Towards Sustainable Temperature Sensor Production through CO2-Derived Polycarbonate-Based Composites

Abstract

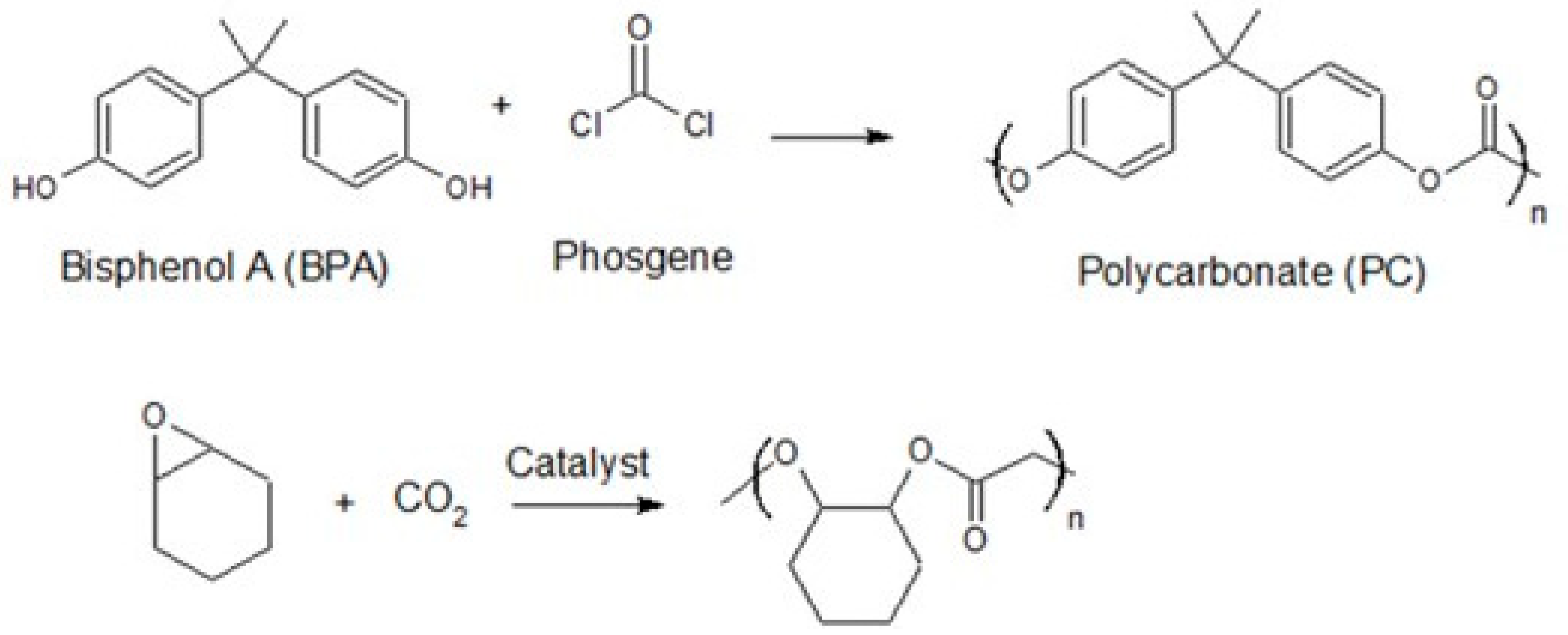

:1. Introduction

2. Materials and Methods

2.1. Reagents

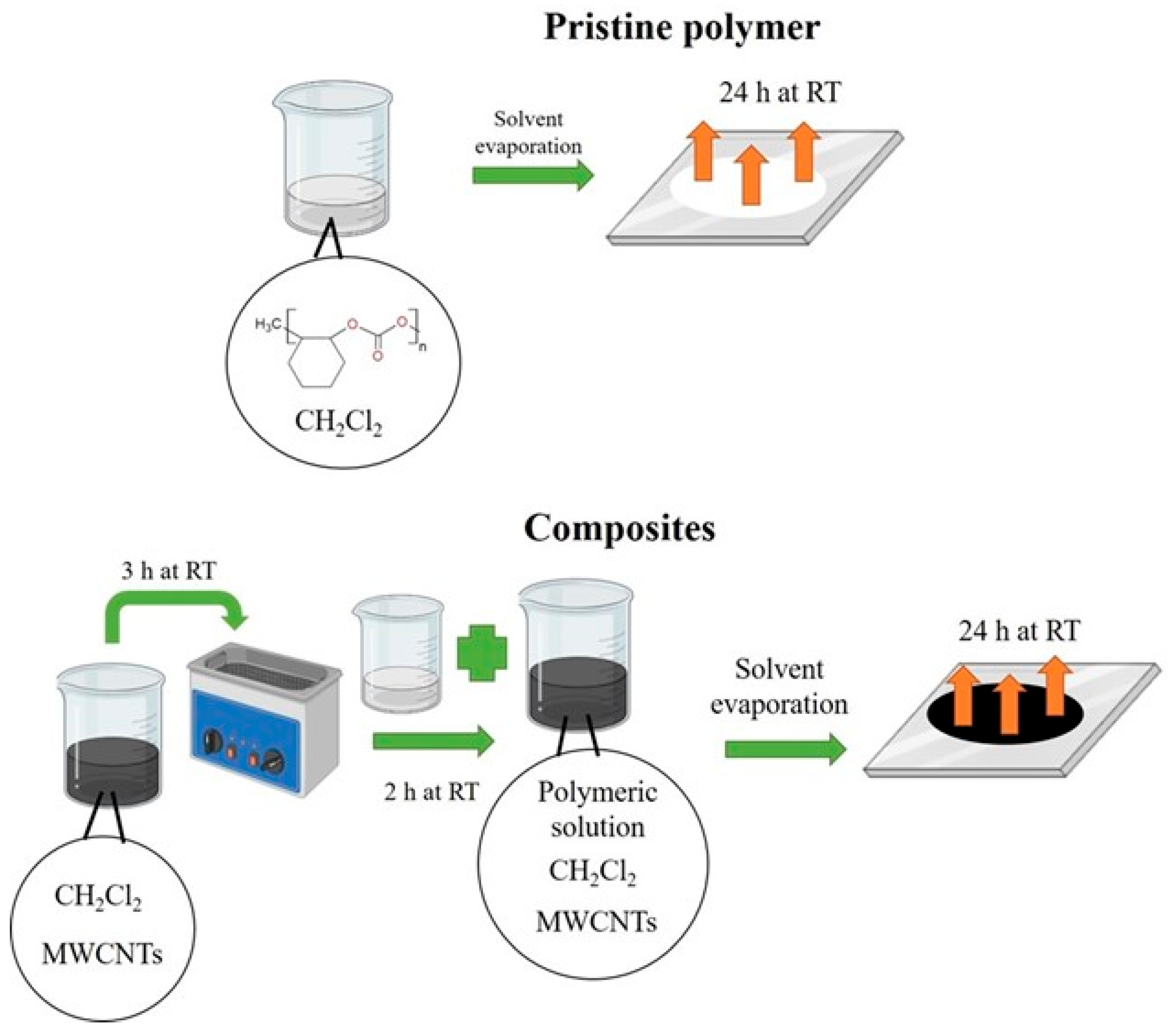

2.2. Composite Films Processing

2.3. Characterization

3. Results

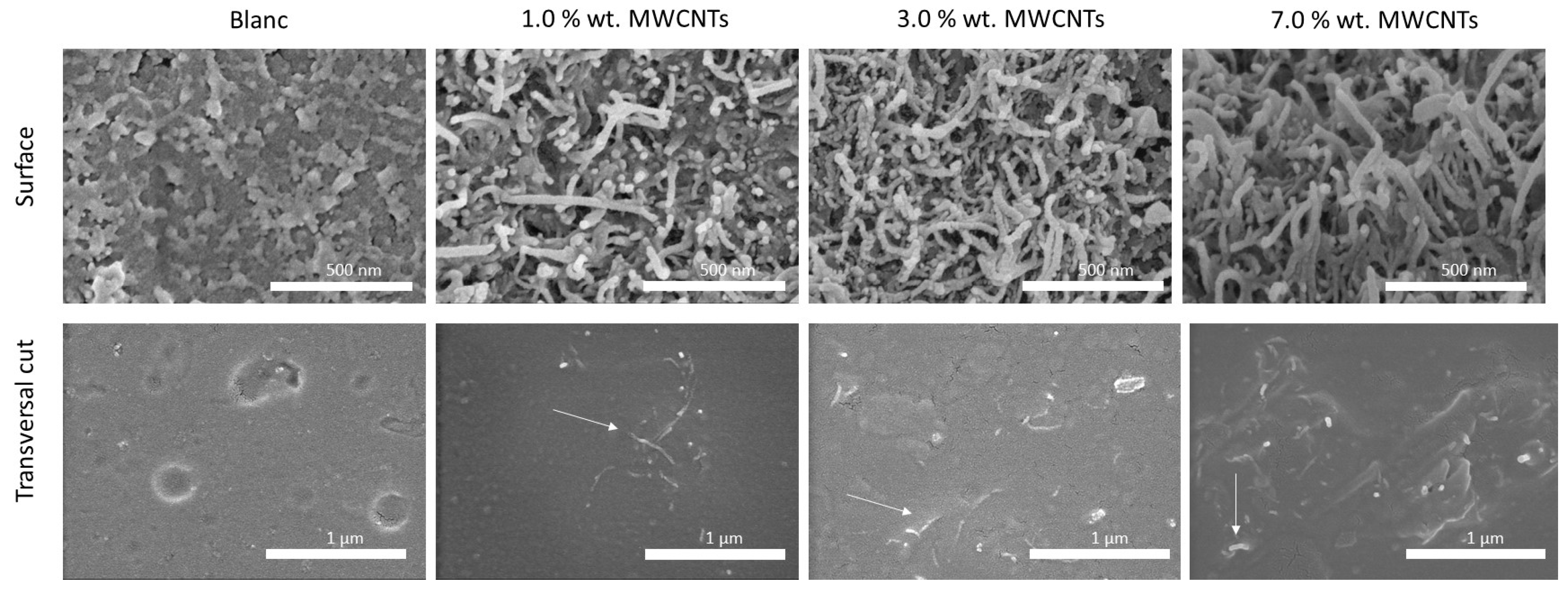

3.1. Morphological and Chemical Characteristics

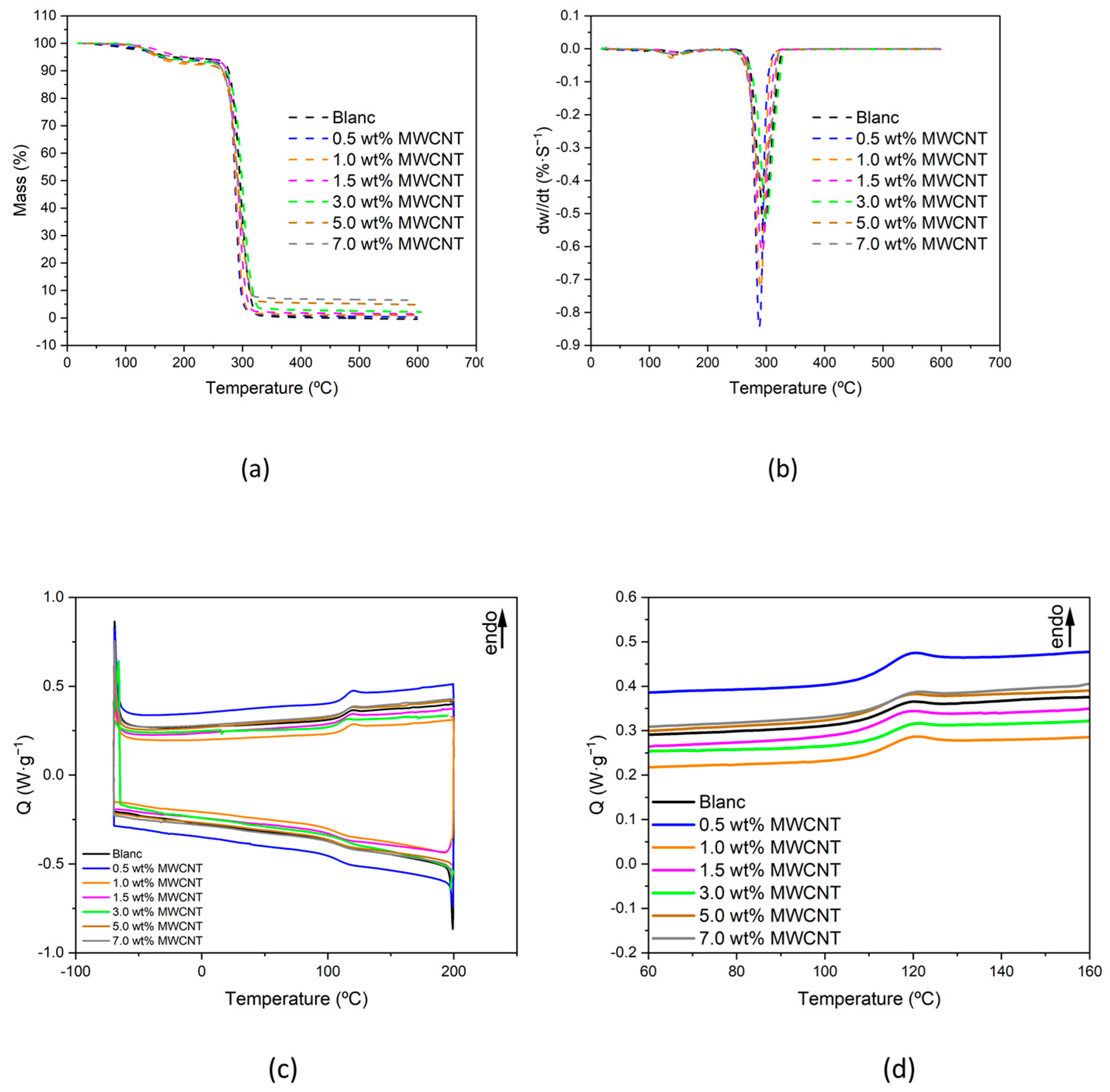

