The Effect of Carbon Nanofibers on the Mechanical Performance of Epoxy-Based Composites: A Review

Abstract

:1. Introduction

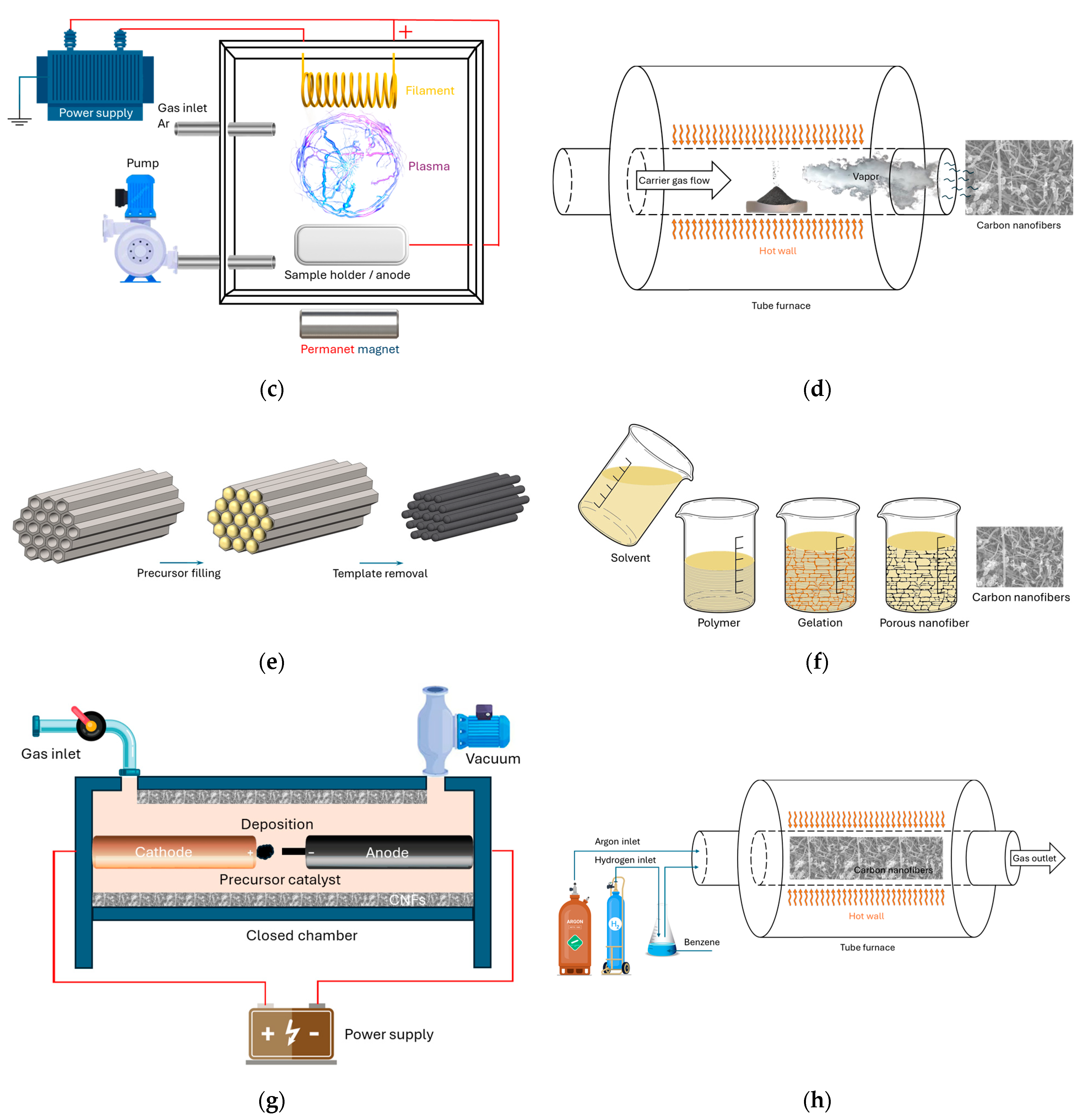

2. Carbon Nanofibers

- (i)

- Platelet CNFs exhibit a structure where graphene layers are oriented perpendicular to the fiber axis, as shown in Figure 1a. These fibrils typically have a width of around 100 nm, and the presence of hydrogen or other heteroatoms is necessary for stabilizing the plates [47]. In the case of bidirectional fibers, a solid particle is usually located in the middle of the fiber [50]. On the other hand, ribbon CNFs feature a stacked arrangement of graphene layers parallel to the fiber axis, as depicted in Figure 1b. Additionally, CNFs can also exhibit a coiled configuration, as illustrated in Figure 1f.

- (ii)

- Fishbone CNFs are characterized by the inclination of graphene layers in relation to the fibril axis. The presence of hydrogen is necessary to stabilize the edges of these CNFs. There are two variations of fishbone CNFs: those with a hollow core, as shown in Figure 1d, and those with a solid core, as depicted in Figure 1c [51].

- (iii)

- Ribbon CNFs consist of unrolled graphene layers that are straight and parallel to the fibril axis. They have non-cylindrical cross-sections, as shown in Figure 1e. Regarding the position of the catalytic solid particle, there is agreement among researchers that it is located at one extreme. However, there is some discrepancy among authors regarding the orientation of the graphite layers in relation to the fibril axis. Some claim that the layers are completely parallel [50], while others suggest that they are slightly inclined [52].

- (iv)

- Stacked-cup CNFs exhibit a continuous layer of rolled (spiral) graphene along the fiber axis. This spiral orientation results in a truncated cone arrangement along the axis, with a wide internal hollow space, as shown in Figure 1g.

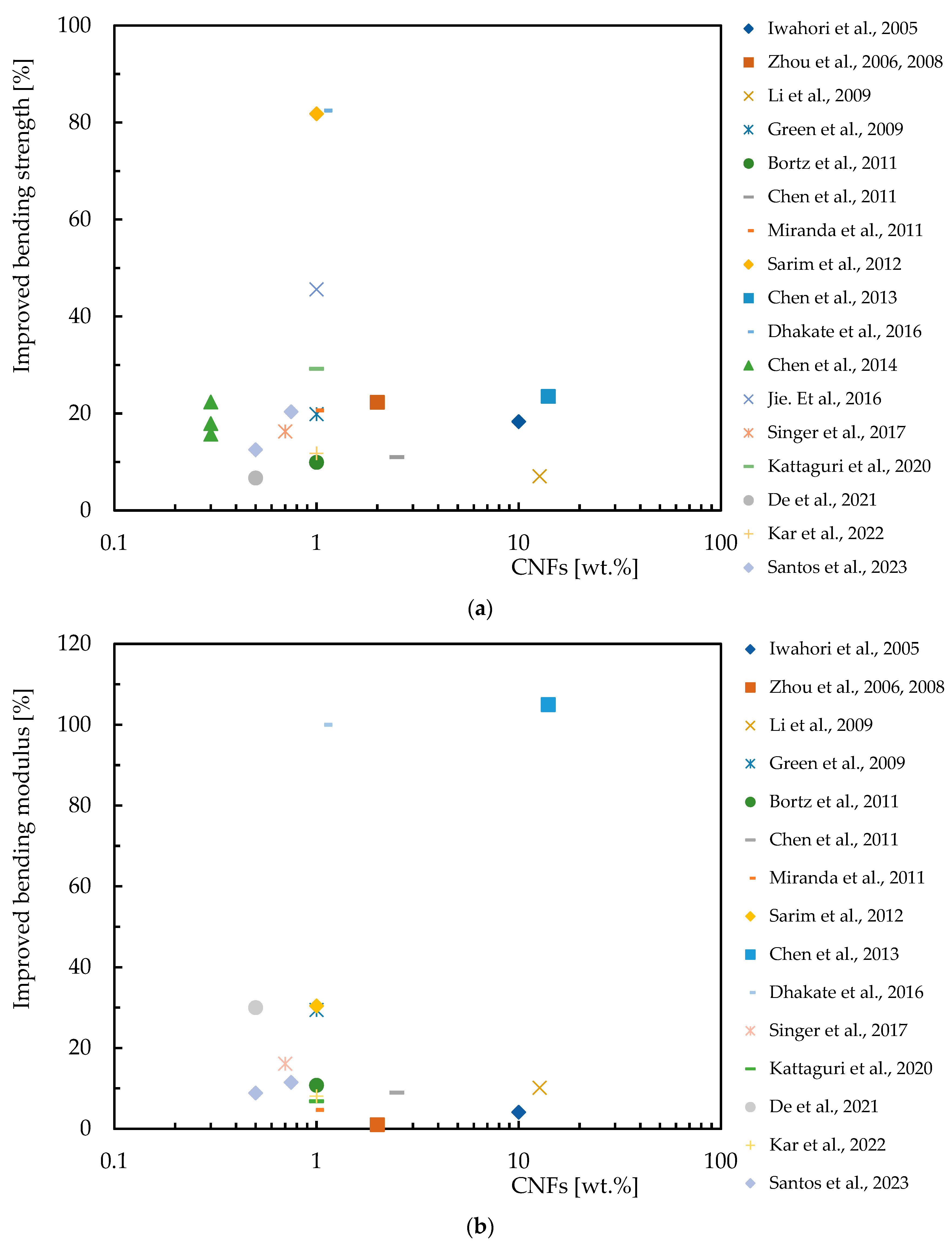

3. Effect of CNFs on the Static Response of Epoxy Matrix Composites

3.1. Static Properties of CNF Multiscale Epoxy Matrix and Composites

| Autor, Ref. | CNFs Type | CNFs Integration Method | Optimum Loading (CNFs wt.%) | Bending Strength [MPa] (Increase (%)) | Bending Modulus [GPa] (Increase (%)) | Failure Strain [%] (Increase (%)) |

|---|---|---|---|---|---|---|

| Patton et al., [80] | VGCNFs | Acetone/epoxy solution infusion. | 18.2 | 123.0 (36.7%) | 7.85 (97.2%) | - |

| High shear mixing. | 15.5 | 112.5 (29.3%) | 6.18 (169.9%) | - | ||

| Blender and two roll mill mixing. | 19.2 | 146.4 (67.9%) | 7.02 | - | ||

| Xu et al., [92] | GCNFs | Mixed and sonicated. | 0.3 | 139.6 ± 4.05 (28.25) | 3.07 (0.52%) | 3.93 (36.7%) |

| Iwahori et al., [81] | CSNFs | Mechanical mixing, passing through a vacuum chamber and post-cure in a hot press. | 10.0 | 135.8 (37.7%) | 3.277 (41.9%) | - |

| Pervin et al., [82] | CNFs | Ultrasonic cavitation. | 4.0 | 99.4 ± 4.6 (17%) | 2.81 ± 0.12 (27%) | - |

| Zhamu et al., [83] | GNFs | Mixed by low-power sonication and cured in a vacuum oven. | 0.3 | 166.4 ± 2.0 (25.9%) | 3.356 ± 0.056 (20.6%) | 0.068 ± 0.005 (30.8%) |

| Sui et al., [93] | CNFs | Mechanical mixing. | 0.3 | 137.7 ± 4.2 (32%) | 2.92 ± 0.04 (9%) | 7.5 ± 1.9 (70%) |

| Sancaktar et al., [94] | ECNFs | Non-woven ECNFs fabrics were impregnated with epoxy resin. | 0.98 | ~220.0 (−33%) | - | - |

| Bal, [84] | CNFs | Dispersed in acetone by sonication, mixed with resin and sonicated at controlled power levels, and followed degassing process in vacuum oven. | 0.75 | - | 2.69 (60%) | - |

| Ardanuy et al., [85] | VGCNFs | Mixing by hand and ultrasound bath. | 0.1 | 105.0 ± 15 (4%) | 4.0 ± 0.3 (21.2%) | 3.8 ± 1.0 (−34.2%) |

| Zhang et al., [95] | VGCNFs | Ultrasonic and then mixing followed by ultrasonic again. | 0.2 | ~120.0 (over 200%) | ~2.7 (under 10%) | - |

| Zhang et al., [96] | CNFs | Ultrasonically dispersed, mixed, and rotary evaporator. | 0.3 | ~80.0 (over 400%) | - | - |

| Shokrieh et al., [97] | VGCNFs | High speed mechanical mixing and sonicated via probe sonicator. | 0.25 | ~121.0 (10%) | ~3.18 (6%) | - |

| Chen et al., [90] | ECNFs | Surfaces oxidation and functionalization. The nano-epoxy mixture was first subjected to ultrasonication, followed by mechanical stirring and degassing and finally post-curing. | 0.5 | 412.3 (10%) | 18.8 (14.6%) | - |

| VGCNFs | 424.6 (13.3%) | 18.2 (11.0%) | - | |||

| GCNFs | 418.7 (11.7%) | 18.5 (12.8%) | - | |||

| Ahmadi et al., [98] | CNFs | Dispersed in acetone/epoxy resin under mechanical stirring by high-speed, sonicated, and vacuum oven. | 1.0 | 213.6 ± 4.4 (97.8%) | 5.14 ± 0.28 (143.6%) | - |

| Zeltmann et al., [99] | CNFs | Dispersing was accomplished using a mechanical mixer with a high shear impeller, and cured at RT and post-cured at 90 °C. | 1.0 | 96.9 (−8.6%) | ~2.3 (~5%) | - |

| Gao et al., [33] | CNFs | Rigorously agitation. | 3.0 | 163.9 ± 7.8 (49.2%) | 6.2 ± 0.4 (82.4%) | - |

| Danni et al., [54] | CNFs | Dissolution, magnetic stirring, and sonication to obtain CNF mats. Hand lay-up method to manufacture de composite. | 3.0 | 122.58 (97.2%) | - | - |

| Nimbagal et al., [42] | CNFs | EP was preheated, mixed manually, and sonication and cured at RT. | 0.3 | 76.9 (48.74%) | - | - |

| Santos et al., [34] | CNFs | Simultaneous dispersion in a high-speed shear mixer at high shear rate and sonication for 3 h at RT followed by degassing. | 0.75 | 118.7 ± 1.2 (11.7%) | 3.0 ± 0.08 (11.7%) | 5.2 ± 0.2 (−2%) |

