Preparation Method and Application of Porous Poly(lactic acid) Membranes: A Review

Abstract

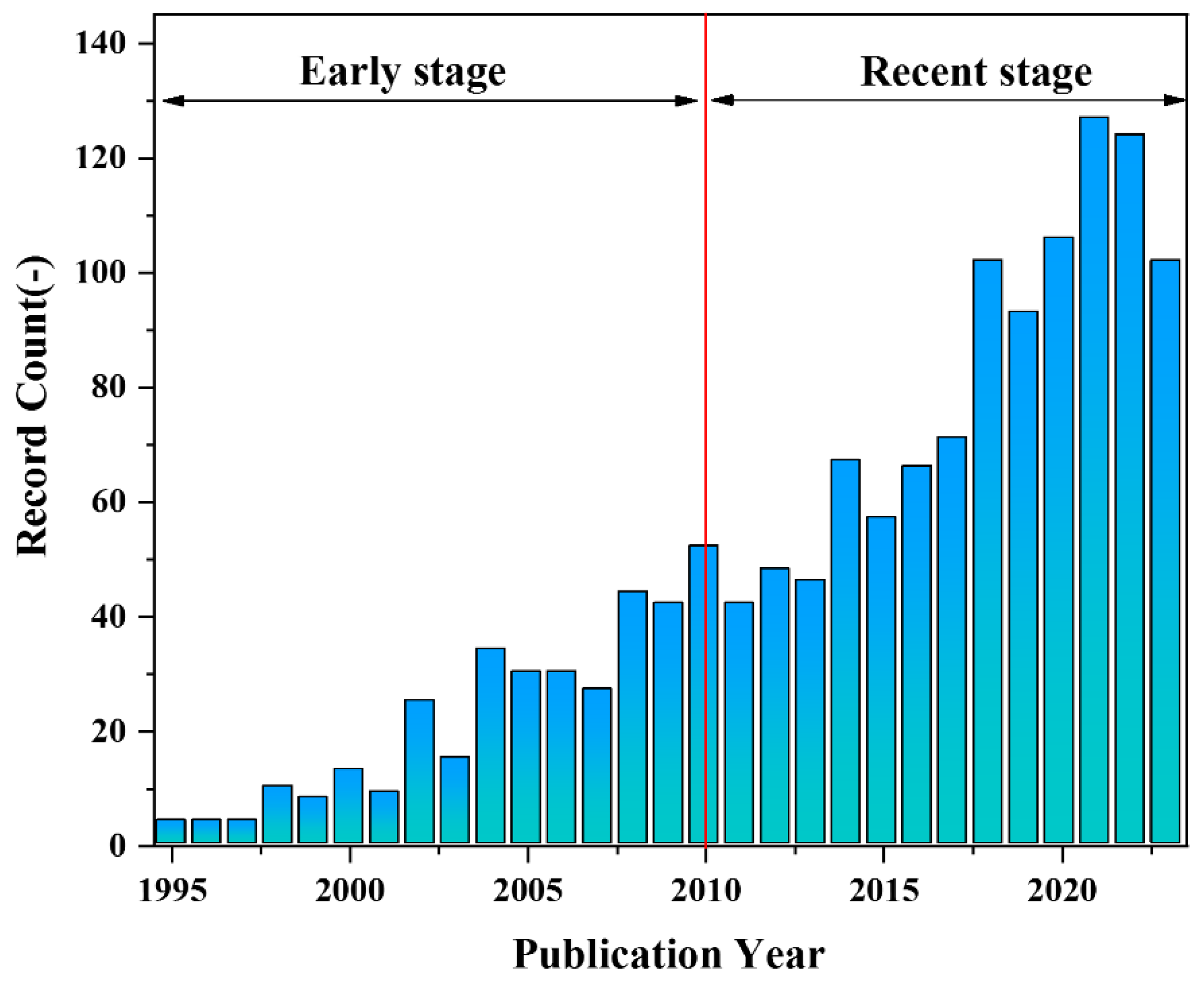

1. Introduction

2. Preparation Method of PLA Porous Membranes

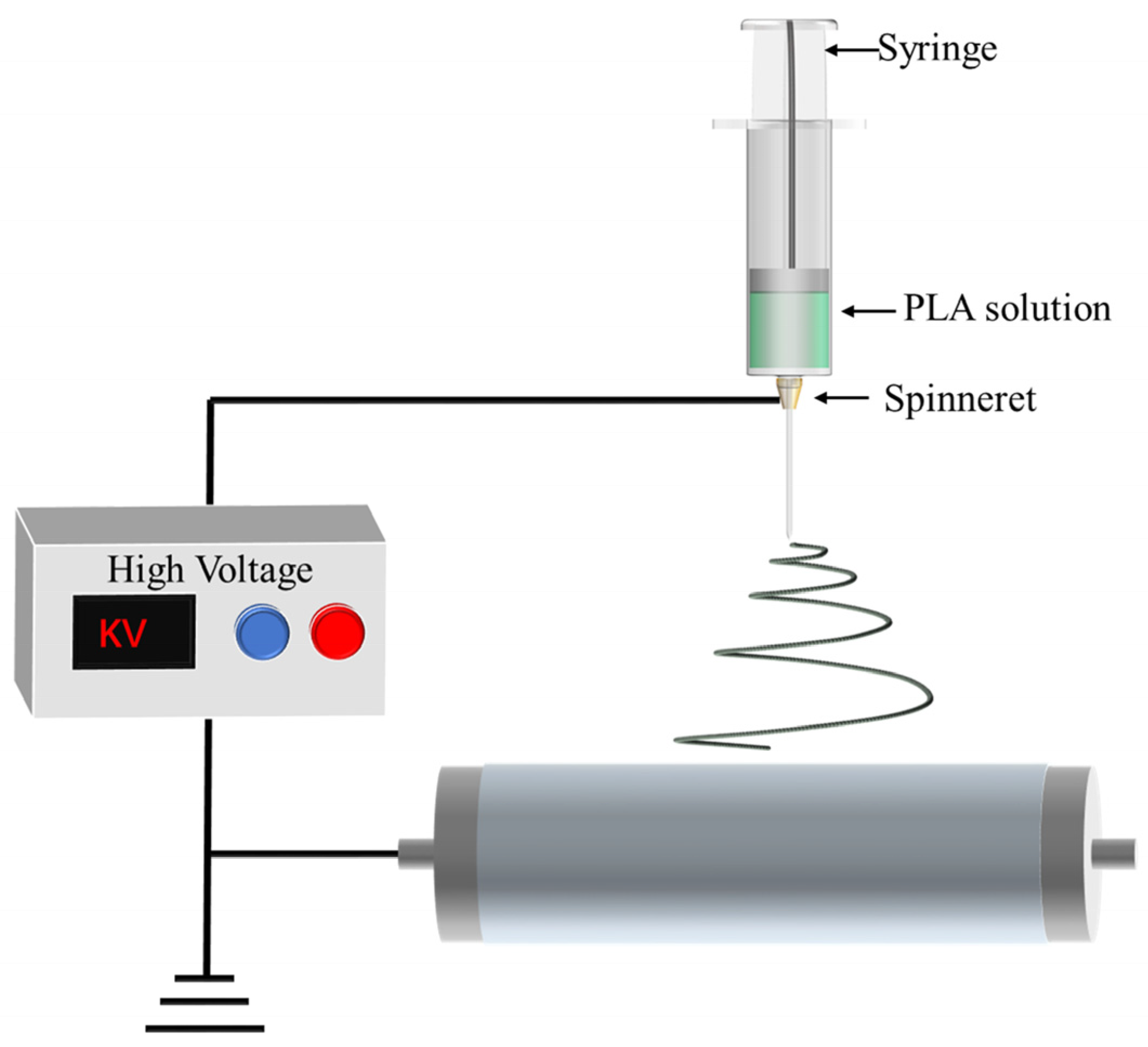

2.1. Electrospinning

2.1.1. PLA Nanofibers with Porous Structure

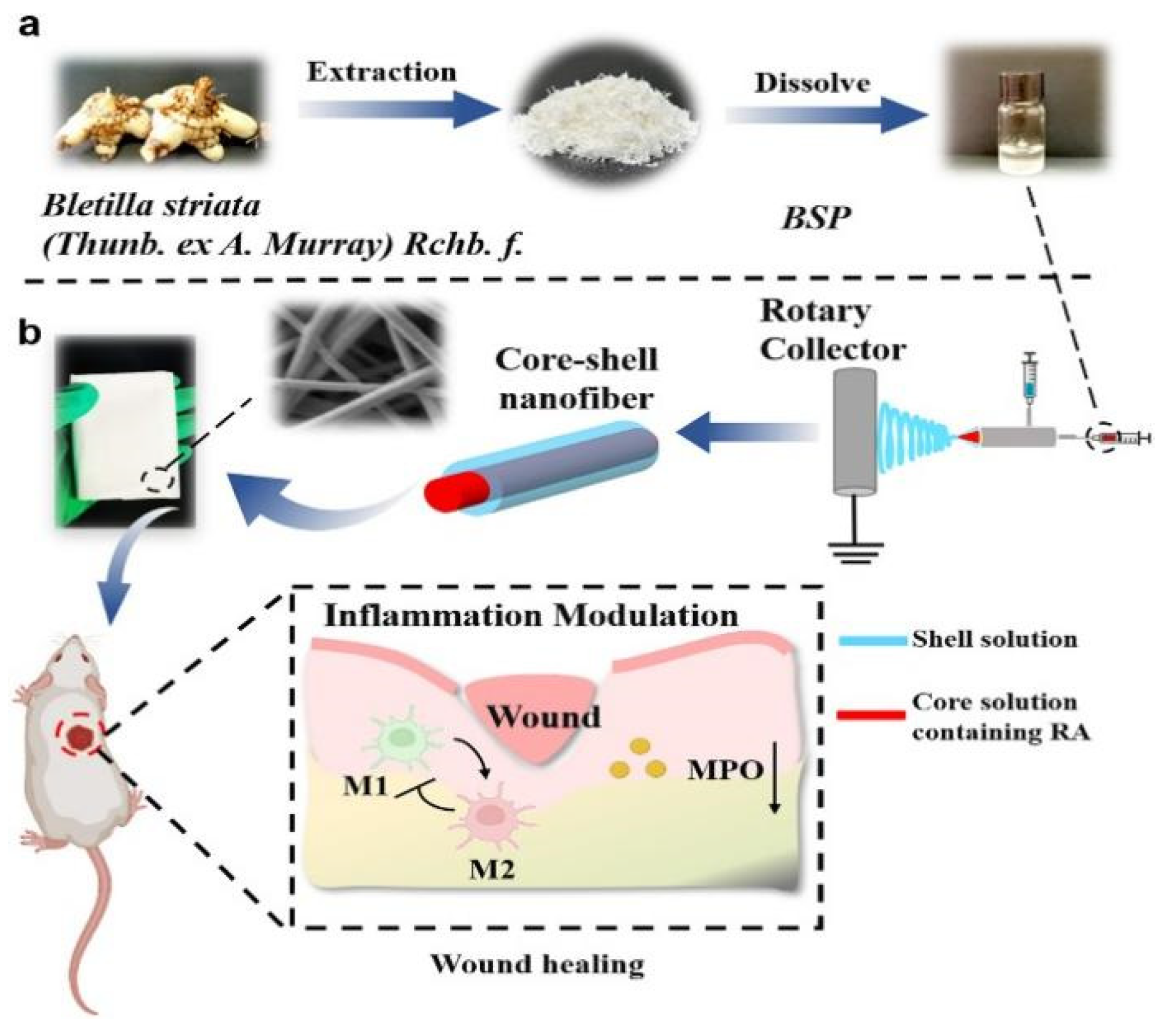

2.1.2. PLA Nanofibers with Shell-Core Structure

