Enhancing High-Temperature Performance of Flexible Pavement with Plastic-Modified Asphalt

Abstract

:1. Introduction

1.1. Plastic-Modified Bitumen

1.2. Plastic-Modified Asphalt Mixture

1.3. Wheel Tracker

1.4. Research Gap

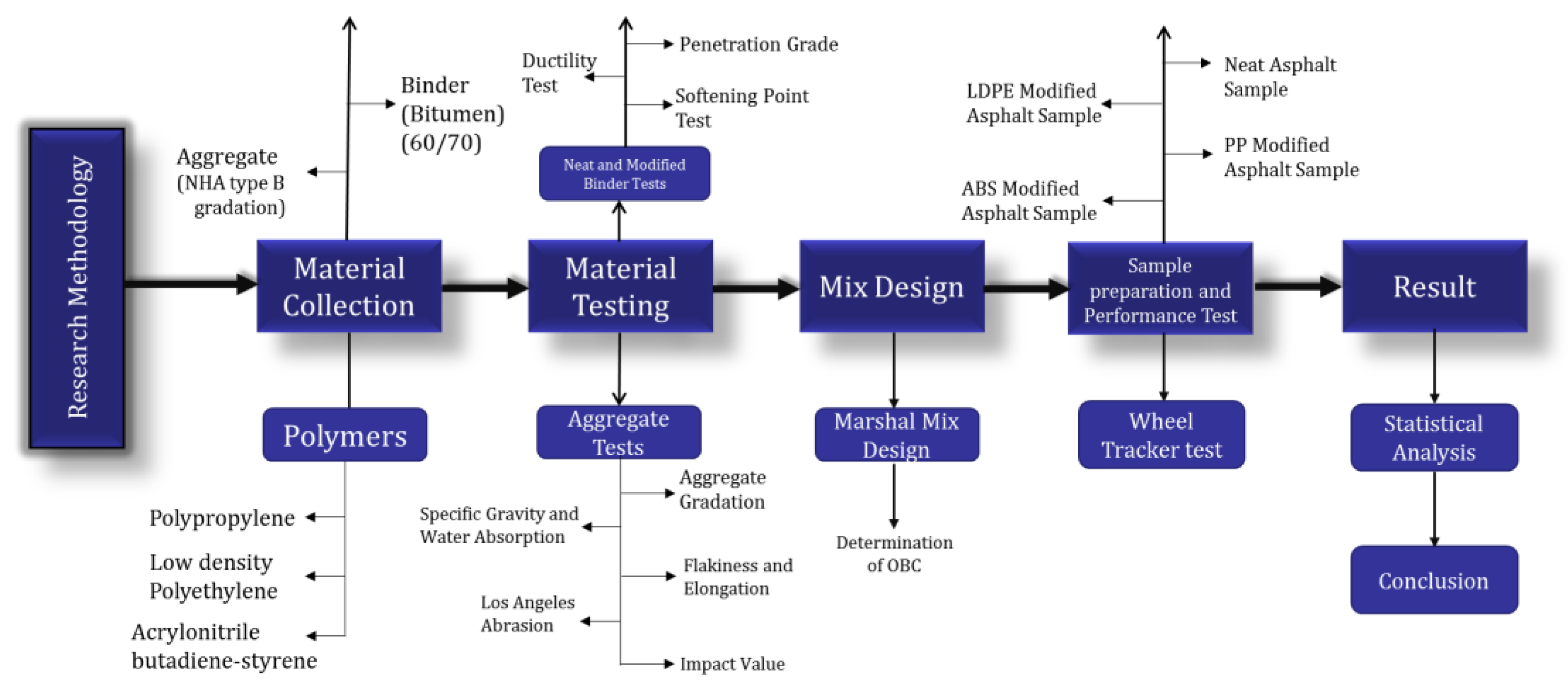

2. Materials and Methods

2.1. Materials

2.2. Aggregate Properties

2.3. Experimental Program

2.4. Sample Preparation

2.5. Marshall Mix Design