| 0.5 | 123.4 ± 2.8 (11.7%) | 3.2 ± 0.09 (11.5%) | 5.4 ± 0.5 (−6.3%) |

| Autor, Ref. | Fiber/Matrix | CNFs Type | CNFs Integration Method | Manufacture Process | Optimum Loading (CNFS wt.%) | Bending Strength [MPa] (Increase (%)) | Bending Modulus [GPa] (Increase (%)) | Failure Strain [%] (Increase (%)) | |

|---|---|---|---|---|---|---|---|---|---|

| Iwahori et al., [81] | CF/EP | CSNFs | Mechanical mixing, passing through a vacuum chamber, and post-cure in a hot press. | Hand lay-up, vacuum application, and post-cure in a hot press. | 10.0 | 789.5 (18.3%) | 53.5 (4%) | - | |

| Zhou et al., [86] | CF/EP | CNFs | High-intensity ultrasonic processing followed by high-speed mechanical mixing and high vacuum. | VARTM | 2.0 | 597.0 ± 21 (22.3%) | 49.4 ± 3.1 (1%) | 1.27 ± 0.03 (8.5%) | |

| Li et al., [75] | CF PrP/EP | VGCNFs | Powder method (applied in the middle plane by hand lay-up process). | Autoclave | 12.7 | 1283.7 (7.1%) | 114.1 (10.1%) | - | |

| Green et al., [88] | E-GF/EP | CNFs | Mechanical mixer. | VARIM and compress | 1.0 | 404.0 ± 18.6 (20%) | 22.0 ± 0.5 (26%) | - | |

| Bortz et al., [100] | CF/EP | CNFs | Hand mixing and TRM. | VARTM | 1.0 | ~310 (over 9%) | ~11.3 (over 10%) | - | |

| Chen et al., [101] | CF/EP | ECNFs | Fabrication of mats of ECNFs. | VARTM with interlaminar regions containing mats of ECNFs. | ~2.5 | 418.5 ± 11.7 (11%) | 32.8 ± 7.8 (9%) | - | |

| Miranda et al., [89] | CF/EP | CNFs | CNFs grown onto the surface of carbon fiber fabrics. | Hot pressed | 1.0 | ~380.0 (17%) | 31.5 | - | |

| Ali et al., [102] | CF/EP | CNFs | CNFs dispersed using a high shear mix, sonicated in a bath ultrasonicator followed by a spray-up process. | VARTM | 1.0 | ~160.0 (over 40%) | ~30.0 (19%) | - | |

| Chen et al., [103] | CF/EP | ECNFs | Thermal treatments of stabilization in air followed by carbonization in argon. | VARTM | 14.0 (Collection time at 10 min) | 465.6 ± 38.4 (23.5%) | 24.8 ± 3.9 (105%) | - | |

| Dhakate et al., [35] | CF PrP/EP | CNFs | Mixed and sonicated. | Impregnated and was applied temperature and pressure (hot plate). | 1.1 | 730.0 (83.4%) | ~40.0 (over 100%) | - | |

| Chen et al., [90] | CF/EP | ECNFs | Surfaces oxidation and functionalization. The nano-epoxy mixture was first subjected to ultrasonication, followed by mechanical stirring and degassing and finally post-curing. | VARTM | 0.3 | 545.0 ± 9.5 (13.6%) | - | - | |

| VGCNFs | 567.3 ± 21.8 (18.3%) | - | - | ||||||

| GCNFs | 552.6 ± 44.8 (15.2%) | - | - | ||||||

| Jie. et al., [104] | CF/EP | CNFs | CVD | Manual stacking followed by heating at 2300 °C. | 1.0 | CF parallel | - | 187.92 (45.6%) | - |

| CF vertical | - | 11.23 (56.6%) | - | ||||||

| Singer et al., [91] | CF/EP | CNFs | TRM dispersion. | Infiltration and cure in a hot press. | 0.7 | ~600.0 (14%) | ~47.5 (14%) | - | |

| Kattaguri et al., [105] | GF/EP | CNFs | EP resin was preheated, mechanical mixing at high speed, sonication, and degassing. | Hand lay-up followed by hot pressing. | 1.0 | ~415.0 (29.0%) | ~23.5 (~7%) | - | |

| De et al., [106] | CF/EP | CNFs | Electrophoretic deposition (EPD) technique. | Hand lay-up, followed hot pressing. | 0.5 [g/L] | 191.0 ± 7.81 (6.7%) | 13.0 ± 0.87 (30%) | 3.14 ± 0.2 (36%) | |

| Kar et al., [107] | GF/EP | CNFs | Magnetic stirring dispersion, ultrasonication, and degassing. | Hand lay-up, followed hot pressing. | 1.0 | ~380 (~13%) | ~20.0 (~8%) | - | |

| Santos et al., [36] | CF/EP | CNFs | Simultaneous dispersion in a high-speed shear mixer at high shear rate and sonication for 3 h at RT, followed by degassing. | Hand lay-up and simultaneous application of vacuum and pressure. | 0.75 | 905.3 ± 13.9 (20.4%) | 61.4 ± 1.8 (11.4%) | 1.5 ± 0.08 (−7%) | |

| 0.5 | 850.9 ± 46.6 (12.5%) | 51.7 ± 1.5 (8.8%) | 1.8 ± 0.09 (4%) | ||||||

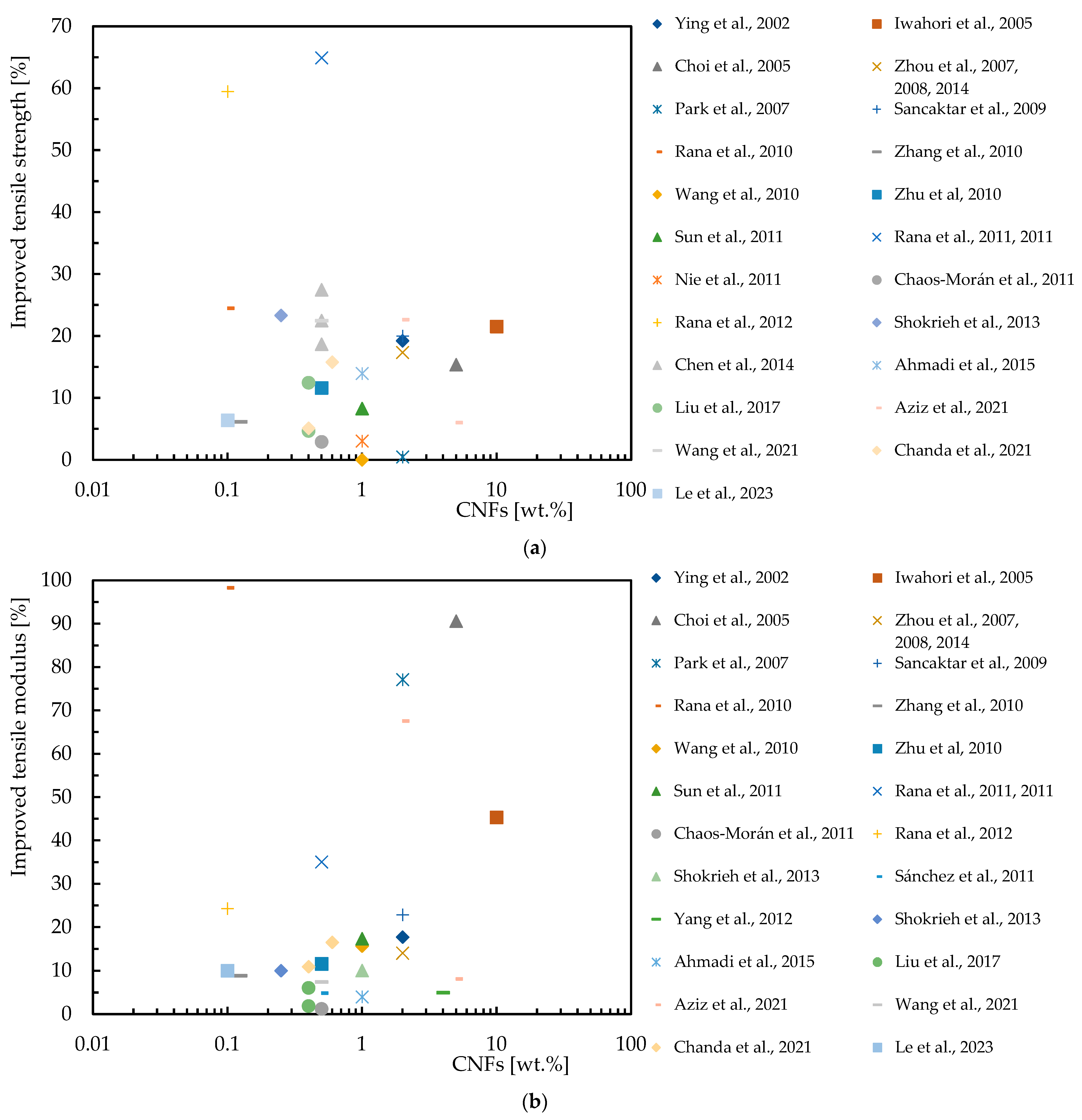

| Autor, Year, Ref. | CNFs Type | CNFs Integration Method | Optimum Loading (CNFs wt.%) | Tensile Strength [MPa] (Increase (%)) | Tensile Modulus [GPa] (Increase (%)) | Tensile Strain [%] (Increase (%)) | |

|---|---|---|---|---|---|---|---|

| Ying et al., [119] | CNFs | A homogeneous suspension of surfactant coated CNFs was obtained by magnetic stirring, ultrasonics and high shear stirring. Subsequently, it was mixed and stirred with epoxy resin. | 2.0 | 62.0 (19.2%) | 1.385 (17.7%) | 8.04 (36.3%) | |

| Iwahori et al., [81] | CSNFs | Mechanical mixing, passing through a vacuum chamber and post-cure in a hot press. | 10.0 | 88.6 (21.6%) | 3.602 (45.3%) | 3.75 (−40.7%) | |

| Choi et al., [113] | VGCNFs | For low viscosity epoxy, the VGCNFs were dispersed in an acetone by sonication and stirring at RT. The epoxy resin was added to the mixture by sonication and stirring under the same conditions. For high viscosity epoxy, the same procedure as above was followed, but without the acetone treatment. The materials were cured and post-cured at RT. | 5.0 | Low viscosity | ~75.0 (15.4%) | ~10.1 (90%) | ~1.87 (−25.2%) |

| High viscosity | ~71.0 (12.7%) | ~9.9 (80%) | ~1.8 (−28%) | ||||

| Zhou et al., [40] | VGCNFs | High-intensity ultrasonic processing followed by high-speed mechanical mixing and high vacuum. | 2.0 | 68.98 ± 2.35 (17.3%) | 3.17 ± 0.15 (14%) | 3.60 ± 0.23 (12.5%) | |

| Park et al., [120] | CNFs | CNFs were dispersed in the epoxy solution through sonication, and residual solvent was removed by vacuum drying. The composites were pre-cured and then post-cured. | 2.0 (vol. %) | ~22.7 (50%) | ~0.85 (77%) | - | |

| Sancaktar et al., [94] | ECNFs | Non-woven ECNFs fabrics were impregnated with epoxy resin. | 2.06 | ~180.0 (20%) | ~7.0 (22%) | ~3.5 (−12%) | |

| Rana et al., [121] | CNFs | Using a combination of ultrasonication and surfactant. | 0.1 | 55.4 (24.5%) | 0.5405 (98.3%) | 11.0 (−6%) | |

| Zhang et al., [122] | CNFs | Dispersion of the CNFs/epoxy mixture using a three-roll calender, followed by stirring to blend with the curing agent, and finally undergoing post-curing. | 0.125 (vol. %) | ~86.0 (6%) | ~2.95 (9%) | ~5.9 (2%) | |

| Wang et al., [123] | VGCNFs | CNFs mixed with an epoxy resin | 1.0 | Pristine | ~69.0 (−%) | ~3.7 (15%) | - |

| CNFs were functionalized and dispersed in epoxy using acetone and sonication. The acetone was then removed from the mixture under vacuum. | 3.0 | Functionalized | ~63.0 (22%) | ~2.9 (11%) | - | ||

| Zhu et al., [108] | CNFs | The CNFs are allowed to wet completely without disturbance, then mechanically stirred, and finally sonicated, all at RT. | 0.5 | Pure | 80.7 (11.6%) | 2.9 (11.5%) | 5.0 (16.3%) |

| Functionalization of CNFs (mechanical stirring at RT) via silanization (ultrasonically stirred) and vacuum drying. The mixing process with the resin is the same as with pure CNFs. | 0.3 | Functionalized | 81.3 (12.4%) | 2.1 (−19.2%) | 6.8 (58.2%) | ||

| Sun et al., [112] | CNFs | CNFs were immersed in dimethylacetamide and CNFs/epoxy nanocomposites were sonicated and mechanically stirred. Evaporation, vacuum degassing followed by curing and post-curing. | 1.0 | 74.4 ± 2.4 (8.3%) | 1.22 ± 0.01 (17.3%) | - | |

| Rana et al., [109] | VGCNFs | Combination of ultrasonication and high-speed mechanical stirring. | 0.5 | ~63.0 (65%) | ~3.2 (35%) | - | |

| Nie et al., [124] | CNFs | CNFs were dispersed in acetone using an ultrasonic probe, added to the resin and sonicated. The acetone solvent was removed by rotatory evaporation. The CNFs/epoxy composite was placed in a vacuum desiccator followed by curing and post-curing. | 1.0 | Original | ~47.5 (3%) | - | - |

| CNFs functionalized by a multistage process including oxidation, reduction, and silanization. The mixing process with the resin is the same as with original CNFs. | 0.5 | Functionalized | ~48.0 (4.1%) | - | - | ||

| Chaos-Morán et al., [125] | CNFs | Functionalization of CNFs by oxidation. Untreated or carboxylated CNFs were mixed with epoxy by magnetic stirred, followed by high shear mixing, sonication, the whole process at 40 °C. Finally placed in a vacuum oven for evaporation. | 0.5 | Original | ~70.5 (3%) | ~2.55 (1.2%) | - |

