In-Plane Compression Properties of Continuous Carbon-Fiber-Reinforced Composite Hybrid Lattice Structures by Additive Manufacturing

Abstract

1. Introduction

2. Methodology

2.1. Materials and Manufacturing Method

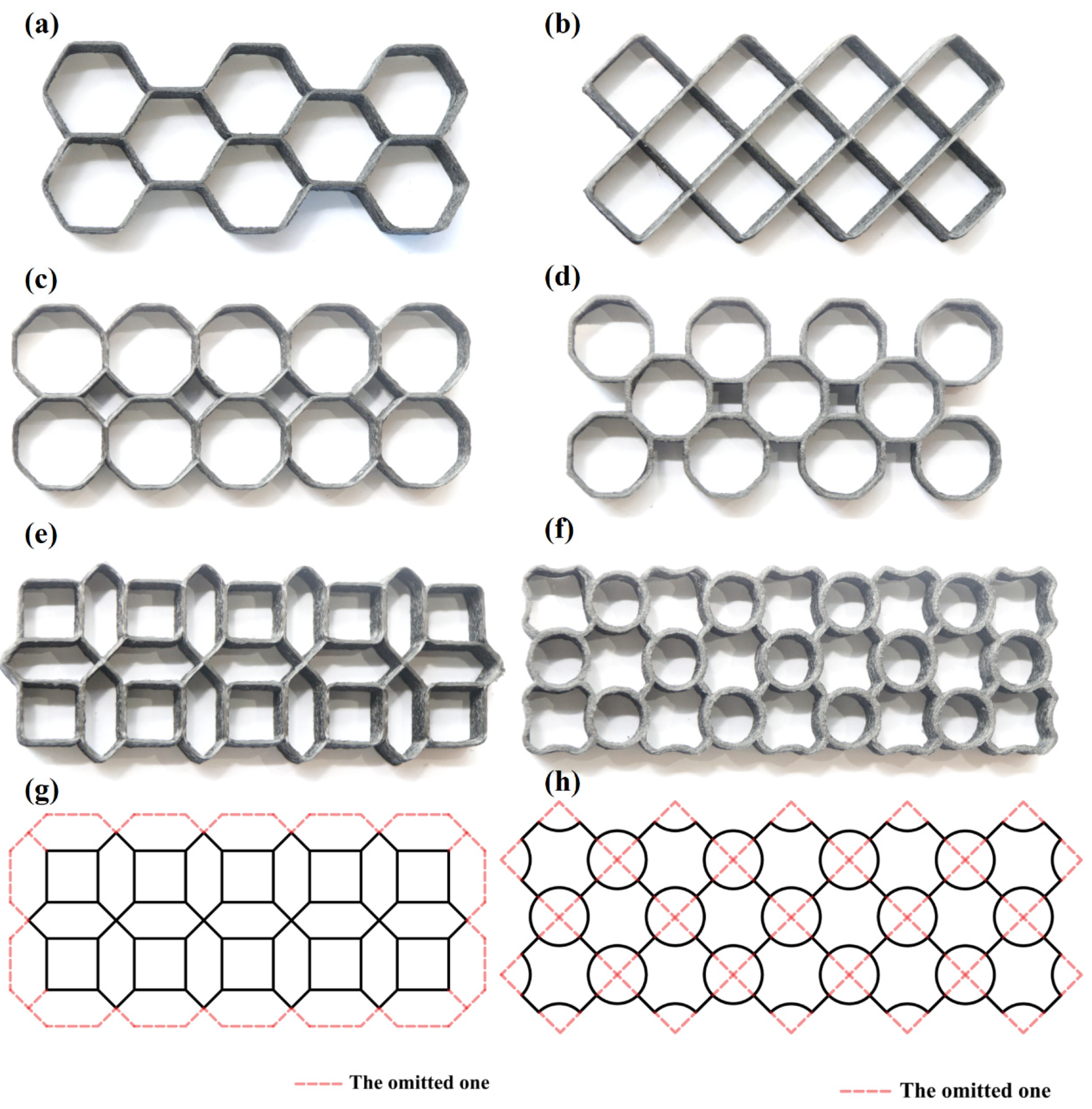

2.2. The Design of Lattice Structures

2.3. Path Arrangement

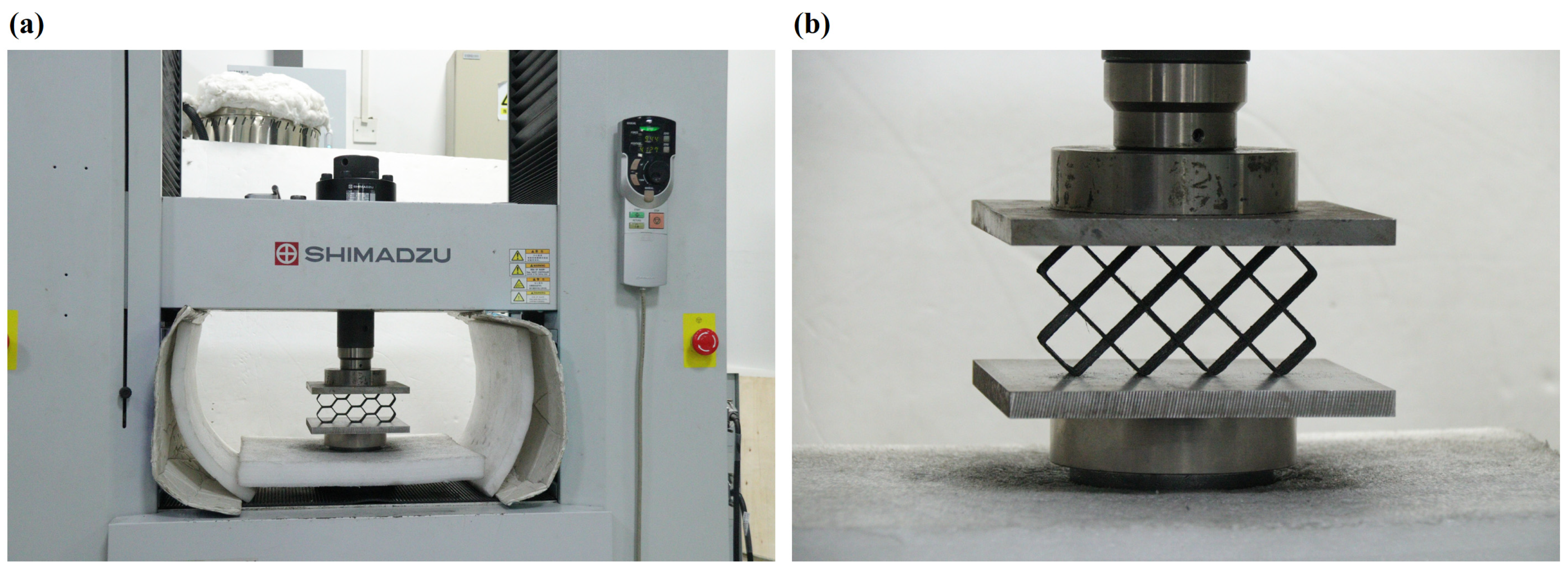

2.4. Test Equipment and Experimental Settings

3. Results and Discussions

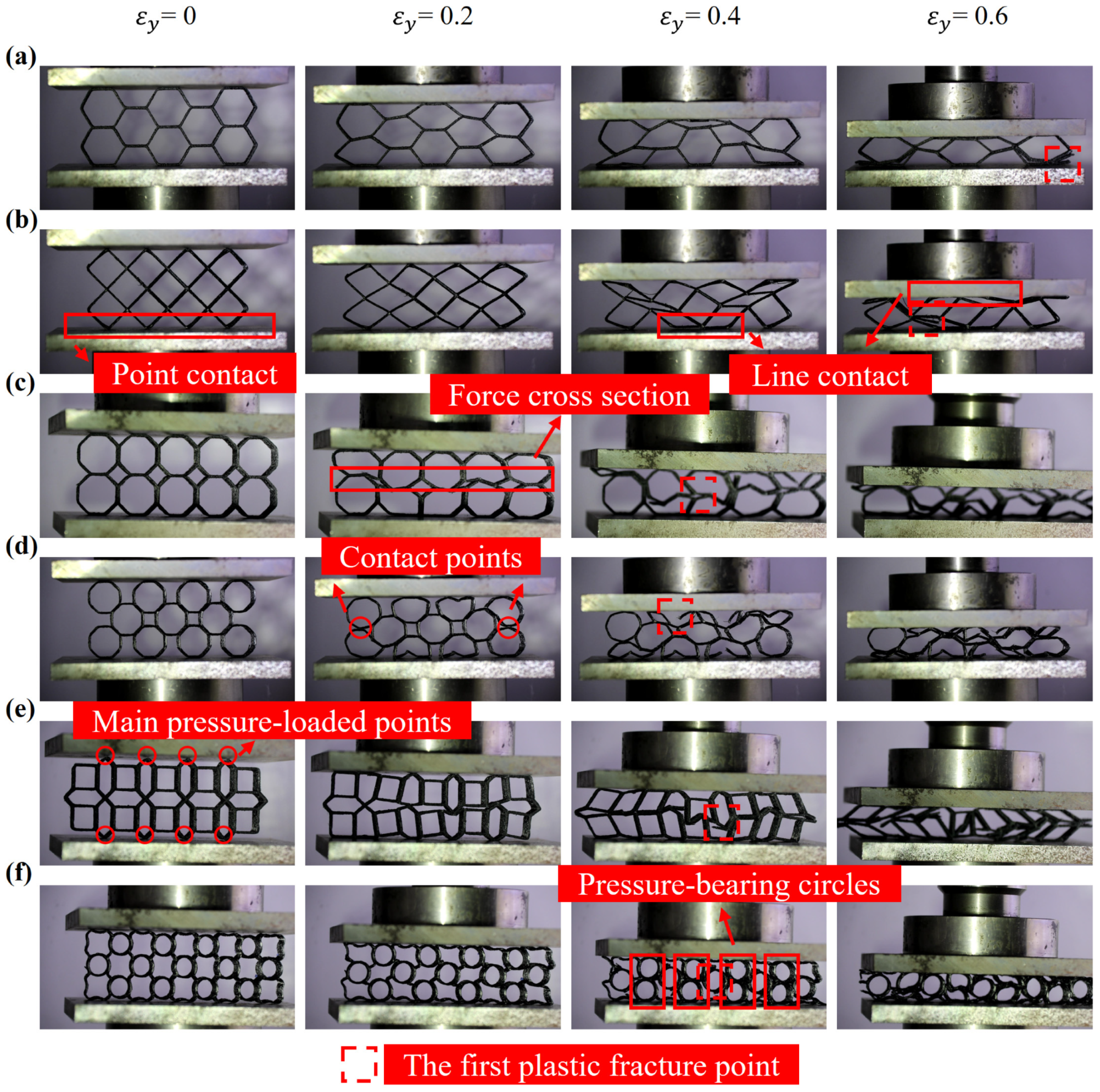

