Effect of Cooling Method on Physical and Mechanical Properties of PVA Fiber-Reinforced High-Strength Concrete Exposed to High Temperature

Abstract

1. Introduction

2. Test Profile

2.1. Specimen Design and Preparation

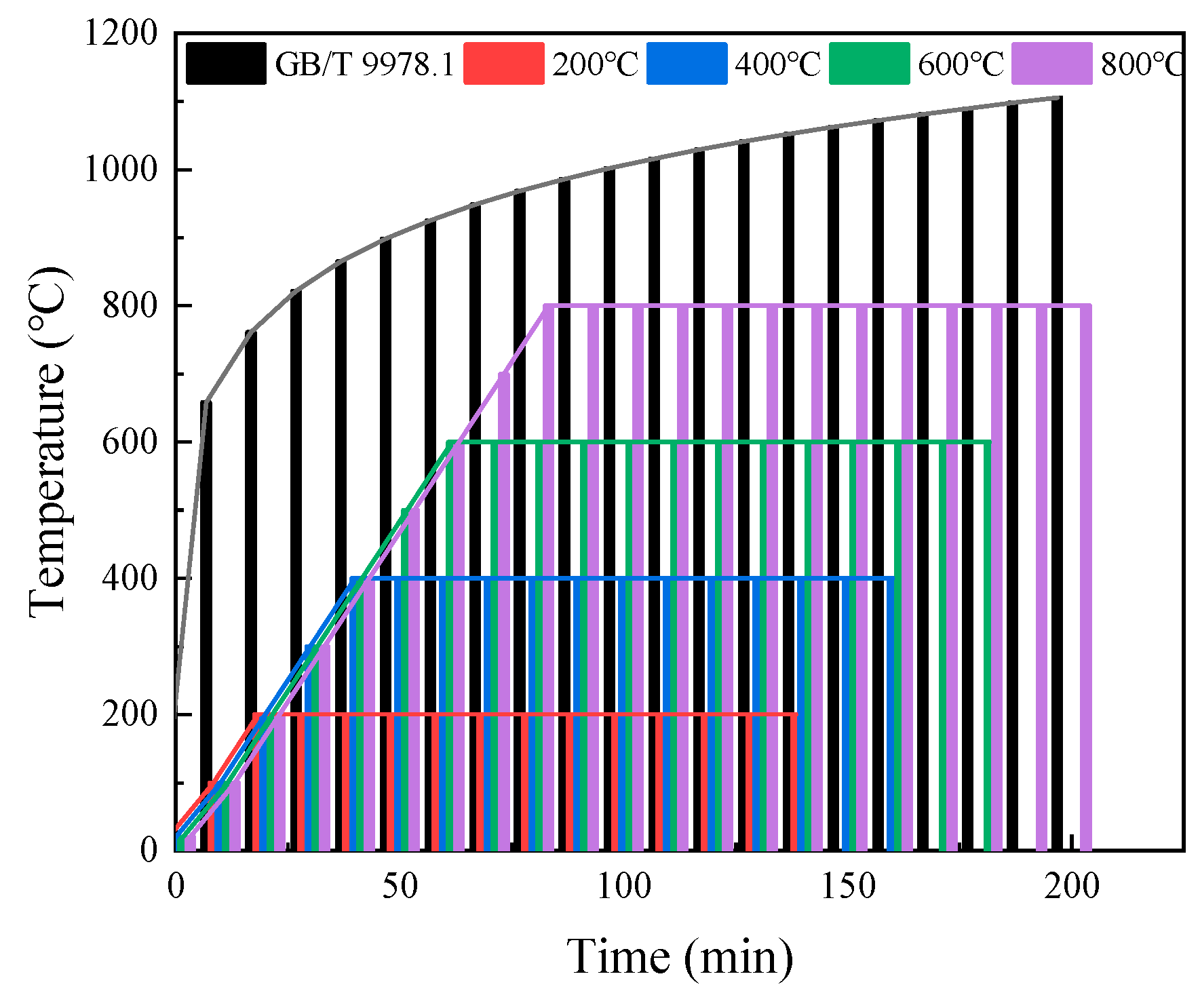

2.2. High Temperature Cooling Test

2.3. Mechanical Property Test

2.3.1. Compressive Strength Remaining in Specimens following Exposure to High Temperatures

2.3.2. Residual Flexural Strength of Specimens after High-Temperature Action

3. Test Results and Analysis

3.1. Appearance Form

3.2. Mass Loss Rate

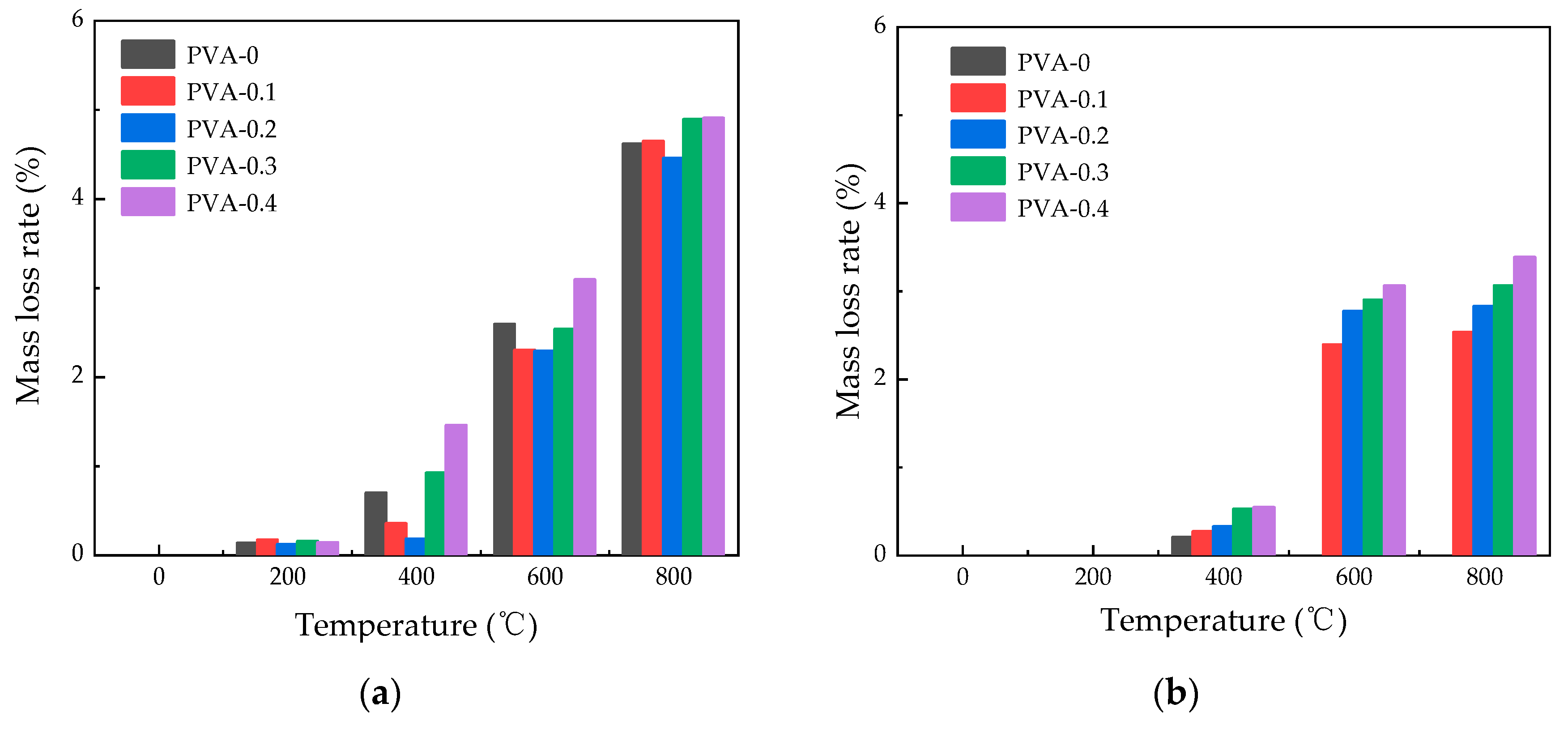

3.2.1. The Mass Loss Rate of Specimens Using Different Cooling Methods

3.2.2. Influence of Heating Temperature on Mass Loss Rate

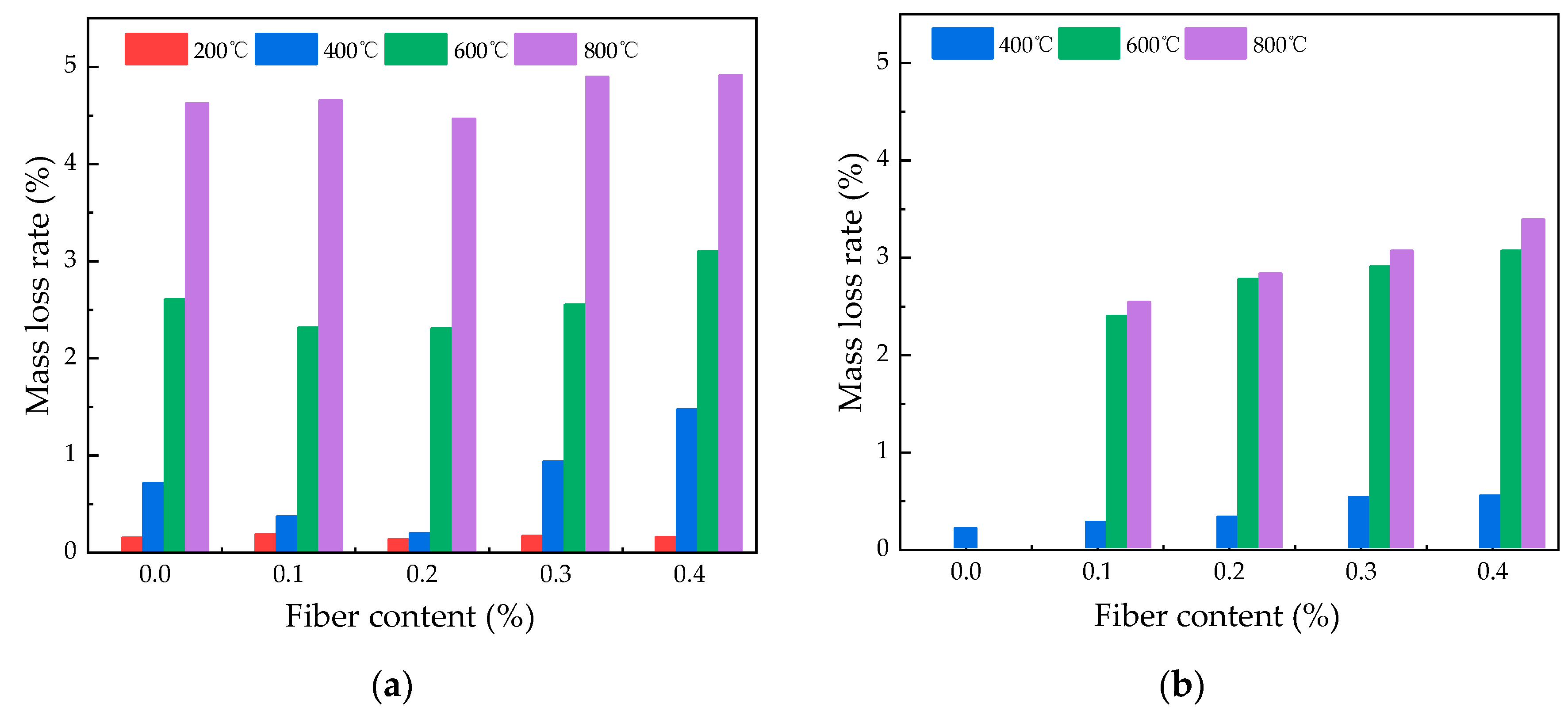

3.2.3. Effect of Fiber Content on Mass Loss Rate

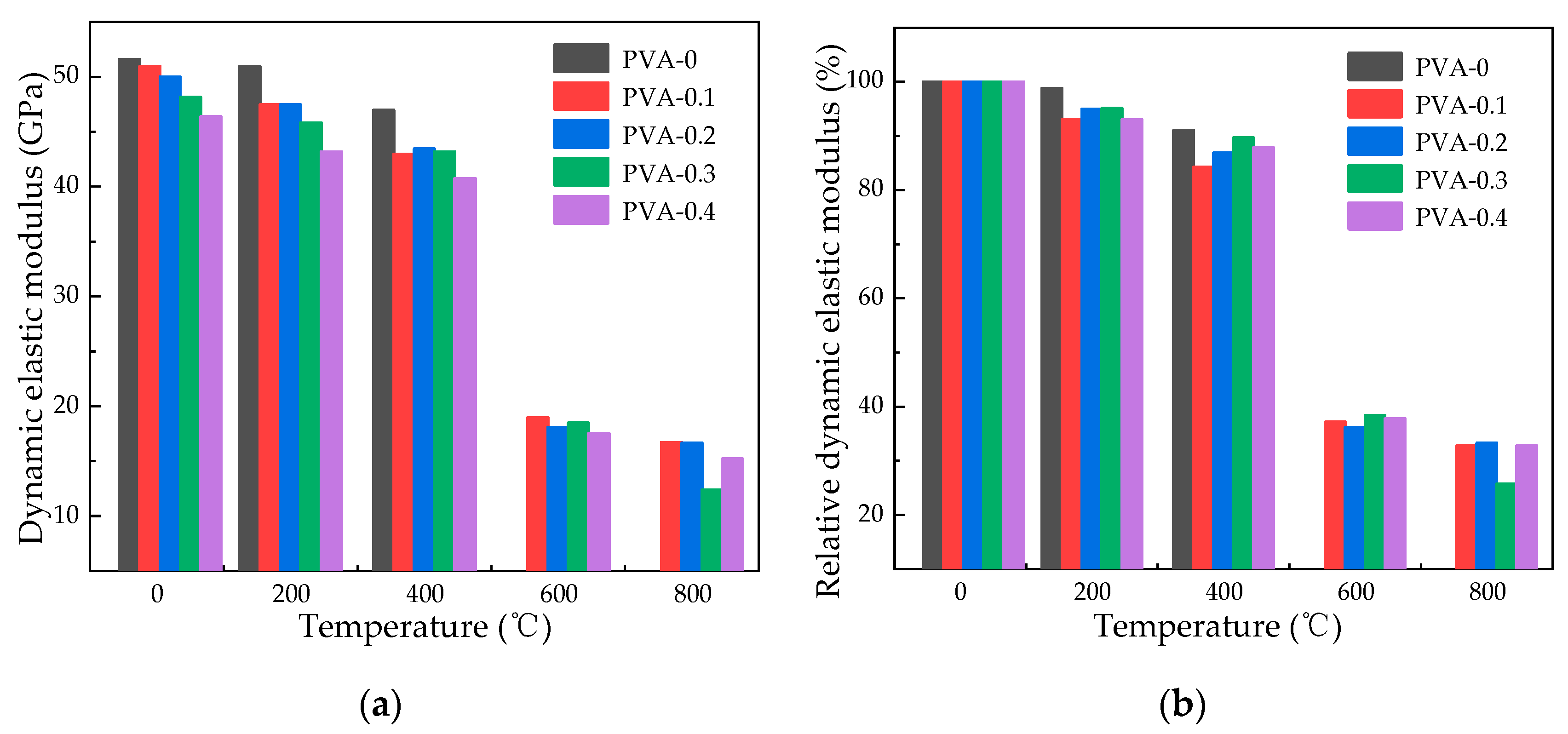

3.3. Dynamic Elastic Modulus

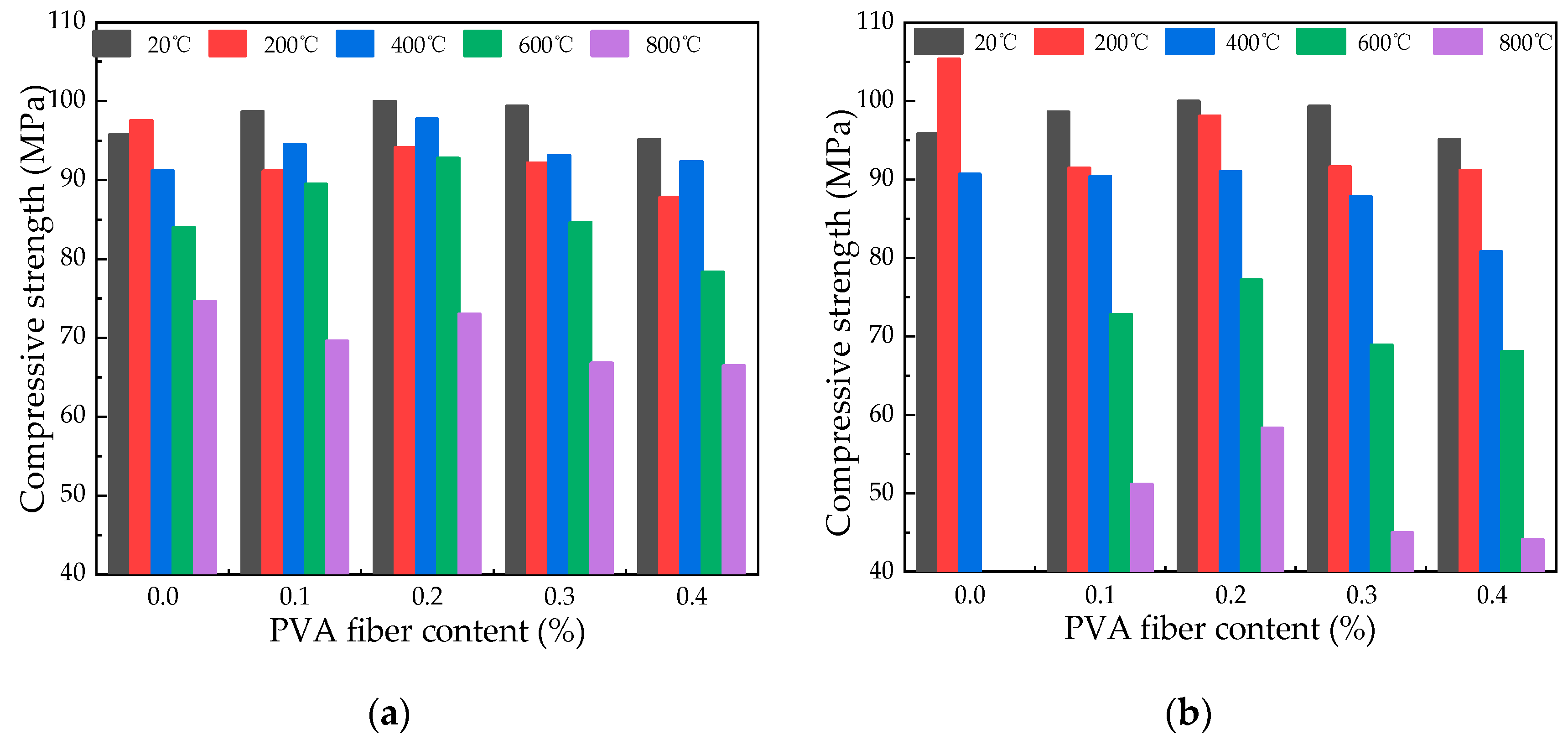

3.4. Compressive Strength

3.4.1. The Compressive Strength Specimens Using Different Cooling Methods

3.4.2. Effect of Temperature on Compressive Strength

3.4.3. Effect of Fiber Content on Compressive Strength

3.4.4. Relation between Compressive Strength and Heating Temperature

