Mechanical Properties of Carbon Fiber-Reinforced Plastic with Two Types of Bolted Connections at Low Temperatures

Abstract

:1. Introduction

2. Materials and Methods

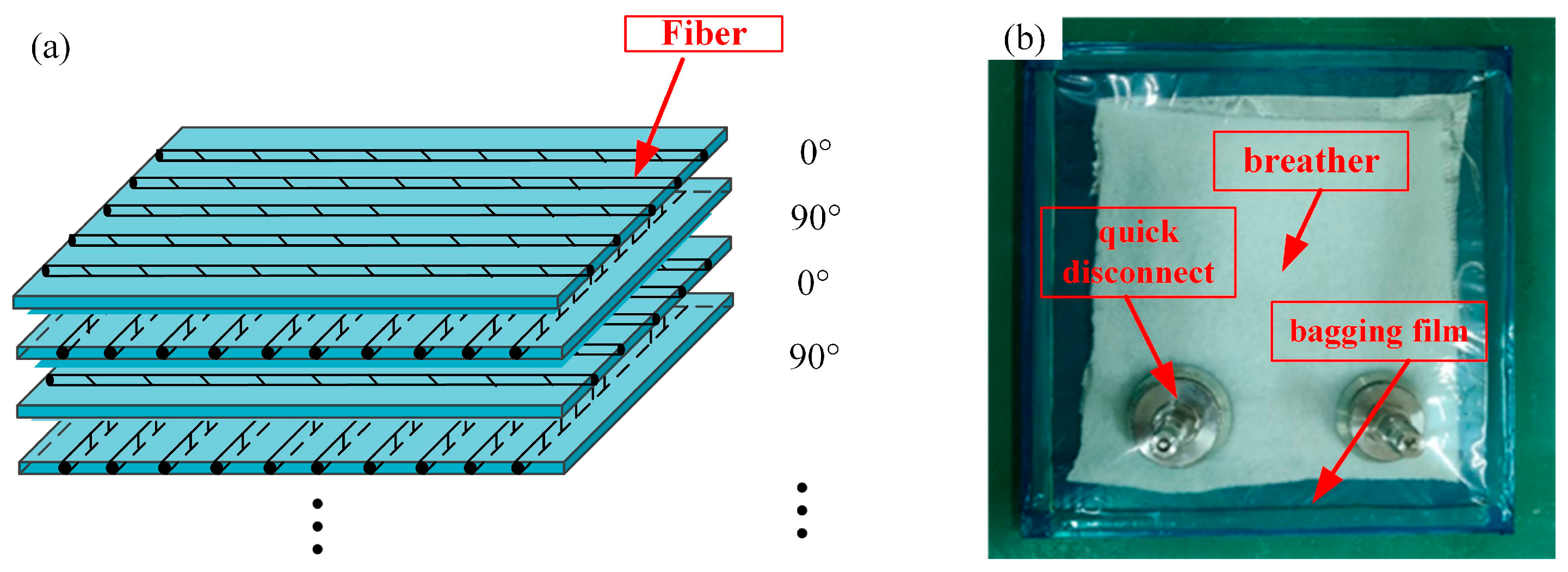