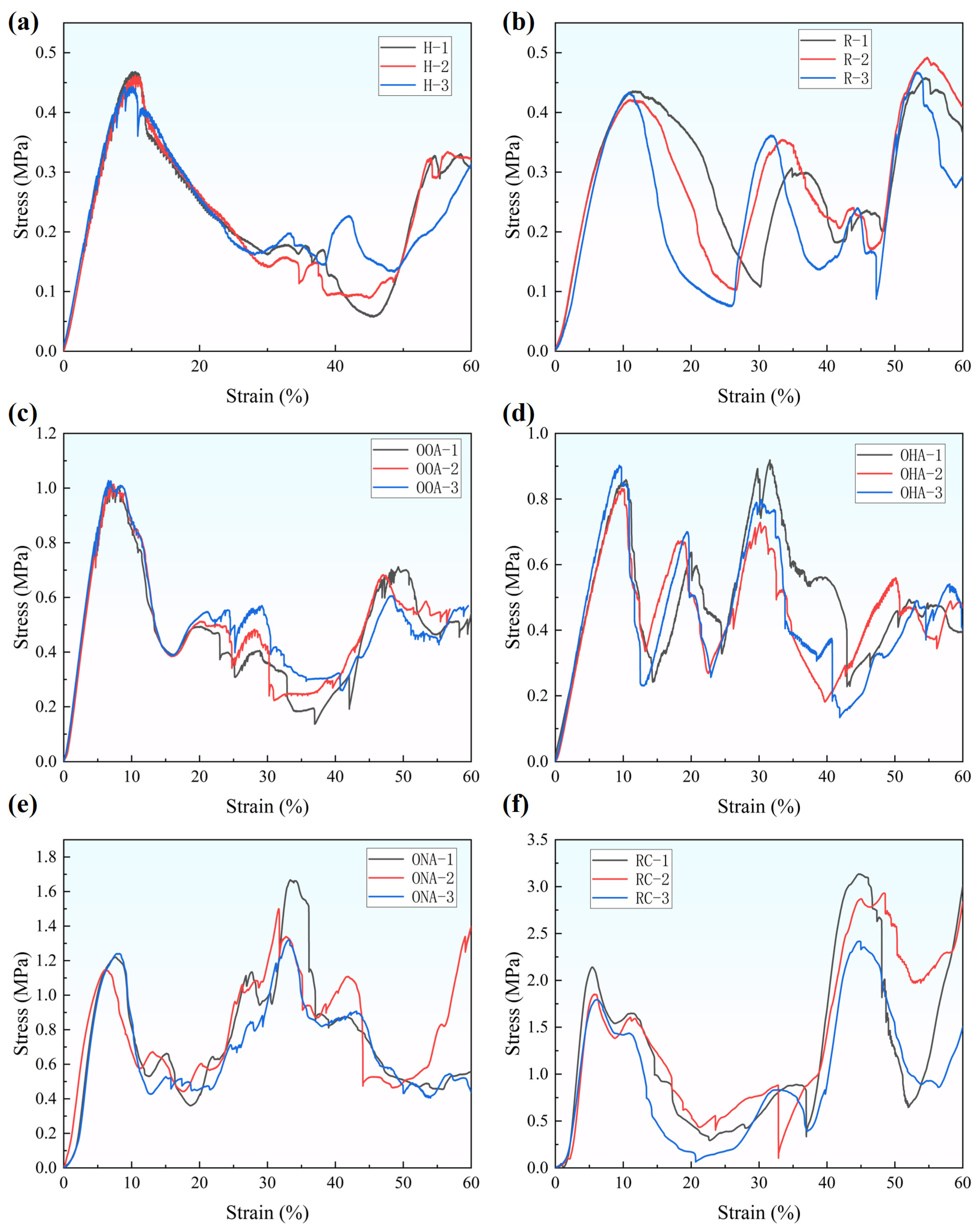

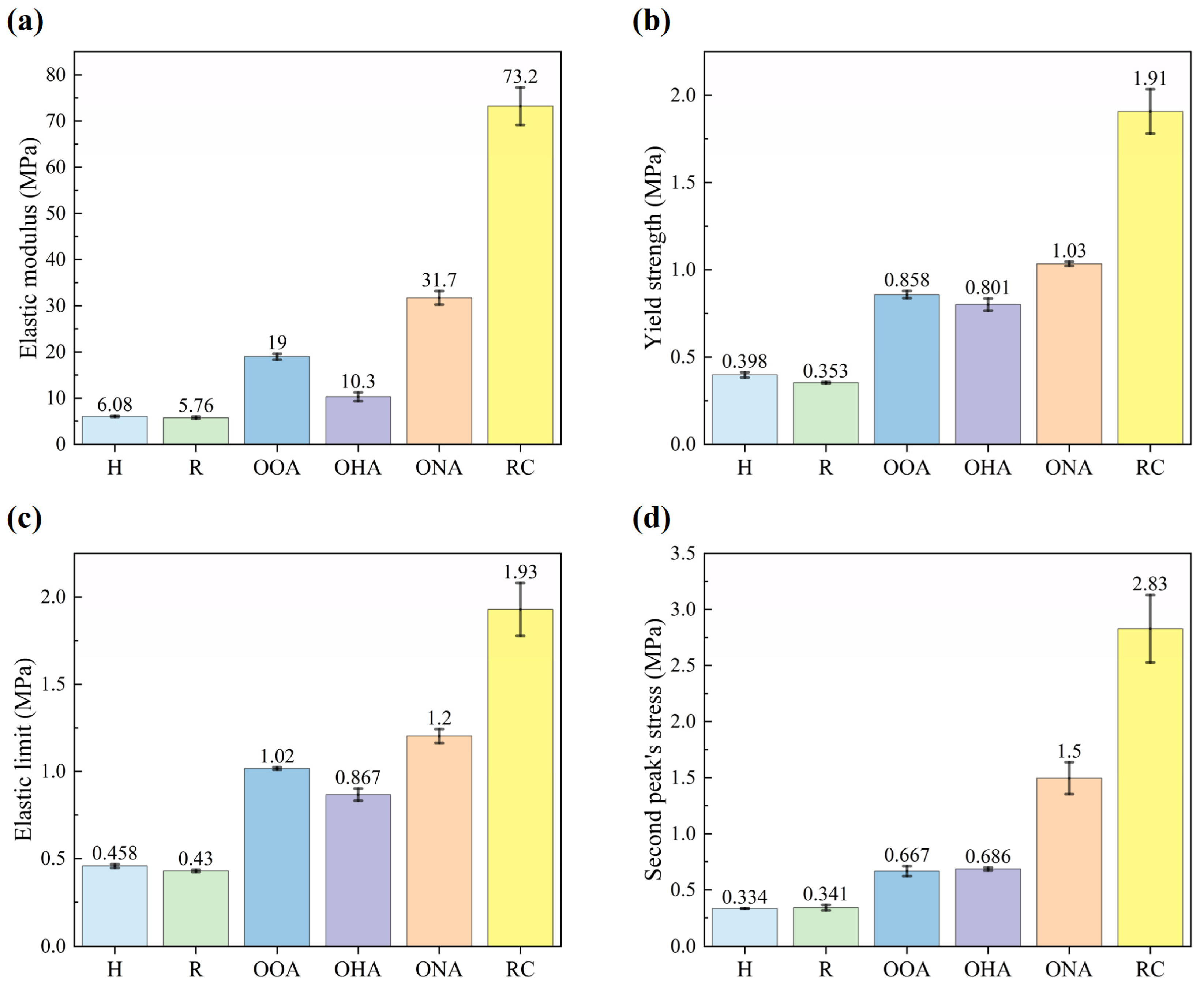

3.1. Quasi-Static Compressive Responses and Mechanical Properties

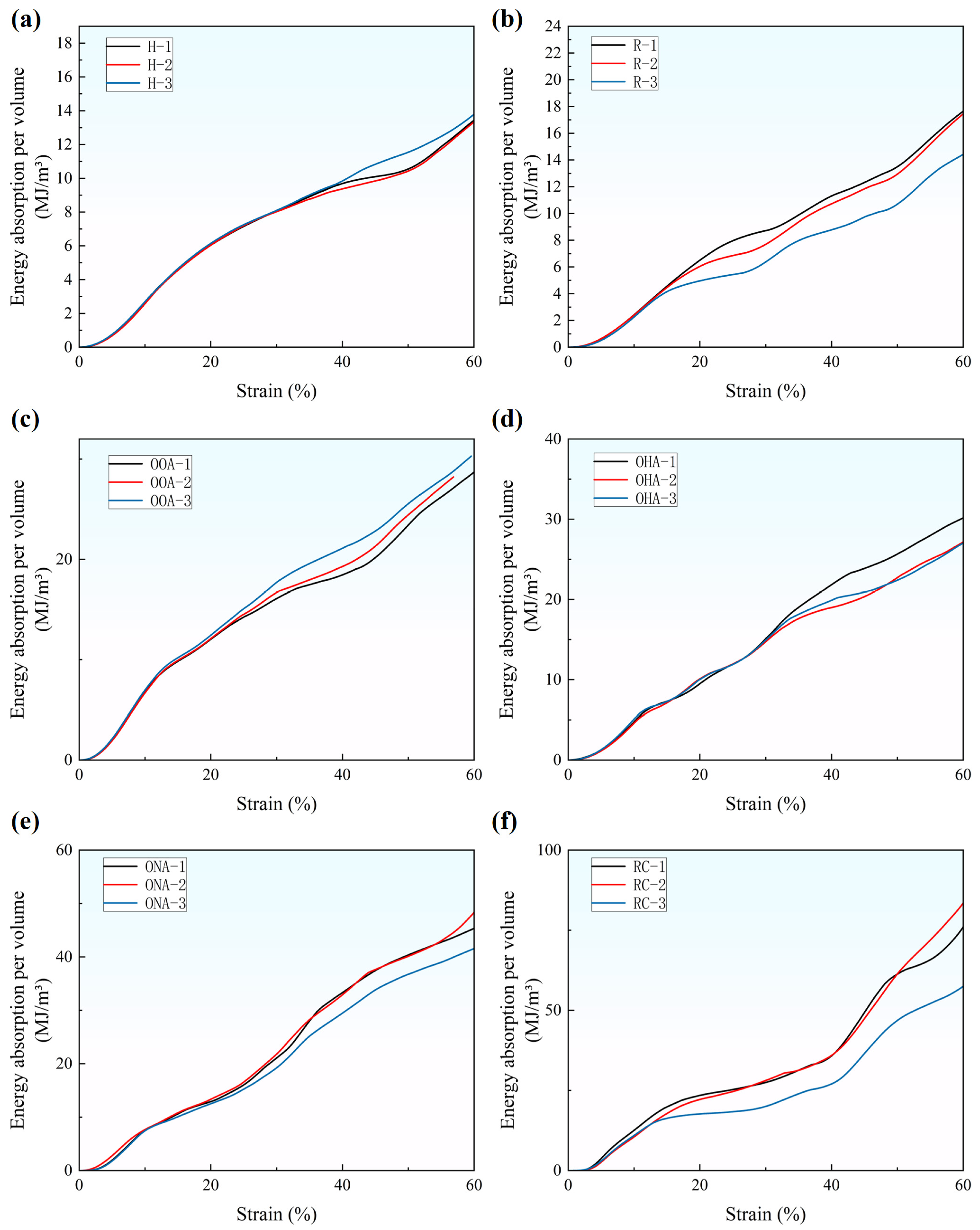

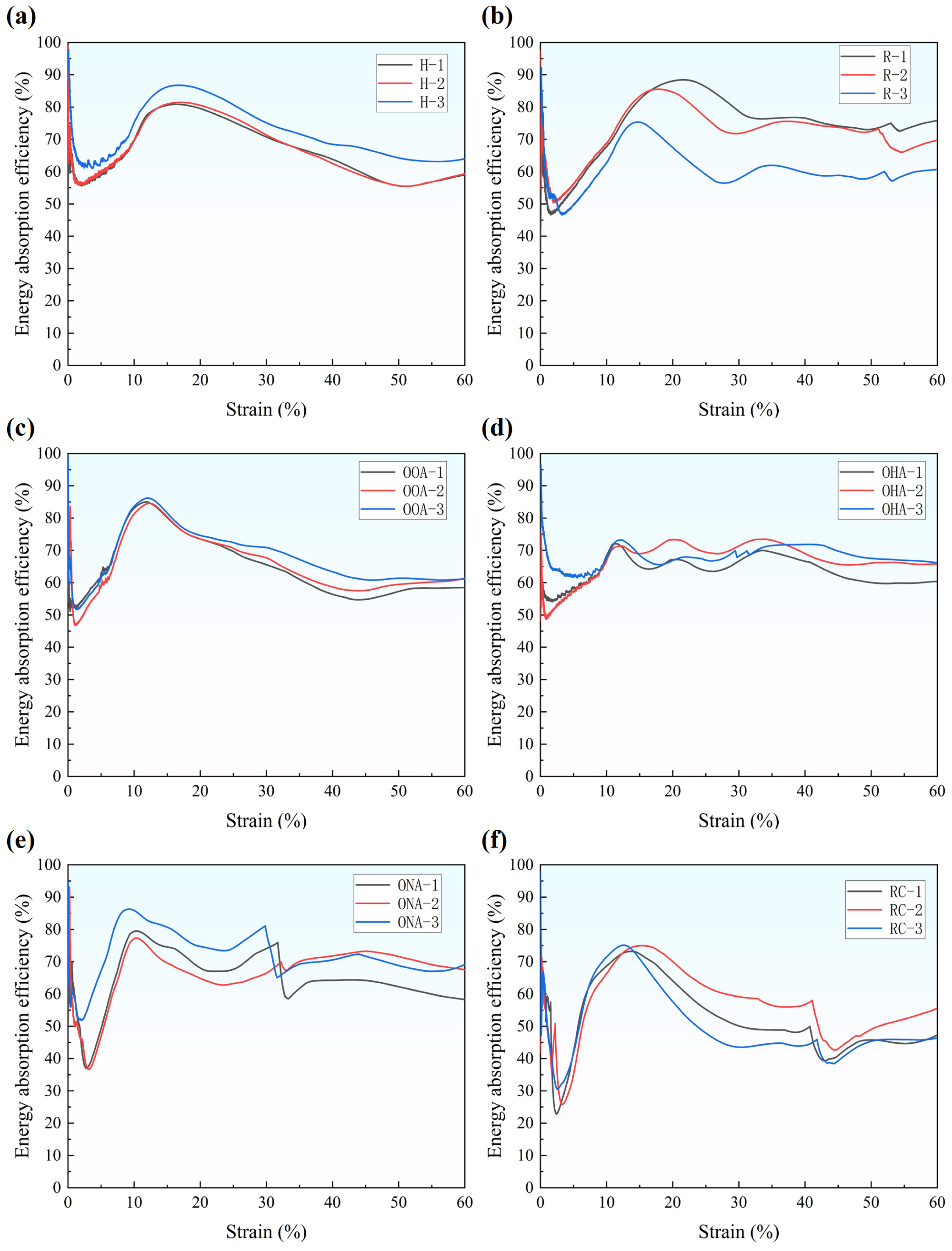

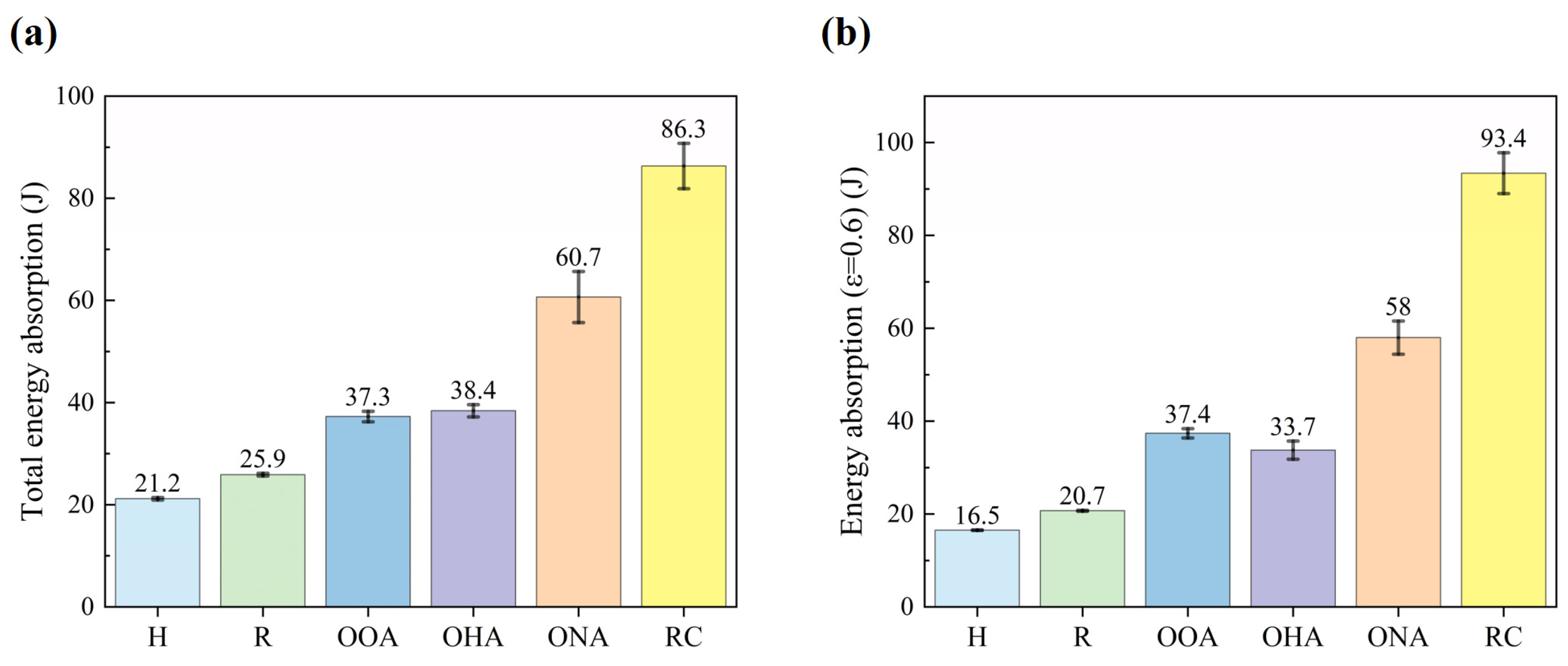

3.2. Energy Absorption Ability

4. Conclusions

- (1)

- Permutation and hybrid mode of lattice structures will influence the mechanical properties and energy absorption