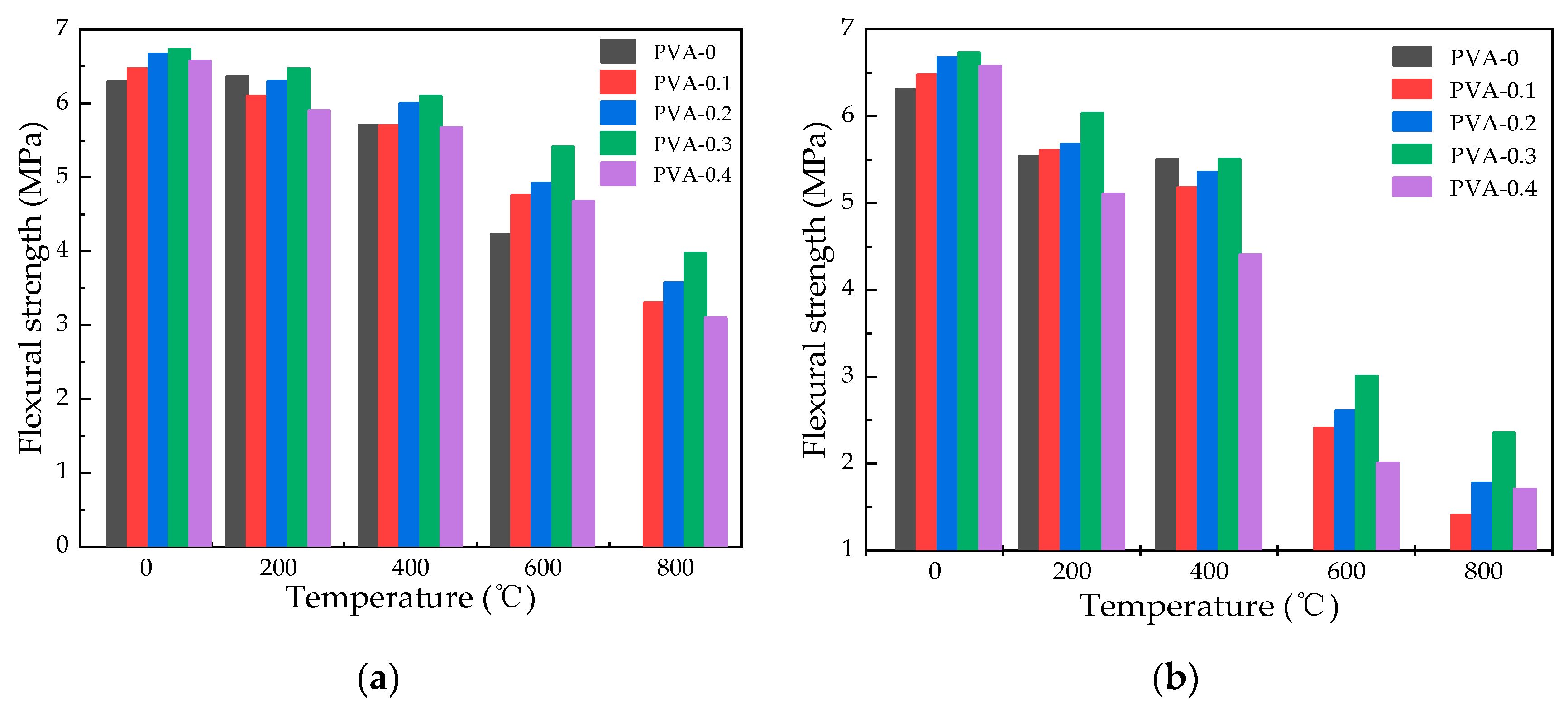

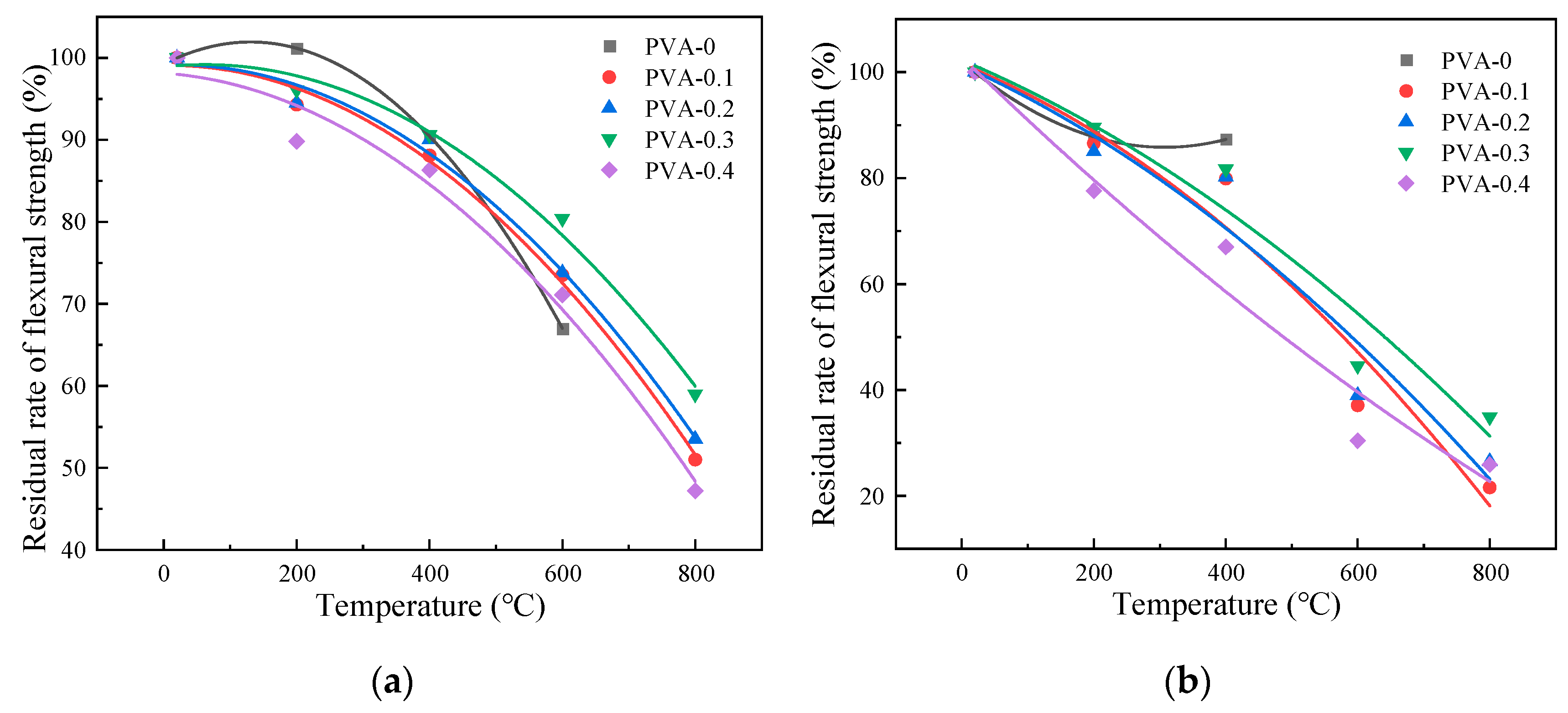

3.5. Flexural Strength

3.5.1. Flexural Strength of Specimens Using Different Cooling Methods

3.5.2. Influence of Heating Temperature on Flexural Strength

3.5.3. Effect of Fiber Content on Flexural Strength

3.5.4. Relation between Flexural Strength and Heating Temperature

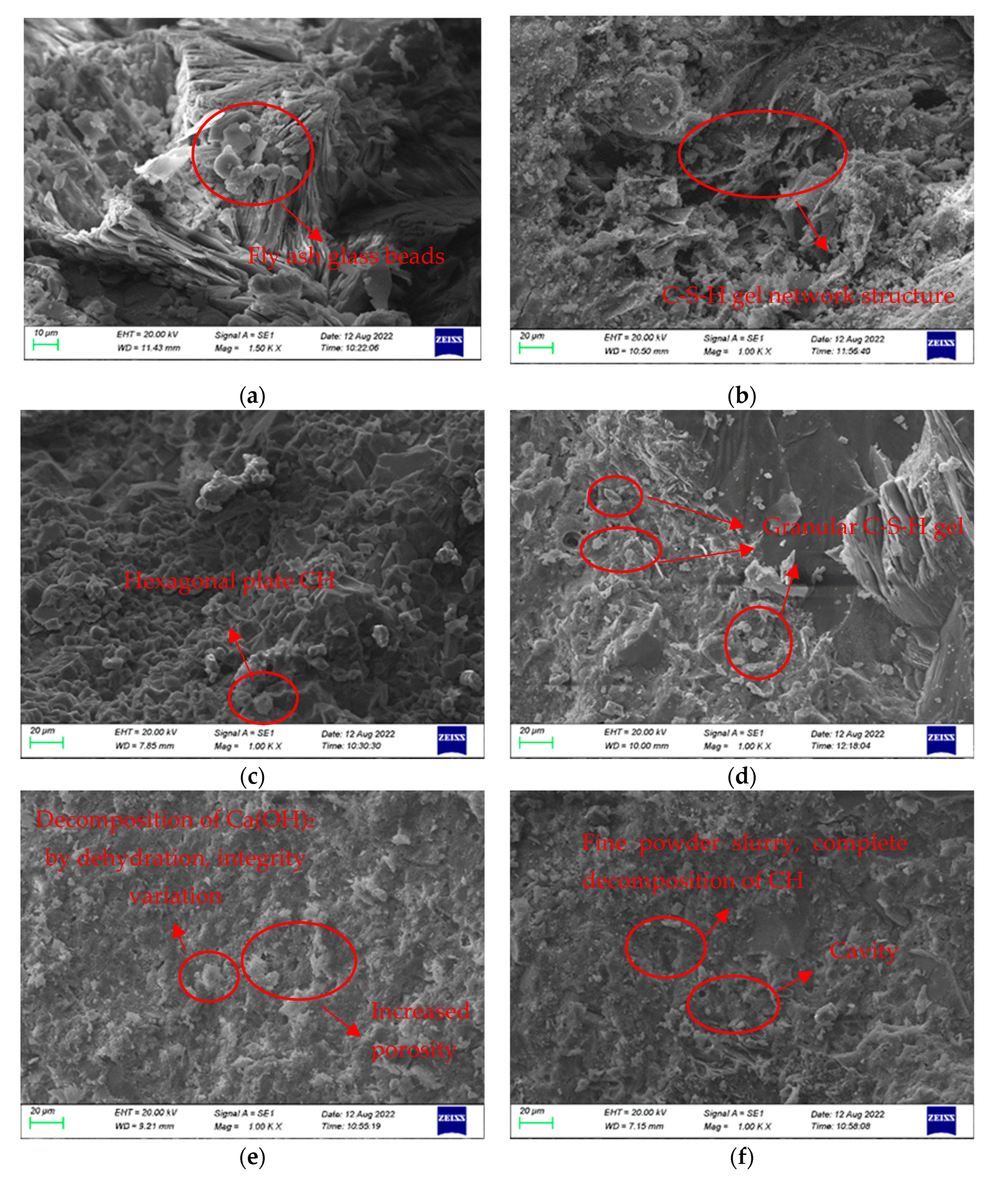

3.6. Scanning Electron Microscope

3.6.1. Changes in the Microstructure of HSC at Various Temperatures

3.6.2. Variation in PVA Concrete Fibers and Melting Pores with Different Temperatures

4. Conclusions

- (1)

- With increasing temperature, the appearance of the specimen changed, shifting in color from dark cyan gray to gray white, with more severe surface damage and an increasing rate of mass loss. Specimens that underwent water spray cooling exhibited a higher degree of surface damage relative to those that cooled naturally.

- (2)

- As the heating temperature rose, the dynamic elastic modulus of specimens with different PVA fiber amounts consistently fell, with a progressively sharper rate of decline. At a heating temperature of 800 °C, the specimens exhibited a residual dynamic elastic modulus of 32.06% after natural cooling, in contrast to 25.72% with water spray cooling.