| Functionalized | ~61.0 (−11%) | ~2.45 (−2.8%) | - | ||||

| Rana et al., [115] | VGCNFs | Functionalized CNFs subjected to a bath sonicator followed by magnetic stirring. CNFs/epoxy dispersion using ultrasonication followed by high-speed mechanical stirring. | 0.1 | Original | 61.4 ± 3.2 (59.5%) | 2.92 ± 0.02 (24.3%) | - |

| Functionalized | 62.4 ± 2.6 (62.1%) | 2.64 ± 0.06 (12.3%) | - | ||||

| Shokrieh et al., [126] | CNFs | CNFs/epoxy was mixed at a high shear rate, followed by sonication and degassing the solution in a vacuum chamber. | 1.0 | - | ~3.4 (10.0%) | - | |

| Sánchez et al., [127] | CNFs | CNFs/epoxy dispersion using a three-roll calender, repeating the process several times. | 5.0 | - | ~6.1 (26.0%) | - | |

| Yang et al., [128] | CNFs | Mix CNFs/epoxy several times at temperature followed by ultrasonication. Cure at RT and post-cure in oven. | 4.0 | 52.69 (−14.3%) | 2.98 (4.9%) | 2.23 (−168.6%) | |

| Shokrieh et al., [97] | VGCNFs | High speed mechanical mixing and sonicated via probe sonicator. | 0.25 | ~74.0 (23%) | ~2.75 (10%) | ~6.5 (−50%) | |

| Colloca et al., [129] | CNFs | Mixing in a high shear mechanical mixer at temperature followed by degassing. Cure at RT and post-cure in oven. | 0.6 (vol. %) | ~25.5 (−%) | ~2.78 (−%) | - | |

| Chen et al., [90] | ECNFs | Surfaces oxidation and functionalization. The nano-epoxy mixture was first subjected to ultrasonication, followed by mechanical stirring, and degassing and finally post-curing. | 0.5 | 54.39 (22.5%) | - | - | |

| VGCNFs | 52.7 (18.7%) | - | - | ||||

| GCNFs | 56.6 (27.5%) | - | - | ||||

| Ahmadi et al., [98] | CNFs | Dispersed in acetone/epoxy resin under mechanical stirring by high-speed, sonicated, and vacuum oven. | 1.0 | 91.87 ± 2.02 (14%) | 2.62 ± 0.10 (4%) | 4.6 ± 0.43 (−11.5%) | |

| Liu et al., [116] | CNFs | CNFs and deionized water were mixed by magnetic stirring, dopamine was added and the suspension was stirred at RT. CNFs were treated by vacuum filtration and washing. Next, pure CNFs/epoxy and modified CNFs/epoxy composites were mixed by high-speed shear followed by ultrasonic treatment and degassed at RT. Cured at RT and post-cured in oven. | 0.4 | Pristine | 64.7 ± 1.4 (4.7%) | 2.608 ± 0.047 (1.9%) | - |

| Modified | 69.5 ± 1.4 (12.5%) | 2.715 ± 0.035 (6.1%) | - | ||||

| Aziz et al., [130] | CNFs | Pure and modified (amine-functionalized) CNFs were dispersed in acetone by sonication. The epoxy was added and sonicated before the acetone was removed in an oven. The mixture was then placed in a vacuum desiccator and cured at temperature. | 5.0 | Pristine | ~51.0 (6%) | ~4.0 (8.1%) | - |

| 2.0 | Modified | ~59.0 (22.7%) | ~6.2 (67.6%) | - | |||

| Wang et al., [117] | CNFs | CNFs/epoxy was mixed with acetone solution using a high-speed mechanical stirrer and sonicated. Then were ultrasonically dispersed, mechanically stirred on temperature, and vacuumed. | 0.5 | 67.0 (22.5%) | 2.9 (7.4%) | 3.8 (18.2%) | |

| Chanda et al., [131] | CNFs | CNFs/epoxy were mixed by hand, sonicated and degassed in a vacuum oven. It was then placed between parallel aluminum electrodes and an electric field applied to produce a CNFs/epoxy composite aligned in the thickness direction. | 0.6 | Random | 49.9 ± 0.2 (15.8%) | 2.539 ± 35.0 (16.5%) | - |

| 0.4 | Aligned | 45.3 ± 0.3 (5.1%) | 2.418 ± 16.0 (10.9%) | - | |||

| Le et al., [111] | CNFs | CNFs and epoxy hardener were hand mixed, followed mixed using ultrasonication. Resin was added to this solution by hand mixing and degassed in a vacuum chamber at RT. Cure at RT and post-cure in oven. | 0.1 | 70.0 (6.4%) | 1.1 (10%) | 0.14 (25%) | |

| Autor, Year, Ref. | Fiber/Matrix | CNFs Type | CNFs Integration Method | Manufacture Process | Optimum Loading (CNFs wt.%) | Tensile Strength [MPa] (Increase (%)) | Tensile Modulus [GPa] (Increase (%)) | Tensile Strain [%] (Increase (%)) | |

|---|---|---|---|---|---|---|---|---|---|

| Iwahori et al., [81] | CF/EP | CSNFs | Mechanical mixing, passing through a vacuum chamber and post-cure in a hot press. | Hand lay-up, vacuum application, and post-cure in a hot press. | 10.0 | 577.2 (0.2%) | 56.24 (−1.7%) | 4.0 (13%) | |

| Bortz et al., [100] | CF/EP | CNFs | Hand mixing and TRM. | VARTM | 1.0 | 165.0 (8%) | 11.8 (5%) | 11.9 (11.2%) | |

| Rana et al., [109] | CF/EP | VGCNFs | Combination of ultrasonication and high-speed mechanical stirring. | Cured under the heat and pressure in a compression molding machine. | 0.5 | ~790.0 (18%) | ~67.0 (37%) | - | |

| Palmeri et al., [132] | CF/EP | CNFs | Shear mixing. | Laid up by hand. | 0.67 | 514.0 (6%) | 52.0 (10%) | 1.07 (5%) | |

| Sarim et al., [102] | CF/EP | CNFs | CNFs dispersed using a high shear mix, sonicated in a bath ultrasonicator, followed by a spray-up process. | VARTM | 1.0 | 196.0 (22.5%) | 12.5 (14%) | - | |

| Rana et al., [115] | CF/EP | VGCNFs | Functionalized CNFs subjected to a bath sonicator followed by magnetic stirring. CNFs/epoxy dispersion using ultrasonication followed by high-speed mechanical stirring. | Hand lay-up and compression molding. | 0.1 | Original | 737.0 ± 69.5 (34.8%) | 65.1 ± 4.4 (10.7%) | - |

| Functionalized | 905.5 ± 11.3 (65.0%) | 79.7 ± 2.9 (36.0%) | |||||||

| Shokrieh et al., [126] | CF/EP | CNFs | CNFs/epoxy was mixed at a high shear rate, followed by sonication and degassing the solution in a vacuum chamber. | Hand lay-up. | 1.0 | - | ~8.3 (12.0%) | - | |

| Zhou et al., [40] | CF/EP | CNFs | High-intensity ultrasonic processor and high-speed mechanical. | VARIM | 2.0 | 617.0 (11%) | 46.1 (2.0%) | 1.51 (4.1%) | |

| Ahmadi et al., [98] | UHMWPE/EP | CNFs | Dispersed in acetone/epoxy resin under mechanical stirring by high-speed, sonicated, and vacuum oven. | Fibers were impregnated into this resin bath and winded on the metal frame. | 1.0 | 176.3 ± 2.6 (118.7%) | 3.42 ± 0.19 (35.7%) | 7.03 ± 0.29 (35.2%) | |

| Anjabin et al., [118] | Basalt/EP | CNFs | Functionalized and mixed using an overhead mechanical stirrer. | Hand lay-up, followed by static pressing. | 0.3 | 328.0 (12.7%) | 19.8 (32.9%) | - | |

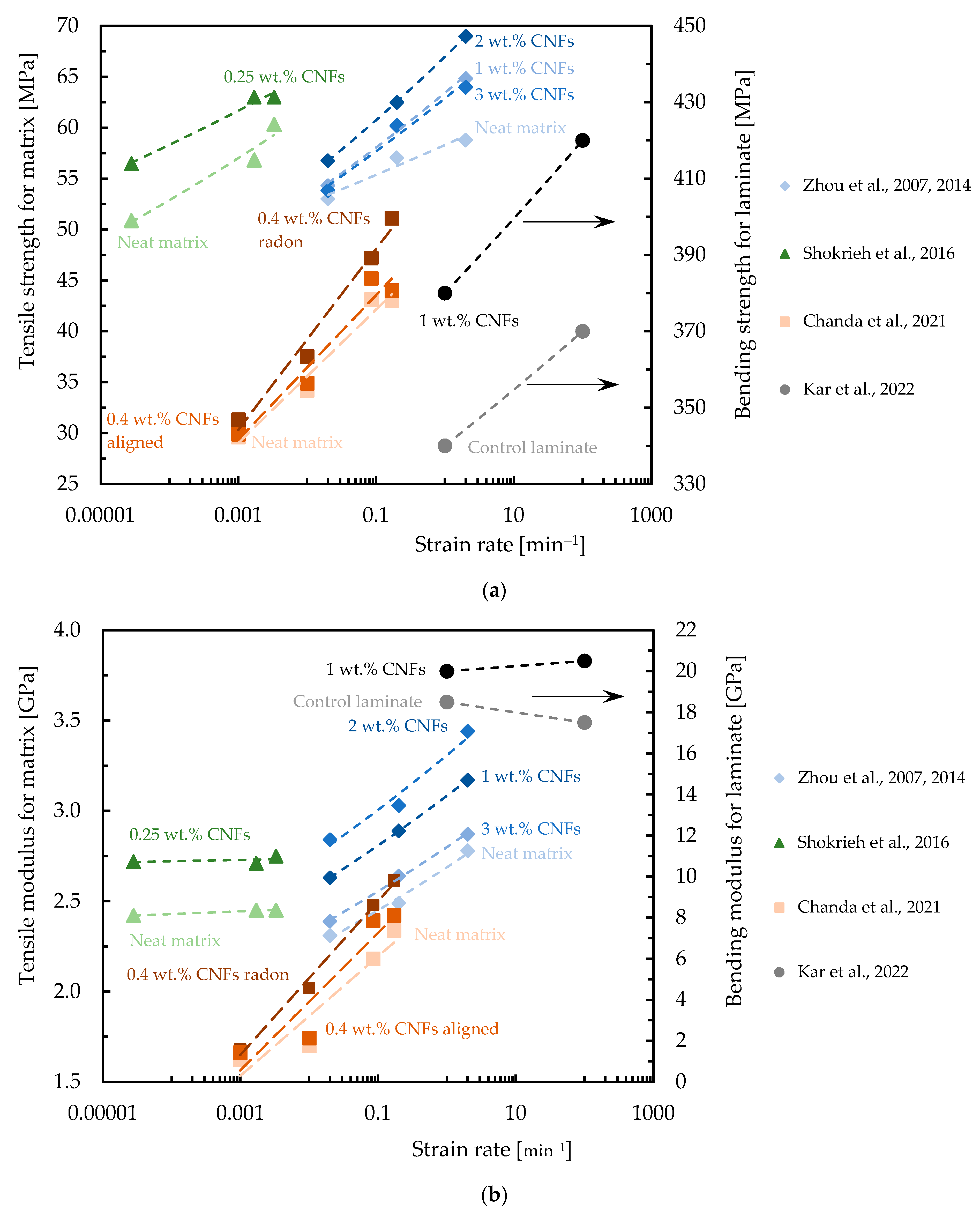

3.2. Effect of CNFs on the Strain Rate Response

| Autor, Ref. | Fiber/Matrix | CNFs Type | CNFs Integration Method | Manufacture Process | Optimum Loading (CNFs wt.%) | Strain Rate |

|---|---|---|---|---|---|---|

| Zhou et al., [114] | -/EP | CNFs | High-intensity ultrasonic processing followed by high-speed mechanical mixing and high vacuum. | - | 2.0 | Tensile strength increase, tensile modulus increase, and failure strain decrease to neat and with 2.0 wt.% CNFs/EP to 0.02 min−1, 0.2 min−1, and 2 min−1 velocities. |

| Poveda et al., [133] | -/EP | CNFs | A mechanical mixer fitted with a high shear impeller was used, the mixture placed on a shaker for degassing and curing at RT. | - | 1.0 to 10.0 | The compressive strength and modulus under quasi-static testing increase. |

| Shokrieh et al., [134] | -/EP | VGCNFs | High speed mixing, sonication, and final degassing of the mixture. | - | 0.25 | Tensile strength and tensile modulus increase to neat EP and tensile strength decrease and tensile modulus increase to 0.25 wt.% CNFs/EP to 0.00167 min−1, 0.1 min−1, and 0.2 min−1 velocities. |

| Chanda et al., [131] | -/EP | CNFs | CNFs/epoxy were mixed by hand, sonicated and degassed in a vacuum oven. It was then placed between parallel aluminum electrodes and an electric field applied to produce a CNFs/epoxy composite aligned in the thickness direction. | - | 0.4 | The elastic modulus and tensile strength increased with increasing strain rates, to aligned composites and random composites, however, transversely aligned composites, compared to random composites, always exhibited lower modulus, strength and failure strain, under strain rates of 0.001, 0.01, 0.085, and 0.17 min−1. |

| Zhou et al., [135] | -/EP | CNFs | Functionalization, mixture subjected to magnetic stirring and vacuum in an oven. Cured and post-cured at high temperatures. | - | 0.75 | To 0.00005 to 60 min−1 Young’s modulus and compressive strength increases. |

| Kar et al., [107] | GF/EP | CNFs | Magnetic stirring dispersion, ultrasonication, and degassing. | Hand lay-up, followed hot pressing. | 1.0 | CNFs composite increases bending strength and bending modulus of GF with CNFs composite at 30 °C when tested at 1 and 100 mm/min loading rate |

