Numerical and Experimental Study on Balanced Performance and Axial Stiffness of Fiber-Reinforced Rubber Pipe

Abstract

1. Introduction

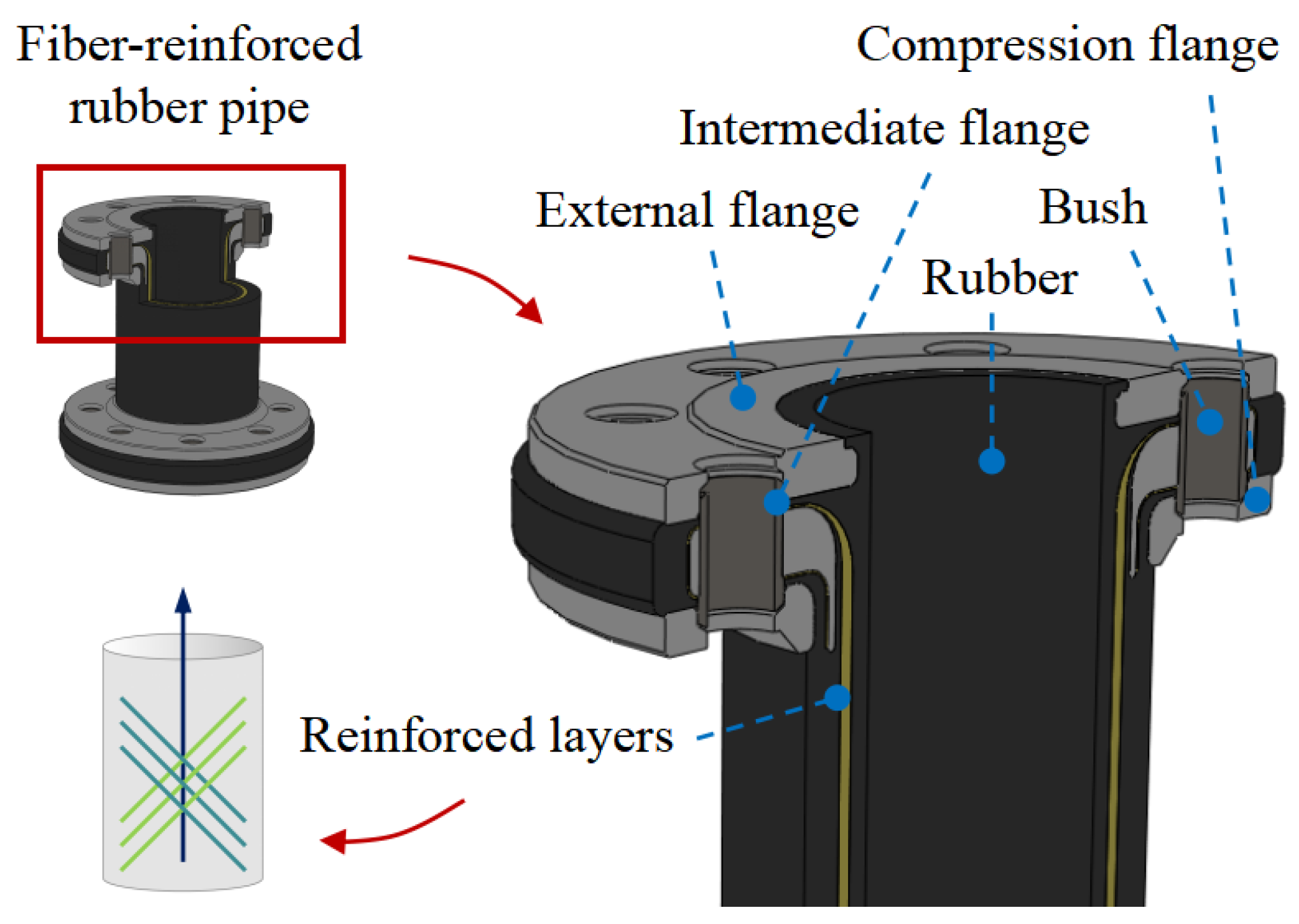

2. Experiment

2.1. Experimental Samples

2.2. Experimental Process

2.3. Experimental Results

3. Numerical Model

3.1. Geometric Model

3.2. Material Property

3.3. Mesh, Interaction, Load, and Boundary Condition

4. Results and Discussion

4.1. The Balanced Performance

4.2. The Axial Stiffness

5. Conclusions

- The balanced performance of the FRR pipe is achieved through the combined effects of the elongation and rotation of the reinforcing fibers, as well as the deformation of the rubber matrix.