- (3)

- The residual strength dwindled with higher temperatures, with compressive strength falling as temperature increased. The peak compressive strength occurred at 0.2% PVA fiber content. Moreover, natural cooling preserved higher compressive strength compared to water spray cooling.

- (4)

- Specimen flexural strength declined with increasing temperature. Fiber content first increased but then reduced in strength, peaking at 0.3% PVA. At a temperature of 800 °C, natural cooling resulted in a residual flexural strength of 3.97 MPa, versus 2.35 MPa with water spray cooling.

- (5)

- It was found by scanning electron microscope that at higher temperatures, the pores in the concrete expanded, cracks continued to develop, and the connection between aggregate and cement mortar gradually separated, forming a large space. As a consequence, the concrete’s ability to withstand compression steadily diminished.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Caetano, H.; Ferreira, G.; Rodrigues, C.P.J.; Pimienta, P. Effect of the high temperatures on the microstructure and compressive strength of high strength fiber concretes. Constr. Build. Mater. 2019, 199, 717–736. [Google Scholar] [CrossRef]

- Li, C.; Gao, W.Q. Experimental study on rebound curve of high-strength concrete. Key Eng. Mater. 2021, 6138, 137–141. [Google Scholar] [CrossRef]

- Li, Y.; Shen, A.Q.; Wu, H. Fractal dimension of basalt fiber reinforced concrete (BFRC) and its correlations to pore structure, strength and shrinkage. Materials 2020, 13, 3238. [Google Scholar] [CrossRef] [PubMed]

- Saify, S.; Radhi, M.S.; Al-Mashhadi, S.A.; Mareai, B.; Jabr, S.F.; Mohammed, Z.A.; Al-Khafaji, Z.; Al-Husseinawi, F. Impact of waste materials (glass powder and silica fume) on features of high-strength concrete. Open Eng. 2023, 13, 20220479. [Google Scholar] [CrossRef]

- Rid, Z.A.; Shah, S.N.R.; Memon, M.J.; Jhatial, A.A.; Keerio, M.A.; Goh, W.I. Evaluation of combined utilization of marble dust powder and fly ash on the properties and sustainability of high-strength concrete. Environ. Sci. Pollut. Res. 2022, 29, 28005–28019. [Google Scholar] [CrossRef] [PubMed]

- Ramalingam, M.; Narayanan, K.; Sivamani, J.; Kathirvel, P.; Murali, G.; Vatin, N.I. Experimental investigation on the potential use of magnetic water as a water reducing agent in high strength concrete. Materials 2022, 15, 5219. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; He, D.; Xu, W.; Zhao, Q.; Teng, S. Compressive strength prediction model of lightweight high-strength concrete. Mag. Civ. Eng. 2022, 115, 11512. [Google Scholar]

