Effect of Complex Well Conditions on the Swelling and Tribological Properties of High-Acrylonitrile Stator Rubber in Screw Pumps

Abstract

1. Introduction

2. Experiments

2.1. Selection of Rubber Materials and Test Medium

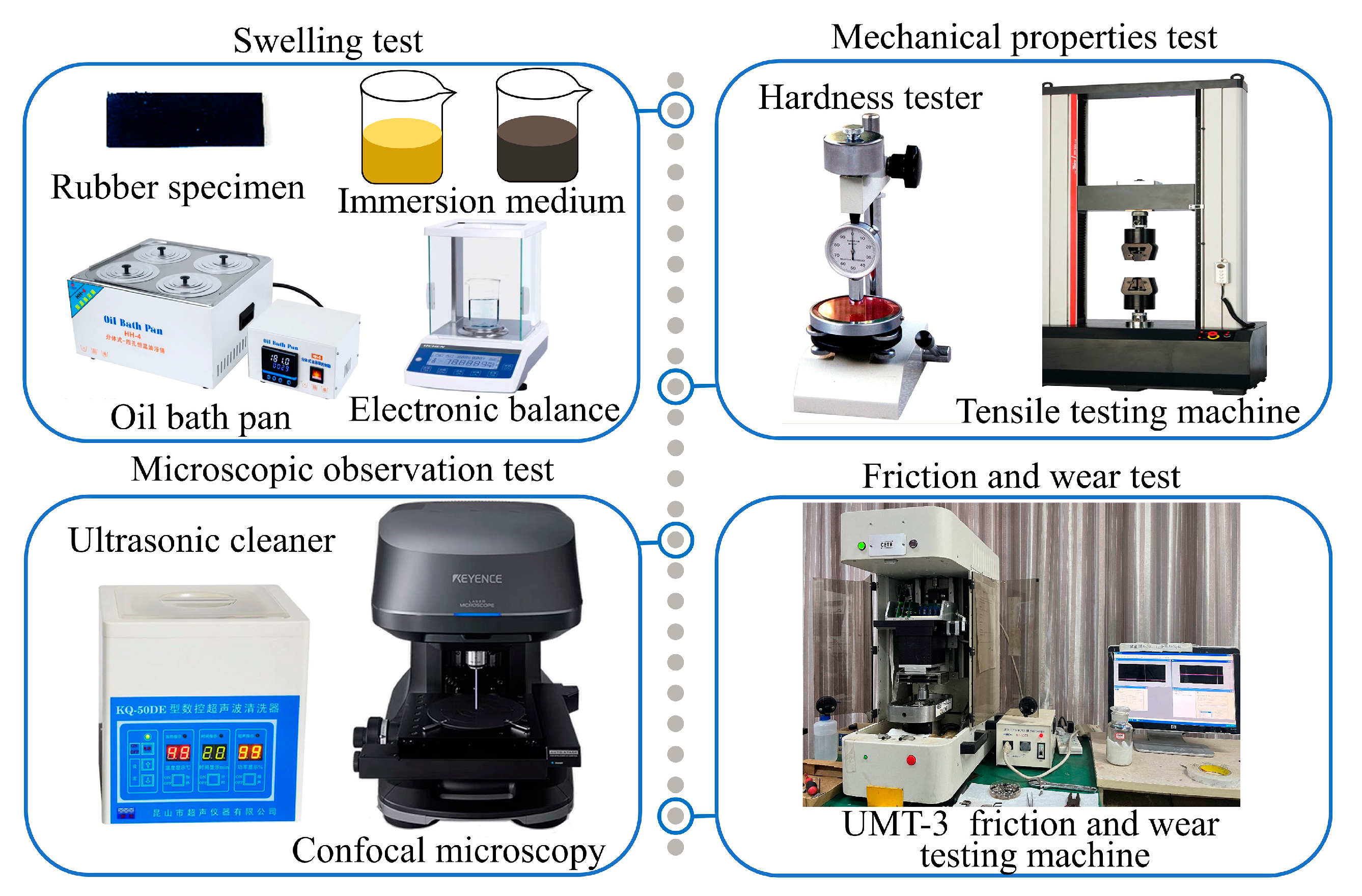

2.2. Major Equipment and Instruments

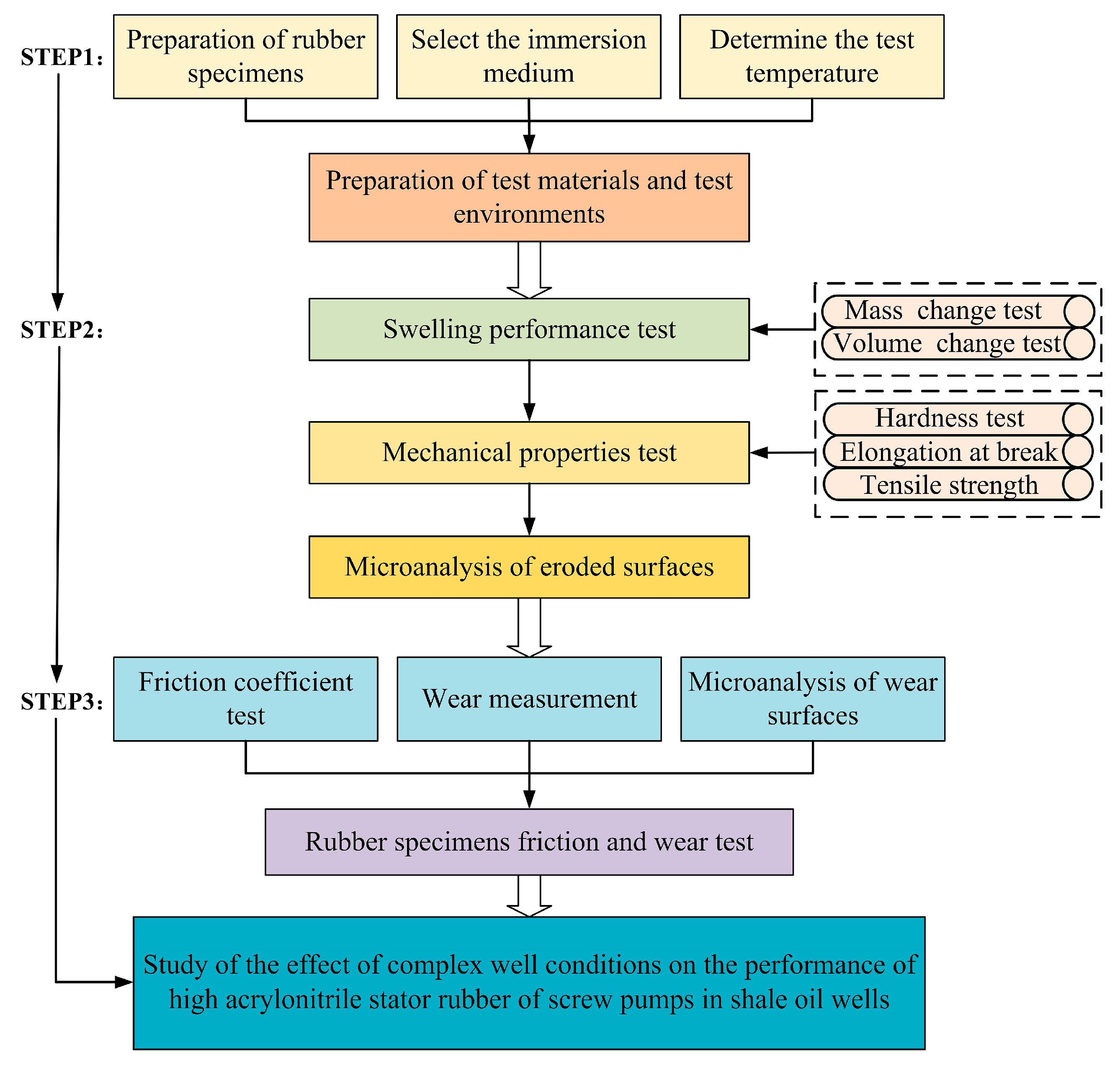

2.3. Test Method

2.3.1. Swelling Properties Test

2.3.2. Mechanical Property Test

2.3.3. Microscopic Observation and Analysis

