Variations in the Thermomechanical and Structural Properties during the Cooling of Shape-Memory R-PETG

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

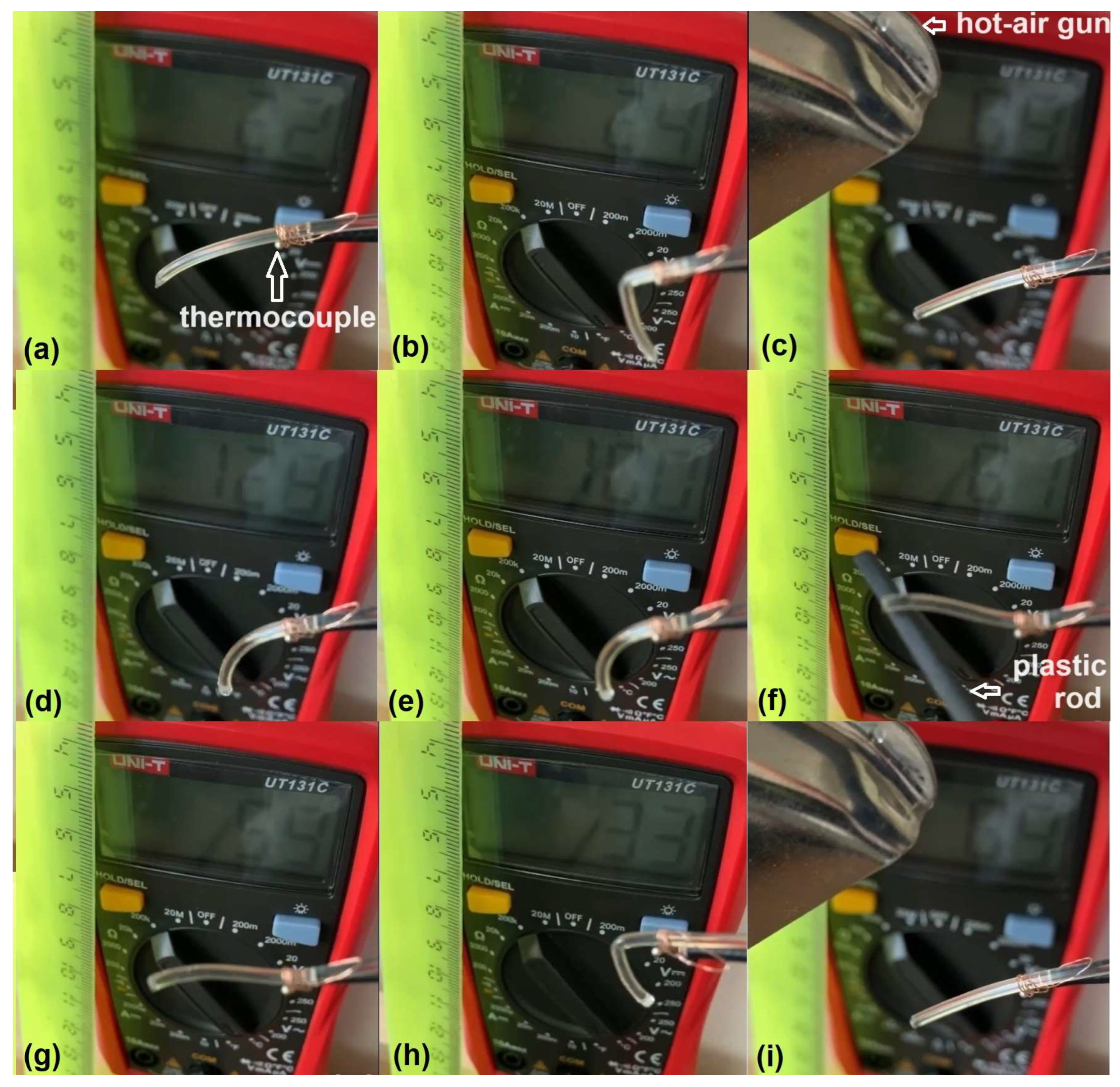

2.2. Testing Methods

3. Results and Discussion

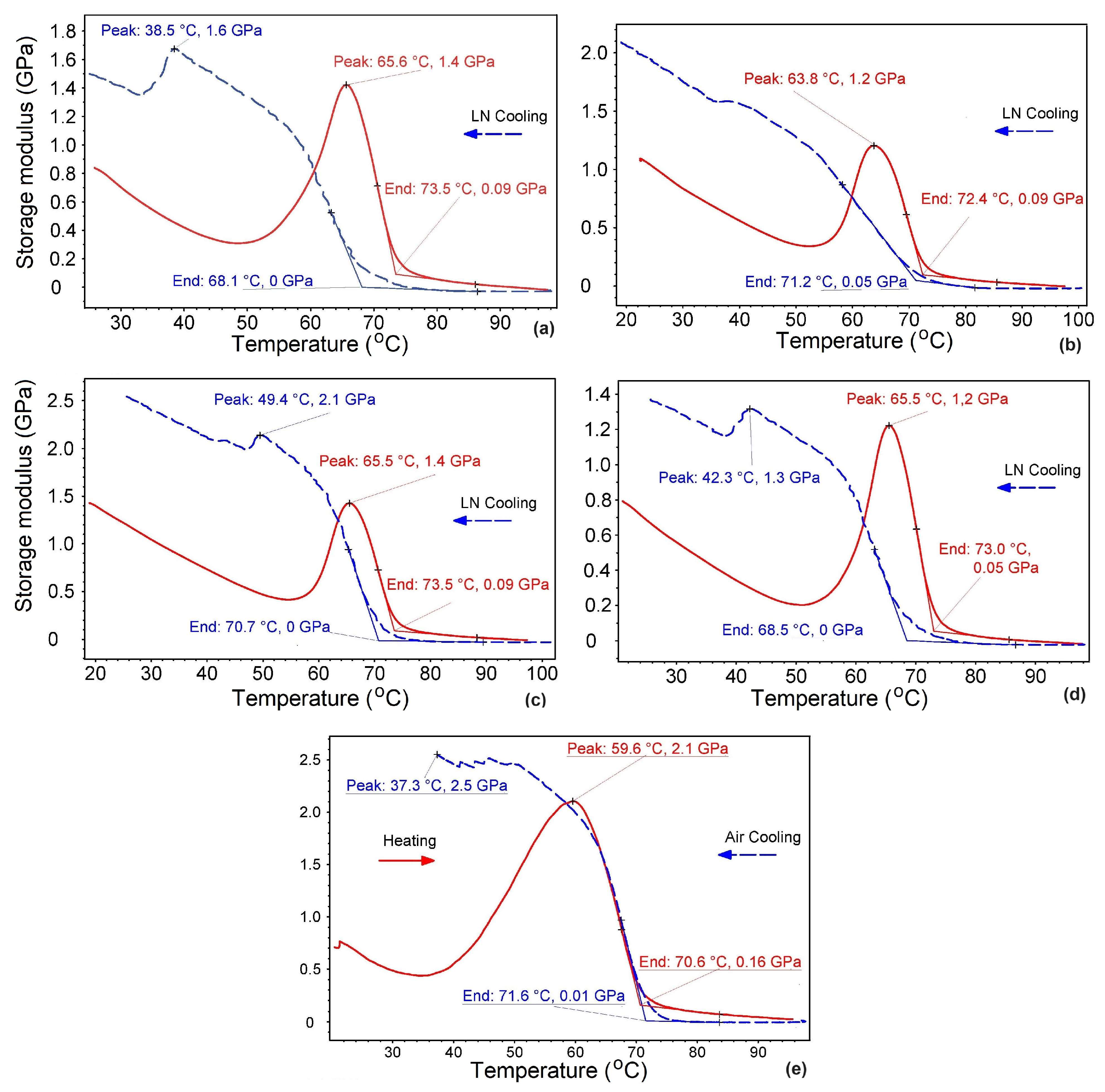

3.1. DMA Study

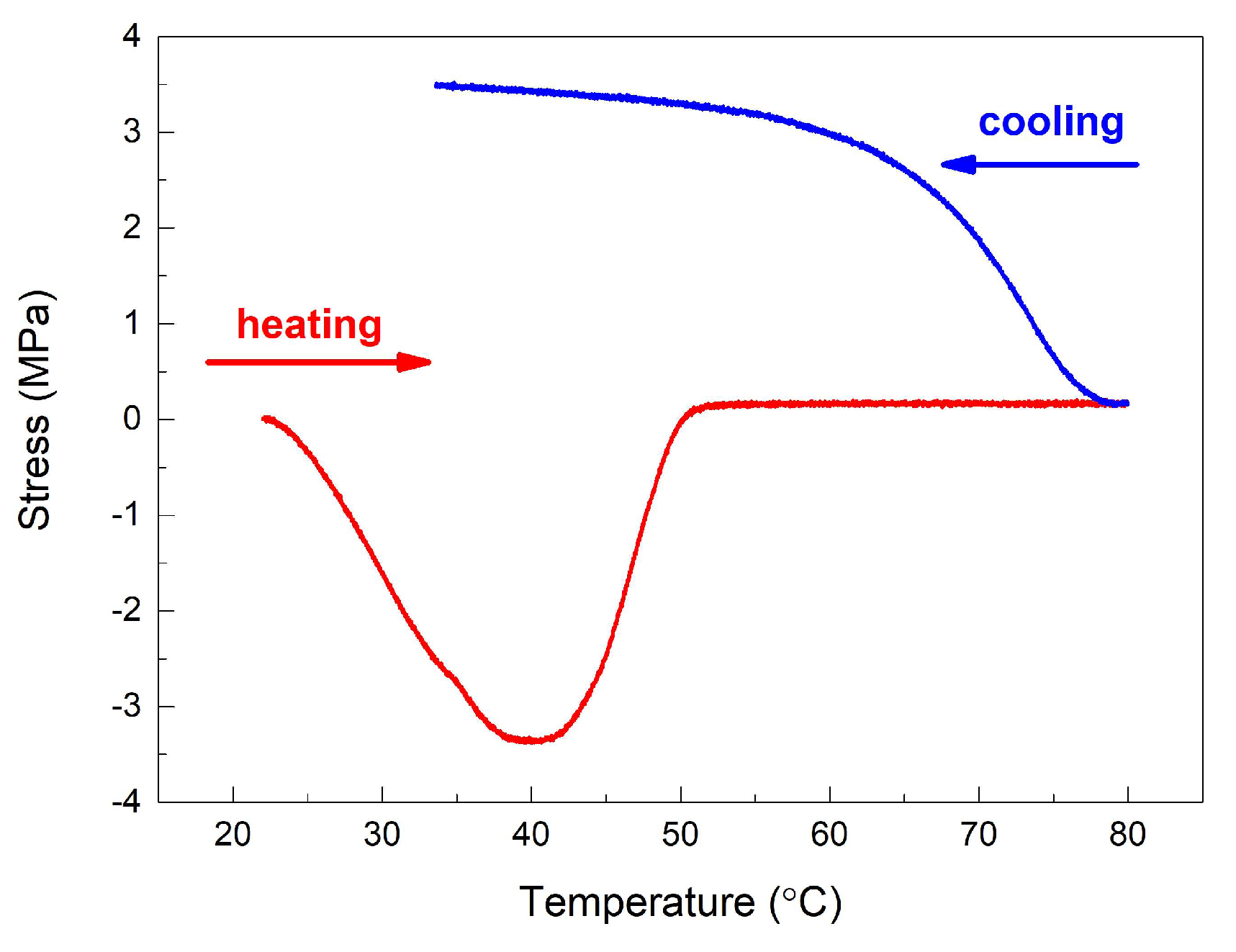

