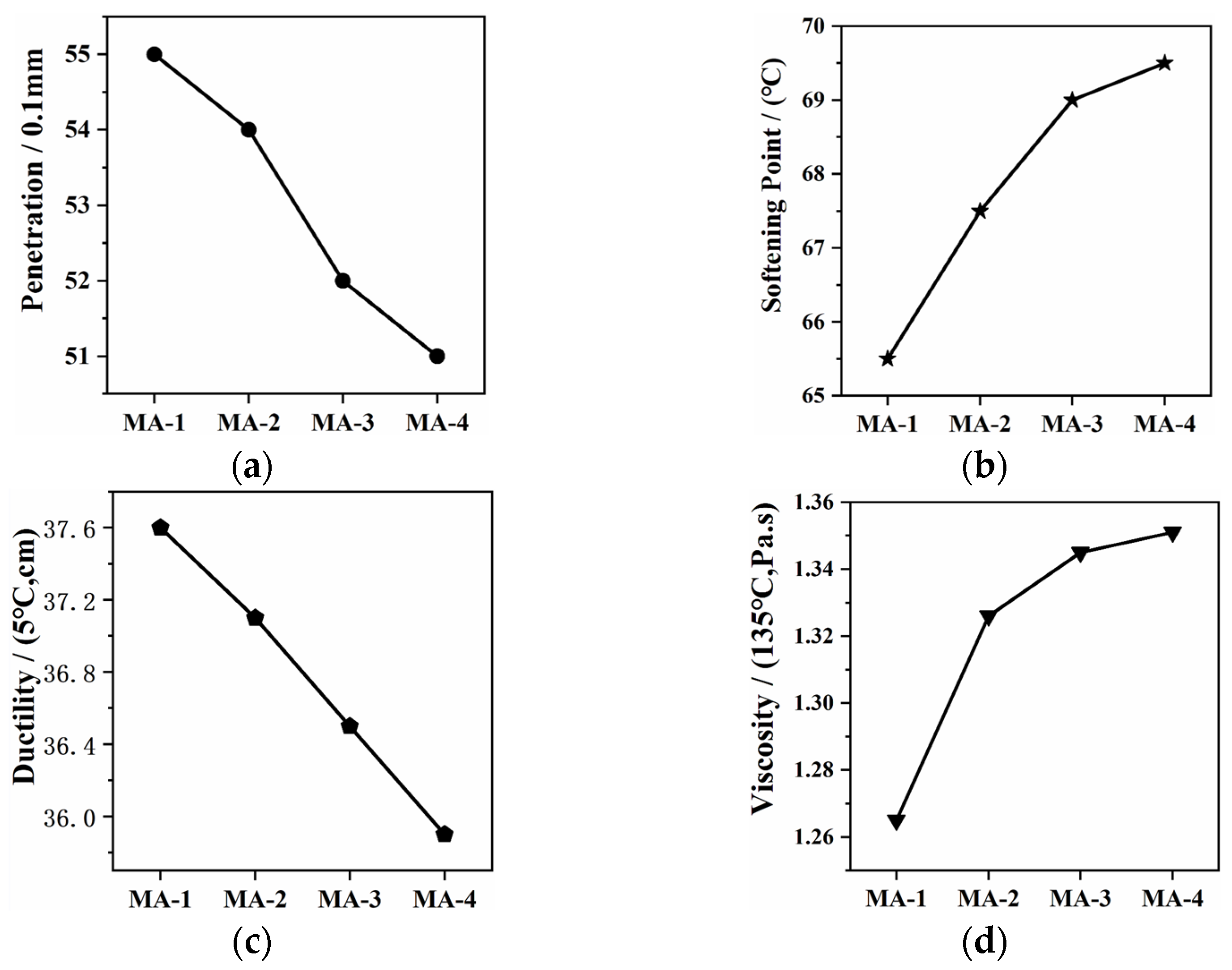

3.1. Physical Properties of GO/SBS-MA

3.2. Microstructure Analysis

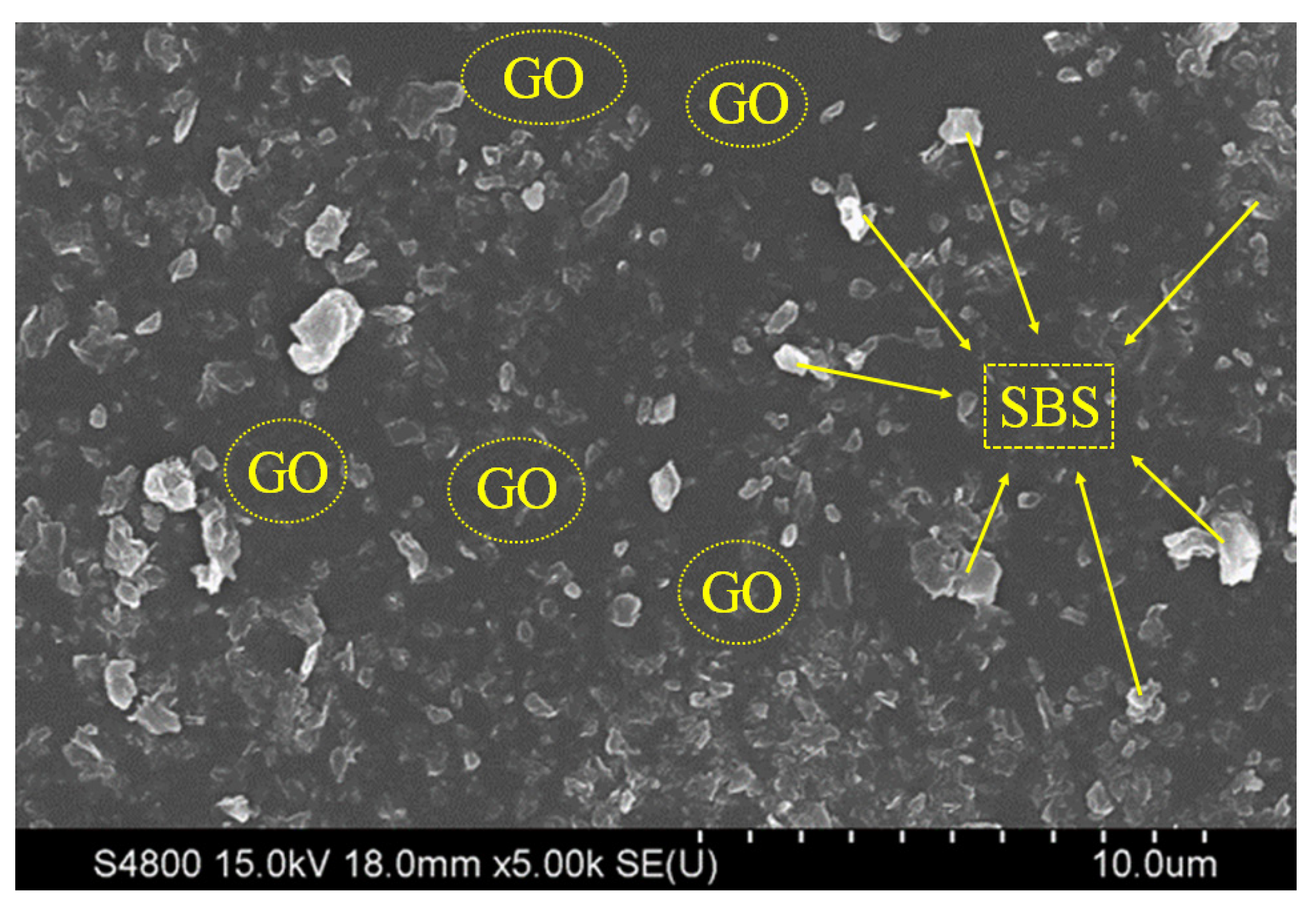

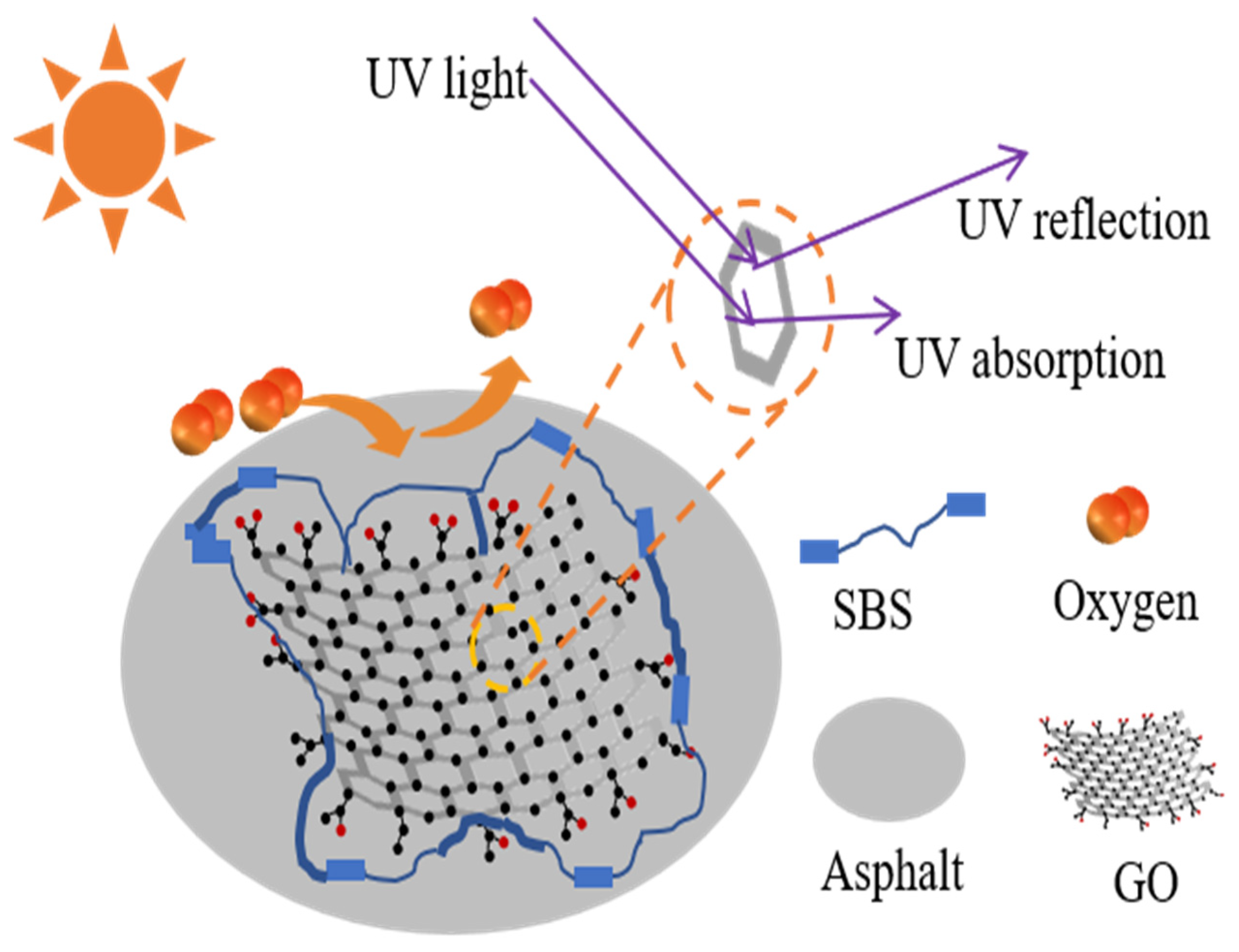

3.2.1. SEM Analysis

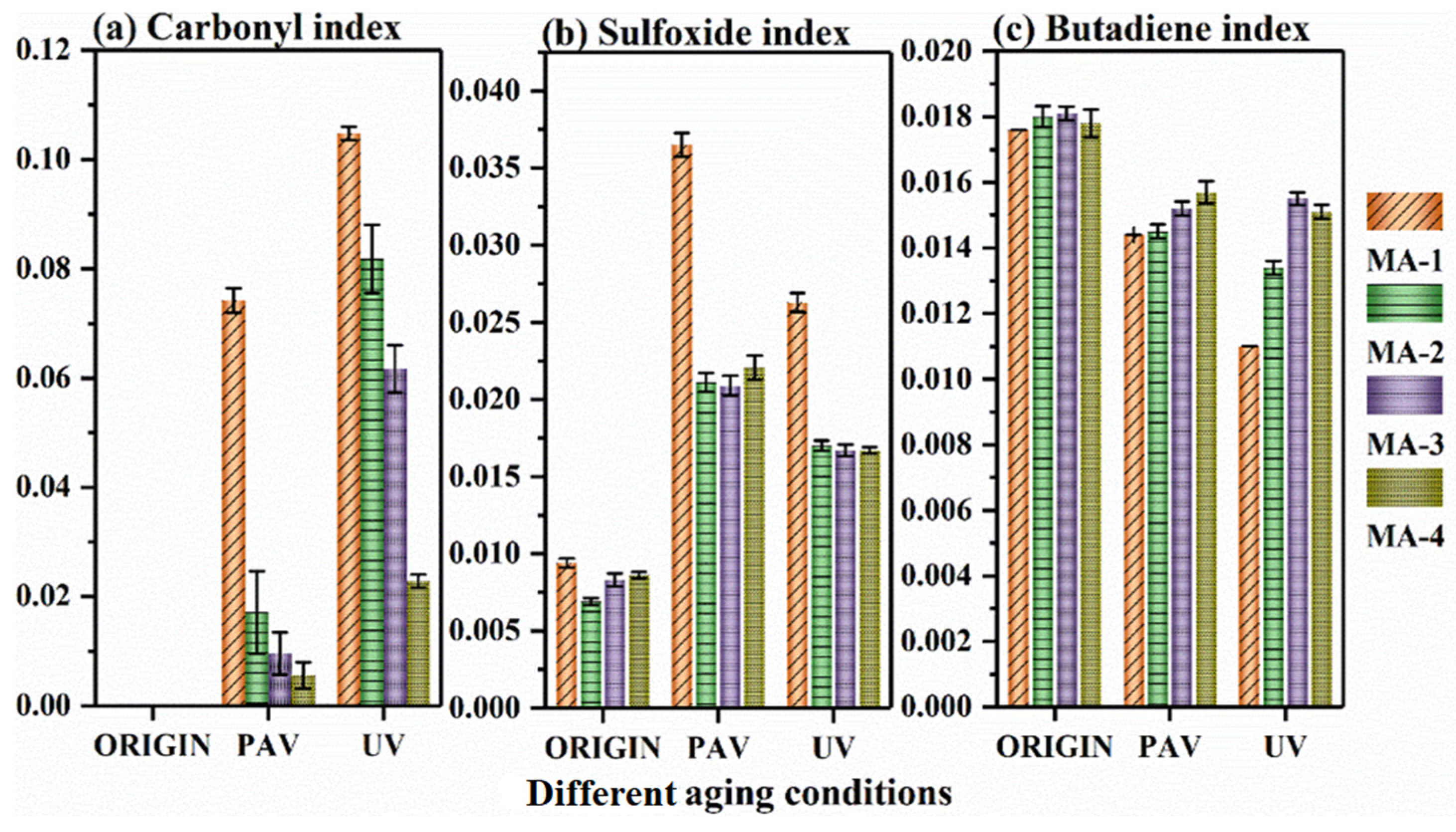

3.2.2. FTIR Analysis

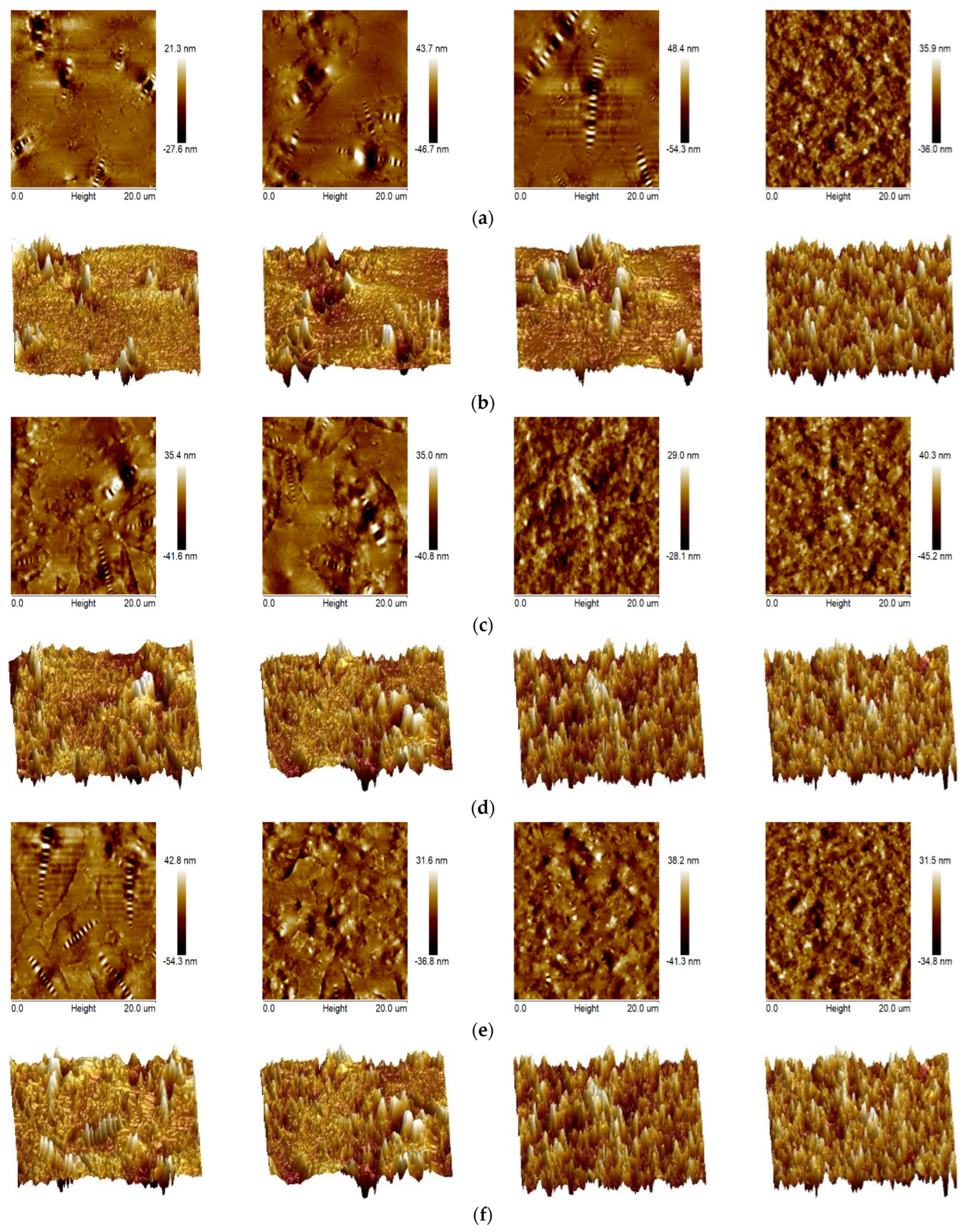

3.2.3. AFM Analysis

3.3. Rheological Properties

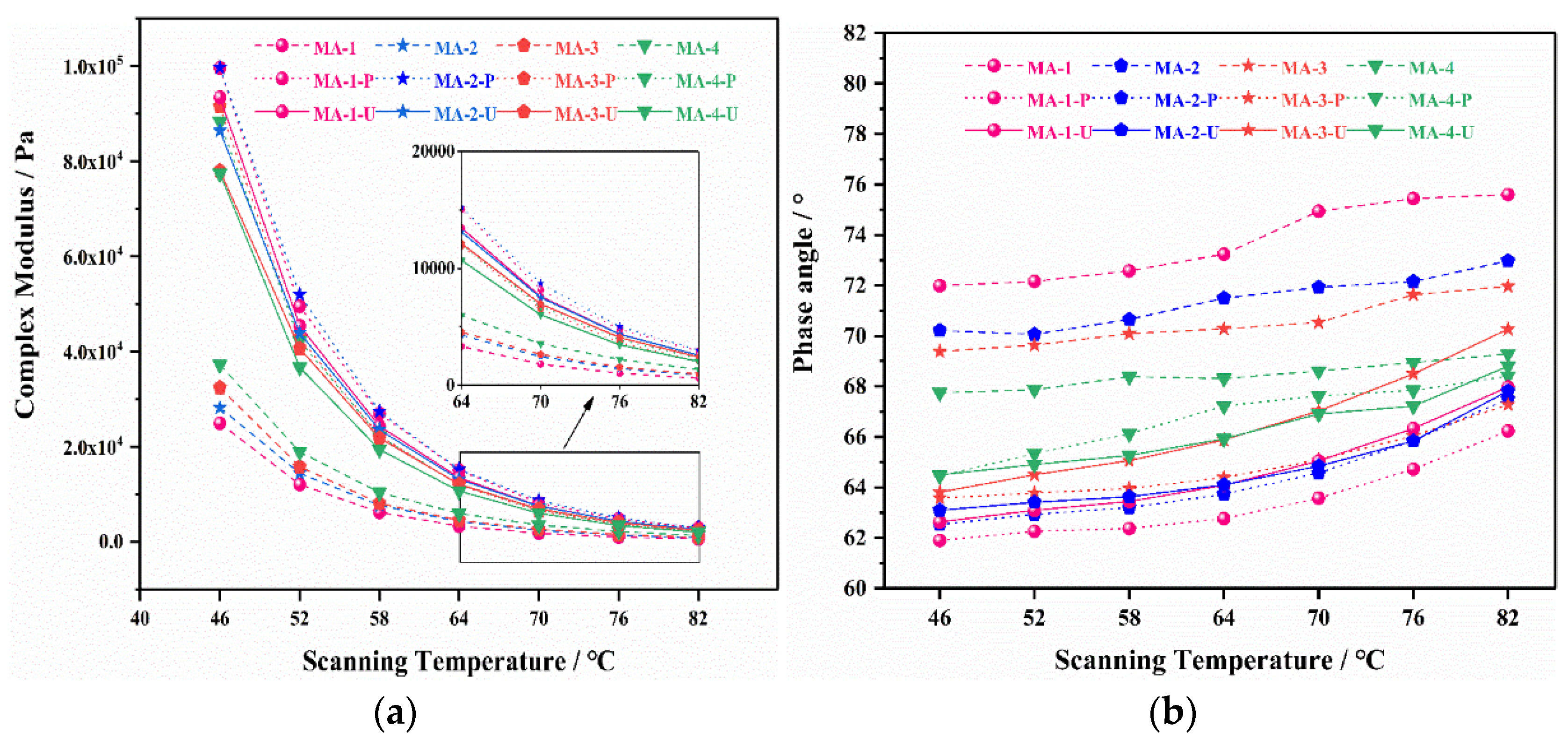

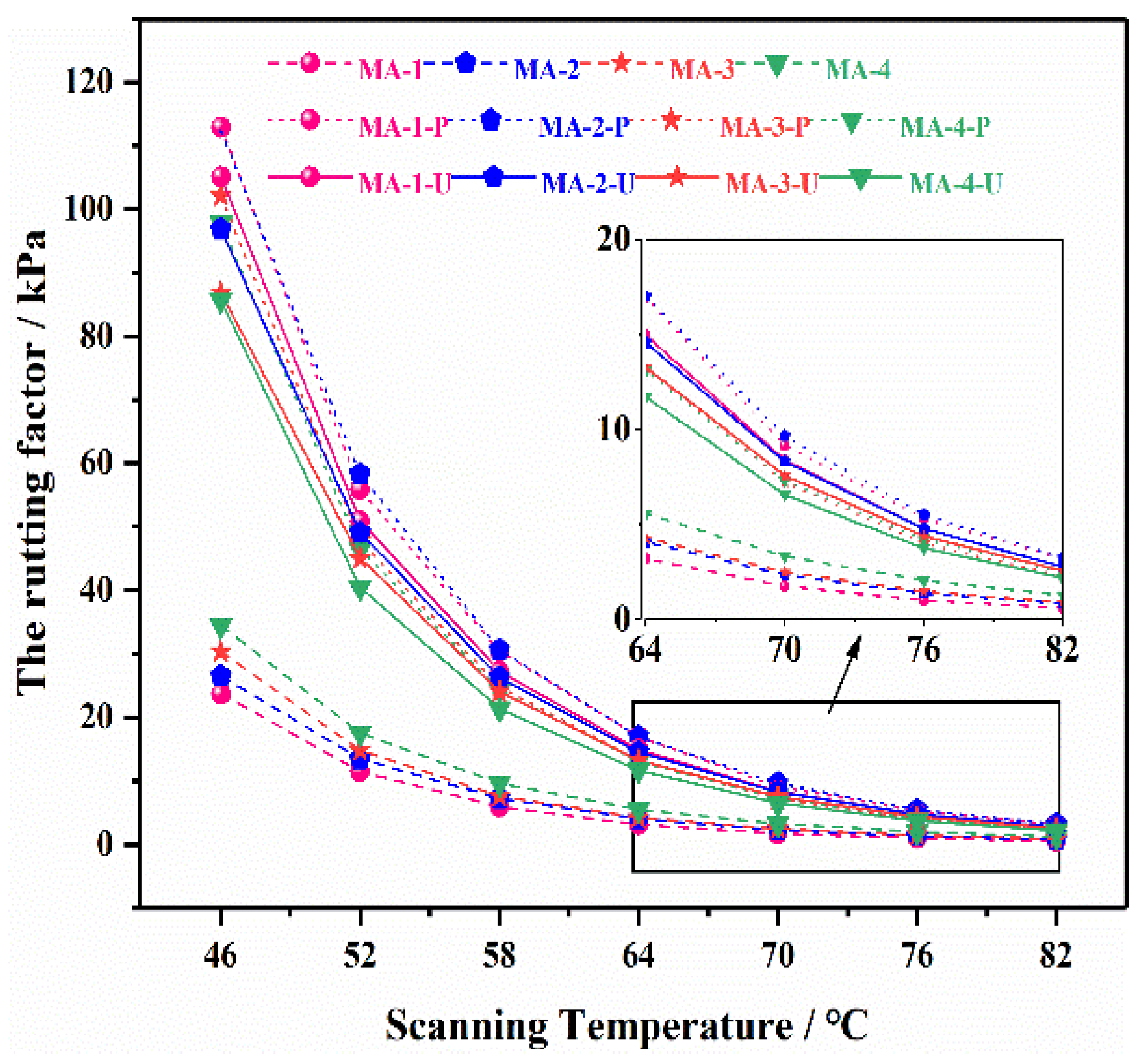

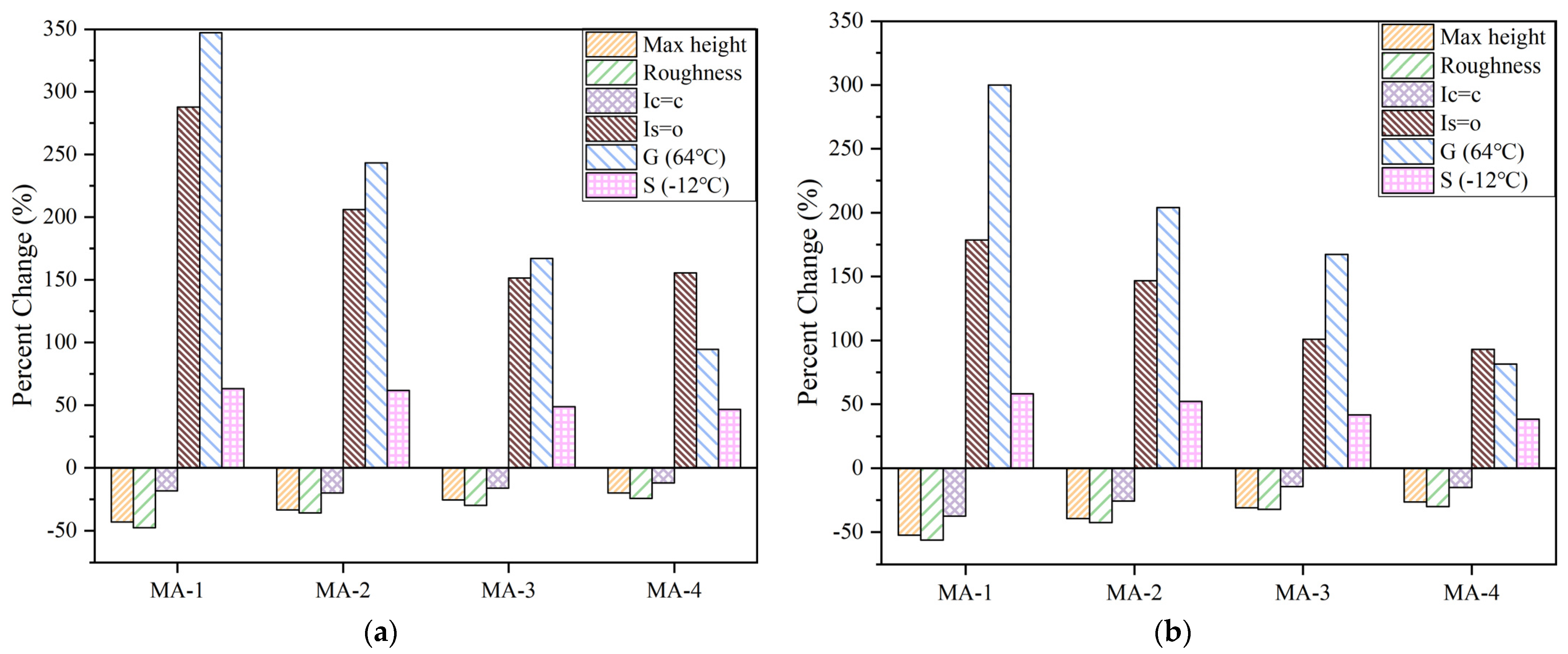

