Epoxidized Soybean Oil Toughened Poly(lactic acid)/Lignin-g-Poly(lauryl methacrylate) Bio-Composite Films with Potential Food Packaging Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of LG-g-PLMA

2.3. Preparation of PLA/LG-g-PLMA/ESO Composite

2.4. Preparation of PLA/LG-g-PLMA/ESO Composite Film

2.5. Characterization

- (1)

- Fourier Transform Infrared Spectroscopy (FT-IR)

- (2)

- Differential Scanning Calorimetry (DSC)

- (3)

- Mechanical Properties

- (4)

- Thermogravimetric Analysis

- (5)

- Rheological Properties

- (6)

- Optical Property

- (7)

- Scanning Electron Microscopy

- (8)

- Oxygen transmission rate

- (9)

- Overall migration

3. Results and Discussion

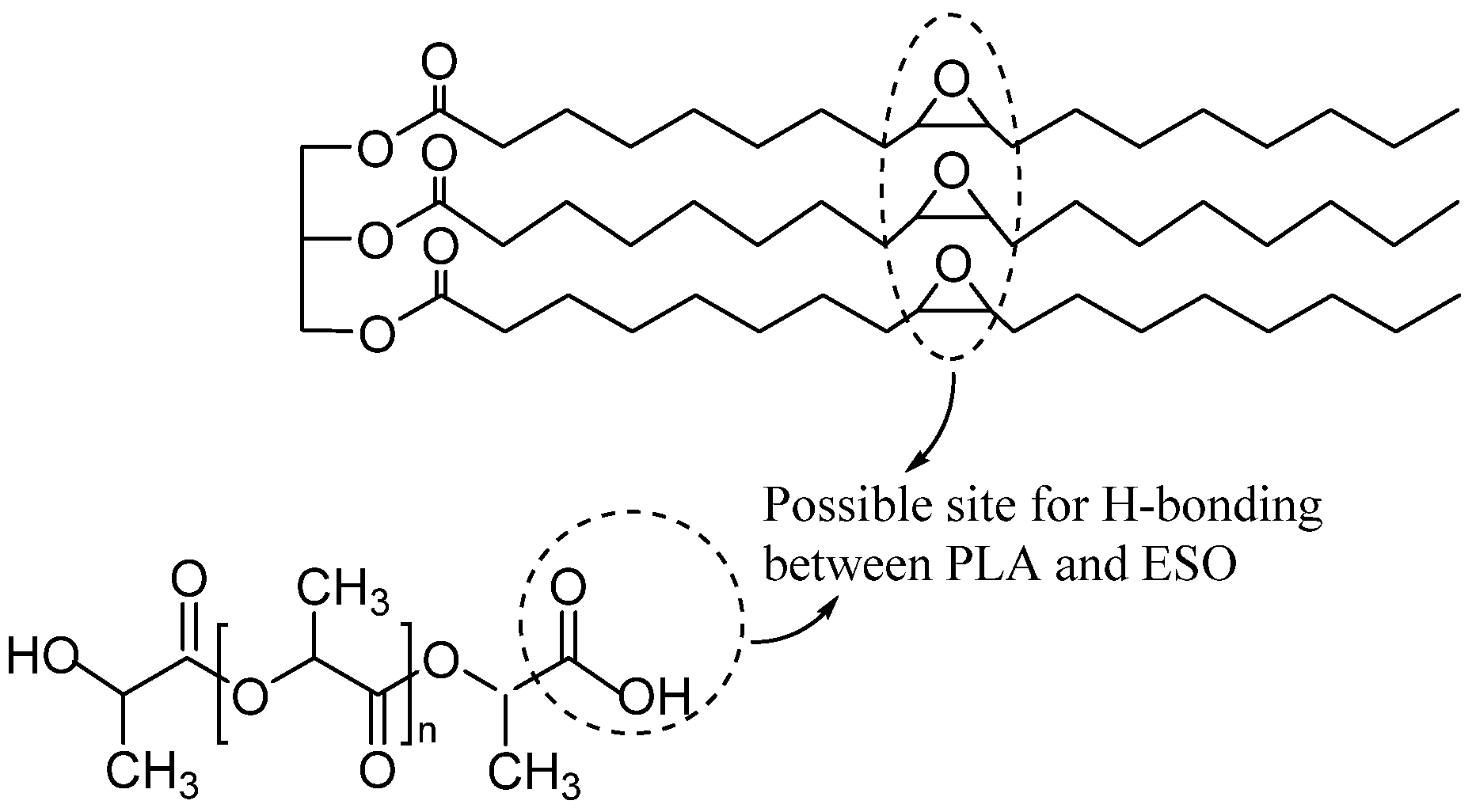

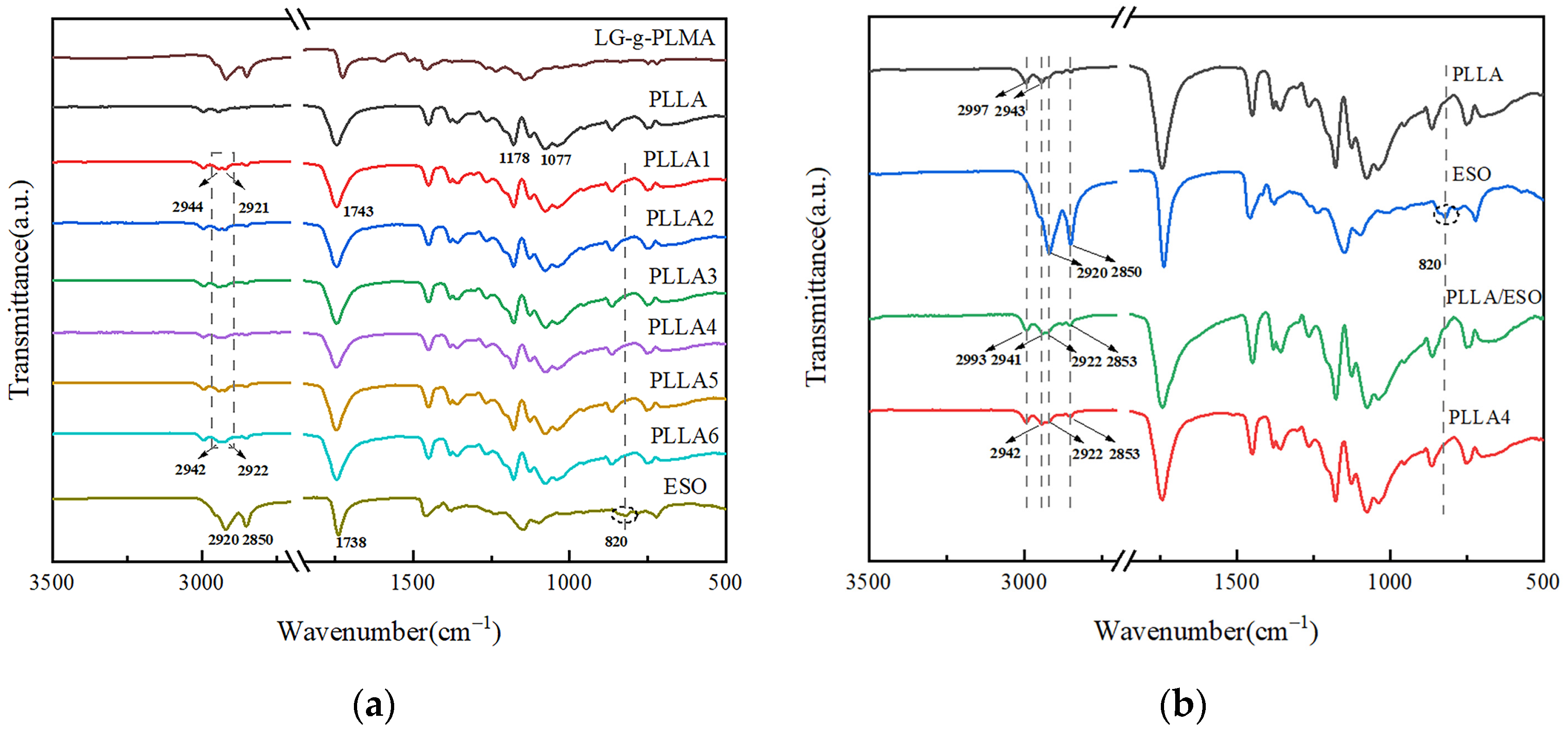

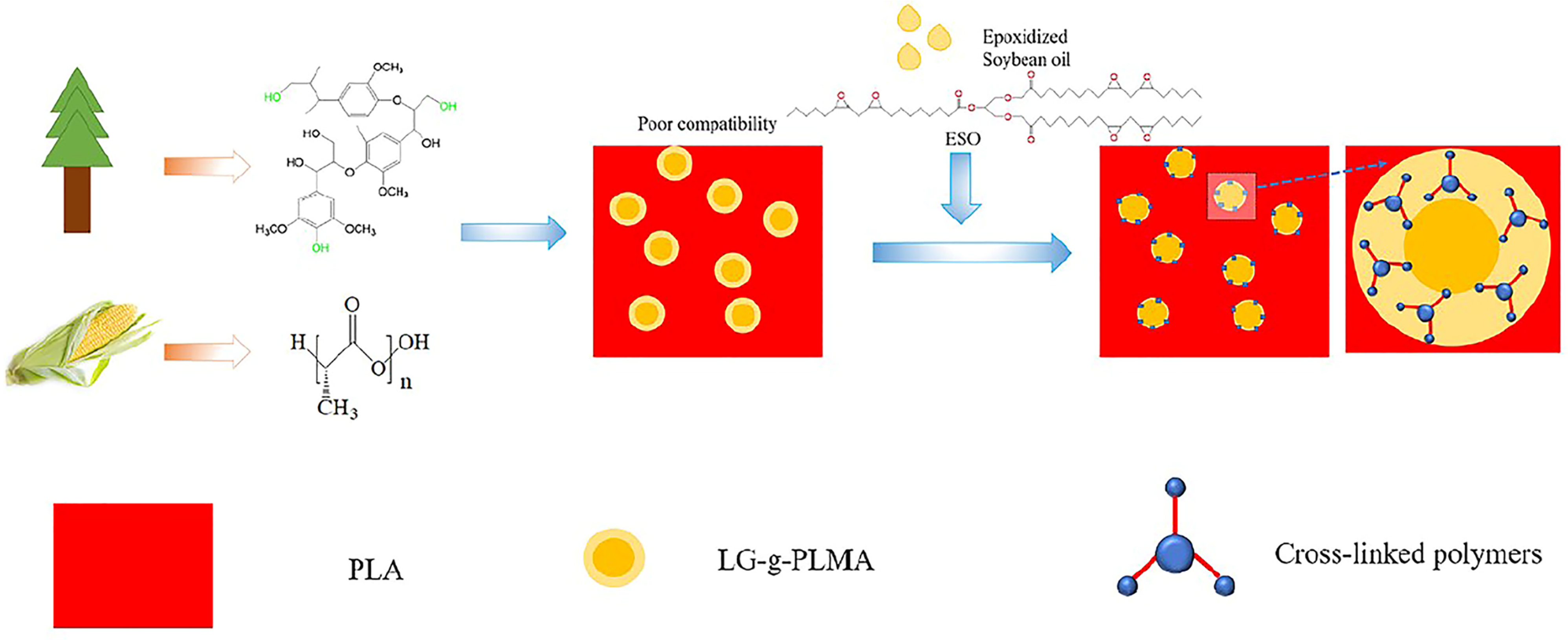