- Ghamari, A.; Powęzka, A.; Kytinou, V.K.; Amini, A. An Innovative Fire-Resistant Lightweight Concrete Infill Wall Reinforced with Waste Glass. Buildings 2024, 14, 626. [Google Scholar] [CrossRef]

- Shen, D.; Feng, Z.; Zhang, T.; Tang, X.; Jiang, G. Estimating stress relaxation and cracking potential of high-strength concrete reinforced with polyvinyl alcohol fiber at early age. J. Mater. Civ. Eng. 2022, 34, 04022223. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Wang, M.; Kang, J.; Li, M. Effect of polyvinyl alcohol fiber on the cracking risk of high strength concrete under uniaxial restrained condition at early age. Constr. Build. Mater. 2021, 300, 124206. [Google Scholar] [CrossRef]

- Xiao, K.T.; Li, J.Z.; Yang, H.Q. Study of crack resistance property of polyvinyl alcohol fiber reinforced concrete. Adv. Mater. Res. 2011, 1334, 178–182. [Google Scholar] [CrossRef]

- Tan, Y.; Xu, Z.; Liu, Z.; Jiang, J. Effect of silica fume and polyvinyl alcohol fiber on mechanical properties and frost resistance of concrete. Buildings 2022, 12, 47. [Google Scholar] [CrossRef]