3.3.1. DSR Analysis

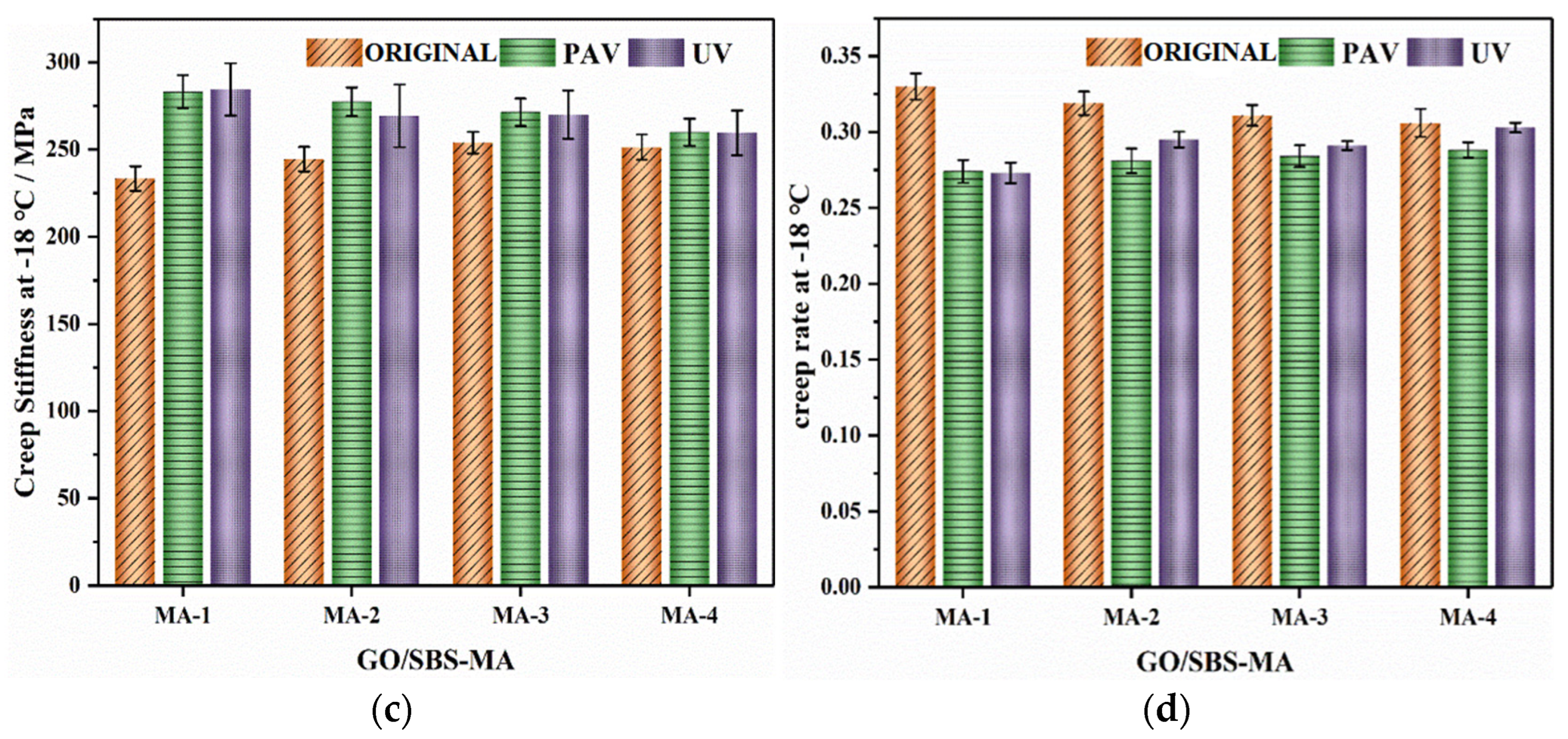

3.3.2. BBR Analysis

4. Conclusions

- According to the physical properties, the penetration and ductility of the GO/SBS-MA declined and the softening point and viscosity increased with increasing GO content. The results revealed that the increase in the GO content improved the high-temperature performance of the asphalt binder, while the low-temperature performance became slightly inferior.