3.1. Structural Characterization of PLA/LG-g-PLMA/ESO

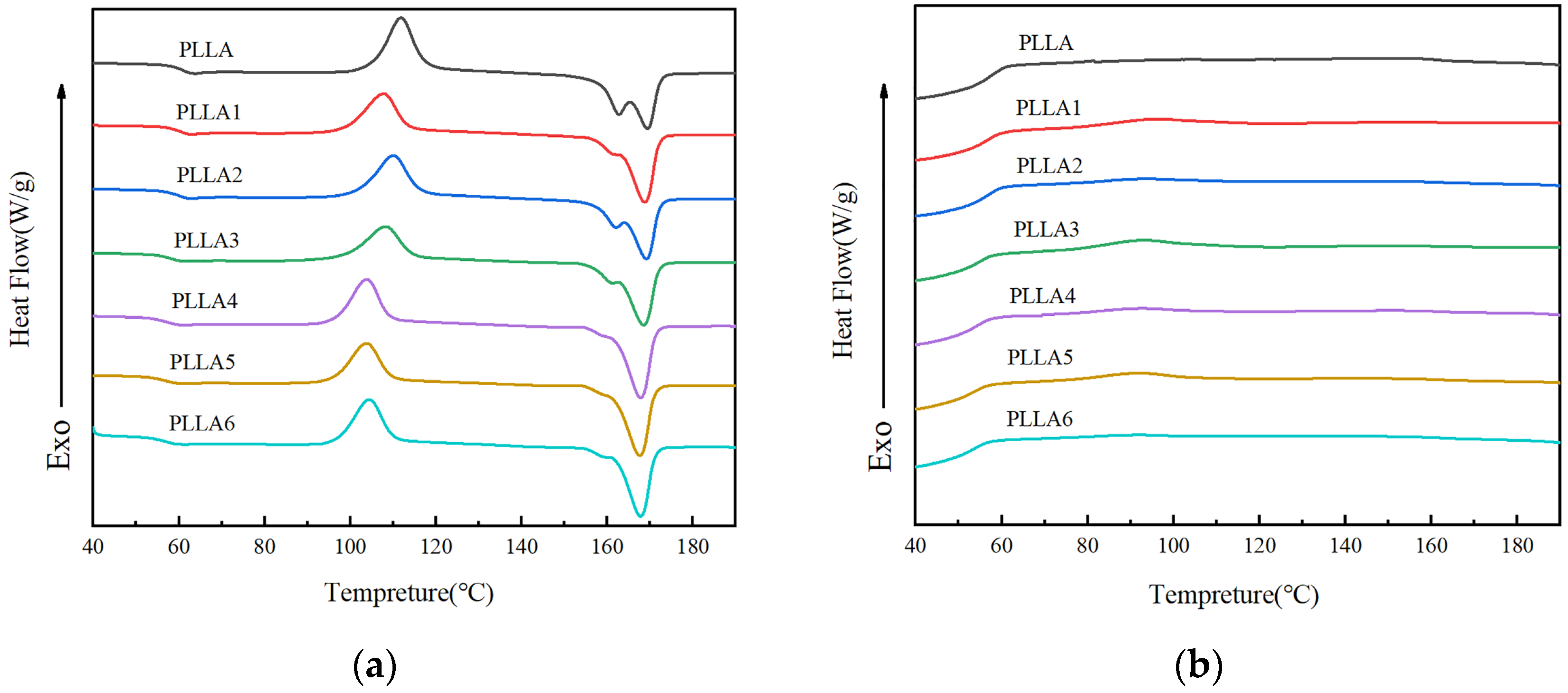

3.2. Thermal Properties

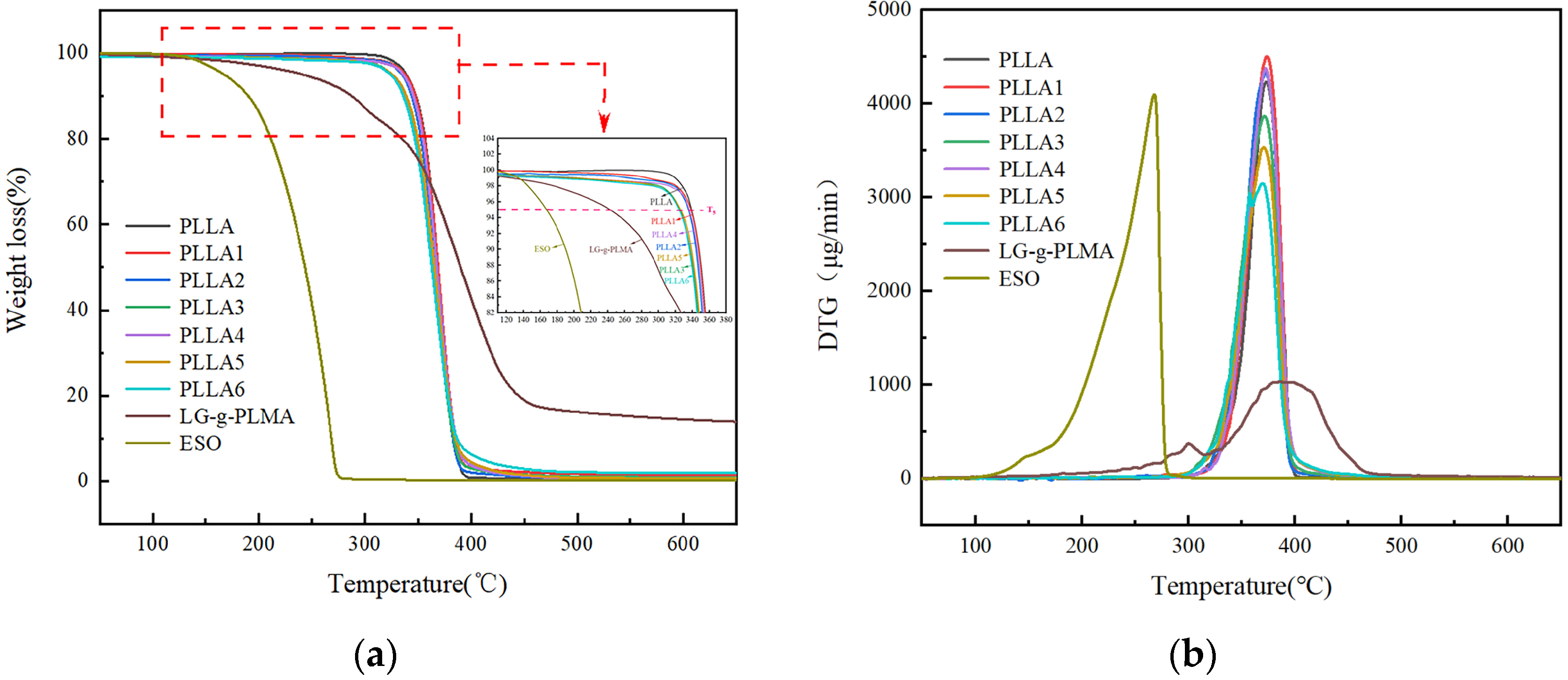

3.3. Thermal Stability

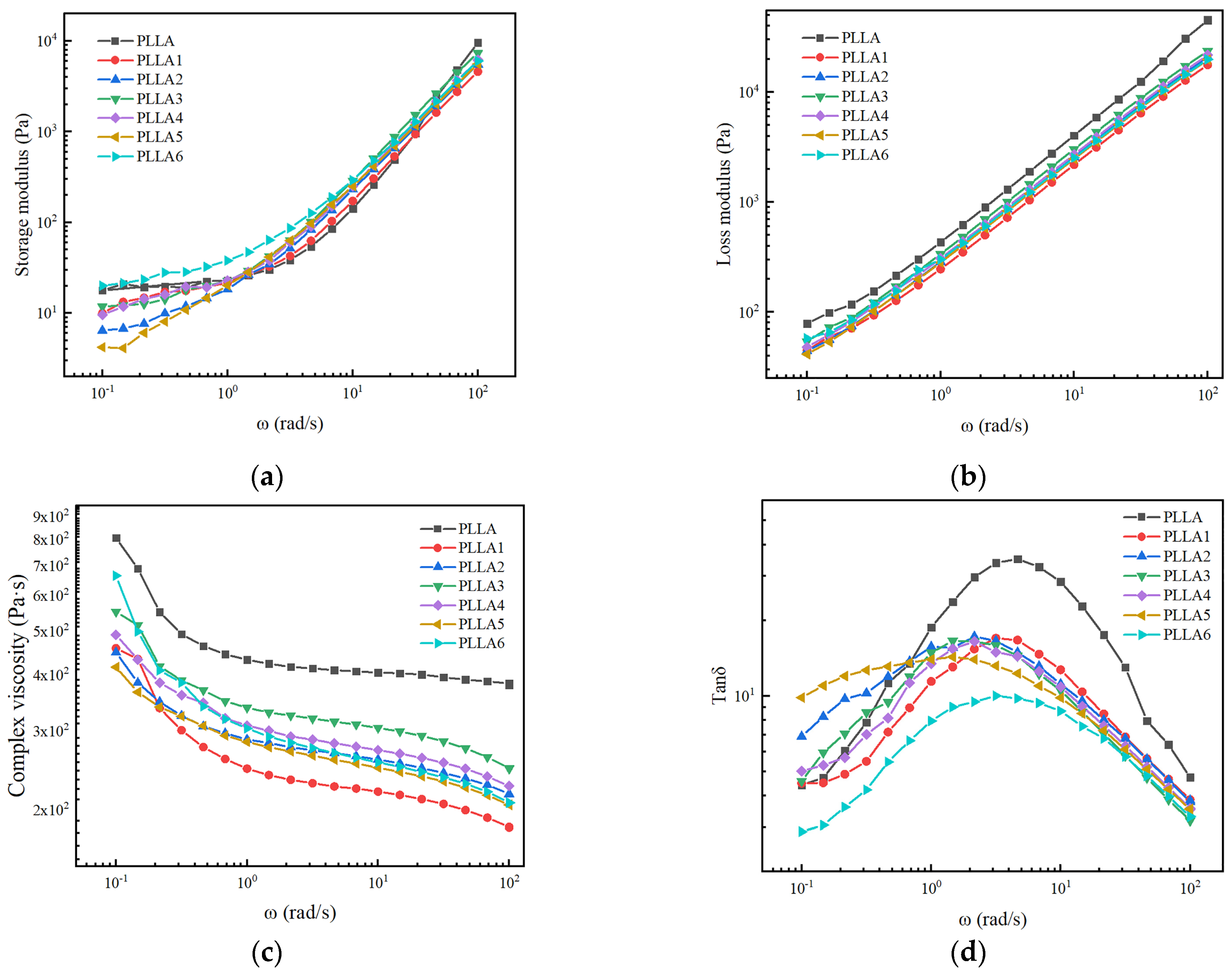

3.4. Rheological Properties

3.5. Mechanical Properties

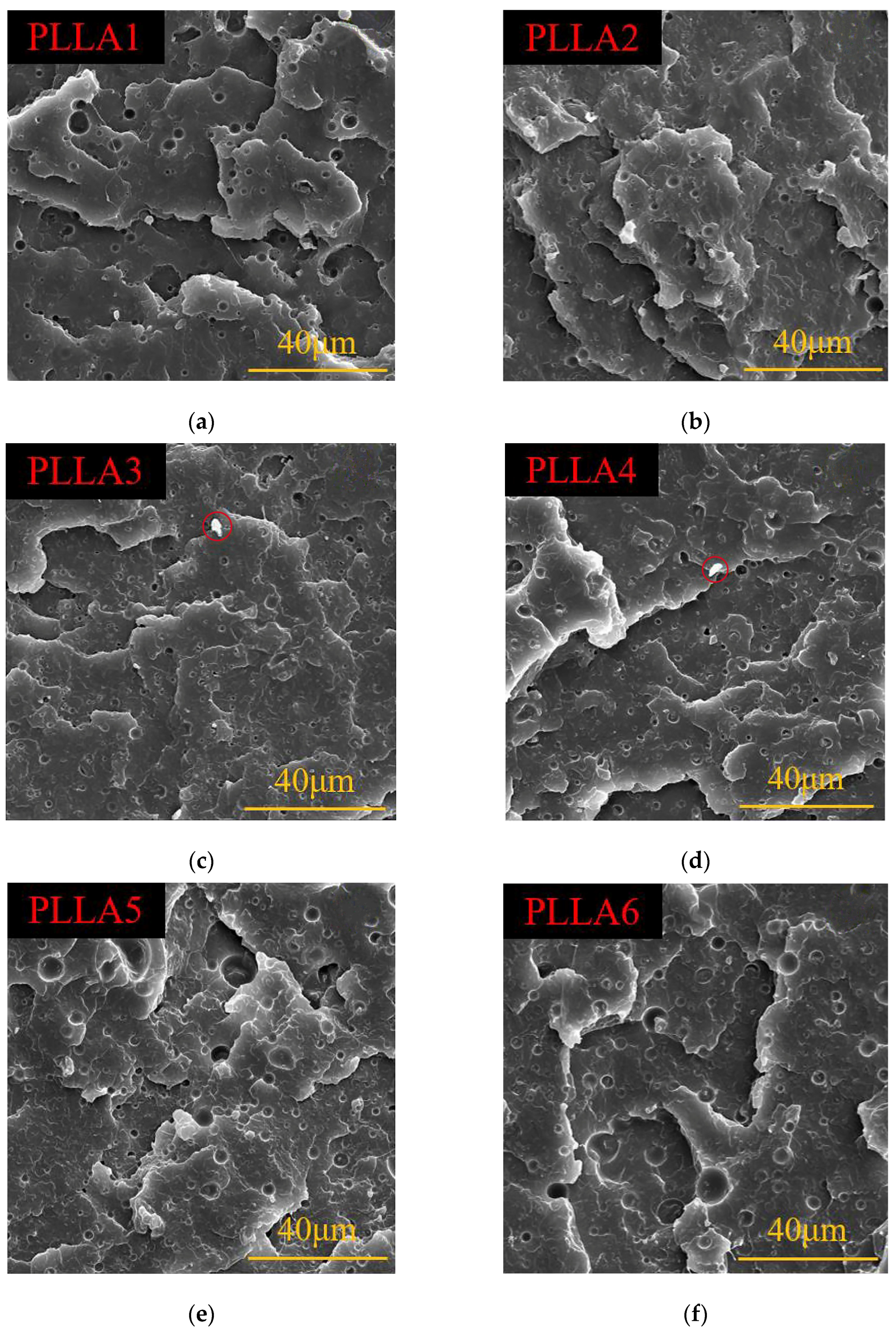

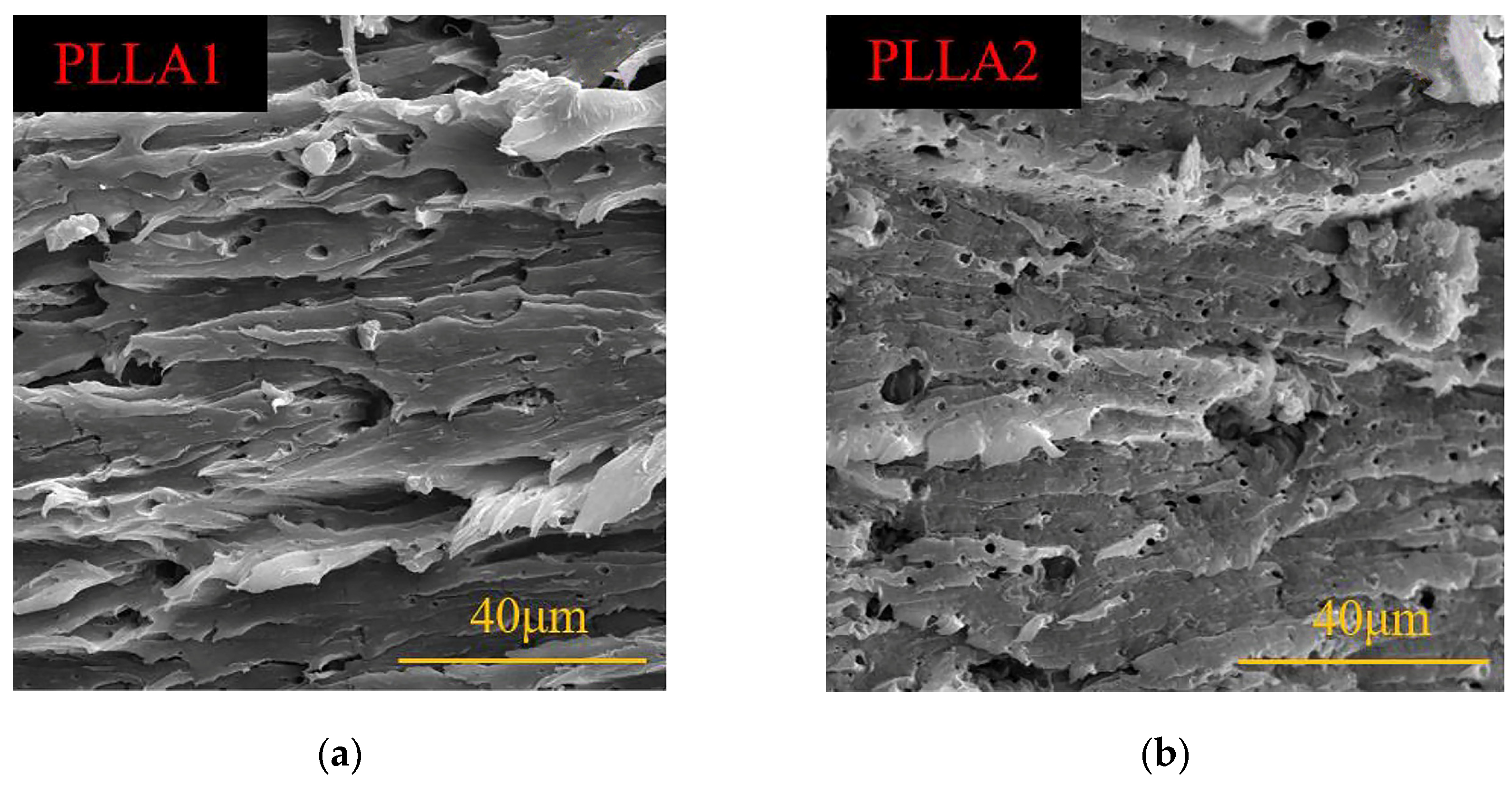

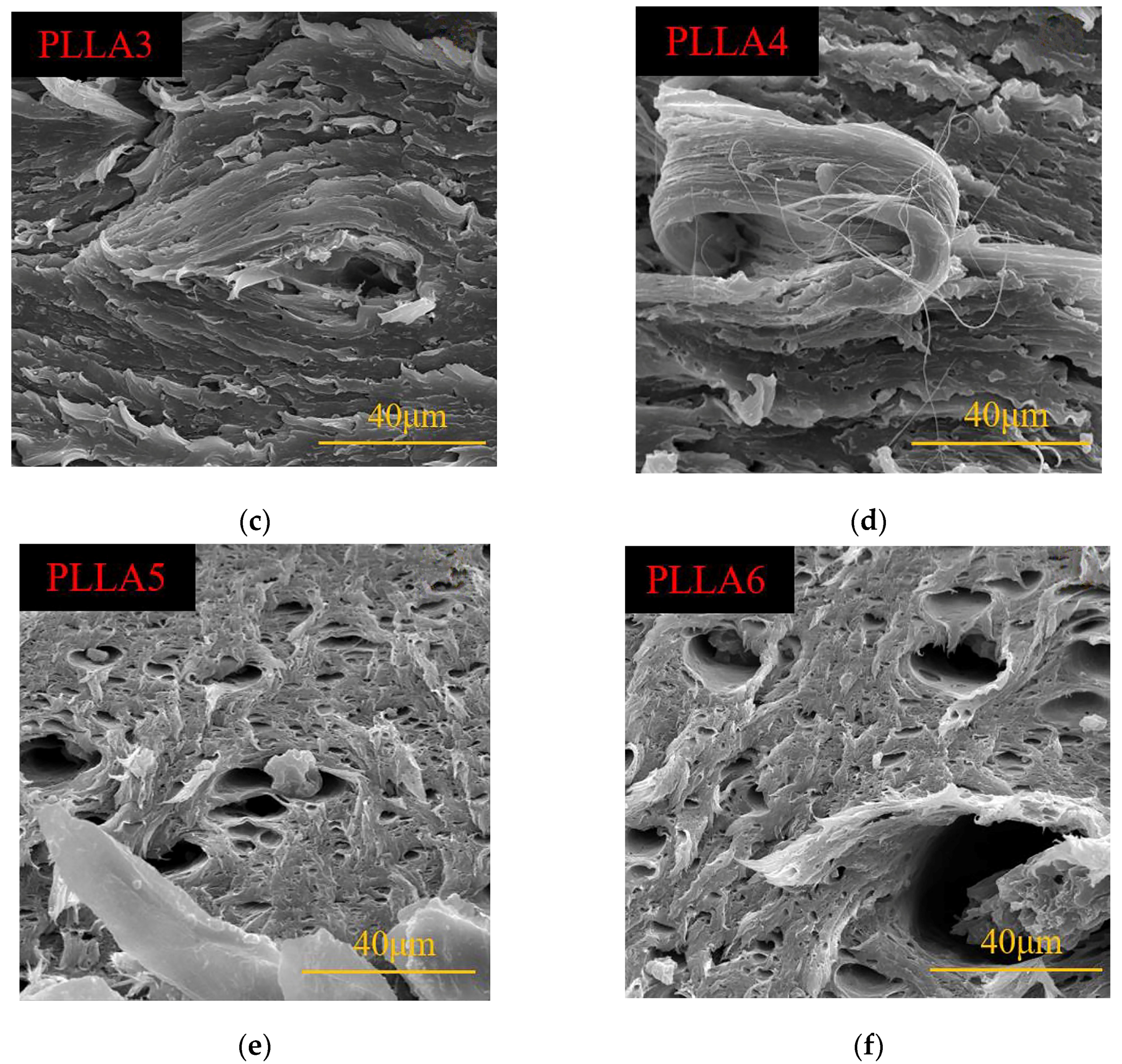

3.6. Morhology Analysis

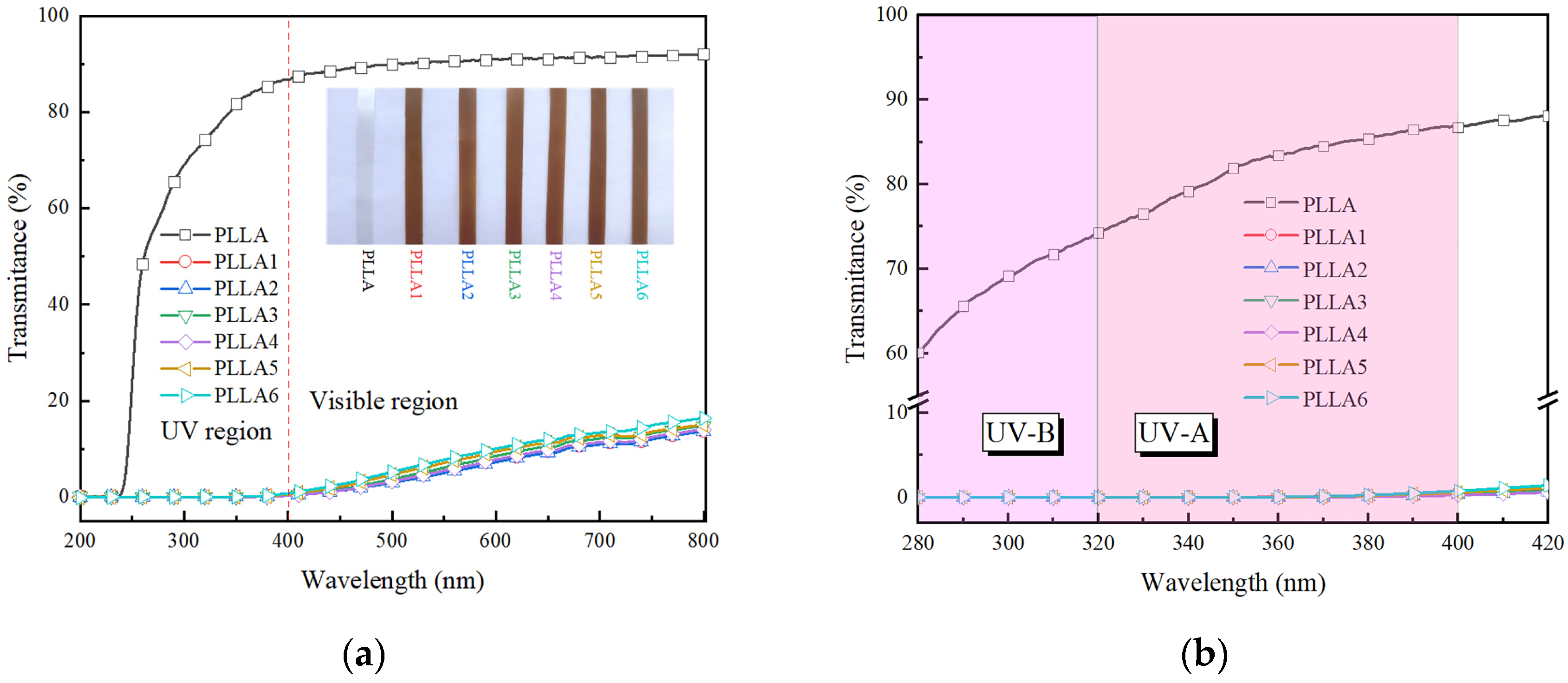

3.7. Optical Properties

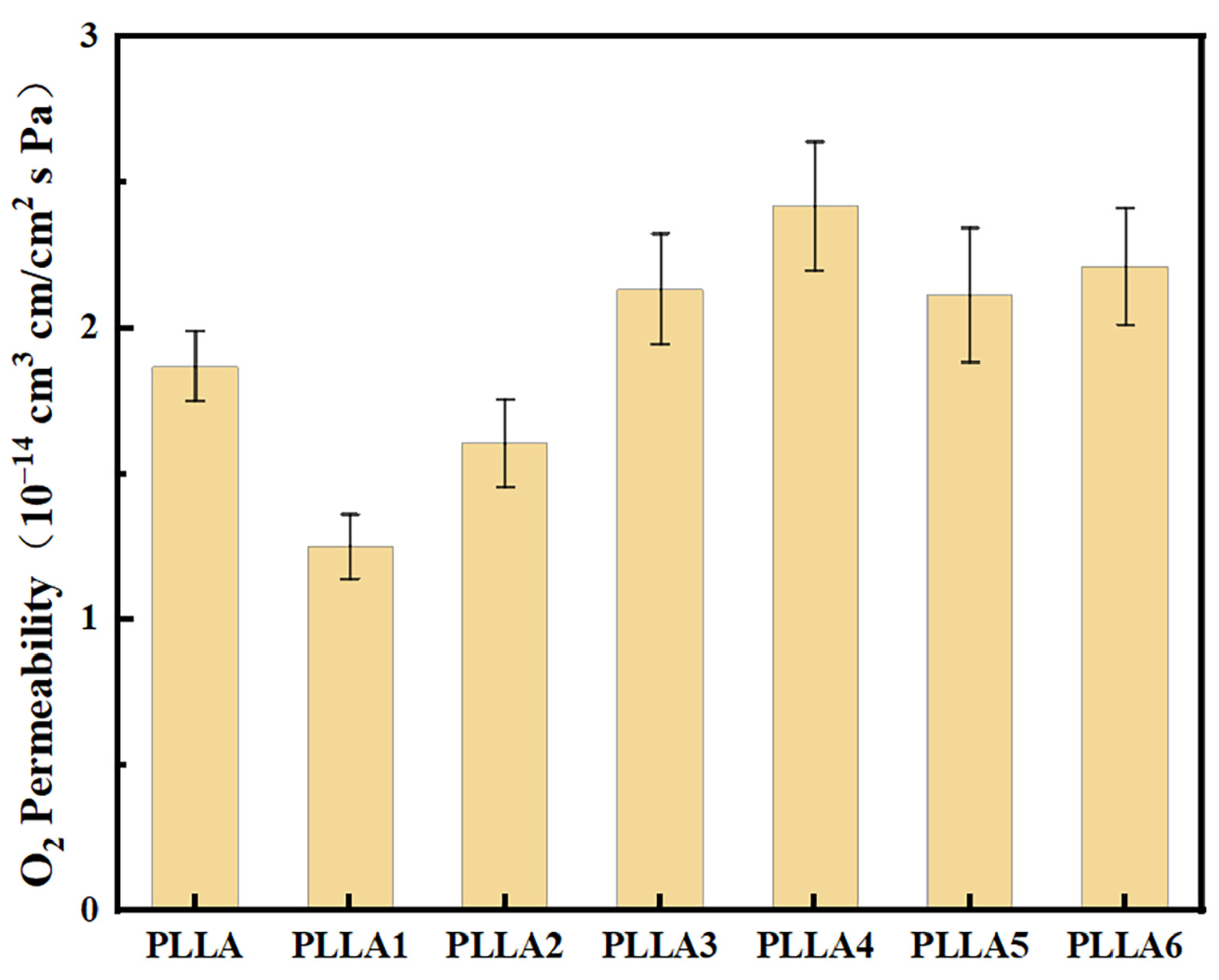

3.8. Gas Barrier Properties

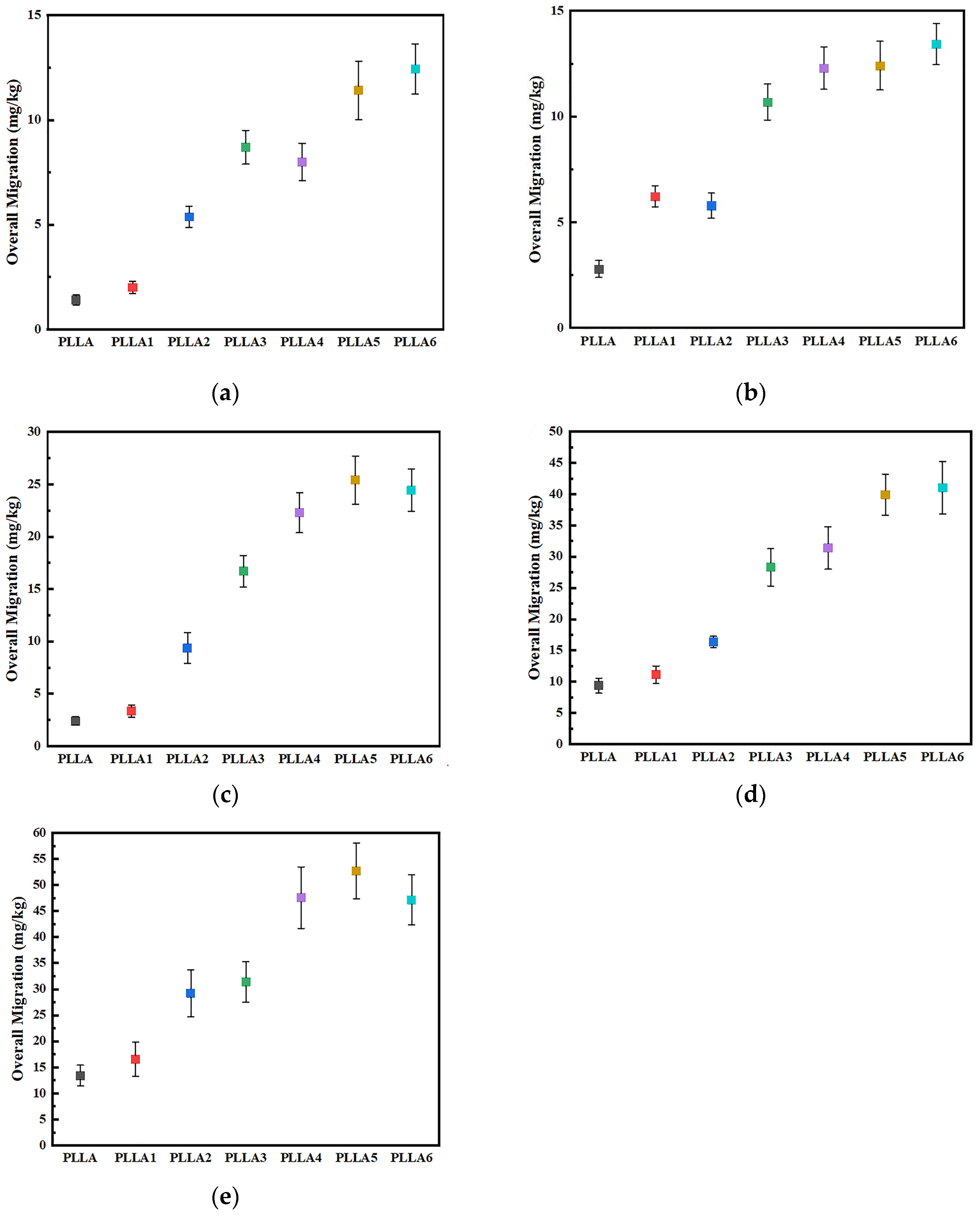

3.9. Overall Migration

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhuang, X.C.; Wang, F.; Hu, X. Biodegradable polymers: A promising solution for green energy devices. Eur. Polym. J. 2024, 204, 112696. [Google Scholar] [CrossRef]