2.3.4. Friction and Wear Property Test

3. Results and Discussion

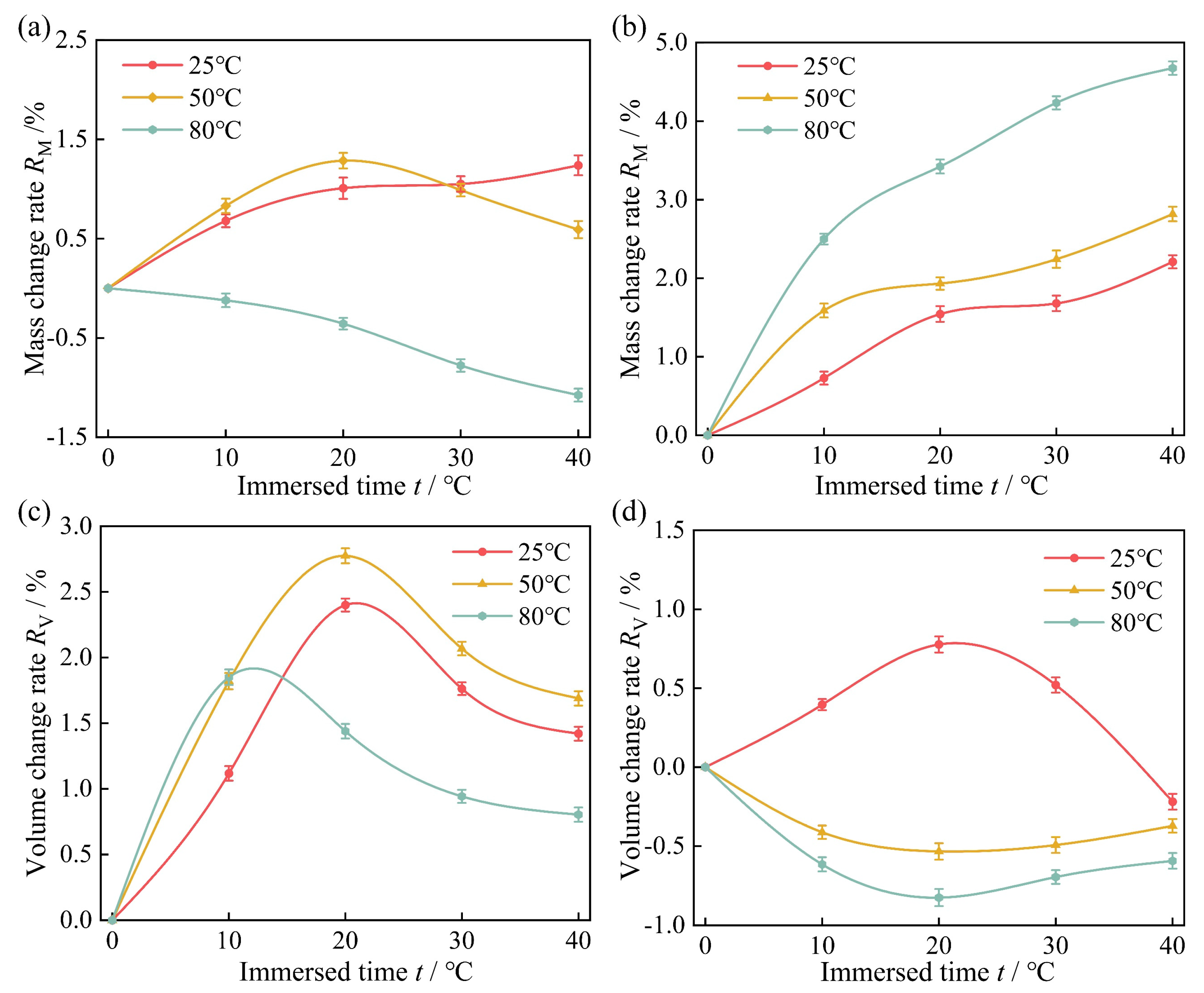

3.1. Analysis of High-Acrylonitrile Rubber Swelling Property Test Results

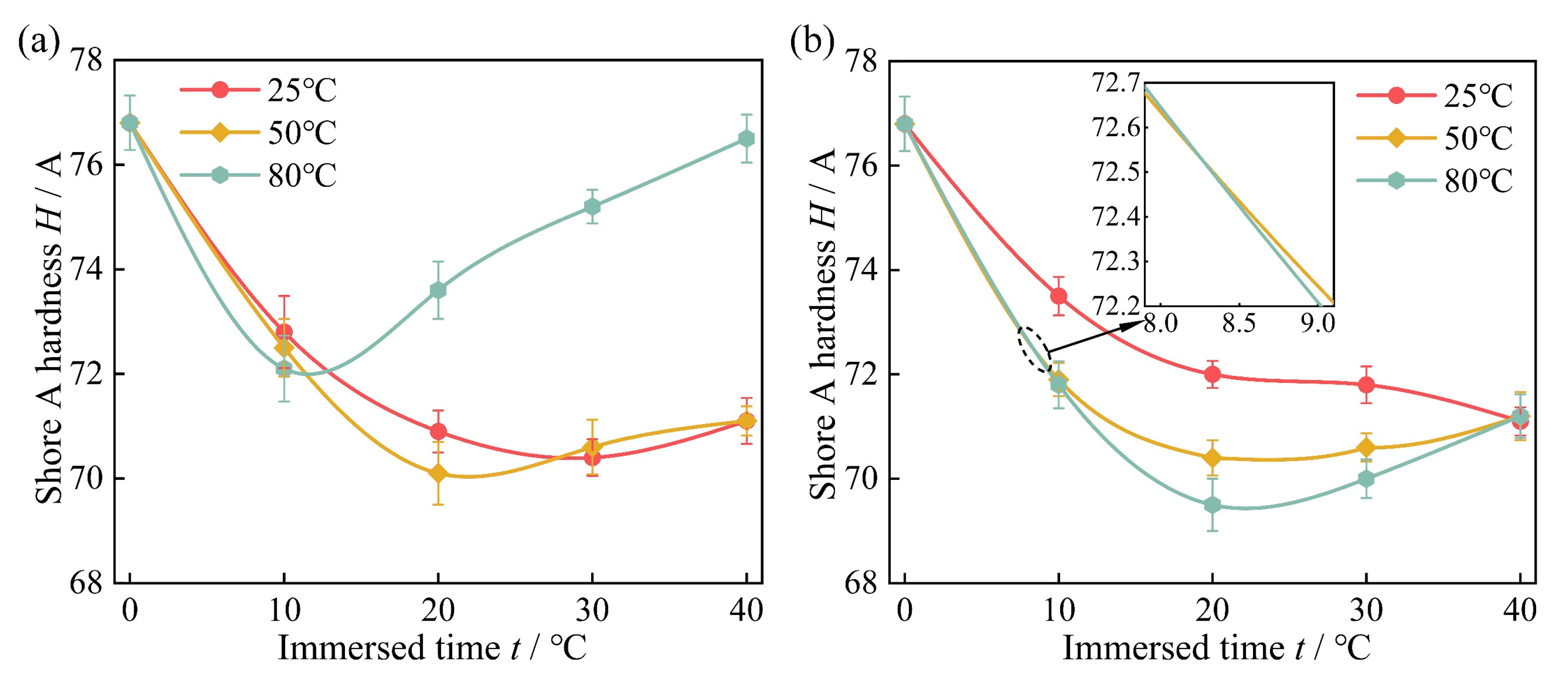

3.2. Analysis of High-Acrylonitrile Rubber Mechanical Property Test Results

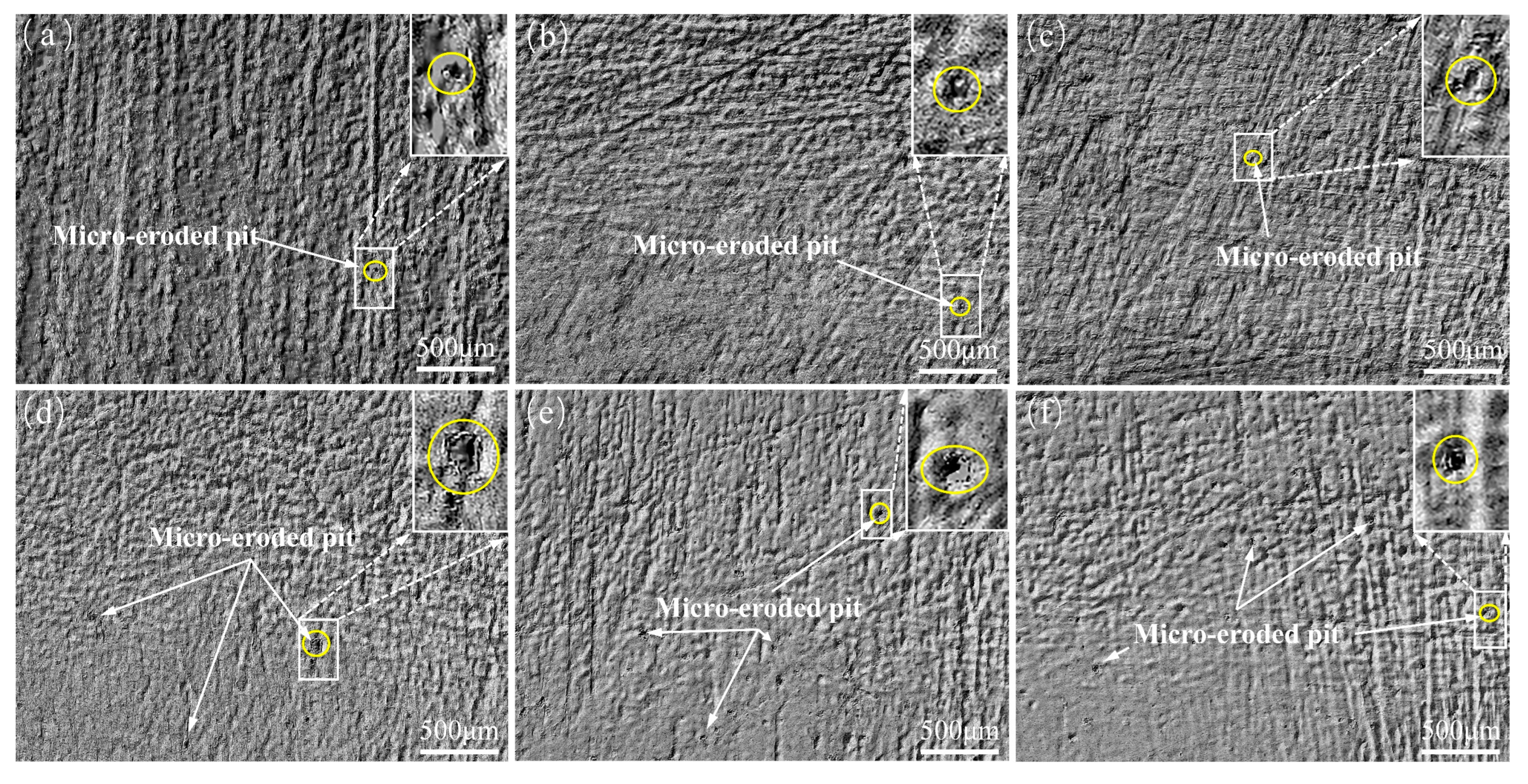

3.3. Microanalysis of Rubber Surfaces after Thermal Expansion and Swelling

