Molding Process Retaining Gold Nanoparticle Assembly Structures during Transfer to a Polycarbonate Surface

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Spherical AuNP

2.3. Functionalization of the AuNP Surface with PEG Ligands

2.4. Assemblies on Substrates

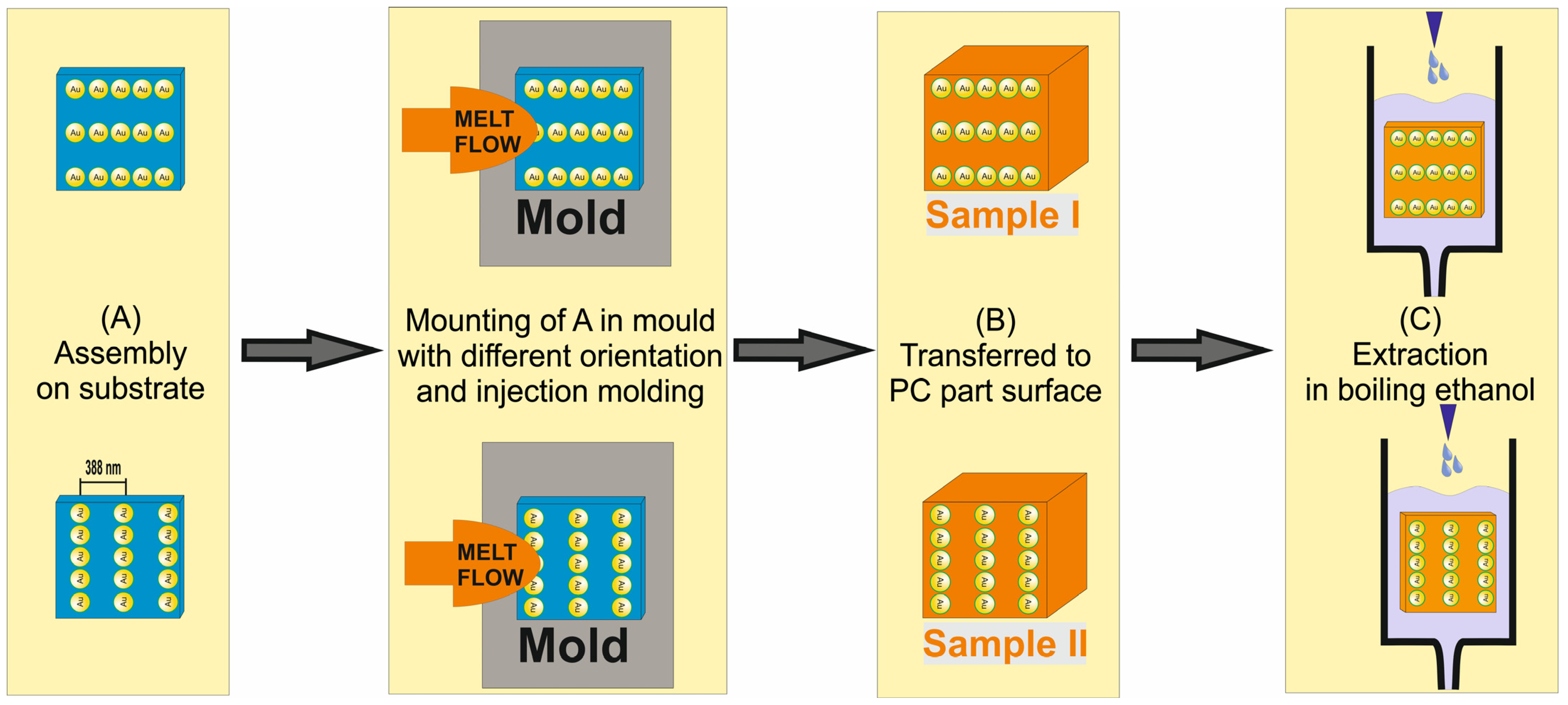

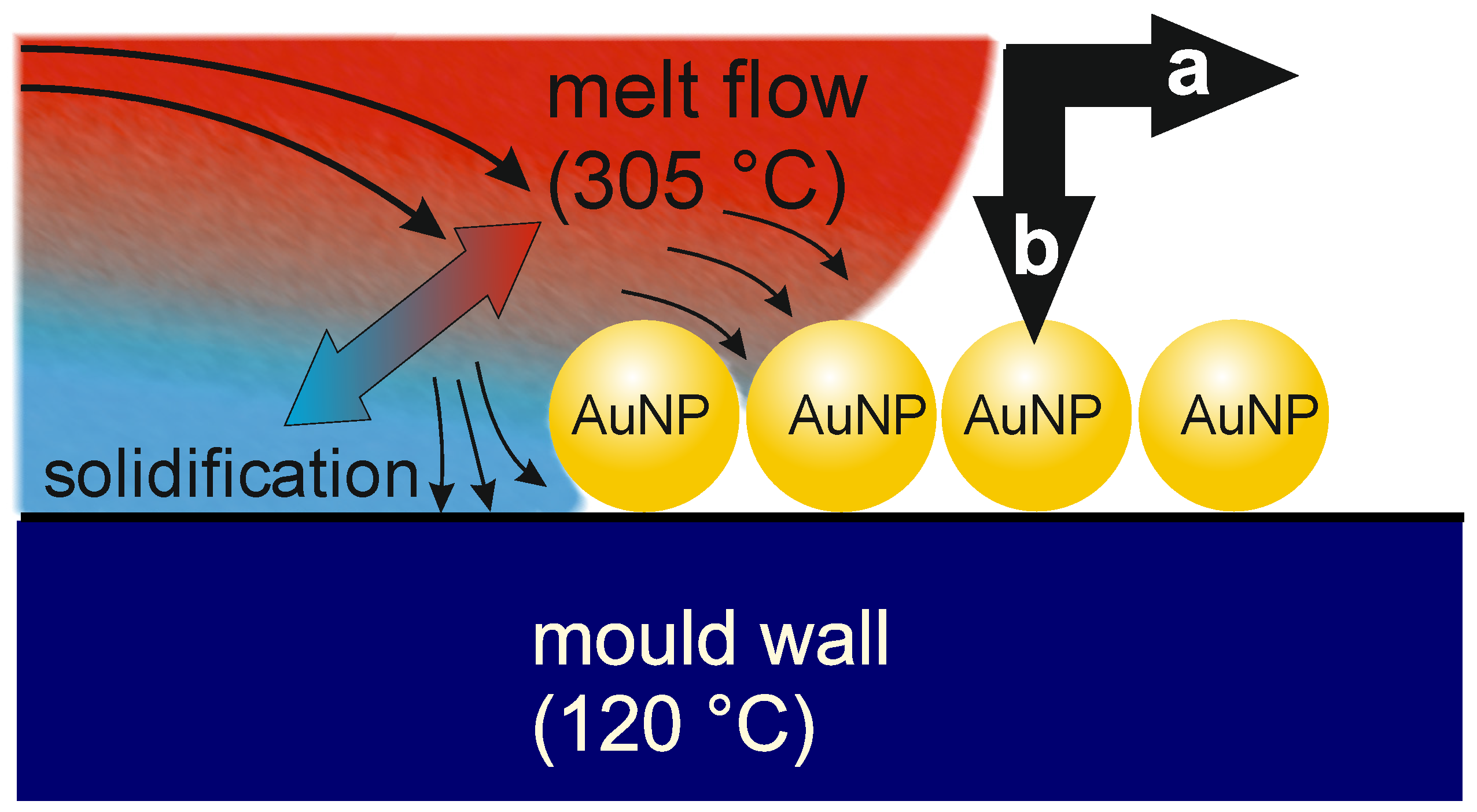

