Crack Length of Elastomeric Sealants and Their Service Life in Contrasting Canadian Climates: Effects of Climate Change

Abstract

1. Introduction

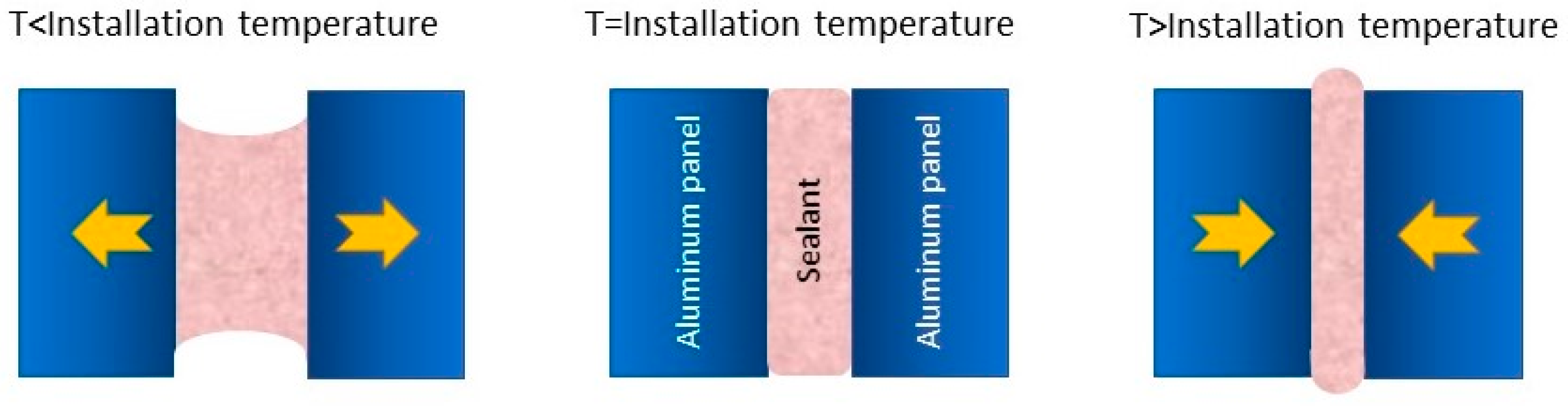

1.1. Theoretical Background

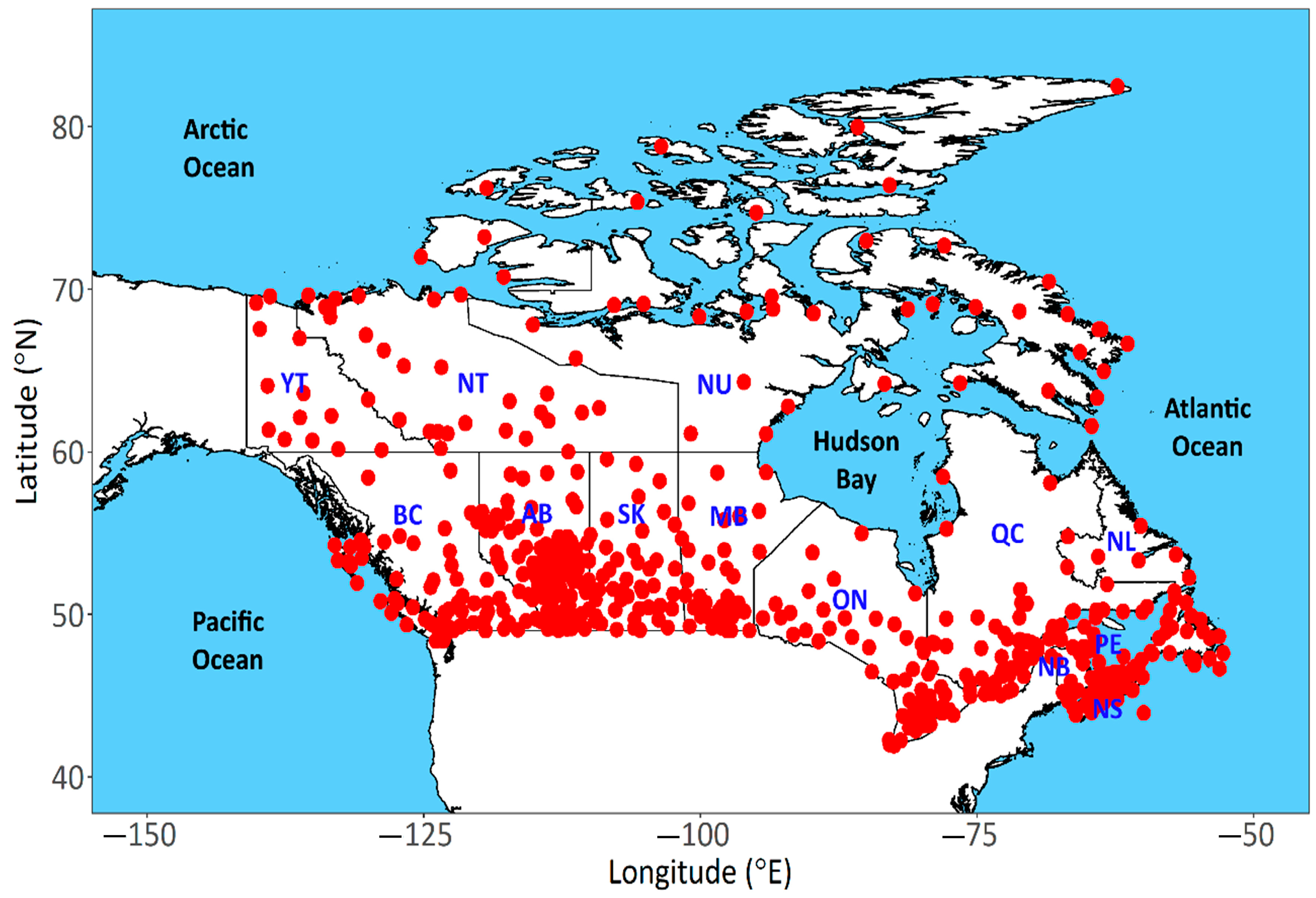

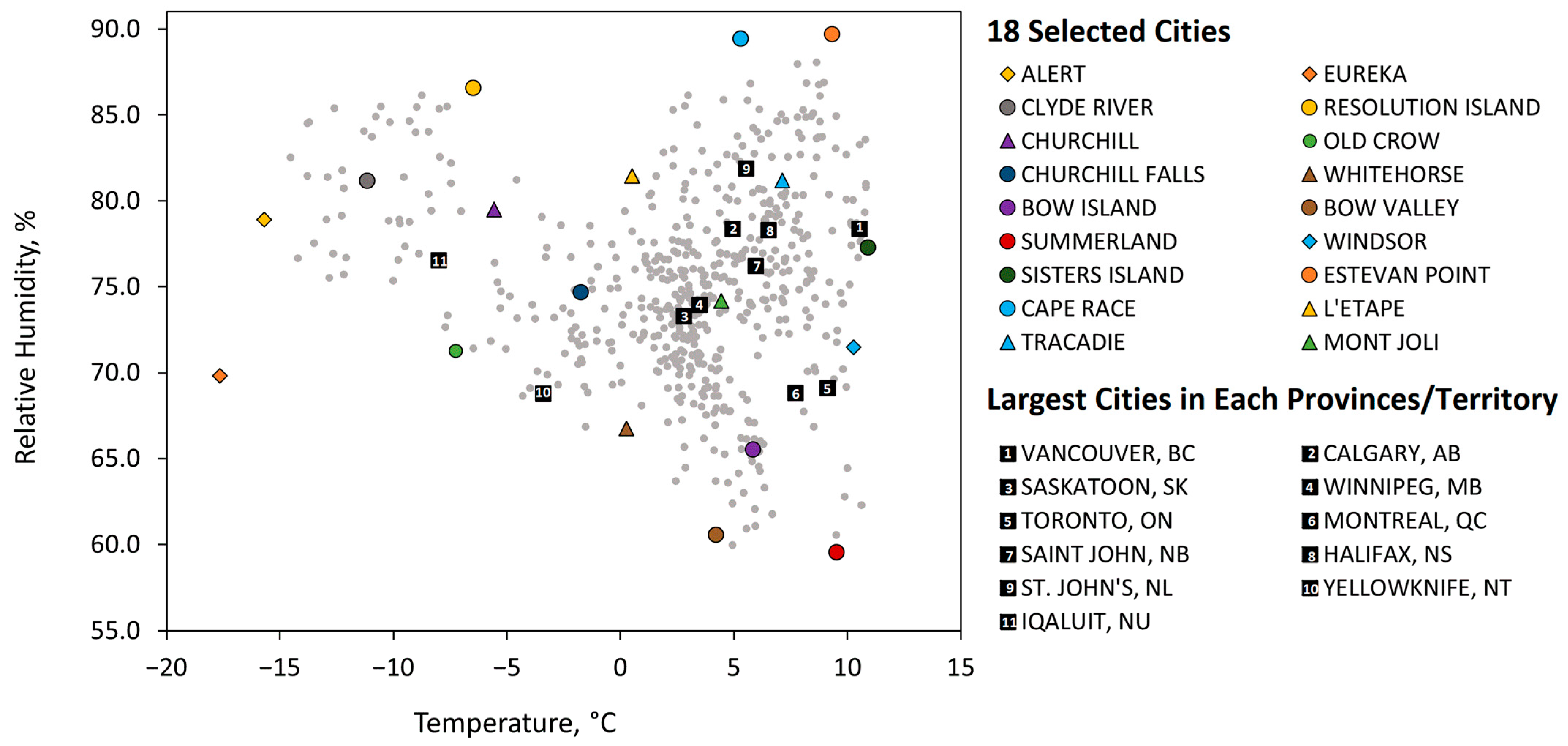