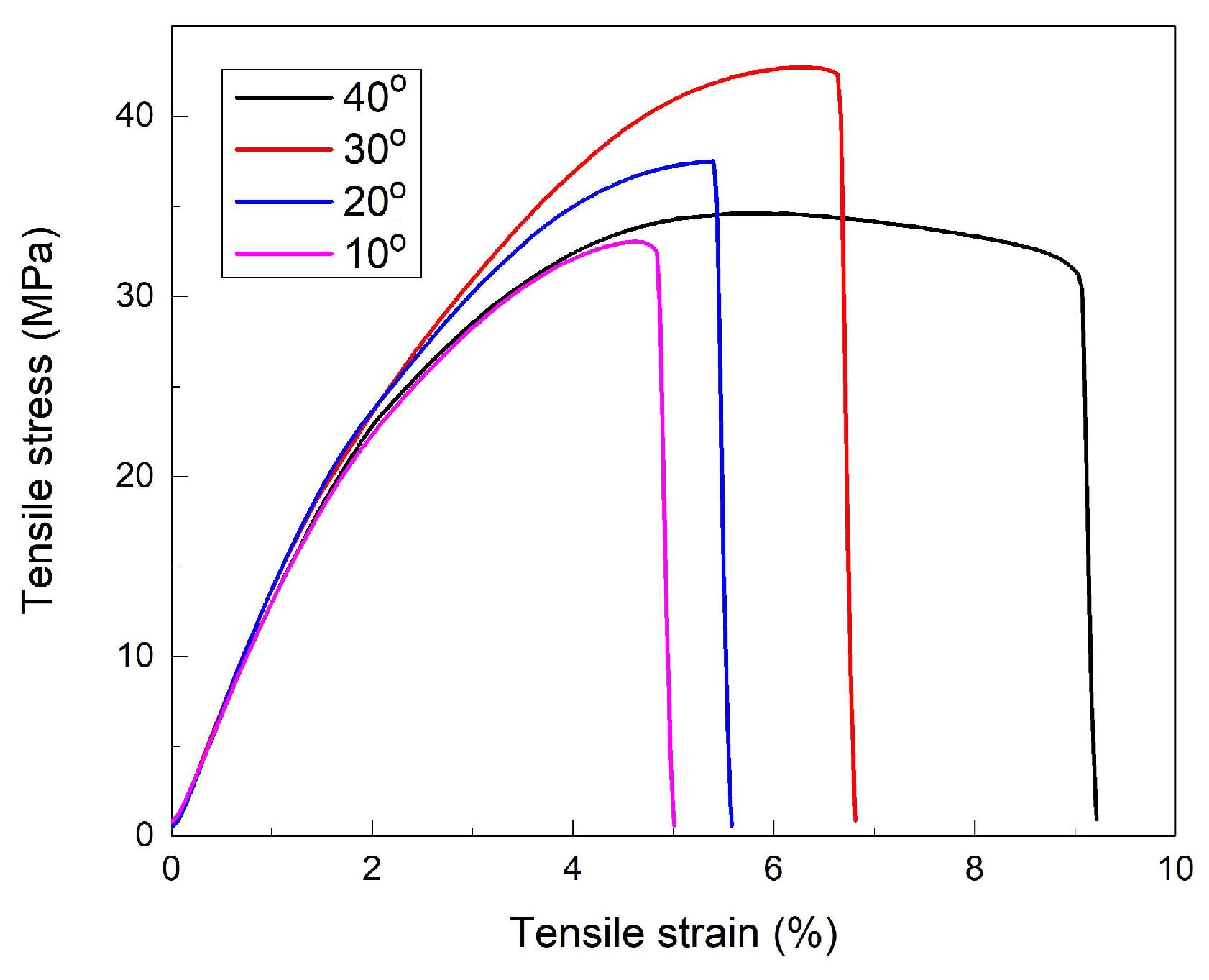

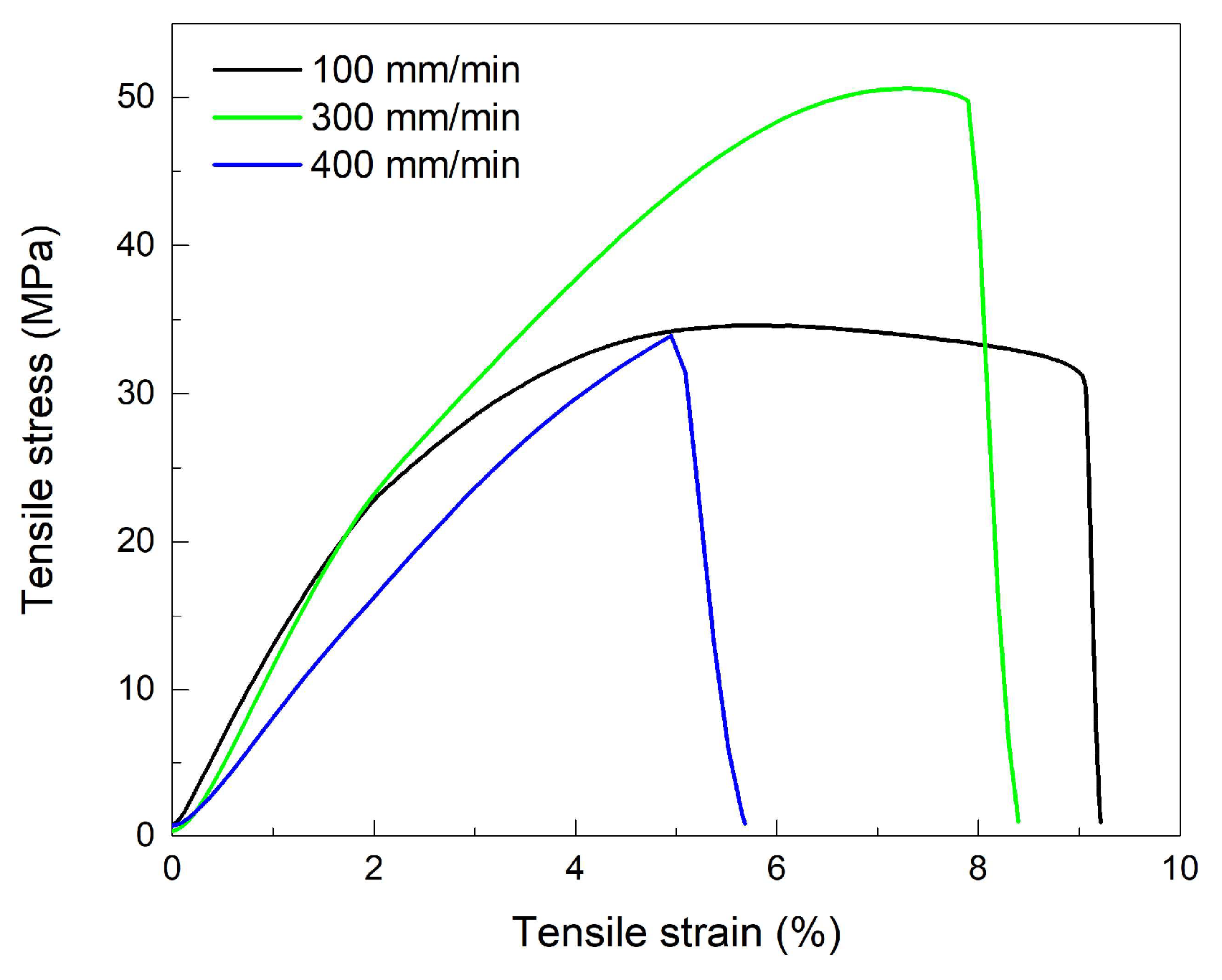

3.2. Tensile Tests

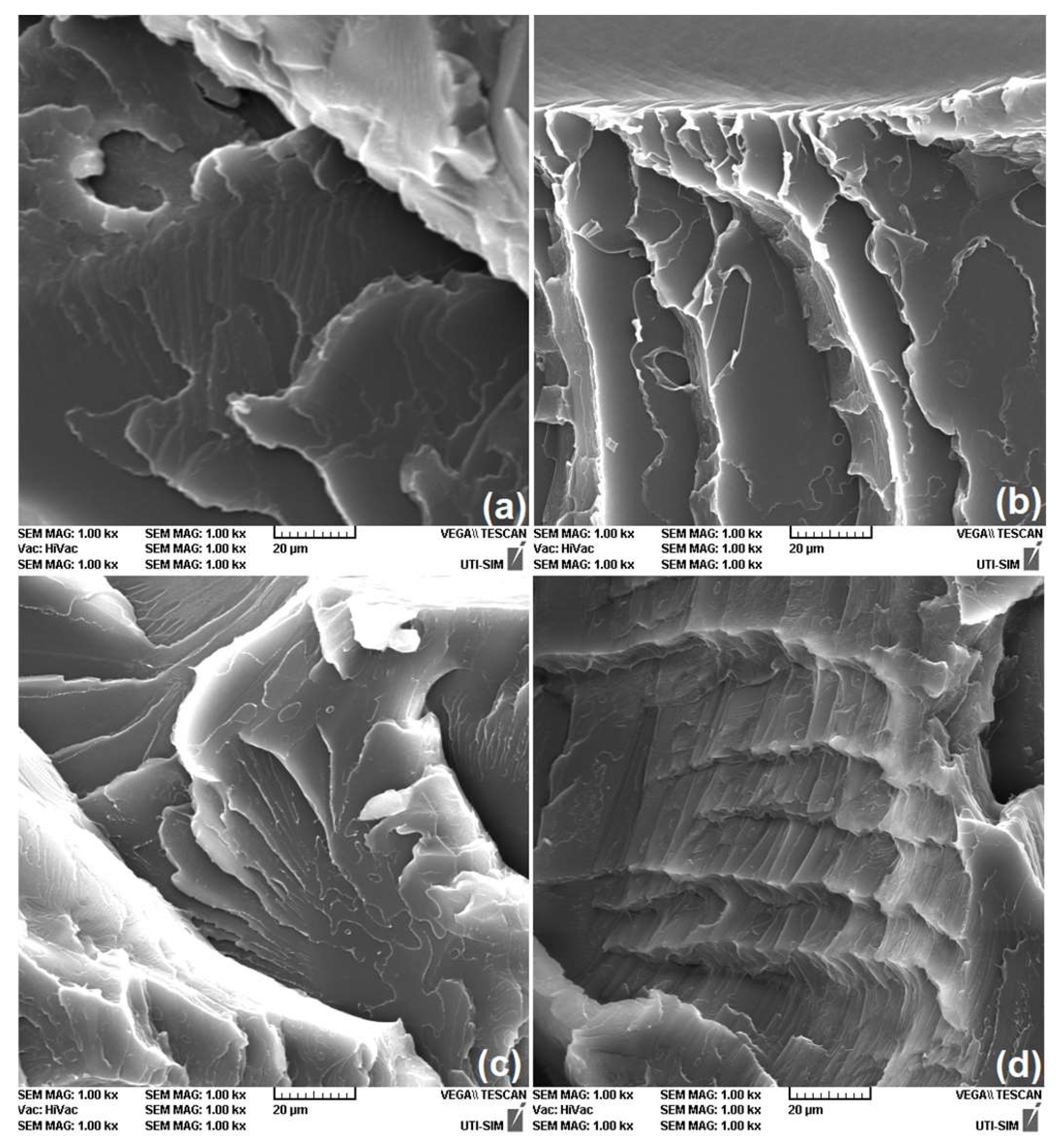

3.3. SEM Analysis

4. Conclusions

- The specimens (almost) completely lost their dynamic and static stiffness when heated beyond 70.6–73.5 °C (storage modulus decreased to 0.05–0.16 GPa) and 50 °C (tensile stress decreased to 0 MPa), respectively, and recovered it during subsequent cooling below 71.6–68.1 °C and 80 °C (at the very beginning of cooling), respectively;