abilities. The size relationship of each parameter is similar, and the elastic modulus is influenced the most.

- (2)

- Multiple permutations have different characteristics of the energy absorption process and mechanical properties. The hypotenuse array and the orthogonal array both have high energy absorption efficiency. Although having similar parameters, the orthogonal array has a great enhancement of elastic modulus compared to the hypotenuse array.

- (3)

- The RC-type, while greatly reducing the filling rate of traditional circular structures, still has mechanical properties and energy absorption ability far exceeding that of single lattice structures such as hexagonal structures.

- (4)

- Hybrid lattice structures can significantly enhance the structure’s properties and exceed single lattice structures’ limit. They can also have more balanced properties compared to their constituent cells. It is also worth noting that a hybrid lattice structure will have lower energy absorption efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Balakrishnan, P.; John, M.J.; Pothen, L.; Sreekala, M.; Thomas, S. Natural fibre and polymer matrix composites and their applications in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 365–383. [Google Scholar]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Seydibeyoglu, M.O.; Mohanty, A.K.; Misra, M. Fiber Technology for Fiber-Reinforced Composites; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Yashas Gowda, T.; Sanjay, M.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer matrix-natural fiber composites: An overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Li, S.; Rao, Y.; Le Duigou, A.; Wang, K.; Ahzi, S. 3D printed continuous fiber reinforced composite lightweight structures: A review and outlook. Compos. Part B Eng. 2023, 250, 110450. [Google Scholar] [CrossRef]