- Yao, X.; Pei, Z.; Zheng, H.; Guan, Q.; Wang, F.; Wang, S.; Ji, Y. Review of Mechanical and Temperature Properties of Fiber Reinforced Recycled Aggregate. Buildings 2022, 12, 1224. [Google Scholar] [CrossRef]

- Voutetaki, M.E.; Naoum, M.C.; Papadopoulos, N.A.; Chalioris, C.E. Cracking diagnosis in fiber-reinforced concrete with synthetic fibers using piezoelectric transducers. Fibers 2021, 10, 5. [Google Scholar] [CrossRef]

- Mpalaskas, A.C.; Matikas, T.E.; Aggelis, D.G. Acoustic emission of fire damaged fiber reinforced concrete. In Smart Materials and Nondestructive Evaluation for Energy Systems 2016; SPIE: Bellingham, WA, USA, 2016; pp. 320–328. [Google Scholar]

- Zhai, Y.; Li, Y.; Li, Y.; Wang, S.; Liu, Y.; Song, K.-I. Impact of high-temperature-water cooling damage on the mechanical properties of concrete. Constr. Build. Mater. 2019, 215, 233–243. [Google Scholar] [CrossRef]

- Yuan, G.L.; Zhang, J.W.; Chen, J.W.; Zhu, D.Y. Deterioration of mechanical properties of high-strength pumpcrete after exposure to high temperatures. Adv. Mater. Res. 2010, 168–170, 564–569. [Google Scholar] [CrossRef]

- Bi, J.; Liu, P.F.; Gan, F. Effects of the cooling treatment on the dynamic behavior of ordinary concrete exposed to high temperatures. Constr. Build. Mater. 2020, 248, 118688. [Google Scholar] [CrossRef]

- Li, Q.T.; Yao, J.C.; Liang, T.L. Experimental Study on the effect of fireproof coating and cooling methods on the mechanical properties of concrete exposed to high temperature. Constr. Build. Mater. 2023, 376, 131045. [Google Scholar] [CrossRef]

- Zhao, Y.; Ding, D.; Bi, J.; Wang, C.; Liu, P. Experimental study on mechanical properties of precast cracked concrete under different cooling methods. Constr. Build. Mater. 2021, 301, 124141. [Google Scholar] [CrossRef]

- JGJ/T 281-2012; Technical Specification for Application of High Strength Concrete. China Construction Industry Press: Beijing, China, 2012.

- JGJ/T 221-2010; Technical Specification for Application of Fiber Reinforced Concrete. Guangming Darly Press: Beijing, China, 2010.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. China Construction Industry Press: Beijing, China, 2016.

- CECS 13:2009; Standard Test Methods for Fiber Reinforced Concrete. China Planning Publishing House: Beijing, China, 2009.

- GB/T 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete. China Construction Industry Press: Beijing, China, 2002.

- GB/T 9978.1-2008; Fire-Resistance Tests-Elements of Building Construction-Part 1: General Requirements. China Construction Industry Press: Beijing, China, 2008.

- GB 50974-2014; Technical Code for Fire Protection Water Supply and Hydrant System. China Planning Publishing House: Beijing, China, 2014.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Construction Industry Press: Beijing, China, 2019.

- Zhang, P.; Zhang, P.S.; Wu, J.J.; Zhang, Y.; Guo, J. Mechanical properties of polyvinyl alcohol fiber-reinforced cementitious composites after high-temperature exposure. Gels 2022, 8, 662. [Google Scholar] [CrossRef]

- Ivanchev, I. Experimental determination of dynamic modulus of elasticity of concrete with ultrasonic pulse velocity method and ultrasonic pulse echo method. Mater. Sci. Eng. R 2022, 1252, 012018. [Google Scholar] [CrossRef]

- Brozovsky, J. Ultrasonic pulse and resonance method–evaluation of the degree of damage to the internal structure of repair mortars caused by exposure to high temperatures. Russ. J. Nondestruct. Test. 2017, 53, 744–753. [Google Scholar] [CrossRef]

- Pan, W.-H.; Sun, X.-D.; Wu, L.-M.; Yang, K.-K.; Tang, N. Damage detection of asphalt concrete using piezo-ultrasonic wave technology. Materials 2019, 12, 443. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yang, E.H.; Tan, H.K. Effects of heating followed by water quenching on strength and microstructure of ultra-high performance concrete. Constr. Build. Mater. 2019, 207, 403–411. [Google Scholar] [CrossRef]

- Jani, N.M.; Nasif, M.S.; Shafiq, N.; Holt, I. Experimental investigation on the effect of varying fiber mix proportion on the mechanical and thermal performances of fiber-reinforced self-compacting concrete under hydrocarbon fire condition. Appl. Sci. 2020, 10, 4586. [Google Scholar] [CrossRef]

- Mydin, O.A.M.; Soleimanzadeh, S. Effect of polypropylene fiber content on flexural strength of lightweight foamed concrete at ambient and elevated temperatures. Adv. App. Sci. Res. 2012, 3, 2837–2846. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Professional: New York, NY, USA, 2013. [Google Scholar]

- Piotr, S. Study of toughness and macro/micro-crack development of fibre-reinforced ultra-high performance concrete after exposure to elevated temperature. Materials 2019, 12, 1210. [Google Scholar] [CrossRef] [PubMed]

- Tantawy, M.A. Effect of High Temperatures on the Microstructure of Cement Paste. Mater. Sci. Chem. Eng. 2017, 5, 33–48. [Google Scholar] [CrossRef]

- Li, D.; He, R.; Wang, S. High Temperature Performance of Cementitious Composites Reinforced with PVA Fibers. Bull. Chin. Ceram. Soc. 2015, 34, 1604–1610. (In Chinese) [Google Scholar]

- Zhang, J.; Liu, H.; Liu, G.; Wang, X.; Geng, J.; Wang, Q.; Hussain, A. Influence on mechanical properties and microstructure analysis of hybrid fiber recycled aggregate concrete after exposure to elevated temperature. J. Adhes. Sci. Technol. 2023, 37, 2328–2347. [Google Scholar] [CrossRef]

| Water (kg/m3) | Cement (kg/m3) | Fly Ash (kg/m3) | Slag (kg/m3) | Silica Fume (kg/m3) | Sand (kg/m3) | Coarse Aggregate (kg/m3) | Water Reducer (kg/m3) | Volume Content of PVA Fiber (%) |

|---|---|---|---|---|---|---|---|---|

| 123 | 461.25 | 61.5 | 61.5 | 30.75 | 650.56 | 1070.44 | 4.92 | 0 |

| 123 | 461.25 | 61.5 | 61.5 | 30.75 | 650.56 | 1070.44 | 4.92 | 0.1 |

| 123 | 461.25 | 61.5 | 61.5 | 30.75 | 650.56 | 1070.44 | 4.92 | 0.2 |

| 123 | 461.25 | 61.5 | 61.5 | 30.75 | 650.56 | 1070.44 | 4.92 | 0.3 |

| 123 | 461.25 | 61.5 | 61.5 | 30.75 | 650.56 | 1070.44 | 4.92 | 0.4 |

| Temperature | PVA Fiber Content | Cooling Type | Physical Performance | Mechanical Property Index | Number of Each Group |