- Stiffness recovery enabled the specimens to be deformed into a new temporary shape that supported the continuation of free-recovery SME cycling;

- At the end of a heating–cooling cycle, the stiffness of both dynamically and statically deformed specimens was greater than it had been initially;

- The specimens deformed by tension at −10 °C, with cross-head speeds of at least 100 mm/min, failed at larger ultimate stresses and lower ultimate strains compared with those deformed at room temperature, with a cross-head speed of 1 mm/min, in accordance with previous results reported on the temperature influence on tensile behavior of 3D-printed PETG [45];

- The largest ultimate strains, at a deformation rate of 100 mm/min, were obtained in the specimens printed at the largest angle, 40°, to the transversal deposition direction, which could be an effect of the intensification of the craze phenomenon;

- With increasing deformation rate, up to 400 mm/min, failure occurred by delamination rather than by crazing.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dong, W.; Zhao, J.; Li, C.; Guo, M.; Zhao, D.; Fan, Q. Study of the amorphous phase in semicrystalline poly(ethylene terephthalate) via dynamic mechanical thermal analysis. Polym. Bull. 2002, 49, 197–203. [Google Scholar] [CrossRef]

- Cristea, M.; Ionita, D.; Simionescu, B.C. A new insight in the dynamo-mechanical behavior of poly(ethylene terephthalate). A new insight in the dynamo-mechanical behavior of poly(ethylene terephthalate). Eur. Polym. J. 2010, 46, 2005–2012. [Google Scholar] [CrossRef]

- Mettler Toledo. Thermal Analysis of Polymers. Selected Applications. Available online: https://www.mt.com/my/en/home/supportive_content/matchar_apps/MatChar_UC311.html (accessed on 4 April 2023).

- Irie, M. Shape memory polymers. In Shape Memory Materials; Otsuka, K., Wayman, C.M., Eds.; Cambridge University Press: Cambridge, UK, 1998; pp. 203–219. [Google Scholar]

- Hergenrother, W.L. Influence of Copolymeric Poly(diethylene Glycol) Terephthalate on the Thermal Stability of Poly(ethylene Terephthalate). J. Polym. Sci. 1974, 12, 875–883. [Google Scholar] [CrossRef]

- De Vos, L.; Van de Voorde, B.; Van Daele, L.; Dubruel, P.; Van Vlierberghe, S. Poly(alkylene terephthalate)s: From current developments in synthetic strategies towards applications. Eur. Polym. J. 2021, 161, 110840. [Google Scholar] [CrossRef]

- Santos, F.A.; Rebelo, H.; Coutinho, M.; Sutherland, L.S.; Cismasiu, C.; Farina, I.; Fraternali, F. Low velocity impact response of 3D printed structures formed by cellular metamaterials and stiffening plates: PLA vs. PETg. Compos. Struct. 2021, 256, 113128. [Google Scholar] [CrossRef]

- Nistico, R. Polyethylene terephthalate (PET) in the packaging industry. Polym. Test. 2020, 90, 106707. [Google Scholar] [CrossRef]

- Holcomb, G.; Caldona, E.B.; Cheng, X.; Advincula, R.C. On the optimized 3D printing and post-processing of PETG materials. MRS Commun. 2022, 12, 381–387. [Google Scholar] [CrossRef]

- Sepahi, M.T.; Abusalma, H.; Jovanovic, V.; Eisazadeh, H. Mechanical Properties of 3D-Printed Parts Made of Polyethylene Terephthalate Glycol. J. Mater. Eng. Perform. 2021, 30, 6851–6861. [Google Scholar] [CrossRef]

- Parihar, A.; Pandita, V.; Kumar, A.; Parihar, D.S.; Puranik, N.; Bajpai, T.; Khan, R. 3D Printing: Advancement in Biogenerative Engineering to Combat Shortage of Organs and Bioapplicable Materials. Regene Eng. Transl. Med. 2022, 8, 173–199. [Google Scholar] [CrossRef]

- Szykiedans, K.; Credo, W.; Osiński, D. Selected mechanical properties of PETG 3-D prints. Proc. Eng. 2017, 177, 455–461. [Google Scholar] [CrossRef]

- Pricop, B.; Sava, Ș.-D.; Lohan, N.-M.; Bujoreanu, L.-G. DMA Investigation of the Factors Influencing the Glass Transition in 3D Printed Specimens of Shape Memory Recycled PET. Polymers 2022, 14, 2248. [Google Scholar] [CrossRef] [PubMed]

- Sava, Ș.-D.; Lohan, N.-M.; Pricop, B.; Popa, M.; Cimpoeșu, N.; Comăneci, R.-I.; Bujoreanu, L.-G. On the Thermomechanical Behavior of 3D-Printed Specimens of Shape Memory R-PETG. Polymers 2023, 15, 2378. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; Wang, Y.; Zhao, Z. Mechanical performance and damage monitoring of CFRP thermoplastic laminates with an open hole repaired by 3D printed patches. Compos. Struct. 2023, 303, 116308. [Google Scholar] [CrossRef]