- Hadidi, M.; Jafarzadeh, S.; Forough, M.; Garavand, F.; Alizadeh, S.; Salehabadi, A.; Khaneghah, A.M.; Jafari, S.M. Plant protein-based food packaging films; recent advances in fabrication, characterization, and applications. Trends Food Sci. Tech. 2022, 120, 154–173. [Google Scholar] [CrossRef]

- Rizzarelli, P.; Leanza, M.; Rapisarda, M. Investigations into the characterization, degradation, and applications of biodegradable polymers by mass spectrometry. Mass. Spectrom. Rev. 2023, 1–42. [Google Scholar] [CrossRef] [PubMed]

- de França, J.O.C.; Valadares, D.D.; Paiva, M.F.; Dias, S.C.L.; Dias, J.A. Polymers Based on PLA from Synthesis Using D,L-Lactic Acid (or Racemic Lactide) and Some Biomedical Applications: A Short Review. Polymers 2022, 14, 2317. [Google Scholar] [CrossRef] [PubMed]

- Rajeshkumar, G.; Seshadri, S.A.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Maran, J.P.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites-A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Yang, F.W.; Ye, X.L.; Zhong, J.; Lin, Z.W.; Wu, S.J.; Hu, Y.; Zheng, W.X.; Zhou, W.Y.; Wei, Y.; Dong, X.M. Recycling of waste crab shells into reinforced poly (lactic acid) biocomposites for 3D printing. Int. J. Biol. Macromol. 2023, 234, 122974. [Google Scholar] [CrossRef]

- Holler, M.; Alberdi-Cedeño, J.; Auñon-Lopez, A.; Pointner, T.; Martínez-Yusta, A.; König, J.; Pignitter, M. Polylactic acid as a promising sustainable plastic packaging for edible oils. Food Packaging Shelf. 2023, 36, 101051. [Google Scholar] [CrossRef]

