Synergistic Enhancement of the Friction and Wear Performance for UHMWPE Composites under Different Aging Times

Abstract

:1. Introduction

2. Experimental Section

2.1. Material Preparation

2.2. Tribological Performance Tests

2.3. Characterization

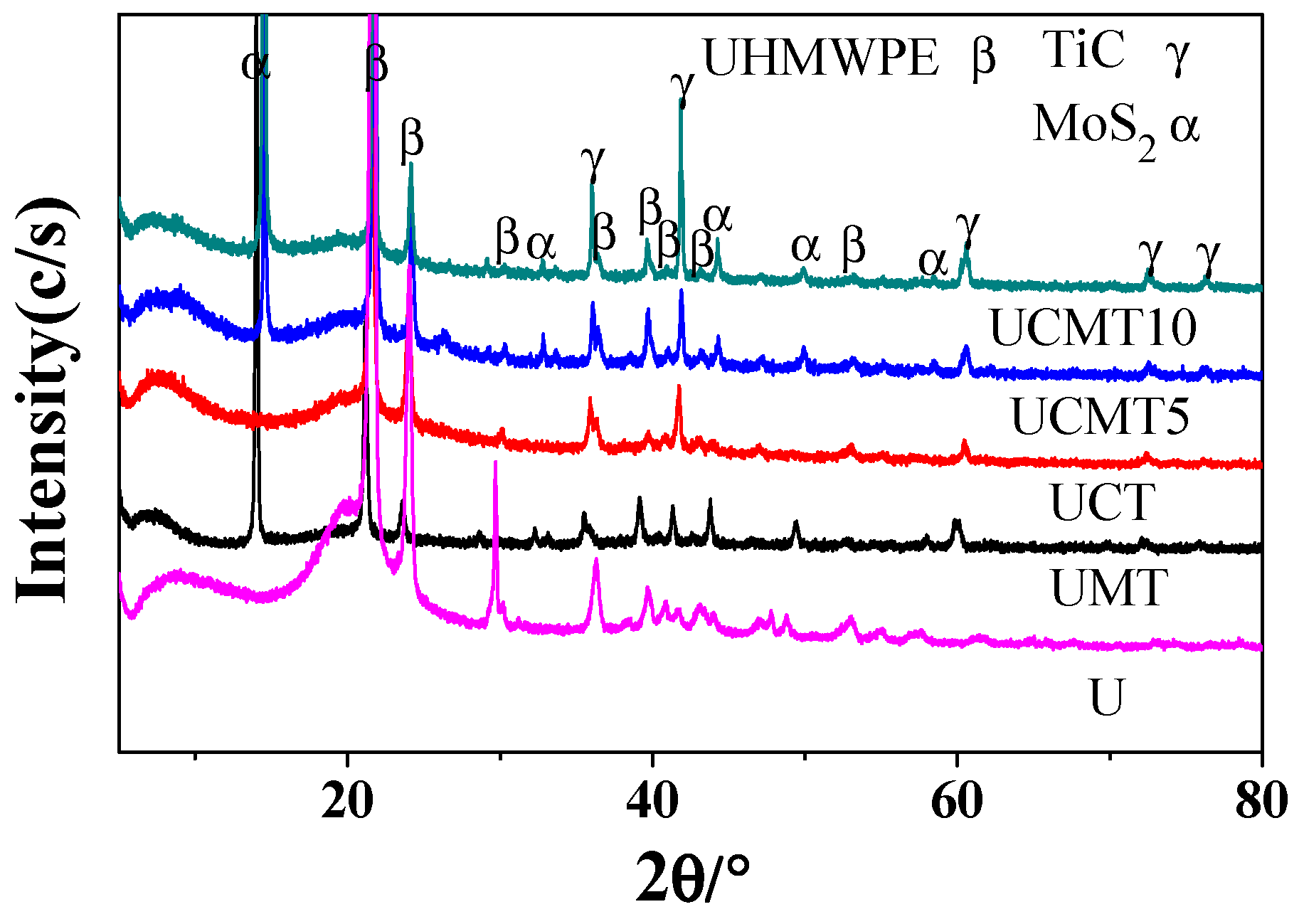

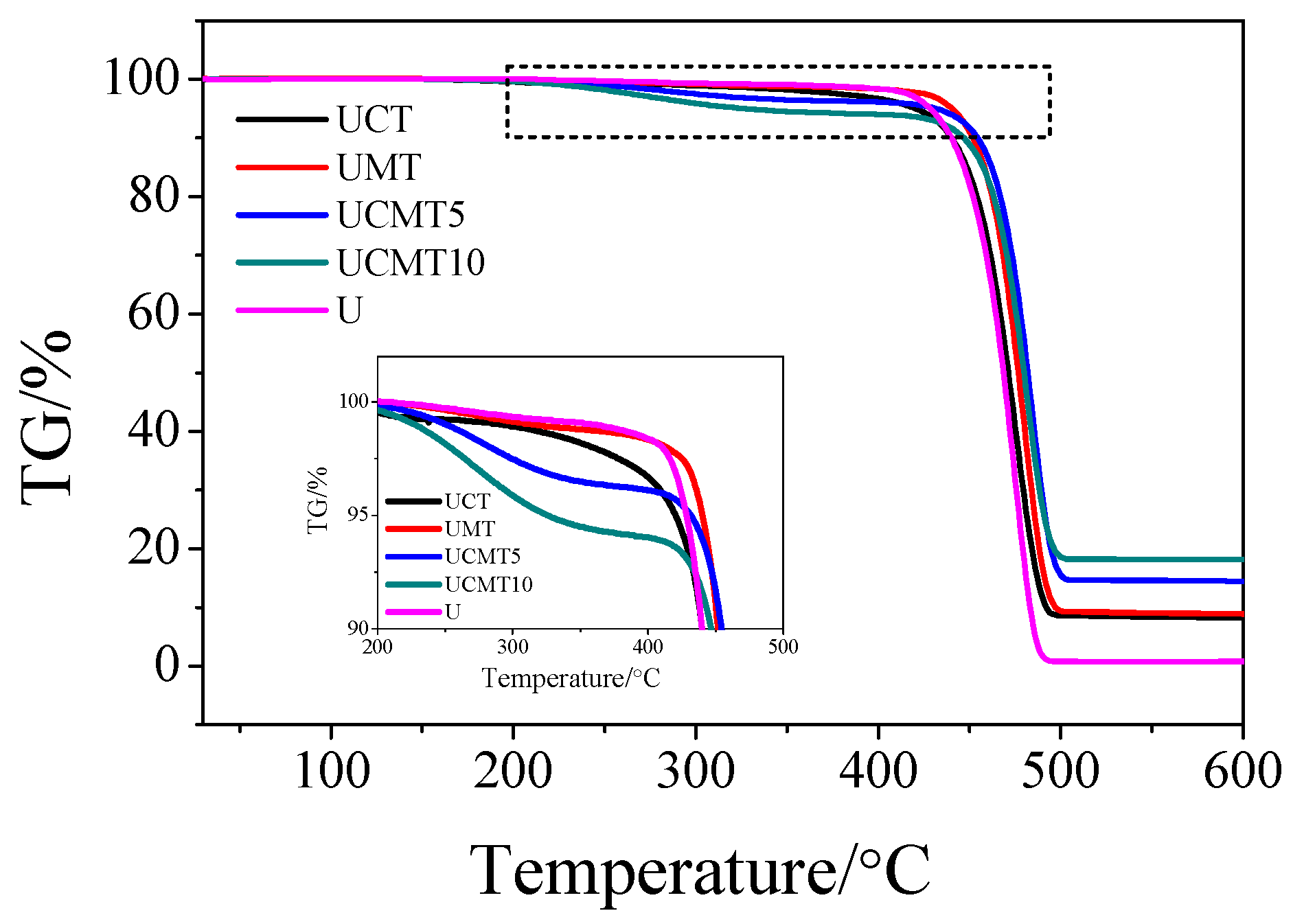

3. Results and Discussion

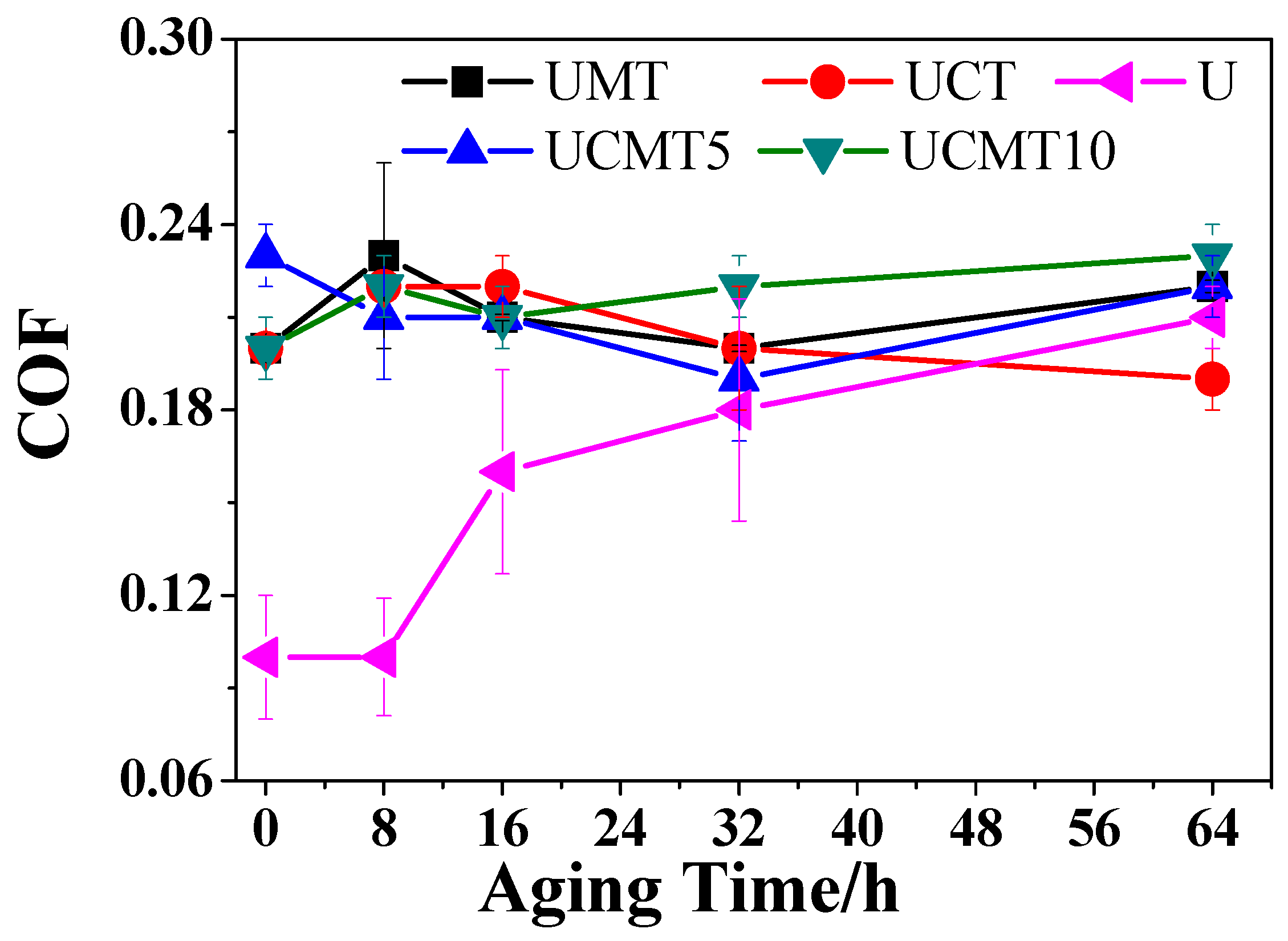

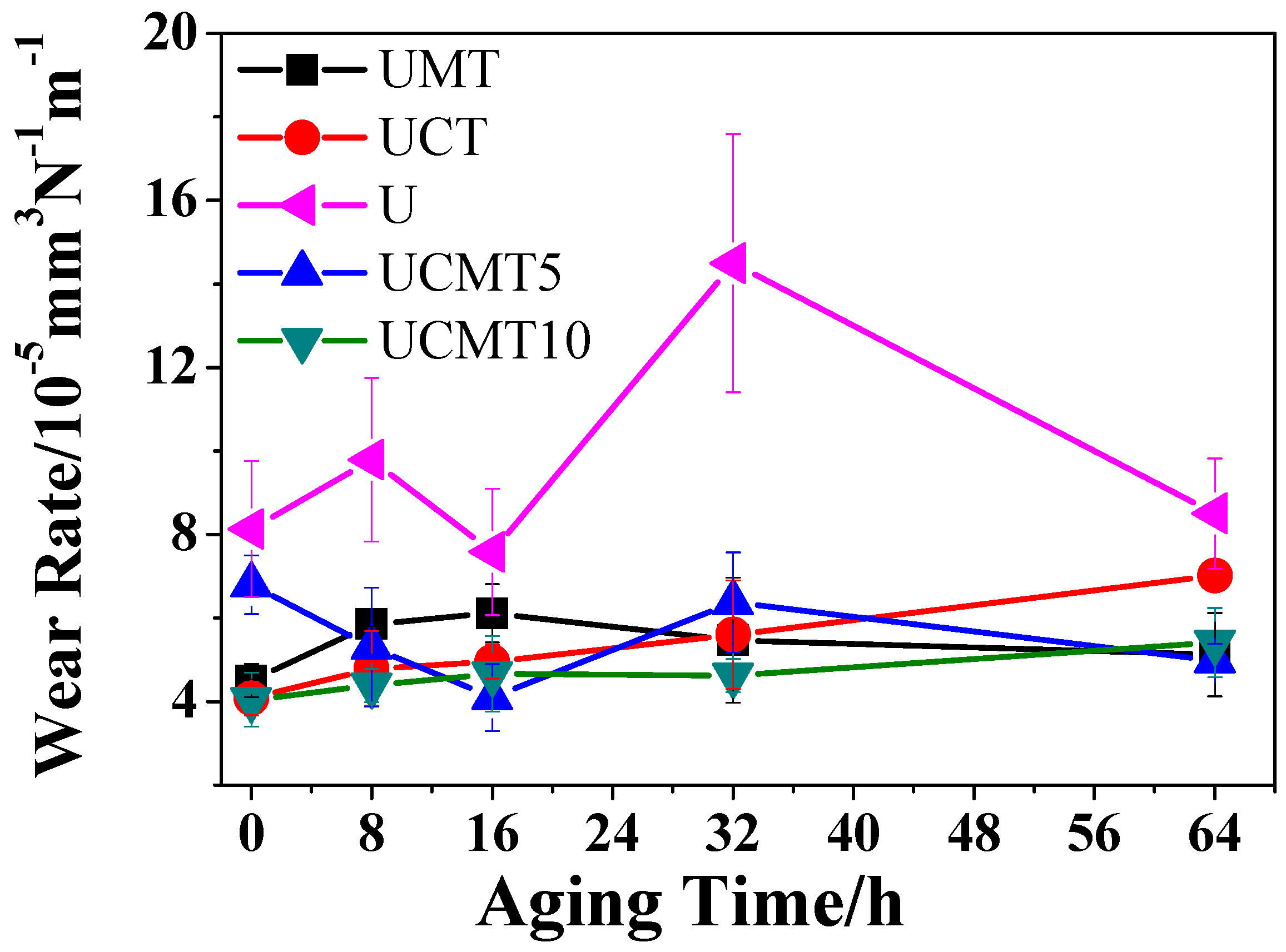