- When the pipe is in a state of balanced performance, its axial stiffness exhibits a nonlinear increase with increasing internal pressure. When the internal pressure is 1.5 MPa, the axial stiffness of the pipe increases by 33.9% compared with that when the internal pressure is 0 MPa. Furthermore, the end effects induced by internal pressure result in more stress concentration areas within the pipe compared to the condition without internal pressure.

- The winding angle of the fiber-reinforced layer significantly affects both the balanced performance and the axial stiffness of the pipe. However, the trends in these mechanical properties differ. When the winding angle changes by +3.56° and −3.56°, the axial deformation of the pipe is 44.93 times and 49.86 times that in the balanced state, respectively. Correspondingly, the reaction force of the pipe is 21.65 times and 16.51 times that in the balanced state, respectively. However, as the winding angle decreases, the axial stiffness of the pipe tends to decrease. Therefore, for customized designs, it is essential to consider both properties comprehensively when selecting the fiber winding angle.

- The quasi-static analysis indicates that the strain energy in the rubber matrix significantly contributes to the balanced performance and axial stiffness calculations for the pipe. During the balanced performance simulation, the strain energy of the rubber matrix accounts for 26.91% of the total strain energy. However, during the axial stiffness calculation, this value more than doubles. Consequently, the role of rubber is crucial and should not be underestimated in studies addressing the balanced performance and axial stiffness of FRR pipes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alabtah, F.G.; Mahdi, E.; Eliyan, F.F. The use of fiber reinforced polymeric composites in pipelines: A review. Compos. Struct. 2021, 276, 114595. [Google Scholar] [CrossRef]

- Karim, M.A.; Abdullah, M.Z.; Deifalla, A.F.; Azab, M.; Waqar, A. An assessment of the processing parameters and application of fibre-reinforced polymers (FRPs) in the petroleum and natural gas industries: A review. Results Eng. 2023, 18, 101091. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, P.; Duan, M.; Yang, X.; Shi, W.; An, C.; Li, Z. Investigation on structural behavior of ring-stiffened composite offshore rubber hose under internal pressure. Appl. Ocean. Res. 2018, 79, 7–19. [Google Scholar] [CrossRef]

- Zhou, Y.; Duan, M.; Ma, J.; Sun, G. Theoretical analysis of reinforcement layers in bonded flexible marine hose under internal pressure. Eng. Struct. 2018, 168, 384–398. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L. Optimization of filament winding parameters for the design of a composite pipe. Compos. Part B Eng. 2018, 148, 207–216. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A review on FRP composites applications and durability concerns in the construction sector. J. Reinf. Plast. Compos. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Lou, M.; Wang, Y.; Tong, B.; Wang, S. Effect of temperature on tensile properties of reinforced thermoplastic pipes. Compos. Struct. 2020, 241, 112119. [Google Scholar] [CrossRef]

- Zheng, J.; Shi, J.; Shi, J.; Zhong, S.; Rao, J.; Li, G.; Li, X. Short-term burst pressure of polyethylene pipe reinforced by winding steel wires under various temperatures. Compos. Struct. 2015, 121, 163–171. [Google Scholar] [CrossRef]

- Conley, J.; Weller, B.; Slingerland, E. The use of reinforced thermoplastic pipe in oil and gas gathering and produced water pipelines. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Calgary, AB, Canada, 16–19 June 2008; p. SPE-113718. [Google Scholar]

- Al-Hadhrami, L.; Maslehuddin, M.; Ali, M. Chemical resistance and mechanical properties of glass fiber–reinforced plastic pipes for oil, gas, and power-plant applications. J. Compos. Constr. 2016, 20, 04015031. [Google Scholar] [CrossRef]

- Eslami, S.; Honarbakhsh-Raouf, A.; Eslami, S. Effects of moisture absorption on degradation of E-glass fiber reinforced Vinyl Ester composite pipes and modelling of transient moisture diffusion using finite element analysis. Corros. Sci. 2015, 90, 168–175. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, W.; Lu, H.; Bu, Y.; Yin, Y.; Wang, S.; Fan, Y. Mechanical Characteristics of Fiber-Reinforced Flexible Pipe Subjected to Axial Tensile Load. J. Mar. Sci. Eng. 2023, 11, 586. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, W.; Lu, H.; Yan, J.; Yin, Y.; Bu, Y. Study on the mechanical characteristics of a fibre reinforced flexible pipe under radial compression loads. Front. Mater. 2023, 10, 1118046. [Google Scholar] [CrossRef]