| Santos et al., [136] | EP | CNFs | Simultaneous dispersion in a high-speed shear mixer at high shear rate and sonication for 3 h at RT followed by degassing. | - | 0.75 | Independently of the resin and weight percentages of the CNFs, both materials are strain-rate sensitive when subjected to bending strain rates of 0.00015 to 1.15 min−1. The bending stress and modulus increase for higher values of strain rate values. |

| 0.5 | ||||||

| Santos et al., [36] | CF/EP | CNFs | Simultaneous dispersion in a high-speed shear mixer at high shear rate and sonication for 3 h at RT followed by degassing. | Hand lay-up and simultaneous application of vacuum and pressure. | 0.75 | Laminates produced with CNFs nano-reinforced resins show a greater sensitivity to strain rate than the corresponding control laminates by approximately 10% for bending strength and 3% to 13% for bending modulus. |

| 0.5 |

3.3. Effect of CNFs on Stress Relaxation and Creep Behavior

| Autor, Ref. | Fiber/Matrix | CNFs Type | CNFs Integration Method | Manufacture Process | Optimum Loading (CNFs wt.%) | Stress Relation | Creep |

|---|---|---|---|---|---|---|---|

| Santos et al. [34] | EP | CNFs | Simultaneous dispersion in a high-speed shear mixer at high shear rate and sonication for 3 h at RT followed by degassing. | - | 0.75 | Stress relaxation and creep behavior were shown to be strongly dependent on the applied load level and the addition of CNFs significantly reduces both phenomena. | |

| 0.5 | |||||||

| Santos et al. [137] | CF/EP | CNFs | Simultaneous dispersion in a high-speed shear mixer at high shear rate and sonication for 3 h at RT followed by degassing. | Hand lay-up and simultaneous application of vacuum and pressure. | 0.75 | The addition of CNFs may not have a good effect on the stress relaxation and creep behavior of the laminates. | |

| 0.5 | |||||||

3.4. Effect of CNFs on the Interlaminar Shear Strength (ILSS)

| Autor, Ref. | Fiber/Resin | CNFs Type | CNFs Integration Method | Manufacture Process | Optimum Loading (CNFs wt.%) | ILSS [MPa] (Increase (%)) |

|---|---|---|---|---|---|---|

| Quaresimin et al., [149] | CF PrP/EP | VGCNFs | Dispersed in the EP system according to an attrition milling process. | Hand lay-up of prepreg. Curing performed using a vacuum bag and additional pressure. | 7.5 | ~50.0 (~14%) |

| Green et al., [88] | E-GF/EP | CNFs | Mechanical mixer. | VARIM and compress. | 0.1 | 43.85 ± 1.0 (23.6%) |

| Bortz et al., [100] | CF/EP | CNFs | Hand mixing and TRM. | VARTM | 1.0 | ~50.0 (−4%) |

| Chen et al., [101] | CF/EP | ECNFs | Fabrication of mats of ECNFs. | VARTM with interlaminar regions containing mats of ECNFs. | ~2.5 | 51.2 ± 4.9 (86.2%) |

| Palmeri et al., [132] | CF/EP | CNFs | Shear mixing. | hand placed | 0.67 | 132.3.0 (15%) |

| Rodrigues et al., [141] | CF/EP | CNFs | Oxidized CNFs (O-CNFs) and amidized CNFs (A-CNFs). | VARTM | 1.0 | 59.58 (12.4%) |

| Khan et al., [142] | CF/EP | CNFs | Simple soaking, hot compression molding, and vacuum infiltration. | Bucky paper interleaves. | 10.0 | ~70.0 (31%) |

| Miranda et al., [89] | CF/EP | CNFs | CNFs grown onto the surface of CF fabrics. | Hot pressed | 0.2 | ~33.0 (−10%) |

| Arai et al., [150] | CF PrP/EP | VGCNFs | CNFs were inserted between prepregs layers using a sifter. | Autoclave | Area density of 10 [g/m2] | 52.2 (24.9%) |

| Sarim et al., [102] | CF/EP | CNFs | CNFs dispersed using a high shear mix, sonicated in a bath ultrasonicator followed by a spray-up process. | VARTM | 1.0 | ~375.0 (25%) |

| Khan et al., [143] | CF/EP | CNFs | Simple soaking, hot compression molding, and vacuum infiltration. | Bucky paper interleaves. | 10.0 | ~69.0 (31%) |

| Chen et al., [103] | CF/EP | ECNFs | Thermal treatments of stabilization in air followed by carbonization in argon. | VARTM | 14.0 | 88.3 ± 5.8 (221.1%) |

| Anand et al., [144] | E-GF/EP | CNFs | Mechanical probe sonicator and mechanical mixing. | RFI | 0.5 | 83.6 ± 0.52 (33.1%) |

| Chen et al., [90] | CF/EP | ECNFs | Surfaces oxidation and functionalization. The nano-epoxy mixture was first subjected to ultrasonication, followed by mechanical stirring, and degassing and finally post-curing. | VARTM | 0.3 | 45.8 ± 7.1 (42.2%) |

| VGCNFs | 38.3 ± 3.5 (18.9%) | |||||

| GCNFs | 37.4 ± 1.3 (16.1%) | |||||

| Zhou et al., [40] | CF/EP | CNFs | High-intensity ultrasonic processor and high-speed mechanical. | VARIM | 2.0 | 41.6 ± 1.7 (15.9%) |

| Lake et al., [44] | CF/EP | CNFs | Producing a nanofiber mat composed of highly graphitic CNFs in an isotropic array. | VARTM | 5.0 | 2250 (14.5%) |

| Ma et al., [145] | CF/EP | CNFs | High intensity ultrasonic atomizer probe and mechanical mixing. | Filter membrane-assisted. | 3.0 | 64.0 (50.9%) |

| No filter membrane-assisted. | 1.0 | 45.5 (7.3%) | ||||

| Srikanth et al., [151] | CF/EP | CNFs | Probe ultrasonicator followed by ball milling and aminofunctionalized. | Fabric layers were impregnated and compressed. | 1.0 | 41.0 ± 1.1 (28.1%) |

| Taheri-Behrooz et al., [152] | E-GF/EP | CNFs | Mixed and stirred, then sonicated using probe sonicator. | Vacuum-assisted hand lay-up. | 0.25 | 44.76 ± 0.28 (19.5%) |

| Dhakate et al., [35] | CF PrP/EP | CNFs | Mixed and sonicated. | Impregnated and was applied temperature and pressure (hot plate). | 1.1 | 55.0 (103.7%) |

| Kirmse et al., [153] | CF PrP/EP | CNFs | Flow-transferring a resin film containing electrical-field aligned CNFs. | Autoclave-vacuum bag. | 1.0 | 53.93 (35.1%) |

| Yao et al., [146] | CF/EP | VGCNFs | Synthesis and spraying of the polymergrafted VGCNFs functionalized. | Degassed under vacuum, hot compressed. | 0.4 | 83.0 ± 8 (72.9%) |

| Anjabin et al., [118] | Basalt/EP | CNFs | Functionalized and mixed using an overhead mechanical stirrer. | Hand lay-up, followed by static pressing. | 0.3 | 80.2 (73.6%) |

| Kirmse et al., [154] | CF PrP/EP | CNFs z-threads | Shear mixing | Autoclave | 0.85 | 44.81 (50.1%) |

| De et al., [106] | CF/EP | CNFs | Electrophoretic deposition (EDP) technique. | Hand lay-up, followed hot pressing. | 0.5 [g/L] | ~36.0 (16%) |

| Kirmse et al., [155] | CF PrP/EP | CNFs | High-sheared, sonicated, and degassed mixture. | Non-isothermal flow-transfer process. | 1.0 | 69.72 ± 2.51 (7.4%) |

| Ranabhat et al., [147] | CF/EP | CNFs | Radial flow alignment technique. | Out-of-autoclave vacuum-bag-only (with 20% acetone in resin to create voids). | 0.5 | 54.5 (24.2%) |

| Ravindran et al., [41] | CF/EP | CNFs | Hand-mixing followed by a TRM. | High pressure compression molding process. | 1.0 | 39.0 ± 1.9 (−5.6%) |

| He et al., [148] | CF/EP | CNFs | TRM | Multilayer resin film infusion-compressive molding (with 10 min infusion). | 0.3 | 53.65 (5.4%) |

| Yao et al., [79] | CF/EP | CNFs | Chemical vapor deposition. | Vacuum and temperature. | - | 72.1 (18.6%) |

| Mrzljak et al., [156] | CF/EP | CNFs | Mechanical stirring under a vacuum and milled in a TRM and E-field was application to align the CNFs. | Hand-layup process and pressed in a hot press applied during curing. | 0.7 random | 55.5 ± 3.5 (6.1%) |

| Santos et al., [36] | CF/EP | CNFs | Simultaneous dispersion in a high-speed shear mixer at high shear rate and sonication for 3 h at RT followed by degassing. | Hand lay-up and simultaneous application of vacuum and pressure. | 0.75 | 55.4 ± 1.7 (8.6%) |

| 0.5 | 54.0 ± 3.2 (9.3%) |

3.5. Effect of CNFs on the Mode I and Mode II Interlaminar Fracture

| Autor, Ref. | Fiber/Matrix | CNFs Type | CNFs Integration Method | Manufacture Process | Optimum Loading (CNFs wt.%) | GIC [kJ/m2] (Increase (%)) | GIIC [kJ/m2] (Increase (%)) | |

|---|---|---|---|---|---|---|---|---|

| Kostopoulos et al., [165] | CF/EP | CNFs | - | Hand lay-up followed autoclave process. | 1.0 | ~0.8 (100% by MBT); ~1.0 (100% by areas method) | ~2.6 (50% by MBT); ~2.2 (57% by areas method) | |

| Kostopoulos et al., [166] | CF/EP | CNFs | Mixing and vacuum. | Hand lay-up followed autoclave process. | 1.0 | 0.91 (133.3% by MBT); 1.0 (100% by area method); | - | |

| Tsantzalis et al., [167] | CF/EP | CNFs | Temperature and vacuum. | Hand lay-up followed autoclave process. | 1.0 | ~0.8 (100% by MBT); ~1.0 (100% by areas method) | - | |

| Quaresimin et al., [149] | CF PrP/EP | VGCNFs | Dispersed in the EP system according to an attrition milling process. | Prepeg hand lay-up. Curing using a vacuum bag between a platen press under vacuum and additional pressure. | 7.5 | ~0.09 (initiation decrease ~ 55%); ~0.14 (propagation decrease ~ 70%) | ~1.5 (over 100%) | |

| Arai et al., [157] | VGCF PrP/EP | VGCNFs | VGCNFs/EP interlayer: VGCNFs/ethanol mixed manually and dispersed using a roller. | Autoclave | 20 [g/m2] | ~0.65 (23.8%) | ~0.28 (100%) | |

| Li et al., [75] | VGCF PrP/EP | VGCNFs | Powder method (applied in the middle plane by hand lay-up process). | Autoclave | 20 [g/m2] | 0.432 (95.5% critical load); 0.616 (26% fracture resistance) | - | |

| Yokozeki et al., [159] | CF/EP | CSCNFs | CSCNFs dispersed EP (sprinkle) and CSCNFs dispersed film between layers (planetary mixer, and dispersed using the wet mill with ceramic beads). | Hand lay-up followed autoclave. | 5.0 wt.% CSCNFs-dispersed EP with 10.0 wt.% CSCNFs-dispersed film between layers. | 0.227 (167%) | 1.753 (208.6%) | |

| Bortz et al., [100] | CF/EP | CNFs | Hand mixing and TRM. | VARTM | 1.0 | ~0.42 (35%) | - | |

| Gude et al., [160] | CF PrP/EP | CNFs | Dispersion | Autoclave | 0.5 | 0.0991 ± 0.0077 by area method; 0.096 ± 0.0087 by CBT; 0.0967 ± 0.0082 by ECM; (~15% for all methods) | ||

| Kostopoulos et al., [161] | CF/EP | VGCNFs | Mixing and declassification by applying vacuum. | Hand lay-up and cured in an autoclave, using the vacuum bag technique. | 1.0 | 0.79 (100% by MTB); 1.002 (100% by areas method) | 2.626 (86.4% by MTB); 2.195 (55.8% by areas method) | |

| Palmeri et al., [132] | CF/EP | CNFs | Shear mixing | Hand placed | 0.67 | ~1.40 (decrease ~ 20%) | - | |

| Khan et al., [142] | CF/EP | CNFs | Simple soaking, hot compression molding and vacuum infiltration. | Bucky paper interleaves. | 10.0 | - | ~2.49 (104%) | |

| Hu et al., [76] | CF PrP/EP | VFCNFs | Manually dispersed (zigzag pattern) using the powder method. | Autoclave | 20 [g/m2] | 0.432 (95.5% critical load); ~0.62 (~30% fracture resistance) | - | |

| Zhu et al., [158] | S2-GF/EP | CNFs | Functionalized: magnetically stirred, sonicated in an ultrasonic bath with temperature. | Wet filament winding method and hot pressing. | 0.5 | Neat | 0.165 ± 0.014 (onset 30%); 0.903 ± 0.0015 (propagation 47%) | 0.783 ± 0.0037 (onset 39%); 0.996 ± 0.0067 (propagation 46%) |

| Functionalized | 0.176 ± 0.0084 (onset 39%); 0.968 ± 0.0041 (propagation 57%) | 0.843 ± 0.011 (onset 49%); 0.963 ± 0.0023 (propagation 41%) | ||||||

| Koissin et al., [168] | CF/EP | CNFs | Infusion | Hand lay-up | 2.6 | ~1.1 (crack start ~ 95%); ~0.9 (crack stop 140%) | - | |

| Arai et al., [169] | CF/EP | VGCNFs | planetary centrifugal mixer. | VARTM | 10 [g/m2] | ~0 55 (20%) | - | |

| Wang et al., [170] | CF/EP | CNFs | CNFs functionalized, sonication, and vacuum applied at the end. | Vacuum and hot pressure applied. | 0.5 | ~0.30 (13.6%) | ~0.51 (21.7%) | |