- Jayan, J.S.; Appukuttan, S.; Wilson, R.; Joseph, K.; George, G.; Oksman, K. An introduction to fiber reinforced composite materials. In Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–24. [Google Scholar]

- Whitney, J.; Riley, M. Elastic properties of fiber reinforced composite materials. AIAA J. 1966, 4, 1537–1542. [Google Scholar] [CrossRef]

- Ansari, M.T.A.; Singh, K.K.; Azam, M.S. Fatigue damage analysis of fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2018, 37, 636–654. [Google Scholar] [CrossRef]

- Helou, M.; Kara, S. Design, analysis and manufacturing of lattice structures: An overview. Int. J. Comput. Integr. Manuf. 2018, 31, 243–261. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and optimization of lattice structures: A review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Beaman, J.; Bourell, D.L.; Seepersad, C.; Kovar, D. Additive manufacturing review: Early past to current practice. J. Manuf. Sci. Eng. 2020, 142, 110812. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Yang, L.; Zhou, L.; Lin, Y.; Hu, Y.; Yan, C.; Shi, Y. Failure mode analysis and prediction model of additively manufactured continuous carbon fiber-reinforced polylactic acid. Polym. Compos. 2024, 45, 7205–7221. [Google Scholar] [CrossRef]

- Hu, Y.; Lin, Y.; Yang, L.; Wu, S.; Tang, D.; Yan, C.; Shi, Y. Additive manufacturing of carbon fiber-reinforced composites: A review. Appl. Compos. Mater. 2024, 31, 353–398. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núnez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular solids. MRS Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure–Using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Yang, S. Advanced honeycomb designs for improving mechanical properties: A review. Compos. Part B Eng. 2021, 227, 109393. [Google Scholar] [CrossRef]

- Tao, W.; Leu, M.C. Design of lattice structure for additive manufacturing. In Proceedings of the 2016 International Symposium on Flexible Automation (ISFA), Cleveland, OH, USA, 1–3 August 2016; pp. 325–332. [Google Scholar]

- Jin, J.; Wu, S.; Yang, L.; Zhang, C.; Li, Y.; Cai, C.; Yan, C.; Shi, Y. Ni–Ti multicell interlacing Gyroid lattice structures with ultra-high hyperelastic response fabricated by laser powder bed fusion. Int. J. Mach. Tools Manuf. 2024, 195, 104099. [Google Scholar] [CrossRef]

- Monkova, K.; Vasina, M.; Zaludek, M.; Monka, P.P.; Tkac, J. Mechanical vibration damping and compression properties of a lattice structure. Materials 2021, 14, 1502. [Google Scholar] [CrossRef]

- Li, P.; Yang, F.; Bian, Y.; Zhang, S.; Wang, L. Deformation pattern classification and energy absorption optimization of the eccentric body centered cubic lattice structures. Int. J. Mech. Sci. 2021, 212, 106813. [Google Scholar] [CrossRef]

- Alomar, Z.; Concli, F. Compressive behavior assessment of a newly developed circular cell-based lattice structure. Mater. Des. 2021, 205, 109716. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, H.; Yu, C.; Wang, Z.; Huang, Y. Metastructure based broadband structural stealth with material-structure-function integration. Compos. Sci. Technol. 2024, 253, 110661. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Tian, R.; Xue, Q.; Guan, H.; Yang, X. Quasi-static compression and dynamic crushing behaviors of novel hybrid re-entrant auxetic metamaterials with enhanced energy-absorption. Compos. Struct. 2022, 288, 115399. [Google Scholar] [CrossRef]

- Jimbo, K.; Tateno, T. Design optimization of infill pattern structure and continuous fiber path for CFRP-AM: Simultaneous optimization of topology and fiber arrangement for minimum material cost. Precis. Eng. 2022, 74, 447–459. [Google Scholar] [CrossRef]

- Jin, Y.; He, Y.; Fu, G.; Zhang, A.; Du, J. A non-retraction path planning approach for extrusion-based additive manufacturing. Robot. Comput.-Integr. Manuf. 2017, 48, 132–144. [Google Scholar] [CrossRef]

- Sugiyama, K.; Matsuzaki, R.; Malakhov, A.V.; Polilov, A.N.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of optimized composites with variable fiber volume fraction and stiffness using continuous fiber. Compos. Sci. Technol. 2020, 186, 107905. [Google Scholar] [CrossRef]

- Park, K.-M.; Min, K.-S.; Roh, Y.-S. Design optimization of lattice structures under compression: Study of unit cell types and cell arrangements. Materials 2021, 15, 97. [Google Scholar] [CrossRef]

- Mu, Y.; Jin, Y.; Ji, H.; Luo, J.; Li, G.; Xu, M.; Li, H.; Deng, B.; Du, J. Mechanical performance of interpenetrating phase composites with multi-sheet lattice structures. Int. J. Mech. Sci. 2024, 276, 109369. [Google Scholar] [CrossRef]

- Pandelidi, C.; Bateman, S.; Piegert, S.; Hoehner, R.; Kelbassa, I.; Brandt, M. The technology of continuous fibre-reinforced polymers: A review on extrusion additive manufacturing methods. Int. J. Adv. Manuf. Technol. 2021, 113, 3057–3077. [Google Scholar] [CrossRef]