- Khan, S.B.; Irfan, S.; Lam, S.S.; Sun, X.; Chen, S. 3D printed nanofiltration membrane technology for waste water distillation. J. Water Proc. Eng. 2022, 49, 102958. [Google Scholar] [CrossRef]

- Yang, J.; Cheng, Y.; Gong, X.; Yi, S.; Li, C.-W.; Jiang, L.; Yi, C. An integrative review on the applications of 3D printing in the field of in vitro diagnostics. Chin. Chem. Lett. 2022, 33, 2231–2242. [Google Scholar] [CrossRef]

- Soleyman, E.; Aberoumand, M.; Rahmatabadi, D.; Soltanmohammadi, K.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. Assessment of controllable shape transformation, potential applications, and tensile shape memory properties of 3D printed PETG. J. Mater. Res. Technol. 2022, 18, 4201–4215. [Google Scholar] [CrossRef]

- Soleyman, E.; Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Ghasemi, I.; Abrinia, K.; Baniassadi, M.; Wang, K.; Baghani, M. Shape memory performance of PETG 4D printed parts under compression in cold, warm, and hot programming. Smart Mater. Struct. 2022, 31, 085002. [Google Scholar] [CrossRef]

- Guo, J.; Xiao, R.; Tian, C.; Jiang, M. Optimizing physical aging in poly(ethylene terephthalate)-glycol (PETG). J. Non-Cryst. Solids 2018, 502, 15–21. [Google Scholar] [CrossRef]

- Pricop, B.; Soyler, U.; Ozkal, B.; Lohan, N.M.; Paraschiv, A.L.; Suru, M.G.; Bujoreanu, L.G. Influence of mechanical alloying on the behavior of Fe-Mn-Si-Cr-Ni shape memory alloys made by powder metallurgy. In Materials Science Forum; Prokoshkin, S., Resnina, N., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2013; Volume 738, pp. 237–241. [Google Scholar]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-memory polymers and their composites: Stimulus methods and applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Maraveas, C.; Kyrtopoulos, I.V.; Arvanitis, K.G. Evaluation of the Viability of 3D Printing in Recycling Polymers. Polymers 2024, 16, 1104. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO 527-1. 2012. Available online: https://www.iso.org/standard/56045.html (accessed on 4 July 2024).

- Loskot, J.; Jezbera, D.; Loskot, R.; Busovsky, D.; Barylski, A.; Glowka, K.; Duda, P.; Aniołek, K.; Voglov, K.; Zubko, M. Influence of print speed on the microstructure, morphology, and mechanical properties of 3D-printed PETG products. Polym. Test. 2023, 123, 108055. [Google Scholar] [CrossRef]

- Krishna Chaitanya, S.; Dhanalakshmi, K. Design and investigation of a shape memory alloy actuated gripper. Smart Mater. Struct. 2014, 14, 541–558. [Google Scholar] [CrossRef]

- Pintos, P.B.; de León, A.S.; Molina, S.I. Large Format Additive Manufacturing of Polyethylene terephthalate (PET) by Material, Extrusion. Addit. Manuf. 2023; in press. [Google Scholar] [CrossRef]

- Montserrat, S.; Calventus, Y.; Hutchinson, J.M. Effect of cooling rate and frequency on the calorimetric measurement of the glass transition. Polymer. 2005, 46, 12181–12189. [Google Scholar] [CrossRef]

- Aminu, T.Q.; Bahr, D.F. Flow-induced bending deformation of electrospun polymeric filtration membranes using the “leaky” bulge test. Polymer 2021, 235, 124274. [Google Scholar] [CrossRef]

- Chen, Y.; Quino, G.; Pellegrino, A. A comprehensive investigation on the temperature and strain rate dependent mechanical response of three polymeric syntactic foams for thermoforming and energy absorption applications. Polym. Test. 2024; in press. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, L.; Mulholland, T.; Osswald, T.A. Effects of raster angle on the mechanical properties of PLA and Al/PLA composite part produced by fused deposition modeling. Polym. Adv. Technol. 2019, 30, 2122–2135. [Google Scholar] [CrossRef]

- Zhou, Y.-G.; Zou, J.-R.; Wu, H.-H.; Xu, B.-P. Balance between bonding and deposition during fused deposition modeling of polycarbonate and acrylonitrile-butadiene-styrene composites. Polym. Comp. 2019, 41, 60–72. [Google Scholar] [CrossRef]

- Couderc, H.; Saiter, A.; Grenet, J.; Saiter, J.M. Gradient of molecular dynamics at the glass transition of PETg–Montmorillonite nanocomposites. Phys. B 2011, 406, 2908–2913. [Google Scholar] [CrossRef]