2.6. Wheel Tracking

3. Results and Discussion

3.1. Penetration Test

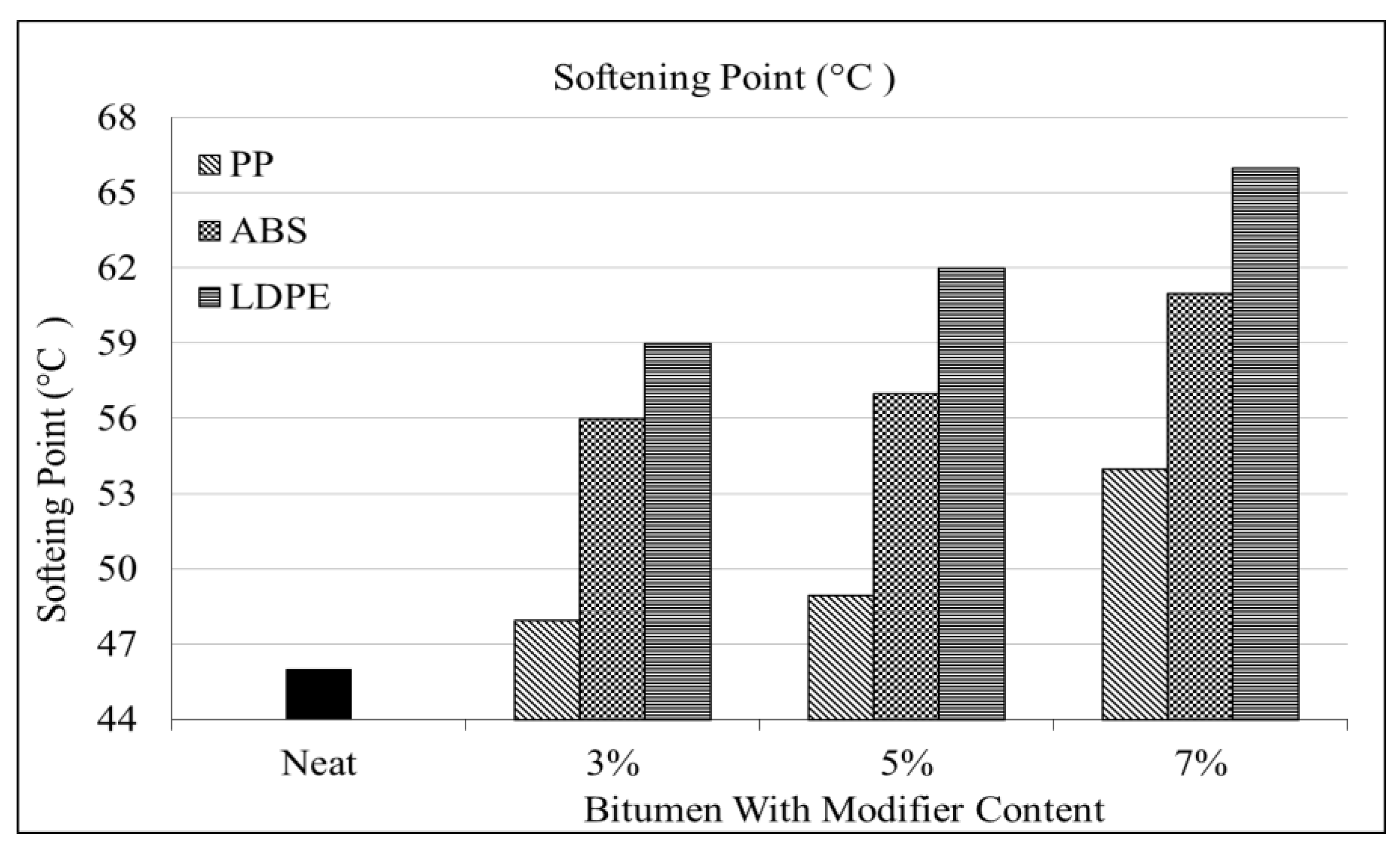

3.2. Softening Point

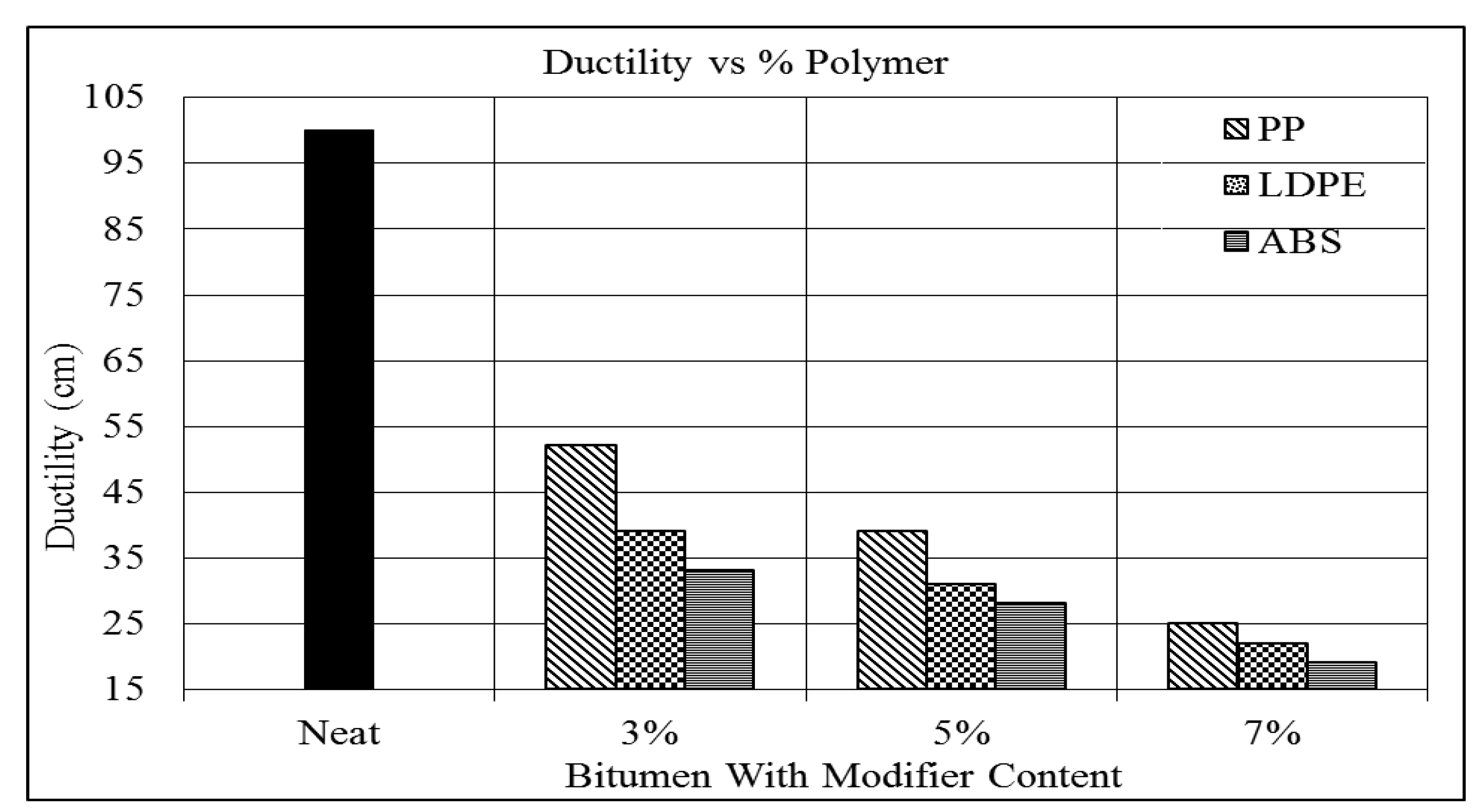

3.3. Ductility

3.4. Viscosity Test