2.5. Transfer by Injection Molding

2.6. SEM and Orientation Analysis

2.7. Optical Spectroscopy

3. Results and Discussion

3.1. Sample Concept

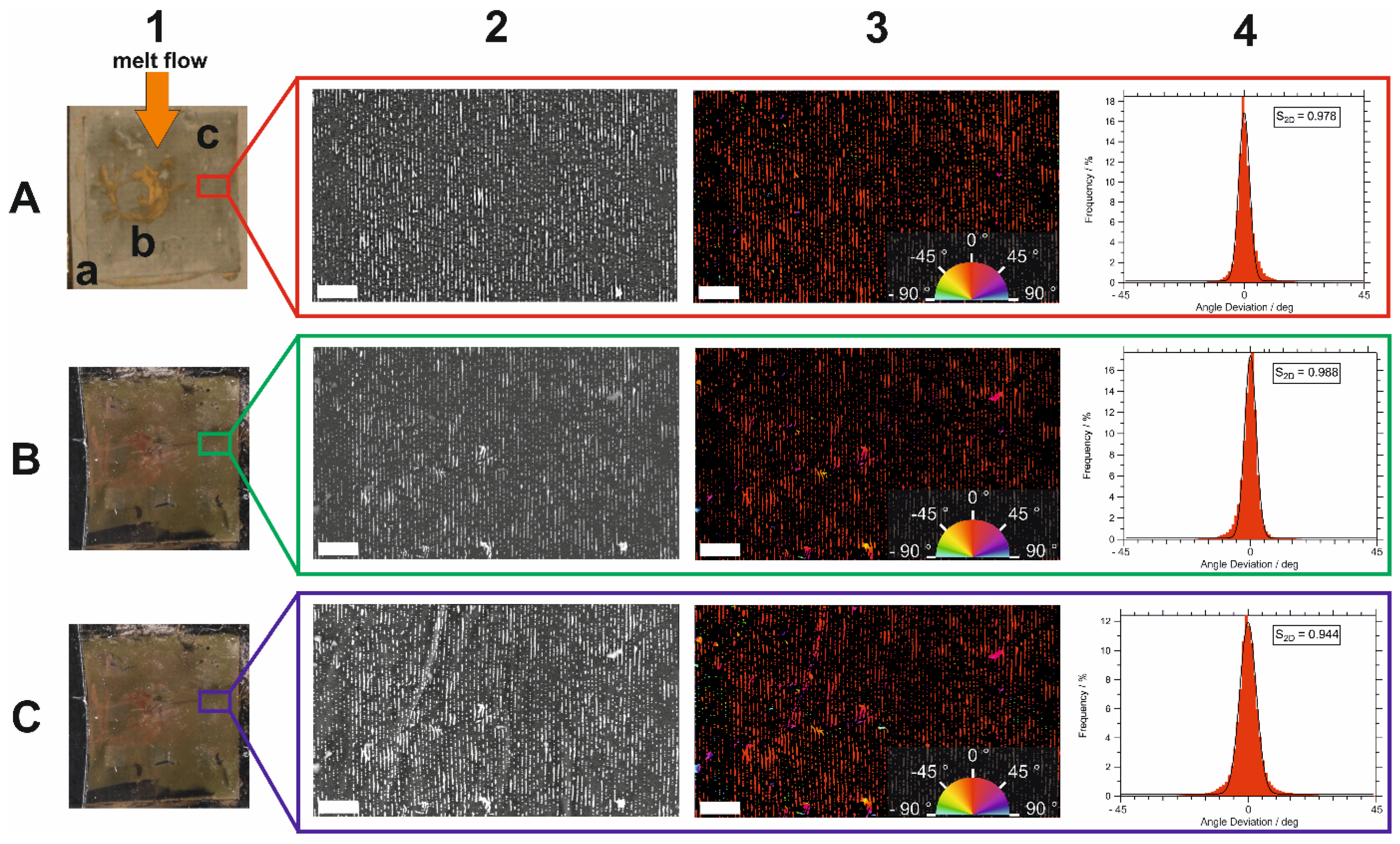

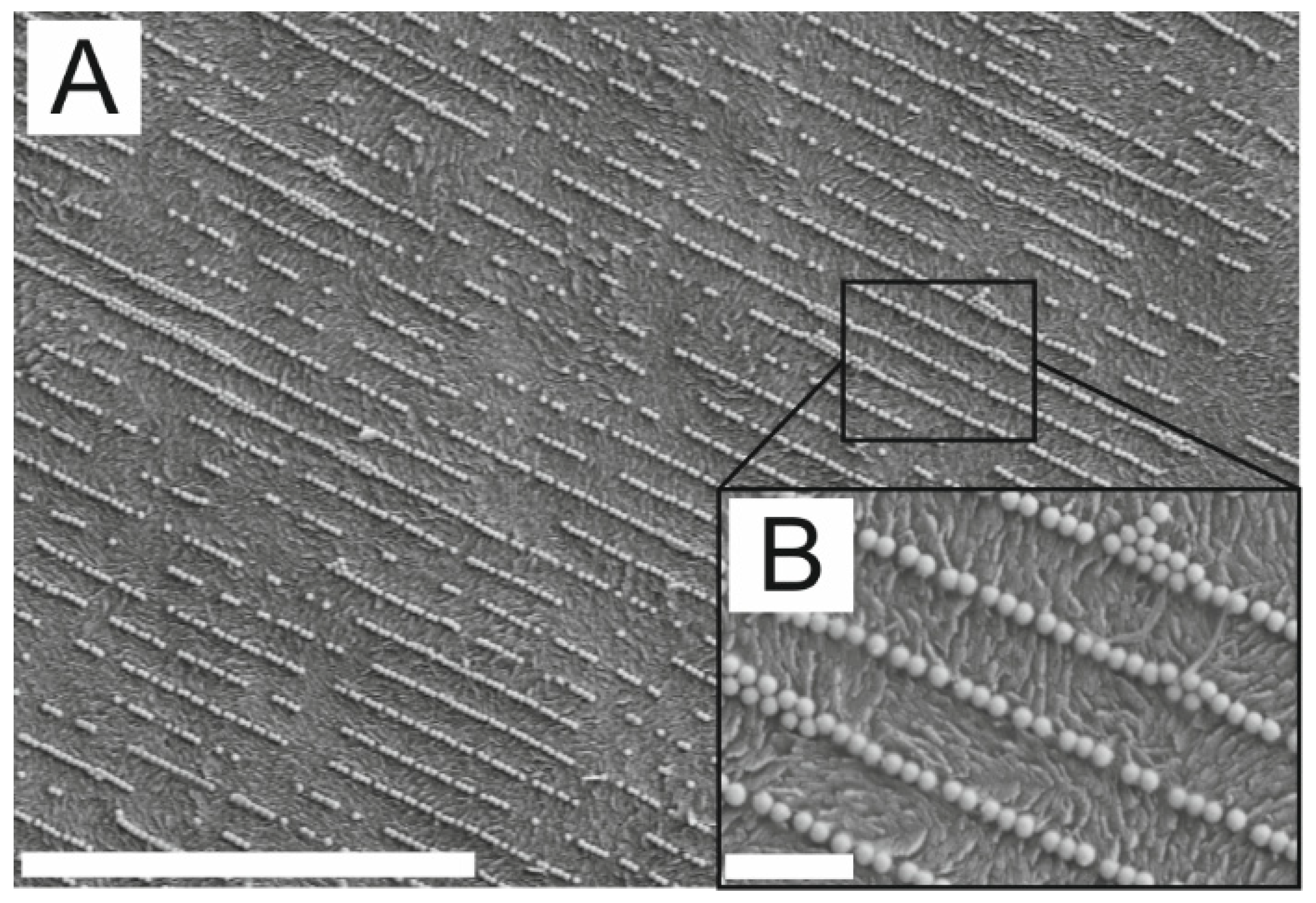

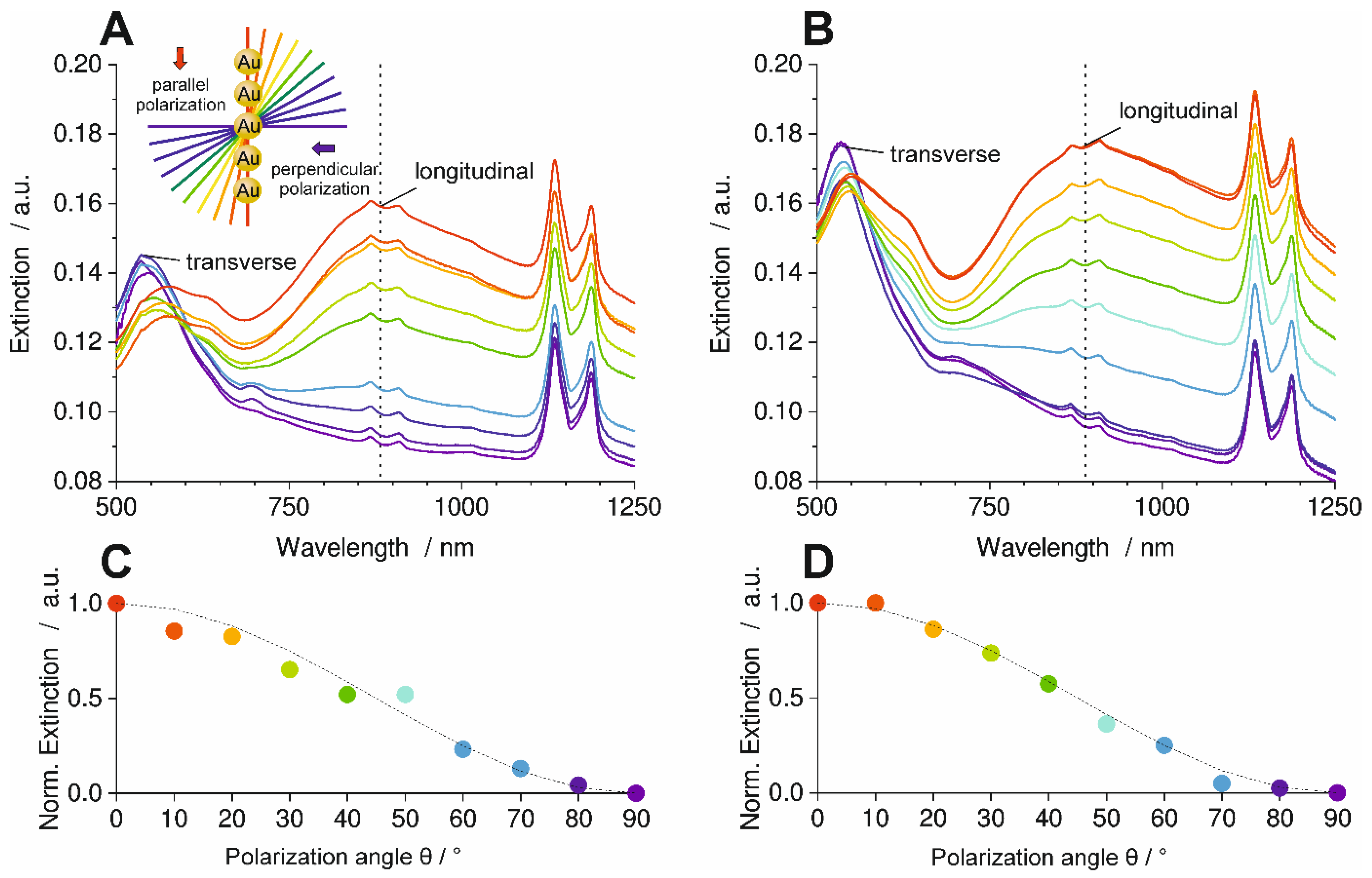

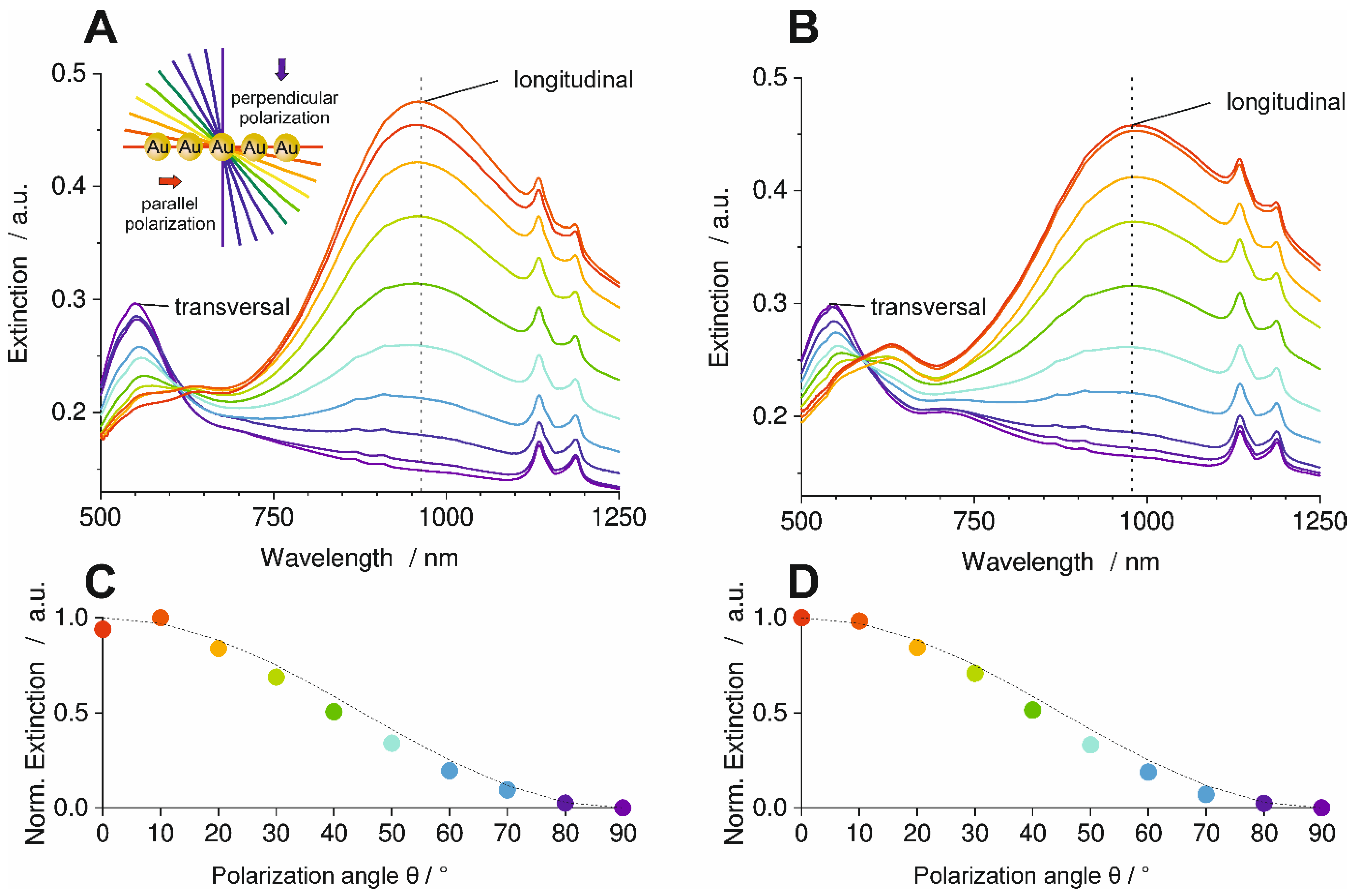

3.2. Orientation Analysis of AuNP Lines Aligned Parallel to the Melt Flow Direction (Sample I)

