Investigation of the Compressive Strength and Void Analysis of Cement Pastes with Superabsorbent Polymer

Abstract

:1. Introduction

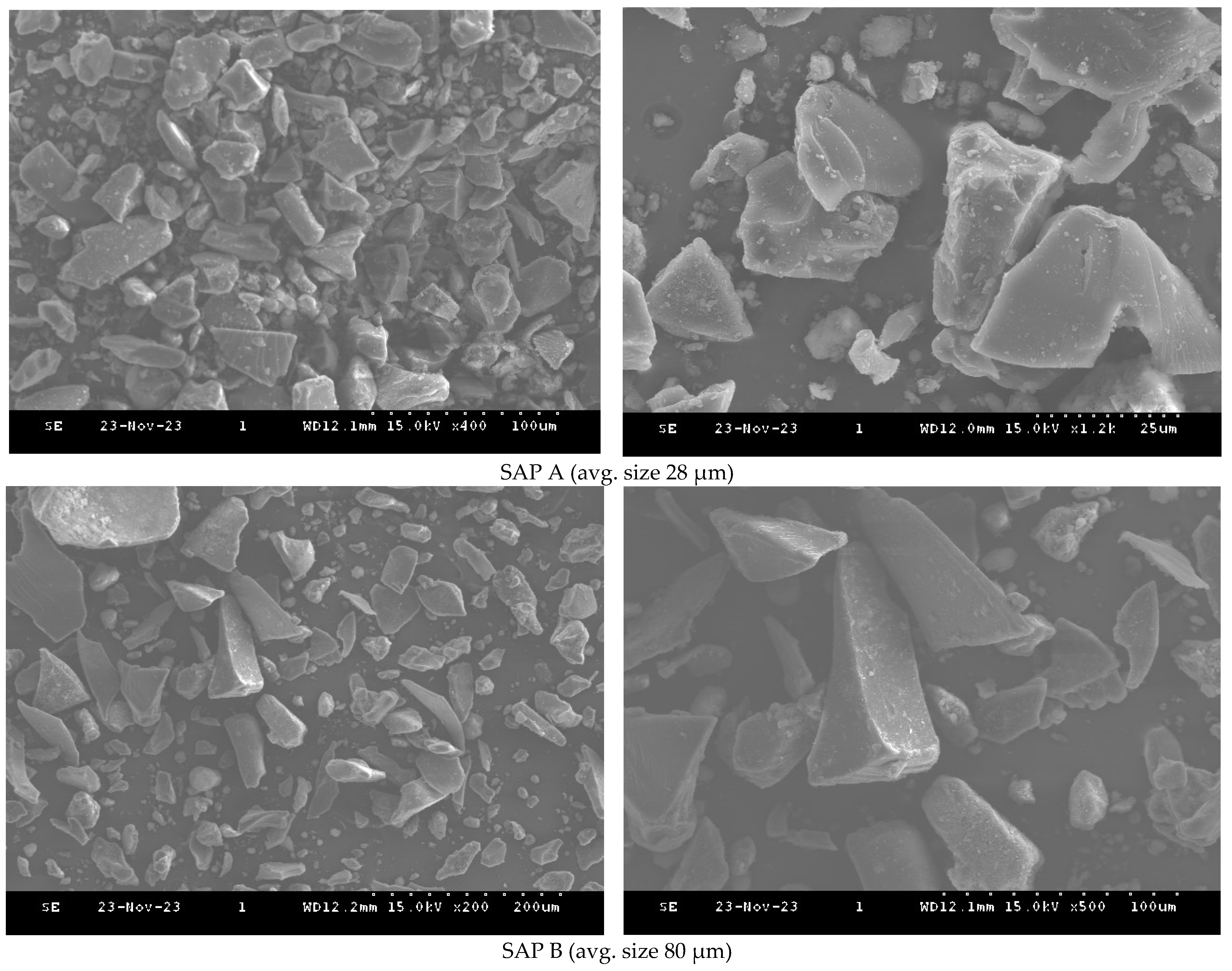

2. Materials and Methods

3. Results and Discussion