- According to the FTIR analysis, increasing the content of GO could prevent the production of carbonyl and sulfoxide groups and restrain the breakdown of C=C bonds in the polybutadiene (PB) segment. The results indicated that GO could inhibit the degradation of SBS and the aging of asphalt binders.

- From the AFM analysis, it was observed that the needle-like aggregates on the surface of the GO/SBS-MA after aging were more than that of unaged asphalt. The distributions of the needle-like aggregates were more homogeneous with an increase in the GO content. These findings show that GO had a significant influence on the formation of the aggregated structure and that it enhanced the high-temperature stability of the asphalt binder.

- According to the rheological properties, asphalt binders with a higher content of GO not only exhibit a better high-temperature performance, but they also undermine the adverse impact caused by aging, while GO causes a disadvantageous effect on the low-temperature performance of asphalt binders.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Han, M.; Li, J.; Muhammad, Y.; Hou, D.; Zhang, F.; Yin, Y.; Duan, S. Effect of polystyrene grafted graphene nanoplatelets on the physical and chemical properties of asphalt binder. Constr. Build. Mater. 2018, 174, 108–119. [Google Scholar] [CrossRef]

- Liu, J.; Hao, P.; Jiang, W.; Sun, B. Rheological properties of SBS modified asphalt incorporated polyvinylpyrrolidone stabilized graphene nanoplatelets. Constr. Build. Mater. 2021, 298, 123850. [Google Scholar] [CrossRef]

- Sun, X.; Qin, X.; Liu, Z.; Yin, Y.; Zou, C.; Jiang, S. New preparation method of bitumen samples for UV aging behavior in-vestigation. Constr. Build. Mater. 2020, 233, 117278. [Google Scholar] [CrossRef]

- Hu, M.; Sun, G.; Sun, D.; Zhang, Y.; Ma, J.; Lu, T. Effect of thermal aging on high viscosity modified asphalt binder: Rheological property, chemical composition and phase morphology. Constr. Build. Mater. 2020, 241, 118023. [Google Scholar] [CrossRef]