- Liu, S.; Qin, S.H.; He, M.; Zhou, D.F.; Qin, Q.D.; Wang, H. Current applications of poly(lactic acid) composites in tissue engineering and drug delivery. Compos. Part. B-Eng. 2020, 199, 108238. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA based biocomposites for sustainable products: A review. Adv. Ind. Eng. Poly Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Song, X.Y.; Zhang, C.L.; Yang, Y.; Yang, F.; Weng, Y.X. Cardanol derivatives as compatibilizers for strengthening and toughening polylactic acid/bamboo fiber bio-composites. Polym. Composite. 2023, 44, 5675–5688. [Google Scholar] [CrossRef]

- Shi, K.; Liu, G.S.; Sun, H.; Weng, Y.X. Polylactic Acid/Lignin Composites: A Review. Polymers 2023, 15, 2807. [Google Scholar] [CrossRef]

- Gomez-Caturla, J.; Tejada-Oliveros, R.; Ivorra-Martinez, J.; Garcia-Sanoguera, D.; Balart, R.; Garcia-Garcia, D. Development and Characterization of New Environmentally Friendly Polylactide Formulations with Terpenoid-Based Plasticizers with Improved Ductility. J. Polym. Environ. 2023, 32, 749–762. [Google Scholar] [CrossRef]

- Ju, Z.; Brosse, N.; Hoppe, S.; Wang, Z.; Ziegler-Devin, I.; Zhang, H.; Shu, B. Thermal and mechanical properties of polyethylene glycol (PEG)-modified lignin/polylactic acid (PLA) biocomposites. Int. J. Biol. Macromol. 2024, 262, 129997. [Google Scholar] [CrossRef] [PubMed]

- Mondal, S.; Jatrana, A.; Maan, S.; Sharma, P. Lignin modification and valorization in medicine, cosmetics, environmental remediation and agriculture: A review. Environ. Chem. Lett. 2023, 21, 2171–2197. [Google Scholar] [CrossRef]