2.1. Preparation of the CFRP Laminate

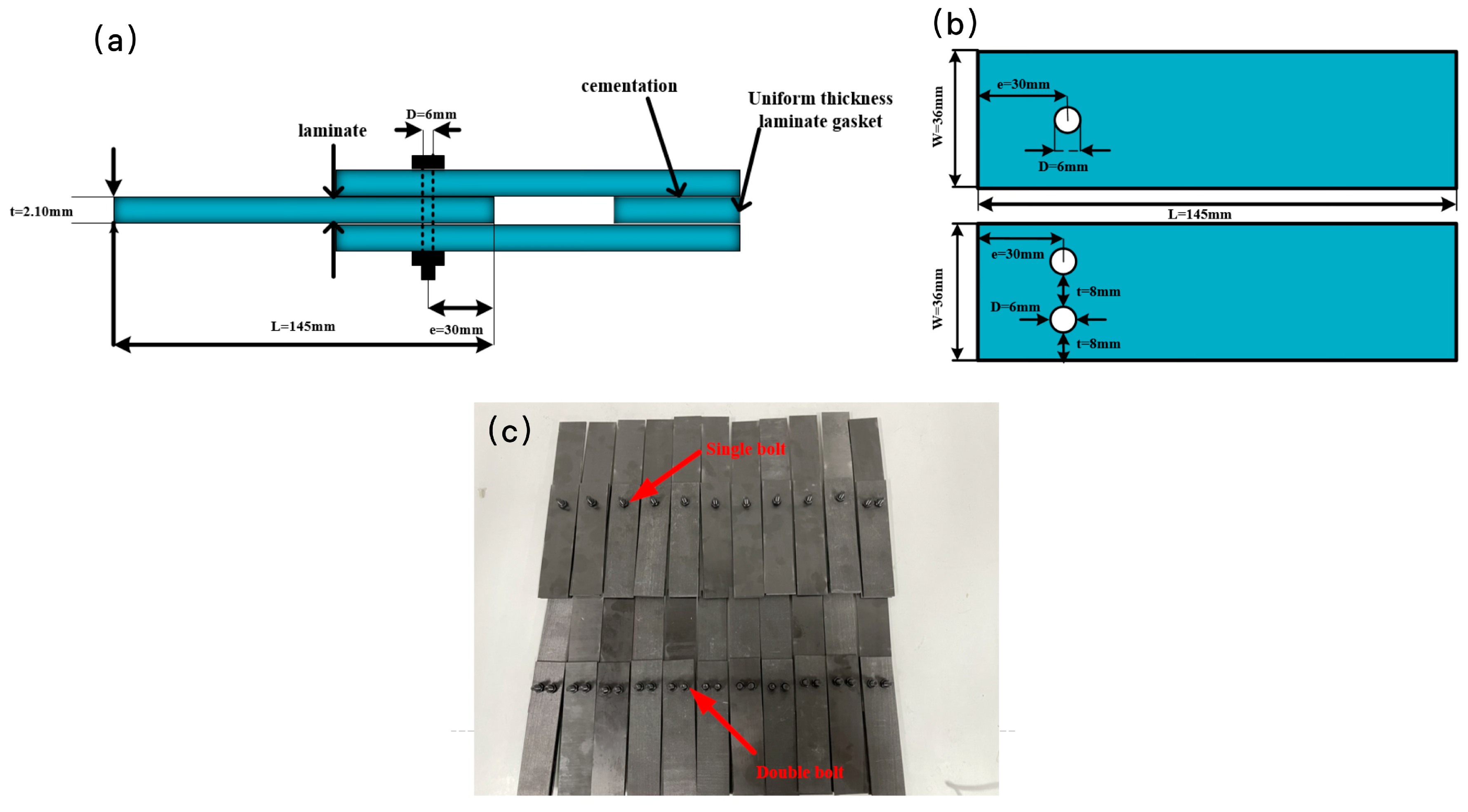

2.2. Fabrication of the Bolt Connection Specimen

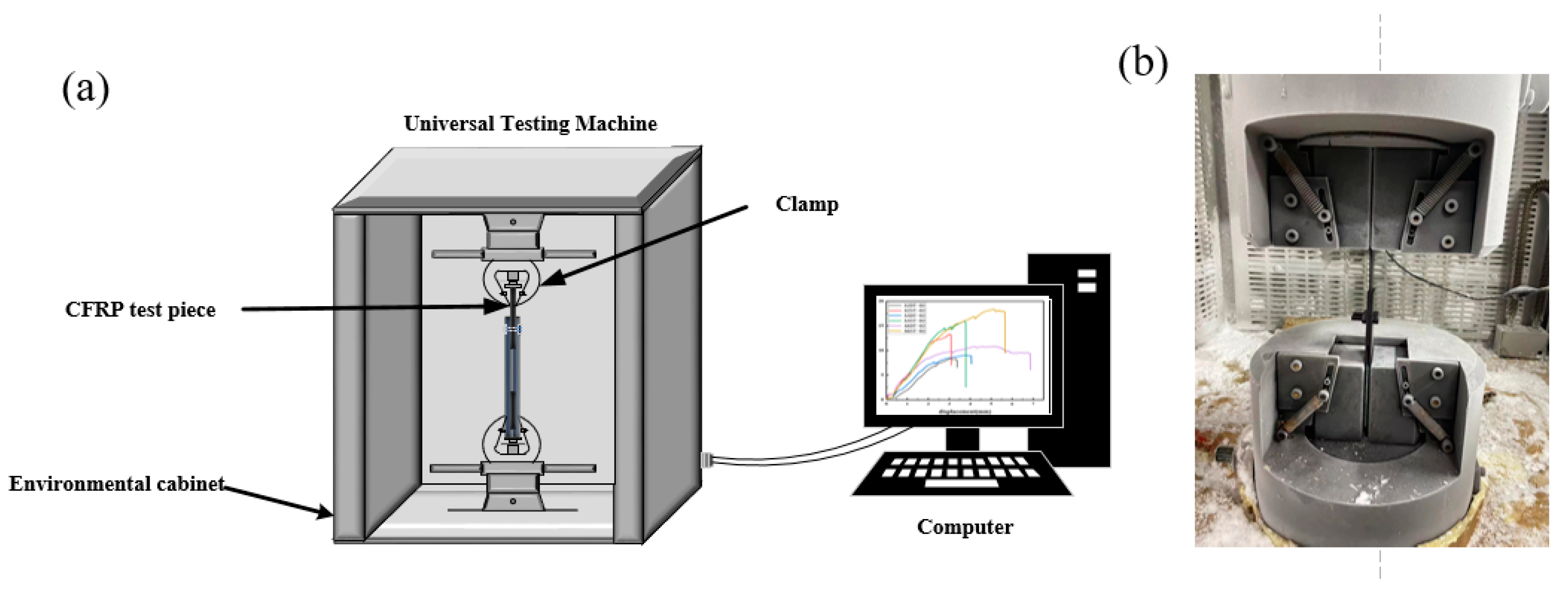

2.3. The Tensile Test

3. Results and Discussion