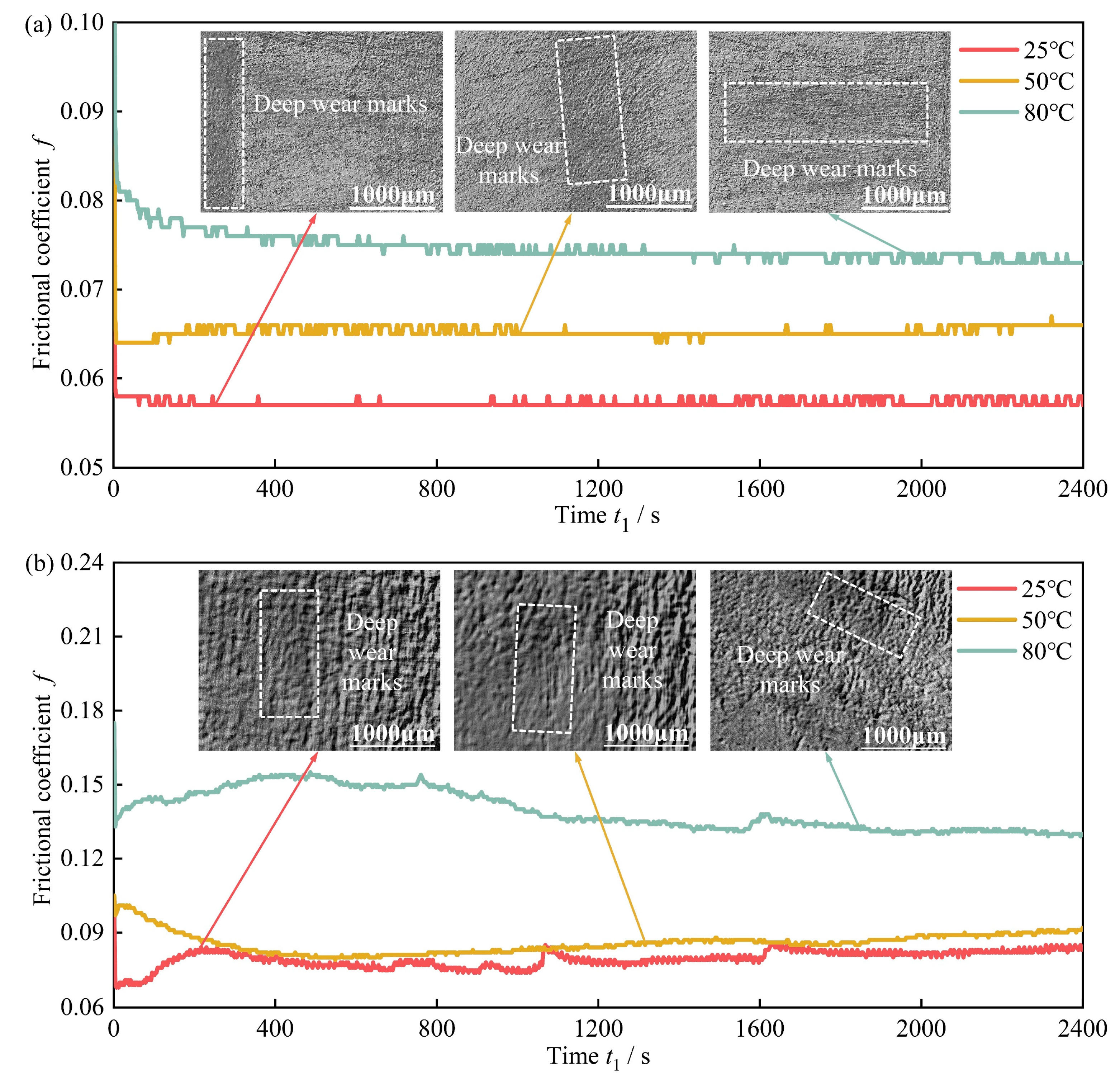

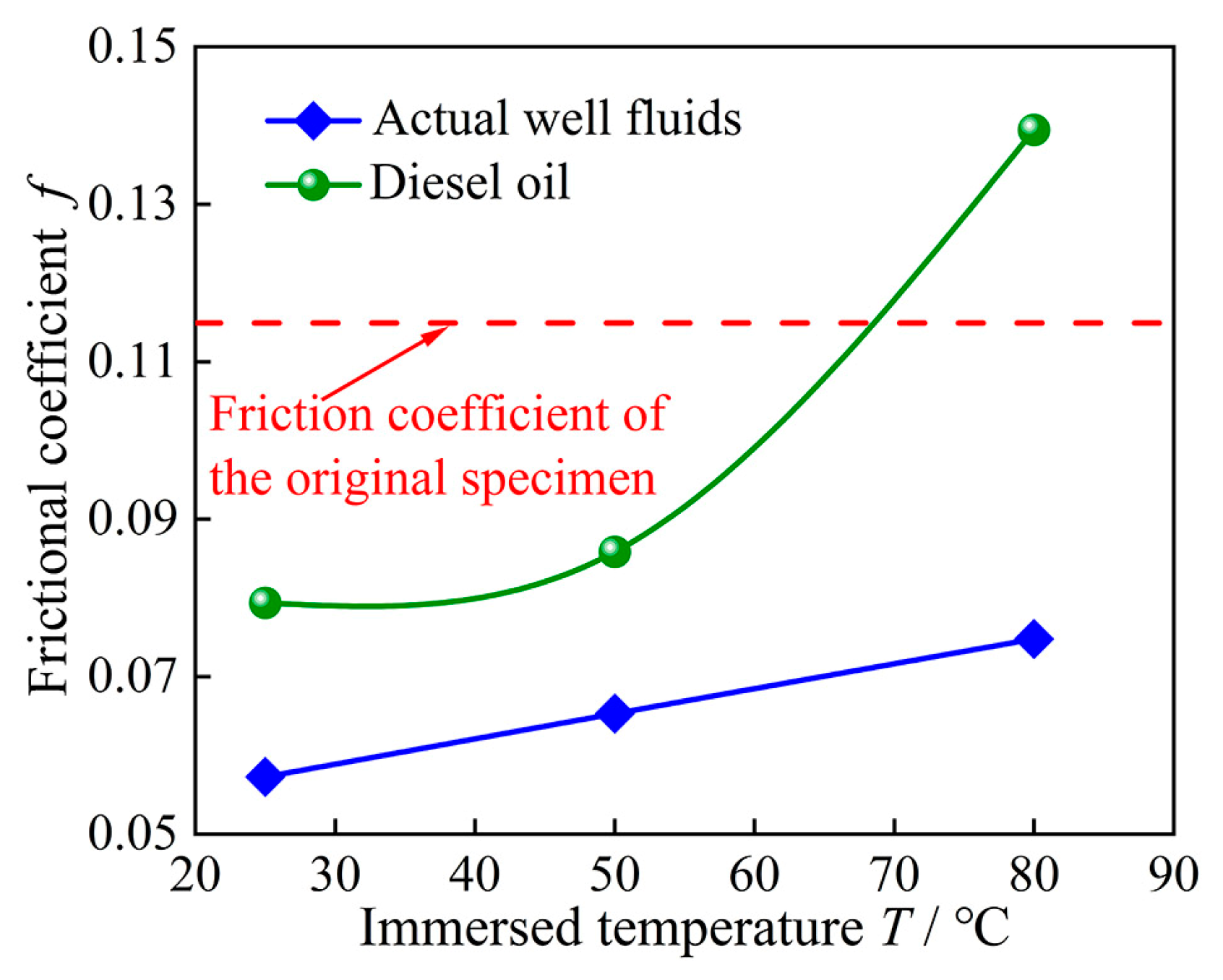

3.4. Analysis of High-Acrylonitrile Rubber Friction and Wear Property Test Results

4. Conclusions

- (1)

- With increasing thermal expansion and swelling time, the mass, volume, and hardness of high-acrylonitrile stator rubber underwent fast changes over the first ten days and then became slow. The elongation at break and tensile strength of rubber significantly reduced, and the surface damage became more serious due to the penetration of the immersion medium on the rubber surface.

- (2)

- High-acrylonitrile rubber exhibited both thermal expansion and swelling behaviors, along with cross-linking and breaking reactions of molecular chains, when immersed to both actual well fluids and diesel oil. Thermal expansion and swelling led to increased mass and volume, accompanied by a decrease in hardness. Conversely, cross-linking, chain breakage, and precipitation of rubber molecules led to decreases in mass and volume, elongation at break, and tensile strength, coupled with an increase in hardness.

- (3)

- Temperature significantly impacted the comprehensive properties of the rubber. An increase in temperature shifted the inflection points of the mass and volume change rate curves and hardness change curves. At higher temperatures, the rate of change of mass and volume was negative.