| 1.0 | ~0.29 (9%) | ~0.61 (45.3%) | ||||||

| Ma et al., [145] | CF/EP | CNFs | High intensity ultrasonic atomizer probe and mechanical mixing. | Filter membrane-assisted. | 3.0 | - | ~0.815 (~90%) | |

| Ladani et al., [162] | CF/EP | CNFs | TRM to disperse and E-field application. | Cured at RT. | 1.6 | 2.345 (1650%) | - | |

| Wu et al., [171] | CF/EP | VGCNFs | Magnetic stirring to functionalise the CNFs (ultraprobe sonication and simultaneous stirring). Sonication of the EP and subjected to a magnetic field. | Joints bonded using the Fe3O4 at CNFs/EP were cured at RT. | 0.4 | 0.328 (144.8% aligned) | - | |

| 0.242 (80.6% random) | ||||||||

| Gude et al., [172] | CF PrP/EP | CNFs | EP adhesive was dispersed in chloroform and mixed by ultrasonication. | Two surface treatments applied to the laminates: grit blasting and atmospheric plasma and cured in the autoclave with vacuum bag. | 0.5 | ~0.090 (~10% peel-ply) | - | |

| 0.2755 ± 0.0091 (26.5% grit blasted) | ||||||||

| 0.1739 ± 0.0361 (4.7% plasma) | ||||||||

| Hsiao et al., [173] | CF PrP/EP | CNFs | Magnetic stirrer, high shear mixing followed by agitation in a sonicator and then degassing. | Hand wet lay-up process and placed on a hot plate. | 0.3 | 0.348 (14%) | - | |

| Ladani et al., [174] | CF/EP | CNFs | TRM | Wet hand-layup process and cured at RT in the hydraulic press. | 1.0 | 1.123 (67.6%) | - | |

| Ladani et al., [175] | CF/EP | CNFs | TRM and E-field application. | DCB joints as a 2 mm thick adhesive layer bonding. | 2.0 | 2.16 (1490% random) | - | |

| 2.27 (1570% aligned) | ||||||||

| Wu et al., [176] | E-GF/EP | VGCNFs | TRM, hand lay-up process and E-field application. | Vacuum bag, the matrix was then cured at RT. | 0.7 | Initiation toughness: | ~0.6 (50% random) ~0.8 (100% aligned) | - |

| Steady state toughness: | ~1.5 (25% random); ~2.16 (80% aligned) | |||||||

| Ladani et al., [164] | CF PrP/EP | CNFs | TRM and E-field application. | Autoclave | 1.0 | 1.29 ± 0.112 (862.7% random) | - | |

| 1.642 ± 0.161 (1125% aligned) | ||||||||

| Ravindran et al., [177] | CF PrP + E-GF PrP/EP | CNFs | TRM and E-field application. | Autoclave | 1.0 | 1.260 (830% random) | - | |

| Ladani et al., [178] | CF PrP/EP | CNFs | TRM dispersion. | Nano EP adhesive layer was cured at RT. | 2.0 | ~2.16 (1570%) | - | |

| Ravindran et al., [163] | CF/EP | CNFs | Hand mixing and TRM. | Liquid compression molding. | 1.0 | 1.40 ± 0.12 (91%) | 2.88 ± 0.24 (42%) | |

| Ravindran et al., [38] | CF/EP | CNFs | CNFs hand-mixed into the EP and passed four times through a TRM. | Wet compression molding process (consolidation in a hydraulic press). | 5.0 | 0.84 ± 0.15 (240% initiation toughness) | - | |

| 2.04 (179.5% steady state toughness) | ||||||||

| Ravindran et al., [179] | CF/EP | CNFs | Hand-mixed into liquid EP, then passed four times through a TRM. | Liquid compression molding approach. | 5.0 | - | 3.39 ± 0.14 (66%) | |

| Ekhtiyari et al., [180] | E-GF/EP | CNFs | High speed mechanical stirring and ultrasonic agitation. | Hand lay-up process. | 0.25 | ~0.70 (13.5%) | - | |

| Ravindran et al., [39] | CF PrP/EP | CNFs | CNFs hand-mixed into the ER and passed four times through a TRM. | Wet-hand lay-up process and vacuum. | 1.0 | 1.40 ± 0.12 (91.8%) | 2.88 ± 0.24 (41.2%) | |

| Kavosi et al., [181] | CF PrP/EP | CNFs | Functionalized | VARTM | 2.0 | ~0.5 (25%) | - | |

| Ravindran et al., [41] | CF/EP | CNFs | Hand-mixing followed by a TRM. | High pressure compression molding process. | 1.0 | 1.40 ± 0.12 (91% initiation toughness) | 2.88 ± 0.24 (42% initiation toughness) | |

| 0.55 (~120% steady state toughness) | 1.25 (~5% steady state toughness) | |||||||

3.6. Effect of CNFs on the Low-Velocity Impact Response

| Autor, Ref. | Fiber/Matrix | CNFs Type | CNFs Integration Method | Manufacture Process | Optimum Loading (CNFs wt.%) | Impact Energy [J] | Energy to Peak Load Increase [%] | Energy to Max Load Increase [%] | Absorbed Energy Increase [%] | Damage Area Characteristics |

|---|---|---|---|---|---|---|---|---|---|---|

| Bhuiyan et al., [186] | Polyurethane sandwich CF/EP face sheets | CNFs | Sonication, high-speed mechanical mixer. | VARTM | 0.2 | 44 | 7.7 | 46.8 | 16.8 | For 0.2 wt.% CNFs, 20.3% less base width damaged and 18.0% less indentation depth, compared to the control sandwich. |

| Ito et al., [185] | CF PrP/EP | VGCNFs | VGCNFs interlayer. | Autoclave | 20 [g/m2] | 8.69 | - | - | −8.3 | The damaged area is much smaller when VGCNFs interlayer is inserted between the carbon laminate layers. |

| Arai et al., [187] | CF/EP | CNFs | Planetary centrifugal mixing. | Hand lay-up, vacuum, and hot cure. | 2.5 | 8.69 | - | - | −5.6 | Less delamination area for the lamination with 2.5 wt.% CNFs |

| Rahman et al., [184] | CF PrP/EP | CNFs | CNFs oxidized, mechanical stirrer, sonicated, and degasification at RT. | OOA-VBO | 1.0 | 30 | ~19.0 | - | 0 | The damage area decreased with the incorporation of O-CNFs at all impact energy levels and a maximum reduction of 67% in damage area is obtained at 20 J. |

| Ivañez et al., [188] | Sandwich structures with woven CF/EP face-sheets and Nomex | CNFs | Mechanical stirrer and simultaneously ultrasonic bath. | Manual filling of the damage. | 0.75 | 10 to 30 | In repaired sandwich structures with CNFs/EP is higher than in baseline specimens. | In repaired sandwich structures is less than in baseline specimens. | To the impact energy of 10 J no damage was identified on repaired sandwiches and at an impact energy of 30 J, some cracks appear around the area of impact. | |

| Ravindran et al., [41] | CF/EP | CNFs | Hand-mixing followed by a TRM. | High pressure compression molding process. | 1.0 | 10 to 50 | ~4.0 increase to 50 J impact energy | - | - | For impact energy of 10, 20, 30, 40 and 50 J there was a reduction in the damaged area in the order of 1.5%, 13%, 17% 9.9% and 11%, in the nano laminates reinforced with 1.0 wt.% CNFs in comparison with the control laminate. |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, S.; Huang, M.; Hao, R.; He, S.; Liu, H.; Liu, W.; Zhu, C. Recent Advances in Thermally Conductive Polymer Composites. High Perform. Polym. 2022, 34, 1081–1101. [Google Scholar] [CrossRef]

- Kangishwar, S.; Radhika, N.; Sheik, A.A.; Chavali, A.; Hariharan, S. A Comprehensive Review on Polymer Matrix Composites: Material Selection, Fabrication, and Application. Polym. Bull. 2023, 80, 47–87. [Google Scholar] [CrossRef]

- Hodd, K. Epoxy Resins. In Comprehensive Polymer Science and Supplements; Elsevier: Amsterdam, The Netherlands, 1989; Volume 11, pp. 667–699. [Google Scholar]

- Unnikrishnan, K.P.; Thachil, E.T. Toughening of Epoxy Resins. Des. Monomers Polym. 2006, 9, 129–152. [Google Scholar] [CrossRef]

- Feng, J.; Guo, Z. Temperature-Frequency-Dependent Mechanical Properties Model of Epoxy Resin and Its Composites. Compos. Part B Eng. 2016, 85, 161–169. [Google Scholar] [CrossRef]

- Xiong, T.; Wang, N.; Liao, J.; Zhang, Y. Modified Boron nitride-basalt Fiber/Epoxy Resin Composite Laminates and Their Enhanced Mechanical Properties. Polym. Adv. Technol. 2021, 32, 3621–3632. [Google Scholar] [CrossRef]

- Lee, D.Y.; Kim, H.J.; Kim, H.; Lim, C.; Chung, I.; Seo, B. Polyol and Polyurethane Containing Bisphenol-Z: Synthesis and Application for Toughening Epoxy. J. Appl. Polym. Sci. 2022, 139, e53013. [Google Scholar] [CrossRef]

- Gonçalves, F.A.M.M.; Santos, M.; Cernadas, T.; Alves, P.; Ferreira, P. Influence of Fillers on Epoxy Resins Properties: A Review. J. Mater. Sci. 2022, 57, 15183–15212. [Google Scholar] [CrossRef]

- Filipe, L.; Alves, F.; Marques, A. Materiais de Construção; Publindústria: Porto, Portugal, 2013; pp. 271–310. ISBN 9789897230493. [Google Scholar]

- Deng, S.; Djukic, L.; Paton, R.; Ye, L. Thermoplastic-Epoxy Interactions and Their Potential Applications in Joining Composite Structures—A Review. Compos. Part A Appl. Sci. Manuf. 2015, 68, 121–132. [Google Scholar] [CrossRef]

- Tee, Z.Y.; Yeap, S.P.; Hassan, C.S.; Kiew, P.L. Nano and Non-Nano Fillers in Enhancing Mechanical Properties of Epoxy Resins: A Brief Review. Polym.-Plast. Technol. Mater. 2022, 61, 709–725. [Google Scholar] [CrossRef]

- Ana, M.D. Handbook of Epoxy Blends; Parameswaranpillai, J., Hameed, N., Pionteck, J., Woo, E.M., Eds.; Springer International Publishing: Cham, Switzerland, 2015; ISBN 978-3-319-18158-5. [Google Scholar]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, Thermal, and Electrical Properties of Graphene-Epoxy Nanocomposites—A Review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef]

- Kopsidas, S.; Olowojoba, G.B. Multifunctional Epoxy Composites Modified with a Graphene Nanoplatelet/Carbon Nanotube Hybrid. J. Appl. Polym. Sci. 2021, 138, 50890. [Google Scholar] [CrossRef]

- Yazman, Ş.; Uyaner, M.; Karabörk, F.; Akdemir, A. Effects of Nano Reinforcing/Matrix Interaction on Chemical, Thermal and Mechanical Properties of Epoxy Nanocomposites. J. Compos. Mater. 2021, 55, 4257–4272. [Google Scholar] [CrossRef]

- Periasamy, K.; Kandare, E.; Das, R.; Darouie, M.; Khatibi, A.A. Interfacial Engineering Methods in Thermoplastic Composites: An Overview. Polymers 2023, 15, 415. [Google Scholar] [CrossRef] [PubMed]

- Białkowska, A.; Bakar, M.; Kucharczyk, W.; Zarzyka, I. Hybrid Epoxy Nanocomposites: Improvement in Mechanical Properties and Toughening Mechanisms—A Review. Polymers 2023, 15, 1398. [Google Scholar] [CrossRef]

- Gojny, F.; Wichmann, M.; Fiedler, B.; Schulte, K. Influence of Different Carbon Nanotubes on the Mechanical Properties of Epoxy Matrix Composites—A Comparative Study. Compos. Sci. Technol. 2005, 65, 2300–2313. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Fiedler, B.; Bauhofer, W.; Schulte, K. Influence of Nano-Modification on the Mechanical and Electrical Properties of Conventional Fibre-Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1525–1535. [Google Scholar] [CrossRef]

- Singh, S.; Srivastava, V.K.; Prakash, R. Influences of Carbon Nanofillers on Mechanical Performance of Epoxy Resin Polymer. Appl. Nanosci. 2015, 5, 305–313. [Google Scholar] [CrossRef]

- Yang, T.; Lu, S.; Song, D.; Zhu, X.; Almira, I.; Liu, J.; Zhu, Y. Effect of Nanofiller on the Mechanical Properties of Carbon Fiber/Epoxy Composites under Different Aging Conditions. Materials 2021, 14, 7810. [Google Scholar] [CrossRef]

- Georgakilas, V.; Perman, J.A.; Tucek, J.; Zboril, R. Broad Family of Carbon Nanoallotropes: Classification, Chemistry, and Applications of Fullerenes, Carbon Dots, Nanotubes, Graphene, Nanodiamonds, and Combined Superstructures. Chem. Rev. 2015, 115, 4744–4822. [Google Scholar] [CrossRef]

- Feng, L.; Liu, Z. Biomedical Applications of Carbon Nanomaterials. In Biomedical Applications and Toxicology of Carbon Nanomaterials; Wiley: Weinheim, Germany, 2016; pp. 131–162. [Google Scholar]

- Zhang, B.; Kang, F.; Tarascon, J.; Kim, J. Recent Advances in Electrospun Carbon Nanofibers and Their Application in Electrochemical Energy Storage. Prog. Mater. Sci. 2016, 76, 319–380. [Google Scholar] [CrossRef]

- Adhikari, J.; Rizwan, M.; Keasberry, N.A.; Ahmed, M.U. Current Progresses and Trends in Carbon Nanomaterials-based Electrochemical and Electrochemiluminescence Biosensors. J. Chin. Chem. Soc. 2020, 67, 937–960. [Google Scholar] [CrossRef]

- Mokhena, T.C.; Matabola, K.P.; Mokhothu, T.H.; Mtibe, A.; Mochane, M.; Ndlovu, G.; Andrew, J.E. Electrospun Carbon Nanofibres: Preparation, Characterization and Application for Adsorption of Pollutants from Water and Air. Sep. Purif. Technol. 2022, 288, 120666. [Google Scholar] [CrossRef]