1.2. Study Area and Climate Data

2. Analysis and Results

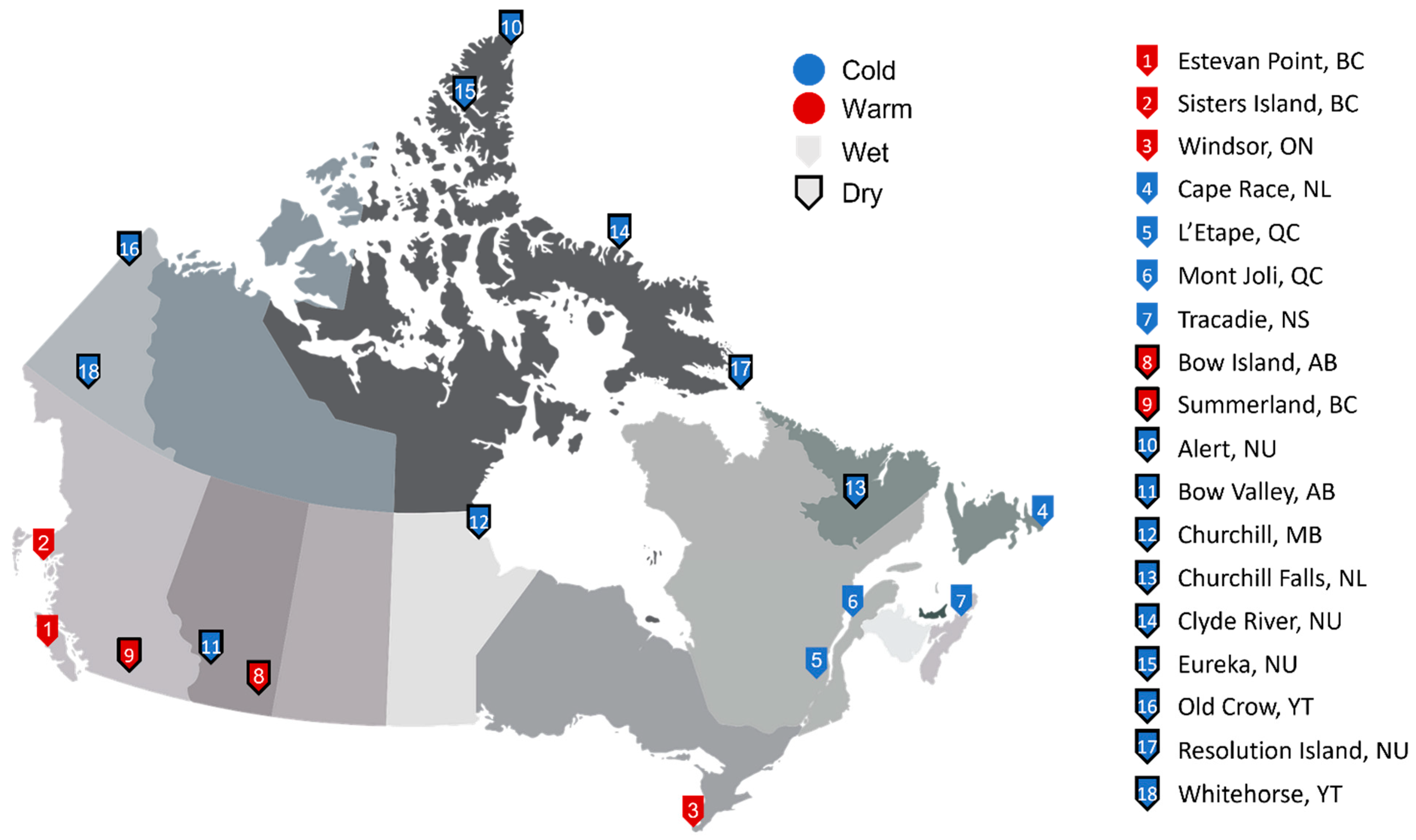

2.1. Mapping and Categorization of the Climate Regions

- Wet: Average annual rainfall > 500 mm;

- Dry: Average annual rainfall < 500 mm;

- Warm: Average annual temperature ≥ 5 °C;

- Cold: Average annual temperature < 5 °C.