3.2. Thermal Analysis

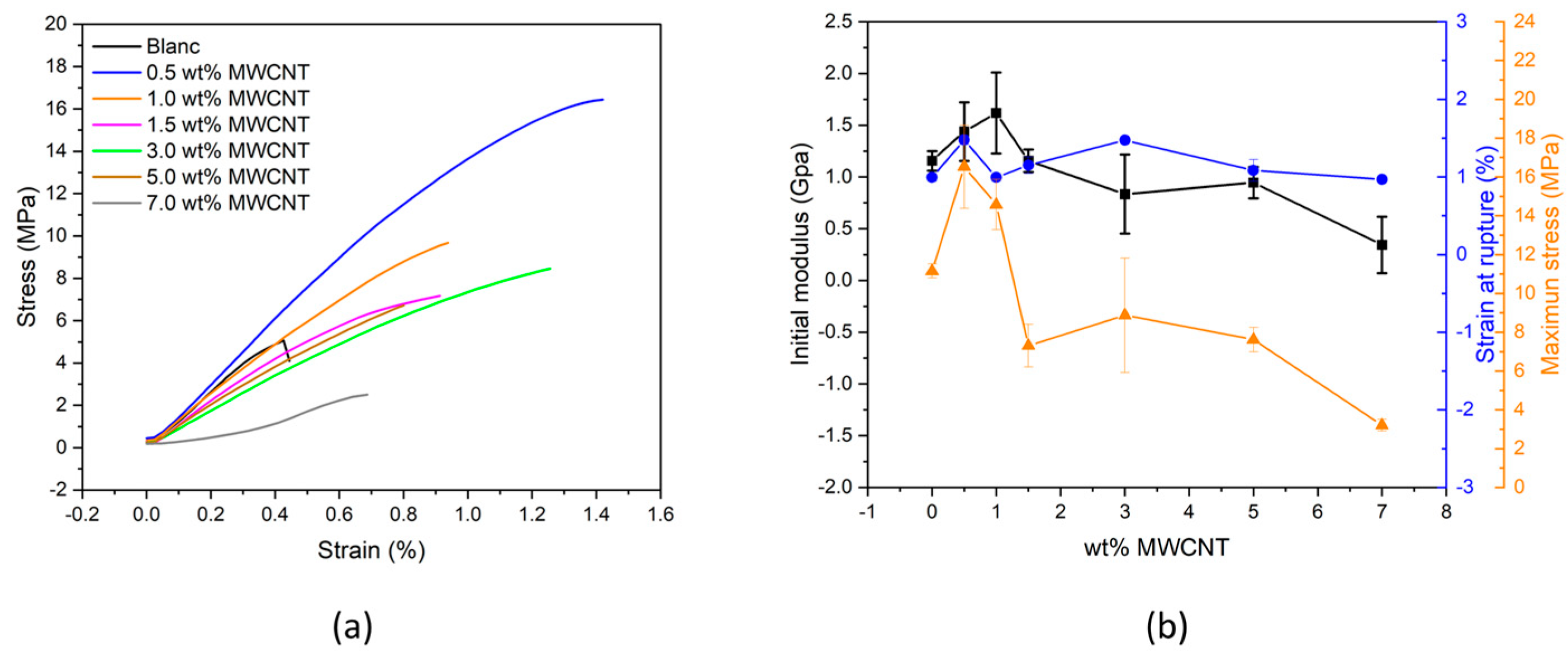

3.3. Mechanical Properties

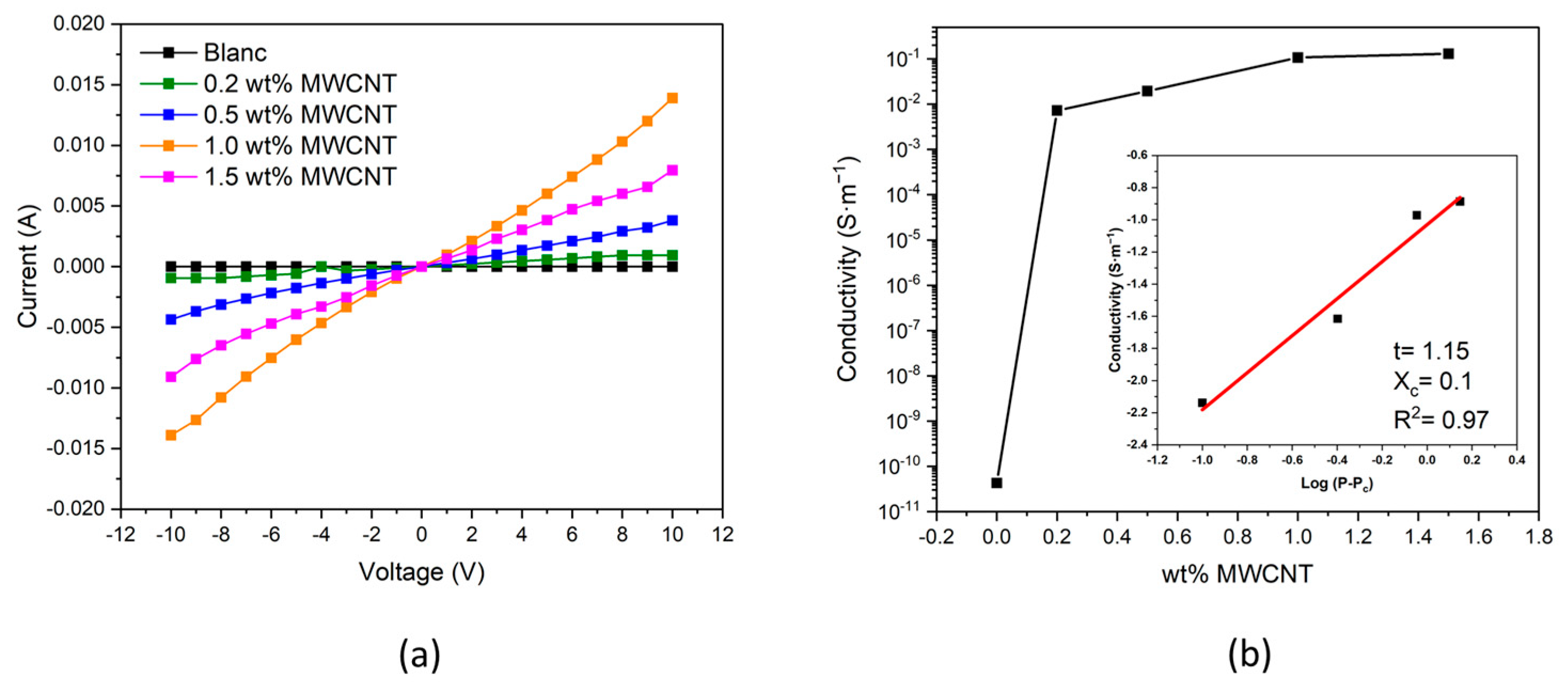

3.4. Electrical Properties

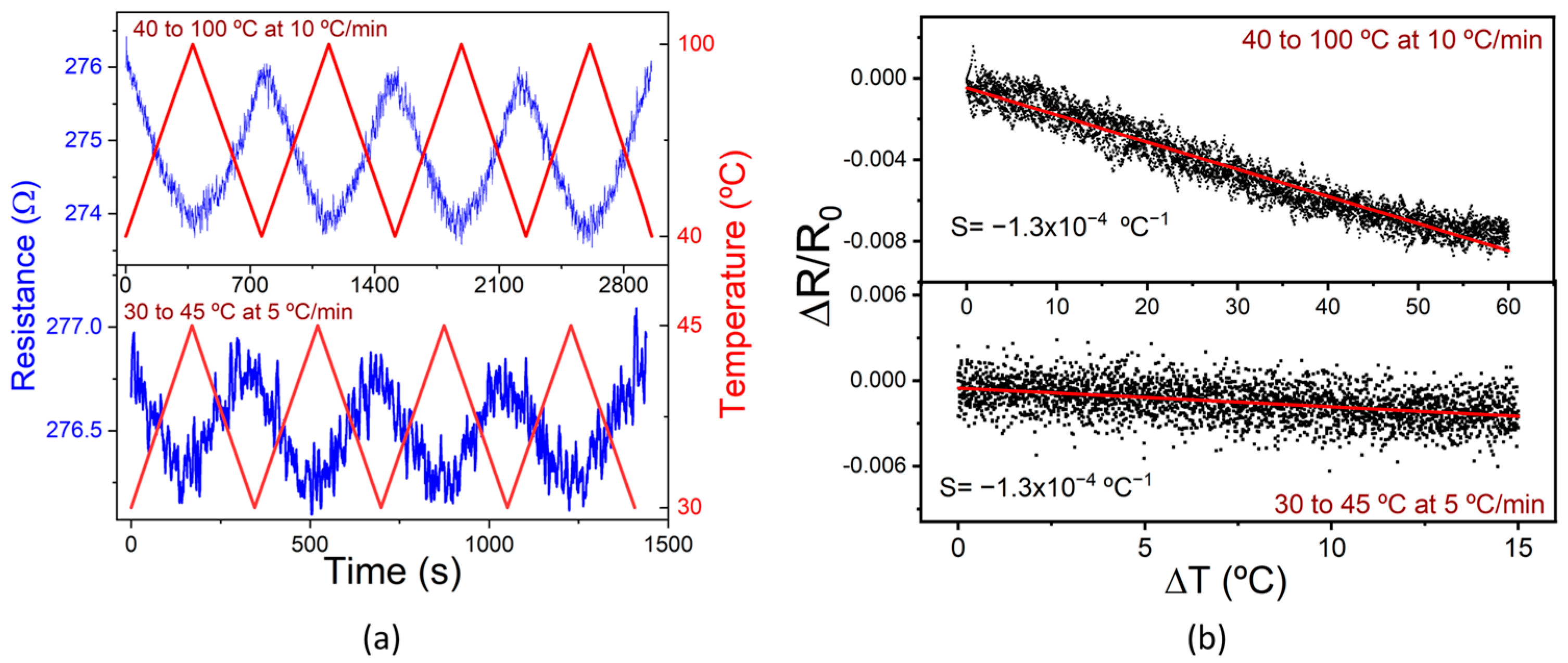

3.5. Thermoresistive Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yoro, K.O.; Daramola, M.O. CO2 Emission Sources, Greenhouse Gases, and the Global Warming Effect. In Advances in Carbon Capture: Methods, Technologies and Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–28. ISBN 9780128196571. [Google Scholar]

- Martin, R. CO2 Emissions of All World Countries; JRC/IEA/PBL 2022 Report; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Muthuraj, R.; Mekonnen, T. Recent Progress in Carbon Dioxide (CO2) as Feedstock for Sustainable Materials Development: Co-Polymers and Polymer Blends. Polymer 2018, 145, 348–373. [Google Scholar] [CrossRef]

- Ma, Z.; Legrand, U.; Pahija, E.; Tavares, J.R.; Boffito, D.C. From CO2 to Formic Acid Fuel Cells. Ind. Eng. Chem. Res. 2021, 60, 803–815. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, X.; Wen, X.; Zhou, Y.; Zhou, L.; Li, H.; Tao, L.; Li, Q.; Du, S.; Liu, T.; et al. Coupling N2 and CO2 in H2O to Synthesize Urea under Ambient Conditions. Nat. Chem. 2020, 12, 717–724. [Google Scholar] [CrossRef]

- Ullas Krishnan, J.N.; Jakka, S.C.B. Carbon Dioxide: No Longer a Global Menace: A Future Source for Chemicals. Mater. Today Proc. 2022, 58, 812–822. [Google Scholar] [CrossRef]

- De la Colina Martínez, A.L.; Martínez Barrera, G.; Barrera Díaz, C.E.; Ávila Córdoba, L.I.; Ureña Núñez, F.; Delgado Hernández, D.J. Recycled Polycarbonate from Electronic Waste and Its Use in Concrete: Effect of Irradiation. Constr. Build. Mater. 2019, 201, 778–785. [Google Scholar] [CrossRef]