- Zaman, I.; Manshoor, B.; Khalid, A.; Araby, S. From Clay to Graphene for Polymer Nanocomposites—A Survey. J. Polym. Res. 2014, 21, 429. [Google Scholar] [CrossRef]

- Rashid, A.B.; Haque, M.; Islam, S.M.M.; Uddin Labib, K.M.R. Nanotechnology-Enhanced Fiber-Reinforced Polymer Composites: Recent Advancements on Processing Techniques and Applications. Heliyon 2024, 10, e24692. [Google Scholar] [CrossRef] [PubMed]

- Al-Saleh, M.H. Towards a Cost-Effective Carbon Nanofillers-Based Composites for EMI Shielding Applications. Synth. Met. 2023, 293, 117271. [Google Scholar] [CrossRef]

- Jiang, S.; Chen, Y.; Duan, G.; Mei, C.; Greiner, A.; Agarwal, S. Electrospun Nanofiber Reinforced Composites: A Review. Polym. Chem. 2018, 9, 2685–2720. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, S.; Wang, J.; Yu, A.; Wei, G. Carbon Nanofiber-Based Functional Nanomaterials for Sensor Applications. Nanomaterials 2019, 9, 1045. [Google Scholar] [CrossRef]

- Yadav, D.; Amini, F.; Ehrmann, A. Recent Advances in Carbon Nanofibers and Their Applications—A Review. Eur. Polym. J. 2020, 138, 109963. [Google Scholar] [CrossRef]

- Gao, X.; Lan, J.; Jia, X.; Cai, Q.; Yang, X. Improving Interfacial Adhesion with Epoxy Matrix Using Hybridized Carbon Nanofibers Containing Calcium Phosphate Nanoparticles for Bone Repairing. Mater. Sci. Eng. C 2016, 61, 174–179. [Google Scholar] [CrossRef]

- Santos, P.; Silva, A.P.; Reis, P.N.B. Effect of Carbon Nanofibers on the Viscoelastic Response of Epoxy Resins. Polymers 2023, 15, 821. [Google Scholar] [CrossRef]

- Dhakate, S.R.; Chaudhary, A.; Gupta, A.; Pathak, A.K.; Singh, B.P.; Subhedar, K.M.; Yokozeki, T. Excellent Mechanical Properties of Carbon Fiber Semi-Aligned Electrospun Carbon Nanofiber Hybrid Polymer Composites. RSC Adv. 2016, 6, 36715–36722. [Google Scholar] [CrossRef]

- Santos, P.; Silva, A.P.; Reis, P.N.B. Effect of Carbon Nanofibers on the Strain Rate and Interlaminar Shear Strength of Carbon/Epoxy Composites. Materials 2023, 16, 4332. [Google Scholar] [CrossRef] [PubMed]

- Bortz, D.R.; Merino, C.; Martin-Gullon, I. Carbon Nanofibers Enhance the Fracture Toughness and Fatigue Performance of a Structural Epoxy System. Compos. Sci. Technol. 2011, 71, 31–38. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Synergistic Delamination Toughening of Composites Using Multi-Scale Carbon Reinforcements. Compos. Part B Eng. 2019, 161, 18–28. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Strengthening of Composite T-Joints Using 1D and 2D Carbon Nanoparticles. Compos. Struct. 2021, 255, 112982. [Google Scholar] [CrossRef]

- Zhou, Y.; Jeelani, S.; Lacy, T. Experimental Study on the Mechanical Behavior of Carbon/Epoxy Composites with a Carbon Nanofiber-Modified Matrix. J. Compos. Mater. 2014, 48, 3659–3672. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Kinloch, A.J.; Wang, C.-H.; Mouritz, A.P. Improving the Delamination Resistance and Impact Damage Tolerance of Carbon Fibre-Epoxy Composites Using Multi-Scale Fibre Toughening. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106624. [Google Scholar] [CrossRef]

- Nimbagal, V.; Banapurmath, N.R.; Umarfarooq, M.A.; Revankar, S.; Sajjan, A.M.; Soudagar, M.E.M.; Shahapurkar, K.; Alamir, M.A.; Alarifi, I.M.; Elfasakhany, A. Mechanical and Fracture Properties of Carbon Nano Fibers/Short Carbon Fiber Epoxy Composites. Polym. Compos. 2023, 44, 3977–3989. [Google Scholar] [CrossRef]

- Wang, Y.; Yao, D.; He, Z.; Wang, D.; Zheng, Y. Enhanced Mechanical and Damping Properties of Epoxy Using Aggregated Nanoparticles Organic-Inorganic Hybrid as a Filler. Compos. Interfaces 2022, 29, 523–536. [Google Scholar] [CrossRef]

- Lake, C.L.; Lake, P.D. Carbon Nanofiber Multifunctional Mat. In Nanotube Superfiber Materials; Elsevier: Amsterdam, The Netherlands, 2014; pp. 313–331. ISBN 9781455778638. [Google Scholar]

- Ruiz-Cornejo, J.C.; Sebastián, D.; Lázaro, M.J. Synthesis and Applications of Carbon Nanofibers: A Review. Rev. Chem. Eng. 2020, 36, 493–511. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Y.; Gong, C.; Liu, B.; Wei, G. Production, Structural Design, Functional Control, and Broad Applications of Carbon Nanofiber-Based Nanomaterials: A Comprehensive Review. Chem. Eng. J. 2020, 402, 126189. [Google Scholar] [CrossRef]

- Martin-Gullon, I.; Vera, J.; Conesa, J.A.; González, J.L.; Merino, C. Differences between Carbon Nanofibers Produced Using Fe and Ni Catalysts in a Floating Catalyst Reactor. Carbon 2006, 44, 1572–1580. [Google Scholar] [CrossRef]

- Guseva Canu, I.; Bateson, T.F.; Bouvard, V.; Debia, M.; Dion, C.; Savolainen, K.; Yu, I.-J. Human Exposure to Carbon-Based Fibrous Nanomaterials: A Review. Int. J. Hyg. Environ. Health 2016, 219, 166–175. [Google Scholar] [CrossRef] [PubMed]

- Laurila, T.; Sainio, S.; Caro, M.A. Hybrid Carbon Based Nanomaterials for Electrochemical Detection of Biomolecules. Prog. Mater. Sci. 2017, 88, 499–594. [Google Scholar] [CrossRef]

- Rodriguez, N.M.; Chambers, A.; Baker, R.T.K. Catalytic Engineering of Carbon Nanostructures. Langmuir 1995, 11, 3862–3866. [Google Scholar] [CrossRef]

- Drzal, L.T.; Rich, M.J.; Koenig, M.F.; Lloyd, P.F. Adhesion of Graphite Fibers to Epoxy Matrices: II. The Effect of Fiber Finish. J. Adhes. 1983, 16, 133–152. [Google Scholar] [CrossRef]

- Yoon, S.; Lim, S.; Hong, S.; Qiao, W.; Whitehurst, D.D.; Mochida, I.; An, B.; Yokogawa, K. A Conceptual Model for the Structure of Catalytically Grown Carbon Nano-Fibers. Carbon 2005, 43, 1828–1838. [Google Scholar] [CrossRef]

- Lu, W.; He, T.; Xu, B.; He, X.; Adidharma, H.; Radosz, M.; Gasem, K.; Fan, M. Progress in Catalytic Synthesis of Advanced Carbon Nanofibers. J. Mater. Chem. A 2017, 5, 13863–13881. [Google Scholar] [CrossRef]

- Danni, N.; Sasikumar, T.; Fazil, A.A. Mechanical Properties of Electrospun CNF / PVA Nanofiber Mats as Reinforcement in Polymer Matrix Composites. Int. J. Appl. Chem. 2016, 12, 107–119. [Google Scholar]

- Teo, K.B.K.; Lee, S.; Chhowalla, M.; Semet, V.; Binh, V.T.; Groening, O.; Castignolles, M.; Loiseau, A.; Pirio, G.; Legagneux, P.; et al. Plasma Enhanced Chemical Vapour Deposition Carbon Nanotubes/Nanofibres How Uniform Do They Grow? Nanotechnology 2003, 14, 204–211. [Google Scholar] [CrossRef]

- Denysenko, I.; Ostrikov, K.; Cvelbar, U.; Mozetic, M.; Azarenkov, N.A. Carbon Nanofiber Growth in Plasma-Enhanced Chemical Vapor Deposition. J. Appl. Phys. 2008, 104, 073301. [Google Scholar] [CrossRef]

- Bao, Y.; Zhan, L.; Wang, C.; Wang, Y.; Yang, G.; Yang, J.; Qiao, W.; Ling, L. Synthesis of Carbon Nanofiber/Carbon-Foam Composite for Catalyst Support in Gas-Phase Catalytic Reactions. New Carbon Mater. 2011, 26, 341–346. [Google Scholar] [CrossRef]

- Wang, Y.; Zheng, M.; Lu, H.; Feng, S.; Ji, G.; Cao, J. Template Synthesis of Carbon Nanofibers Containing Linear Mesocage Arrays. Nanoscale Res. Lett. 2010, 5, 913–916. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Lin, D.; Liu, C.; Wang, W.; Kang, L.; Ran, F. Carbon Nanofibers Prepared by Electrospinning Accompanied with Phase-Separation Method for Supercapacitors: Effect of Thermal Treatment Temperature. J. Mater. Res. 2018, 33, 1120–1130. [Google Scholar] [CrossRef]

- Pacheco, M.; Pacheco, J.; Valdivi, R. Synthesis of Carbon Nanofibers by a Glow-Arc Discharge. In Nanofibers; InTech: London, UK, 2010; ISBN 9789537619862. [Google Scholar]

- Ci, L.; Li, Y.; Wei, B.; Liang, J.; Xu, C.; Wu, D. Preparation of Carbon Nanofibers by the Floating Catalyst Method. Carbon 2000, 38, 1933–1937. [Google Scholar] [CrossRef]

- Ismar, E.; Sarac, A.S. Carbon Nanomaterials; IGI Global: Hershey, PA, USA, 2019; Volume i, pp. 1–33. ISBN 9781522579212. [Google Scholar]

- Mohamed, A. Synthesis, Characterization, and Applications Carbon Nanofibers. In Carbon-Based Nanofillers and Their Rubber Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 243–257. ISBN 9780128132487. [Google Scholar]

- Ikuno, T.; Ryu, J.-T.; Oyama, T.; Ohkura, S.; Baek, Y.-G.; Honda, S.; Katayama, M.; Hirao, T.; Oura, K. Characterization of Low Temperature Growth Carbon Nanofibers Synthesized by Using Plasma Enhanced Chemical Vapor Deposition. Vacuum 2002, 66, 341–345. [Google Scholar] [CrossRef]

- Sacco, L.N.; Vollebregt, S. Overview of Engineering Carbon Nanomaterials Such As Carbon Nanotubes (CNTs), Carbon Nanofibers (CNFs), Graphene and Nanodiamonds and Other Carbon Allotropes inside Porous Anodic Alumina (PAA) Templates. Nanomaterials 2023, 13, 260. [Google Scholar] [CrossRef] [PubMed]

- Arora, N.; Sharma, N.N. Arc Discharge Synthesis of Carbon Nanotubes: Comprehensive Review. Diam. Relat. Mater. 2014, 50, 135–150. [Google Scholar] [CrossRef]

- Aziz, S.; Rashid, S.; Mohd Salleh, M.A. Theoretical Prediction of CNT-CF/PP Composite Tensile Properties Using Various Numerical Modeling Methods. Fuller. Nanotub. Carbon Nanostructures 2013, 21, 411–416. [Google Scholar] [CrossRef]

- Meyyappan, M. A Review of Plasma Enhanced Chemical Vapour Deposition of Carbon Nanotubes. J. Phys. D Appl. Phys. 2009, 42, 213001. [Google Scholar] [CrossRef]

- Bauman, Y.I.; Mishakov, I.V.; Rudneva, Y.V.; Plyusnin, P.E.; Shubin, Y.V.; Korneev, D.V.; Vedyagin, A.A. Formation of Active Sites of Carbon Nanofibers Growth in Self-Organizing Ni–Pd Catalyst during Hydrogen-Assisted Decomposition of 1,2-Dichloroethane. Ind. Eng. Chem. Res. 2019, 58, 685–694. [Google Scholar] [CrossRef]

- Painuli, R.; Yadav, P.K.; Raghav, S.; Kumar, D. Synthesis of Carbon Nanofibers and Its Application in Environmental Remediation. In Environmental Remediation through Carbon Based Nano Composites; Springer: Singapore, 2021; pp. 325–342. ISBN 9789811566981. [Google Scholar]

- Yang, L. Carbon Nanostructures. In Nanotechnology-Enhanced Orthopedic Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 97–120. ISBN 9780857098443. [Google Scholar]

- Fernández, A.; Peretyagin, P.; Solís, W.; Torrecillas, R.; Borrell, A. Functionalization of Carbon Nanofibres Obtained by Floating Catalyst Method. J. Nanomater. 2015, 2015, 95014. [Google Scholar] [CrossRef]

- Rana, S.; Bhattacharyya, A.; Parveen, S.; Fangueiro, R.; Alagirusamy, R.; Joshi, M. Processing and Performance of Carbon/Epoxy Multi-Scale Composites Containing Carbon Nanofibres and Single Walled Carbon Nanotubes. J. Polym. Res. 2013, 20, 314. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. A Review of Vapor Grown Carbon Nanofiber/Polymer Conductive Composites. Carbon 2009, 47, 2–22. [Google Scholar] [CrossRef]

- Li, Y.; Hori, N.; Arai, M.; Hu, N.; Liu, Y.; Fukunaga, H. Improvement of Interlaminar Mechanical Properties of CFRP Laminates Using VGCF. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2004–2012. [Google Scholar] [CrossRef]

- Hu, N.; Li, Y.; Nakamura, T.; Katsumata, T.; Koshikawa, T.; Arai, M. Reinforcement Effects of MWCNT and VGCF in Bulk Composites and Interlayer of CFRP Laminates. Compos. Part B Eng. 2012, 43, 3–9. [Google Scholar] [CrossRef]