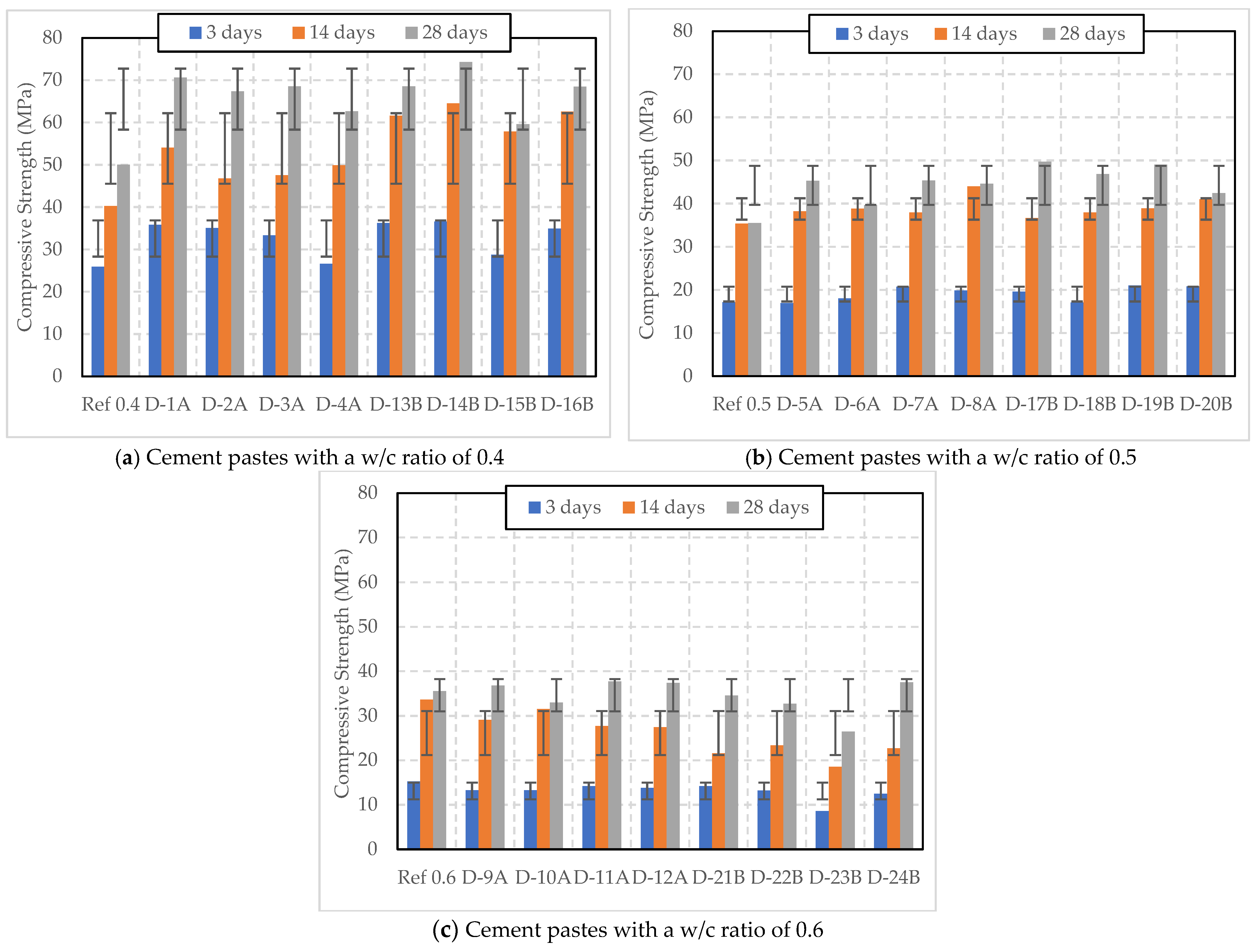

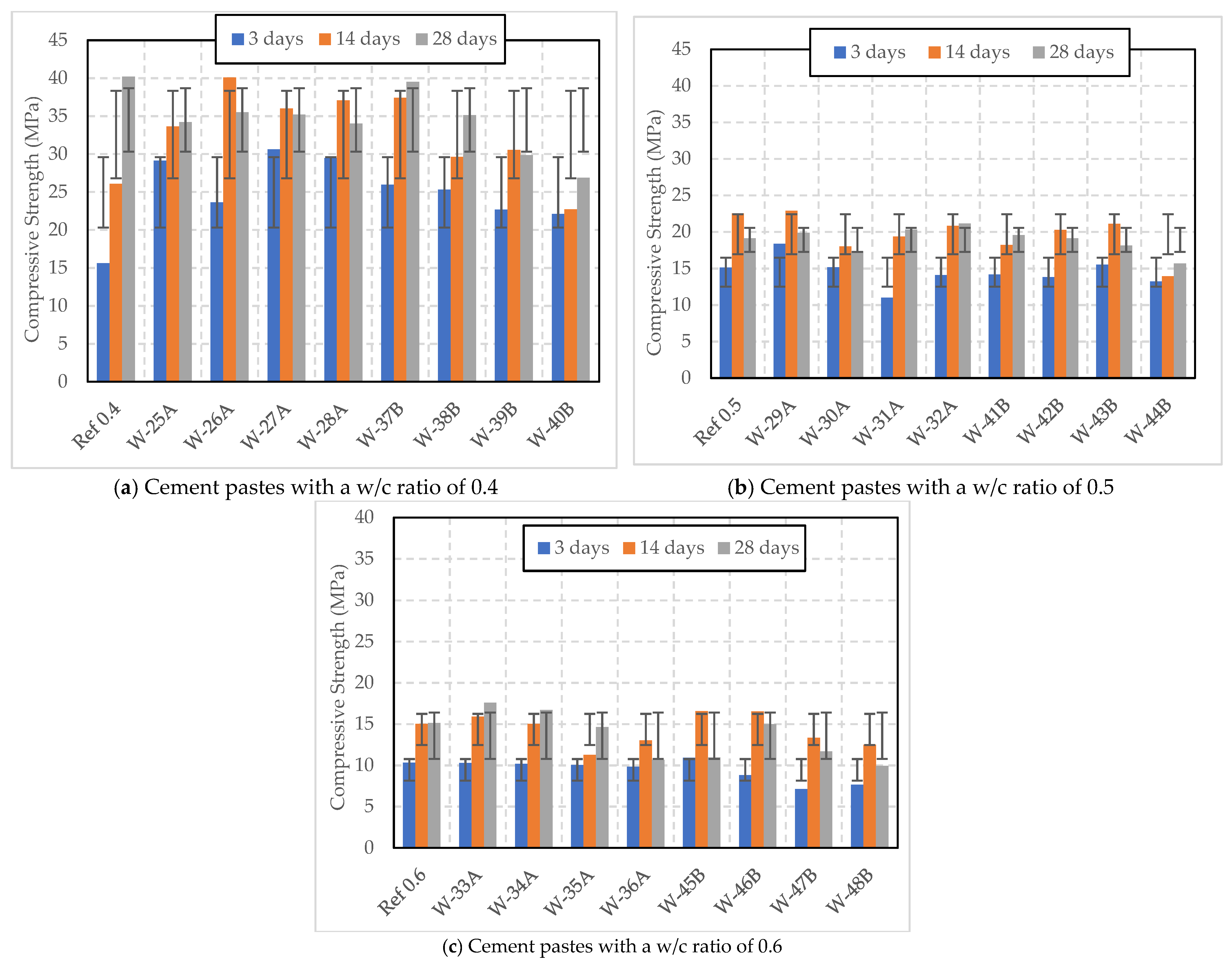

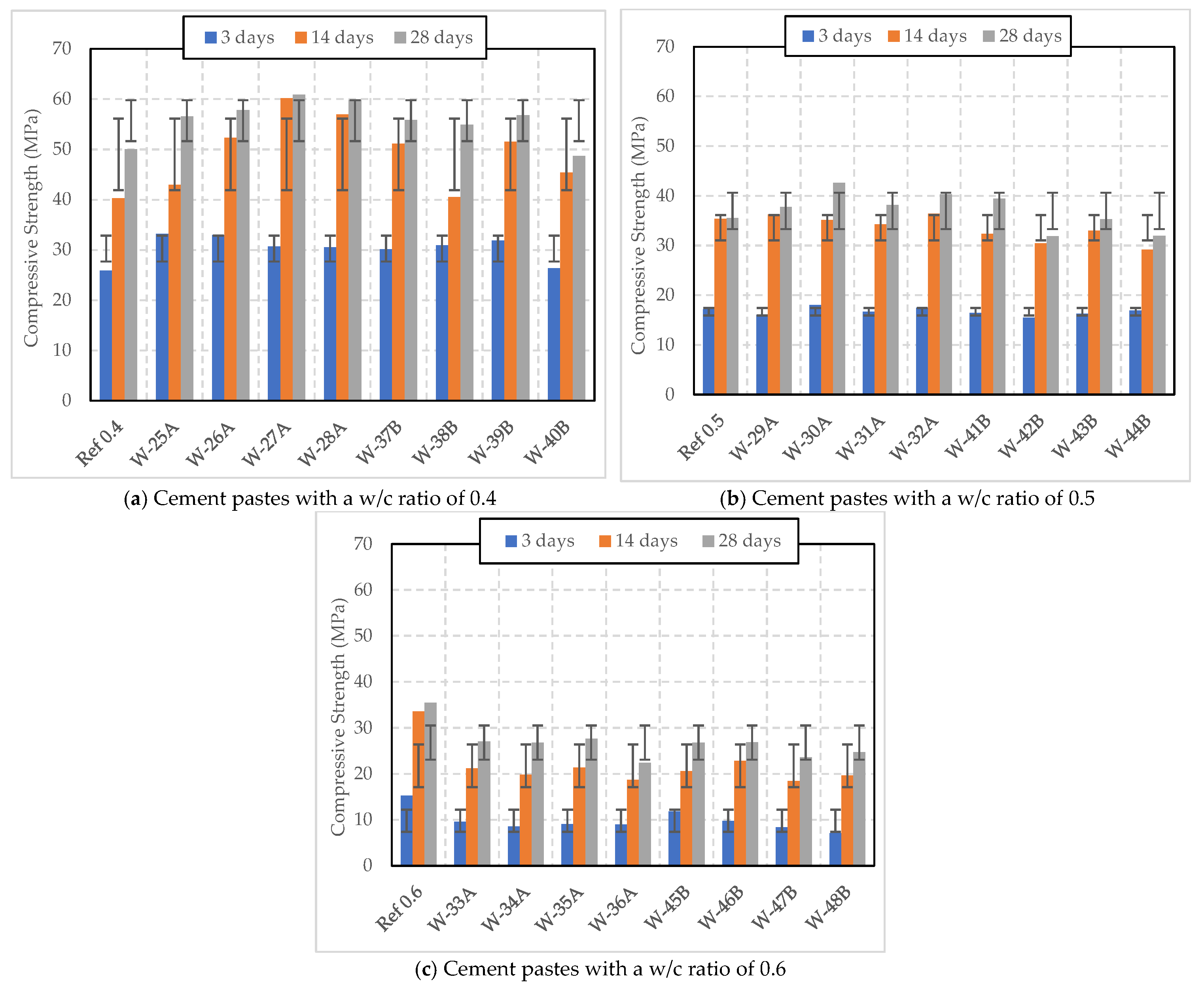

3.1. Compressive Strength

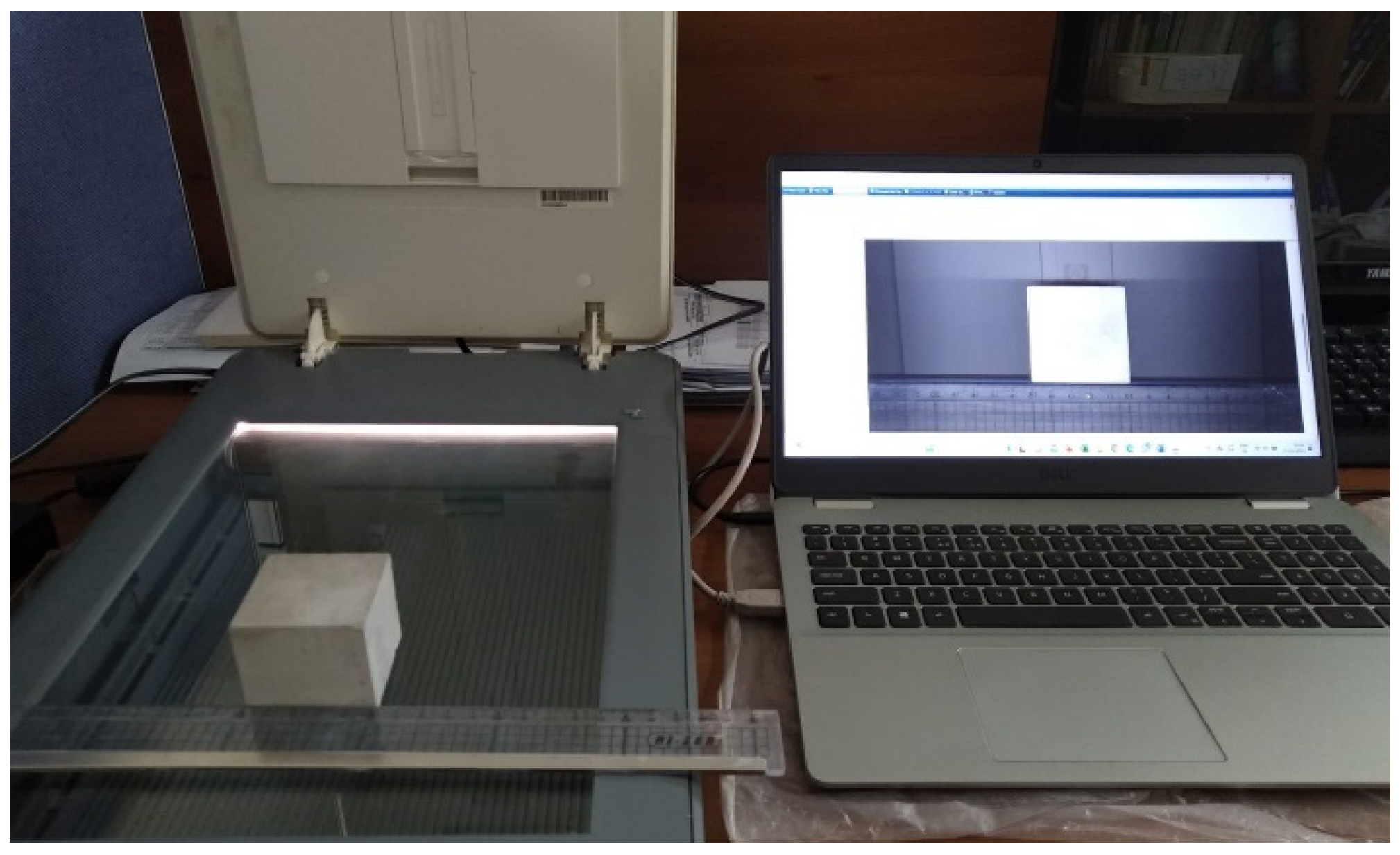

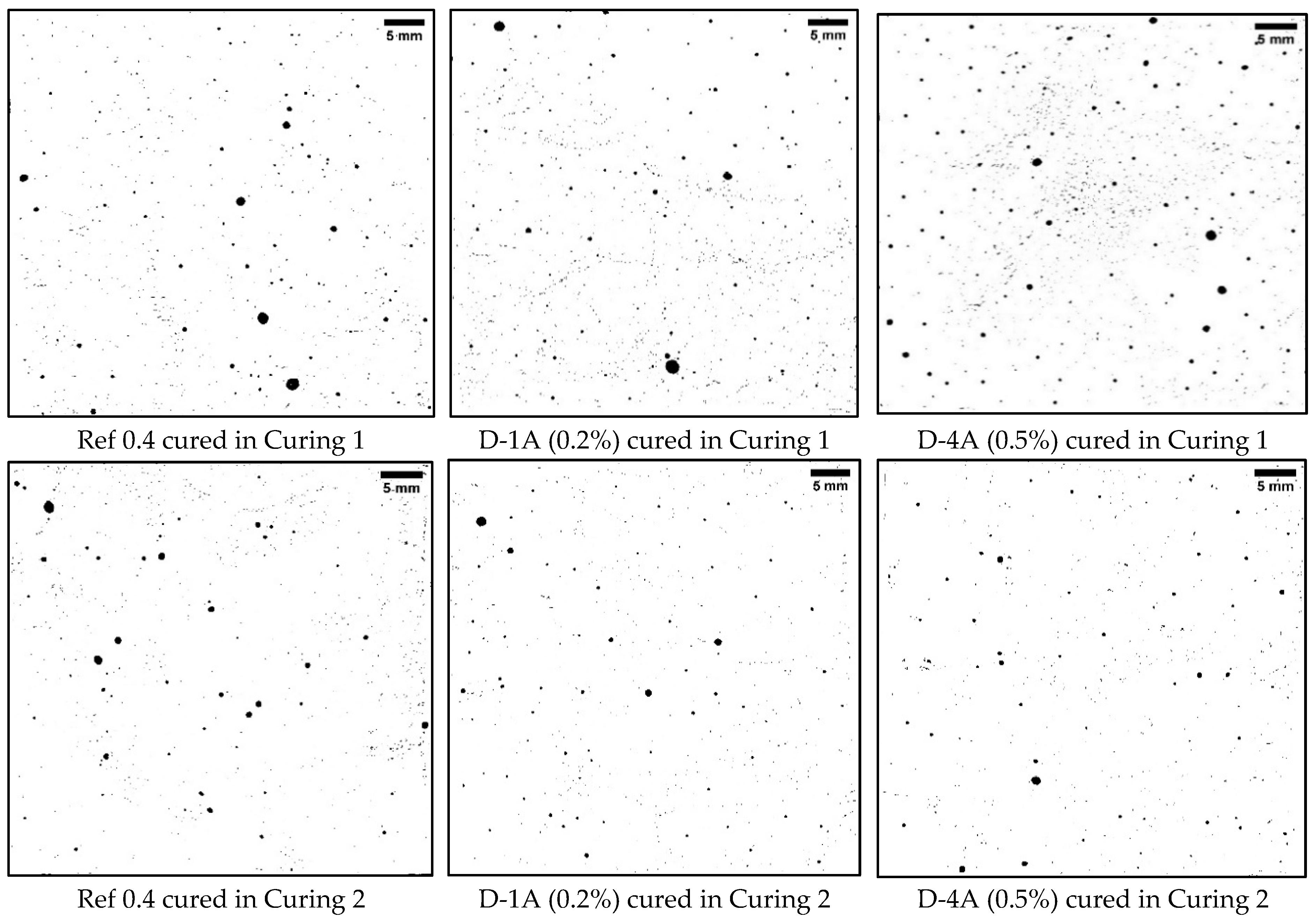

3.2. Void Analysis by ImageJ