- Wu, M.; Wu, M.; Pan, M.; Jiang, F.; Hui, B.; Zhou, L. Synthesization and Characterization of -Poly (Lauryl Methacrylate) ARGET ATRP. Int. J. Biol. Macromol. 2022, 207, 522–530. [Google Scholar] [CrossRef] [PubMed]

- Esakkimuthu, E.S.; DeVallance, D.; Pylypchuk, I.; Moreno, A.; Sipponen, M.H. Multifunctional lignin-poly (lactic acid) biocomposites for packaging applications. Front. Bioeng. Biotech. 2022, 10, 1025076. [Google Scholar] [CrossRef] [PubMed]

- Cavallo, E.; He, X.Y.; Luzi, F.; Dominici, F.; Cerrutti, P.; Bernal, C.; Foresti, M.L.; Torre, L.; Puglia, D. UV Protective, Antioxidant, Antibacterial and Compostable Polylactic Acid Composites Containing Pristine and Chemically Modified Lignin Nanoparticles. Molecules 2021, 26, 126. [Google Scholar] [CrossRef]

- Boarino, A.; Schreier, A.; Leterrier, Y.; Klok, H.A. Uniformly Dispersed Poly(lactic acid)-Grafted Lignin Nanoparticles Enhance Antioxidant Activity and UV-Barrier Properties of Poly(lactic acid) Packaging Films. Acs Appl. Polym. Mater. 2022, 47, 4808–4817. [Google Scholar] [CrossRef]

- Kumar, A.; Tumu, V.R.; Chowdhury, S.R.; Reddy, S.V.S.R. A green physical approach to compatibilize a bio-based poly (lactic acid)/lignin blend for better mechanical, thermal and degradation properties. Int. J. Biol. Macromol. 2019, 121, 588–600. [Google Scholar] [CrossRef]

- Hambardzumyan, A.; Foulon, L.; Chabbert, B.; Aguié-Béghin, V. Natural Organic UV-Absorbent Coatings Based on Cellulose and Lignin: Designed Effects on Spectroscopic Properties. Biomacromolecules 2012, 13, 4081–4088. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Zhang, L.H.; Zhao, X.; Zhai, S.Y.; Wang, Q.; Li, C.; Zhang, X. Utilization of lignin upon successive fractionation and esterification in polylactic acid (PLA)/lignin biocomposite. Int. J. Biol. Macromol. 2022, 203, 49–57. [Google Scholar] [CrossRef] [PubMed]

- Ou, W.X.; Weng, Y.X.; Zeng, J.B.; Li, Y.D. Fully biobased poly(lactic acid)/lignin composites compatibilized by epoxidized natural rubber. Int. J. Biol. Macromol. 2023, 236, 123960. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.Q.; Ma, Z.W.; Xu, X.D.; Liu, X.H.; Liu, L.N.; Huang, G.B.; Liu, L.; Wang, H.; Song, P.G. Grafting Lignin with Bioderived Polyacrylates for Low-Cost, Ductile, and Fully Biobased Poly(lactic acid) Composites. Acs Sustain. Chem. Eng. 2020, 8, 2267–2276. [Google Scholar] [CrossRef]

- Mastalygina, E.E.; Aleksanyan, K.V. Recent Approaches to the Plasticization of Poly(lactic Acid) (PLA) (A Review). Polymers 2024, 16, 87. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Weng, Y.X.; Zhang, C.L. Development of biobased plasticizers with synergistic effects of plasticization, thermal stabilization, and migration resistance: A review. J. Vinyl Addit. Tech. 2024, 30, 26–43. [Google Scholar] [CrossRef]

- Guo, J.B.; Wang, J.; He, Y.; Sun, H.; Chen, X.L.; Zheng, Q.; Xie, H.B. Triply Biobased Thermoplastic Composites of Polylactide/Succinylated Lignin/Epoxidized Soybean Oil. Polymers 2020, 12, 632. [Google Scholar] [CrossRef] [PubMed]

- Hasanoglu, Z.; Sivri, N.; Alanalp, M.B.; Durmus, A. Preparation of polylactic acid (PLA) films plasticized with a renewable and natural oil. Int. J. Biol. Macromol. 2024, 257, 128631. [Google Scholar] [CrossRef] [PubMed]

- Hou, B.Y.; Wang, Y.N.; Li, B.J.; Li, N.; Yang, D.; Liu, H.C.; Li, J.C. Bio-based flame-retardant plasticizers derived from l-lactic acid: Effects of valence states of phosphorus structure on fire safety, flexibility and transparency of poly(lactic acid). Chem. Eng. J. 2023, 474, 145563. [Google Scholar] [CrossRef]

- Zhao, T.H.; Yuan, W.Q.; Li, Y.D.; Weng, Y.X.; Zeng, J.B. Relating Chemical Structure to Toughness via Morphology Control in Fully Sustainable Sebacic Acid Cured Epoxidized Soybean Oil Toughened Polylactide Blends. Macromolecules 2018, 51, 2027–2037. [Google Scholar] [CrossRef]

- Shar, A.S.; Wang, N.N.; Chen, T.Y.; Zhao, X.Y.; Weng, Y.X. Development of PLA/Lignin Bio-Composites Compatibilized by Ethylene Glycol Diglycidyl Ether and Poly (ethylene glycol) Diglycidyl Ether. Polymers 2023, 15, 4049. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Z.; Yang, Y.; Feng, J.X.; Zhang, X.M.; Zhang, C.Z.; Tang, Z.B.; Zhu, J. Preparation and characterization of poly(lactic acid)/starch composites toughened with epoxidized soybean oil. Carbohydr. Polym. 2013, 92, 810–816. [Google Scholar] [CrossRef] [PubMed]

- Zych, A.; Perotto, G.; Trojanowska, D.; Tedeschi, G.; Bertolacci, L.; Francini, N.; Athanassiou, A. Super Tough Polylactic Acid Plasticized with Epoxidized Soybean Oil Methyl Ester for Flexible Food Packaging. Acs Appl. Polym. Mater. 2021, 3, 5087–5095. [Google Scholar] [CrossRef]

- Cheng, S.W.; Jiang, Y.K.; Yin, J.; Zhang, L.G.; Han, L.; Zhu, G.X.; Zhang, Y. PBSeT/lignin: A complete bio-based biodegradable plastic with excellent mechanical and anti-UV properties. Eur. Polym. J. 2024, 203, 112638. [Google Scholar] [CrossRef]

- Fankhauser-Noti, A.; Fiselier, K.; Biedermann-Brem, S.; Grob, K. Assessment of epoxidized soy bean oil (ESBO) migrating into foods: Comparison with ESBO-like epoxy fatty acids in our normal diet. Food Chem. Toxicol. 2006, 44, 1279–1286. [Google Scholar] [CrossRef] [PubMed]

- Goswami, S.R.; Nair, S.S.; Zhang, X.; Tanguy, N.; Yan, N. Starch Maleate/Epoxidized Soybean Oil/Polylactic Acid Films with Improved Ductility and Biodegradation Potential for Packaging Fatty Foods. Acs Sustain. Chem. Eng. 2022, 10, 14185–14194. [Google Scholar] [CrossRef]

- Shi, K.; Liu, G.S.; Sun, H.; Yang, B.; Weng, Y.X. Grafting Polymerization of Long-Chain Hydrophobic Acrylic Monomer onto Lignin and Its Application in Poly(Lactic Acid)-Based Wholly Green UV Barrier Composite Films. Acs Omega 2023, 8, 26926–26937. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y.H.; Yan, S.F.; Yin, J.B.; Fan, Y.Q.; Chen, X.S. Crystallization Behavior of Biodegradable Poly(L-lactic acid) Filled with a Powerful Nucleating Agent: N, N′-Bis(benzoyl) Suberic Acid Dihydrazide. J. Appl. Polym. Sci. 2011, 121, 1408–1416. [Google Scholar] [CrossRef]

- GB/T1040.3-2006; Plastics—Determination of Tensile Properties—Part 3: Test Conditions for Films and Sheets. Standardization Administration of the P.R.C.: Beijing, China, 2006.

- ASTM D3985; Standard Test Method for Oxygen Gas Transmission Rate Through Plastic Film and Sheeting Using a Coulometric Sensor. ASTM: West Conshohocken, PA, USA, 2017.