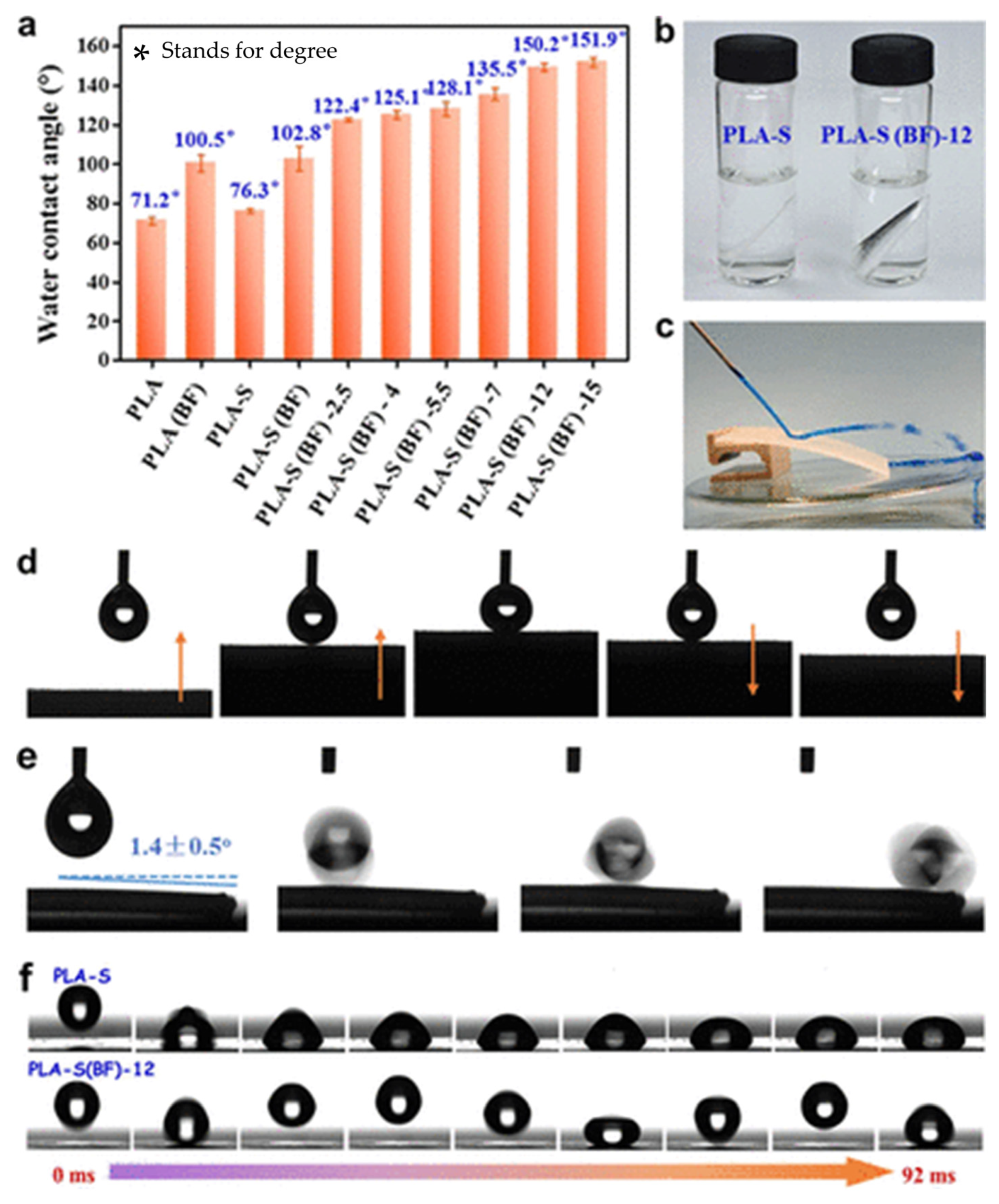

2.2. Breath-Figure Method

2.3. Phase Inversion Method (PI)

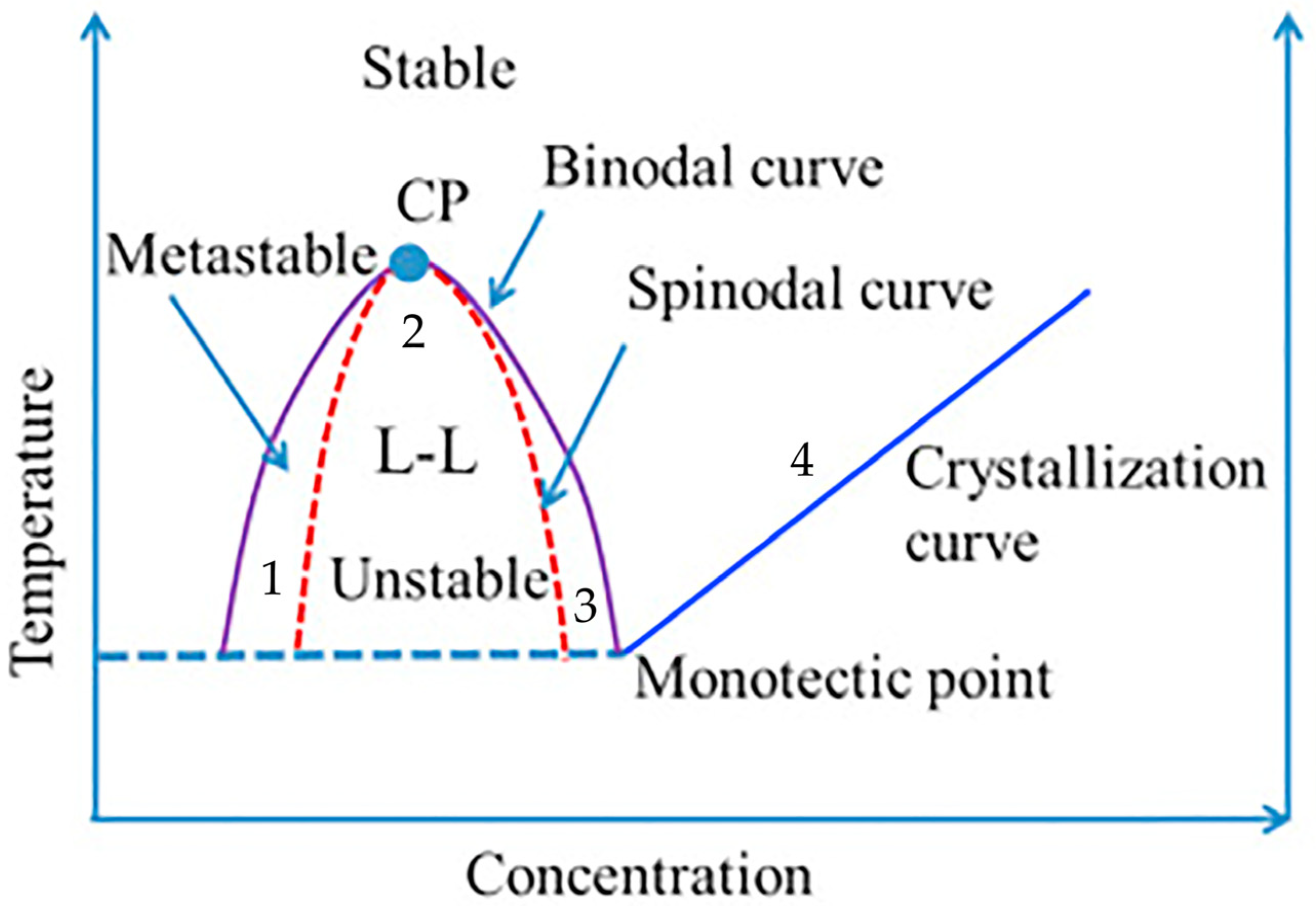

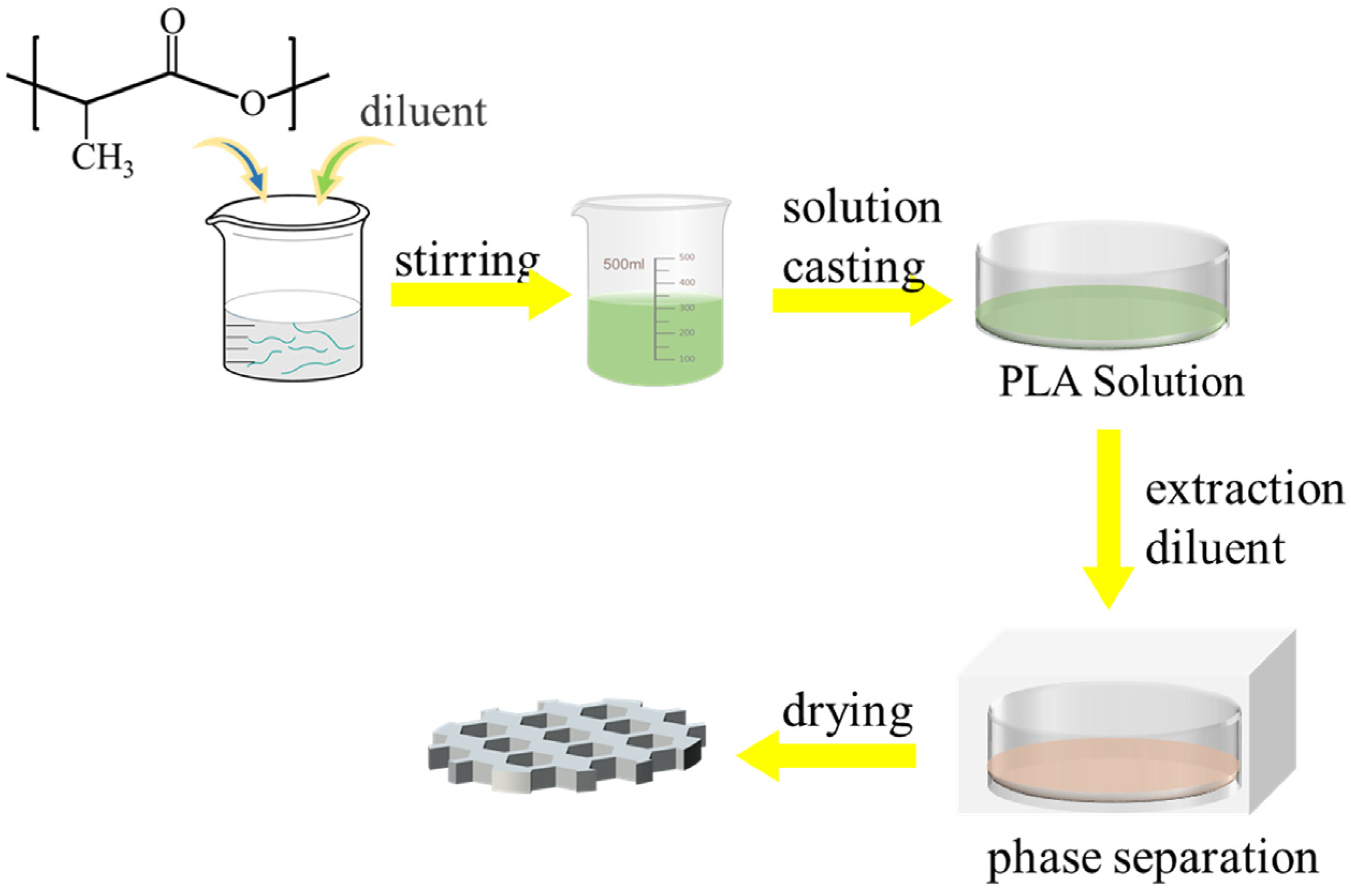

2.3.1. Thermally Induced Phase Separation

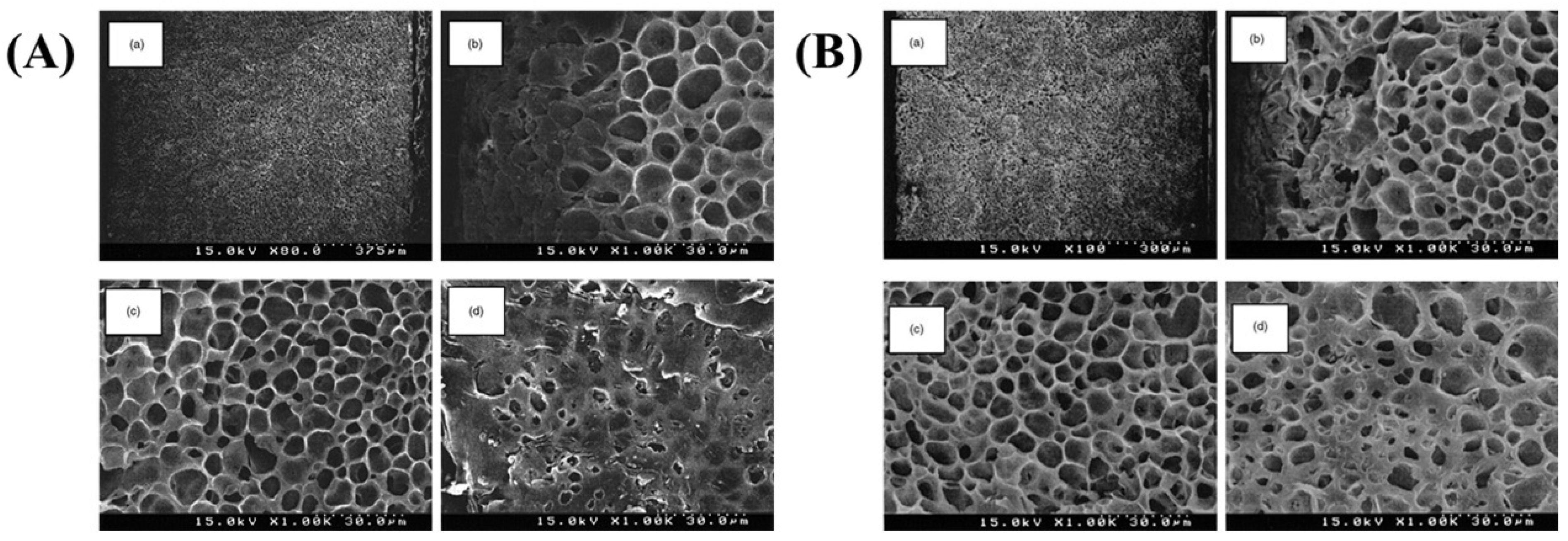

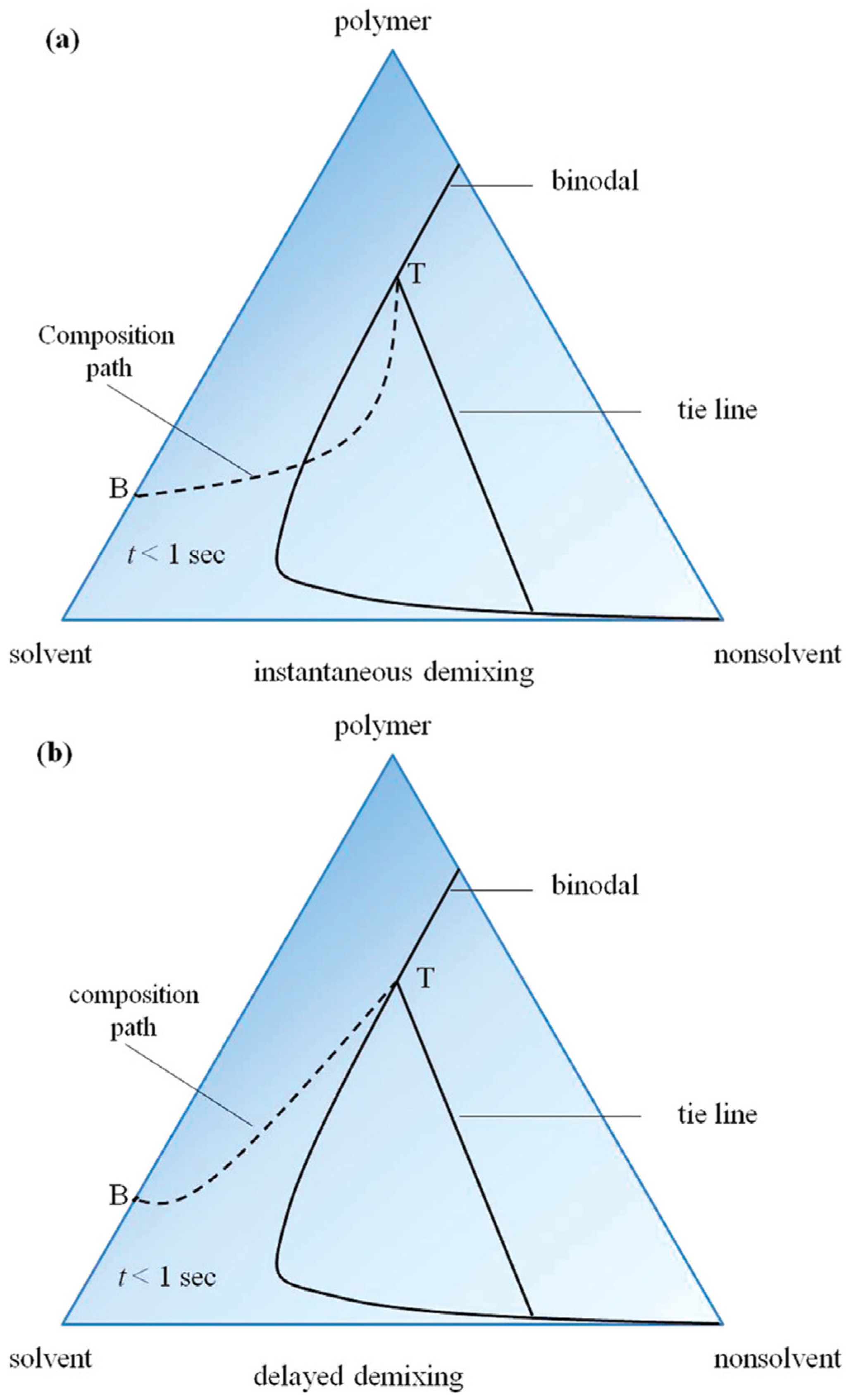

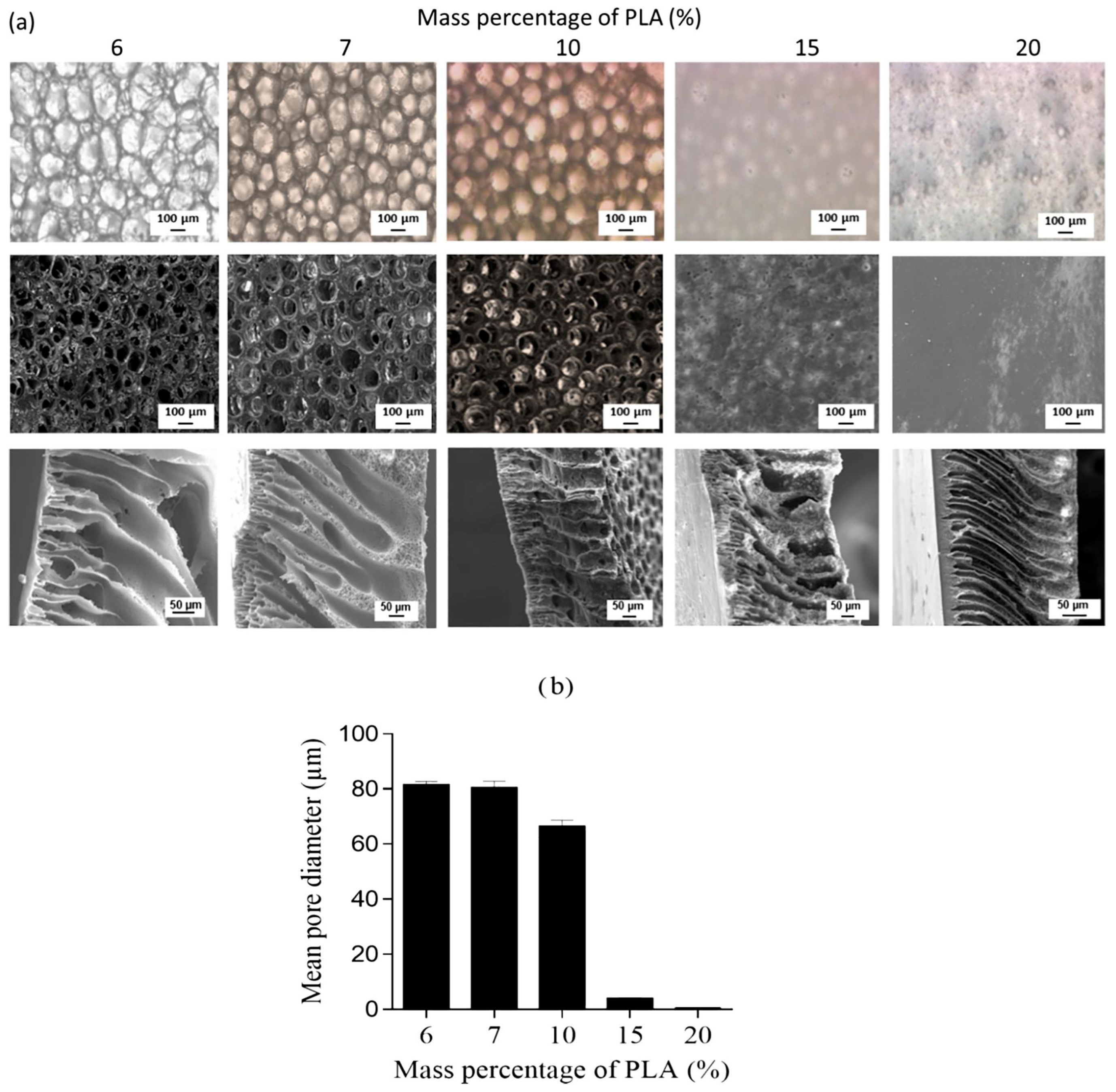

2.3.2. Non-Solvent-Induced Phase Separation

| Species | Comments | |

|---|---|---|

| Solvent | DCM [106,107,108,109] | Solvent should be compatible with coagulation media. |

| NMP [11,13,110], | ||

| DMAc [111,112], | ||

| Acetic acid [113], | ||

| DMF [105,114,115,116], | ||

| DMSO [117] | ||

| 1,4-dioxane [75,103] | ||

| Non-solvent | Ethanol [109], | Due to cost considerations, non-solvents of PLA are often water. |