3.3. Analysis of Variance (ANOVA) on Air Void Analysis Data

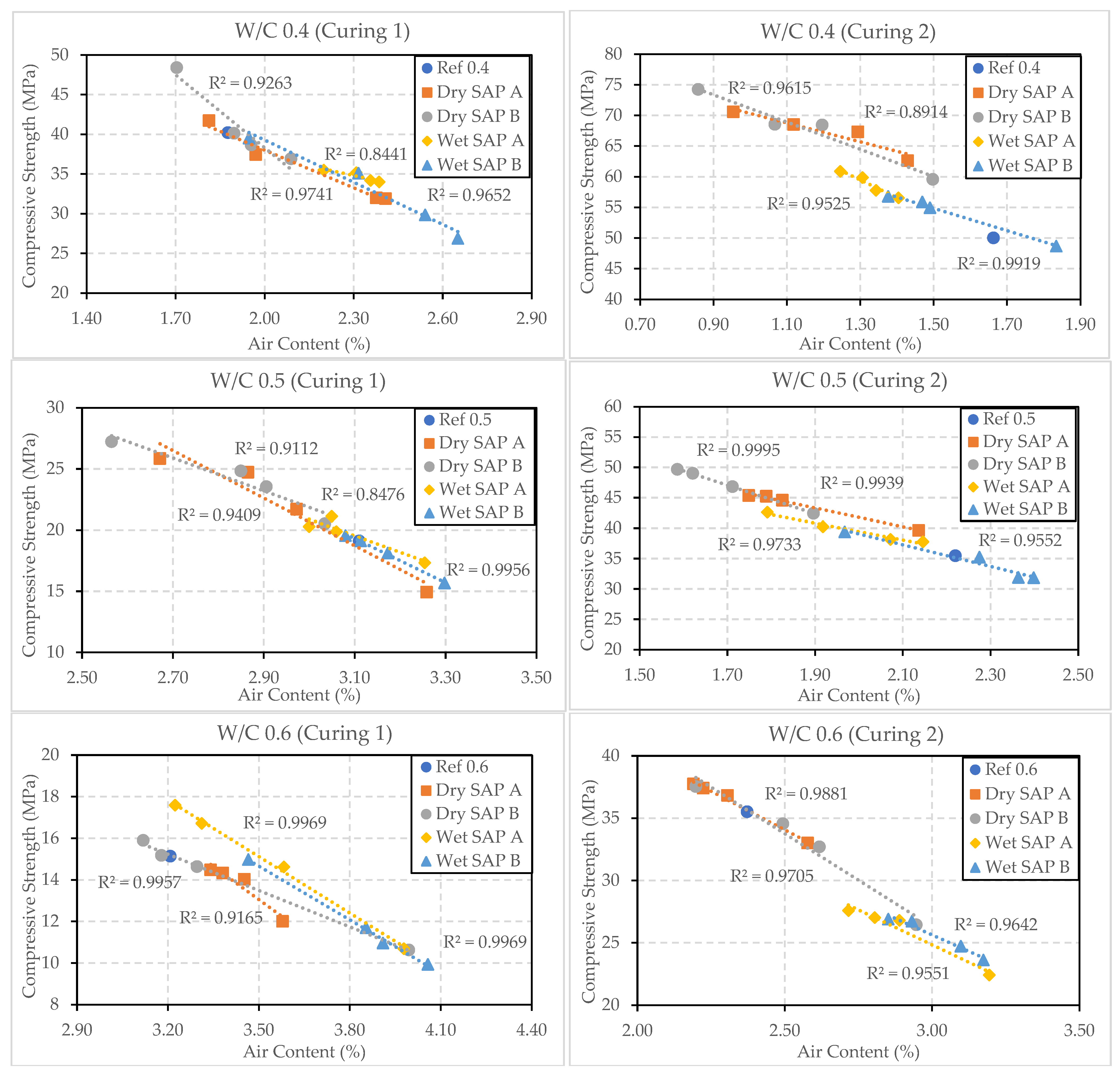

3.4. Relationship between 28-Day Compressive Strength and Air Content

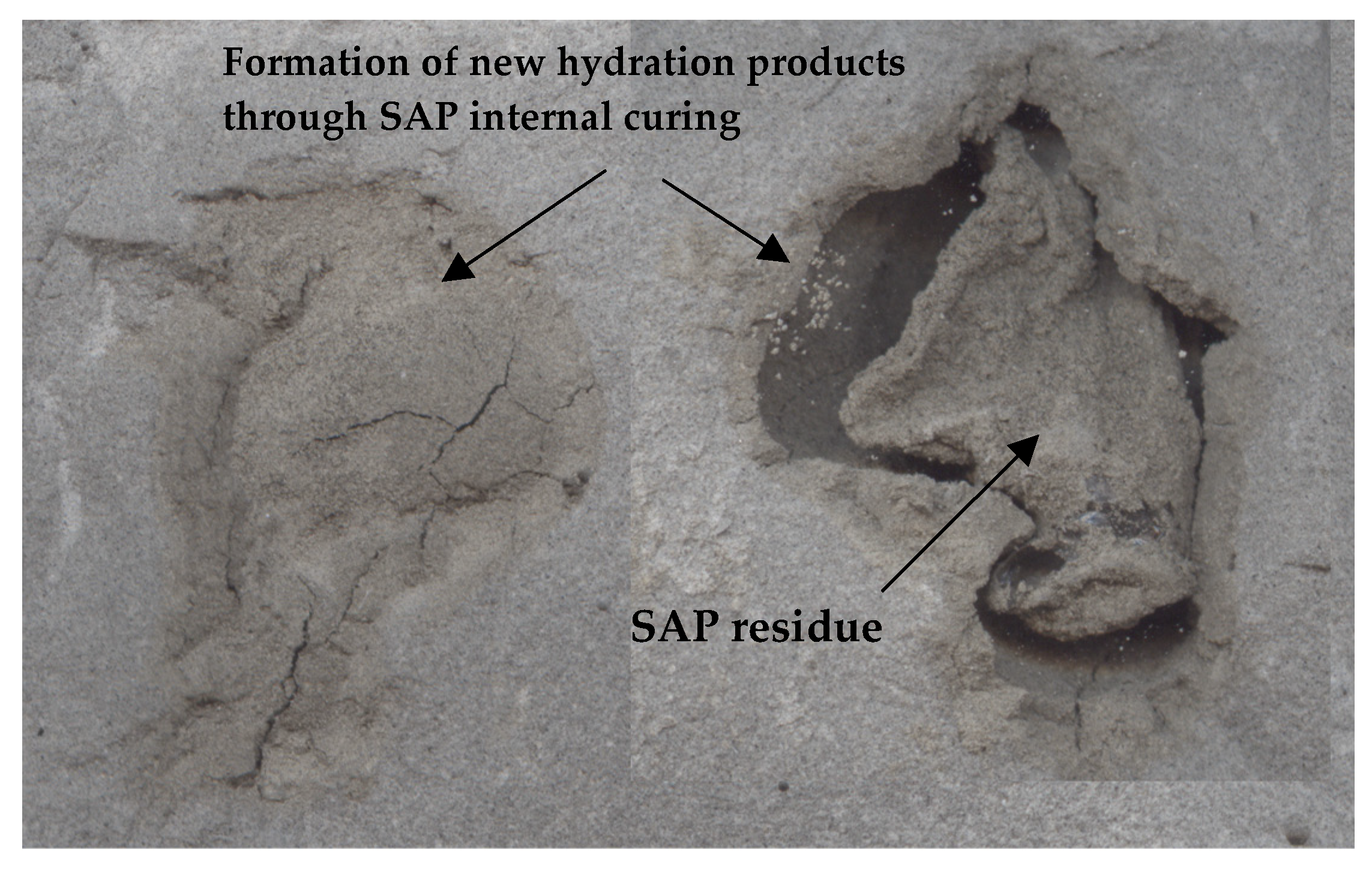

3.5. Microstructural Analysis

4. Conclusions

- An increase in the w/c ratio resulted in a decrease in strength for samples cured under Curing 1 conditions. However, samples with a w/c ratio of 0.4 exhibited higher strength when cured under Curing 2 conditions.