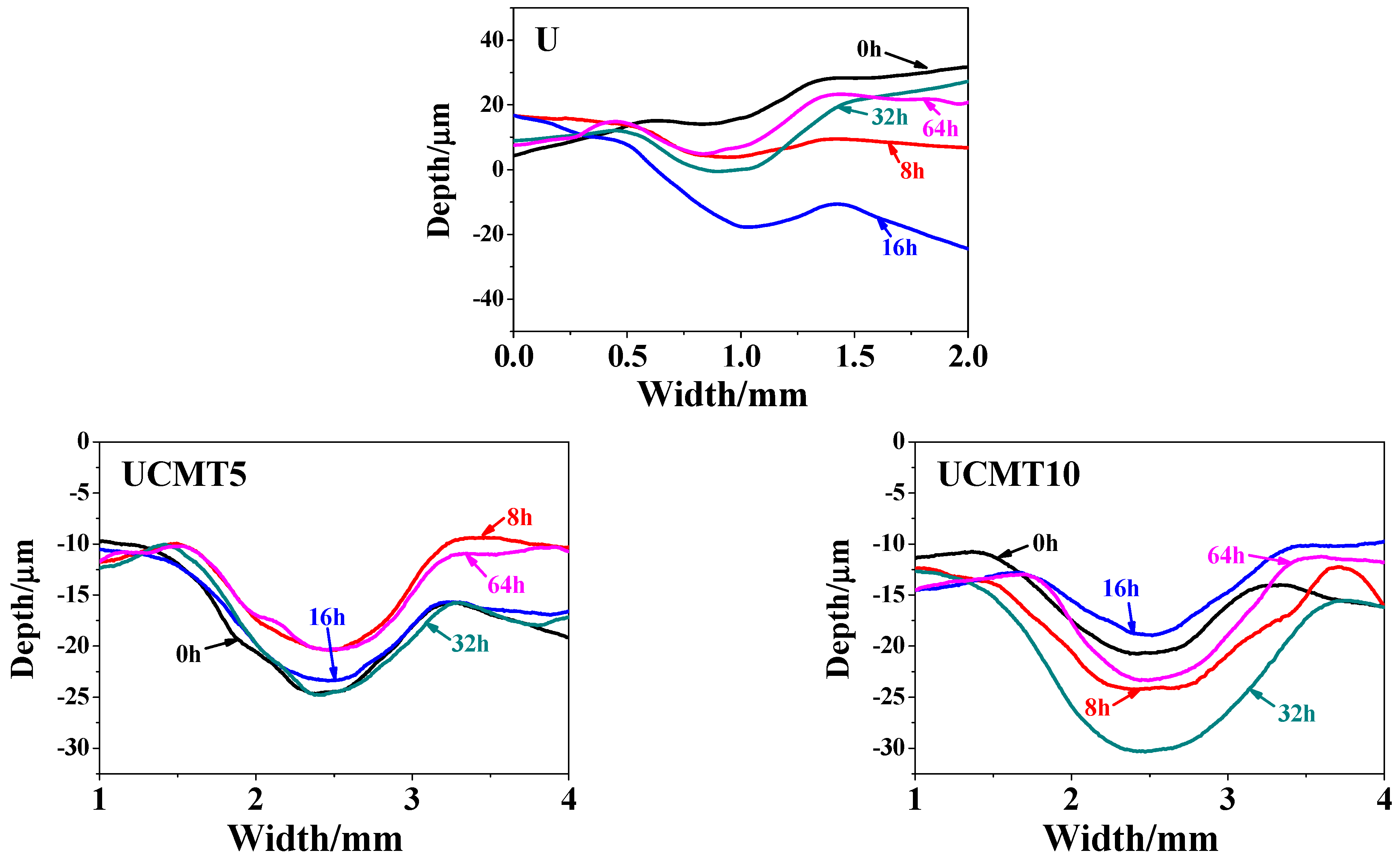

3.1. Friction and Wear Performance Test

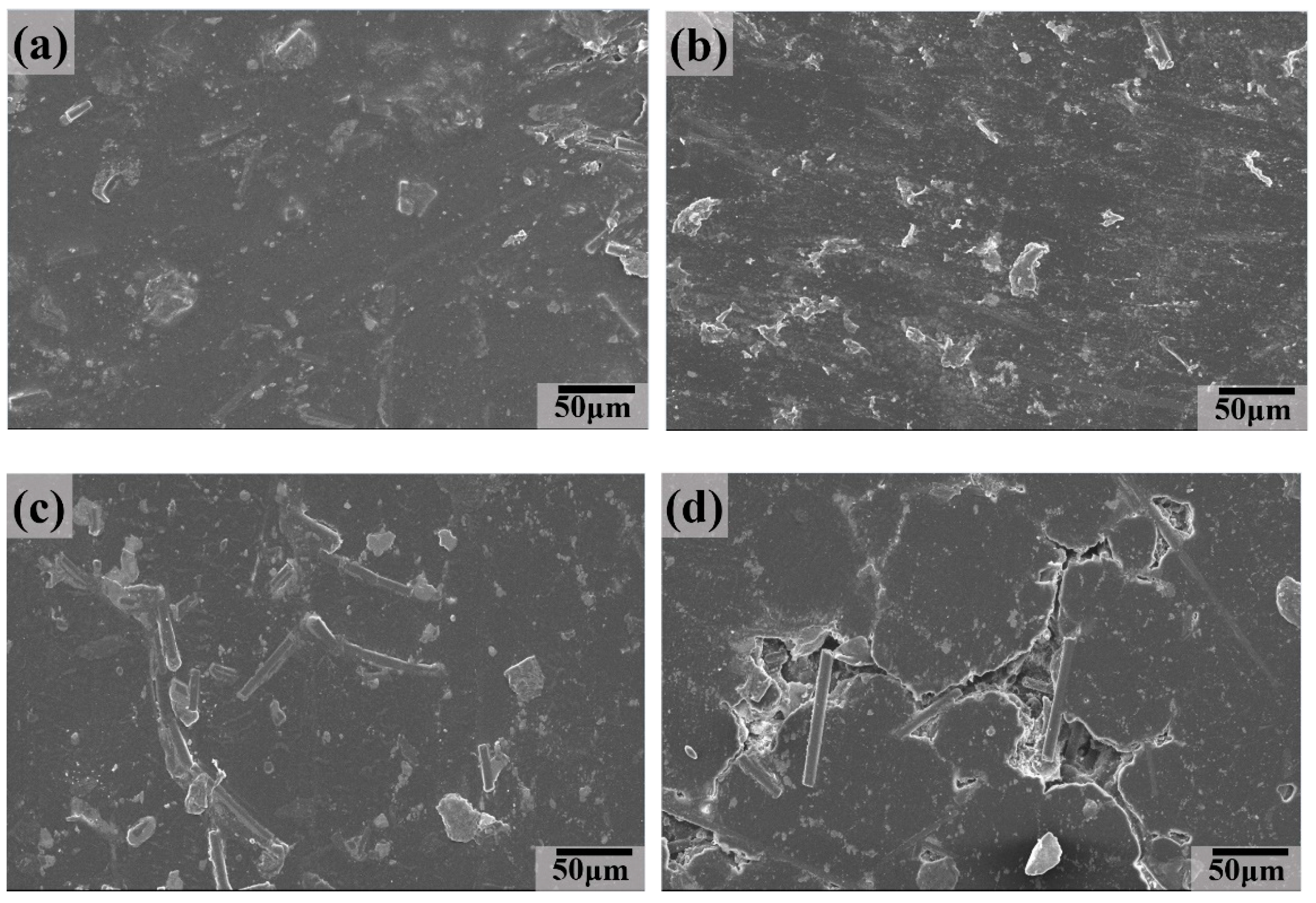

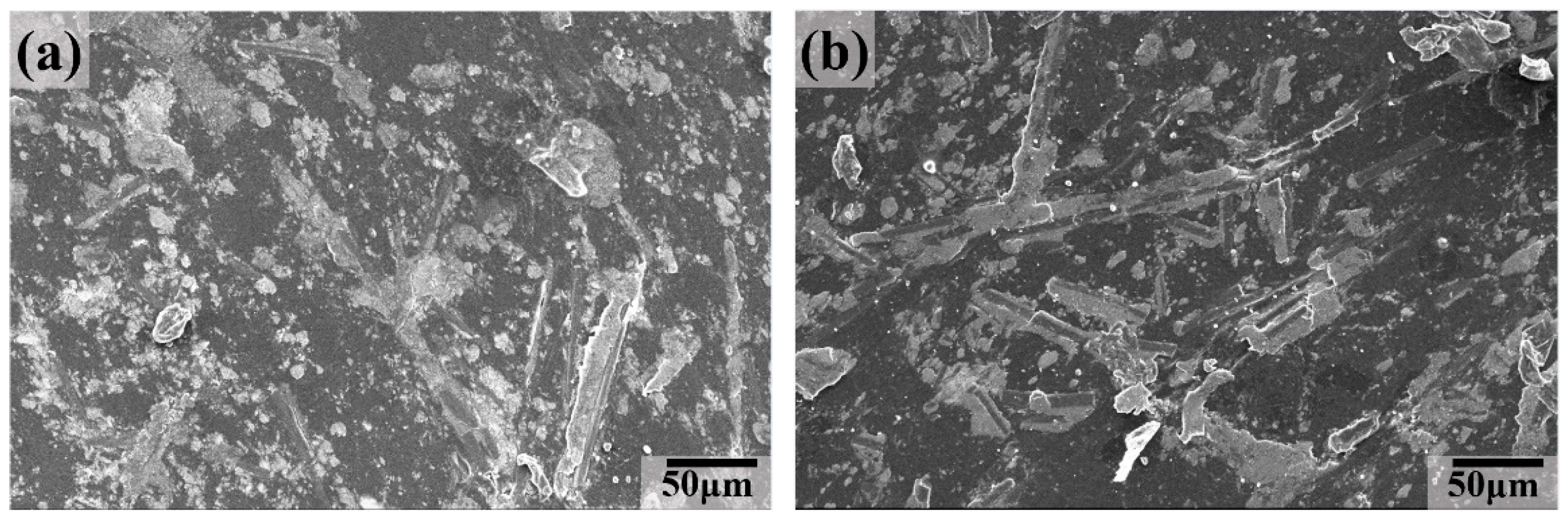

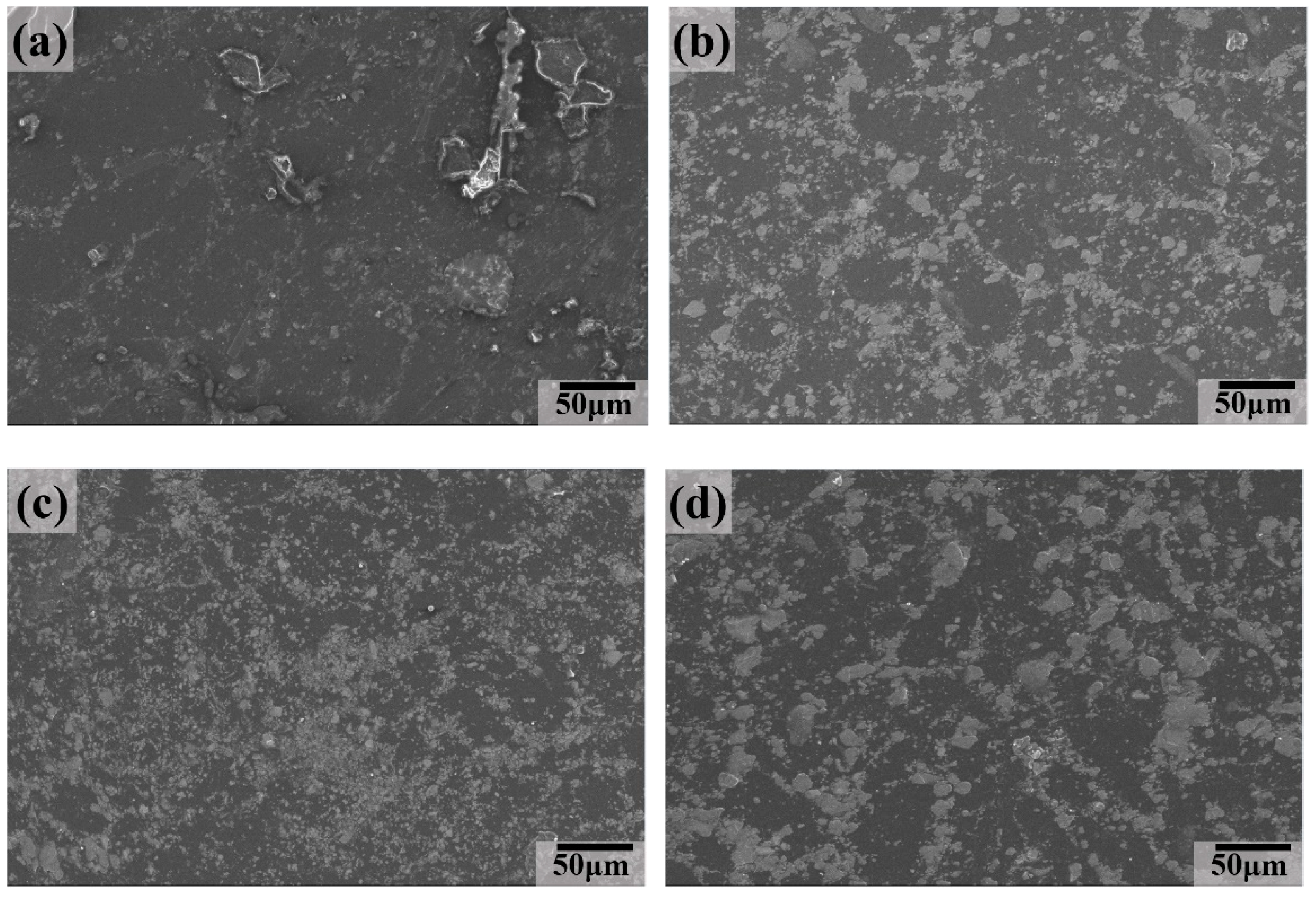

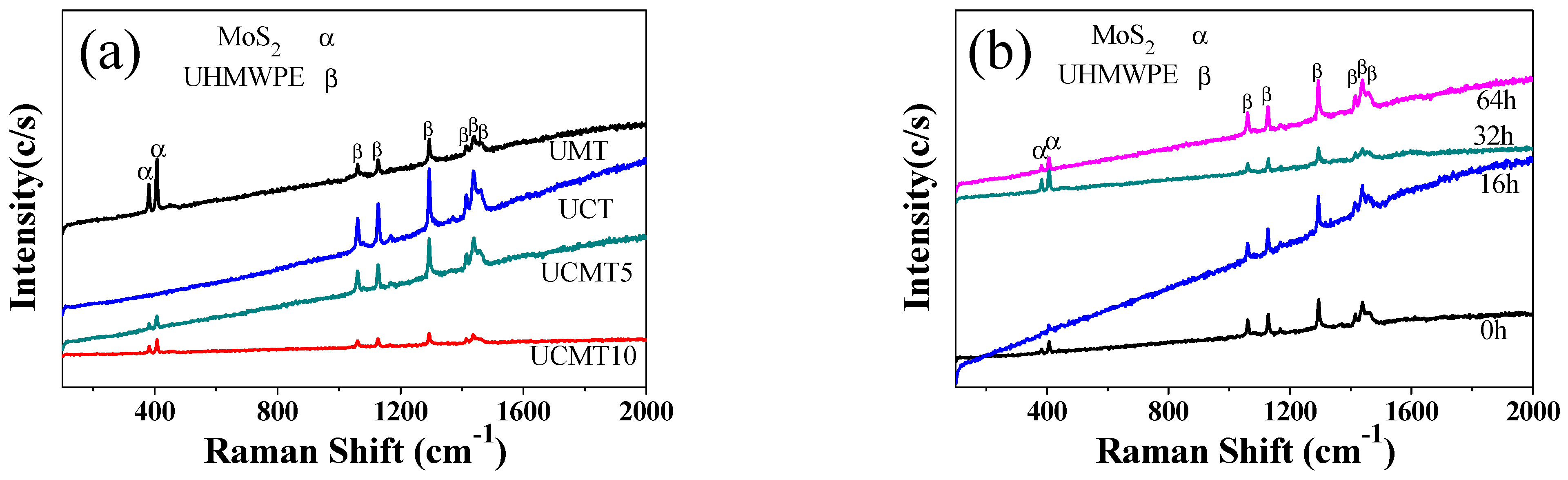

3.2. Worn Surface Analysis

4. Conclusions

- (1)

- The composites show excellent tribological performance at different aging times from 0 to 64 h. The COF and wear rate are approximately (0.19–0.23) and (4.09–7.01 × 10−5 mm3/Nm).

- (2)

- In general, with an increase in the aging time, the COF in the mass decreases first and then increases to the maximum value. The wear rate in the mass increases slightly with an increase in the aging time.

- (3)

- The low COF and wear properties for composites were attributed to the synergistic lubrication and reinforcement of TiC, MoS2, and CF. The SEM images presented that the main wear mechanisms were abrasive and fatigue wear.