| Hexane [107], | ||

| Water [11,13,106,110,112,113,114,115,116,117,118], | ||

| NMP [108] |

3. Applications

3.1. Tissue Engineering

3.2. Oil–Water Separation

3.3. Other Applications

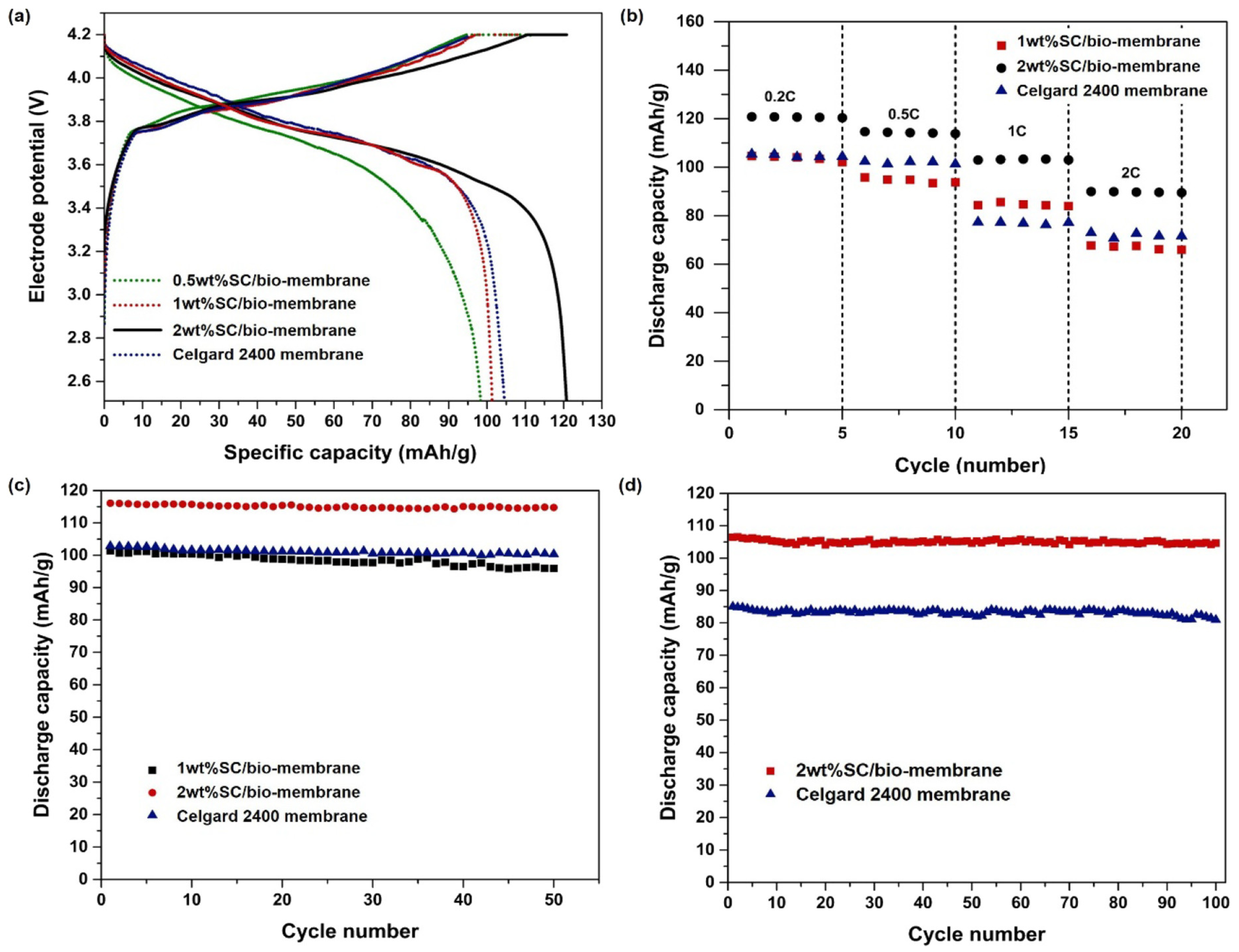

3.3.1. Porous Polymer Electrolytes

3.3.2. Drug Delivery

3.3.3. Artificial Blood Vessel

4. Summary and Prospect

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Cheng, S.; Li, H.; Zuo, D. Effect of different concentrations of spraying chitosan solution on structure and properties of PVDF porous membrane. Colloid. Polym. Sci. 2021, 299, 797–805. [Google Scholar] [CrossRef]

- Wei, N.; Li, Z.; Li, Q.; Yang, E.; Xu, R.; Song, X.; Sun, J.; Dou, C.; Tian, J.; Cui, H. Scalable and low-cost fabrication of hydrophobic PVDF/WS2 porous membrane for highly efficient solar steam generation. J. Colloid Interface Sci. 2021, 588, 369–377. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Guo, X.; Pei, C.; Dong, W.; Yao, Y. Hydrophilic modification of polypropylene membrane via tannic and titanium complexation for high-efficiency oil/water emulsion separation driven by self-gravity. Polym. Eng. Sci. 2022, 62, 2131–2142. [Google Scholar] [CrossRef]

- Zhu, X.; Zhu, L.; Xue, J.; Xue, Q. Preparation of micro-nano particles modified discarded face-mask by a versatile thermocompression modification approach and its application to emulsion separation. Sep. Sci. Technol. 2023, 58, 695–703. [Google Scholar] [CrossRef]

- Dong, C.; Xu, X.; Zhang, J.; Wang, H.; Xiang, Y.; Zhu, H.; Forsyth, M.; Lu, S. Proton transport of porous triazole-grafted polysulfone membranes for high temperature polymer electrolyte membrane fuel cell. Int. J. Hydrogen Energy 2022, 47, 8492–8501. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, F.; Zhang, S.; Zhang, Y.; Liu, S. Preparation of Nonstoichiometric Silica with Multi-Active Groups and Effect of Its Doping on Polysulfone Membrane Capabilities. Sep. Sci. Technol. 2012, 47, 2311–2319. [Google Scholar] [CrossRef]

- Zhang, S.-C.; Liu, T.; Wang, Y.-J. Porous and single-skinned polyethersulfone membranes support the growth of HepG2 cells: A potential biomaterial for bioartificial liver systems. J. Biomater. Appl. 2012, 27, 359–366. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Yang, Y.; Wang, X.; Wang, Q.; Wang, S.; Gao, X.; Gao, C. Harvesting Microalgae Biomass Using Sulfonated Polyethersulfone (SPES)/PES Porous Membranes in Forward Osmosis Processes. J. Ocean Univ. China 2020, 19, 1345–1352. [Google Scholar] [CrossRef]

- Sakdaronnarong, C.; Srimarut, N.; Lucknakhul, N.; Na-songkla, N.; Jonglertjunya, W. Two-step acid and alkaline ethanolysis/alkaline peroxide fractionation of sugarcane bagasse and rice straw for production of polylactic acid precursor. Biochem. Eng. J. 2014, 85, 49–62. [Google Scholar] [CrossRef]

- Fan, Y.; Miao, X.; Hou, C.; Wang, J.; Lin, J.; Bian, F. High tensile performance of PLA fiber-reinforced PCL composite via a synergistic process of strain and crystallization. Polymers 2023, 270, 125778. [Google Scholar] [CrossRef]

- Gao, A.L.; Zhao, Y.Q.; Yang, Q.; Fu, Y.Y.; Xue, L.X. Facile preparation of patterned petal-like PLA surfaces with tunable water micro-droplet adhesion properties based on stereo-complex co-crystallization from non-solvent induced phase separation processes. J. Mater. Chem. 2016, 4, 12058–12064. [Google Scholar] [CrossRef]

- Shebi, A.; Lisa, S. Evaluation of biocompatibility and bactericidal activity of hierarchically porous PLA-TiO2 nanocomposite films fabricated by breath-figure method. Mater. Chem. Phys. 2019, 230, 308–318. [Google Scholar] [CrossRef]

- Su, Y.Z.; Zhao, Y.Q.; Zheng, W.G.; Yu, H.W.; Liu, Y.F.; Xu, L.Q. Asymmetric Sc-PLA Membrane with Multi-scale Microstructures: Wettability, Antifouling, and Oil-Water Separation. ACS Appl. Mater. Interfaces 2020, 12, 55520–55526. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Jia, H.; Pan, Y.; Liu, C.; Shen, C.; Liu, X. Porous poly (l-lactide)/poly (d-lactide) blend film with enhanced flexibility and heat resistance via constructing a regularly oriented pore structure. Macromolecules 2023, 56, 7606–7616. [Google Scholar] [CrossRef]

- Thiangtham, S.; Saito, N.; Manuspiya, H. Asymmetric Porous and Highly Hydrophilic Sulfonated Cellulose/Biomembrane Functioning as a Separator in a Lithium-Ion Battery. ACS Appl. Energy Mater. 2022, 5, 6206–6218. [Google Scholar] [CrossRef]

- Bakhshi, R.; Mohammadi-Zerankeshi, M.; Mehrabi-Dehdezi, M.; Alizadeh, R.; Labbaf, S.; Abachi, P. Additive manufacturing of PLA-Mg composite scaffolds for hard tissue engineering applications. J. Mech. Behav. Biomed. Mater. 2023, 138, 105655. [Google Scholar] [CrossRef]

- Osorio-Arciniega, R.; Garcia-Hipolito, M.; Alvarez-Fregoso, O.; Alvarez-Perez, M.A. Composite Fiber Spun Mat Synthesis and In Vitro Biocompatibility for Guide Tissue Engineering. Molecules 2021, 26, 7597. [Google Scholar] [CrossRef]

- Heydari, P.; Parham, S.; Kharazi, A.Z.; Javanmard, S.H.; Asgary, S. In Vitro Comparison Study of Plasma Treated Bilayer PGS/PCL and PGS/PLA Scaffolds for Vascular Tissue Engineering. Fibers Polym. 2022, 23, 2384–2393. [Google Scholar] [CrossRef]

- Mokhtari, N.; Kharazi, A.Z. Blood compatibility and cell response improvement of poly glycerol sebacate/poly lactic acid scaffold for vascular graft applications. J. Biomed. Mater. Res. Part A 2021, 109, 2673–2684. [Google Scholar] [CrossRef]

- Zhang, F.; Bambharoliya, T.; Xie, Y.; Liu, L.; Celik, H.; Wang, L.; Akkus, O.; King, M.W. A hybrid vascular graft harnessing the superior mechanical properties of synthetic fibers and the biological performance of collagen filaments. Mater. Sci. Eng. C 2021, 118, 111418. [Google Scholar] [CrossRef]

- Banitaba, S.N.; Gharehaghaji, A.A.; Jeddi, A.A.A. Fabrication and characterization of hollow electrospun PLA structure through a modified electrospinning method applicable as vascular graft. Bull. Mater. Sci. 2021, 44, 158. [Google Scholar] [CrossRef]

- Ebrahimifar, M.; Taherimehr, M. Evaluation of in-vitro drug release of polyvinylcyclohexane carbonate as a CO2-derived degradable polymer blended with PLA and PCL as drug carriers. J. Drug Delivery Sci. Technol. 2021, 63, 102491. [Google Scholar] [CrossRef]

- Jeong, H.; Lim, H.; Lee, D.Y.; Song, Y.-S.; Kim, B.-Y. Preparation and drug release behavior of nifedipine-loaded poly(lactic acid)/polyethylene glycol microcapsules. J. Nanosci. Nanotechnol. 2021, 21, 3735–3741. [Google Scholar] [CrossRef] [PubMed]

- Seo, K.H.; Lee, K.E.; Yanilmaz, M.; Kim, J. Exploring the diverse morphology of porous poly(Lactic Acid) fibers for developing long-term controlled antibiotic delivery systems. Pharmaceutic 2022, 14, 1272. [Google Scholar] [CrossRef] [PubMed]

- Mo, J.; Wang, Y.; Lin, J.; Ke, Y.; Zhou, C.; Wang, J.; Wen, J.; Gan, F.; Wang, L.; Ma, C. Polylactic acid/multi-wall carbon nanotubes composite fibrous membrane and their applications in oil-water separation. Surf. Interfaces 2023, 39, 102908. [Google Scholar] [CrossRef]

- Zhang, D.; Jin, X.-Z.; Huang, T.; Zhang, N.; Qi, X.; Yang, J.-h.; Zhou, Z.; Wang, Y. Electrospun fibrous membranes with dual-scaled porous structure: Super hydrophobicity, super lipophilicity, excellent water adhesion, and anti-icing for highly efficient oil adsorption/separation. ACS Appl. Mater. Interfaces 2019, 11, 5073–5083. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, J.; Reizabal, A.; Correia, D.; Fidalgo-Marijuan, A.; Gonçalves, R.; Silva, M.; Lanceros-Mendez, S.; Costa, C. Lithium-ion battery separator membranes based on poly (L-lactic acid) biopolymer. Mater. Today Energy 2020, 18, 100494. [Google Scholar] [CrossRef]

- Zhong, L.; Gong, X. Phase separation-induced superhydrophobic polylactic acid films. Soft Matter 2019, 15, 9500–9506. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Yuan, W. A hierarchical functionalized biodegradable PLA electrospun nanofibrous membrane with superhydrophobicity and antibacterial properties for oil/water separation. J. Chem. 2018, 42, 17615–17624. [Google Scholar] [CrossRef]

- Hu, S.; Wu, J.; Cui, Z.; Si, J.; Wang, Q.; Peng, X. Study on the mechanical and thermal properties of polylactic acid/hydroxyapatite@ polydopamine composite nanofibers for tissue engineering. J. Appl. Polym. Sci. 2020, 137, 49077. [Google Scholar] [CrossRef]

- Zhou, J.-f.; Wang, Y.-g.; Cheng, L.; Wu, Z.; Sun, X.-d.; Peng, J. Preparation of polypyrrole-embedded electrospun poly (lactic acid) nanofibrous scaffolds for nerve tissue engineering. Neural Regener. Res. 2016, 11, 1644–1652. [Google Scholar] [CrossRef]

- Mao, Z.; Li, J.; Huang, W.; Jiang, H.; Zimba, B.L.; Chen, L.; Wan, J.; Wu, Q. Preparation of poly (lactic acid)/graphene oxide nanofiber membranes with different structures by electrospinning for drug delivery. RSC Adv. 2018, 8, 16619–16625. [Google Scholar] [CrossRef] [PubMed]