- GB 31604.1; National Food Safety Standard—General Rules for Migration Test of Food Contact Materials and Articles. Standardization Administration of the P.R.C.: Beijing, China, 2023.

- Bouti, M.; Irinislimane, R.; Belhaneche-Bensemra, N. Properties Investigation of Epoxidized Sunflower Oil as Bioplasticizer for Poly (Lactic Acid). J. Polym. Environ. 2022, 30, 232–245. [Google Scholar] [CrossRef]

- Han, Y.; Shi, J.W.; Mao, L.X.; Wang, Z.; Zhang, L.Q. Improvement of Compatibility and Mechanical Performances of PLA/PBAT Composites with Epoxidized Soybean Oil as Compatibilizer. Ind. Eng. Chem. Res. 2020, 59, 21779–21790. [Google Scholar] [CrossRef]

- Xu, Y.Q.; Qu, J.P. Mechanical and Rheological Properties of Epoxidized Soybean Oil Plasticized Poly(lactic acid). J. Appl. Polym. Sci. 2009, 112, 3185–3191. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Garcia-Garcia, D.; Dominici, F.; Torre, L.; Sanchez-Nacher, L.; Balart, R. PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur. Polym. J. 2017, 91, 248–259. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Samper, M.D.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Balart, R. Plasticization effect of epoxidized cottonseed oil (ECSO) on poly(lactic acid). Ind. Crop Prod. 2017, 104, 278–286. [Google Scholar] [CrossRef]

- Wang, N.N.; Zhang, C.L.; Zhu, W.Q.; Weng, Y.X. Improving Interfacial Adhesion of PLA/Lignin Composites by One-Step Solvent-Free Modification Method. J. Renew. Mater. 2020, 8, 1139–1149. [Google Scholar] [CrossRef]

- Zhao, T.H.; He, Y.; Li, Y.D.; Wang, M.; Zeng, J.B. Dynamic vulcanization of castor oil in a polylactide matrix for toughening. RSC Adv. 2016, 6, 79542–79553. [Google Scholar] [CrossRef]

- Thakur, S.; Cisneros-Lopez, E.O.; Pin, J.M.; Misra, M.; Mohanty, A.K. Green Toughness Modifier from Downstream Corn Oil in Improving Poly(lactic acid) Performance. Acs Appl. Polym. Mater. 2019, 1, 3396–3406. [Google Scholar] [CrossRef]

- Liu, W.D.; Qiu, J.H.; Fei, M.E.; Qiu, R.H.; Sakai, E. Manufacturing of Thermally Remoldable Blends from Epoxidized Soybean Oil and Poly(lactic acid) via Dynamic Cross-Linking in a Twin-Screw Extruder. Ind. Eng. Chem. Res. 2018, 57, 7516–7524. [Google Scholar] [CrossRef]

- Yuan, W.Q.; Zhang, H.; Weng, Y.X.; Li, Y.D.; Zeng, J.B. Fully biobased polylactide/epoxidized soybean oil resin blends with balanced stiffness and toughness by dynamic vulcanization. Polym. Test. 2019, 78, 105981. [Google Scholar] [CrossRef]

- Liu, W.D.; Qiu, J.H.; Zhu, L.X.; Fei, M.E.; Qiu, R.H.; Sakai, E.; Ito, K.; Song, G.L.; Tang, G.Y. Tannic acid-induced crosslinking of epoxidized soybean oil for toughening poly(latic acid) via dynamic vulcanization. Polymer 2018, 148, 109–118. [Google Scholar] [CrossRef]

- Gore, A.H.; Prajapat, A.L. Biopolymer Nanocomposites for Sustainable UV Protective Packaging. Front. Mater. 2022, 9, 855727. [Google Scholar] [CrossRef]

| Sample | PLA (wt%) | LG-g-PLMA (wt%) | ESO (phr) |

|---|---|---|---|

| PLLA | 100 | ||

| PLLA1 | 95 | 5 | 0 |

| PLLA2 | 95 | 5 | 1 |

| PLLA3 | 95 | 5 | 3 |

| PLLA4 | 95 | 5 | 5 |

| PLLA5 | 95 | 5 | 7 |

| PLLA6 | 95 | 5 | 9 |

| Sample | Tg (°C) | Tcc (°C) | Tm (°C) | ΔHcc (J/g) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| PLLA | 61.38 | 111.24 | 158.15/168.83 | 30.79 | 36.61 | 6.21 |

| PLLA1 | 60.08 | 107.85 | 162.63/168.77 | 23.10 | 35.78 | 13.58 |

| PLLA2 | 60.29 | 110.00 | 162.83/169.22 | 25.78 | 36.33 | 11.37 |

| PLLA3 | 58.83 | 108.17 | 162.02/168.61 | 22.33 | 35.41 | 14.39 |

| PLLA4 | 56.96 | 103.82 | 161.78/167.84 | 23.09 | 34.93 | 13.31 |

| PLLA5 | 56.76 | 103.79 | 161.35/167.67 | 21.87 | 35.28 | 15.39 |

| PLLA6 | 57.17 | 104.36 | 161.96/167.74 | 23.68 | 33.08 | 11.12 |

| Sample | T5% (°C) | Tmax (°C) | Residues at 700 °C (%) |

|---|---|---|---|

| PLLA | 339.1 | 374.2 | 0.29 |

| PLLA1 | 338.7 | 373.8 | 1.67 |

| PLLA2 | 336.3 | 372.9 | 0.59 |

| PLLA3 | 325.7 | 371.7 | 1.02 |

| PLLA4 | 337.1 | 372.6 | 0.58 |

| PLLA5 | 326.6 | 370.9 | 0.75 |

| PLLA6 | 324.9 | 369.8 | 2.13 |

| Sample | Tensile Strength (MPa) | Elongation at Break (%) | Elastic Modulus (MPa) | Tensile Toughness (MJ/m3) |

|---|---|---|---|---|

| PLLA | 44.6 ± 1.3 | 4.4 ± 0.3 | 656.2 ± 42.1 | 3.2 ± 0.2 |

| PLLA1 | 42.6 ± 2.6 | 5.6 ± 0.7 | 493.0 ± 20.5 | 4.1 ± 0.1 |

| PLLA2 | 37.0 ± 2.8 | 12.7 ± 2.1 | 439.2 ± 18.6 | 5.9 ± 0.2 |

| PLLA3 | 34.8 ± 3.1 | 24.7 ± 3.9 | 472.2 ± 22.7 | 12.6 ± 1.6 |

| PLLA4 | 32.2 ± 2.5 | 104.6 ± 8.3 | 381.3 ± 18.6 | 44.7 ± 2.8 |

| PLLA5 | 31.0 ± 2.3 | 85.7 ± 7.1 | 426.6 ± 13.9 | 41.4 ± 2.9 |

| PLLA6 | 26.5 ± 2.7 | 72.6 ± 6.9 | 367.2 ± 15.8 | 29.3 ± 2.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Shi, K.; Liu, G.; Sun, H.; Weng, Y. Epoxidized Soybean Oil Toughened Poly(lactic acid)/Lignin-g-Poly(lauryl methacrylate) Bio-Composite Films with Potential Food Packaging Application. Polymers 2024, 16, 2025. https://doi.org/10.3390/polym16142025

Zhou Y, Shi K, Liu G, Sun H, Weng Y. Epoxidized Soybean Oil Toughened Poly(lactic acid)/Lignin-g-Poly(lauryl methacrylate) Bio-Composite Films with Potential Food Packaging Application. Polymers. 2024; 16(14):2025. https://doi.org/10.3390/polym16142025

Chicago/Turabian StyleZhou, Yingxin, Kang Shi, Guoshuai Liu, Hui Sun, and Yunxuan Weng. 2024. "Epoxidized Soybean Oil Toughened Poly(lactic acid)/Lignin-g-Poly(lauryl methacrylate) Bio-Composite Films with Potential Food Packaging Application" Polymers 16, no. 14: 2025. https://doi.org/10.3390/polym16142025

APA StyleZhou, Y., Shi, K., Liu, G., Sun, H., & Weng, Y. (2024). Epoxidized Soybean Oil Toughened Poly(lactic acid)/Lignin-g-Poly(lauryl methacrylate) Bio-Composite Films with Potential Food Packaging Application. Polymers, 16(14), 2025. https://doi.org/10.3390/polym16142025