- Sushmita, K.; Madras, G.; Bose, S. The Journey of Polycarbonate-Based Composites towards Suppressing Electromagnetic Radiation. Funct. Compos. Mater. 2021, 2, 1–38. [Google Scholar] [CrossRef]

- Yu, W.; Maynard, E.; Chiaradia, V.; Arno, M.C.; Dove, A.P. Aliphatic Polycarbonates from Cyclic Carbonate Monomers and Their Application as Biomaterials. Chem. Rev. 2021, 121, 10865–10907. [Google Scholar] [CrossRef] [PubMed]

- Hotaka, T.; Kondo, F.; Niimi, R.; Togashi, F.; Morita, Y. Industrialization of Automotive Glazing by Polycarbonate and Hard-Coating. Polym. J. 2019, 51, 1249–1263. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, R.; Tong, Y.; Zhao, X.; Zhang, T.; Tang, Q.; Liu, Y. Strain-Discriminable Pressure/Proximity Sensing of Transparent Stretchable Electronic Skin Based on PEDOT:PSS/SWCNT Electrodes. ACS Appl. Mater. Interfaces 2020, 12, 55083–55093. [Google Scholar] [CrossRef] [PubMed]

- Hoeks, T.; Goossens, J.; Vermeulen, H.; Shaikh, A.A.G. Improved Chemical Resistance of Transparent Bisphenol A Polycarbonate Materials. Polym. Eng. Sci. 2022, 62, 1377–1385. [Google Scholar] [CrossRef]

- Ďurovcová, I.; Kyzek, S.; Fabová, J.; Makuková, J.; Gálová, E.; Ševčovičová, A. Genotoxic Potential of Bisphenol A: A Review. Environ. Pollut. 2022, 306, 119346. [Google Scholar] [CrossRef]

- Tsuda, A. In Situ Photo-on-Demand Phosgenation Reactions with Chloroform for Syntheses of Polycarbonates and Polyurethanes. Polym. J. 2023, 55, 903–912. [Google Scholar] [CrossRef]

- Ye, S.; Wang, S.; Lin, L.; Xiao, M.; Meng, Y. CO2 Derived Biodegradable Polycarbonates: Synthesis, Modification and Applications. Adv. Ind. Eng. Polym. Res. 2019, 2, 143–160. [Google Scholar] [CrossRef]

- Li, K.; Xu, Z. Decomposition of Polycarbonate/Acrylonitrile-Butadiene-Styrene Blends in e-Waste Packaging Resin and Recovery of Debrominated Carbon Materials by Supercritical Water Oxidation Process. J. Hazard Mater. 2021, 404, 124056. [Google Scholar] [CrossRef] [PubMed]

- Cruz, H.; Bui, D.N.; Son, Y. Effect of Aspect Ratio and Bulk Density of Carbon Nanotube on the Electrical Conductivity of Polycarbonate/Multi-Walled Carbon Nanotube Nanocomposites. J. Appl. Polym. Sci. 2022, 139, 51909. [Google Scholar] [CrossRef]

- Sohel, M.A.; Mondal, A.; Arif, P.M.; Thomas, S.; SenGupta, A. Effects of Graphene on Thermal Properties and Thermal Stability of Polycarbonate/Graphene Nanocomposite. J. Thermoplast. Compos. Mater. 2023, 36, 326–344. [Google Scholar] [CrossRef]

- Li, Y.; Pötschke, P.; Pionteck, J.; Voit, B. Electrical and Vapor Sensing Behaviors of Polycarbonate Composites Containing Hybrid Carbon Fillers. Eur. Polym. J. 2018, 108, 461–471. [Google Scholar] [CrossRef]

- Guo, J.; Yu, Y.; Cai, L.; Wang, Y.; Shi, K.; Shang, L.; Pan, J.; Zhao, Y. Microfluidics for Flexible Electronics. Mater. Today 2021, 44, 105–135. [Google Scholar] [CrossRef]

- Bagotia, N.; Choudhary, V.; Sharma, D.K. Studies on Toughened Polycarbonate/Multiwalled Carbon Nanotubes Nanocomposites. Compos. B Eng. 2017, 124, 101–110. [Google Scholar] [CrossRef]

- Duc, B.N.; Son, Y. Enhanced Dispersion of Multi Walled Carbon Nanotubes by an Extensional Batch Mixer in Polymer/MWCNT Nanocomposites. Compos. Commun. 2020, 21, 100420. [Google Scholar] [CrossRef]

- Gupta, A.; Goyal, R.K. Electrical Properties of Polycarbonate/Expanded Graphite Nanocomposites. J. Appl. Polym. Sci. 2019, 136, 47274. [Google Scholar] [CrossRef]

- Gao, X.; Isayev, A.I.; Zhang, X. Continuous Film Casting of Polycarbonate/Single-Walled Carbon Nanotubes Composites with Ultrasound-Assisted Twin-Screw Extruder: Effect of Screw Configuration. J. Appl. Polym. Sci. 2022, 139, e53172. [Google Scholar] [CrossRef]

- Biswas, M.C.; Jony, B.; Nandy, P.K.; Chowdhury, R.A.; Halder, S.; Kumar, D.; Ramakrishna, S.; Hassan, M.; Ahsan, M.A.; Hoque, M.E.; et al. Recent Advancement of Biopolymers and Their Potential Biomedical Applications. J. Polym. Environ. 2022, 30, 51–74. [Google Scholar] [CrossRef]