|---|---|---|---|---|---|

| 20 °C | 0~0.4% (Level 5, amplitude 0.1%) | Natural cooling and water spray cooling | Apparent change, mass loss rate, and micro-analysis | Dynamic elastic modulus, compressive strength, and flexural strength | Three |

| 200 °C | |||||

| 400 °C | |||||

| 600 °C | |||||

| 800 °C |

| Cooling Method | Fiber Content (%) | Mass Loss Rate: AV (MPa), CV (%) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 200 °C | 400 °C | 600 °C | 800 °C | ||||||||||||

| AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | ||

| Natural cooling | 0 | 0 | - | - | 0 | - | - | 0.132 | 0.02 | 0.16 | 2.463 | 0.42 | 0.17 | 4.853 | 0.63 | 0.13 |

| 0.1 | 0 | - | - | 0.133 | 0.04 | 0.28 | 0.200 | 0.03 | 0.14 | 2.692 | 0.32 | 0.12 | 4.899 | 0.69 | 0.14 | |

| 0.2 | 0 | - | - | 0.069 | 0.01 | 0.15 | 0.335 | 0.05 | 0.15 | 2.808 | 0.45 | 0.16 | 4.637 | 0.51 | 0.11 | |

| 0.3 | 0 | - | - | 0.066 | 0.01 | 0.15 | 0.332 | 0.04 | 0.11 | 2.935 | 0.41 | 0.14 | 5.014 | 0.75 | 0.15 | |

| 0.4 | 0 | - | - | 0.067 | 0.01 | 0.16 | 0.336 | 0.04 | 0.11 | 3.589 | 0.39 | 0.11 | 5.254 | 0.89 | 0.17 | |

| Water spray cooling | 0 | 0 | - | - | 0 | - | - | 0.202 | 0.04 | 0.18 | - | - | - | |||

| 0.1 | 0 | - | - | 0 | - | - | 0.266 | 0.05 | 0.19 | 2.389 | 0.50 | 0.21 | 2.530 | 0.53 | 0.21 | |

| 0.2 | 0 | - | - | 0 | - | - | 0.321 | 0.05 | 0.17 | 2.770 | 0.53 | 0.19 | 2.526 | 0.45 | 0.18 | |

| 0.3 | 0 | - | - | 0 | - | - | 0.521 | 0.10 | 0.20 | 2.897 | 0.49 | 0.17 | 3.060 | 0.61 | 0.20 | |

| 0.4 | 0 | - | - | 0 | - | - | 0.540 | 0.10 | 0.18 | 3.060 | 0.58 | 0.19 | 3.382 | 0.64 | 0.19 | |

| Cooling Method | Fiber Content (%) | Dynamic Elastic Modulus: AV (MPa), CV (%) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 200 °C | 400 °C | 600 °C | 800 °C | ||||||||||||

| AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | ||

| Natural cooling | 0 | 51.61 | 7.23 | 0.14 | 50.97 | 7.65 | 0.15 | 48.75 | 7.31 | 0.15 | 34.72 | 4.86 | 0.14 | 17.08 | 2.73 | 0.16 |

| 0.1 | 50.97 | 5.61 | 0.11 | 47.27 | 6.62 | 0.14 | 50.00 | 8.00 | 0.16 | 35.28 | 4.94 | 0.14 | 17.14 | 2.57 | 0.15 | |

| 0.2 | 50.00 | 6.00 | 0.12 | 46.69 | 9.44 | 0.19 | 49.06 | 6.87 | 0.14 | 35.85 | 4.66 | 0.13 | 18.63 | 2.24 | 0.12 | |

| 0.3 | 48.15 | 7.22 | 0.15 | 43.18 | 6.48 | 0.15 | 45.55 | 6.38 | 0.14 | 33.64 | 5.38 | 0.16 | 15.44 | 2.32 | 0.15 | |

| 0.4 | 46.39 | 6.96 | 0.15 | 43.43 | 6.95 | 0.16 | 43.94 | 4.83 | 0.11 | 33.30 | 5.00 | 0.15 | 15.06 | 2.56 | 0.17 | |

| Water spraying cooling | 0 | 51.61 | 7.74 | 0.15 | 50.97 | 6.63 | 0.13 | 46.98 | 7.52 | 0.16 | - | - | - | - | - | - |

| 0.1 | 50.97 | 6.63 | 0.13 | 47.47 | 7.60 | 0.16 | 42.98 | 7.31 | 0.17 | 18.96 | 3.03 | 0.16 | 16.7 | 3.01 | 0.18 | |

| 0.2 | 50.00 | 6.50 | 0.13 | 47.47 | 8.07 | 0.17 | 43.45 | 7.82 | 0.18 | 18.09 | 3.08 | 0.17 | 16.64 | 3.16 | 0.19 | |

| 0.3 | 48.15 | 6.74 | 0.14 | 45.83 | 5.50 | 0.12 | 43.18 | 6.05 | 0.14 | 18.49 | 3.51 | 0.19 | 12.39 | 2.60 | 0.21 | |

| 0.4 | 46.39 | 5.57 | 0.12 | 43.18 | 6.91 | 0.16 | 40.75 | 6.93 | 0.17 | 17.54 | 3.51 | 0.20 | 15.21 | 2.43 | 0.16 | |

| Cooling Method | Fiber Content (%) | Compressive Strength: AV (MPa), CV (%) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 200 °C | 400 °C | 600 °C | 800 °C | ||||||||||||

| AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | ||

| Natural cooling | 0 | 6.30 | 0.57 | 0.09 | 6.37 | 0.76 | 0.12 | 5.70 | 0.74 | 0.13 | 4.22 | 0.59 | 0.14 | - | - | - |

| 0.1 | 6.47 | 0.71 | 0.11 | 6.10 | 1.22 | 0.20 | 5.70 | 1.08 | 0.19 | 4.76 | 0.71 | 0.15 | 3.30 | 0.50 | 0.15 | |

| 0.2 | 0.67 | 1.00 | 0.15 | 6.30 | 1.01 | 0.16 | 6.00 | 1.02 | 0.17 | 4.92 | 0.54 | 0.11 | 3.57 | 0.50 | 0.14 | |

| 0.3 | 6.73 | 0.94 | 0.14 | 6.47 | 1.04 | 0.16 | 6.10 | 1.22 | 0.20 | 5.41 | 1.08 | 0.20 | 3.97 | 0.60 | 0.15 | |

| 0.4 | 6.57 | 1.12 | 0.17 | 5.90 | 0.77 | 0.13 | 5.67 | 0.85 | 0.15 | 4.67 | 1.07 | 0.23 | 3.10 | 0.37 | 0.12 | |

| Water spraying cooling | 0 | 95.85 | 17.25 | 0.18 | 105.39 | 15.81 | 0.15 | 90.68 | 17.23 | 0.19 | - | - | - | - | - | - |

| 0.1 | 98.64 | 14.80 | 0.15 | 85.32 | 19.62 | 0.23 | 90.41 | 17.18 | 0.19 | 72.81 | 13.11 | 0.18 | 51.17 | 9.21 | 0.18 | |