3.3. Orientation Analysis of AuNP Lines Perpendicular to the Flow Direction (Sample II)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mulvaney, P. Surface Plasmon Spectroscopy of Nanosized Metal Particles. Langmuir 1996, 12, 788–800. [Google Scholar] [CrossRef]

- Halas, N.J.; Lal, S.; Chang, W.-S.; Link, S.; Nordlander, P. Plasmons in Strongly Coupled Metallic Nanostructures. Chem. Rev. 2011, 111, 3913–3961. [Google Scholar] [CrossRef] [PubMed]

- Nakayama, K.; Tanabe, K.; Atwater, H.A. Plasmonic Nanoparticle Enhanced Light Absorption in Gaas Solar Cells. Appl. Phys. Lett. 2008, 93, 121904. [Google Scholar] [CrossRef]

- Anker, J.N.; Hall, W.P.; Lyandres, O.; Shah, N.C.; Zhao, J.; Van Duyne, R.P. Biosensing with Plasmonic Nanosensors. Nat. Mater. 2008, 7, 442–453. [Google Scholar] [CrossRef] [PubMed]

- Steiner, A.M.; Lissel, F.; Fery, A.; Lauth, J.; Scheele, M. Prospects of Coupled Organic–Inorganic Nanostructures for Charge and Energy Transfer Applications. Angew. Chem. Int. Ed. 2021, 60, 1152–1175. [Google Scholar] [CrossRef]

- Kumar, S.; Goel, P.; Singh, J.P. Flexible and Robust Sers Active Substrates for Conformal Rapid Detection of Pesticide Residues from Fruits. Sens. Actuators B Chem. 2017, 241, 577–583. [Google Scholar] [CrossRef]

- Menendez, J.P.; Erismann, F.; Gauvin, M.A. The Advantages of Plastic Optical Components. Opt. Photon. News 1999, 10, 28–30. [Google Scholar] [CrossRef]