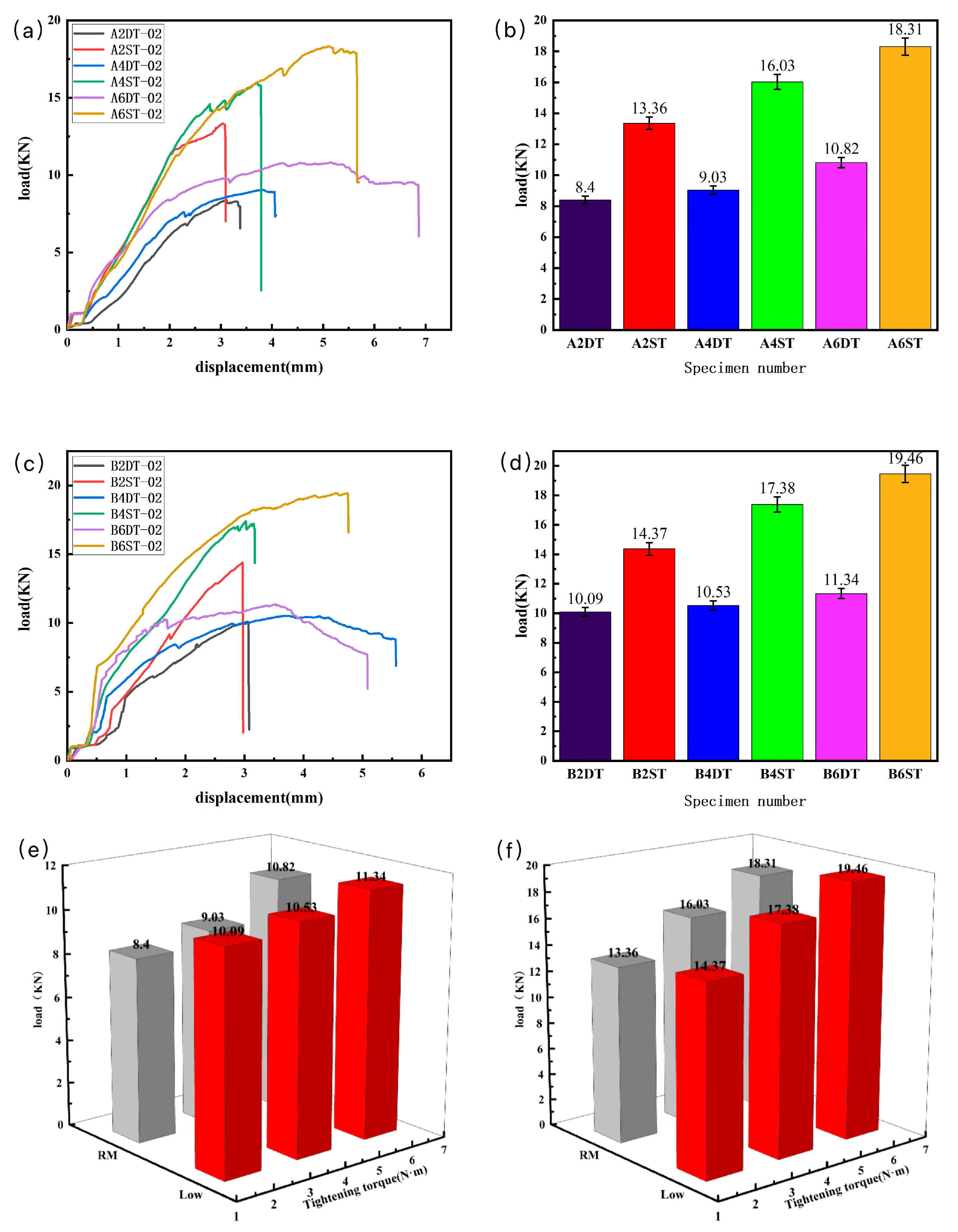

3.1. Static Load Tensile Tests

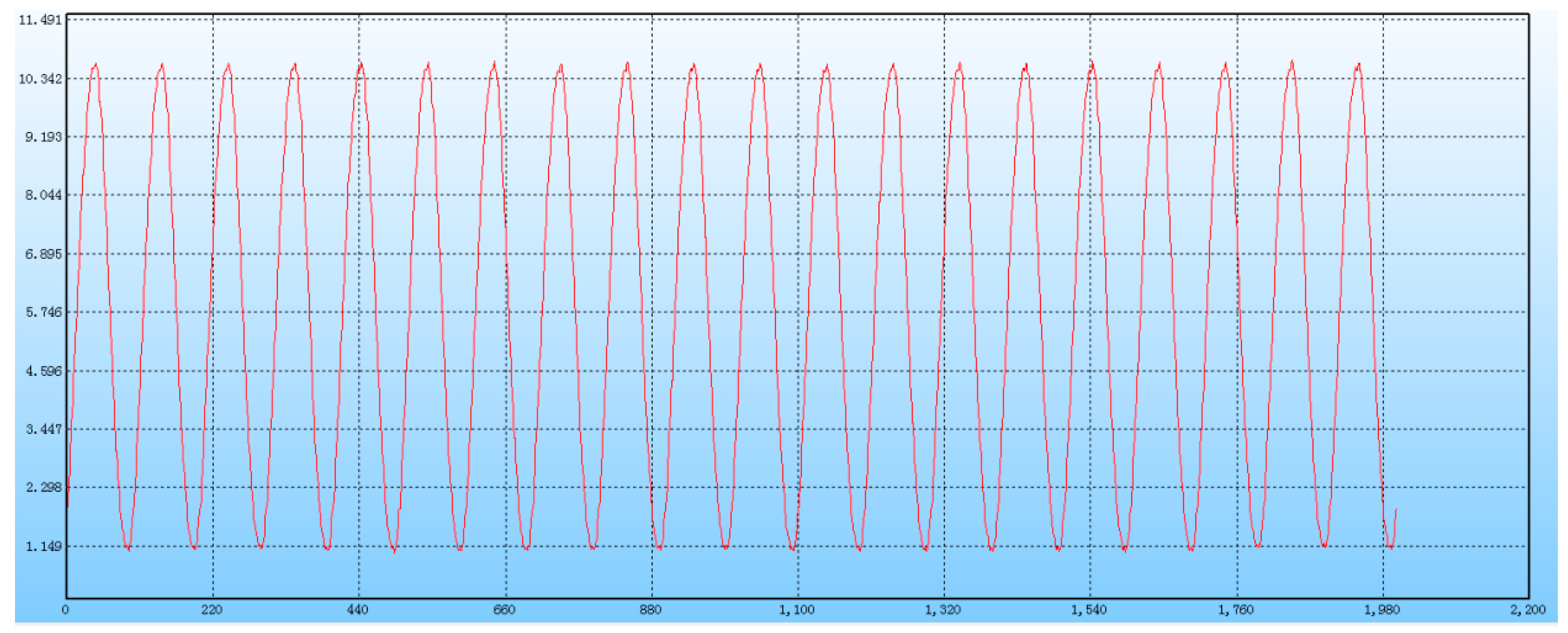

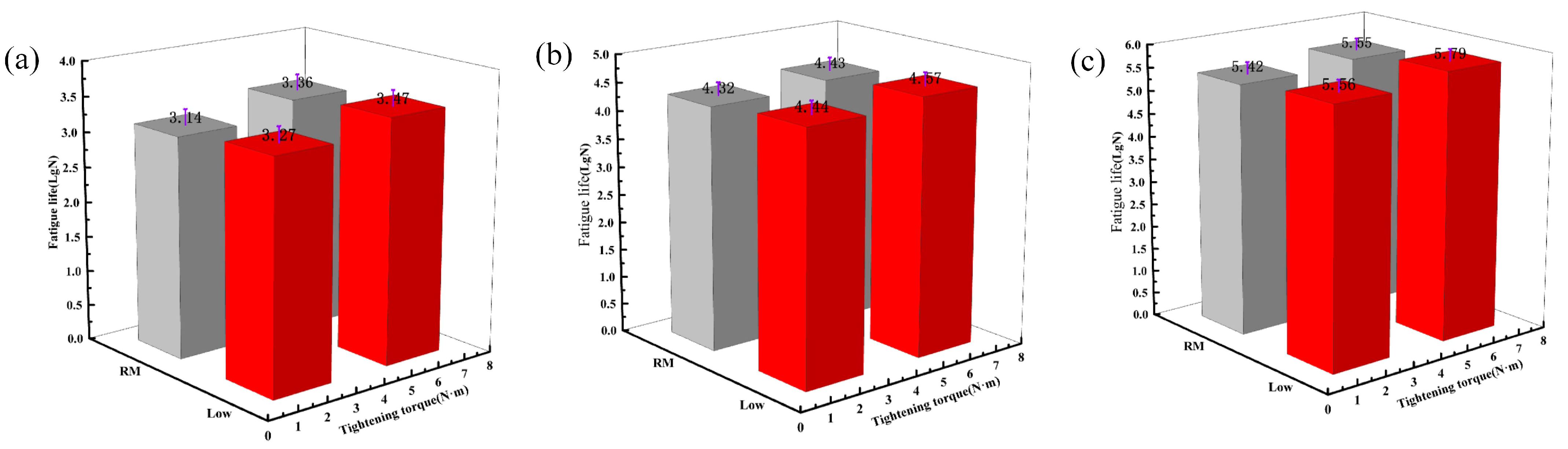

3.2. Tensile Fatigue Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Nezhad, H.Y.; Egan, B.; Merwick, F.; McCarthy, C.T. Bearing damage characteristics of fibre-reinforced countersunk composite bolted joints subjected to quasi-static shear loading. Compos. Struct. 2017, 166, 184–192. [Google Scholar] [CrossRef]