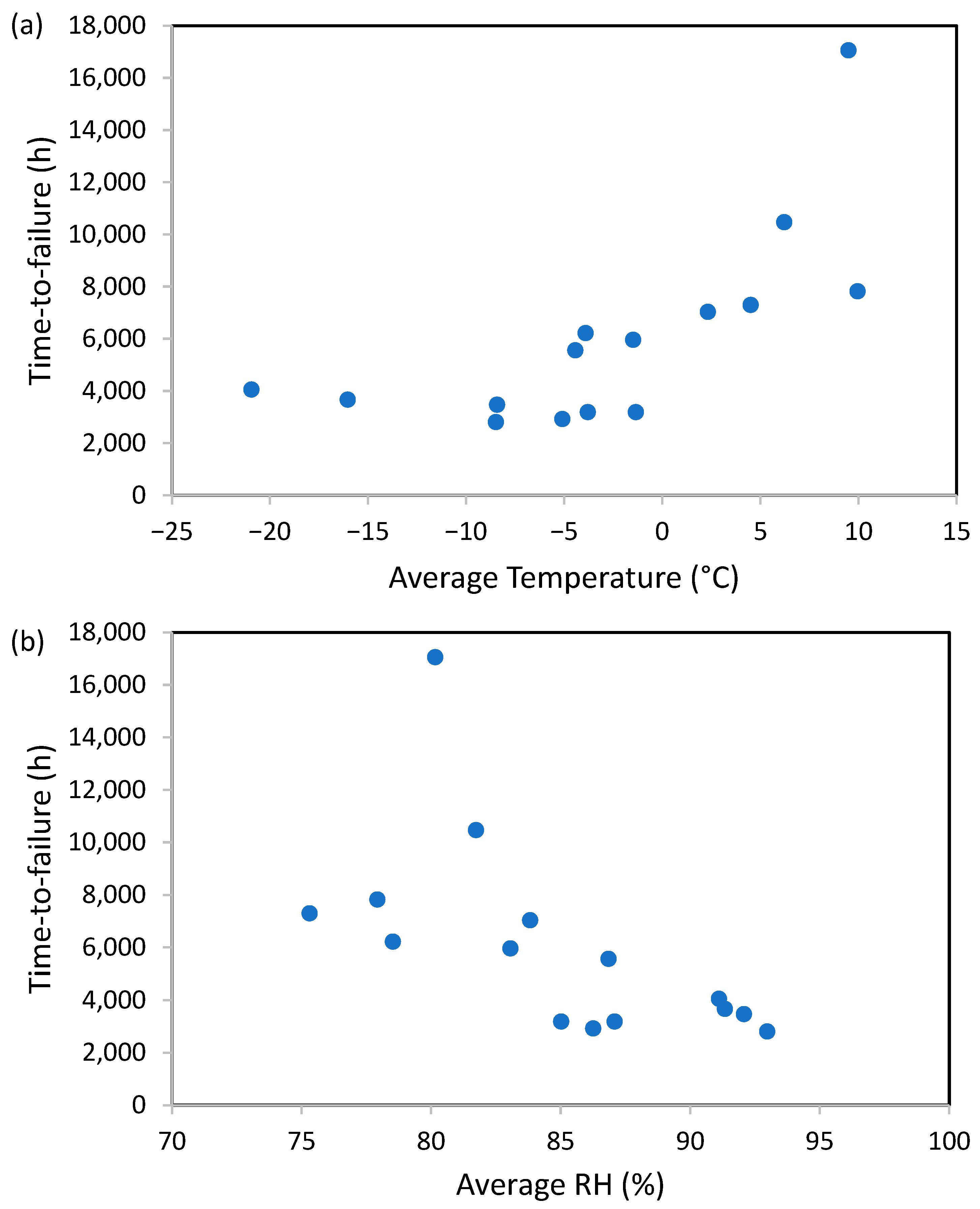

2.2. Significance of Installation Temperature on Crack Growth

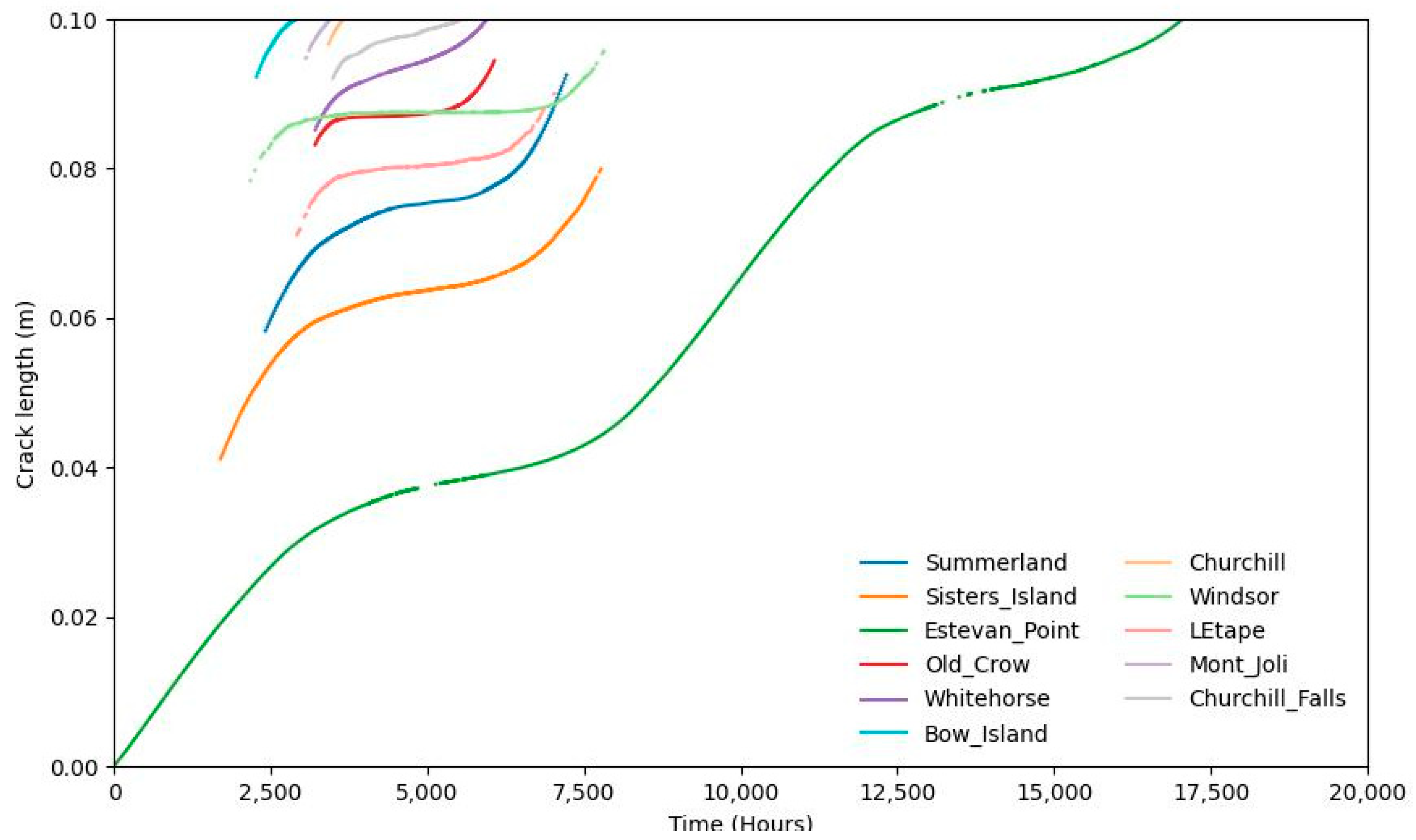

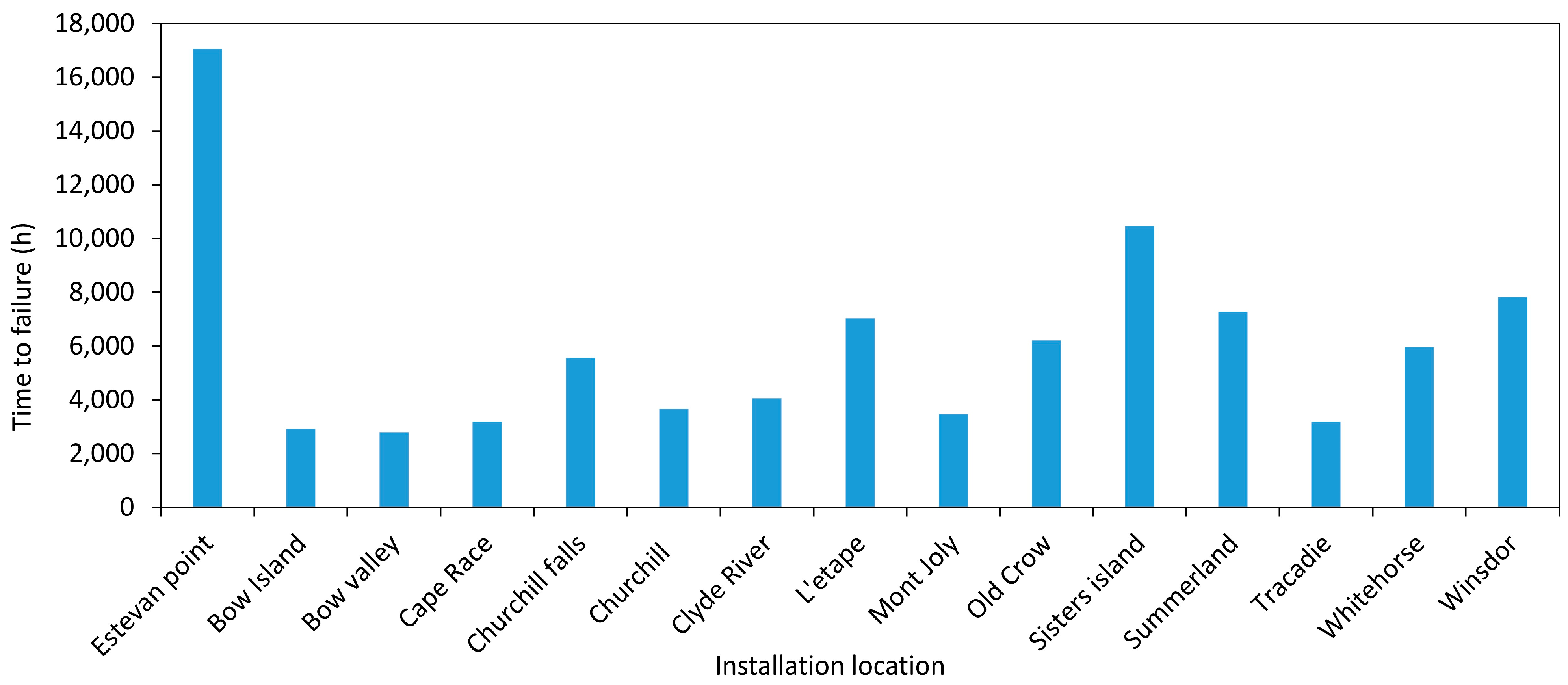

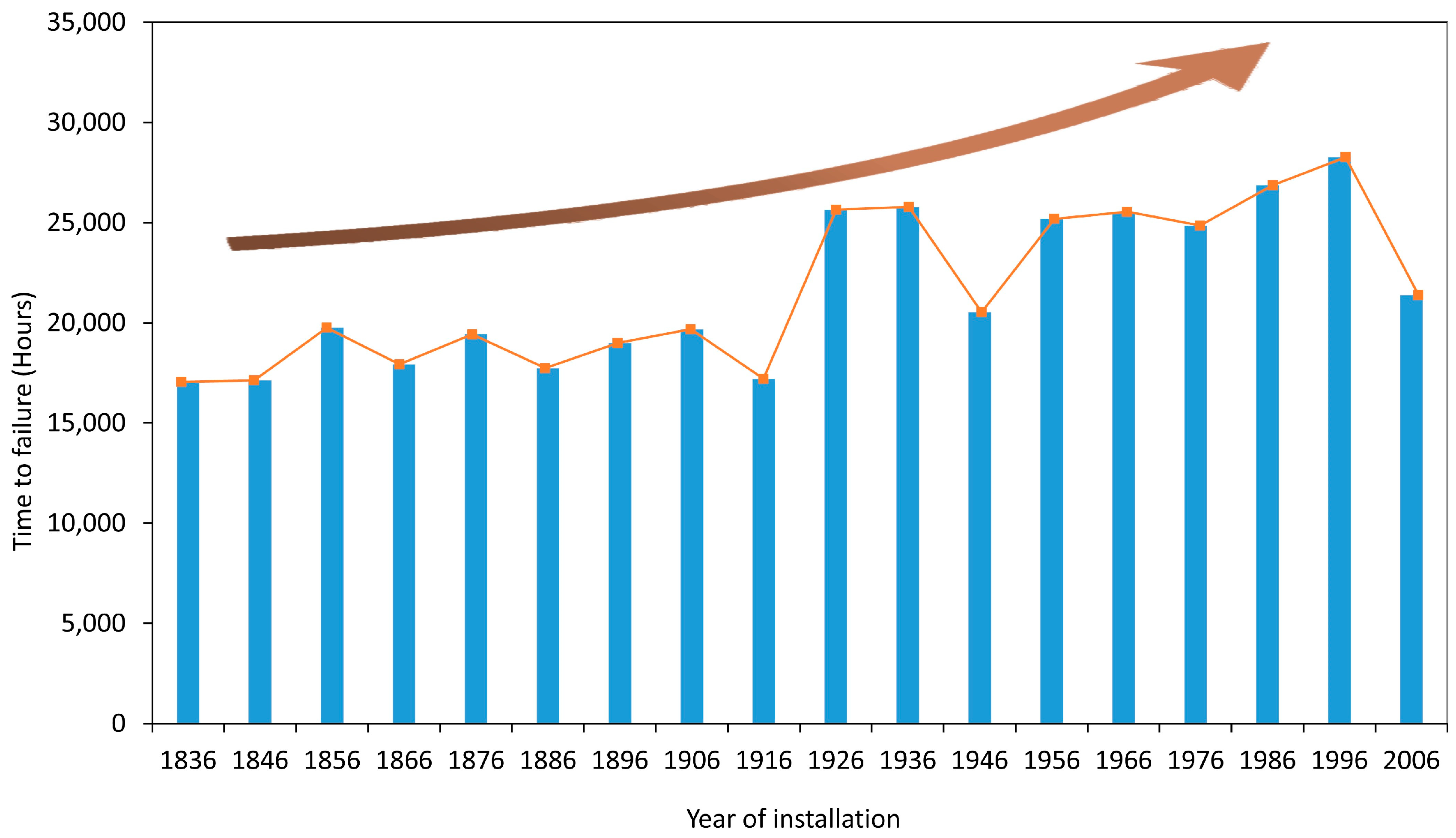

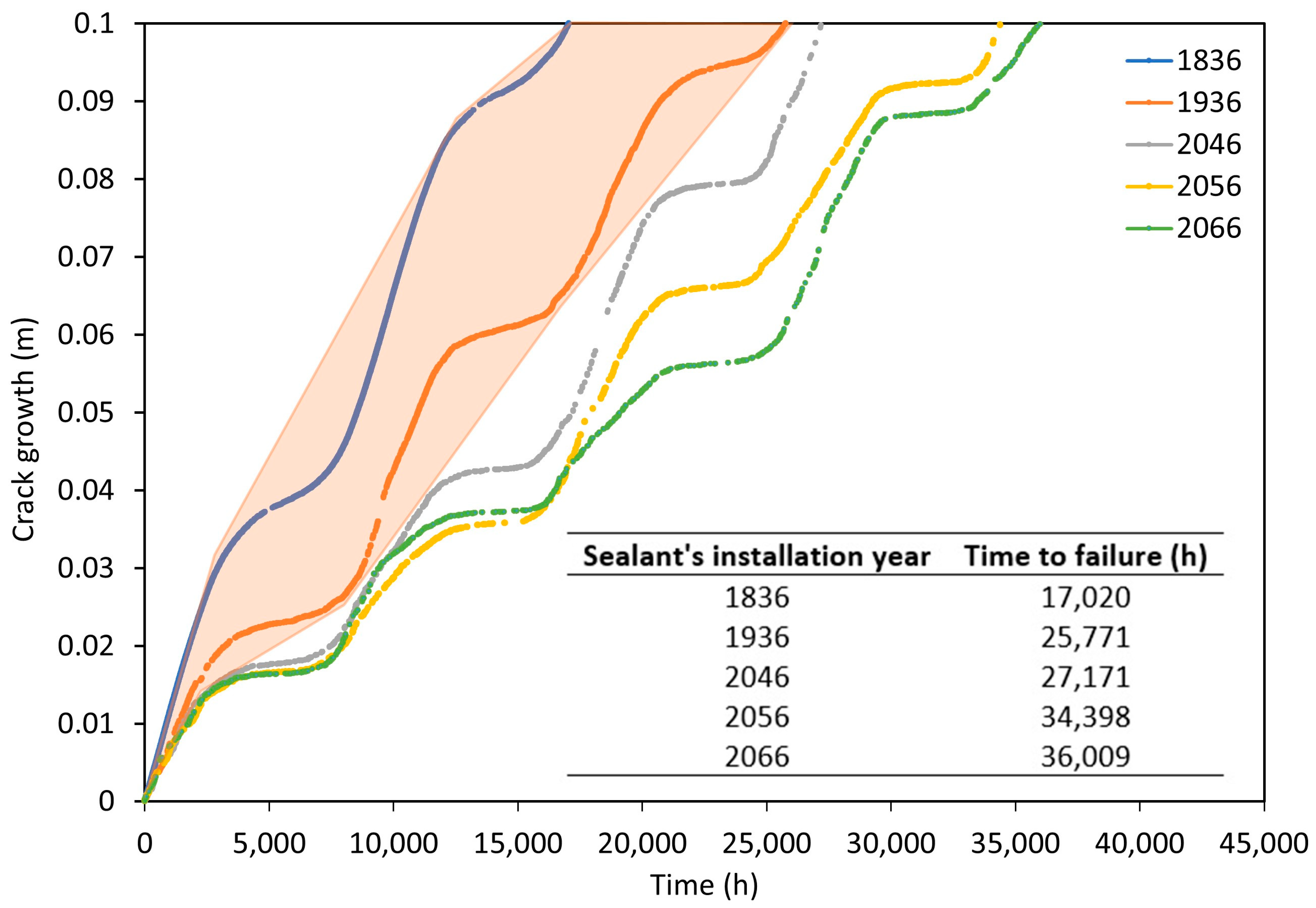

2.3. Time to Failure Analysis

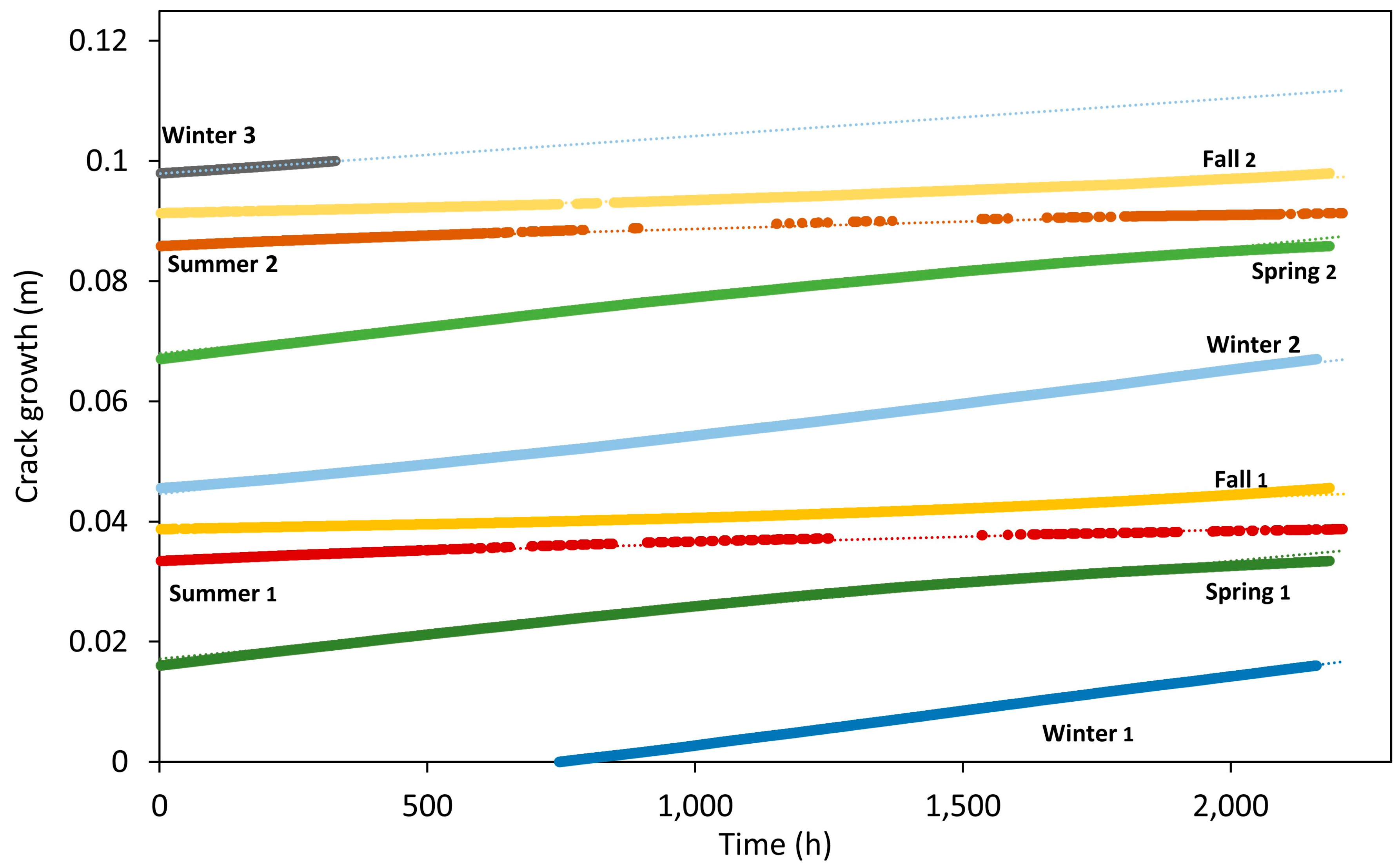

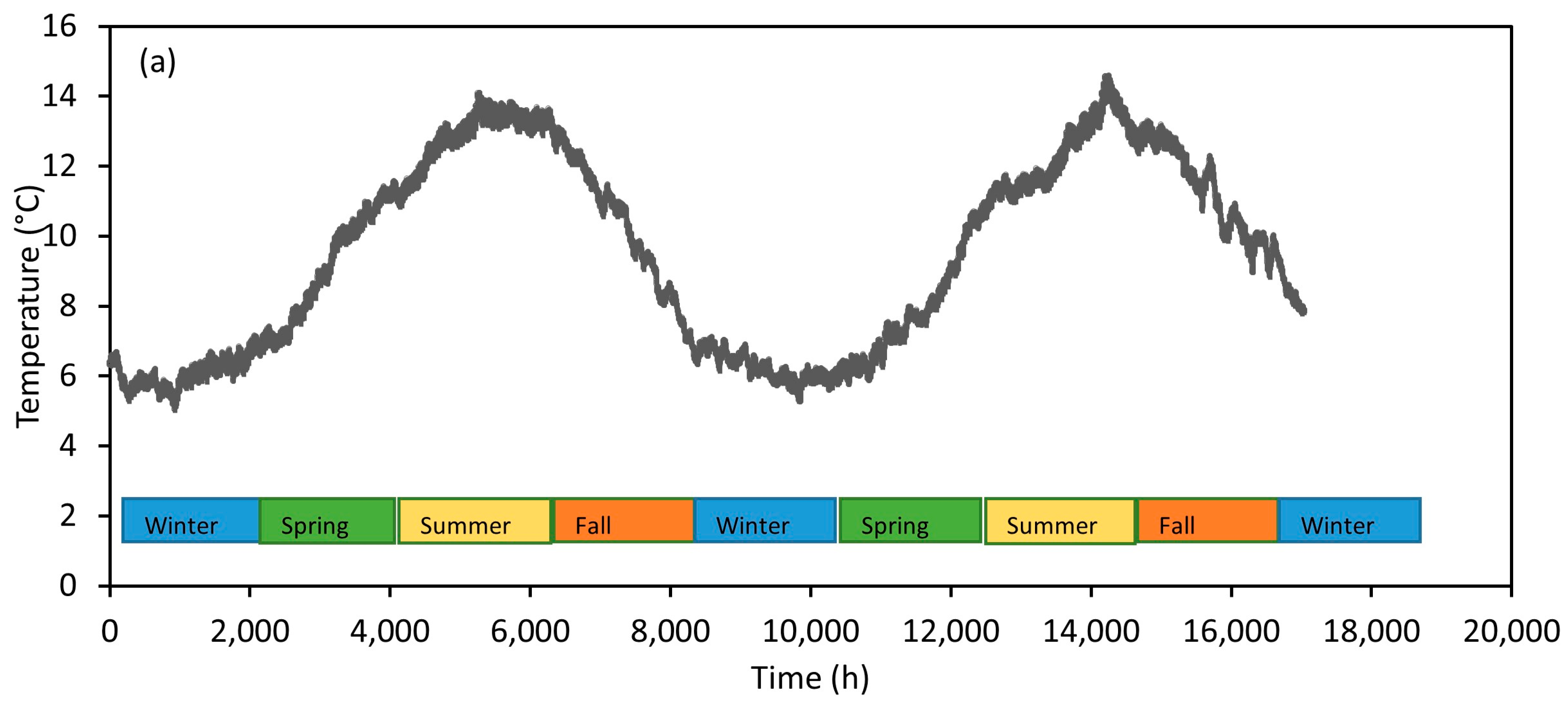

2.4. Seasonal Crack Growth Patterns

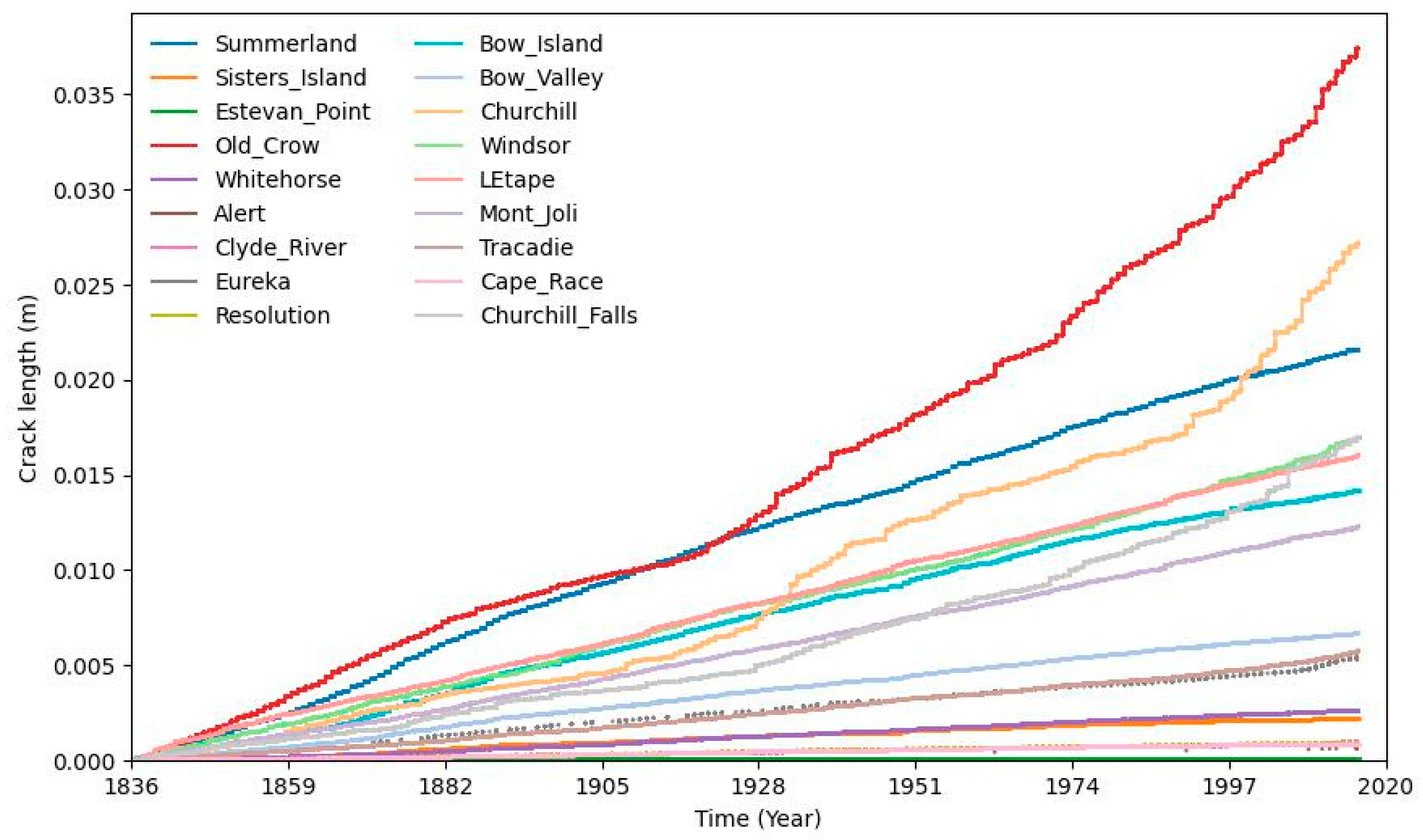

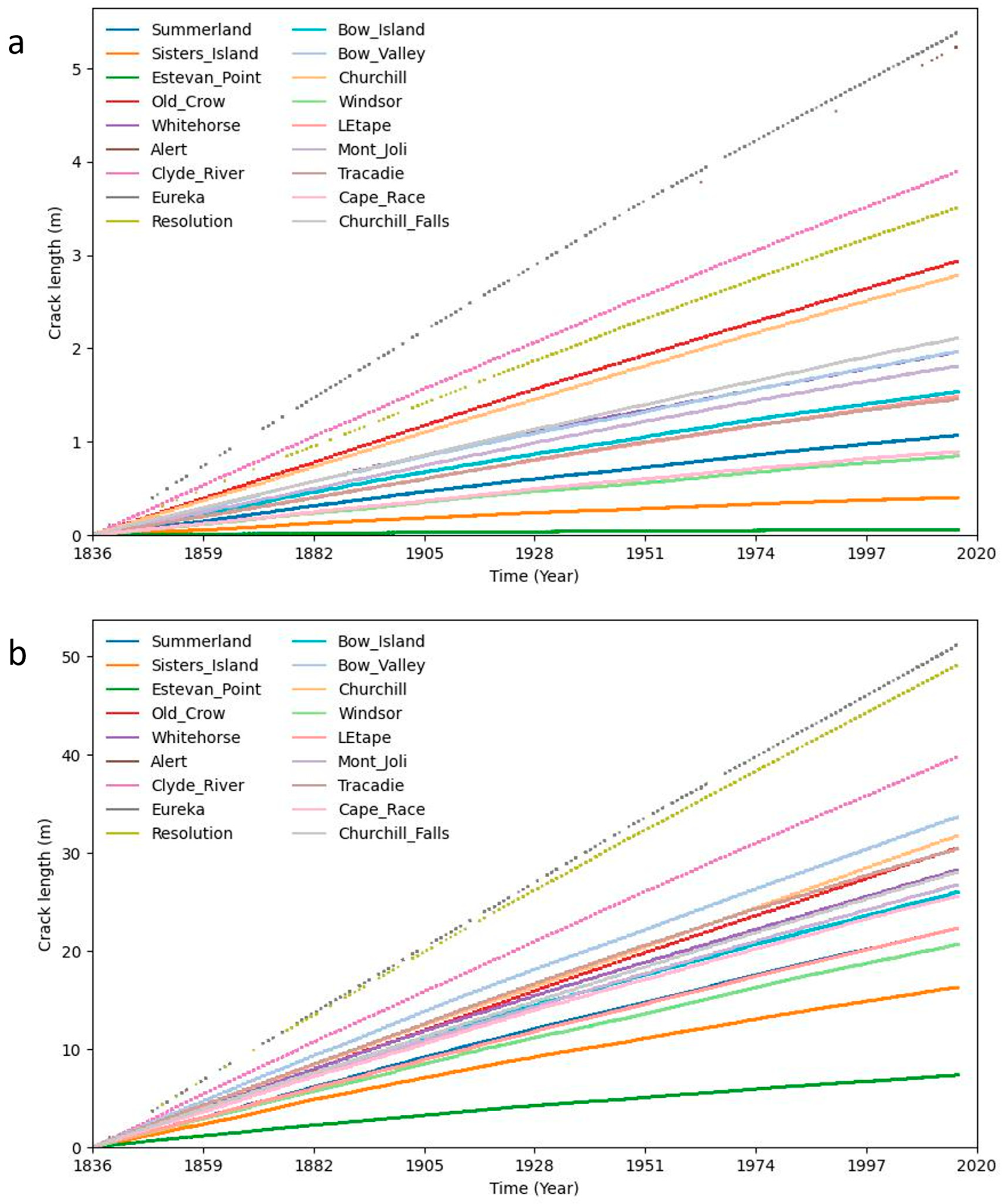

2.5. Climate Change Effect on Crack Growth

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Oh, S.; Ham, S.; Lee, S. Drone-Assisted Image Processing Scheme Using Frame-Based Location Identification