- Ding, Y.; Xi, Y.; Li, X.; Tang, B.; Deng, M.; Yan, H. Aging Simulation of SBS Modifier during Service Life of Modified Asphalt. J. Mater. Civ. Eng 2022, 34, 04022173. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, H.; Shi, C. Investigation of aging performance of SBS modified asphalt with various aging methods. Constr. Build. Mater. 2017, 145, 445–451. [Google Scholar] [CrossRef]

- Zhang, H.; Duan, H.; Zhu, C.; Chen, Z.; Luo, H. Mini-review on the application of nanomaterials in improving anti-aging properties of asphalt. Energy Fuels 2021, 35, 11017–11036. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S. A review of nanomaterials’ effect on mechanical performance and aging of asphalt mixtures. Appl. Sci. 2019, 9, 3657. [Google Scholar] [CrossRef]

- Li, J.; Yang, J.; Liu, Y.; Zhao, Z.; Tang, X.; Luo, J.; Muhammad, Y. Fabrication of IPDI-LDHs/SBS modified asphalt wit-h enhanced thermal aging and UV aging resistance. Constr. Build. Mater. 2021, 302, 124131. [Google Scholar] [CrossRef]

- Bhat, F.S.; Mir, M.S. A study investigating the influence of nano Al2O3 on the performance of SBS modified asphalt binder. Constr. Build. Mater. 2021, 271, 121499. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Dalmazzo, D. SIIV—5th International Congress -Sustainability of Road Infrastructures Rheological Characterization of Bituminous Binders Modified with Carbon Nanotubes. Procedia-Soc. Behav. Sci. 2012, 53, 546–555. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.M.; Wu, Y.L.; Wang, H.R.; Chen, M.; Sun, H.D.; Fan, L. Properties and modification mechanism of asphalt with graphene as modifier. Constr. Build. Mater. 2021, 272, 121919. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Yakovlev, A.V. Effect of Additions of Electrochemically Oxidized Graphite on the Physicochemical and Mechanical Properties of Modified Epoxy Composites. Russian Journal of Applied Chemistry. Russ. J. Appl. Chem. 2019, 92, 1439–1446. [Google Scholar] [CrossRef]

- Chen, F.; Balieu, R. A state-of-the-art review of intrinsic and enhanced electrical properties of asphalt materials: Theories, analyses and applications. Mater. Des. 2020, 195, 109067. [Google Scholar] [CrossRef]

- Hu, K.; Yu, C.; Yang, Q.; Chen, Y.; Chen, G.; Ma, R. Multi–scale enhancement mechanisms of graphene oxide on styrene–butadiene–styrene modified asphalt: An exploration from molecular dynamics simulations. Mater. Des. 2021, 208, 109901. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, Z.; Li, Y.; Pang, L.; Amirkhanian, S.; Riara, M. Evaluation of aging resistance of graphene oxide modified asphalt. Appl. Sci. 2017, 7, 702. [Google Scholar] [CrossRef]

- Yu, R.; Zhu, X.; Hu, J.; Zhao, W.; Fang, C. Preparation of graphene oxide and its modification effect on base asphalt. Fuller. Nanotub. Carbon Nanostructures 2019, 27, 256–264. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, K.; Shi, X. Performance evaluation and modification mechanism analysis of asphalt binders modified by graphene oxide. Constr. Build. Mater. 2018, 163, 880–889. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, K.; Wu, J.; Muhunthan, B.; Shi, X. Evaluation of mechanical performance and modification mechanism of asphalt modified with graphene oxide and warm mix additives. J. Clean. Prod. 2018, 193, 87–96. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Amirkhanian, S. Investigation of the graphene oxide and asphalt interaction and its effect on asphalt pavement performance. Constr. Build. Mater. 2018, 165, 572–584. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, Y.; Liu, Q.; Liu, P.; He, Y.; Zeng, Y. Preparation and modification mechanism analysis of graphene oxide modified asphalts. Constr. Build. Mater. 2020, 238, 117706. [Google Scholar] [CrossRef]

- Wang, R.; Yue, M.; Xiong, Y.; Yue, J. Experimental study on mechanism, aging, rheology and fatigue performance of carbon nanomaterial/SBS-modified asphalt binders. Constr. Build. Mater. 2021, 268, 121189. [Google Scholar] [CrossRef]

- Li, S.; Xu, W.; Zhang, F.; Wu, H.; Ge, Q. Effect of Graphene Oxide on Aging Properties of Polyurethane-SBS Modified Asphalt and Asphalt Mixture. Polymers 2022, 14, 3496. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Xu, W.; Zhang, F.; Wu, H.; Zhao, P. Effect of Graphene Oxide on the Low-Temperature Crack Resistance of Polyurethane-SBS-Modified Asphalt and Asphalt Mixtures. Polymers 2022, 14, 453. [Google Scholar] [CrossRef]

- Huang, J.; Liu, Y.; Subhan, S.; Quan, X.; Zhong, H.; Li, J.; Zhao, Z. Fast deposition of Fe3+ chelated tannic acid network via salt induction over graphene oxide based SBS modified asphalt. Constr. Build. Mater. 2021, 307, 125009. [Google Scholar] [CrossRef]

- Yang, J.; Wu, M.; Chen, F.; Fei, Z.; Zhong, M. Preparation, characterization, and supercritical carbon dioxide foaming of polystyrene/graphene oxide composites. J. Supercrit. Fluids 2011, 56, 201–207. [Google Scholar] [CrossRef]

- Chen, X.; Ning, Y.; Gu, Y.; Zhao, R.; Tong, J.; Wang, J.; Zhang, X.; Wen, W. Evaluating the rheological, chemical and morphological properties of SBS modified asphalt-binder under multiple aging and rejuvenation cycles. Appl. Sci. 2021, 11, 9242. [Google Scholar] [CrossRef]

- ASTM D6114; Standard Specification for Asphalt-Rubber Binder. ASTM International: West Conshohocken, PA, USA, 2023.