- (4)

- High-acrylonitrile rubber exhibited an altered average friction coefficient after immersion in actual well fluid and diesel oil. The friction coefficient decreased after immersion in actual well fluid under the condition of actual well fluid lubrication but increased after immersion in diesel oil at 80 °C. Thermal expansion and swelling contributed to increased wear compared with the original specimens. The friction coefficient and wear quantity increased with increasing immersion temperature.

- (5)

- The effect of diesel oil on rubber properties exceeded that of actual well fluid, with a substantial decrease in rubber tensile properties in diesel oil compared with the same temperature conditions in actual wall fluid. The wear quantity after temperature expansion and swelling was 1.36, 1.67, and 1.59 times higher in diesel oil compared with actual well fluid for the respective temperature conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sathyamoorthy, S.; Steyn, A.; McGilvray, J.; Fuchs, H.; Ainebyona, B.; Kyomugisha, P.; Vijapurapu, S.; Kagga, N.; Rindfuss, R.; Basiima, D. First application of progressing cavity pumps for appraisal well testing in the Ugandan Albertine Graben Basin. SPE Prod. Oper. 2013, 28, 85–94. [Google Scholar] [CrossRef]

- Ramos, M.A.; Brown, J.C.; Rojas, M.; Kuyucu, O.; Flores, J.G. Producing extra-heavy oil from the Orinoco Belt, Cerro Negro Area, Venezuela, using bottom-drive progressive cavity pumps. SPE Prod. Oper. 2007, 22, 151–155. [Google Scholar] [CrossRef]

- Tian, Z.; Li, Z.; Liu, S.; Wang, D. Optimization and characteristic analysis of screw rotor of a twin-screw pump. J. Vibroeng. 2022, 25, 171–188. [Google Scholar] [CrossRef]

- Hao, Z.; Zhu, S.; Pei, X.; Huang, P.; Tong, Z.; Wang, B.; Li, D. Submersible direct-drive progressing cavity pump rodless lifting technology. Pet. Explor. Dev. 2019, 46, 621–628. [Google Scholar] [CrossRef]

- Chen, J.; Wang, F.; Shi, G.; Cao, G.; He, Y.; Ge, W.; Liu, H.; Wu, H. Finite element analysis for adhesive failure of progressive cavity pump with stator of even thickness. J. Pet. Sci. Eng. 2014, 125, 146–153. [Google Scholar] [CrossRef]

- Al-Safran, E.; Aql, A.; Nguyen, T. Analysis and Prediction of Fluid Flow Behavior in Progressing Cavity Pumps. J. Fluids Eng. 2017, 139, 121102. [Google Scholar] [CrossRef]

- Tavosi, S.; Alimardani, M.; Ghoreishy, M.H.R.; Tavakol, M. Fatigue failure modeling in rubber stator of downhole motors: Dependency to materials and geometry, and its application to life prediction. Eng. Fail. Anal. 2024, 159, 108072. [Google Scholar] [CrossRef]

- Liu, X.; Liu, C.; Hao, Z.; Zheng, Y.; Zhang, K.; Wang, J.; Wei, S.; Hao, A.; Tao, J.; Cheng, H. Non-symmetric distributions of solids deposition for solid-water stratified flow in deviated tubing strings. Pet. Sci. 2023, 20, 3048–3061. [Google Scholar] [CrossRef]

- Rosa, L.; Davis, K.F.; Rulli, M.C. Environmental consequences of oil production from oil sands. Earth’s Future 2017, 5, 158–170. [Google Scholar] [CrossRef]

- Lv, X.; Wang, S.; Huo, X. The effect of water content in crude oil on the tribological behavior of screw pump’s stator rubber. Chin. Sci. Bull. 2014, 59, 2868–2874. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, C.; Li, C.; Chen, L.; Li, J.; Yang, X.; Xie, H. Structural design and numerical analysis of an all-metal screw motor for drilling applications in high-temperature and high-pressure environments in ultra-deep wells. Appl. Sci. 2023, 13, 8630. [Google Scholar] [CrossRef]

- Shi, C.; Zhu, X.; Chen, Y.; Tang, L. Failure analysis of general stator and uniform wall thickness stator. Eng. Fail. Anal. 2018, 94, 239–248. [Google Scholar] [CrossRef]

- Zhao, J.; Yu, M.; Qian, C.; Wang, S.; Wang, Z. Thermal-oxidative aging behavior of graphene and graphene oxide-filled nitrile butadiene rubber: A molecular simulation approach. Polym. Eng. Sci. 2023, 63, 660–671. [Google Scholar] [CrossRef]

- Borisova, K.E.; Ivanova, T.N.; Latypov, R.G. Study of screw pump stator and rotor working capacity to increase the output. Procedia Eng. 2016, 206, 688–691. [Google Scholar] [CrossRef]

- Wang, M.; Huang, Z.; Qian, W.; Li, G. Study of the effect of laser textured rotors on the starting performance of metal–rubber mating pairs under different lubricating media environments. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2024, 238, 450–463. [Google Scholar] [CrossRef]

- Tagelsir, Y.; Li, S.; Lv, X.; Wang, S.; Wang, S.; Osman, Z. Swelling and tribological properties of melt-mixed rubber blends under crude oil. Mater. Res. Express 2018, 5, 015313. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, H.; Chen, Y.; Ji, J.; You, Z.; Zhang, Y. A review on compatibility between crumb rubber and asphalt binder. Constr. Build. Mater. 2021, 297, 123820. [Google Scholar] [CrossRef]

- Coronado, M.; Montero, G.; Valdez, B.; Stoytcheva, M.; Eliezer, A.; García, C.; Campbell, H.; Pérez, A. Degradation of nitrile rubber fuel hose by biodiesel use. Energy 2014, 68, 364–369. [Google Scholar] [CrossRef]

- Zhu, Z.; Cheng, Q.; Jiang, C.; Zhang, J.W.; Jiang, H. Scratch behavior of the aged hydrogenated nitrile butadiene rubber. Wear 2016, 352–353, 155–159. [Google Scholar] [CrossRef]