- Song, J.H. Manufacturing Method of Carbon and Glass Fabric Composites with Dispersed Nanofibers Using Vacuum-Assisted Resin Transfer Molding. e-Polymers 2014, 14, 345–352. [Google Scholar] [CrossRef]

- Endo, M.; Kim, Y.; Hayashi, T.; Nishimura, K.; Matusita, T.; Miyashita, K.; Dresselhaus, M. Vapor-Grown Carbon Fibers (VGCFs). Carbon 2001, 39, 1287–1297. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, C.; Wang, Y.; Qin, J.; Cui, B.; Wang, Q.; Wei, H. Effect of Microstructures of Carbon Nanoproducts Grown on Carbon Fibers on the Interfacial Properties of Epoxy Composites. Langmuir 2022, 38, 2392–2400. [Google Scholar] [CrossRef]

- Patton, R.D.; Pittman, C.U., Jr.; Wang, L.; Hill, J.R. Vapor Grown Carbon Fiber Composites with Epoxy and Poly(Phenylene Sulfide) Matrices. Compos. Part A Appl. Sci. Manuf. 1999, 30, 1081–1091. [Google Scholar] [CrossRef]

- Iwahori, Y.; Ishiwata, S.; Sumizawa, T.; Ishikawa, T. Mechanical Properties Improvements in Two-Phase and Three-Phase Composites Using Carbon Nano-Fiber Dispersed Resin. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1430–1439. [Google Scholar] [CrossRef]

- Pervin, F.; Zhou, Y.; Rangari, V.K.; Jeelani, S. Testing and Evaluation on the Thermal and Mechanical Properties of Carbon Nano Fiber Reinforced SC-15 Epoxy. Mater. Sci. Eng. A 2005, 405, 246–253. [Google Scholar] [CrossRef]

- Zhamu, A.; Hou, Y.; Zhong, W.-H.; Stone, J.J.; Li, J.; Lukehart, C.M. Properties of a Reactive-graphitic-carbon-nanofibers-reinforced Epoxy. Polym. Compos. 2007, 28, 605–611. [Google Scholar] [CrossRef]

- Bal, S. Experimental Study of Mechanical and Electrical Properties of Carbon Nanofiber/Epoxy Composites. Mater. Des. (1980–2015) 2010, 31, 2406–2413. [Google Scholar] [CrossRef]

- Ardanuy, M.; Rodríguez-Perez, M.A.; Algaba, I. Electrical Conductivity and Mechanical Properties of Vapor-Grown Carbon Nanofibers/Trifunctional Epoxy Composites Prepared by Direct Mixing. Compos. Part B Eng. 2011, 42, 675–681. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Rangari, V.K.; Jeelani, S. Fabrication and Evaluation of Carbon Nano Fiber Filled Carbon/Epoxy Composite. Mater. Sci. Eng. A 2006, 426, 221–228. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Jeelani, S.; Mallick, P.K. Improvement in Mechanical Properties of Carbon Fabric–Epoxy Composite Using Carbon Nanofibers. J. Mater. Process. Technol. 2008, 198, 445–453. [Google Scholar] [CrossRef]

- Green, K.J.; Dean, D.R.; Vaidya, U.K.; Nyairo, E. Multiscale Fiber Reinforced Composites Based on a Carbon Nanofiber/Epoxy Nanophased Polymer Matrix: Synthesis, Mechanical, and Thermomechanical Behavior. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1470–1475. [Google Scholar] [CrossRef]

- de Miranda, A.N.; Pardini, L.C.; dos Santos, C.A.M.; Vieira, R. Evaluation of Carbon Fiber Composites Modified by in Situ Incorporation of Carbon Nanofibers. Mater. Res. 2011, 14, 560–563. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, W.; Zhao, Y.; Xi, M.; Xu, T.; Fong, H. Nano-Epoxy Resins Containing Electrospun Carbon Nanofibers and the Resulting Hybrid Multi-Scale Composites. Compos. Part B Eng. 2014, 58, 43–53. [Google Scholar] [CrossRef]

- Singer, G.; Rennhofer, H.; Sinn, G.; Unterlass, M.M.; Wendrinsky, J.; Windberger, U.; Lichtenegger, H.C. Processing of Carbon Nanotubes and Carbon Nanofibers towards High Performance Carbon Fiber Reinforced Polymers. Key Eng. Mater. 2017, 742, 31–37. [Google Scholar] [CrossRef]

- Xu, L.R.; Bhamidipati, V.; Zhong, W.-H.; Li, J.; Lukehart, C.M.; Lara-Curzio, E.; Liu, K.C.; Lance, M.J. Mechanical Property Characterization of a Polymeric Nanocomposite Reinforced by Graphitic Nanofibers with Reactive Linkers. J. Compos. Mater. 2004, 38, 1563–1582. [Google Scholar] [CrossRef]

- Sui, G.; Zhong, W.H.; Liu, M.C.; Wu, P.H. Enhancing Mechanical Properties of an Epoxy Resin Using “Liquid Nano-Reinforcements”. Mater. Sci. Eng. A 2009, 512, 139–142. [Google Scholar] [CrossRef]

- Sancaktar, E.; Aussawasathien, D. Nanocomposites of Epoxy with Electrospun Carbon Nanofibers: Mechanical Behavior. J. Adhes. 2009, 85, 160–179. [Google Scholar] [CrossRef]

- Zhang, J.; Niu, H.; Zhou, J.; Wang, X.; Lin, T. Synergistic Effects of PEK-C/VGCNF Composite Nanofibres on a Trifunctional Epoxy Resin. Compos. Sci. Technol. 2011, 71, 1060–1067. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, T.; Cheung, S.C.P.; Wang, C.H. The Effect of Carbon Nanofibres on Self-Healing Epoxy/Poly(ε-Caprolactone) Blends. Compos. Sci. Technol. 2012, 72, 1952–1959. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Esmkhani, M.; Vahedi, F.; Shahverdi, H.R. Improvement of Mechanical and Electrical Properties of Epoxy Resin with Carbon Nanofibers. Iran. Polym. J. 2013, 22, 721–727. [Google Scholar] [CrossRef]

- Ahmadi, M.; Masoomi, M.; Safi, S. Mechanical Property Characterization of Carbon Nanofiber/Epoxy Nanocomposites Reinforced by GMA-Grafted UHMWPE Fibers. Compos. Part B Eng. 2015, 83, 43–49. [Google Scholar] [CrossRef]

- Zeltmann, S.E.; Poveda, R.L.; Gupta, N. Accelerated Environmental Degradation and Residual Flexural Analysis of Carbon Nanofiber Reinforced Composites. Polym. Degrad. Stab. 2015, 121, 348–358. [Google Scholar] [CrossRef]

- Bortz, D.R.; Merino, C.; Martin-Gullon, I. Mechanical Characterization of Hierarchical Carbon Fiber/Nanofiber Composite Laminates. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1584–1591. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, L.; Rahman, A.; Zhou, Z.; Wu, X.-F.; Fong, H. Hybrid Multi-Scale Epoxy Composite Made of Conventional Carbon Fiber Fabrics with Interlaminar Regions Containing Electrospun Carbon Nanofiber Mats. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2036–2042. [Google Scholar] [CrossRef]

- Sarim, A.; Zhang, B.M.; Wang, C.C. Mechanical Enhancement of Carbon Fiber/Epoxy Composites Based on Carbon Nano Fibers by Using Spraying Methodology. Appl. Mech. Mater. 2012, 245, 203–208. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, Y.; Zhou, Z.; Rahman, A.; Wu, X.-F.; Wu, W.; Xu, T.; Fong, H. Fabrication and Mechanical Properties of Hybrid Multi-Scale Epoxy Composites Reinforced with Conventional Carbon Fiber Fabrics Surface-Attached with Electrospun Carbon Nanofiber Mats. Compos. Part B Eng. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Jie, C.; Long, H.; Peng, X.; Xiang, X. Mechanical Properties of Carbon/Carbon Composites with the Fibre/Matrix Interface Modified by Carbon Nanofibers. Mater. Sci. Eng. A 2016, 656, 21–26. [Google Scholar] [CrossRef]

- Kattaguri, R.; Fulmali, A.O.; Prusty, R.K.; Ray, B.C. Effects of Acid, Alkaline, and Seawater Aging on the Mechanical and Thermomechanical Properties of Glass Fiber/Epoxy Composites Filled with Carbon Nanofibers. J. Appl. Polym. Sci. 2020, 137, 48434. [Google Scholar] [CrossRef]

- De, S.; Fulmali, A.O.; Nuli, K.C.; Prusty, R.K.; Prusty, B.G.; Ray, B.C. Improving Delamination Resistance of Carbon Fiber Reinforced Polymeric Composite by Interface Engineering Using Carbonaceous Nanofillers through Electrophoretic Deposition: An Assessment at Different In-service Temperatures. J. Appl. Polym. Sci. 2021, 138, 50208. [Google Scholar] [CrossRef]

- Kar, R.N.; Fulmali, A.O.; Ganesh Gupta K, B.N.V.S.; Prusty, R.K.; Ray, B.C. Effect of In-Situ Temperature and Loading Rate on the out-of-Plane Performance of Carbon Nanofiber Embedded Glass Fiber/Epoxy Composite. Mater. Today Proc. 2022, 62, 6115–6119. [Google Scholar] [CrossRef]

- Zhu, J.; Wei, S.; Ryu, J.; Budhathoki, M.; Liang, G.; Guo, Z. In Situ Stabilized Carbon Nanofiber (CNF) Reinforced Epoxy Nanocomposites. J. Mater. Chem. 2010, 20, 4937. [Google Scholar] [CrossRef]

- Rana, S.; Alagirusamy, R.; Joshi, M. Development of Carbon Nanofibre Incorporated Three Phase Carbon/Epoxy Composites with Enhanced Mechanical, Electrical and Thermal Properties. Compos. Part A Appl. Sci. Manuf. 2011, 42, 439–445. [Google Scholar] [CrossRef]

- Rana, S.; Alagirusamy, R.; Joshi, M. Effect of Carbon Nanofiber Dispersion on the Tensile Properties of Epoxy Nanocomposites. J. Compos. Mater. 2011, 45, 2247–2256. [Google Scholar] [CrossRef]

- Le, B.; Fu, G.; Khaliq, J.; Huo, D.; Shyha, I. Experimental Investigation on Thermomechanical Properties and Micro-Machinability of Carbon Nanofibre Reinforced Epoxy Nanocomposites. J. Manuf. Process. 2023, 99, 781–793. [Google Scholar] [CrossRef]

- Sun, L.-H.; Ounaies, Z.; Gao, X.-L.; Whalen, C.A.; Yang, Z.-G. Preparation, Characterization, and Modeling of Carbon Nanofiber/Epoxy Nanocomposites. J. Nanomater. 2011, 2011, 307589. [Google Scholar] [CrossRef]

- Choi, Y.-K.; Sugimoto, K.; Song, S.-M.; Gotoh, Y.; Ohkoshi, Y.; Endo, M. Mechanical and Physical Properties of Epoxy Composites Reinforced by Vapor Grown Carbon Nanofibers. Carbon 2005, 43, 2199–2208. [Google Scholar] [CrossRef]

- Zhou, Y.; Pervin, F.; Jeelani, S. Effect Vapor Grown Carbon Nanofiber on Thermal and Mechanical Properties of Epoxy. J. Mater. Sci. 2007, 42, 7544–7553. [Google Scholar] [CrossRef]

- Rana, S.; Alagirusamy, R.; Fangueiro, R.; Joshi, M. Effect of Carbon Nanofiber Functionalization on the In-plane Mechanical Properties of Carbon/Epoxy Multiscale Composites. J. Appl. Polym. Sci. 2012, 125, 1951–1958. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Y.; Wang, P.; Li, Y.; Jiang, Q.; Hu, X.; Wei, Y.; Qiu, Y.; Shahabadi, S.I.S.; Lu, X. A Biomimetic Approach to Improve the Dispersibility, Interfacial Interactions and Toughening Effects of Carbon Nanofibers in Epoxy Composites. Compos. Part B Eng. 2017, 113, 197–205. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, Z.; Zhu, W.; Wan, B.; Han, B.; Cai, G.; Yin, X.; Bai, Y. Hygrothermal Aging Behavior and Aging Mechanism of Carbon Nanofibers/Epoxy Composites. Constr. Build. Mater. 2021, 294, 123538. [Google Scholar] [CrossRef]

- Anjabin, R.; Khosravi, H. Property Improvement of a Fibrous Composite Using Functionalized Carbon Nanofibers. Polym. Compos. 2019, 40, 4281–4288. [Google Scholar] [CrossRef]

- Ying, Z.; Du, J.-H.; Bai, S.; Li, F.; Liu, C.; Cheng, H.-M. Mechanical Properties of Surfactant-Coating Carbon Nanofiber/Epoxy Composite. Int. J. Nanosci. 2002, 1, 425–430. [Google Scholar] [CrossRef]

- Park, J.-M.; Kim, D.-S.; Kim, S.-J.; Kim, P.-G.; Yoon, D.-J.; DeVries, K.L. Inherent Sensing and Interfacial Evaluation of Carbon Nanofiber and Nanotube/Epoxy Composites Using Electrical Resistance Measurement and Micromechanical Technique. Compos. Part B Eng. 2007, 38, 847–861. [Google Scholar] [CrossRef]

- Rana, S.; Alagirusamy, R.; Joshi, M. Mechanical Behavior of Carbon Nanofibre-reinforced Epoxy Composites. J. Appl. Polym. Sci. 2010, 118, 2276–2283. [Google Scholar] [CrossRef]

- Zhang, G.; Karger-Kocsis, J.; Zou, J. Synergetic Effect of Carbon Nanofibers and Short Carbon Fibers on the Mechanical and Fracture Properties of Epoxy Resin. Carbon 2010, 48, 4289–4300. [Google Scholar] [CrossRef]