- Pimentel, E.; Costa, P.; Tubio, C.R.; Vilaça, J.L.; Costa, C.M.; Lanceros-Méndez, S.; Miranda, D. Printable Piezoresistive Polymer Composites for Self-Sensing Medical Catheter Device Applications. Compos. Sci. Technol. 2023, 239, 110071. [Google Scholar] [CrossRef]

- Franco, M.; Alves, R.; Perinka, N.; Tubio, C.; Costa, P.; Lanceros-Mendéz, S. Water-Based Graphene Inks for All-Printed Temperature and Deformation Sensors. ACS Appl. Electron. Mater. 2020, 2, 2857–2867. [Google Scholar] [CrossRef]

- Reizabal, A.; Gonçalves, S.; Brito-Pereira, R.; Costa, P.; Costa, C.M.; Pérez-Álvarez, L.; Vilas-Vilela, J.L.; Lanceros-Méndez, S. Optimized Silk Fibroin Piezoresistive Nanocomposites for Pressure Sensing Applications Based on Natural Polymers. Nanoscale Adv. 2019, 1, 2284–2292. [Google Scholar] [CrossRef] [PubMed]

- Costa, P.; Dios, J.R.; Cardoso, J.; Campo, J.J.; Tubio, C.R.; Gonalves, B.F.; Castro, N.; Lanceros-Méndez, S. Polycarbonate Based Multifunctional Self-Sensing 2D and 3D Printed Structures for Aeronautic Applications. Smart Mater. Struct. 2021, 30, 085032. [Google Scholar] [CrossRef]

- Torabi, A.; Jafari, S.H.; Khonakdar, H.A.; Goodarzi, V.; Yu, L.; Altstädt, V.; Skov, A.L. Development of Electroactive Nanocomposites Based on Poly(Vinylidene Fluoride-Hexafluoropropylene)/Polycarbonate Blends with Improved Dielectric, Thermal, and Mechanical Properties. J. Polym. Res. 2022, 29, 425. [Google Scholar] [CrossRef]

- Huang, J.; Worch, J.C.; Dove, A.P.; Coulembier, O. Update and Challenges in Carbon Dioxide-Based Polycarbonate Synthesis. ChemSusChem 2020, 13, 469–487. [Google Scholar] [CrossRef]

- Liao, X.; Cui, F.C.; He, J.H.; Ren, W.M.; Lu, X.B.; Zhang, Y.T. A Sustainable Approach for the Synthesis of Recyclable Cyclic CO2-Based Polycarbonates. Chem. Sci. 2022, 13, 6283–6290. [Google Scholar] [CrossRef]

- Ramlee, N.A.; Tominaga, Y. Mechanical and Degradation Properties in Alkaline Solution of Poly(Ethylene Carbonate)/Poly(Lactic Acid) Blends. Polymer 2019, 166, 44–49. [Google Scholar] [CrossRef]

- Haneef, I.N.H.M.; Buys, Y.F.; Shaffiar, N.M.; Haris, N.A.; Hamid, A.M.A.; Shaharuddin, S.I.S. Mechanical, Morphological, Thermal Properties and Hydrolytic Degradation Behavior of Polylactic Acid/Polypropylene Carbonate Blends Prepared by Solvent Casting. Polym. Eng. Sci. 2020, 60, 2876–2886. [Google Scholar] [CrossRef]

- Thorat, S.D.; Phillips, P.J.; Semenov, V.; Gakh, A. Physical Properties of Aliphatic Polycarbonates Made from CO2 and Epoxides. J. Appl. Polym. Sci. 2003, 89, 1163–1176. [Google Scholar] [CrossRef]

- Balam, A.; Cen-Puc, M.; Rodríguez-Uicab, O.; Abot, J.L.; Avilés, F. Cyclic Thermoresistivity of Freestanding and Polymer Embedded Carbon Nanotube Yarns. Adv. Eng. Mater. 2020, 22, 2000220. [Google Scholar] [CrossRef]

- Pradhan, S.S.; Unnikrishnan, L.; Mohanty, S.; Nayak, S.K. Effect of Graphite Flake and Multi-Walled Carbon Nanotube on Thermal, Mechanical, Electrical, and Electromagnetic Interference Shielding Properties of Polycarbonate Nanocomposite. Polym. Compos. 2021, 42, 4043–4055. [Google Scholar] [CrossRef]

- Taraghi, I.; Paszkiewicz, S.; Fereidoon, A.; Szymczyk, A.; Stanik, R.; Gude, M.; Linares, A.; Ezquerra, T.A.; Piesowicz, E.; Wilpiszewska, K.; et al. Thermally and Electrically Conducting Polycarbonate/Elastomer Blends Combined with Multiwalled Carbon Nanotubes. J. Thermoplast. Compos. Mater. 2021, 34, 1488–1503. [Google Scholar] [CrossRef]

- Hacioglu, F.; Tayfun, U.; Ozdemir, T.; Tincer, T. Characterization of Carbon Fiber and Glass Fiber Reinforced Polycarbonate Composites and Their Behavior under Gamma Irradiation. Prog. Nucl. Energy 2021, 134, 103665. [Google Scholar] [CrossRef]