- The strength of cement pastes with dry SAP and varying w/c ratios was affected by Curing 1 conditions. However, cement pastes with a w/c ratio of 0.4 and a dosage of dry SAP B (0.2% and 0.5%) demonstrated improved compressive strength compared to the reference and other samples. In addition, the combination of dry SAP and Curing 1 conditions increased early strength but had a significant impact on later strength, especially after 14 days in most samples. Curing 2 conditions substantially enhanced strength over time in most samples with dry SAP and varying w/c ratios. Cement pastes containing dry SAP A and B with a w/c ratio of 0.4 and 0.5 exhibited higher strength than the reference. The internal water provided by SAP and external water curing helped improve the strength of the cement paste over time.

- The impact of the curing conditions on strength was similar for both dry and wet SAP additions. When cement paste with wet SAP was cured under Curing 1 conditions, there was a decrease in compressive strength compared to the reference. However, a few samples (W-37B, W-33A, and W-34A) showed better strength than the reference. Under Curing 2 conditions, cement paste with wet SAP resulted in improved strength when the w/c ratio was 0.4 and 0.5. There was a greater reduction in compressive strength when the w/c ratio was 0.6.

- When comparing dry SAP and wet SAP samples, the dry SAP samples cured under Curing 2 conditions exhibited a higher increase in strength than the wet SAP samples cured under the same conditions. This indicates that dry SAP and Curing 2 conditions improved strength to a greater extent than the reference sample.

- Samples with dry SAP generally exhibited higher SSAs compared to samples with wet SAP, indicating finer air voids and more surface area within the cement paste structure. Samples with wet SAP tended to have larger air voids, as indicated by their lower SSAs and higher spacing factors compared to samples with dry SAP. Additionally, the samples cured under Curing 1 conditions showed a higher total air content than the samples cured under Curing 2 conditions.

- Internal water curing provided by SAP helped in the formation of hydration products such as C-S-H, ettringite, and Portlandite crystals. However, the water provision by SAP was inadequate to completely fill the voids with hydration products, although it reduced the pore size.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Barrett, T.J.; Miller, A.E.; Weiss, W.J. Reducing shrinkage cracking with internal curing: From theory to practice. Indian Concr. J. 2014, 88, 61–71. [Google Scholar]

- Kovler, K. Smart additives for self-curing concrete. Mater. Res. Soc. Symp. Proc. 2012, 1488, 23–30. [Google Scholar] [CrossRef]

- Xu, F.; Lin, X.; Zhou, A. Performance of internal curing materials in high-performance concrete: A review. Constr. Build. Mater. 2021, 311, 125250. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Kovler, K.; Bentur, A. Efficiency of lightweight aggregates for internal curing of high strength concrete to eliminate autogenous shrinkage. Mater. Struct. 2002, 35, 97–101. [Google Scholar] [CrossRef]

- Antico, F.C.; Rojas, P.; Briones, F.; Araya-Letelier, G. Animal fibers as water reservoirs for internal curing of mortars and their limits caused by fiber clustering. Constr. Build. Mater. 2021, 267, 120918. [Google Scholar] [CrossRef]

- Ramalingam, V.; Ramesh, K.; Duraipandi, M.; Jayesh, U.; Kuppusamy, S. Water absorbing polymer balls as internal water curing agent in concrete to support hydration reaction. Rev. Constr. 2022, 21, 83–92. [Google Scholar] [CrossRef]

- Wong, H.S. Concrete with Superabsorbent polymer. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Woodhead Publishing: Cambridge, UK, 2018; pp. 467–499. [Google Scholar] [CrossRef]

- Qin, X.; Lin, Y.; Mao, J.; Sun, X.; Xie, Z.; Huang, Q. Research of water absorption and release mechanism of superabsorbent polymer in cement paste. Polymers 2023, 15, 3062. [Google Scholar] [CrossRef] [PubMed]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials II. Experimental observations. Cem. Concr. Res. 2002, 32, 973–978. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Reinhardt, H.W.; Cusson, D.; Friedrich, S.; Lura, P.; Friedemann, K.; Stallmach, F.; Mönnig, S.; Wyrzykowski, M.; Esteves, L.P.; et al. Application of Superabsorbent Polymers (SAP) in Concrete Construction: State of the Art Report Prepared by Technical Committee 225-SAP; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Wyrzykowski, M.; Schröfl, C.; Snoeck, D.; Lura, P.; Belie, N.D.; Mignon, A.; Vlierberghe, S.V.; Klemm, A.J.; Almeida, F.C.R.; et al. Application of super absorbent polymers (SAP) in concrete construction—Update of RILEM state-of-the-art-report. Mater. Struct. 2021, 54, 80. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Assmann, A. Enhanced durability of concrete by superabsorbent polymers. Proc. Int. Symp. Brittle Matrix Compos. 2009, 9, 291–300. [Google Scholar] [CrossRef]

- Sikora, K.S.; Klemm, A.J. Effect of superabsorbent polymers on workability and hydration process in fly ash cementitious composites. J. Mater. Civ. Eng. 2015, 27, 04014170-3. [Google Scholar] [CrossRef]

- Snoeck, D.; Schaubroeck, D.; Dubruel, P.; Belie, N.D. Effect of high amounts of superabsorbent polymers and additional water on the workability, microstructure and strength of mortars with a water-to-cement ratio of 0.50. Constr. Build. Mater. 2014, 72, 148–157. [Google Scholar] [CrossRef]

- Sun, B.; Wu, H.; Song, W.; Li, Z.; Yu, J. Design methodology and mechanical properties of Superabsorbent Polymer (SAP) cement-based materials. Constr. Build. Mater. 2019, 204, 440–449. [Google Scholar] [CrossRef]

- Craeye, B.; Geirnaert, M.; Schutter, G.D. Super absorbing polymers as an internal curing agent for migration of early-age cracking of high-performance concrete bridge decks. Concr. Build. Mater. 2011, 25, 1–13. [Google Scholar] [CrossRef]

- Monnig, S. Superabsorbing Additions in Concrete-Application, Modelling, and Comparison of Different Internal Water Sources. Ph.D. Thesis, Institut für Werkstoffe im Bauwesen der Universität Stuttgart, Stuttgart, Germany, 2009. [Google Scholar]

- Niu, X.; Zhang, Y.; Elakneswaran, Y.; Sasaki, M.; Takayama, T.; Kawai, H. Effect of Superabsorbent Polymer (SAP) Size on Microstructure and Compressive Strength of Concrete. Polymers 2024, 16, 197. [Google Scholar] [CrossRef]

- Li, L.; Chai, H.; Hu, Y.; He, R.; Wang, Z. Feasibility study on superabsorbent polymer (SAP) as internal curing agent for cement-based grouting material. Constr. Build. Mater. 2024, 411, 134286. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, H.; Wang, Z.; Xue, C.; He, R. Performance of cement mortar incorporating superabsorbent polymer (SAP) using different dosing methods. Materials 2019, 12, 1619. [Google Scholar] [CrossRef]

- Kalinowski, M.; Woyeciechowski, P.; Sokolowska, J. Effect of mechanically-induced fragmentation of polyacrylic superabsorbent polymer (SAP) hydrogel on the properties of cement composites. Constr. Build. Mater. 2020, 263, 120135. [Google Scholar] [CrossRef]