- Xing, J.; Geng, P.; Yang, T. Stress and deformation of multiple winding angle hybrid filament-wound thick cylinder under axial loading and internal and external pressure. Compos. Struct. 2015, 131, 868–877. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, S.; Han, P.; Ruan, W.; Tang, G.; Cao, Y. Behaviour of steel wire-reinforced thermoplastic pipe under combined bending and internal pressure. Ships Offshore Struct. 2018, 13, 696–704. [Google Scholar] [CrossRef]

- Gao, H.; Shuai, C.; Ma, J.; Xu, G. Study on theoretical model of burst pressure of fiber reinforced arc-shaped rubber hose with good balance performance. Polym. Polym. Compos. 2021, 29, 919–930. [Google Scholar]

- Gao, H.; Shuai, C.; Xu, G. Establishment and verification of theoretical model for forming design of balanced curved rubber hose. Polym. Polym. Compos. 2021, 29, 470–483. [Google Scholar]

- Jaszak, P.; Skrzypacz, J.; Adamek, K. The design method of rubber-metallic expansion joint. Open Eng. 2018, 8, 532–538. [Google Scholar] [CrossRef]

- Xu, G.; Shuai, C. Axial and lateral stiffness of spherical self-balancing fiber reinforced rubber pipes under internal pressure. Sci. Eng. Compos. Mater. 2021, 28, 96–106. [Google Scholar] [CrossRef]

- Fang, P.; Xu, Y.; Gao, Y.; Ali, L.; Bai, Y. Mechanical responses of a fiberglass flexible pipe subject to tension & internal pressure. Thin-Walled Struct. 2022, 181, 110107. [Google Scholar]

- Rogers, T. Problems for helically wound cylinders. In Continuum Theory of the Mechanics of Fibre-Reinforced Composites; Springer: Berlin/Heidelberg, Germany, 1984; pp. 147–178. [Google Scholar]

- Evans, J.; Gibson, A. Composite angle ply laminates and netting analysis. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 2002, 458, 3079–3088. [Google Scholar] [CrossRef]

- Gu, F.; Huang, C.k.; Zhou, J.; Li, L.p. Mechanical response of steel wire wound reinforced rubber flexible pipe under internal pressure. J. Shanghai Jiaotong Univ. (Sci.) 2009, 14, 747–756. [Google Scholar] [CrossRef]

- Kabir, H.; Aghdam, M.M. A generalized 2D Bézier-based solution for stress analysis of notched epoxy resin plates reinforced with graphene nanoplatelets. Thin-Walled Struct. 2021, 169, 108484. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, Y.; Liu, J. A domain-decomposition generalized finite difference method for stress analysis in three-dimensional composite materials. Appl. Math. Lett. 2020, 104, 106226. [Google Scholar] [CrossRef]

- Wei, D.; An, C.; Wu, C.; Duan, M.; Estefen, S.F. Torsional structural behavior of composite rubber hose for offshore applications. Appl. Ocean Res. 2022, 128, 103333. [Google Scholar] [CrossRef]

- Ruan, W.; Qi, K.; Han, X.; Sun, B.; Gao, X.; Li, J. Multi-scale coupling numerical modeling of metallic strip flexible pipe during reel-lay process. Ocean Eng. 2023, 283, 115209. [Google Scholar] [CrossRef]

- Chen, W.; Xiong, H.; Bai, Y. Failure behavior analysis of steel strip–reinforced flexible pipe under combined tension and internal pressure. J. Thermoplast. Compos. Mater. 2020, 33, 727–753. [Google Scholar] [CrossRef]

- Tonatto, M.L.; Tita, V.; Araujo, R.T.; Forte, M.M.; Amico, S.C. Parametric analysis of an offloading hose under internal pressure via computational modeling. Mar. Struct. 2017, 51, 174–187. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, T.; Ruan, W.; Chen, W. Mechanical behavior of metallic strip flexible pipe subjected to tension. Compos. Struct. 2017, 170, 1–10. [Google Scholar] [CrossRef]

- Soden, P.; Kitching, R.; Tse, P.; Tsavalas, Y.; Hinton, M. Influence of winding angle on the strength and deformation of filament-wound composite tubes subjected to uniaxial and biaxial loads. Compos. Sci. Technol. 1993, 46, 363–378. [Google Scholar] [CrossRef]

- Krishnan, P.; Majid, M.A.; Afendi, M.; Gibson, A.; Marzuki, H.A. Effects of winding angle on the behaviour of glass/epoxy pipes under multiaxial cyclic loading. Mater. Des. 2015, 88, 196–206. [Google Scholar] [CrossRef]