for Crack and Energy Loss Detection in Building Envelopes. Energies 2021, 14, 6359. [Google Scholar] [CrossRef]

- Chen, K.; Reichard, G.; Xu, X.; Akanmu, A. Automated Crack Segmentation in Close-Range Building Façade Inspection Images Using Deep Learning Techniques. J. Build. Eng. 2021, 43, 102913. [Google Scholar] [CrossRef]

- Riahinezhad, M.; Hallman, M.; Masson, J.F. Critical Review of Polymeric Building Envelope Materials: Degradation, Durability and Service Life Prediction. Buildings 2021, 11, 299. [Google Scholar] [CrossRef]

- Wolf, A.T. State-of-the-Art Report of RILEM Technical Committee 139-DBS, Durability of Building Sealants; RILEM Proceedings; RILEM Publications: Cachan, France, 1999; ISBN 9782912143129. [Google Scholar]

- Petrie, E.M. Handbook of Adhesives and Sealants; McGraw-Hill Education: New York, NY, USA, 2007; ISBN 0071479163. [Google Scholar]

- Wallau, W.; Recknagel, C. Test Methodology for Performance Assessment of Structural Sealant Glazing Systems at Superimposed Mechanical and Climatic Loading. Polym. Test. 2019, 79, 106030. [Google Scholar] [CrossRef]

- Feero, B.A. Durability and Waterproofing Investigations of the Building Envelope. Master’s Thesis, The University of Texas at Austin, Austin, TX, USA, 2015. [Google Scholar]

- Masson, J.F. Bituminous Sealants for Pavement Joints and Cracks: Building the Basis for a Performance-Based Specification. In Proceedings of the Rilem Symposium on Durability of Building and Construction Sealants, Seneffe, Belgium, 2–3 February 1999; pp. 315–328. [Google Scholar]

- Masson, J.F.; Lauzier, C.; Collins, P.; Lacasse, M.A. Sealant Degradation during Crack Sealing of Pavements. J. Mater. Civ. Eng. 1998, 10, 250–255. [Google Scholar] [CrossRef]

- White, C.C.; Tan, K.T.; Hunston, D.L.; Sam Williams, R. Durability of Building Joint Sealants. In Service Life Prediction of Polymeric Materials Global Perspectives; Springer: New York, NY, USA, 2009; pp. 115–128. [Google Scholar] [CrossRef]

- Karpati, K.K. Performance of Polyurethane Sealants on a Strain-Cycling Exposure Rack. Mater. Struct. 1989, 22, 60–63. [Google Scholar] [CrossRef]