- Cheng, B.; Li, X.; Liu, Y.; Chen, M.; Du, S. Effect of superabsorbent polymers on the self-healing properties of pre-damaged concrete. Processes 2022, 10, 2333. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, S.Y.; Choi, Y.S.; Yang, E. Effect of internal pores formed by a superabsorbent polymer on durability and drying shrinkage of concrete specimens. Materials 2021, 14, 5199. [Google Scholar] [CrossRef]

- Riyazi, S.; Kevern, J.; Mulheron, M. Super absorbent polymers (SAPs) as physical air entrainment in cement mortars. Constr. Build. Mater. 2017, 147, 669–676. [Google Scholar] [CrossRef]

- Snoeck, D.; Schröfl, C.; Mechtcherine, V. Recommendation of RILEM TC 260-RSC: Testing sorption by superabsorbent polymers (SAP) prior to implementation in cement-based materials. Mater. Struct. 2018, 51, 116. [Google Scholar] [CrossRef]

- Huang, X.; Liu, X.; Rong, H.; Yang, X.; Duan, Y.; Ren, T. Effect of super-absorbent polymer (SAP) incorporation method on mechanical and shrinkage properties of internally cured concrete. Materials 2022, 15, 7854. [Google Scholar] [CrossRef] [PubMed]

- Beushausen, H.; Gillmer, M.; Alexander, M. The influence of superabsorbent polymers on strength and durability properties of blended cement mortars. Cem. Concr. Compos. 2014, 52, 73–80. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Z.; Lu, Z. Effect of pre-soaked superabsorbent polymer on shrinkage of high-strength concrete. Mater. Struct. 2015, 48, 2741–2758. [Google Scholar] [CrossRef]

- Elsen, J.; Lens, N.; Vyncke, J.; Aarre, T.; Quenard, D.; Smolej, V. Quality Assurance and Quality Control of Air Entrained Concrete. Cem. Concr. Res. 1994, 24, 1267–1276. [Google Scholar] [CrossRef]

- Malendowska, A.; Wawrzenczyk, J.; Kowalczyk, H. Development of the Measuring Techniques for Estimating the Air Void System Parameters in Concrete Using 2D Analysis Method. Materials 2020, 13, 428. [Google Scholar] [CrossRef]

- Ojala, T.; Chen, Y.; Punkki, J.; Al-Neshawy, F. Characteristics of Entrained Air Voids in Hardened Concrete with the Method of Digital Image Analysis Coupled with Schwartz-Saltykov Conversion. Materials 2021, 14, 2439. [Google Scholar] [CrossRef] [PubMed]

- ASTM C457-06; Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2006.

- Zhu, Q. Effect of Multivalent Ions on the Swelling and Mechanical Behavior of Superabsorbent Polymers (SAPs) for Mitigation of Mortar Autogenous Shrinkage. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Yu, P.; Mo, L.; Deng, M. Synergetic effect of MEA and SAP on the deformation and mechanical properties of concrete. Mag. Concr. Res. 2019, 72, 1289–1296. [Google Scholar] [CrossRef]

- Klemm, A.J.; Sikora, K.S. The effect of superabsorbent polymers (SAP) on microstructure and mechanical properties of fly ash cementitious mortars. Constr. Build. Mater. 2013, 49, 134–143. [Google Scholar] [CrossRef]

- Pourjavadi, A.; Fakoorpoor, S.M.; Hosseini, P.; Khaloo, A. Interactions between superabsorbent polymers and cement-based composite incorporating colloidal silica nanoparticles. Cem. Concr. Compos. 2013, 37, 196–204. [Google Scholar] [CrossRef]

| Chemical Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO |

| Ratio in weight (%) | 62.00 | 20.50 | 5.11 | 3.30 | 2.60 |

| D-1A | D-2A | D-3A | D-4A | D-5A | D-6A | D-7A | D-8A | D-9A | D-10A | D-11A | D-12A | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| W/C | 0.4 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 |

| SAP/C (%) | 0.2 | 0.3 | 0.4 | 0.5 | 0.2 | 0.3 | 0.4 | 0.5 | 0.2 | 0.3 | 0.4 | 0.5 |

| Total Air (Air Content) | Air ≤ 1 mm | Specific Surface Area (SSA) | Spacing Factor | ||||

|---|---|---|---|---|---|---|---|

| Sample | % | Stdv. | (%) | Stdv. | (mm−1) | Stdv. | (mm) |

| Ref 0.4 | 1.88 | 0.08 | 1.61 | 0.07 | 66.37 | 4.74 | 0.14 |

| D-1A (0.2%) | 1.81 | 0.09 | 1.53 | 0.09 | 77.06 | 2.29 | 0.12 |

| D-2A (0.3%) | 1.97 | 0.10 | 1.97 | 0.10 | 83.46 | 1.31 | 0.11 |

| D-3A (0.4%) | 2.41 | 0.12 | 2.41 | 0.12 | 85.03 | 9.63 | 0.10 |

| D-4A (0.5%) | 2.38 | 0.14 | 2.33 | 0.14 | 81.89 | 2.58 | 0.10 |

| D-13B (0.2%) | 1.90 | 0.09 | 1.73 | 0.09 | 67.69 | 15.20 | 0.14 |

| D-14B (0.3%) | 1.95 | 0.10 | 1.91 | 0.10 | 83.89 | 3.48 | 0.11 |

| D-15B (0.4%) | 2.09 | 0.10 | 2.04 | 0.10 | 86.27 | 7.35 | 0.10 |

| D-16B (0.5%) | 1.70 | 0.06 | 1.56 | 0.06 | 76.11 | 17.08 | 0.13 |

| W-25A (0.2%) | 2.36 | 0.15 | 1.47 | 0.06 | 50.28 | 4.16 | 0.17 |

| W-26A (0.3%) | 2.20 | 0.12 | 1.28 | 0.07 | 38.28 | 5.10 | 0.22 |

| W-27A (0.4%) | 2.31 | 0.16 | 0.72 | 0.03 | 24.25 | 1.17 | 0.35 |

| W-28A (0.5%) | 2.39 | 0.13 | 1.20 | 0.05 | 33.58 | 6.75 | 0.25 |

| W-37B (0.2%) | 1.95 | 0.10 | 1.95 | 0.11 | 53.53 | 1.23 | 0.17 |

| W-38B (0.3%) | 2.32 | 0.12 | 2.16 | 0.13 | 54.88 | 5.59 | 0.15 |

| W-39B (0.4%) | 2.54 | 0.10 | 2.00 | 0.10 | 56.34 | 9.44 | 0.14 |

| W-40B (0.5%) | 2.65 | 0.11 | 2.27 | 0.10 | 56.17 | 2.54 | 0.14 |

| Total Air (Air Content) | Air ≤ 1 mm | Specific Surface Area (SSA) | Spacing Factor | ||||