- Krishnan, P.; Abdul Majid, M.; Yi, A.J.; Afendi, M.; Yaacob, S.; Gibson, A. An automated portable multiaxial pressure test rig for qualifications of glass/epoxy composite pipes. Sci. Eng. Compos. Mater. 2018, 25, 243–252. [Google Scholar] [CrossRef]

- Xia, M.; Takayanagi, H.; Kemmochi, K. Analysis of multi-layered filament-wound composite pipes under internal pressure. Compos. Struct. 2001, 53, 483–491. [Google Scholar] [CrossRef]

- Stabla, P.; Lubecki, M.; Smolnicki, M. The effect of mosaic pattern and winding angle on radially compressed filament-wound CFRP composite tubes. Compos. Struct. 2022, 292, 115644. [Google Scholar] [CrossRef]

- Sebeay, T.A.; Ahmed, A. Numerical investigation into GFRP composite pipes under hydrostatic internal pressure. Polymers 2023, 15, 1110. [Google Scholar] [CrossRef] [PubMed]

- Khaniki, H.B.; Ghayesh, M.H.; Chin, R.; Amabili, M. A review on the nonlinear dynamics of hyperelastic structures. Nonlinear Dyn. 2022, 110, 963–994. [Google Scholar] [CrossRef]

| Manufacturing Parameter | Value |

|---|---|

| Length (mm) | 166 |

| Inner diameter (mm) | 65 |

| External diameter (mm) | 100 |

| Innermost fiber-reinforced layer diameter (mm) | 73 |

| Outermost fiber-reinforced layer diameter (mm) | 80 |

| Number of layers of fiber-reinforced layer | 4 |

| Fiber winding angle (°) | ±36.9 |

| Test Sample | Length (mm) | Discrepancy in Lenth (mm) | External Diameter (mm) | Discrepancy in External Diameter (mm) |

|---|---|---|---|---|

| 1 | 166.1 | +0.1 | 102.23 | +2.23 |

| 2 | 165.8 | −0.2 | 104.14 | +4.14 |

| 3 | 166.2 | +0.2 | 105.73 | +5.73 |

| 4 | 166.3 | +0.3 | 100.32 | +0.32 |

| Test Sample | Axial Deformation (mm) |

|---|---|

| 1 | −0.05 |

| 2 | 0.25 |

| 3 | 0.35 |

| 4 | −0.05 |

| Rubber | L1 | L2 | L3 | L4 | |

|---|---|---|---|---|---|

| Strain energy (mJ) | 1043.89 | 750.24 | 681.04 | 654.15 | 750.49 |

| Ratio | 26.91% | 19.34% | 17.55% | 16.86% | 19.34% |

| Axial Stiffness (N/mm) | |||

|---|---|---|---|

| Internal Pressure (MPa) | Experimental Mean Value | Numerical Result | Percentage |

| 0 | 933.02 | 932.02 | −0.11% |

| 0.5 | 1077.31 | 1040.98 | −3.37% |

| 1 | 1201.41 | 1146.35 | −4.58% |

| 1.5 | 1330.19 | 1248.24 | −6.16% |

| Load | Strain Energy and Ratio | Rubber | L1 | L2 | L3 | L4 |

|---|---|---|---|---|---|---|

| Tension | Strain energy (mJ) | 2714.75 | 557.08 | 537.31 | 581.48 | 700.91 |

| Ratio | 53.32% | 10.94% | 10.55% | 11.42% | 13.77% | |

| Compression | Strain energy (mJ) | 2867.62 | 492.86 | 426.74 | 409.42 | 446.81 |

| Ratio | 61.76% | 10.61% | 9.19% | 8.82% | 9.62% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

You, J.; Zhao, Y.; Zhang, B. Numerical and Experimental Study on Balanced Performance and Axial Stiffness of Fiber-Reinforced Rubber Pipe. Polymers 2024, 16, 2088. https://doi.org/10.3390/polym16142088

You J, Zhao Y, Zhang B. Numerical and Experimental Study on Balanced Performance and Axial Stiffness of Fiber-Reinforced Rubber Pipe. Polymers. 2024; 16(14):2088. https://doi.org/10.3390/polym16142088

Chicago/Turabian StyleYou, Jingyue, Yinglong Zhao, and Ben Zhang. 2024. "Numerical and Experimental Study on Balanced Performance and Axial Stiffness of Fiber-Reinforced Rubber Pipe" Polymers 16, no. 14: 2088. https://doi.org/10.3390/polym16142088

APA StyleYou, J., Zhao, Y., & Zhang, B. (2024). Numerical and Experimental Study on Balanced Performance and Axial Stiffness of Fiber-Reinforced Rubber Pipe. Polymers, 16(14), 2088. https://doi.org/10.3390/polym16142088