- Buscemi, S.; Palumbo, V.D.; Maffongelli, A.; Fazzotta, S.; Palumbo, F.S.; Licciardi, M.; Fiorica, C.; Puleio, R.; Cassata, G.; Fiorello, L.; et al. Electrospun PHEA-PLA/PCL Scaffold for Vascular Regeneration: A Preliminary in Vivo Evaluation. Trans. Proc. 2017, 49, 716–721. [Google Scholar] [CrossRef]

- Afifi, A.M.; Nakajima, H.; Yamane, H.; Kimura, Y.; Nakano, S. Fabrication of Aligned Poly (l-lactide) Fibers by Electrospinning and Drawing. Macromol. Mater. Eng. 2009, 294, 658–665. [Google Scholar] [CrossRef]

- Samatham, R.; Kim, K. Electric current as a control variable in the electrospinning process. Polym. Eng. Sci. 2006, 46, 954–959. [Google Scholar] [CrossRef]

- Moon, S.; Choi, J.; Farris, R.J. Highly porous polyacrylonitrile/polystyrene nanofibers by electrospinning. Fibers Polym. 2008, 9, 276–280. [Google Scholar] [CrossRef]

- Park, J.Y.; Lee, I.H. Controlled release of ketoprofen from electrospun porous polylactic acid (PLA) nanofibers. J. Polym. Res. 2011, 18, 1287–1291. [Google Scholar] [CrossRef]

- Zhang, H.; Niu, Q.; Wang, N.; Nie, J.; Ma, G. Thermo-sensitive drug controlled release PLA core/PNIPAM shell fibers fabricated using a combination of electrospinning and UV photo-polymerization. Eur. Polym. J. 2015, 71, 440–450. [Google Scholar] [CrossRef]

- Tian, R.; Zhang, P.; Lv, R.; Na, B.; Liu, Q.; Ju, Y. Formation of highly porous structure in the electrospun polylactide fibers by swelling-crystallization in poor solvents. RSC Adv. 2015, 5, 37539–37544. [Google Scholar] [CrossRef]

- Bognitzki, M.; Frese, T.; Steinhart, M.; Greiner, A.; Wendorff, J.H.; Schaper, A.; Hellwig, M. Preparation of fibers with nanoscaled morphologies: Electrospinning of polymer blends. Polym. Eng. Sci. 2001, 41, 982–989. [Google Scholar] [CrossRef]

- Yang, H.; Wang, L.; Xiang, C.; Li, L. Electrospun porous PLLA and poly (LLA-co-CL) fibers by phase separation. New J. Chem. 2018, 42, 5102–5108. [Google Scholar] [CrossRef]

- Zhong, G.; Qiu, M.; Zhang, J.; Jiang, F.; Yue, X.; Huang, C.; Zhao, S.; Zeng, R.; Zhang, C.; Qu, Y. Fabrication and characterization of PVA@PLA electrospinning nanofibers embedded with Bletilla striata polysaccharide and Rosmarinic acid to promote wound healing. Int. J. Biol. Macromol. 2023, 234, 123693. [Google Scholar] [CrossRef]

- Chen, X.; Li, H.H.; Lu, W.P.; Guo, Y.C. Antibacterial Porous Coaxial Drug-Carrying Nanofibers for Sustained Drug-Releasing Applications. Nanomaterials 2021, 11, 1316. [Google Scholar] [CrossRef]

- Tian, L.; Prabhakaran, M.P.; Hu, J.; Chen, M.; Besenbacher, F.; Ramakrishna, S. Coaxial electrospun poly(lactic acid)/silk fibroin nanofibers incorporated with nerve growth factor support the differentiation of neuronal stem cells. RSC Adv. 2015, 5, 49838–49848. [Google Scholar] [CrossRef]

- Zhang, P.; Tian, R.; Lv, R.; Na, B.; Liu, Q. Water-permeable polylactide blend membranes for hydrophilicity-based separation. Chem. Eng. J. 2015, 269, 180–185. [Google Scholar] [CrossRef]

- Lo, J.S.C.; Daoud, W.; Tso, C.Y.; Lee, H.H.; Firdous, I.; Deka, B.J.; Lin, C.S.K. Optimization of polylactic acid-based medical textiles via electrospinning for healthcare apparel and personal protective equipment. Sustain. Chem. Pharm. 2022, 30, 100891. [Google Scholar] [CrossRef]

- Ertek, D.A.; Sanli, N.O.; Menceloglu, Y.Z.; Avaz Seven, S. Environmentally friendly, antibacterial materials from recycled keratin incorporated electrospun PLA films with tunable properties. Eur. Polym. J. 2023, 185, 111804. [Google Scholar] [CrossRef]

- Scaffaro, R.; Lopresti, F.; Botta, L. Preparation, characterization and hydrolytic degradation of PLA/PCL co-mingled nanofibrous mats prepared via dual-jet electrospinning. Eur. Polym. J. 2017, 96, 266–277. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, Q.; Wu, J.; Zhang, Y.; Guo, J.; Yu, J.; Shu, X.; Chen, Q. Flexible, robust and self-peeling PLA/AgNWs nanofiber membranes with photothermally antibacterial properties for wound dressing. Appl. Surf. Sci. 2023, 615, 156284. [Google Scholar] [CrossRef]

- Gulzar, S.; Tagrida, M.; Nilsuwan, K.; Prodpran, T.; Benjakul, S. Electrospinning of gelatin/chitosan nanofibers incorporated with tannic acid and chitooligosaccharides on polylactic acid film: Characteristics and bioactivities. Food Hydrocolloids 2022, 133, 107916. [Google Scholar] [CrossRef]

- Guo, Y.; Ghobeira, R.; Sun, Z.; Shali, P.; Morent, R.; De Geyter, N. Atmospheric pressure plasma jet treatment of PLA/PAni solutions: Enhanced morphology, improved yield of electrospun nanofibers and concomitant doping behaviour. Polymers 2022, 262, 125502. [Google Scholar] [CrossRef]

- Niu, Y.; Stadler, F.J.; Fang, J.; Galluzzi, M. Hyaluronic acid-functionalized poly-lactic acid (PLA) microfibers regulate vascular endothelial cell proliferation and phenotypic shape expression. Colloids Surf. B 2021, 206, 111970. [Google Scholar] [CrossRef]

- Wu, Z.C.; Zhang, Z.J.; Wei, W.; Yin, Y.Q.; Huang, C.X.; Ding, J.; Duan, Q.S. Investigation of a novel poly (lactic acid) porous material toughened by thermoplastic polyurethane. J. Mater. Sci. 2022, 57, 5456–5466. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Micale, G.D.M. PLA-based functionally graded laminates for tunable controlled release of carvacrol obtained by combining electrospinning with solvent casting. React. Funct. Polym. 2020, 148, 104490. [Google Scholar] [CrossRef]

- Gutiérrez-Sánchez, M.; Escobar-Barrios, V.A.; Pozos-Guillén, A.; Escobar-García, D.M. RGD-functionalization of PLA/starch scaffolds obtained by electrospinning and evaluated in vitro for potential bone regeneration. Mater. Sci. Eng. C 2019, 96, 798–806. [Google Scholar] [CrossRef] [PubMed]

- Min, T.; Zhou, L.; Sun, X.; Du, H.; Bian, X.; Zhu, Z.; Wen, Y. Enzyme-responsive food packaging system based on pectin-coated poly (lactic acid) nanofiber films for controlled release of thymol. Food Res. Int. 2022, 157, 111256. [Google Scholar] [CrossRef]

- François, B.; Pitois, O.; François, J. Polymer films with a self-organized honeycomb morphology. Adv. Mater. 1995, 7, 1041–1044. [Google Scholar] [CrossRef]

- Li, Q.Z.; Zhang, G.Y.; Huang, J.; Zhao, Q.L.; Wei, L.H.; He, Z.H.; Ma, Z. Synthesis and Property of Well-defined Polymethylene/Polylactide Diblock Copolymer. Acta Chim. Sinica 2011, 69, 497–502. [Google Scholar]

- Bertrand, A.; Bousquet, A.; Lartigau-Dagron, C.; Billon, L. Hierarchically porous bio-inspired films prepared by combining “breath figure” templating and selectively degradable block copolymer directed self-assembly. Chem. Commun. 2016, 52, 9562–9565. [Google Scholar] [CrossRef]

- Chen, Y.; Gao, X.-R.; Huang, H.-D.; Xu, L.; Ji, X.; Zhong, G.-J.; Lin, H.; Li, Z.-M. Superhydrophobic, Self-Cleaning, and Robust Properties of Oriented Polylactide Imparted by Surface Structuring. ACS Sustain. Chem. Eng. 2021, 9, 6296–6304. [Google Scholar] [CrossRef]

- Bai, H.; Du, C.; Zhang, A.J.; Li, L. Breath Figure Arrays: Unconventional Fabrications, Functionalizations, and Applications. Angew. Chem. Int. Ed. 2013, 52, 12240–12255. [Google Scholar] [CrossRef] [PubMed]

- Escale, P.; Rubatat, L.; Billon, L.; Save, M. Recent advances in honeycomb-structured porous polymer films prepared via breath figures. Eur. Polym. J. 2012, 48, 1001–1025. [Google Scholar] [CrossRef]

- Huang, J.; Zhu, J.; Sun, W.; Ji, J. Versatile and functional surface patterning of in situ breath figure pore formation via solvent treatment. ACS Appl. Mater. Interfaces 2020, 12, 47048–47058. [Google Scholar] [CrossRef]

- Kong, Q.; Li, Z.; Ding, F.; Ren, X. Hydrophobic N-halamine based POSS block copolymer porous films with antibacterial and resistance of bacterial adsorption performances. Chem. Eng. J. 2021, 410, 128407. [Google Scholar] [CrossRef]

- Preuksarattanawut, C.; Nisaratanaporn, E.; Siralertmukul, K. Highly ordered porous PLA films prepared by breath figure method. J. Met. Mater. Miner. 2019, 29, 106–112. [Google Scholar] [CrossRef]

- Guo, Y.; Sun, X.; Wang, R.; Tang, H.; Wang, L.; Zhang, L.; Qin, S. Construction of porous poly (l-lactic acid) surface via carbon quantum dots-assisted static Breath-Figures method. Colloids Surf. A 2022, 647, 129110. [Google Scholar] [CrossRef]

- Ding, L.Y.; Ju, Y.L.; Sun, W.; Chen, J. Preparation of Functional Patterned Protein Arrays via the Combination of Inverse Emulsion and Breath Figure Method. Chem. J. Chin. Univ. Chin. 2018, 39, 1311–1318. [Google Scholar] [CrossRef]

- Qin, S.; Li, H.; Yuan, W.Z.; Zhang, Y.M. Fabrication of polymeric honeycomb microporous films: Breath figures strategy and stabilization of water droplets by fluorinated diblock copolymer micelles. J. Mater. Sci. 2012, 47, 6862–6871. [Google Scholar] [CrossRef]

- Cheng, K.-Y.; Chang, C.-H.; Yang, Y.-W.; Liao, G.-C.; Liu, C.-T.; Wu, J.-S. Enhancement of cell growth on honeycomb-structured polylactide surface using atmospheric-pressure plasma jet modification. Appl. Surf. Sci. 2017, 394, 534–542. [Google Scholar] [CrossRef]

- Yin, H.; Zhan, F.; Li, Z.; Huang, H.; Marcasuzaa, P.; Luo, X.; Feng, Y.; Billon, L. CO2-Triggered ON/OFF Wettability Switching on Bioinspired Polylactic Acid Porous Films for Controllable Bioadhesion. Biomac. 2021, 22, 1721–1729. [Google Scholar] [CrossRef]

- Yao, B.; Zhu, Q.; Yao, L.; Hao, J. Fabrication of honeycomb-structured poly(ethylene glycol)-block-poly(lactic acid) porous films and biomedical applications for cell growth. Appl. Surf. Sci. 2015, 332, 287–294. [Google Scholar] [CrossRef]

- Ponnusamy, T.; Lawson, L.B.; Freytag, L.C.; Blake, D.A.; Ayyala, R.S.; John, V. In vitro degradation and release characteristics of spin coated thin films of PLGA with a “breath figure” morphology. Biomatter 2012, 2, 77–86. [Google Scholar] [CrossRef]