3.5. Types of Modifiers

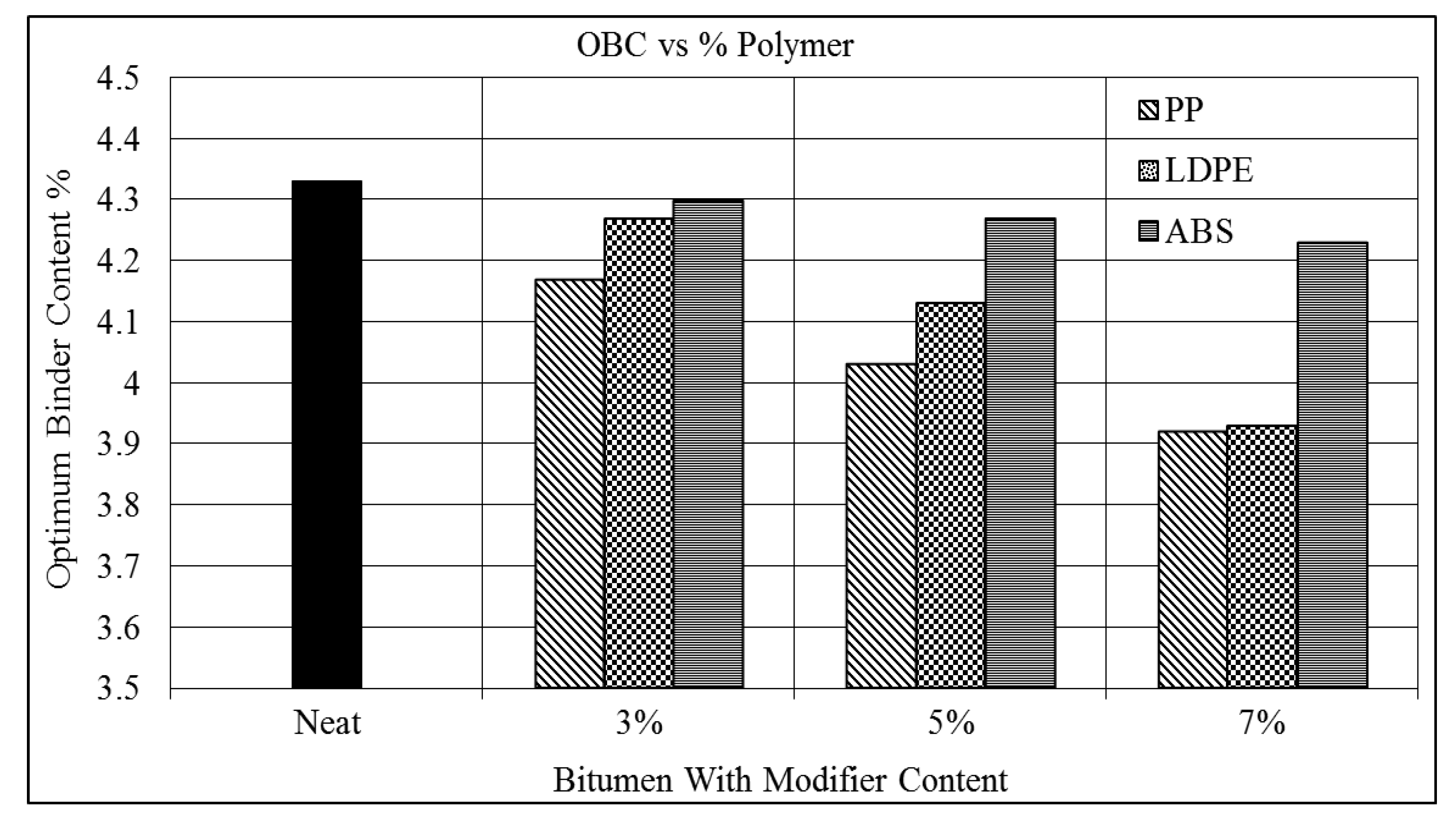

3.5.1. Polypropylene (PP)

3.5.2. Low-Density Polyethylene (LDPE)

| Sr. No | % Polymer | OBC (%) | Stability (kg) | Unit Weight (kg/m3) | Flow (0.25 mm) |