- Jiang, B.; Jia, X.; Wang, Z.; Wang, T.; Guo, F.; Wang, Y. Influence of thermal aging in oil on the friction and wear properties of nitrile butadiene rubber. Tribol. Lett. 2019, 67, 86. [Google Scholar] [CrossRef]

- Maroufkhani, M.; Katbab, A.; Liu, W.; Zhang, J. Polylactide (PLA) and acrylonitrile butadiene rubber (NBR) blends: The effect of ACN content on morphology, compatibility and mechanical properties. Polymer 2017, 115, 37–44. [Google Scholar] [CrossRef]

- Davydova, M.L.; Fedorova, A.F. Research changes in the properties of butadiene-nitrile rubber under various aging conditions. J. Elastomers Plast. 2022, 54, 185–195. [Google Scholar] [CrossRef]

- Li, T.; Chen, S.; Wan, S.; Cai, S.; He, X. The effect of functional zirconium phosphate on aging resistance of nitrile butadiene rubber composites. Polym. Compos. 2020, 41, 1867–1877. [Google Scholar] [CrossRef]

- Zhu, L.; Cheung, C.; Zhang, W.; Huang, Z. Compatibility of different biodiesel composition with acrylonitrile butadiene rubber (NBR). Fuel 2015, 158, 288–292. [Google Scholar] [CrossRef]

- Liu, S.; Jing, Y.; Tu, J.; Zou, H.; Yong, Z.; Liu, G. Systematic investigation on the swelling behaviors of acrylonitrile-butadiene rubber via solubility parameter and flory-huggins interaction parameter. J. Appl. Polym. Sci. 2022, 139, 52172. [Google Scholar] [CrossRef]

- Cadambi, M.R.; Ghassemieh, E. The ageing behaviour of hydrogenated nitrile butadiene rubber/nanoclay nanocomposites in various mediums. J. Elastomers Plast. 2012, 44, 353–367. [Google Scholar] [CrossRef]

- Wang, H.; Wang, S.; Lv, X. The effects of temperature on the mechanical and tribological properties of progressing cavity pump NBR stator rubber. Mechanika 2016, 22, 308–312. [Google Scholar] [CrossRef]

- Zu, H.; Sun, J.; Ye, W.; Li, D. Study on dynamic mechanical characteristics and Fatigue life prediction of single progressing cavity pump. China Mech. Eng. 2024. Available online: http://kns.cnki.net/kcms/detail/42.1294.th.20240325.1910.004.html (accessed on 22 June 2024).

- Lv, X.; Wang, H.; Wang, S. Effect of swelling nitrile rubber in cyclohexane on its ageing, friction and wear characteristics. Wear 2015, 328–329, 414–421. [Google Scholar] [CrossRef]

- Wang, H.; Wang, S.; Lv, X.; Wang, Z. The swelling properties and tribological behaviour of nitrile rubber with different acrylonitrile contents in crude oil medium researching. Mater. Res. Innov. 2015, 19, 771–775. [Google Scholar] [CrossRef]

- Song, S.; Wang, S.; Li, Y.; Nie, R. Swelling effect on sliding wear behavior of nitrile rubber under dry conditions. Lubr. Eng. 2021, 46, 57–61. [Google Scholar]

- Song, S.; Wang, S.; Nie, R.; Li, Y. Swelling effect on two-body sliding wear behavior of nitrile rubber under water lubrication. Lubr. Eng. 2021, 46, 63–67. [Google Scholar]

- Song, X.; Lv, X. Effect of cyclohexane on friction and wear behavior of stator rubber. China Rubber Ind. 2020, 67, 23–29. [Google Scholar]

- Bavin, R.R.; Fursov, I.D.; Vasil’ev, S.G.; Tarasov, V.P.; Zabrodin, V.A.; Volkov, V.I. Features of rubber swelling in transformer oil, according to NMR data. Russ. J. Phys. Chem. A 2016, 90, 1650–1655. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, D.; Di, H.; Cai, X.; Kuang, S.; Ding, N.; Du, F. Effect of high temperature diesel oil immersion on properties of NBR vulcanizates. China Rubber Ind. 2022, 69, 138–143. [Google Scholar]

- Wang, H.; Liu, X.; Apostolidis, P.; Erkens, S.; Skarpas, A. Experimental investigation of rubber swelling in bitumen. Transp. Res. Rec. 2020, 2674, 203–212. [Google Scholar] [CrossRef]

- Qi, M.; Jia, X.; Wang, G.; Xu, Z.; Zhang, Y. Research on high temperature friction properties of PTFE/Fluorosilicone rubber/silicone rubber. Polym. Test. 2020, 91, 106817. [Google Scholar] [CrossRef]

- Shi, C.; Wan, X.; Deng, J.; Zhu, X. Research on fatigue lifetime prediction of stator rubber bushing based on rubber aged experiment. J. Test. Eval. 2022, 50, 2209–2226. [Google Scholar] [CrossRef]

- Persson, B.N.J.; Tosatti, E. Qualitative theory of rubber friction and wear. J. Chem. Phys. 2000, 112, 2021–2029. [Google Scholar] [CrossRef]

- Qian, C.; Li, Y.; Zhao, J.; Wang, S.; He, E. Thermal-oxidative aging and tribological properties of carbon nanotube/nitrile butadiene rubber composites with varying acrylonitrile content: Molecular dynamics simulations. Polym. Eng. Sci. 2023, 63, 1516–1527. [Google Scholar] [CrossRef]

- Song, X. Study on Mechanical and Wear Behavior of Stator Rubber Swelling with Cyclohexane Mixture; Shenyang University of Technology: Shenyang, China, 2019. (In Chinese) [Google Scholar]

- Peng, S.; Huang, Z.; Wang, M.; Xiong, C.; Chen, K. Study on the influence of surface texture parameters of oil production screw motor rotor on the tribological properties of its friction pair. Processes 2023, 11, 618. [Google Scholar] [CrossRef]

- Shangguan, B.; Liu, K.; Wang, L.; Xu, C.; Yu, B. A method for modelling of fatigue life for rubbers and rubber isolators. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 623–636. [Google Scholar] [CrossRef]

- GB/T 2941-2006; Rubber—General procedures for preparing and conditioning test pieces for physical test methods. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China and Standardization Administration of the People’s Republic of China: Beijing, China, 2006.