|---|---|---|---|---|---|---|---|

| Sample | % | Stdv. | % | Stdv. | (mm−1) | Stdv. | (mm) |

| Ref 0.4 | 1.66 | 0.06 | 1.48 | 0.06 | 66.99 | 1.29 | 0.14 |

| D-1A (0.2%) | 0.95 | 0.04 | 0.87 | 0.04 | 72.36 | 2.46 | 0.17 |

| D-2A (0.3%) | 1.29 | 0.08 | 1.29 | 0.08 | 85.22 | 6.20 | 0.13 |

| D-3A (0.4%) | 1.12 | 0.06 | 1.07 | 0.06 | 87.25 | 3.09 | 0.13 |

| D-4A (0.5%) | 1.43 | 0.08 | 1.43 | 0.08 | 91.09 | 8.33 | 0.11 |

| D-13B (0.2%) | 1.07 | 0.04 | 0.98 | 0.04 | 74.68 | 16.47 | 0.16 |

| D-14B (0.3%) | 0.86 | 0.04 | 0.78 | 0.04 | 69.24 | 2.22 | 0.18 |

| D-15B (0.4%) | 1.50 | 0.09 | 1.50 | 0.09 | 67.65 | 1.56 | 0.15 |

| D-16B (0.5%) | 1.20 | 0.07 | 0.99 | 0.08 | 44.46 | 7.92 | 0.25 |

| W-25A (0.2%) | 1.40 | 0.06 | 1.40 | 0.06 | 62.79 | 1.33 | 0.11 |

| W-26A (0.3%) | 1.34 | 0.06 | 0.95 | 0.04 | 54.53 | 3.68 | 0.16 |

| W-27A (0.4%) | 1.25 | 0.05 | 1.07 | 0.05 | 65.30 | 4.99 | 0.13 |

| W-28A (0.5%) | 1.31 | 0.06 | 1.23 | 0.07 | 65.84 | 0.36 | 0.16 |

| W-37B (0.2%) | 1.47 | 0.06 | 1.41 | 0.07 | 66.13 | 3.04 | 0.15 |

| W-38B (0.3%) | 1.49 | 0.08 | 1.49 | 0.09 | 59.35 | 1.28 | 0.17 |

| W-39B (0.4%) | 1.38 | 0.06 | 1.38 | 0.06 | 57.21 | 3.05 | 0.18 |

| W-40B (0.5%) | 1.83 | 0.09 | 1.76 | 0.09 | 52.97 | 2.20 | 0.18 |

| Total Air (Air Content) | Air ≤ 1 mm | Specific Surface Area (SSA) | Spacing Factor | ||||

|---|---|---|---|---|---|---|---|

| Sample | % | Stdv. | % | Stdv. | (mm−1) | Stdv. | (mm) |

| Ref 0.5 | 3.11 | 0.12 | 2.92 | 0.13 | 56.31 | 8.05 | 0.12 |

| D-5A (0.2%) | 3.26 | 0.16 | 3.26 | 0.16 | 76.62 | 10.33 | 0.09 |

| D-6A (0.3%) | 2.87 | 0.13 | 2.77 | 0.13 | 62.23 | 6.07 | 0.12 |

| D-7A (0.4%) | 2.67 | 0.13 | 2.62 | 0.14 | 67.80 | 5.16 | 0.11 |

| D-8A (0.5%) | 2.97 | 0.16 | 2.91 | 0.16 | 79.05 | 2.51 | 0.09 |

| D-17B (0.2%) | 2.91 | 0.13 | 2.85 | 0.13 | 64.00 | 6.49 | 0.11 |

| D-18B (0.3%) | 3.03 | 0.18 | 3.03 | 0.18 | 68.23 | 7.36 | 0.10 |

| D-19B (0.4%) | 2.57 | 0.11 | 2.51 | 0.11 | 67.31 | 0.26 | 0.11 |

| D-20B (0.5%) | 2.85 | 0.15 | 2.71 | 0.16 | 74.84 | 0.62 | 0.10 |

| W-29A (0.2%) | 3.06 | 0.13 | 3.00 | 0.12 | 47.84 | 0.47 | 0.15 |

| W-30A (0.3%) | 3.25 | 0.14 | 3.25 | 0.14 | 53.29 | 1.57 | 0.13 |

| W-31A (0.4%) | 3.00 | 0.13 | 2.94 | 0.13 | 52.58 | 0.40 | 0.13 |

| W-32A (0.5%) | 3.05 | 0.14 | 3.00 | 0.15 | 53.45 | 6.61 | 0.13 |

| W-41B (0.2%) | 3.08 | 0.13 | 3.08 | 0.12 | 56.82 | 12.38 | 0.12 |

| W-42B (0.3%) | 3.11 | 0.12 | 2.91 | 0.12 | 52.04 | 8.35 | 0.13 |

| W-43B (0.4%) | 3.17 | 0.12 | 3.05 | 0.12 | 54.55 | 0.28 | 0.13 |

| W-44B (0.5%) | 3.30 | 0.14 | 3.11 | 0.14 | 61.27 | 15.34 | 0.11 |

| Total Air (Air Content) | Air ≤ 1 mm | Specific Surface Area (SSA) | Spacing Factor | ||||

|---|---|---|---|---|---|---|---|

| Sample | % | Stdv. | % | Stdv. | (mm−1) | Stdv. | (mm) |

| Ref 0.5 | 2.22 | 0.10 | 2.22 | 0.10 | 72.09 | 1.97 | 0.11 |

| D-5A (0.2%) | 1.79 | 0.08 | 1.79 | 0.08 | 70.74 | 6.01 | 0.13 |

| D-6A (0.3%) | 2.14 | 0.08 | 1.90 | 0.09 | 66.96 | 3.72 | 0.12 |

| D-7A (0.4%) | 1.75 | 0.09 | 1.75 | 0.09 | 83.28 | 3.39 | 0.11 |

| D-8A (0.5%) | 1.83 | 0.11 | 1.83 | 0.11 | 90.13 | 0.01 | 0.10 |

| D-17B (0.2%) | 1.59 | 0.08 | 1.59 | 0.08 | 71.65 | 4.40 | 0.13 |

| D-18B (0.3%) | 1.71 | 0.09 | 1.71 | 0.09 | 72.91 | 0.76 | 0.12 |

| D-19B (0.4%) | 1.62 | 0.08 | 1.62 | 0.08 | 78.11 | 13.15 | 0.12 |

| D-20B (0.5%) | 1.90 | 0.09 | 1.80 | 0.09 | 73.68 | 6.73 | 0.12 |

| W-29A (0.2%) | 2.15 | 0.08 | 2.07 | 0.07 | 55.07 | 3.85 | 0.15 |

| W-30A (0.3%) | 1.79 | 0.09 | 1.73 | 0.10 | 48.26 | 4.24 | 0.18 |

| W-31A (0.4%) | 2.07 | 0.09 | 1.94 | 0.09 | 42.28 | 1.35 | 0.20 |

| W-32A (0.5%) | 1.92 | 0.10 | 1.39 | 0.07 | 38.42 | 2.52 | 0.22 |

| W-41B (0.2%) | 1.97 | 0.07 | 1.97 | 0.06 | 46.86 | 0.20 | 0.18 |

| W-42B (0.3%) | 2.40 | 0.10 | 2.29 | 0.09 | 62.26 | 6.01 | 0.13 |

| W-43B (0.4%) | 2.27 | 0.10 | 2.27 | 0.10 | 63.10 | 2.91 | 0.13 |

| W-44B (0.5%) | 2.36 | 0.10 | 2.36 | 0.10 | 66.58 | 3.39 | 0.12 |

| Total Air (Air Content) | Air ≤ 1 mm | Specific Surface Area (SSA) | Spacing Factor | ||||