- Loeb, S.; Sourirajan, S. High-flow semipermeable membranes for separation of water from saline solutions. Adv. Chem. Ser. 1962, 38, 117–132. [Google Scholar] [CrossRef]

- Fijol, N.; Abdelhamid, H.N.; Pillai, B.; Hall, S.A.; Thomas, N.; Mathew, A.P. 3D-printed monolithic biofilters based on a polylactic acid (PLA)—Hydroxyapatite (HAp) composite for heavy metal removal from an aqueous medium. RSC Adv. 2021, 11, 32408–32418. [Google Scholar] [CrossRef]

- Xing, Q.; Dong, X.; Li, R.; Yang, H.; Han, C.C.; Wang, D. Morphology and performance control of PLLA-based porous membranes by phase separation. Polymer 2013, 54, 5965–5973. [Google Scholar] [CrossRef]

- Figoli, A.; Marino, T.; Galiano, F. Polymeric membranes in biorefinery. Membr. Technol. Biorefining 2016, 29–59. [Google Scholar] [CrossRef]

- Lloyd, D.R.; Kinzer, K.E.; Tseng, H. Microporous membrane formation via thermally induced phase separation. I. Solid-liquid phase separation. J. Membr. Sci. 1990, 52, 239–261. [Google Scholar] [CrossRef]

- Lloyd, D.R.; Kim, S.S.; Kinzer, K. Microporous membrane formation via thermally-induced phase separation. II. Liquid—Liquid phase separation. J. Membr. Sci. 1991, 64, 1–11. [Google Scholar] [CrossRef]

- Kim, S.S.; Lloyd, D. Microporous membrane formation via thermally-induced phase separation. III. Effect of thermodynamic interactions on the structure of isotactic polypropylene membranes. J. Membr. Sci. 1991, 64, 13–29. [Google Scholar] [CrossRef]

- Lim, G.B.; Kim, S.S.; Ye, Q.; Wang, Y.F.; Lloyd, D. Microporous membrane formation via thermally-induced phase separation. IV. Effect of isotactic polypropylene crystallization kinetics on membrane structure. J. Membr. Sci. 1991, 64, 31–40. [Google Scholar] [CrossRef]

- Kim, S.S.; Lim, G.B.; Alwattari, A.A.; Wang, Y.F.; Lloyd, D. Microporous membrane formation via thermally-induced phase separation. V. Effect of diluent mobility and crystallization on the structure of isotactic polypropylene membranes. J. Membr. Sci. 1991, 64, 41–53. [Google Scholar] [CrossRef]

- Alwattari, A.A.; Lloyd, D. Microporous membrane formation via thermally-induced phase separation. VI. Effect of diluent morphology and relative crystallization kinetics on polypropylene membrane structure. J. Membr. Sci. 1991, 64, 55–67. [Google Scholar] [CrossRef]

- Lloyd, D.R.; Lim, G. Microporous membrane formation via thermally-induced phase separation. VII. Effect of dilution, cooling rate, and nucleating agent addition on morphology. J. Membr. Sci. 1993, 79, 27–34. [Google Scholar] [CrossRef]

- Chinyerenwa, A.C.; Wang, H.; Zhang, Q.; Zhuang, Y.; Munna, K.H.; Ying, C.; Yang, H.; Xu, W. Structure and thermal properties of porous polylactic acid membranes prepared via phase inversion induced by hot water droplets. Polymer 2018, 141, 62–69. [Google Scholar] [CrossRef]

- Rajabzadeh, S.; Maruyama, T.; Sotani, T.; Matsuyama, H.J.S.; Technology, P. Preparation of PVDF hollow fiber membrane from a ternary polymer/solvent/nonsolvent system via thermally induced phase separation (TIPS) method. Sep. Purif. Technol. 2008, 63, 415–423. [Google Scholar] [CrossRef]

- Cui, Z.; Hassankiadeh, N.T.; Zhuang, Y.; Drioli, E.; Lee, Y.M. Crystalline polymorphism in poly(vinylidenefluoride) membranes. Prog. Polym. Sci. 2015, 51, 94–126. [Google Scholar] [CrossRef]

- Liu, Q.; Tian, S.; Zhao, C.; Chen, X.; Lei, I.; Wang, Z.; Ma, P.X. Porous nanofibrous poly(l-lactic acid) scaffolds supporting cardiovascular progenitor cells for cardiac tissue engineering. Acta Biomater. 2015, 26, 105–114. [Google Scholar] [CrossRef]

- Tanaka, T.; Lloyd, D. Formation of poly (L-lactic acid) microfiltration membranes via thermally induced phase separation. J. Membr. Sci. 2004, 238, 65–73. [Google Scholar] [CrossRef]

- Soltanolkottabi, F. Application of Fourier’s law in thermally induced phase separation (TIPS) process for porous poly(L-lactide) films. Polym. Bull. 2022, 80, 7011–7021. [Google Scholar] [CrossRef]

- Hsu, S.h.; Huang, S.; Wang, Y.C.; Kuo, Y.C. Novel nanostructured biodegradable polymer matrices fabricated by phase separation techniques for tissue regeneration. Acta Biomater. 2013, 9, 6915–6927. [Google Scholar] [CrossRef]

- Önder, Ö.C.; Yilgör, E.; Yilgör, I. Fabrication of rigid poly(lactic acid) foams via thermally induced phase separation. Polymer 2016, 107, 240–248. [Google Scholar] [CrossRef]

- Onder, O.C.; Yilgor, E.; Yilgor, I. Critical parameters controlling the properties of monolithic poly(lactic acid) foams prepared by thermally induced phase separation. J. Polym. Sci. Part B-Polym. Phys. 2019, 57, 98–108. [Google Scholar] [CrossRef]

- Gay, S.; Lefebvre, G.; Bonnin, M.; Nottelet, B.; Boury, F.; Gibaud, A.; Calvignac, B. PLA scaffolds production from Thermally Induced Phase Separation: Effect of process parameters and development of an environmentally improved route assisted by supercritical carbon dioxide. J. Supercrit. Fluids 2018, 136, 123–135. [Google Scholar] [CrossRef]

- Chen, J.-S.; Tu, S.-L.; Tsay, R.-Y. A morphological study of porous polylactide scaffolds prepared by thermally induced phase separation. J. Taiwan Inst. Chem. Eng. 2010, 41, 229–238. [Google Scholar] [CrossRef]

- Kanno, T.; Uyama, H. Unique leafy morphology of poly(lactic acid) monoliths controlled via novel phase separation technology. RSC Adv. 2017, 7, 33726–33732. [Google Scholar] [CrossRef]

- Gandolfi, M.G.; Zamparini, F.; Degli Esposti, M.; Chiellini, F.; Aparicio, C.; Fava, F.; Fabbri, P.; Taddei, P.; Prati, C. Polylactic acid-based porous scaffolds doped with calcium silicate and dicalcium phosphate dihydrate designed for biomedical application. Mater. Sci. Eng. 2018, 82, 163–181. [Google Scholar] [CrossRef]

- Farzamfar, S.; Naseri-Nosar, M.; Sahrapeyma, H.; Ehterami, A.; Goodarzi, A.; Rahmati, M.; Lakalayeh, G.A.; Ghorbani, S.; Vaez, A.; Salehi, M. Tetracycline hydrochloride-containing poly (epsilon-caprolactone)/poly lactic acid scaffold for bone tissue engineering application: In vitro and in vivo study. Int. J. Polym. Mater. Polym. Biomater. 2019, 68, 472–479. [Google Scholar] [CrossRef]

- Carfì Pavia, F.; Palumbo, F.S.; La Carrubba, V.; Bongiovì, F.; Brucato, V.; Pitarresi, G.; Giammona, G. Modulation of physical and biological properties of a composite PLLA and polyaspartamide derivative obtained via thermally induced phase separation (TIPS) technique. Mater. Sci. Eng. C 2016, 67, 561–569. [Google Scholar] [CrossRef]

- La Carrubba, V.; Pavia, F.C.; Brucato, V.; Piccarolo, S. PLLA/PLA scaffolds prepared via Thermally Induced Phase Separation (TIPS): Tuning of properties and biodegradability. Int. J. Mater. Form. 2008, 1, 619–622. [Google Scholar] [CrossRef]

- Salehi, M.; Bastami, F.; Rad, M.R.; Nokhbatolfoghahaei, H.; Paknejad, Z.; Nazeman, P.; Hassani, A.; Khojasteh, A. Investigation of cell-free poly lactic acid/nanoclay scaffolds prepared via thermally induced phase separation technique containing hydroxyapatite nanocarriers of erythropoietin for bone tissue engineering applications. Polym. Adv. Technol. 2021, 32, 670–680. [Google Scholar] [CrossRef]

- Dong, X.; Lu, D.; Harris, T.A.; Escobar, I. Polymers and solvents used in membrane fabrication: A review focusing on sustainable membrane development. Membranes 2021, 11, 309. [Google Scholar] [CrossRef]

- Guillen, G.R.; Pan, Y.J.; Li, M.H.; Hoek, E.M.V. Preparation and Characterization of Membranes Formed by Nonsolvent Induced Phase Separation: A Review. Ind. Eng. Chem. Res. 2011, 50, 3798–3817. [Google Scholar] [CrossRef]

- Hu, R.; Pi, Y.; Wang, N.; Zhang, Q.; Feng, J.; Xu, W.; Dong, X.; Wang, D.; Yang, H. The formation of the S-shaped edge-on lamellae on the thin porous polylactic acid membrane via phase separation induced by water microdroplets. J. Appl. Polym. Sci. 2016, 133, 43355. [Google Scholar] [CrossRef]

- Moriya, A.; Maruyama, T.; Ohmukai, Y.; Sotani, T.; Matsuyama, H. Preparation of poly (lactic acid) hollow fiber membranes via phase separation methods. J. Membr. Sci. 2009, 342, 307–312. [Google Scholar] [CrossRef]

- Al Tawil, E.; Monnier, A.; Nguyen, Q.T.; Deschrevel, B. Microarchitecture of poly(lactic acid) membranes with an interconnected network of macropores and micropores influences cell behavior. Eur. Polym. J. 2018, 105, 370–388. [Google Scholar] [CrossRef]

- Kang, Y.; Chen, P.; Shi, X.T.; Zhang, G.C.; Wang, C.L. Preparation of open-porous stereocomplex PLA/PBAT scaffolds and correlation between their morphology, mechanical behavior, and cell compatibility. RSC Adv. 2018, 8, 12933–12943. [Google Scholar] [CrossRef]

- Fotsing, E.R.; Rezabeigi, E.; Ross, A.; Wood-Adams, P.M.; Drew, R. Acoustical characteristics of ultralight polylactic acid foams fabricated via solution phase inversion. J. Porous Mater. 2019, 26, 1781–1794. [Google Scholar] [CrossRef]

- Liu, W.; Huang, N.; Yang, J.; Peng, L.; Li, J.; Chen, W. Characterization and application of porous polylactic acid films prepared by nonsolvent-induced phase separation method. Food Chem. 2022, 373, 131525. [Google Scholar] [CrossRef]

- Li, G.; Wang, L.; Lei, X.; Peng, Z.; Wan, T.; Maganti, S.; Huang, M.; Murugadoss, V.; Seok, I.; Jiang, Q.; et al. Flexible, yet robust polyaniline coated foamed polylactic acid composite electrodes for high-performance supercapacitors. Adv. Compos. Hybrid Mater. 2022, 5, 853–863. [Google Scholar] [CrossRef]

- Gao, A.; Zhang, G.; Zhao, S.; Cui, J.; Yan, Y. A solution for trade-off phenomenon based on symmetric-like membrane with nano-scale pore structure. Sep. Purif. Technol. 2019, 227, 115693. [Google Scholar] [CrossRef]

- Ampawan, S.; Phreecha, N.; Chantarak, S.; Chinpa, W. Selective separation of dyes by green composite membrane based on polylactide with carboxylated cellulose microfiber from empty fruit bunch. Int. J. Biol. Macromol. 2023, 225, 1607–1619. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.J.; Liu, F.; Yu, X.M.; Xue, L.X. Poly(Lactic Acid) Hemodialysis Membranes with Poly(Lactic Acid)-block-Poly(2-Hydroxyethyl Methacrylate) Copolymer As Additive: Preparation, Characterization, and Performance. ACS Appl. Mater. Interfaces 2015, 7, 17748–17755. [Google Scholar] [CrossRef]