- Karpati, K.K. Investigation of Factors Influencing Outdoor Performance of Two-Part Polysulfide Sealants. J. Coat. Technol. 1984, 56, 57–60. [Google Scholar]

- Karpati, K.K. Weathering of Silicone Sealant on Strain-Cycling Exposure Rack. Adhes. Age 1980, 23, 41–47. [Google Scholar]

- Riahinezhad, M.; Masson, J.; Lacasse, M.; Hallman, M. Overview of Durability and Methods of Service Life Prediction for Building Adhesive and Sealant Products. In Proceedings of the Seventh Symposium on the Durability of Building and Construction Sealants and Adhesives, Toronto, ON, Canada, 9–10 June 2021; ASTM International: West Conshohockhen, PA, USA, 2022; pp. 1–18. [Google Scholar]

- Hayles, C.; Huddleston, M.; Chinowsky, P.; Helman, J. Quantifying the Effects of Projected Climate Change on the Durability and Service Life of Housing in Wales, UK. Buildings 2022, 12, 184. [Google Scholar] [CrossRef]

- White, C.; Tan, K.; Hunston, D. Durability of Building Joint Sealants; NIST: Gaithersburg, MD, USA, 2008. [Google Scholar]

- Zhang, Z.; Si, X.; Hu, C.; Kong, X. Degradation Modeling–Based Remaining Useful Life Estimation: A Review on Approaches for Systems with Heterogeneity. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2015, 229, 343–355. [Google Scholar] [CrossRef]

- Marechal, J.C.; Kalifa, P. The Prediction of Long-Term Sealant Performance from Dynamic Accelerated Weathering. In Durability of Building Materials and Components 7 (Volume 1); E & FN Spon: London, UK, 1996; pp. 54–64. ISBN 0419206906. [Google Scholar]

- Wolf, A.T. Recommendation of RILEM TC 190-SBJ: Service-Life Prediction of Sealed Building and Construction Joints: Determination of Changes in Adhesion, Cohesion and Appearance of Elastic Weatherproofing Sealants after Exposure of Statically Cured Specimens to Outd. Mater. Struct. Constr. 2008, 41, 1487–1495. [Google Scholar] [CrossRef]

- Rosendahl, P.L.; Staudt, Y.; Schneider, A.P.; Schneider, J.; Becker, W. Nonlinear Elastic Finite Fracture Mechanics: Modeling Mixed-Mode Crack Nucleation in Structural Glazing Silicone Sealants. Mater. Des. 2019, 182, 108057. [Google Scholar] [CrossRef]

- Galatolo, R.; Lazzeri, R. Experiments and Model Predictions for Fatigue Crack Propagation in Riveted Lap-Joints with Multiple Site Damage. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 307–319. [Google Scholar] [CrossRef]

- Lacasse, M.A.; Giffin, G.B.; Margeson, J.C. Laboratory Cyclic Fatigue Test of Silicone Sealant Mini-Specimens. In Science and Technology of Building Seals, Sealants, Glazing, and Waterproofing: Seventh Volume; ASTM International: West Conshohockhen, PA, USA, 1998; pp. 51–65. [Google Scholar]

- Lacasse, M.A.; Bryce, J.E.; Margeson, J.C. Evaluation of Cyclic Fatigue as a Means of Assessing the Performance of Construction Joint Sealants: Polyurethane Sealants. In Science and Technology of Building Seals, Sealants, Glazing, and Waterproofing: Fifth Volume; ASTM International: West Conshohockhen, PA, USA, 1996. [Google Scholar]

- Lacasse, M.A.; Bryce, J.E.; Margeson, J.C. Evaluation of Cyclic Fatigue as a Means of Assessing the Performance of Construction Joint Sealants: Silicone Sealants. In Science and Technology of Building Seals, Sealants, Glazing, and Waterproofing: Fourth Volume; ASTM International: West Conshohockhen, PA, USA, 1995; pp. 49–64. [Google Scholar]

- Shephard, N.E. Measuring and Predicting Sealant Adhesion; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 1995; ISBN 9798641434797. [Google Scholar]

- Paris, P.C.; Gomez, M.P.; Anderson, W.E. A Rational Analytical Theory of Fatigue, The Trend in Engineering. Trend Eng. 1961, 13, 9–14. [Google Scholar]

- Lacasse, M.A.; Cornick, S.M.; Shephard, N. Estimating The Service Life Of Jointing Products And Systems Application Of A Crack Growth Model To Different Climates. In Proceedings of the 9th International Conference on Building Materials and Components, Brisbane, Australia, 17–20 March 2002; pp. 1–11. [Google Scholar]

- Lake, G.J. Fatigue and Fracture of Elastomers. Rubber Chem. Technol. 1995, 68, 435–460. [Google Scholar] [CrossRef]

- Environment and Natural Resources. A Healthy Environment and a Healthy Economy Contains New Measures for the Buildings Sector. Available online: https://www.canada.ca/en/services/environment/weather/climatechange/climate-plan/climate-plan-overview/healthy-environment-healthy-economy/annex-homes-buildings.html (accessed on 1 April 2024).

- Statistics Canada. Human Activity and the Environment: Annual Statistics; Statistics Canada: Ottawa, ON, Canada, 2008.

- Engineering Climate Datasets. Available online: https://climate.weather.gc.ca/prods_servs/engineering_e.html (accessed on 1 April 2024).

- Canadian Weather Energy and Engineering Datasets (CWEEDS). Available online: https://collaboration.cmc.ec.gc.ca/cmc/climate/Engineer_Climate/CWEEDS_FMCEG/ (accessed on 1 April 2024).

- Gaur, A.; Lacasse, M. Climate Data to Support the Adaptation of Buildings to Climate Change in Canada. Data 2022, 7, 42. [Google Scholar] [CrossRef]

- Slivinski, L.C.; Compo, G.P.; Whitaker, J.S.; Sardeshmukh, P.D.; Giese, B.S.; McColl, C.; Allan, R.; Yin, X.; Vose, R.; Titchner, H.; et al. Towards a More Reliable Historical Reanalysis: Improvements for Version 3 of the Twentieth Century Reanalysis System. Q. J. R. Meteorol. Soc. 2019, 145, 2876–2908. [Google Scholar] [CrossRef]

- Canadian Climate Normals. Available online: https://climate.weather.gc.ca/climate_normals/ (accessed on 1 April 2024).

- Li, H.; Yi, Z.; Cheng, G.; Wen, H.; Xie, Y. Effects of Ultraviolet Radiation, High Temperature and Alkaline Chemicals on Ageing of Silicone Sealants Used in Ballastless Track Expansion Joints. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 1015–1021. [Google Scholar] [CrossRef]

- Fedor, G.; Brennan, P. Correlation of Accelerated and Natural Weathering of Sealants; Q-Lab: Westlake, OH, USA, 2005. [Google Scholar]

- Handegord, G.O.; Karpati, K.K. Joint Movement and Sealant Selection. In Canadian Building Digest; National Research Council of Canada. Division of Building Research: Ottawa, ON, Canada, 1973. [Google Scholar]

- What Is Climate Change. Available online: https://climate.nasa.gov/what-is-climate-change/ (accessed on 1 April 2024).

- Davidson, D. Climate Change. The Canadian Encyclopedia. 2011. Available online: https://www.thecanadianencyclopedia.ca/en/article/climate-change (accessed on 1 April 2024).