- Li, Y.; Ge, D.; Ju, Z.; Lv, S.; Xue, Y.; Xue, Y.; Peng, L. Study on Performance and Mechanism of SBR and Bio-Oil Recycled SBS Modified Asphalt. Polymers 2022, 14, 5096. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Sun, L.; Qin, Y. Aging mechanism of SBS modified asphalt based on chemical reaction kinetics. Constr. Build. Mater. 2015, 91, 47–56. [Google Scholar] [CrossRef]

- Yadykova, A.Y.; Strelets, L.A.; Ilyin, S.O. Infrared Spectral Classification of Natural Bitumens for Their Rheological and Thermophysical Characterization. Molecules 2023, 28, 2065. [Google Scholar] [CrossRef]

- Yu, C.; Hu, K.; Yang, Q.; Chen, Y. Multi–scale observation of oxidative aging on the enhancement of high temperature property of SBS–modified asphalt. Constr. Build. Mater. 2021, 313, 125478. [Google Scholar] [CrossRef]

- Li, H.; Tong, P.; Zhang, X.; Lin, X.; Li, B. Influence of ultraviolet and oxygen coupling aging on rheological properties and functional group index of warm mix asphalt binder. Materials 2020, 13, 4216. [Google Scholar] [CrossRef]

- Yu, R.; Wang, Q.; Wang, W.; Xiao, Y.; Wang, Z.; Zhou, X.; Zhang, X.; Zhu, X.; Fang, C. Polyurethane/graphene oxide nanocomposite and its modified asphalt binder: Preparation, properties and molecular dynamics simulation. Mater. Des. 2021, 209, 109994. [Google Scholar] [CrossRef]

- Li, Z.; Zeng, J.; Li, Y.; Zhao, Z.; Cong, P.; Wu, Y. Effect of bitumen composition on micro-structure and rheological properties of styrene–butadiene–styrene modified asphalt before and after aging. Mater. Struct. 2022, 55, 165. [Google Scholar] [CrossRef]

- Hofko, B.; Eberhardsteiner, L.; Füssl, J.; Grothe, H.; Handle, F.; Hospodka, M.; Grossegger, D.; Nahar, S.N.; Schmets, A.J.M.; Scarpas, A. Impact of maltene and asphaltene fraction on mechanical behavior and microstructure of bitumen. Mater. Struct. 2016, 49, 829–841. [Google Scholar] [CrossRef]

- Guo, T.; Wang, C.; Chen, H.; Li, Z.; Chen, Q.; Han, A.; Jiang, D.; Wang, Z. Rheological properties of graphene/tourmaline composite modified asphalt. Petrol. Sci. Technol. 2019, 37, 2190–2198. [Google Scholar] [CrossRef]

| Property | Unit | Value | Standard [28] |

|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 72 | ASTM D5-13 |

| Softening point | °C | 49.5 | ASTM D36-76 |

| Ductility (15 °C) | cm | >100 | ASTM D113-99 |

| Viscosity (135 °C) | Pa·s | 0.535 | ASTM D2170 |

| Flash point | °C | 284 | ASTM D92 |

| Solubility | % | 99.6 | ASTM D2042 |

| Appearance | Purity | Number of Layers | Carbon Content | Oxygen Content | Lamellar Diameter |

|---|---|---|---|---|---|

| Black powder | 98% | 1~2 | <85 wt.% | >7 wt.% | 0.5~10 μm |

| Technical Index | Test Result | Unit |

|---|---|---|

| Styrene content | 31 | Wt/% |

| Volatile content | 0.38 | Wt/% |

| 300% tensile stress | 2.41 | MPa |

| Tensile strength | 26.8 | MPa |

| Elongation at break | 735 | % |

| Hardness | 81 | Shore A |

| Molecular weight (Mn) | 135,783 | g/mol |

| Material | Weight (g) |

|---|---|

| Base asphalt | 600.0 |

| GO/SBS composites | 30.0 |

| Stabilizer | 1.2 |

| Compatibilizer | 6.0 |

| Position of Absorption Peak/cm−1 | Functional Group [31] |

|---|---|

| 2920, 2850 | The asymmetric and symmetric stretches of CH2 |

| 1699 | Carbonyl |

| 1600 | Conjugated double bond (benzene ring skeleton vibration) |

| 1455, 1375 | CH3 and CH2 bending vibration |

| 1173 | C-O in ether, ester, and anhydride |

| 1032 | Sulfoxide group |

| 966 | Polybutadiene segment |

| 699 | C-H on benzene ring of polystyrene segment |

| 650~910 | C-H on substituent of benzene ring |

| GO/SBS-MA | After PAV Aging | After UV Aging | ||

|---|---|---|---|---|

| Max Height/% | Roughness/% | Max Height/% | Roughness/% | |

| MA-1 | −42.9 | −47.6 | −52.4 | −56.2 |

| MA-2 | −33.3 | −35.7 | −39.3 | −42.4 |

| MA-3 | −25.5 | −29.8 | −30.9 | −32.1 |

| MA-4 | −20.0 | −24.3 | −26.3 | −30.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Jia, Y.; Liu, W.; Huang, Z.; Wang, H.; Li, Z.; Zhu, C. The Effects of Aging on Microstructures and Rheological Properties of Modified Asphalt with GO/SBS Composite. Polymers 2024, 16, 1504. https://doi.org/10.3390/polym16111504

Xie H, Jia Y, Liu W, Huang Z, Wang H, Li Z, Zhu C. The Effects of Aging on Microstructures and Rheological Properties of Modified Asphalt with GO/SBS Composite. Polymers. 2024; 16(11):1504. https://doi.org/10.3390/polym16111504

Chicago/Turabian StyleXie, Haiwei, Yixuan Jia, Weidong Liu, Zhipeng Huang, Hanyu Wang, Zuzhong Li, and Chunsheng Zhu. 2024. "The Effects of Aging on Microstructures and Rheological Properties of Modified Asphalt with GO/SBS Composite" Polymers 16, no. 11: 1504. https://doi.org/10.3390/polym16111504

APA StyleXie, H., Jia, Y., Liu, W., Huang, Z., Wang, H., Li, Z., & Zhu, C. (2024). The Effects of Aging on Microstructures and Rheological Properties of Modified Asphalt with GO/SBS Composite. Polymers, 16(11), 1504. https://doi.org/10.3390/polym16111504