|---|---|---|---|---|---|

| 0 | Neat | 4.33 ± 0.067 | 1030 | 2342 | 8 |

| 1 | 3% LDPE | 4.27 ± 0.13 | 2125 | 2200 | 7 |

| 2 | 5% LDPE | 4.13 ± 0.06 | 2126 | 2126 | 6.9 |

| 3 | 7% LDPE | 3.93 ± 0.087 | 2130 | 2130 | 6.5 |

3.5.3. Acrylonitrile Butadiene Styrene (ABS)

| Sr. No | Description | OBC (%) | Stability (kg) | Unit Weight (kg) | Flow |

|---|---|---|---|---|---|

| 0 | Neat | 4.33 ± 0.067 | 1030 | 2342 | 8 |

| 1 | 3% ABS | 4.3 ± 0.03 | 2100 | 2102 | 7.2 |

| 2 | 5% ABS | 4.27 ± 0.033 | 2113 | 2113 | 7.4 |

| 3 | 7% ABS | 4.23 ± 0.088 | 2120 | 2219 | 7.6 |

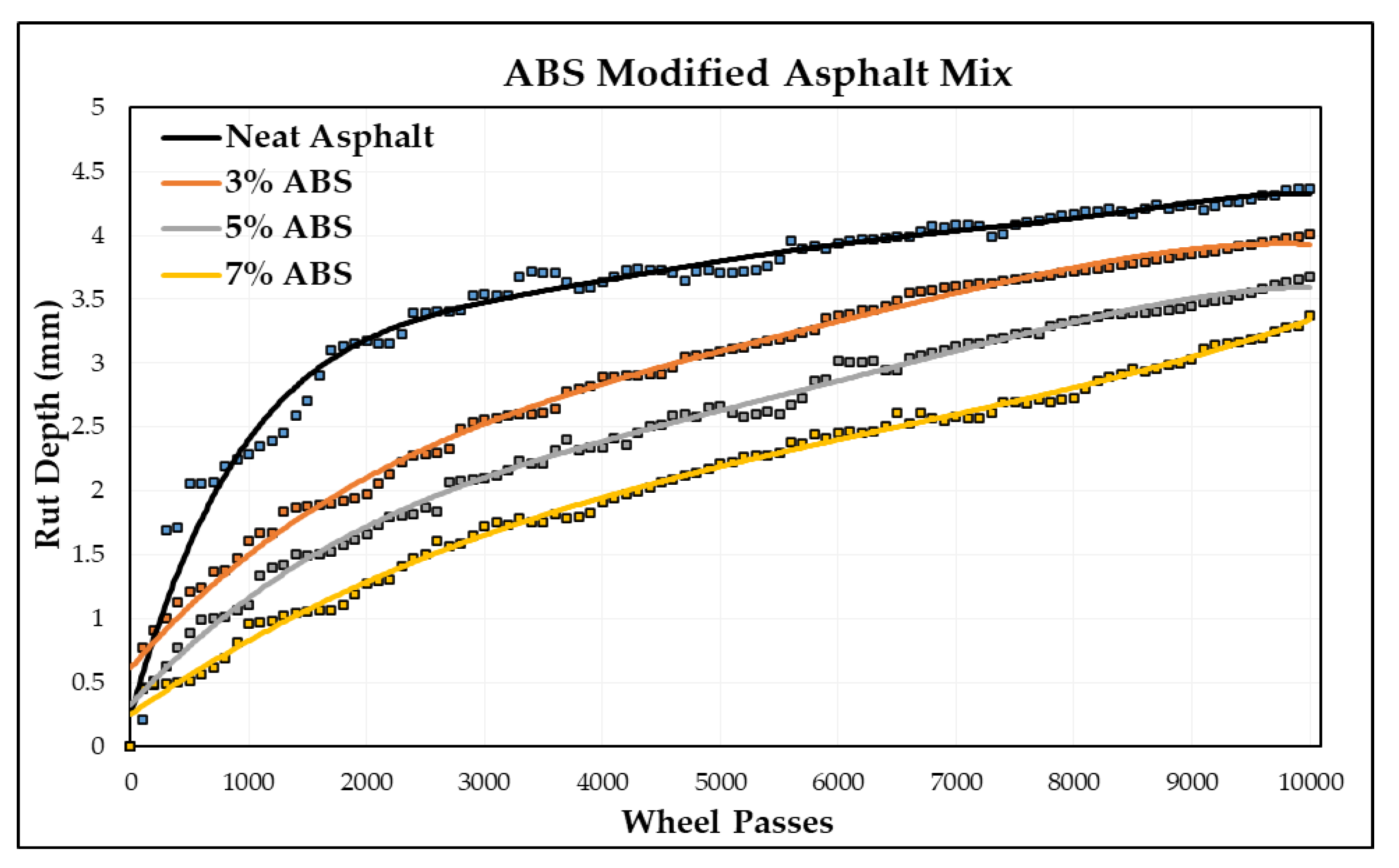

3.6. Wheel Tracker

4. Discussion

5. Conclusions

- Utilizing ABS, PP, and LDPE as bitumen modifiers enhances its rheological properties, as shown by reduced ductility and penetration levels, and a higher softening point. The results suggest that higher polymer concentrations make bitumen harder and stiffer;

- All three polymers show a consistent trend of decreasing penetration values, with LDPE consistently having the lowest penetration value among the three modifiers;

- The ductility test shows a significant drop in ductility for the polymer-modified binders compared to neat bitumen. Adding polymers makes the bitumen harder and stiffer, reducing its ductility. PP had the highest level of ductility among the polymers tested.