- San Ha, N.; Pham, T.M.; Tran, T.T.; Hao, H.; Lu, G. Mechanical properties and energy absorption of bio-inspired hierarchical circular honeycomb. Compos. Part B Eng. 2022, 236, 109818. [Google Scholar]

- Yang, L.; Wu, S.; Yan, C.; Chen, P.; Zhang, L.; Han, C.; Cai, C.; Wen, S.; Zhou, Y.; Shi, Y. Fatigue properties of Ti-6Al-4V Gyroid graded lattice structures fabricated by laser powder bed fusion with lateral loading. Addit. Manuf. 2021, 46, 102214. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah, A.Z. A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Wang, K.; Wang, D.; Liu, Y.; Gao, H.; Yang, C.; Peng, Y. Path Planning and Bending Behaviors of 3D Printed Continuous Carbon Fiber Reinforced Polymer Honeycomb Structures. Polymers 2023, 15, 4485. [Google Scholar] [CrossRef] [PubMed]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot. Comput.-Integr. Manuf. 2015, 34, 8–19. [Google Scholar] [CrossRef]

- Yamamoto, K.; Luces, J.V.S.; Shirasu, K.; Hoshikawa, Y.; Okabe, T.; Hirata, Y. A novel single-stroke path planning algorithm for 3D printers using continuous carbon fiber reinforced thermoplastics. Addit. Manuf. 2022, 55, 102816. [Google Scholar] [CrossRef]

- Li, Q.; Magkiriadis, I.; Harrigan, J.J. Compressive strain at the onset of densification of cellular solids. J. Cell. Plast. 2006, 42, 371–392. [Google Scholar] [CrossRef]

- Hyer, M.W.; White, S.R. Stress Analysis of Fiber-Reinforced Composite Materials; DEStech Publications, Inc.: Singapore, 2009. [Google Scholar]

- Yang, L.; Li, Y.; Wu, S.; Chen, P.; Wu, H.; Su, J.; Wang, H.; Liu, J.; Yan, C.; Shi, Y. Tailorable and predictable mechanical responses of additive manufactured TPMS lattices with graded structures. Mater. Sci. Eng. A 2022, 843, 143109. [Google Scholar] [CrossRef]

- Song, J.; Wang, Y.; Zhou, W.; Fan, R.; Yu, B.; Lu, Y.; Li, L. Topology optimization-guided lattice composites and their mechanical characterizations. Compos. Part B Eng. 2019, 160, 402–411. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X.; Wang, J.; Chen, T.; Wang, C.H. Crushing analysis for novel bio-inspired hierarchical circular structures subjected to axial load. Int. J. Mech. Sci. 2018, 140, 407–431. [Google Scholar] [CrossRef]

| /mm | n | /°C | /°C | |

|---|---|---|---|---|

| 0.2 | 100 | 45 | 210 | 90 |

| Types | L/mm | H/mm | t/mm | m/g |

|---|---|---|---|---|

| H | 119.00 | 52.85 | 19.62 | 12.4 |

| R | 110.51 | 54.75 | 19.50 | 12.4 |

| OOA | 121.34 | 49.32 | 19.90 | 13.6 |

| OHA | 114.40 | 53.37 | 19.81 | 12.9 |

| ONA | 127.60 | 50.15 | 20.10 | 18.8 |

| RC | 129.17 | 45.20 | 20.05 | 20.6 |

| Types | /KN | /mm | ||

|---|---|---|---|---|

| H | 1.71 | 0.54 | 0.75 | 39.38 |

| R | 2.09 | 0.64 | 0.74 | 40.36 |

| OOA | 2.74 | 1.16 | 0.61 | 32.13 |

| OHA | 2.98 | 1.06 | 0.68 | 36.16 |

| ONA | 3.23 | 1.92 | 0.63 | 31.51 |

| RC | 4.19 | 3.60 | 0.57 | 26.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, L.; Shi, J.; Chen, Z.; Wang, Z.; Zhi, Y.; Yang, L.; Xiao, X. In-Plane Compression Properties of Continuous Carbon-Fiber-Reinforced Composite Hybrid Lattice Structures by Additive Manufacturing. Polymers 2024, 16, 1882. https://doi.org/10.3390/polym16131882

Jin L, Shi J, Chen Z, Wang Z, Zhi Y, Yang L, Xiao X. In-Plane Compression Properties of Continuous Carbon-Fiber-Reinforced Composite Hybrid Lattice Structures by Additive Manufacturing. Polymers. 2024; 16(13):1882. https://doi.org/10.3390/polym16131882

Chicago/Turabian StyleJin, Lingqi, Jun Shi, Zhixin Chen, Zhiyang Wang, Yangfan Zhi, Lei Yang, and Xinyi Xiao. 2024. "In-Plane Compression Properties of Continuous Carbon-Fiber-Reinforced Composite Hybrid Lattice Structures by Additive Manufacturing" Polymers 16, no. 13: 1882. https://doi.org/10.3390/polym16131882

APA StyleJin, L., Shi, J., Chen, Z., Wang, Z., Zhi, Y., Yang, L., & Xiao, X. (2024). In-Plane Compression Properties of Continuous Carbon-Fiber-Reinforced Composite Hybrid Lattice Structures by Additive Manufacturing. Polymers, 16(13), 1882. https://doi.org/10.3390/polym16131882