- (4)

- Regarding the difference in aging times, the testing temperature and surface structure changes during the sliding process also had important effects on the friction behavior of the composites. As a further investigation, it is believed that the transfer film and structural changes in the UHMWPE surface were the main reasons for the fluctuation of COFs and wear rates, so it will be interesting to investigate the influencing factors of transfer membrane formation.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Duraccio, D.; Strongone, V.; Malucelli, G.; Auriemma, F.; De Rosa, C.; Mussano, F.; Genova, T.; Faga, M. The role of alumina-zirconia loading on the mechanical and biological properties of UHMWPE for biomedical applications. Compos. Part B 2019, 164, 800–808. [Google Scholar] [CrossRef]

- Yang, R.; Chen, X.; Tian, Y.; Chen, H.; Boshkov, N.; Li, H. An attempt to improve cavitation erosion resistance of UHMWPE coatings through enhancing thermal conductivity via the incorporation of copper frames. Surf. Coat. Technol. 2021, 425, 127705. [Google Scholar] [CrossRef]

- Hirwani, J.; Sinha, S. Bio-tribological studies of structalit/UHMWPE composites as an alternative to UHMWPE for hip joint application. Wear 2023, 518–519, 204630. [Google Scholar] [CrossRef]

- Shelly, D.; Lee, S.; Park, S. Compatibilization of ultra-high molecular weight polyethylene (UHMWPE) fibers and their composites for superior mechanical performance: A concise review. Compos. Part B 2024, 275, 111294. [Google Scholar] [CrossRef]

- Subhedar, P.; Padmanabhan, D.; Agrawal, R.; Singh, G. A comprehensive review summarising the reinforcement of UHMWPE composite scaffolds as an artificial implant biomaterials. Mater. Today 2023, in press. [CrossRef]

- Visco, A.; Brahimi, S.; Giudice, F.; Scolaro, C.; Sili, A. Vitamin E effects on the wear resistance of UHMWPE sheets against an EBM-produced Ti6Al4V pin. Mater. Lett. 2024, 356, 135602. [Google Scholar] [CrossRef]

- Wu, J.; Yang, T.; Dong, P.; Zhang, Q.; Wang, K. Simultaneously enhanced antioxidation and wear resistance in UHMWPE molded plastic by adding natural polyphenol antioxidant. Polymer 2024, 304, 127145. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, L.; Wei, B.; Lu, C.; Li, L. Organic-inorganic core-shell materials as reinforced fillers of UHMWPE to improve its tribological and mechanical properties. Colloids Surf. A 2024, 691, 133820. [Google Scholar] [CrossRef]

- Qin, H.; Zhou, X.; Zhao, X.; Xing, J.; Yan, Z. A new rubber/UHMWPE alloy for water-lubricated stern bearings. Wear 2015, 328–329, 257–261. [Google Scholar] [CrossRef]

- Sharma, S.; Bijwe, J.; Panier, S.; Sharma, M. Abrasive wear performance of SiC-UHMWPE nano-composites—Influence of amount and size. Wear 2015, 332–333, 863–871. [Google Scholar] [CrossRef]

- Sreekanth, P.; Kanagaraj, S. Influence of multi walled carbon nanotubes reinforcement and gamma irradiation on the wear behaviour of UHMWPE. Wear 2015, 334–335, 82–90. [Google Scholar] [CrossRef]

- Yang, G.; Meng, G.; Gao, H.; Lin, Q. Micromorphology and mechanical properties of UHMWPE/CNF composites under accelerated aging. Polym. Compos. 2022, 43, 3716–3730. [Google Scholar] [CrossRef]

- Padhan, M.; Marathe, U.; Bijwe, J. A comparative assessment of nano and microparticles of carbides for performance augmentation of UHMWPE in abrasive and erosive wear modes. Wear 2023, 514–515, 204568. [Google Scholar] [CrossRef]

- Cai, T.; Zhan, S.; Yang, T.; Jia, D.; Tu, J.; Li, Y.; Li, J.; Duan, H. Influence mechanism of organic-modified α-zirconium phosphate on tribological properties of UHMWPE. Wear 2023, 512–513, 204548. [Google Scholar] [CrossRef]

- Meng, Z.; Wang, Y.; Liu, H.; Yan, Y.; Yan, F. Reinforced UHMWPE composites by grafting TiO2 on ATP nanofibers for improving thermal and tribological properties. Tribol. Int. 2022, 172, 107585. [Google Scholar] [CrossRef]

- Uyor, U.; Popoola, A.; Popoola, O. Enhancement of the tribological and thermal properties of UHMWPE based ternary nanocomposites containing graphene and titanium titride. J. Polym. Eng. 2024, 44, 34–44. [Google Scholar] [CrossRef]

- Wu, Y.; Dong, C.; Bai, X.; Yuan, C. Enhancing friction and vibration reduction properties of a polymer using h-BN particles. Wear 2023, 536, 205142. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, K.; Ye, J.; Li, X.; Zhao, X.; Qu, T.; Liu, Q.; Gao, B. The effects of filler type on the friction and wear performance of PEEK and PTFE composites under hybrid wear conditions. Wear 2022, 490–491, 204178. [Google Scholar] [CrossRef]

- Song, F.; Yang, Z.; Zhao, G.; Wang, Q.; Zhang, X.; Wang, T. Tribological performance of filled PTFE-based friction material for ultrasonic motor under different temperature and vacuum degrees. J. Appl. Polym. Sci. 2017, 134, 45358. [Google Scholar] [CrossRef]

- Xu, J.; Han, T.; Zhang, C.; Luo, J. Superlubricating UHMWPE composites with functionalized carbon nanotubes reinforcement applicable to artificial joints. Tribol. Int. 2024, 191, 109142. [Google Scholar] [CrossRef]

- Gürgen, S. Wear performance of UHMWPE based composites including nano-sized fumed silica. Compos. Part B 2019, 173, 106967. [Google Scholar] [CrossRef]

- Gürgen, S. Wear behavior of UHMWPE composites under oxidative effect. Polym. Degrad. Stab. 2022, 199, 109912. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Amato, R.; Gómez, E. Experimental analysis of tribological behavior of UHMWPE against AISI420C and against TiAl6V4 alloy under dry and lubricated conditions. Tribol. Int. 2015, 92, 154–161. [Google Scholar] [CrossRef]