- Muhammad, S.; Jar, P.-Y.B. Determining stress–strain relationship for necking in polymers based on macrodeformation behavior. Finite Elem. Anal. Des. 2013, 70–71, 36–43. [Google Scholar] [CrossRef]

- Dal, H.; Gultekin, O.; Basdemir, S.; Acan, A.K. Ductile–brittle failure of amorphous glassy polymers: A phase-field approach. Comput. Methods Appl. Mech. Engrg. 2022, 401, 115639. [Google Scholar] [CrossRef]

- Mazidi, M.M.; Aghjeh, M.K.R.; Pegoretti, A. Toughened ternary and quaternary polymer alloys of core-shell morphology; correlations among processing, microstructure, micromechanics, and macroscopic mechanical performance in reactive systems. Polymer 2023, 282, 126186. [Google Scholar] [CrossRef]

- Hayes, M.D.; Edwards, D.B.; Shah, A.R. Fractography in Failure Analysis of Polymers; Elsevier: Amsterdam, The Netherlands, 2015; pp. 48–92. [Google Scholar]

- Kinloch, A.J.; Young, R.J. Fracture Behavior of Polymers; Chapman & Hall: London, UK, 1995; pp. 147–181. [Google Scholar]

- Collyer, A.A. Rubber Toughened Engineering Plastics; Springer: Berlin/Heidelberg, Germany, 1994; pp. 12–20. [Google Scholar]

- Xiu, L.; Wenbo, L.; Boyuan, Y. Strain-amplitude and Strain-rate Dependent Craze Damage of Poly(methyl methacrylate). Polym. Polym. Compos. 2014, 22, 737–741. [Google Scholar] [CrossRef]

- Safaei, S.; Ayatollahi, M.R.; Saboori, B. Fracture behavior of GPPS brittle polymer under mixed mode I/III loading. Theor. Appl. Fract. Mech. 2017, 91, 103–115. [Google Scholar] [CrossRef]

- Alarifi, M.I. Mechanical properties and numerical simulation of FDM 3D printed PETG/carbon composite unit structures. J. Mater. Res. Technol. 2023, 23, 656–669. [Google Scholar] [CrossRef]

- Greenhalgh, E.S. (Ed.) Failure Analysis and Fractography of Polymer Composites; Woodhead Publishing Series in Composites Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2009; pp. 164–237. [Google Scholar] [CrossRef]

- Makki, T.; Vattathurvalappil, S.H.; Theravalappil, R.; Nazir, A.; Alhajeri, A.; Azeem, M.A.; Mahdi, E.; Ummer, A.C.; Ali, U. 3D and 4D printing: A review of virgin polymers used in fused deposition modeling. Compos. Part C Open Access 2024, 14, 100472. [Google Scholar] [CrossRef]

- Lakshman Sri, S.V.; Karthick, A.; Dinesh, C. Evaluation of mechanical properties of 3D printed PETG and Polyamide (6) polymers. Chem. Phys. Impact 2024, 8, 8100491. [Google Scholar] [CrossRef]

- Brady, M.J. The effect of thermal ageing on impact-modified engineering resins. Polymer 1992, 33, 2981–2988. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sava, Ș.-D.; Pricop, B.; Comăneci, R.-I.; Cimpoeșu, N.; Popa, M.; Lohan, N.-M.; Bujoreanu, L.-G. Variations in the Thermomechanical and Structural Properties during the Cooling of Shape-Memory R-PETG. Polymers 2024, 16, 1965. https://doi.org/10.3390/polym16141965

Sava Ș-D, Pricop B, Comăneci R-I, Cimpoeșu N, Popa M, Lohan N-M, Bujoreanu L-G. Variations in the Thermomechanical and Structural Properties during the Cooling of Shape-Memory R-PETG. Polymers. 2024; 16(14):1965. https://doi.org/10.3390/polym16141965

Chicago/Turabian StyleSava, Ștefan-Dumitru, Bogdan Pricop, Radu-Ioachim Comăneci, Nicanor Cimpoeșu, Mihai Popa, Nicoleta-Monica Lohan, and Leandru-Gheorghe Bujoreanu. 2024. "Variations in the Thermomechanical and Structural Properties during the Cooling of Shape-Memory R-PETG" Polymers 16, no. 14: 1965. https://doi.org/10.3390/polym16141965

APA StyleSava, Ș.-D., Pricop, B., Comăneci, R.-I., Cimpoeșu, N., Popa, M., Lohan, N.-M., & Bujoreanu, L.-G. (2024). Variations in the Thermomechanical and Structural Properties during the Cooling of Shape-Memory R-PETG. Polymers, 16(14), 1965. https://doi.org/10.3390/polym16141965