- Ren, J.; Li, K.; Zhang, S.; Yao, X.; Tian, S. Preparation of Carbon/Carbon Composite by Pyrolysis of Ethanol and Methane. Mater. Des. 2015, 65, 174–178. [Google Scholar] [CrossRef]

- McCarthy, M.A.; Lawlor, V.P.; Stanley, W.F.; McCarthy, C.T. Bolt–hole Clearance Effects and Strength Criteria in Single-bolt, Single-lap, Composite Bolted Joints. Compos. Sci. Technol. 2002, 62, 1415–1431. [Google Scholar] [CrossRef]

- Kelly, G.; Hallström, S. Bearing Strength of Carbon Fiber/epoxy Laminates: Effects of Bolt–hole Clearance. Compos. Part B Eng. 2004, 35, 331–343. [Google Scholar] [CrossRef]

- McCarthy, M.A.; McCarthy, C.T.; Padhi, G.S. A Simple Method for Determining the Effects of Bolt–hole Clearance on Load Distribution in Single-column Multi-bolt Composite Joints. Compos. Struct. 2006, 73, 78–87. [Google Scholar] [CrossRef]

- Qin, T.; Zhao, L.; Zhang, J. Fastener effects on mechanical behaviors of double-lap composite joints. Compos. Struct. 2013, 100, 413–423. [Google Scholar] [CrossRef]

- Park, C.Y.; Grandt, A.F. Effect of load transfer on the cracking behavior at a countersunk fastener hole. Int. J. Fatigue 2007, 29, 146–157. [Google Scholar] [CrossRef]

- Baldan, A. Adhesively-bonded joints and repairs in metallic alloys polymers and composite materials adhesives adhesion theories and surface pretreatment. J. Mater. Sci. 2004, 39, 1–49. [Google Scholar] [CrossRef]

- Yun, J.-H.; Choi, J.-H.; Kweon, J.-H. A study on the strength improvement of the multi-bolted joint. Compos. Struct. 2014, 108, 409–416. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, Z.; Zhou, J.; Wu, X. Experimental and Numerical Investigation on Bolted Composite Joint Made by Vacuum Assisted Resin Injection. Compos. Part B Eng. 2013, 45, 1620–1628. [Google Scholar] [CrossRef]

- Srinivasa, D.T.; Finegan, J.; Ronald, F.G. Mechanics of Mechanically Fastened Joints in Polymer–matrix Composite Structures-A review. Compos. Sci. Technol. 2013, 69, 301–329. [Google Scholar]

- Coman, C.-D.; Constantinescu, D.M. Temperature effects on joint strength and failure modes of hybrid aluminum–composite countersunk bolted joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 2204–2218. [Google Scholar] [CrossRef]

- Schön, J.; Starikov, R. Experimental study on fatigue resistance of composite joints with protruding-head bolts. Compos. Struct. 2002, 55, 1–11. [Google Scholar]

- Santiuste, C.; Olmedo, A.; Soldani, X.; Miguélez, H. Delamination prediction in orthogonal machining of carbon long fiber-reinforced polymer composites. J. Reinf. Plast. Compos. 2012, 31, 875–885. [Google Scholar] [CrossRef]

- Xiao, Y.; Ishikawa, T. Bearing strength and failure behavior of bolted composite joints (part I: Experimental investigation). Compos. Sci. Technol. 2005, 65, 1022–1031. [Google Scholar] [CrossRef]

- Catalanotti, G.; Camanho, P. A semi-analytical method to predict net-tension failure of mechanically fastened joints in composite laminates. Compos. Sci. Technol. 2013, 76, 69–76. [Google Scholar] [CrossRef]

- Arteiro, A.; Catalanotti, G.; Xavier, J.; Camanho, P. Notched response of non-crimp fabric thin-ply laminates. Compos. Sci. Technol. 2013, 79, 97–114. [Google Scholar] [CrossRef]

- Wang, D.; Ye, L.; Tang, Y.; Lu, Y. Monitoring of Delamination Onset and Growth During Mode I and Mode II Interlaminar Fracture Tests Using Guided Waves. Compos. Sci. Technol. 2012, 72, 145–151. [Google Scholar] [CrossRef]