| 0.2 | 99.99 | 11.00 | 0.11 | 98.10 | 18.64 | 0.19 | 91.00 | 19.11 | 0.21 | 77.18 | 15.44 | 0.20 | 58.32 | 7.58 | 0.13 | |

| 0.3 | 99.36 | 21.86 | 0.22 | 91.62 | 15.58 | 0.17 | 87.84 | 19.32 | 0.22 | 68.94 | 9.65 | 0.14 | 45.00 | 9.45 | 0.21 | |

| 0.4 | 95.13 | 16.17 | 0.17 | 91.17 | 16.41 | 0.18 | 72.18 | 12.99 | 0.18 | 68.13 | 8.86 | 0.13 | 44.10 | 9.70 | 0.22 | |

| Cooling Type | PVA Fiber Content (%) | Fitting Parameters | Correlation Coefficient (Adjusted R2) | ||

|---|---|---|---|---|---|

| A | B | C | |||

| Natural cooling | 0 | 100.7247 | 0.00501 | −4.27698 10−5 | 0.97402 |

| 0.1 | 97.2198 | 0.01824 | −6.18422 10−5 | 0.82934 | |

| 0.2 | 97.3256 | 0.02481 | −6.66056 10−5 | 0.84297 | |

| 0.3 | 97.9483 | 0.01021 | −5.88231 10−5 | 0.91934 | |

| 0.4 | 98.2009 | 0.00905 | −5.5638 10−5 | 0.86399 | |

| Water spray cooling | 0 | 97.49357 | 0.1323 | −3.4883 10−4 | 1.00000 |

| 0.1 | 99.0554 | 0.01265 | −8.94966 10−5 | 0.98919 | |

| 0.2 | 99.8766 | −0.00639 | −7.30479 10−5 | 0.99978 | |

| 0.3 | 98.5374 | 0.00317 | −8.64584 10−5 | 0.97878 | |

| 0.4 | 100.4377 | −0.01777 | −6.03896 10−5 | 0.96817 | |

| Cooling Method | Fiber Content (%) | Flexural Strength: AV (MPa), CV (%) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 200 °C | 400 °C | 600 °C | 800 °C | ||||||||||||

| AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | AV | SD | CV | ||

| Natural cooling | 0 | 6.30 | 0.57 | 0.09 | 6.37 | 0.76 | 0.12 | 5.70 | 0.74 | 0.13 | 4.22 | 0.59 | 0.14 | - | - | - |

| 0.1 | 6.47 | 0.71 | 0.11 | 6.10 | 1.22 | 0.20 | 5.70 | 1.08 | 0.19 | 4.76 | 0.71 | 0.15 | 3.30 | 0.50 | 0.15 | |

| 0.2 | 0.67 | 1.00 | 0.15 | 6.30 | 1.01 | 0.16 | 6.00 | 1.02 | 0.17 | 4.92 | 0.54 | 0.11 | 3.57 | 0.50 | 0.14 | |

| 0.3 | 6.73 | 0.94 | 0.14 | 6.47 | 1.04 | 0.16 | 6.10 | 1.22 | 0.20 | 5.41 | 1.08 | 0.20 | 3.97 | 0.60 | 0.15 | |

| 0.4 | 6.57 | 1.12 | 0.17 | 5.90 | 0.77 | 0.13 | 5.67 | 0.85 | 0.15 | 4.67 | 1.07 | 0.23 | 3.10 | 0.37 | 0.12 | |

| Water spraying cooling | 0 | 6.30 | 0.95 | 0.15 | 1.38 | 0.25 | 5.50 | 5.50 | 0.99 | 0.18 | - | - | - | - | - | - |

| 0.1 | 6.47 | 0.84 | 0.13 | 1.01 | 0.18 | 5.17 | 5.17 | 1.14 | 0.22 | 2.40 | 0.53 | 0.22 | 1.40 | 0.25 | 0.18 | |

| 0.2 | 6.67 | 1.07 | 0.16 | 0.62 | 0.11 | 5.35 | 5.35 | 0.80 | 0.15 | 2.60 | 0.47 | 0.18 | 1.77 | 0.37 | 0.21 | |

| 0.3 | 6.73 | 0.74 | 0.11 | 0.96 | 0.16 | 5.50 | 5.50 | 1.16 | 0.21 | 3.00 | 0.63 | 0.21 | 2.35 | 0.49 | 0.21 | |

| 0.4 | 6.57 | 1.25 | 0.19 | 0.77 | 0.15 | 4.40 | 4.40 | 0.75 | 0.17 | 2.00 | 0.32 | 0.16 | 1.70 | 0.32 | 0.19 | |

| Cooling Type | PVA Fiber Content (%) | Fitting Parameters | Correlation Coefficient (Adjusted R2) | ||

|---|---|---|---|---|---|

| A | B | C | |||

| Natural cooling | 0 | 99.209 | 0.04150 | −1.58585 10−4 | 0.99999 |

| 0.1 | 99.076 | 0.00114 | −7.56218 10−5 | 0.99157 | |

| 0.2 | 89.112 | 0.00277 | −7.44423 10−5 | 0.98812 | |

| 0.3 | 98.881 | 0.00904 | −7.2109 10−5 | 0.98306 | |

| 0.4 | 98.126 | −0.00561 | −7.07223 10−5 | 0.96345 | |

| Water spray cooling | 0 | 102.0427 | −0.10557 | 1.71784 10−4 | 1.000000 |

| 0.1 | 101.484 | −0.04981 | −6.79887 10−5 | 0.91146 | |

| 0.2 | 101.277 | −0.05613 | −5.18946 10−5 | 0.89419 | |

| 0.3 | 102.270 | −0.05275 | −4.49774 10−5 | 0.89637 | |

| 0.4 | 102.830 | −0.12127 | 2.64135 10−5 | 0.91491 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Wang, Y.; Hu, C.; Hu, L.; Zhang, L.; Wang, J.; Ding, W. Effect of Cooling Method on Physical and Mechanical Properties of PVA Fiber-Reinforced High-Strength Concrete Exposed to High Temperature. Polymers 2024, 16, 2286. https://doi.org/10.3390/polym16162286

Wu J, Wang Y, Hu C, Hu L, Zhang L, Wang J, Ding W. Effect of Cooling Method on Physical and Mechanical Properties of PVA Fiber-Reinforced High-Strength Concrete Exposed to High Temperature. Polymers. 2024; 16(16):2286. https://doi.org/10.3390/polym16162286

Chicago/Turabian StyleWu, Jian, Yuxi Wang, Chaoqun Hu, Liangjie Hu, Lidan Zhang, Jianhui Wang, and Weigao Ding. 2024. "Effect of Cooling Method on Physical and Mechanical Properties of PVA Fiber-Reinforced High-Strength Concrete Exposed to High Temperature" Polymers 16, no. 16: 2286. https://doi.org/10.3390/polym16162286

APA StyleWu, J., Wang, Y., Hu, C., Hu, L., Zhang, L., Wang, J., & Ding, W. (2024). Effect of Cooling Method on Physical and Mechanical Properties of PVA Fiber-Reinforced High-Strength Concrete Exposed to High Temperature. Polymers, 16(16), 2286. https://doi.org/10.3390/polym16162286