- Wang, D.H.; Sihn, S.; Roy, A.K.; Baek, J.-B.; Tan, L.-S. Nanocomposites Based on Vapor-Grown Carbon Nanofibers and an Epoxy: Functionalization, Preparation and Characterization. Eur. Polym. J. 2010, 46, 1404–1416. [Google Scholar] [CrossRef]

- Nie, Y.; Hübert, T. Effect of Carbon Nanofiber (CNF) Silanization on the Properties of CNF/Epoxy Nanocomposites. Polym. Int. 2011, 60, 1574–1580. [Google Scholar] [CrossRef]

- Chaos-Morán, R.; Salazar, A.; Ureña, A. Mechanical Analysis of Carbon Nanofiber/Epoxy Resin Composites. Polym. Compos. 2011, 32, 1640–1651. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Daneshvar, A.; Akbari, S.; Chitsazzadeh, M. The Use of Carbon Nanofibers for Thermal Residual Stress Reduction in Carbon Fiber/Epoxy Laminated Composites. Carbon 2013, 59, 255–263. [Google Scholar] [CrossRef]

- Sánchez, M.; Rams, J.; Campo, M.; Jiménez-Suárez, A.; Ureña, A. Characterization of Carbon Nanofiber/Epoxy Nanocomposites by the Nanoindentation Technique. Compos. Part B Eng. 2011, 42, 638–644. [Google Scholar] [CrossRef]

- Yang, Z.; McElrath, K.; Bahr, J.; D’Souza, N.A. Effect of Matrix Glass Transition on Reinforcement Efficiency of Epoxy-Matrix Composites with Single Walled Carbon Nanotubes, Multi-Walled Carbon Nanotubes, Carbon Nanofibers and Graphite. Compos. Part B Eng. 2012, 43, 2079–2086. [Google Scholar] [CrossRef]

- Colloca, M.; Gupta, N.; Porfiri, M. Tensile Properties of Carbon Nanofiber Reinforced Multiscale Syntactic Foams. Compos. Part B Eng. 2013, 44, 584–591. [Google Scholar] [CrossRef]

- Aziz, I.; Duran, H.; Saleem, M.; Yameen, B.; Arshad, S.N. The Role of Interface on Dynamic Mechanical Properties, Dielectric Performance, Conductivity, and Thermal Stability of Electrospun Carbon Nanofibers Reinforced Epoxy. Polym. Compos. 2021, 42, 4366–4379. [Google Scholar] [CrossRef]

- Chanda, A.; Sinha, S.K.; Datla, N.V. The Influence of Fiber Alignment, Structure and Concentration on Mechanical Behavior of Carbon Nanofiber/Epoxy Composites: Experimental and Numerical Study. Polym. Compos. 2021, 42, 1155–1173. [Google Scholar] [CrossRef]

- Palmeri, M.J.; Putz, K.W.; Ramanathan, T.; Brinson, L.C. Multi-Scale Reinforcement of CFRPs Using Carbon Nanofibers. Compos. Sci. Technol. 2011, 71, 79–86. [Google Scholar] [CrossRef]

- Poveda, R.L.; Gupta, N. Carbon-Nanofiber-Reinforced Syntactic Foams: Compressive Properties and Strain Rate Sensitivity. JOM 2014, 66, 66–77. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Kashani, A.R.S.; Mosalmani, R. A Dynamic Constitutive-Micromechanical Model to Predict the Strain Rate-Dependent Mechanical Behavior of Carbon Nanofiber/Epoxy Nanocomposites. Iran. Polym. J. 2016, 25, 487–501. [Google Scholar] [CrossRef]

- Zhou, Z.; Gao, D.; Lin, G.; Sun, W. Static and Dynamic Mechanical Properties of Epoxy Nanocomposites Reinforced by Hybridization with Carbon Nanofibers and Block Ionomers. Eng. Fract. Mech. 2022, 271, 108638. [Google Scholar] [CrossRef]

- Pina dos Santos, P.S.; Maceiras, A.; Valvez, S.; Reis, P.N.B. Mechanical Characterization of Different Epoxy Resins Enhanced with Carbon Nanofibers. Frat. Integrità Strutt. 2020, 15, 198–212. [Google Scholar] [CrossRef]

- Santos, P.; Silva, A.P.; Reis, P. Effect of Carbon Nanofibers on the Viscoelastic Response of Carbon/Epoxy Composites. J. Reinf. Plast. Compos. 2023, 07316844231203787. [Google Scholar] [CrossRef]

- Hossain, M.K.; Hossain, M.E.; Dewan, M.W.; Hosur, M.; Jeelani, S. Effects of Carbon Nanofibers (CNFs) on Thermal and Interlaminar Shear Responses of E-Glass/Polyester Composites. Compos. Part B Eng. 2013, 44, 313–320. [Google Scholar] [CrossRef]

- Subramaniyan, A.K.; Sun, C.T. Enhancing Compressive Strength of Unidirectional Polymeric Composites Using Nanoclay. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2257–2268. [Google Scholar] [CrossRef]

- Fan, Z.; Santare, M.H.; Advani, S.G. Interlaminar Shear Strength of Glass Fiber Reinforced Epoxy Composites Enhanced with Multi-Walled Carbon Nanotubes. Compos. Part A Appl. Sci. Manuf. 2008, 39, 540–554. [Google Scholar] [CrossRef]

- Rodriguez, A.J.; Guzman, M.E.; Lim, C.-S.; Minaie, B. Mechanical Properties of Carbon Nanofiber/Fiber-Reinforced Hierarchical Polymer Composites Manufactured with Multiscale-Reinforcement Fabrics. Carbon 2011, 49, 937–948. [Google Scholar] [CrossRef]

- Khan, S.U.; Kim, J.K. Interlaminar Shear Properties of CFRP Composites with CNF-Bucky Paper Interleaves. In Proceedings of the ICCM International Conferences on Composite Materials, Jeju, Republic of Korea, 21–26 August 2011; pp. 1–6. Available online: https://hdl.handle.net/1783.1/54411 (accessed on 21 July 2024).

- Khan, S.U.; Kim, J.-K. Improved Interlaminar Shear Properties of Multiscale Carbon Fiber Composites with Bucky Paper Interleaves Made from Carbon Nanofibers. Carbon 2012, 50, 5265–5277. [Google Scholar] [CrossRef]

- Anand, A.; Harshe, R.; Joshi, M. On the Processing and Properties of Carbon Nanofiber Reinforced Hybrid Structural Composites. J. Compos. Mater. 2013, 47, 2937–2943. [Google Scholar] [CrossRef]

- Ma, L.; Wu, L.; Cheng, X.; Zhuo, D.; Weng, Z.; Wang, R. Improving the Interlaminar Properties of Polymer Composites Using a Situ Accumulation Method to Construct the Multi-Scale Reinforcement of Carbon Nanofibers/Carbon Fibers. Compos. Part A Appl. Sci. Manuf. 2015, 72, 65–74. [Google Scholar] [CrossRef]

- Yao, H.; Zhou, G.; Wang, W.; Peng, M. Effect of Polymer-Grafted Carbon Nanofibers and Nanotubes on the Interlaminar Shear Strength and Flexural Strength of Carbon Fiber/Epoxy Multiscale Composites. Compos. Struct. 2018, 195, 288–296. [Google Scholar] [CrossRef]

- Hsiao, K.; Johnson, M.; Kirmse, S.; Ranabhat, B. Carbon Nanofiber Z-Threaded Carbon Fiber Reinforced Polymer Composite (ZT-CFRP) Laminate Parts Produced Using a Magnetic Compaction Force Assisted Additive Manufacturing (MCFA-AM) Technique. In Proceedings of the SAMPE 2020|Virtual Series; NA SAMPE, Virtual, 8 June 2020; Volume 2020. [Google Scholar]

- He, Y.; Ju, S.; Duan, K.; Tang, J.; Bai, S.; Jiang, D.; Pei, Y.; Zhang, J. Tuning the Through-Thickness Orientation of 1D Nanocarbons to Enhance the Electrical Conductivity and ILSS of Hierarchical CFRP Composites. Sci. Eng. Compos. Mater. 2021, 28, 453–465. [Google Scholar] [CrossRef]

- Quaresimin, M.; Varley, R.J. Understanding the Effect of Nano-Modifier Addition upon the Properties of Fibre Reinforced Laminates. Compos. Sci. Technol. 2008, 68, 718–726. [Google Scholar] [CrossRef]

- Arai, M.; Matsushita, K.; Hirota, S. Criterion for Interlaminar Strength of CFRP Laminates Toughened with Carbon Nanofiber Interlayer. Compos. Part A Appl. Sci. Manuf. 2011, 42, 703–711. [Google Scholar] [CrossRef]

- Srikanth, I.; Kumar, S.; Singh, V.; Rangababu, B.; Ghosal, P.; Subrahmanyam, C. Effect of Carbon Nanofibre Addition on the Mechanical Properties of Different V f Carbon-Epoxy Composites. Bull. Mater. Sci. 2015, 38, 309–317. [Google Scholar] [CrossRef]

- Taheri-Behrooz, F.; Esmkhani, M.; Yaghoobi-Chatroodi, A.; Ghoreishi, S.M. Out-of-Plane Shear Properties of Glass/Epoxy Composites Enhanced with Carbon-Nanofibers. Polym. Test. 2016, 55, 278–286. [Google Scholar] [CrossRef]

- Kirmse, S.; Hsiao, K.T. Enhancing the Interlaminar Shear Strength of Unidirectional Carbon Fiber Reinforced Plastic (CFRP) Laminate Using a Nanofiber Z-Threading Strategy. In Proceedings of the CAMX 2018 (The Composites and Advanced Materials Expo), Dallas, TX, USA, 15–18 October 2018. [Google Scholar]

- Kirmse, S.; Ranabhat, B.; Hsiao, K. A Preliminary Study of the Electrical and Interlaminar Shear Properties of a Porous CFRP Composite Laminate Containing Carbon Nanofiber Z-Threads. In Proceedings of the CAMX 2019; NA SAMPE, Anaheim, CA, USA, 23–26 September 2019. [Google Scholar]

- Kirmse, S.; Ranabhat, B.; Hsiao, K.-T. Experimental and Analytical Investigation on the Interlaminar Shear Strength of Carbon Fiber Composites Reinforced with Carbon Nanofiber Z-Threads. Mater. Today Commun. 2020, 25, 101512. [Google Scholar] [CrossRef]

- Mrzljak, S.; Zanghellini, B.; Gerdes, L.; Helwing, R.; Schuller, R.; Sinn, G.; Lichtenegger, H.; Walther, F.; Rennhofer, H. Effect of Carbon Nanofibre Orientation on Fatigue Properties of Carbon Fibre-Reinforced Polymers. J. Compos. Mater. 2023, 57, 1149–1164. [Google Scholar] [CrossRef]

- Arai, M.; Noro, Y.; Sugimoto, K.; Endo, M. Mode I and Mode II Interlaminar Fracture Toughness of CFRP Laminates Toughened by Carbon Nanofiber Interlayer. Compos. Sci. Technol. 2008, 68, 516–525. [Google Scholar] [CrossRef]

- Zhu, Y.; Bakis, C.E.; Adair, J.H. Effects of Carbon Nanofiller Functionalization and Distribution on Interlaminar Fracture Toughness of Multi-Scale Reinforced Polymer Composites. Carbon 2012, 50, 1316–1331. [Google Scholar] [CrossRef]

- Yokozeki, T.; Iwahori, Y.; Ishibashi, M.; Yanagisawa, T.; Imai, K.; Arai, M.; Takahashi, T.; Enomoto, K. Fracture Toughness Improvement of CFRP Laminates by Dispersion of Cup-Stacked Carbon Nanotubes. Compos. Sci. Technol. 2009, 69, 2268–2273. [Google Scholar] [CrossRef]

- Gude, M.R.; Prolongo, S.G.; Gómez-del Río, T.; Ureña, A. Mode-I Adhesive Fracture Energy of Carbon Fibre Composite Joints with Nanoreinforced Epoxy Adhesives. Int. J. Adhes. Adhes. 2011, 31, 695–703. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Karapappas, P.; Loutas, T.; Vavouliotis, A.; Paipetis, A.; Tsotra, P. Interlaminar Fracture Toughness of Carbon Fibre-Reinforced Polymer Laminates with Nano- and Micro-Fillers. Strain 2011, 47, e269–e282. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Zhang, J.; Mouritz, A.P.; Wang, C.H. Improving the Toughness and Electrical Conductivity of Epoxy Nanocomposites by Using Aligned Carbon Nanofibres. Compos. Sci. Technol. 2015, 117, 146–158. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Hierarchical Mode I and Mode II Interlaminar Toughening of Z-Pinned Composites Using 1D and 2D Carbon Nanofillers. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105470. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Mouritz, A.P.; Wang, C.H. Enhancing Fatigue Resistance and Damage Characterisation in Adhesively-Bonded Composite Joints by Carbon Nanofibres. Compos. Sci. Technol. 2017, 149, 116–126. [Google Scholar] [CrossRef]

- Kostopoulos, V.; Tsotra, P.; Karapappas, P.; Vavouliotis, A.; Tsantzalis, S.; Friedrich, K. Enhancement of the Mechanical Performance of Carbon Fiber Reinforced Epoxy Resin Composites by the Introduction of Carbon Nano-Fibers (CNF). In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 14th AIAA/ASME/AHS Adaptive Structures Conference 7th, Newport, RI, USA, 1–4 May 2006; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2006; Volume 5, pp. 3273–3282. [Google Scholar]

- Kostopoulos, V.; Tsotra, P.; Karapappas, P.; Tsantzalis, S.; Vavouliotis, A.; Loutas, T.H.; Paipetis, A.; Friedrich, K.; Tanimoto, T. Mode I Interlaminar Fracture of CNF or/and PZT Doped CFRPs via Acoustic Emission Monitoring. Compos. Sci. Technol. 2007, 67, 822–828. [Google Scholar] [CrossRef]

- Tsantzalis, S.; Karapappas, P.; Vavouliotis, A.; Tsotra, P.; Kostopoulos, V.; Tanimoto, T.; Friedrich, K. On the Improvement of Toughness of CFRPs with Resin Doped with CNF and PZT Particles. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1159–1162. [Google Scholar] [CrossRef]