- Liu, F.; Li, B.B.; Sun, D.; Li, F.G.; Pei, X.Y. The effect of chitosan (CS) coagulation bath on structure and performance of polylactic acid (PLA) microfiltration membrane. Korean J. Chem. Eng. 2022, 39, 1307–1315. [Google Scholar] [CrossRef]

- Shu, Z.; Zhang, C.C.; Yan, L.Z.; Lei, H.Q.; Peng, C.X.; Liu, S.; Fan, L.H.; Chu, Y.Y. Antibacterial and osteoconductive polycaprolactone/polylactic acid/nano-hydroxyapatite/Cu@ZIF-8 GBR membrane with asymmetric porous structure. Int. J. Biol. Macromol. 2023, 224, 1040–1051. [Google Scholar] [CrossRef] [PubMed]

- Hazra, R.S.; Dutta, D.; Mamnoon, B.; Nair, G.; Knight, A.; Mallik, S.; Ganai, S.; Reindl, K.; Jiang, L.; Quadir, M. Polymeric Composite Matrix with High Biobased Content as Pharmaceutically Relevant Molecular Encapsulation and Release Platform. ACS Appl. Mater. Interfaces 2021, 13, 40229–40248. [Google Scholar] [CrossRef]

- Thiangtham, S.; Runt, J.; Saito, N.; Manuspiya, H. Fabrication of biocomposite membrane with microcrystalline cellulose (MCC) extracted from sugarcane bagasse by phase inversion method. Cellulose 2020, 27, 1367–1384. [Google Scholar] [CrossRef]

- Moriya, A.; Shen, P.; Ohmukai, Y.; Maruyama, T.; Matsuyama, H. Reduction of fouling on poly(lactic acid) hollow fiber membranes by blending with poly(lactic acid)–polyethylene glycol–poly(lactic acid) triblock copolymers. J. Membr. Sci. 2012, 415–416, 712–717. [Google Scholar] [CrossRef]

- Han, W.; Ren, J.; Xuan, H.; Ge, L. Controllable degradation rates, antibacterial, free-standing and highly transparent films based on polylactic acid and chitosan. Colloids Surf. A 2018, 541, 128–136. [Google Scholar] [CrossRef]

- Song, X.; Yin, X.; Cai, Y.; Wei, Q.; Liu, W. Preparation and characterization of PLA porous film by breath figure method. New Chem. Mater. 2018, 46, 59–63. [Google Scholar]

- Hua, M.; Chen, D.; Xu, Z.; Fang, Y.; Song, Y. Fabrication of high-expansion, fully degradable polylactic acid-based foam with exponent oil/water separation. J. Appl. Polym. Sci. 2022, 139, e53234. [Google Scholar] [CrossRef]

- Lopresti, F.; Campora, S.; Tirri, G.; Capuana, E.; Carfì Pavia, F.; Brucato, V.; Ghersi, G.; La Carrubba, V. Core-shell PLA/Kef hybrid scaffolds for skin tissue engineering applications prepared by direct kefiran coating on PLA electrospun fibers optimized via air-plasma treatment. Mater. Sci. Eng. C 2021, 127, 112248. [Google Scholar] [CrossRef]

- Farahani, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Tayebi, L.; Mostafavi, E. Polylactic Acid Piezo-Biopolymers: Chemistry, Structural Evolution, Fabrication Methods, and Tissue Engineering Applications. J. Funct. Biomater. 2021, 12, 71. [Google Scholar] [CrossRef]

- Nie, T.; Xue, L.; Ge, M.; Ma, H.; Zhang, J. Fabrication of poly(L-lactic acid) tissue engineering scaffolds with precisely controlled gradient structure. Mater. Lett. 2016, 176, 25–28. [Google Scholar] [CrossRef]

- Pinto, A.M.; Moreira, S.; Gonçalves, I.C.; Gama, F.M.; Mendes, A.M.; Magalhães, F.D. Biocompatibility of poly (lactic acid) with incorporated graphene-based materials. Colloids Surf. B 2013, 104, 229–238. [Google Scholar] [CrossRef]

- Li, J.; Liu, F.; Yu, X.; Wu, Z.; Wang, Y.; Xiong, Z.; He, J. APTES assisted surface heparinization of polylactide porous membranes for improved hemocompatibility. RSC Adv. 2016, 6, 42684–42692. [Google Scholar] [CrossRef]

- Promnil, S.; Ruksakulpiwat, C.; Numpaisal, P.; Ruksakulpiwat, Y. Electrospun Poly(lactic acid) and Silk Fibroin Based Nanofibrous Scaffold for Meniscus Tissue Engineering. Polymers 2022, 14, 2435. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wang, H.; Chen, Q.; Gang, H.; Zhou, Y.; Gu, S.; Liu, X.; Xu, W.; Zhang, B.; Yang, H. Polylactic acid scaffold with directional porous structure for large-segment bone repair. Int. J. Biol. Macromol. 2022, 216, 810–819. [Google Scholar] [CrossRef]

- Eftekhari-pournigjeh, F.; Saeed, M.; Rajabi, S.; Tamimi, M.; Pezeshki-Modaress, M. Three-dimensional biomimetic reinforced chitosan/gelatin composite scaffolds containing PLA nano/microfibers for soft tissue engineering application. Int. J. Biol. Macromol. 2023, 225, 1028–1037. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Ning, F.; Wang, Y. Additive manufacturing of biodegradable iron-based particle reinforced polylactic acid composite scaffolds for tissue engineering. J. Mater. Process. Technol. 2021, 289, 116952. [Google Scholar] [CrossRef]

- Liu, R.T.; Zhang, S.Y.; Zhao, C.; Yang, D.; Cui, T.T.; Liu, Y.D.; Min, Y.G. Regulated Surface Morphology of Polyaniline/Polylactic Acid Composite Nanofibers via Various Inorganic Acids Doping for Enhancing Biocompatibility in Tissue Engineering. Nanoscale Res. Lett. 2021, 16, 4. [Google Scholar] [CrossRef]

- Oktay, B.; Ahlatcıoğlu Özerol, E.; Sahin, A.; Gunduz, O.; Ustundag, C. Production and characterization of PLA/HA/GO nanocomposite scaffold. Chem. Sel. 2022, 7, e202200697. [Google Scholar] [CrossRef]

- Bogdanova, A.; Pavlova, E.; Polyanskaya, A.; Volkova, M.; Biryukova, E.; Filkov, G.; Trofimenko, A.; Durymanov, M.; Klinov, D.; Bagrov, D. Acceleration of Electrospun PLA Degradation by Addition of Gelatin. Int. J. Mol. Sci. 2023, 24, 3535. [Google Scholar] [CrossRef] [PubMed]

- Kovaleva, P.A.; Pariy, I.O.; Chernozem, R.V.; Zadorozhnyy, M.Y.; Permyakova, E.S.; Kolesnikov, E.A.; Surmeneva, M.A.; Surmenev, R.A.; Senatov, F.S. Shape memory effect in hybrid polylactide-based polymer scaffolds functionalized with reduced graphene oxide for tissue engineering. Eur. Polym. J. 2022, 181, 111694. [Google Scholar] [CrossRef]

- Orafa, Z.; Irani, S.; Zamanian, A.; Bakhshi, H.; Nikukar, H.; Ghalandari, B. Coating of Laponite on PLA Nanofibrous for Bone Tissue Engineering Application. Macromol. Res. 2021, 29, 191–198. [Google Scholar] [CrossRef]

- Shan, X.; Huang, P.; Yang, L.; Feng, R.; Wang, Z. Robust polypropylene/ethylene-propylene-diene terpolymer thermoplastic vulcanizates film for green oil-water separation. J. Polym. Res. 2022, 29, 94. [Google Scholar] [CrossRef]

- Yin, Z.; Pan, Y.; Bao, M.; Li, Y. Superhydrophobic magnetic cotton fabricated under low carbonization temperature for effective oil/water separation. Sep. Purif. Technol. 2021, 266, 118535. [Google Scholar] [CrossRef]

- Zeng, X.; Zhao, L.; Fan, G.; Yan, C. Experimental study on the design of light phase outlets for a novel axial oil-water separator. Chem. Eng. Res. Des. 2021, 165, 308–319. [Google Scholar] [CrossRef]

- Yin, C.; Meng, Z. Evaluation of oil-water sepa tion performance of photocatalytic self-cleaning chitosan/aminated graphene/TiO2 superhydrophobic mesh membrane. Fresenius Environ.Bull. 2022, 31, 238–248. [Google Scholar]

- Mittag, A.; Rahman, M.M.; Hafez, I.; Tajvidi, M. Development of Lignin-Containing Cellulose Nanofibrils Coated Paper-Based Filters for Effective Oil-Water Separation. Membranes 2022, 13, 1. [Google Scholar] [CrossRef]

- Zhou, Z.; Liu, L.; Yuan, W. A superhydrophobic poly (lactic acid) electrospun nanofibrous membrane surface-functionalized with TiO2 nanoparticles and methyltrichlorosilane for oil/water separation and dye adsorption. New J. Chem. 2019, 43, 15823–15831. [Google Scholar] [CrossRef]

- Sun, X.; Xue, B.; Tian, Y.; Qin, S.; Xie, L. 3D porous poly (l-lactic acid) materials with controllable multi-scale microstructures and their potential application in oil-water separation. Appl. Surf. Sci. 2018, 462, 633–640. [Google Scholar] [CrossRef]

- Eang, C.; Opaprakasit, P. Electrospun Nanofibers with Superhydrophobicity Derived from Degradable Polylactide for Oil/Water Separation Applications. J. Polym. Environ. 2020, 28, 1484–1491. [Google Scholar] [CrossRef]

- Du, G.; Duan, Y.; Yuan, Q.; Hu, S. Preparation of PLA/rGO nanofiber membrane by electrospinning method and its application in oil-water separation. J. Funct. Mater. 2022, 53, 3162–3166. [Google Scholar] [CrossRef]

- Guo, Y.; Sun, X.; Xue, B.; Zhou, Y.; Xie, L.; Zheng, Q. Carbon quantum dots-driven surface morphology transformation towards superhydrophobic poly(lactic acid) film. Colloids Surf. A 2023, 656, 130547. [Google Scholar] [CrossRef]

- Zeng, Q.; Ma, P.; Su, X.; Lai, D.; Lai, X.; Zeng, X.; Li, H. Facile fabrication of superhydrophobic and magnetic poly (lactic acid) nonwoven fabric for oil–water separation. Ind. Eng. Chem. 2020, 59, 9127–9135. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, H.; Chen, Z.; Chen, N.; Pang, X.; Zhang, L.; Minari, T.; Liu, X.; Liu, H.; Chen, J.; et al. Recyclable oil-absorption foams via secondary phase separation. ACS Sustain. Chem. Eng. 2018, 6, 13834–13843. [Google Scholar] [CrossRef]

- Zhu, C.; Jiang, W.; Hu, J.; Sun, P.; Li, A.; Zhang, Q. Polylactic acid nonwoven fabric surface modified with stereocomplex crystals for recyclable use in oil/water separation. ACS Appl. Polym. Mater. 2020, 2, 2509–2516. [Google Scholar] [CrossRef]

- Wang, X.L.; Pan, Y.M.; Liu, X.H.; Liu, H.; Li, N.; Liu, C.T.; Schubert, D.W.; Shen, C.Y. Facile Fabrication of Superhydrophobic and Eco-Friendly Poly(lactic acid) Foam for Oil-Water Separation via Skin Peeling. ACS Appl. Mater. Interfaces 2019, 11, 14362–14367. [Google Scholar] [CrossRef]

- Mo, J.; Wang, Y.; Wang, J.; Zhao, J.; Ke, Y.; Han, S.; Gan, F.; Wang, L.; Ma, C. Hydrophobic/oleophilic polylactic acid electrospun fibrous membranes with the silicone semi-interpenetrated networks for oil-water separation. J. Mater. Sci. 2022, 57, 16048–16063. [Google Scholar] [CrossRef]