- Riccio, A. Effects of geometrical and material features on damage onset and propagation, in single-lap bolted composite joints under tensile load: Part Ⅰ-Experimental studies. J. Compos. Mater. 2005, 39, 2071–2090. [Google Scholar] [CrossRef]

- Matthews, F.L.; Davies, G.A.O.; Hitchings, D.; Soutis, C. Finite Element Modeling of Composite Materials and Structures; Woodhead Publishing Series in Composites Science and Engineering; CRC Press: Boca Raton, FL, USA, 2000; pp. 175–193. [Google Scholar]

- Galińska, A. Mechanical joining of fiber reinforced polymer composites to metals—A review. Part I: Bolted joining. Polymers 2020, 12, 2252. [Google Scholar] [CrossRef]

- Denk, L.; Hatta, H.; Somiya, S.; Hiroaki, M. Fracture Behavior of Multi-holed C/C Composites. Adv. Compos. Mater. 2003, 12, 107–122. [Google Scholar] [CrossRef]

- Aly-Hassan, M.S.; Hatta, H.; Wakayama, S.; Watanabe, M.; Miyagawa, K. Comparison of 2D and 3D carbon/carbon composites with respect to damage and fracture resistance. Carbon 2003, 41, 1069–1078. [Google Scholar] [CrossRef]

- Wu, P.S.; Sun, C.T. Modeling bearing failure initiation in pin-contact of composite laminates. Mech. Mater. 1998, 29, 325–335. [Google Scholar] [CrossRef]

- Liu, F.; Yao, W.; Shi, X.; Zhao, L.; Zhang, J. Bearing Failure Optimization of Composite Double-lap Bolted Joints Based on a Three-step Strategy Marked by Feasible Region Reduction and Model Decoupling. Comput. Mater. Contin. 2020, 62, 977–999. [Google Scholar] [CrossRef]

- Starikov, R.; Schön, J. Local fatigue behavior of cfrp bolted joints. Compos. Sci. Technol. 2002, 62, 243–253. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Sen, A.; Das, S. An investigation on the anti-loosening characteristics of threaded fasteners under vibratory conditions. Mech. Mach. Theory 2010, 45, 1215–1225. [Google Scholar] [CrossRef]

- Dhôte, J.; Comer, A.; Stanley, W.; Young, T. Investigation into compressive properties of liquid shim for aerospace bolted joints. Compos. Struct. 2014, 109, 224–230. [Google Scholar] [CrossRef]

- Shindo, Y.; Takeda, T.; Narita, F. Mechanical response of nonwoven polyester fabric/epoxy composites at cryogenic temperatures. Cryogenics 2012, 52, 564–568. [Google Scholar] [CrossRef]

- Castellanos, A.G.; Cinar, K.; Guven, I.; Prabhakar, P. Low-Velocity Impact Response of Woven Carbon Composites in Arctic Conditions. J. Dyn. Behav. Mater. 2018, 4, 308–316. [Google Scholar] [CrossRef]

- Wang, H.; Cao, M.; Siddique, A.; Sun, B.; Gu, B. Numerical analysis of thermal expansion behaviors and interfacial thermal stress of 3D braided composite materials. Comput. Mater. Sci. 2017, 138, 77–91. [Google Scholar] [CrossRef]

- He, Y.; Yang, S.; Liu, H.; Shao, Q.; Chen, Q.; Lu, C.; Jiang, Y.; Liu, C.; Guo, Z. Reinforced carbon fiber laminates with oriented carbon nanotube epoxy nanocomposites: Magnetic field assisted alignment and cryogenic temperature mechanical properties. J. Colloid Interface 2018, 517, 40–51. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Hua, Y.; Qu, C.-B.; Xiao, H.-M.; Fu, S.-Y. Greatly enhanced cryogenic mechanical properties of short carbon fiber/polyethersulfone composites by graphene oxide coating. Compos. Part A Appl. Sci. Manuf. 2016, 89, 47–55. [Google Scholar] [CrossRef]

- Han, C.L.; Wang, G.-D.; Li, N.; Wang, M.; Liu, X.L.; Ma, J.H. Study on interlaminar performance of CNTs/epoxy film enhanced GFRP under low-temperature cycle. Compos. Struct. 2021, 272, 114191. [Google Scholar] [CrossRef]

- Feng, Q.; Yang, J.; Liu, Y.; Xiao, H.; Fu, S. Simultaneously enhanced cryogenic tensile strength, ductility and impact resistance of epoxy resins by polyethylene glycol. Mater. Sci. Technol. 2014, 30, 90–96. [Google Scholar] [CrossRef]

- Chu, X.X.; Wu, Z.X.; Huang, R.J.; Zhou, Y.; Li, L.F. Mechanical and thermal expansion properties of glass fibers reinforced peek composites at cryogenic temperatures. Cryogenics 2010, 50, 84–88. [Google Scholar] [CrossRef]