- Yang, J.; Xiang, M.; Zhu, Y.; Yang, Z.; Ou, J. Influences of Carbon Nanotubes/Polycarbonate Composite on Enhanced Local Laser Marking Properties of Polypropylene. Polym. Bull. 2022, 80, 1321–1333. [Google Scholar] [CrossRef]

- Dios, J.R.; Gonzalo, B.; Tubio, C.R.; Cardoso, J.; Gonçalves, S.; Miranda, D.; Correia, V.; Viana, J.C.; Costa, P.; Lanceros-Méndez, S. Functional Piezoresistive Polymer-Composites Based on Polycarbonate and Polylactic Acid for Deformation Sensing Applications. Macromol. Mater. Eng. 2020, 305, 2000379. [Google Scholar] [CrossRef]

- Mendes-Felipe, C.; Oliveira, J.; Costa, P.; Ruiz-Rubio, L.; Iregui, A.; González, A.; Vilas, J.L.; Lanceros-Mendez, S. Stimuli Responsive UV Cured Polyurethane Acrylated/Carbon Nanotube Composites for Piezoresistive Sensing. Eur. Polym. J. 2019, 120, 109226. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y. Simulation of Percolation Threshold, Tunneling Distance, and Conductivity for Carbon Nanotube (CNT)-Reinforced Nanocomposites Assuming Effective CNT Concentration. Polymers 2020, 12, 114. [Google Scholar] [CrossRef] [PubMed]

- Yoon, K.H.; Lee, Y.S. Effects of Multi-Walled Carbon Nanotube and Flow Types on the Electrical Conductivity of Polycarbonate/Carbon Nanotube Nanocomposites. Carbon Lett. 2019, 29, 57–63. [Google Scholar] [CrossRef]

- Poothanari, M.A.; Abraham, J.; Kalarikkal, N.; Thomas, S. Excellent Electromagnetic Interference Shielding and High Electrical Conductivity of Compatibilized Polycarbonate/Polypropylene Carbon Nanotube Blend Nanocomposites. Ind. Eng. Chem. Res. 2018, 57, 4287–4297. [Google Scholar] [CrossRef]

- Sidi Salah, L.; Ouslimani, N.; Chouai, M.; Danlée, Y.; Huynen, I.; Aksas, H. Predictive Optimization of Electrical Conductivity of Polycarbonate Composites at Different Concentrations of Carbon Nanotubes: A Valorization of Conductive Nanocomposite Theoretical Models. Materials 2021, 14, 1687. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Huang, Y.; Zhao, C.; Chang, E.; Ameli, A.; Naguib, H.E.; Park, C.B. Theoretical Modeling and Experimental Verification of Percolation Threshold with MWCNTs’ Rotation and Translation around a Growing Bubble in Conductive Polymer Composite Foams. Compos. Sci. Technol. 2020, 199, 108345. [Google Scholar] [CrossRef]

- Cen-Puc, M.; Oliva-Avilés, A.I.; Avilés, F. Thermoresistive Mechanisms of Carbon Nanotube/Polymer Composites. Phys. E Low Dimens. Syst. Nanostruct. 2018, 95, 41–50. [Google Scholar] [CrossRef]

- Mendes-Felipe, C.; Costa, P.; Roppolo, I.; Sangermano, M.; Lanceros-Mendez, S. Bio-Based Piezo- and Thermoresistive Photocurable Sensing Materials from Acrylated Epoxidized Soybean Oil. Macromol. Mater. Eng. 2022, 307, 2100934. [Google Scholar] [CrossRef]

| wt.% MWCNT Content | TGA | DSC | |

|---|---|---|---|

| Tdmax | Tg-onset (°C) | Tg-offset (°C) | |

| 0 | 284.6 ± 9.3 | 111.2 | 118.3 |

| 0.5 | 279.4 ± 8.8 | 111.9 | 119.0 |

| 1.0 | 287.3 ± 5.9 | 112.1 | 118.6 |

| 1.5 | 286.3 ± 5.9 | 110.2 | 118.1 |

| 3.0 | 291.1 ± 7.8 | 111.3 | 117.4 |

| 5.0 | 286.5 ± 4.9 | 112.3 | 117.5 |

| 7.0 | 286.9 ± 6.3 | 111.7 | 120.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Ayerdi, A.; Rubio-Peña, L.; Peřinka, N.; Oyarzabal, I.; Vilas, J.L.; Costa, P.; Lanceros-Méndez, S. Towards Sustainable Temperature Sensor Production through CO2-Derived Polycarbonate-Based Composites. Polymers 2024, 16, 1948. https://doi.org/10.3390/polym16131948

Martín-Ayerdi A, Rubio-Peña L, Peřinka N, Oyarzabal I, Vilas JL, Costa P, Lanceros-Méndez S. Towards Sustainable Temperature Sensor Production through CO2-Derived Polycarbonate-Based Composites. Polymers. 2024; 16(13):1948. https://doi.org/10.3390/polym16131948

Chicago/Turabian StyleMartín-Ayerdi, Ane, Luis Rubio-Peña, Nikola Peřinka, Itziar Oyarzabal, José L. Vilas, Pedro Costa, and Senentxu Lanceros-Méndez. 2024. "Towards Sustainable Temperature Sensor Production through CO2-Derived Polycarbonate-Based Composites" Polymers 16, no. 13: 1948. https://doi.org/10.3390/polym16131948