- Mitchell, J.F.B.; Lowe, J.; Wood, R.A.; Vellinga, M. Extreme Events Due to Human-Induced Climate Change. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2006, 364, 2117–2133. [Google Scholar] [CrossRef]

- Wu, Y.; McGarry, F.J.; Zhu, B.; Keryk, J.R.; Katsoulis, D.E. Temperature Effect on Mechanical Properties of Toughened Silicone Resins. Polym. Eng. Sci. 2005, 45, 1522–1531. [Google Scholar] [CrossRef]

- Ding, S.H.; Liu, D.Z. Durability Evaluation of Building Sealants by Accelerated Weathering and Thermal Analysis. Constr. Build. Mater. 2006, 20, 878–881. [Google Scholar] [CrossRef]

| Location | Province | Station name | Mean Daily T | Std Dev Mean Daily T | Mean Daily Max T | Mean Daily Min T | Daily Mean T Range | Mean Rainfall, mm | Mean Snowfall, cm | Total Precipitation, mm | Std Dev of Total Precipitation | number of Days with Measurable Rainfall | number of Days with Measurable Snowfall | number of Days with Measurable Precipitation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Eureka A | NU | Eureka, NWT | −19.7 | 1 | −16.4 | −23 | 6.6 | 23.4 | 44.1 | 64 | 23.5 | 12 | 46 | 55 |

| Alert | NU | Alert, NWT | −18.2 | 0.7 | −14.8 | −21.6 | 6.8 | 17.5 | 148.1 | 154.4 | 39.5 | 10 | 93 | 98 |

| Clyde River Climate | NU | Clyde, NWT | −12.2 | 0.9 | −8.5 | −15.9 | 7.4 | 45.6 | 168.9 | 206.4 | 100.4 | 17 | 83 | 97 |

| Old Crow Rcs | YT | Old Crow, YT | −10.1 | 0.9 | −4.9 | −15.4 | 10.5 | 108 | 109.7 | 214.7 | 56.1 | 24 | 37 | 64 |

| Churchill A | MB | Churchill A, MB | −7.2 | 0.9 | −3.2 | −11.3 | 8.1 | 221.1 | 195.5 | 402.3 | 87.4 | 58 | 100 | 148 |

| Resolution Island | NU | Resolution Island, NWT | −6.4 | 0.8 | −4.1 | −8.6 | 4.5 | 168.3 | 155.4 | 313.3 | 73.3 | 52 | 94 | 142 |

| Churchill Falls | NL | Churchill Falls, NL | −3.1 | 1.2 | 1.7 | −7.9 | 9.6 | 489.6 | 481 | 962.8 | 127.6 | 96 | 119 | 211 |

| Whitehorse A | NT | Whitehorse A, YT | −1.2 | 1.1 | 4 | −6.3 | 10.3 | 145.5 | 136.6 | 261.2 | 48.4 | 52 | 73 | 120 |

| Mont Joli A | QC | Mont Joli A, QC | 3.2 | 0.7 | 7.4 | −1 | 8.4 | 535.5 | 389.3 | 898.3 | 77.2 | 92 | 79 | 163 |

| Bow Valley | AB | Bow Valley Prov Park, AB | 3.5 | 1.1 | 9.9 | −3.3 | 13.2 | 307.8 | 233 | 539 | 76.4 | 58 | 47 | 103 |

| L’Etape * | QC | Baie St Paul | 4.2 | 0.8 | 9.4 | −1 | 10.4 | 667 | 264.6 | 925.9 | 161.1 | 79 | 34 | 108 |

| Cape Race (AUT) | NL | Cape Race (AUT), NL | 4.3 | 0.6 | 7.6 | 1 | 6.6 | 1220.2 | 166.6 | 1379 | 159.1 | 147 | 33 | 169 |

| Tracadie | NS | Tracadie, NB | 4.6 | 0.9 | 8.7 | 0.3 | 8.4 | 670 | 335 | 996.2 | 121.8 | 91 | 33 | 121 |

| Bow Island | AB | Bow Island Rivers Dev, AB | 5.9 | 1.1 | 12.1 | −0.4 | 12.5 | 249.1 | 94.2 | 342.4 | 97 | 37 | 25 | 61 |

| Summerland CS | BC | Summerland CDA, BC | 8.9 | 0.7 | 13.8 | 4 | 9.8 | 213.5 | 77.7 | 291.1 | 47 | 75 | 28 | 100 |

| Sisters Island * | BC | Alberni Robertson Creek | 8.9 | 0.5 | 14.1 | 3.6 | 10.5 | 2012.9 | 159.5 | 2176.8 | 357.6 | 162 | 19 | 172 |

| Estevan Point CS | BC | Estevan Point, BC | 9.1 | 0.5 | 11.7 | 6.3 | 5.4 | 3066.7 | 44.8 | 3119.9 | 410.2 | 205 | 13 | 207 |

| Windsor A | ON | Windsor A, ON | 9.1 | 0.6 | 13.8 | 4.4 | 9.4 | 737.5 | 117.4 | 848.8 | 127.9 | 105 | 45 | 139 |

| Station Name | Mean Annual T (°C) | Mean Annual T Range (°C) | Mean Annual Rainfall (mm) | Mean Annual Total Precipitation (mm) | Climate Category: Warm vs. Cold | Climate Category: Wet vs. Dry |

|---|---|---|---|---|---|---|

| Eureka, NWT | −19.7 | 6.6 | 23.4 | 64 | Cold | Dry |

| Alert, NWT | −18.2 | 6.8 | 17.5 | 154.4 | Cold | Dry |

| Clyde, NWT | −12.2 | 7.4 | 45.6 | 206.4 | Cold | Dry |

| Old Crow, YT | −10.1 | 10.5 | 108 | 214.7 | Cold | Dry |

| Churchill A, MB | −7.2 | 8.1 | 221.1 | 402.3 | Cold | Dry |

| Resolution Island, NWT | −6.4 | 4.5 | 168.3 | 313.3 | Cold | Dry |

| Churchill Falls, NL | −3.1 | 9.6 | 489.6 | 962.8 | Cold | Dry |

| Whitehorse A, YT | −1.2 | 10.3 | 145.5 | 261.2 | Cold | Dry |

| Mont Joli A, QC | 3.2 | 8.4 | 535.5 | 898.3 | Cold | Wet |

| Bow Valley Prov Park, AB | 3.5 | 13.2 | 307.8 | 539 | Cold | Dry |

| L’Etape, QC | 4.2 | 10.4 | 667 | 925.9 | Cold | Wet |

| Cape Race (AUT), NL | 4.3 | 6.6 | 1220.2 | 1379 | Cold | Wet |

| Tracadie, NB | 4.6 | 8.4 | 670 | 996.2 | Cold | Wet |

| Bow Island Rivers Dev, AB | 5.9 | 12.5 | 249.1 | 342.4 | Warm | Dry |

| Sisters Island, BC | 8.9 | 10.5 | 2012.9 | 2176.8 | Warm | Wet |

| Summerland CDA, BC | 8.9 | 9.8 | 213.5 | 291.1 | Warm | Dry |

| Estevan Point, BC | 9.1 | 5.4 | 3066.7 | 3119.9 | Warm | Wet |

| Windsor A, ON | 9.1 | 9.4 | 737.5 | 848.8 | Warm | Wet |

| Winter | Spring | Summer | Fall | |||||

|---|---|---|---|---|---|---|---|---|

| Slope (mm·h−1) | R2 | Slope (mm·h−1) | R2 | Slope (mm·h−1) | R2 | Slope (mm·h−1) | R2 | |

| First year | 1 × 10−5 | 0.99 | 8 × 10−6 | 0.98 | 2 × 10−6 | 0.97 | 3 × 10−6 | 0.95 |

| Second year | 1 × 10−5 | 0.99 | 9 × 10−6 | 0.99 | 2 × 10−6 | 0.98 | 3 × 10−6 | 0.98 |

| Third year | 6 × 10−6 | 0.99 | NA | NA | NA | NA | NA | NA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 National Research Council of Canada. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riahinezhad, M.; Esmizadeh, E.; Lopez-Carreon, I.; Gaur, A.; Lu, H.; Lacasse, M.A. Crack Length of Elastomeric Sealants and Their Service Life in Contrasting Canadian Climates: Effects of Climate Change. Polymers 2024, 16, 2039. https://doi.org/10.3390/polym16142039

Riahinezhad M, Esmizadeh E, Lopez-Carreon I, Gaur A, Lu H, Lacasse MA. Crack Length of Elastomeric Sealants and Their Service Life in Contrasting Canadian Climates: Effects of Climate Change. Polymers. 2024; 16(14):2039. https://doi.org/10.3390/polym16142039

Chicago/Turabian StyleRiahinezhad, Marzieh, Elnaz Esmizadeh, Itzel Lopez-Carreon, Abhishek Gaur, Henry Lu, and Michael A. Lacasse. 2024. "Crack Length of Elastomeric Sealants and Their Service Life in Contrasting Canadian Climates: Effects of Climate Change" Polymers 16, no. 14: 2039. https://doi.org/10.3390/polym16142039

APA StyleRiahinezhad, M., Esmizadeh, E., Lopez-Carreon, I., Gaur, A., Lu, H., & Lacasse, M. A. (2024). Crack Length of Elastomeric Sealants and Their Service Life in Contrasting Canadian Climates: Effects of Climate Change. Polymers, 16(14), 2039. https://doi.org/10.3390/polym16142039