- Zhen, J.; Zhu, S.; Cheng, J.; Qiao, Z.; Liu, W.; Yang, J. Effects of sliding speed and testing temperature on the tribological behavior of a nickel-alloy based solid-lubricating composite. Wear 2016, 368–369, 45–52. [Google Scholar] [CrossRef]

- Zhen, J.; Han, Y.; Zhu, L.; Hou, W.; Liu, Y.; Huang, W.; Yang, L.; Yuan, L.; Jia, Z.; Zhang, R. MoS2/CF synergistic enhancement to improve the friction and wear properties of UHMWPE composites. Tribol. Int. 2023, 179, 108097. [Google Scholar] [CrossRef]

- Gangwani, P.; Kovač, J.; Emami, N.; Kalin, M. Effect of multi-scale fillers on the tribological behavior of UHMWPE composites in water-lubricated contacts. Tribol. Int. 2024, 196, 109669. [Google Scholar] [CrossRef]

- Lin, Y.; Guo, Z.; Yuan, C. Effects of solid lubricants on the tribological behavior of steel-backed UHMWPE fabric composites. J. Appl. Polym. Sci. 2022, 139, 51674. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, Z.; Yang, Z.; Wang, C.; Yuan, C. Study on tribological properties of a novel composite by filling microcapsules into UHMWPE matrix for water lubrication. Tribol. Int. 2021, 153, 106629. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, Q.; Wu, C.; Huang, J. Effect of carbon fiber reinforcement on the mechanical and tribological properties of polyamide6/polyphenylene sulfide composites. Mater. Des. 2013, 44, 493–499. [Google Scholar] [CrossRef]

- Rahman, M.; Biswas, M.; Hoque, K. Recent development on micro-texturing of UHMWPE surfaces for orthopedic bearings: A review. Biotribology 2022, 31, 100216. [Google Scholar] [CrossRef]

- Cheng, B.; Shang, H.; Duan, H.; Chen, Q.; Li, J.; Shao, T. Influence of laser-induced surface carbonization on the tribological properties of UHMWPE in a seawater environment. Appl. Surf. Sci. 2024, 645, 158873. [Google Scholar] [CrossRef]

- Menezes, P.; Kailas, S. Role of surface texture and roughness parameters on friction and transfer film formation when UHMWPE sliding against steel. Biosurface Biotribology 2016, 2, 1–10. [Google Scholar] [CrossRef]

- Montes, S.; Dominguez, L.; Barceinas, S. Effect of surface texturing of UHMWPE on the coefficient of friction under arthrokinematic and loading conditions corresponding to the walking cycle. Mater. Lett. 2021, 284, 129039. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.; Jia, Y.; Li, X.; Yang, J.; Yan, F.; Li, C. MoS2 nanosheets-decorated carbon fiber hybrid for improving the friction and wear properties of polyimide composite. Compos. Part A 2018, 109, 232–238. [Google Scholar] [CrossRef]

| Materials | Composition | UHMWPE (wt. %) | CF (wt. %) | MoS2 (wt. %) | TiC (wt. %) |

|---|---|---|---|---|---|

| U | UHMWPE | 100 | 0 | 0 | 0 |

| UMT | UHMWPE + MoS2 + TiC | 90 | 0 | 5 | 5 |

| UCT | UHMWPE + CF + TiC | 90 | 5 | 0 | 5 |

| UCMT5 | UHMWPE + MoS2 + CF+TiC | 85 | 5 | 5 | 5 |

| UCMT10 | UHMWPE + MoS2 + CF+TiC | 80 | 5 | 5 | 10 |

| Material | UMT, UCT, UCMT5, UCMT10 |

|---|---|

| Aging time | 0 h, 8 h, 16 h, 32 h, 64 h |

| Sliding speed | 637 rpm/0.33 ms−1 |

| Load | 10 N |

| Test time | 30 min |

| Counterpart materials | GCr15 |

| Aging Time | 0 h | 8 h | 16 h | 32 h | 64 h |

|---|---|---|---|---|---|

| Stress/MPa | |||||

| U | 34 ± 1 | 33 ± 1 | 35 ± 1 | 36 ± 1 | |

| UMT | 28 ± 1 | 25 ± 3 | 21 ± 1 | 22 ± 4 | 26 ± 5 |

| UCT | 34 ± 1 | 38 ± 2 | 31 ± 1 | 39 ± 2 | 21 ± 2 |

| UCMT5 | 25 ± 4 | 25 ± 4 | 24 ± 4 | 24 ± 1 | 21 ± 2 |

| UCMT10 | 19 ± 1 | 20 ± 3 | 21 ± 3 | 21 ± 2 | 21 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Han, Y.; Yuan, L.; Zhen, J.; Jia, Z.; Zhang, R. Synergistic Enhancement of the Friction and Wear Performance for UHMWPE Composites under Different Aging Times. Polymers 2024, 16, 2059. https://doi.org/10.3390/polym16142059

Liu Y, Han Y, Yuan L, Zhen J, Jia Z, Zhang R. Synergistic Enhancement of the Friction and Wear Performance for UHMWPE Composites under Different Aging Times. Polymers. 2024; 16(14):2059. https://doi.org/10.3390/polym16142059

Chicago/Turabian StyleLiu, Yingliang, Yunxiang Han, Lin Yuan, Jinming Zhen, Zhengfeng Jia, and Ran Zhang. 2024. "Synergistic Enhancement of the Friction and Wear Performance for UHMWPE Composites under Different Aging Times" Polymers 16, no. 14: 2059. https://doi.org/10.3390/polym16142059