- Chen, Z.K.; Yang, J.P.; Ni, Q.Q.; Fu, S.Y.; Huang, Y.G. Reinforcement of epoxy resins with multi-walled carbon nanotubes for enhancing cryogenic mechanical properties. Polymer 2009, 50, 4753–4759. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Shindo, Y.; Takeda, T.; Narita, F.; Saito, N.; Watanabe, S.; Sanada, K. Delamination growth mechanisms in woven glass fiber reinforced polymer composites under Mode II fatigue loading at cryogenic temperatures. Compos. Sci. Technol. 2009, 69, 1904–1911. [Google Scholar] [CrossRef]

- Whitley, K.S.; Gates, T.S. Thermal/Mechanical Response of a Polymer Matrix Composite at Cryogenic Temperatures. AIAA J. 2003, 42, 1991–2001. [Google Scholar] [CrossRef]

- Vedernikov, A.; Tucci, F.; Safonov, A.; Carlone, P.; Gusev, S.; Akhatov, I. Investigation on the shape distortions of pultruded profiles at different pulling speed. Procedia Manuf. 2020, 47, 1–5. [Google Scholar] [CrossRef]

| Specimen Number | Maximum Failure Load (KN) | Maximum Load Displacement (mm) | Tensile Strength (MPa) | Average Failure Load (KN) | Average Load Displacement (mm) | Average Strength (MPa) |

|---|---|---|---|---|---|---|

| A2DT-01 | 8.40 | 3.11 | 660.21 | |||

| A2DT-02 | 8.28 | 3.14 | 654.96 | 8.40 | 3.12 | 661.29 |

| A2DT-03 | 8.52 | 3.12 | 668.70 | |||

| A2ST-01 | 13.28 | 2.96 | 523.61 | |||

| A2ST-02 | 13.33 | 3.07 | 534.05 | 13.36 | 3.04 | 532.58 |

| A2ST-03 | 13.46 | 3.09 | 540.07 | |||

| A4DT-01 | 9.00 | 3.80 | 707.36 | |||

| A4DT-02 | 9.03 | 3.83 | 714.29 | 9.03 | 3.83 | 711.77 |

| A4DT-03 | 9.05 | 3.87 | 713.66 | |||

| A4ST-01 | 15.88 | 3.68 | 614.48 | |||

| A4ST-02 | 15.97 | 3.72 | 639.82 | 16.03 | 3.72 | 629.19 |

| A4ST-03 | 16.24 | 3.75 | 633.26 | |||

| A6DT-01 | 10.79 | 5.12 | 848.05 | |||

| A6DT-02 | 10.82 | 5.15 | 855.71 | 10.82 | 5.15 | 857.46 |

| A6DT-03 | 10.86 | 5.18 | 868.61 | |||

| A6ST-01 | 18.25 | 5.07 | 713.81 | |||

| A6ST-02 | 18.33 | 5.10 | 712.60 | 18.31 | 5.09 | 716.77 |

| A6ST-03 | 18.36 | 5.11 | 723.91 |

| Specimen Number | Maximum Failure Load (KN) | Maximum Load Displacement (mm) | Tensile Strength (MPa) | Average Failure Load (KN) | Average Load Displacement (mm) | Average Strength (MPa) |

|---|---|---|---|---|---|---|

| B2DT-01 | 10.04 | 3.06 | 785.38 | |||

| B2DT-02 | 10.09 | 3.05 | 796.81 | 10.09 | 3.06 | 789.94 |

| B2DT-03 | 10.13 | 3.08 | 787.63 | |||

| B2ST-01 | 14.26 | 2.91 | 561.32 | |||

| B2ST-02 | 14.40 | 2.94 | 576.92 | 14.37 | 2.93 | 569.14 |

| B2ST-03 | 14.46 | 2.93 | 569.19 | |||

| B4DT-01 | 10.48 | 3.75 | 830.36 | |||

| B4DT-02 | 10.52 | 3.73 | 820.43 | 10.53 | 3.75 | 824.71 |

| B4DT-03 | 10.59 | 3.76 | 823.33 | |||

| B4ST-01 | 17.32 | 3.05 | 674.25 | |||

| B4ST-02 | 17.39 | 3.03 | 695.56 | 17.38 | 3.03 | 683.98 |

| B4ST-03 | 17.44 | 3.01 | 682.12 | |||

| B6DT-01 | 11.30 | 4.93 | 892.36 | |||

| B6DT-02 | 11.35 | 4.92 | 889.33 | 11.34 | 4.94 | 892.53 |

| B6DT-03 | 11.38 | 4.96 | 895.91 | |||

| B6ST-01 | 19.42 | 4.52 | 763.17 | |||

| B6ST-02 | 19.45 | 4.56 | 769.26 | 19.46 | 4.56 | 765.95 |

| B6ST-03 | 19.51 | 4.61 | 765.43 |

| Room Temperature | Low Temperature |

|---|---|

|  |

|  |

|  |

| Stress Level | Specimen Number | Maximum Load (KN) | Minimum Load (KN) | Fatigue Stress (MPa) | Fatigue Life | Average Fatigue Life | Standard Deviation |