- GB/T 1690-2010; Rubber, vulcanized or thermoplastic—Determination of the effect of liquids. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China and Standardization Administration of the People’s Republic of China: Beijing, China, 2011.

- GB/T 531.1-2008; Rubber, vulcanized or thermoplastic—Determination of indentation hardness—Part 1: Duromerer method (Shore hardness). General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China and Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- GB/T 528-2009; Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China and Standardization Administration of the People’s Republic of China: Beijing, China, 2009.

- Wang, H. Research on Swelling Behavior and Wear Resistance Performance of NBR in the Crude Oil Medium; Shenyang University of Technology: Shenyang, China, 2015. (In Chinese) [Google Scholar]

- Yacine, C.; Safri, A.; Djemiat, D.E.; Benmounah, A. Rheological behavior and microstructural properties of crude oil and emulsions (water/oil-oil/water). Pet. Sci. Technol. 2024, 42, 1047–1063. [Google Scholar] [CrossRef]

- Lam-Maldonado, M.; Aranda-Jiménez, Y.G.; Arvizu-Sanchez, E.; Melo-Banda, J.A.; Díaz-Zavala, N.P.; Pérez-Sánchez, J.F.; Suarez-Dominguez, E.J. Extra heavy crude oil viscosity and surface tension behavior using a flow enhancer and water at different temperatures conditions. Heliyon 2023, 9, 12120. [Google Scholar] [CrossRef] [PubMed]

- Kow, Y.Y.; Chai, B.A.; Ho, H.J. Relationships between swelling temperature and shape memory properties of palmitic acid-based shape memory natural rubber. J. Rubber Res. 2020, 23, 13–22. [Google Scholar] [CrossRef]

- Alcock, B.; Peters, T.A.; Gaarder, H.R.; Jørgensen, J.K. The effect of hydrocarbon ageing on the mechanical properties, apparent crosslink density and CO2 diffusion of a hydrogenated nitrile butadiene rubber (HNBR). Polym. Test. 2015, 47, 22–29. [Google Scholar] [CrossRef]

- Zou, H.; Jing, Y.; Tu, J.; Shi, X.; Kadlack, J.; Yong, Z.; Liu, S. Investigation on the mechanical properties and oil resistance of sulfur cured nitrile rubber/hydrogenated nitrile butadiene rubber blends. Polym. Eng. Sci. 2021, 61, 3050–3059. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Xu, L.; Zhang, P. Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym. Test. 2016, 54, 59–66. [Google Scholar] [CrossRef]

| Immersion Temperature T/°C | Actual Well Fluid | Diesel Oil | ||

|---|---|---|---|---|

| Mean Value | Standard Deviation | Mean Value | Standard Deviation | |

| 25 | 676% | 6.47% | 659% | 7.17% |

| 50 | 455% | 8.92% | 444% | 6.32% |

| 80 | 358% | 5.73% | 338% | 7.78% |

| Thermal Expansion and Swelling Conditions of Rubber Specimens | Mean Value | Standard Deviation |

|---|---|---|

| Non-immersion | 0.1147 | 6.603 × 10−5 |

| Actual well fluid at 25 °C | 0.0573 | 6.78 × 10−5 |

| Actual well fluid at 50 °C | 0.0653 | 4.626 × 10−5 |

| Actual well fluid at 80 °C | 0.0748 | 3.742 × 10−5 |

| Diesel oil at 25 °C | 0.0794 | 3.286 × 10−5 |

| Diesel oil at 50 °C | 0.0858 | 1.34 × 10−4 |

| Diesel oil at 80 °C | 0.1394 | 8.32 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Shi, X.; Hao, Z.; Wei, S.; Sun, Y.; Niu, X.; Liu, C.; Li, M.; Li, Z. Effect of Complex Well Conditions on the Swelling and Tribological Properties of High-Acrylonitrile Stator Rubber in Screw Pumps. Polymers 2024, 16, 2036. https://doi.org/10.3390/polym16142036

Liu X, Shi X, Hao Z, Wei S, Sun Y, Niu X, Liu C, Li M, Li Z. Effect of Complex Well Conditions on the Swelling and Tribological Properties of High-Acrylonitrile Stator Rubber in Screw Pumps. Polymers. 2024; 16(14):2036. https://doi.org/10.3390/polym16142036

Chicago/Turabian StyleLiu, Xinfu, Xiangzhi Shi, Zhongxian Hao, Songbo Wei, Yi Sun, Xinglong Niu, Chunhua Liu, Ming Li, and Zunzhao Li. 2024. "Effect of Complex Well Conditions on the Swelling and Tribological Properties of High-Acrylonitrile Stator Rubber in Screw Pumps" Polymers 16, no. 14: 2036. https://doi.org/10.3390/polym16142036

APA StyleLiu, X., Shi, X., Hao, Z., Wei, S., Sun, Y., Niu, X., Liu, C., Li, M., & Li, Z. (2024). Effect of Complex Well Conditions on the Swelling and Tribological Properties of High-Acrylonitrile Stator Rubber in Screw Pumps. Polymers, 16(14), 2036. https://doi.org/10.3390/polym16142036