|---|---|---|---|---|---|---|---|

| Sample | % | Stdv. | % | Stdv. | (mm−1) | Stdv. | (mm) |

| Ref 0.6 | 3.21 | 0.18 | 3.04 | 0.19 | 68.09 | 3.27 | 0.10 |

| D-9A (0.2%) | 3.38 | 0.23 | 3.33 | 0.24 | 87.67 | 1.05 | 0.07 |

| D-10A (0.3%) | 3.34 | 0.16 | 3.11 | 0.17 | 82.21 | 11.14 | 0.08 |

| D-11A (0.4%) | 3.58 | 0.21 | 3.43 | 0.22 | 86.00 | 7.82 | 0.07 |

| D-12A (0.5%) | 3.45 | 0.19 | 3.41 | 0.20 | 84.30 | 4.99 | 0.08 |

| D-21B (0.2%) | 3.30 | 0.20 | 3.19 | 0.21 | 80.11 | 6.78 | 0.08 |

| D-22B (0.3%) | 3.12 | 0.17 | 3.02 | 0.18 | 76.76 | 7.62 | 0.09 |

| D-23B (0.4%) | 3.99 | 0.28 | 3.90 | 0.29 | 88.57 | 6.24 | 0.07 |

| D-24B (0.5%) | 3.18 | 0.18 | 3.08 | 0.19 | 80.04 | 12.48 | 0.08 |

| W-33A (0.2%) | 3.22 | 0.15 | 2.91 | 0.15 | 55.91 | 1.23 | 0.12 |

| W-34A (0.3%) | 3.31 | 0.15 | 3.24 | 0.16 | 66.44 | 5.91 | 0.10 |

| W-35A (0.4%) | 3.58 | 0.17 | 3.53 | 0.17 | 64.51 | 6.22 | 0.10 |

| W-36A (0.5%) | 3.98 | 0.21 | 3.93 | 0.23 | 73.14 | 4.60 | 0.08 |

| W-45B (0.2%) | 3.91 | 0.20 | 3.91 | 0.21 | 64.49 | 5.75 | 0.09 |

| W-46B (0.3%) | 3.46 | 0.15 | 3.40 | 0.15 | 61.94 | 8.04 | 0.10 |

| W-47B (0.4%) | 3.85 | 0.19 | 3.78 | 0.20 | 65.34 | 2.37 | 0.09 |

| W-48B (0.5%) | 4.06 | 0.23 | 4.06 | 0.76 | 73.52 | 1.12 | 0.08 |

| Total Air (Air Content) | Air ≤ 1 mm | Specific Surface Area (SSA) | Spacing Factor | ||||

|---|---|---|---|---|---|---|---|

| Sample | % | Stdv. | (%) | Stdv. | (mm−1) | Stdv. | (mm) |

| Ref 0.6 | 2.37 | 0.11 | 2.31 | 0.11 | 73.99 | 16.15 | 0.10 |

| D-9A (0.2%) | 2.31 | 0.13 | 2.26 | 0.13 | 75.66 | 11.75 | 0.10 |

| D-10A (0.3%) | 2.58 | 0.13 | 2.58 | 0.13 | 75.06 | 12.62 | 0.10 |

| D-11A (0.4%) | 2.19 | 0.13 | 2.19 | 0.13 | 67.38 | 6.84 | 0.12 |

| D-12A (0.5%) | 2.22 | 0.11 | 2.22 | 0.11 | 69.35 | 12.65 | 0.11 |

| D-21B (0.2%) | 2.49 | 0.12 | 2.41 | 0.12 | 67.07 | 5.59 | 0.11 |

| D-22B (0.3%) | 2.62 | 0.13 | 2.62 | 0.13 | 70.21 | 11.75 | 0.10 |

| D-23B (0.4%) | 2.95 | 0.15 | 2.95 | 0.15 | 72.63 | 3.03 | 0.09 |

| D-24B (0.5%) | 2.20 | 0.12 | 2.20 | 0.12 | 64.68 | 0.41 | 0.12 |

| W-33A (0.2%) | 2.80 | 0.13 | 2.80 | 0.13 | 63.71 | 6.63 | 0.11 |

| W-34A (0.3%) | 2.89 | 0.12 | 2.75 | 0.12 | 56.49 | 0.03 | 0.12 |

| W-35A (0.4%) | 2.72 | 0.11 | 2.64 | 0.11 | 54.94 | 3.59 | 0.13 |

| W-36A (0.5%) | 3.19 | 0.12 | 2.96 | 0.12 | 60.80 | 6.60 | 0.11 |

| W-45B (0.2%) | 2.93 | 0.13 | 2.71 | 0.13 | 52.74 | 0.48 | 0.13 |

| W-46B (0.3%) | 2.85 | 0.12 | 2.85 | 0.11 | 55.90 | 0.53 | 0.12 |

| W-47B (0.4%) | 3.17 | 0.15 | 3.17 | 0.15 | 60.23 | 0.08 | 0.11 |

| W-48B (0.5%) | 3.10 | 0.13 | 3.00 | 0.13 | 55.67 | 1.66 | 0.12 |

| SUMMARY | ||||||

| Groups | Count | Sum | Average | Variance | ||

| Total air (%) | 17 | 36.81 | 2.17 | 0.08 | ||

| Air ≤ 1 mm (%) | 17 | 30.14 | 1.77 | 0.20 | ||

| Specific Surface Area (SSA) (mm−1) | 17 | 1075.08 | 63.24 | 376.70 | ||

| Spacing factor (mm) | 17 | 2.64 | 0.16 | 0.0042 | ||

| ANOVA | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 48,852.94 | 3 | 16,284.31 | 172.79 | 0.00 | 2.75 |

| Within Groups | 6031.718 | 64 | 94.25 | |||

| Total | 54,884.66 | 67 | ||||

| SUMMARY | ||||||

| Groups | Count | Sum | Average | Variance | ||

| Total air (%) | 17 | 51.26 | 3.02 | 0.04 | ||

| Air ≤ 1 mm (%) | 17 | 49.92 | 2.94 | 0.04 | ||

| Specific Surface Area (SSA) (mm−1) | 17 | 1048.23 | 61.66 | 89.04 | ||

| Spacing factor (mm) | 17 | 1.98 | 0.12 | 0.00026 | ||

| ANOVA | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 45,440.29 | 3 | 15,146.76 | 679.80 | 0.00 | 2.75 |

| Within Groups | 1425.993 | 64 | 22.28 | |||

| Total | 46,866.28 | 67 | ||||

| SUMMARY | ||||||

| Groups | Count | Sum | Average | Variance | ||

| Total air (%) | 17 | 22.55 | 1.33 | 0.06 | ||

| Air ≤ 1 mm (%) | 17 | 21.08 | 1.24 | 0.07 | ||

| Specific Surface Area (SSA) (mm−1) | 17 | 1143.06 | 67.24 | 153.25 | ||

| Spacing factor (mm) | 17 | 2.66 | 0.16 | 0.0011 | ||

| ANOVA | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 56,112.22 | 3 | 18,704.07 | 487.76 | 0.00 | 2.75 |

| Within Groups | 2454.18 | 64 | 38.35 | |||

| Total | 58,566.4 | 67 | ||||

| SUMMARY | ||||||

| Groups | Count | Sum | Average | Variance | ||

| Total air (%) | 17 | 33.48 | 1.97 | 0.06 | ||

| Air ≤ 1 mm (%) | 17 | 32.23 | 1.90 | 0.07 | ||

| Specific Surface Area (SSA) (mm−1) | 17 | 1102.38 | 64.85 | 209.41 | ||

| Spacing factor (mm) | 17 | 2.37 | 0.14 | 0.0012 | ||

| ANOVA | ||||||

| Source of Variation | SS | df | MS | F | p-value | F crit |

| Between Groups | 51,465.46 | 3 | 17,155.15 | 327.47 | 0.00 | 2.75 |

| Within Groups | 3352.777 | 64 | 52.39 | |||

| Total | 54,818.24 | 67 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adsul, N.; Kang, S.-T. Investigation of the Compressive Strength and Void Analysis of Cement Pastes with Superabsorbent Polymer. Polymers 2024, 16, 1970. https://doi.org/10.3390/polym16141970

Adsul N, Kang S-T. Investigation of the Compressive Strength and Void Analysis of Cement Pastes with Superabsorbent Polymer. Polymers. 2024; 16(14):1970. https://doi.org/10.3390/polym16141970

Chicago/Turabian StyleAdsul, Nilam, and Su-Tae Kang. 2024. "Investigation of the Compressive Strength and Void Analysis of Cement Pastes with Superabsorbent Polymer" Polymers 16, no. 14: 1970. https://doi.org/10.3390/polym16141970

APA StyleAdsul, N., & Kang, S.-T. (2024). Investigation of the Compressive Strength and Void Analysis of Cement Pastes with Superabsorbent Polymer. Polymers, 16(14), 1970. https://doi.org/10.3390/polym16141970