- Gupta, V.; Probst, P.T.; Goßler, F.R.; Steiner, A.M.; Schubert, J.; Brasse, Y.; König, T.A.F.; Fery, A. Mechanotunable Surface Lattice Resonances in the Visible Optical Range by Soft Lithography Templates and Directed Self-Assembly. ACS Appl. Mater. Interfaces 2019, 11, 28189–28196. [Google Scholar] [CrossRef] [PubMed]

- Aftenieva, O.; Schnepf, M.; Mehlhorn, B.; König, T.A.F. Tunable Circular Dichroism by Photoluminescent Moiré Gratings. Adv. Opt. Mater. 2021, 9, 2001280. [Google Scholar] [CrossRef]

- Schweikart, A.; Fortini, A.; Wittemann, A.; Schmidt, M.; Fery, A. Nanoparticle Assembly by Confinement in Wrinkles: Experiment and Simulations. Soft Matter 2010, 6, 5860–5863. [Google Scholar] [CrossRef]

- Volk, K.; Fitzgerald, J.P.S.; Ruckdeschel, P.; Retsch, M.; König, T.A.F.; Karg, M. Reversible Tuning of Visible Wavelength Surface Lattice Resonances in Self-Assembled Hybrid Monolayers. Adv. Opt. Mater. 2017, 5, 1600971. [Google Scholar] [CrossRef]

- Flauraud, V.; Mastrangeli, M.; Bernasconi, G.D.; Butet, J.; Alexander, D.T.L.; Shahrabi, E.; Martin, O.J.F.; Brugger, J. Nanoscale Topographical Control of Capillary Assembly of Nanoparticles. Nat. Nanotechnol. 2017, 12, 73–80. [Google Scholar] [CrossRef]

- Ni, S.; Wolf, H.; Isa, L. Programmable Assembly of Hybrid Nanoclusters. Langmuir 2018, 34, 2481–2488. [Google Scholar] [CrossRef] [PubMed]

- Grzelak, D.; Tupikowska, M.; Vila-Liarte, D.; Beutel, D.; Bagiński, M.; Parzyszek, S.; Góra, M.; Rockstuhl, C.; Liz-Marzán, L.M.; Lewandowski, W. Liquid Crystal Templated Chiral Plasmonic Films with Dynamic Tunability and Moldability. Adv. Funct. Mater. 2022, 32, 2111280. [Google Scholar] [CrossRef]

- Tebbe, M.; Mayer, M.; Glatz, B.A.; Hanske, C.; Probst, P.T.; Müller, M.B.; Karg, M.; Chanana, M.; König, T.A.F.; Kuttner, C.; et al. Optically Anisotropic Substrates via Wrinkle-Assisted Convective Assembly of Gold Nanorods on Macroscopic Areas. Faraday Discuss. 2015, 181, 243–260. [Google Scholar] [CrossRef]

- Nagel, J.; Kroschwald, F.; Bellmann, C.; Schwarz, S.; Janke, A.; Heinrich, G. Immobilisation of Different Surface-Modified Silica Nanoparticles on Polymer Surfaces via Melt Processing. Colloids Surf. A-Physicochem. Eng. Asp. 2017, 532, 208–212. [Google Scholar] [CrossRef]

- Kroschwald, F.; Nagel, J.; Janke, A.; Simon, F.; Zimmerer, C.; Heinrich, G.; Voit, B. Gold Nanoparticle Layers from Multi-Step Adsorption Immobilised on a Polymer Surface During Injection Molding. J. Appl. Polym. Sci. 2016, 133, 43608. [Google Scholar] [CrossRef]

- Zimmermann, P.S.K.; Schwarz, S.; Vehlow, D.; Blanke, M.; Fery, A.; Nagel, J. Green Approach for Manufacturing of Polymer Surface Structures with Micro Cavities Having Robust Chemical Functionalized Inner Surfaces. ACS Appl. Polym. Mater. 2022, 4, 5189–5198. [Google Scholar] [CrossRef]

- Wang, R.; Zimmermann, P.; Schletz, D.; Hoffmann, M.; Probst, P.; Fery, A.; Nagel, J.; Rossner, C. Nano Meets Macro: Furnishing the Surface of Polymer Molds with Gold-Nanoparticle Arrays. Nano Sel. 2022, 3, 1502–1508. [Google Scholar] [CrossRef]