|---|---|---|---|---|---|---|---|

| 85% | A2SV-01 | 11.36 | 1.14 | 446.43 | 1184 | 1364 | |

| A2SV-02 | 443.58 | 1366 | 146.1597 | ||||

| A2SV-03 | 447.17 | 1542 | |||||

| 80% | A2SV-04 | 10.69 | 1.07 | 414.21 | 18,663 | 20,761 | |

| A2SV-05 | 418.81 | 21,080 | 1599.142 | ||||

| A2SV-06 | 422.71 | 22,541 | |||||

| 75% | A2SV-07 | 10.02 | 1.00 | 395.08 | 254,008 | 261,445 | |

| A2SV-08 | 396.96 | 263,556 | 5420.073 | ||||

| A2SV-09 | 391.26 | 266,771 | |||||

| 85% | A6SV-01 | 15.56 | 1.56 | 610.46 | 1986 | 2287 | |

| A6SV-02 | 597.13 | 2321 | 232.7464 | ||||

| A6SV-03 | 604.58 | 2553 | |||||

| 80% | A6SV-04 | 14.65 | 1.47 | 568.42 | 24,963 | 26,646 | |

| A6SV-05 | 581.22 | 26,725 | 1342.676 | ||||

| A6SV-06 | 565.94 | 28,249 | |||||

| 75% | A6SV-07 | 13.73 | 1.37 | 525.17 | 333,215 | 355,775 | |

| A6SV-08 | 540.46 | 364,130 | 16,130.41 | ||||

| A6SV-09 | 530.24 | 369,981 |

| Stress Level | Specimen Number | Maximum Load (KN) | Minimum Load (KN) | Fatigue Stress (MPa) | Fatigue Life | Average Fatigue Life | Standard Deviation |

|---|---|---|---|---|---|---|---|

| 85% | B2SV-01 | 12.21 | 1.22 | 478.36 | 1735 | 1859 | |

| B2SV-02 | 481.43 | 1864 | 99.26731587 | ||||

| B2SV-03 | 478.24 | 1978 | |||||

| 80% | B2SV-04 | 11.50 | 1.15 | 448.43 | 26,149 | 27,522 | |

| B2SV-05 | 451.29 | 27,783 | 1031.506773 | ||||

| B2SV-06 | 449.05 | 28,635 | |||||

| 75% | B2SV-07 | 10.78 | 1.08 | 414.94 | 336,879 | 360,330 | |

| B2SV-08 | 425.65 | 364,130 | 17,800.66014 | ||||

| B2SV-09 | 425.04 | 379,982 | |||||

| 85% | B6SV-01 | 16.54 | 1.65 | 646.92 | 2784 | 2919 | |

| B6SV-02 | 647.84 | 2941 | 102.4337184 | ||||

| B6SV-03 | 651.07 | 3032 | |||||

| 80% | B6SV-04 | 15.57 | 1.56 | 603.29 | 36,445 | 37,545 | |

| B6SV-05 | 615.80 | 37,258 | 1035.843081 | ||||

| B6SV-06 | 602.13 | 38,933 | |||||

| 75% | B6SV-07 | 14.60 | 1.46 | 572.80 | 584,340 | 612,520 | |

| B6SV-08 | 566.48 | 596,603 | 31,580.16521 | ||||

| B6SV-09 | 578.40 | 656,616 |

| Stress Level | Room Temperature | Low Temperature |

|---|---|---|

| 85% |  |  |

| 80% |  |  |

| 75% |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Guo, F.; Han, C.; Su, W.; Wen, S. Mechanical Properties of Carbon Fiber-Reinforced Plastic with Two Types of Bolted Connections at Low Temperatures. Polymers 2024, 16, 1715. https://doi.org/10.3390/polym16121715

Li H, Guo F, Han C, Su W, Wen S. Mechanical Properties of Carbon Fiber-Reinforced Plastic with Two Types of Bolted Connections at Low Temperatures. Polymers. 2024; 16(12):1715. https://doi.org/10.3390/polym16121715

Chicago/Turabian StyleLi, Hua, Feng Guo, Chenglin Han, Wei Su, and Shuqi Wen. 2024. "Mechanical Properties of Carbon Fiber-Reinforced Plastic with Two Types of Bolted Connections at Low Temperatures" Polymers 16, no. 12: 1715. https://doi.org/10.3390/polym16121715

APA StyleLi, H., Guo, F., Han, C., Su, W., & Wen, S. (2024). Mechanical Properties of Carbon Fiber-Reinforced Plastic with Two Types of Bolted Connections at Low Temperatures. Polymers, 16(12), 1715. https://doi.org/10.3390/polym16121715