- Liu, W.; Wu, X.; Liu, S.; Cheng, X.; Zhang, C. CNT@LDH functionalized poly(lactic acid) membranes with super oil-water separation and real-time press sensing properties. Polym. Compos. 2022, 43, 6548–6559. [Google Scholar] [CrossRef]

- Nugraha, M.W.; Wirzal, M.D.H.; Ali, F.; Roza, L.; Sambudi, N.S. Electrospun polylactic acid/tungsten oxide/amino-functionalized carbon quantum dots (PLA/WO3/N-CQDs) fibers for oil/water separation and photocatalytic decolorization. J. Environ. Sci. Chem. Eng. 2021, 9, 106033. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Y.; Fu, Y. 3D hierarchical biobased gel electrolyte with superior ionic conductivity and flame resistance for suppressing lithium dendrites via alloying and sieving mechanisms. Composites Part B 2022, 230, 109501. [Google Scholar] [CrossRef]

- Khan, N.M.; Kufian, M.Z.; Samsudin, A.S. The Correlation of Free Ions with the Conduction Phase of 1-Ethyl-3-methylimidazolium Chloride in Gel Polymer Electrolyte-Based PMMA/PLA Blend Doped with LiBOB. J. Electron. Mater. 2023, 52, 4247–4260. [Google Scholar] [CrossRef]

- Wan, Y.; Yang, S.; Peng, M.; Gama, M.; Yang, Z.; Deng, X.; Zhou, J.; Ouyang, C.; Luo, H. Controllable synthesis of biomimetic nano/submicro-fibrous tubes for potential small-diameter vascular grafts. J Mater Chem B 2020, 8, 5694–5706. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.; Hang, C.; Ding, L.; Jia, L.; Tang, L.; Mou, L.; Qi, J.; Dong, R.; Zheng, W.; Zhang, Y.; et al. Electronic Blood Vessel. Matter 2020, 3, 1664–1684. [Google Scholar] [CrossRef]

- Domalik-Pyzik, P.; Morawska-Chochól, A. Preliminary Results on Heparin-Modified Double-Layered PCL and PLA-Based Scaffolds for Tissue Engineering of Small Blood Vessels. J. Funct. Biomater. 2022, 13, 11. [Google Scholar] [CrossRef] [PubMed]

- Khalifehzadeh, R.; Ciridon, W.; Ratner, B.D. Surface fluorination of polylactide as a path to improve platelet associated hemocompatibility. Acta Biomater. 2018, 78, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Leyva-Verduzco, A.A.; Castillo-Ortega, M.M.; Chan-Chan, L.H.; Silva-Campa, E.; Galaz-Méndez, R.; Vera-Graziano, R.; Encinas-Encinas, J.C.; Del Castillo-Castro, T.; Rodríguez-Félix, D.E.; Santacruz-Ortega, H. Electrospun tubes based on PLA, gelatin and genipin in different arrangements for blood vessel tissue engineering. Polym. Bull. 2020, 77, 5985–6003. [Google Scholar] [CrossRef]

- Medina-Gonzalez, Y.; Aimar, P.; Lahitte, J.-F.; Remigy, J. Towards green membranes: Preparation of cellulose acetate ultrafiltration membranes using methyl lactate as a biosolvent. Int. J. Sustain. Eng. 2011, 4, 75–83. [Google Scholar] [CrossRef]

- Ratti, R. Ionic liquids: Synthesis and applications in catalysis. Adv. Chem 2014, 2014, 729842. [Google Scholar] [CrossRef]

- Rogers, R.D.; Seddon, K.R. Ionic liquids—Solvents of the future? Science 2003, 302, 792–793. [Google Scholar] [CrossRef] [PubMed]

| PLA Porous Membranes | Properties |

|---|---|

| advantage [10,11,12,13] | Low relative density |

| High specific surface area | |

| Excellent thermal insulation | |

| Good permeability | |

| Biodegradable and biocompatibility | |

| Limitation [14,15] | Low tensile strength |

| High brittleness | |

| Poor heat resistance |

| Polymer | Solvent | Voltage (kV) | Distance (cm) | Pore Size (μm) | Ref. |

|---|---|---|---|---|---|

| PVA/PLA | Water CHL/DMF | 16 | 15 | 0.69 ± 0.09 | [42] |

| PLA | Ac/DMF | 25 | 25 | 0.315 ± 0.246 | [46] |

| PLA/PCL | MC/DMF | 12 | 15 | / | [10] |

| PLA- KER | HFIP and Ac/CHL | 12 | 15 | 1.02 ± 0.16 | [47] |

| PLA/PCL | / | 15 | 15 | / | [48] |

| PLA/AgNWs | DCM | 18 | 15 | 0.25–0.66 | [49] |

| PLA | CHL | 20 | 12 | 0.034–0.143 | [50] |

| PLA/PANI | CHL | 25 | 20 | / | [51] |

| PLA/HA | HFIP | 12 | 20 | 1.41–1.44 | [52] |

| PLA/PVA | CHL/DCM | 17.7 | / | 0.1–0.35 | [21] |

| PLA/TPU | CHL/DMF | 16 | 16 | 0.6417 ± 0.128 | [53] |

| PLA | CHL/Ac | 15 | 15 | <3 | [54] |

| PLA/Starch | CHL | 6 | 15 | 2 | [55] |

| PLA | DCM | 25 | 15 | 0.1~0.16 | [56] |

| Polymer | Solvent | Ambient Humidity (%) | Pore Size (μm) | Degree of Order | Ref. |

|---|---|---|---|---|---|

| PLA | DCM | 80%–85% | 11.05–29.11 | Normal | [65] |

| PM-b-PLA | DCM | 95% | 4.8 | Normal | [58] |

| PLA-b-PS | DCM | / | 0.9~1.2 | High | [59] |

| H-PLA/GST | DCM | 95% | 3.2 ± 2.5 | Normal | [12] |

| PLA/CS/BSA | CHL | / | <10 | Normal | [67] |

| PtBA90-b-PFNEMA/PLA | CHL | 80% | 2.1 | High | [68] |

| PLA/FAS-SiO2 | DCM | 56% | 1~1.8 | Low | [60] |

| PLLA/CQD | CHL | 60% | 1.85~30.59 | Normal | [66] |

| PLA | CHL | 99.9% | 3~4 | Normal | [69] |

| PLA | CHL | 75% | 2.0~2.8 | High | [70] |

| PEG-PLA | CHL | 70–80% | 0.87 | Normal | [71] |

| PLGA | DCM | 70% | 1.4~2.5 | Normal | [72] |

| Polymer | Diluent | Extractant | Pore Size (μm) | Porosity (%) | Ref. |

|---|---|---|---|---|---|

| PLLA | 1,4-dioxane | Water | 3~10 | / | [88] |

| PLA | 1,4-dioxane/DMAC | ethanol | 0.3~0.5 | 87.6 ± 0.4 | [90] |

| PLA | THF/water | ethanol | 7.2~20.3 | 81.4~88.8 | [91] |

| PLA | THF/MeOH | ethanol | 0.17~1.44 | 81.4~90.6 | [92] |

| PLA | 1,4-dioxane | ethanol | 26 ± 7 | 87.3 | [93] |

| PLA | 1,4-dioxane/water | / | / | >70 | [94] |

| PLLA | 1,4-dioxane/2-butanone/water | / | 1.1~28.6 | 90–93% | [95] |

| PLA/CaSi/DCPD | CHL | ethanol | / | 92.4~93.8 | [96] |

| PCL/PLA/TCH | 1,4-dioxane | / | 78.57~81.53 | [97] | |

| PLLA | 1,4-dioxane/DMAC | ethanol | / | 46.9~83% | [89] |

| PLLA/PHEA-PLA | dioxane and deionised water | water | 1–2 | / | [98] |

| PLLA/PLA | dioxane/water | ethylalcohol | / | 87~92% | [99] |

| PLA/nanoclay | 1,4-dioxane | / | / | 80% | [100] |

| Method | The Formation Mechanism of Pores | Advantage | Disadvantage |

|---|---|---|---|

| Electrospinning [10,42,46,47] | Competition between electrostatic interactions and surface tension | The process is easy to control | Wide pore size distribution |

| Water droplet template method [12,59,65,119] | Low-boiling-point solvents evaporate, water droplets condense | The ordered porous structure can be formed at room temperature | Many influencing factors, difficult to control |

| TIPS [90,91,92,93] | The sites occupied by the diluent become micropores after their removal | Controlled pore structure and shape | Choosing the diluent is difficult, energy consumption is relatively high |

| NIPS [11,13,110,114] | Solvent–non-solvent exchange | Room temperature, diverse pore structure | The shape of the hole is not easy to control |

| Polymer | Membrane Preparation Method | Hydrophilicity (°) | Application | Ref. |

|---|---|---|---|---|

| PLA/Kef | Electrospinning | / | Skin tissue engineering | [121] |

| PLA/ZrO2 | Air-jet spinning technique (AJS) | / | Bone tissue engineering | [17] |

| PLA/Chitosan/gelatin | Centrifugally spinning | 99–110 | Soft tissue engineering | [128] |

| PLA/Iron | Fused filament fabrication | 70.9–96.5 | Bone tissue engineering | [129] |

| PANI/PLA | Electrospinning | 36.7–61.6 | Tissue engineering | [130] |

| PLA/SF | Electrospinning | 112.81–142.49 | Meniscus tissue engineering | [126] |

| PLA/HA/GO | Electrospinning | / | Tissue engineering | [131] |

| PLA/Gelatin | Electrospinning | 135 ± 4 | Polyester tissue engineering | [132] |

| PLA-PCL/rGO | Electrospinning | / | Tissue engineering | [133] |

| PLA/LAP/PEO | Electrospinning | 26–111 | Bone tissue engineering | [134] |

| Absorbents | Membrane Preparation Method | Water Contact Angle (°) | Absorption Capacity (g/g) | Ref. |

|---|---|---|---|---|

| AKD-dipped PLA/Gly | Electrospinning | 163 | 10 | [142] |

| PLA/rGO | Electrospinning | 139.2 | / | [143] |

| PDLA/PLLA | Non-solvent-induced phase separation | 168 | 9.7 | [144] |

| PLA/PDA | / | 151.7 | 36 | [145] |

| PLA | Secondary phase separation | 158 | 21 | [146] |

| PLLA/PDLA | Non-solvent-induced phase separation | 130.8 | 11 | [147] |

| PLA | Thermally and non-solvent-induced phase separation | 151 | 31.5 | [148] |

| PLA@silicone semi-IPN | Electrospinning | 158.7 | 83.9 | [149] |

| PLA/CNT@LDH | Electrospinning | 114.01 | 35 | [150] |

| PLA/WO3/N-CQDs | Electrospinning | 132.37 | 35.752 | [151] |

| PLA/TiO2/MTS | Electrospinning | 157.4 ± 0.9 | / | [140] |

| PLA/PDA/AgNPs | Electrospinning | 158.6 ± 1.2 | / | [29] |

| PLA/CNTs | Electrospinning | 157.3 | 114.01 | [25] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Liu, X.; Pu, X.; Shen, Z.; Xu, W.; Yang, J. Preparation Method and Application of Porous Poly(lactic acid) Membranes: A Review. Polymers 2024, 16, 1846. https://doi.org/10.3390/polym16131846

Zhao J, Liu X, Pu X, Shen Z, Xu W, Yang J. Preparation Method and Application of Porous Poly(lactic acid) Membranes: A Review. Polymers. 2024; 16(13):1846. https://doi.org/10.3390/polym16131846

Chicago/Turabian StyleZhao, Jinxing, Xianggui Liu, Xuelian Pu, Zetong Shen, Wenqiang Xu, and Jian Yang. 2024. "Preparation Method and Application of Porous Poly(lactic acid) Membranes: A Review" Polymers 16, no. 13: 1846. https://doi.org/10.3390/polym16131846

APA StyleZhao, J., Liu, X., Pu, X., Shen, Z., Xu, W., & Yang, J. (2024). Preparation Method and Application of Porous Poly(lactic acid) Membranes: A Review. Polymers, 16(13), 1846. https://doi.org/10.3390/polym16131846