- Speranza, V.; Liparoti, S.; Pantani, R. A Method to Obtain the Quantitative Orientation of Semicrystalline Structures in Polymers by Atomic Force Microscopy. Express Polym. Lett. 2021, 15, 1114–1125. [Google Scholar] [CrossRef]

- Probst, P.T.; Sekar, S.; König, T.A.F.; Formanek, P.; Decher, G.; Fery, A.; Pauly, M. Highly Oriented Nanowire Thin Films with Anisotropic Optical Properties Driven by the Simultaneous Influence of Surface Templating and Shear Forces. ACS Appl. Mater. Interfaces 2018, 10, 3046–3057. [Google Scholar] [CrossRef]

- Hanske, C.; Tebbe, M.; Kuttner, C.; Bieber, V.; Tsukruk, V.V.; Chanana, M.; König, T.A.F.; Fery, A. Strongly Coupled Plasmonic Modes on Macroscopic Areas via Template-Assisted Colloidal Self-Assembly. Nano Lett. 2014, 14, 6863–6871. [Google Scholar] [CrossRef]

- Lim, B.; Son, S.; Kim, H.; Nah, S.; Mu Lee, K. Enhanced Deep Residual Networks for Single Image Super-Resolution. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition Workshops, Honolulu, HI, USA, 21–26 July 2017; pp. 136–144. [Google Scholar]

- Bulgarelli, J.; Tazzari, M.; Granato, A.M.; Ridolfi, L.; Maiocchi, S.; de Rosa, F.; Petrini, M.; Pancisi, E.; Gentili, G.; Vergani, B.; et al. Dendritic Cell Vaccination in Metastatic Melanoma Turns “Non-T Cell Inflamed” Into “T-Cell Inflamed” Tumors. Front. Immunol. 2019, 10, 2353. [Google Scholar] [CrossRef]

- Abramoff, M.; Magalhães, P.; Ram, S.J. Image Processing with ImageJ. Biophotonics Int. 2003, 11, 36–42. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. Nih Image to Imagej: 25 Years of Image Analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Püspöki, Z.; Storath, M.; Sage, D.; Unser, M. Transforms and Operators for Directional Bioimage Analysis: A Survey. In Focus on Bio-Image Informatics; De Vos, W.H., Munck, S., Timmermans, J.-P., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 69–93. [Google Scholar]

- Rezakhaniha, R.; Agianniotis, A.; Schrauwen, J.T.C.; Griffa, A.; Sage, D.; Bouten, C.V.C.; van de Vosse, F.N.; Unser, M.; Stergiopulos, N. Experimental Investigation of Collagen Waviness and Orientation in the Arterial Adventitia Using Confocal Laser Scanning Microscopy. Biomech. Model. Mechanobiol. 2012, 11, 461–473. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zimmermann, P.; Schletz, D.; Hoffmann, M.; Probst, P.T.; Fery, A.; Nagel, J. Molding Process Retaining Gold Nanoparticle Assembly Structures during Transfer to a Polycarbonate Surface. Polymers 2024, 16, 1553. https://doi.org/10.3390/polym16111553

Zimmermann P, Schletz D, Hoffmann M, Probst PT, Fery A, Nagel J. Molding Process Retaining Gold Nanoparticle Assembly Structures during Transfer to a Polycarbonate Surface. Polymers. 2024; 16(11):1553. https://doi.org/10.3390/polym16111553

Chicago/Turabian StyleZimmermann, Philipp, Daniel Schletz, Marisa Hoffmann, Patrick T. Probst, Andreas Fery, and Jürgen Nagel. 2024. "Molding Process Retaining Gold Nanoparticle Assembly Structures during Transfer to a Polycarbonate Surface" Polymers 16, no. 11: 1553. https://doi.org/10.3390/polym16111553

APA StyleZimmermann, P., Schletz, D., Hoffmann, M., Probst, P. T., Fery, A., & Nagel, J. (2024). Molding Process Retaining Gold Nanoparticle Assembly Structures during Transfer to a Polycarbonate Surface. Polymers, 16(11), 1553. https://doi.org/10.3390/polym16111553