- As the percentage of plastic polymer increases, the optimal binder content for the asphalt mixtures decreases, while the level of stability almost doubles for all types of the plastic-modified asphalt samples;

- In comparison to PP-modified asphalt, LDPE demonstrates a lower optimum binder content (OBC). ABS-modified asphalt exhibits an even lower OBC;

- Overall, PP and LDPE perform better than ABS-modified asphalt in terms of OBC. A decrease in OBC is a positive outcome, as it reduces the overall cost of pavement construction and leads to more sustainable pavement solutions.

- 1.

- Adding polymers to the asphalt mixture improves its rutting resistance, with higher percentages of plastic polymer providing better results compared to neat asphalt after 10,000 wheel passes;

- 2.

- Modifying asphalt with a 3% polymer content shows that LDPE-modified asphalt has the highest level of rutting resistance, outperforming that of unmodified asphalt, as well as PP and ABS-modified asphalt;

- 3.

- At a 7% polymer content level, the findings highlight significant improvements in rut resistance: ABS reduces rutting by 23%, PP by 30%, and LDPE by 33% compared to unmodified asphalt mixtures.

6. Recommendations

- Perform wheel-tracking tests, increasing the number of wheel passes to assess durability;

- Enhance bitumen by raising the polymer content, incorporating a combination of all three types of plastic to optimize the overall blend;

- Examine the behavior of these modified asphalt mixtures under various stress conditions to evaluate their performance improvements.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, T.; Ma, T.; Huang, X.; Wang, S. Evaluating the rutting resistance of asphalt mixtures using a simplified triaxial repeated load test. Constr. Build. Mater. 2016, 116, 72–78. [Google Scholar] [CrossRef]

- Zhao, Z.; Jiang, J.; Ni, F.; Dong, Q.; Ding, J.; Ma, X. Factors affecting the rutting resistance of asphalt pavement based on the field cores using multi-sequenced repeated loading test. Constr. Build. Mater. 2020, 253, 118902. [Google Scholar] [CrossRef]

- Pan, Y.; Guo, H.; Guan, W.; Zhao, Y. A laboratory evaluation of factors affecting rutting resistance of asphalt mixtures using wheel tracking test. Case Stud. Constr. Mater. 2023, 18, e02148. [Google Scholar] [CrossRef]

- Du, Y.; Chen, J.; Han, Z.; Liu, W. A review on solutions for improving rutting resistance of asphalt pavement and test methods. Constr. Build. Mater. 2018, 168, 893–905. [Google Scholar] [CrossRef]

- Tayfur, S.; Ozen, H.; Aksoy, A. Investigation of rutting performance of asphalt mixtures containing polymer modifiers. Constr. Build. Mater. 2007, 21, 328–337. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Sadek, H.; Xiao, F.; Yan, C. Investigation of the rutting performance of various modified asphalt mixtures using the Hamburg Wheel-Tracking Device test and Multiple Stress Creep Recovery test. Constr. Build. Mater. 2019, 206, 62–70. [Google Scholar] [CrossRef]

- Soenen, H.; De Visscher, J.; Vanelstraete, A.; Redelius, P. Influence of thermal history on rheological properties of various bitumen. Rheol. Acta 2006, 45, 729–739. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Jiang, S. A laboratory and field universal estimation method for tire–pavement interaction noise (TPIN) based on 3D image technology. Sustainability 2022, 14, 12066. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, J.; Zhang, L.; Ji, J.; Wang, Q.; Zhang, S. Effect of boron on the structural stability, mechanical properties, and electronic structures of γ′-Ni3Al in TLP joints of nickel-based single-crystal alloys. Mater. Today Commun. 2022, 31, 103375. [Google Scholar] [CrossRef]

- Gao, Q.; Ding, Z.; Liao, W.-H. Effective elastic properties of irregular auxetic structures. Compos. Struct. 2022, 287, 115269. [Google Scholar] [CrossRef]

- He, H.; Shi, J.; Yu, S.; Yang, J.; Xu, K.; He, C.; Li, X. Exploring green and efficient zero-dimensional carbon-based inhibitors for carbon steel: From performance to mechanism. Constr. Build. Mater. 2024, 411, 134334. [Google Scholar] [CrossRef]

- Guo, J.; Ding, B.; Wang, Y.; Han, Y. Co-optimization for hydrodynamic lubrication and leakage of V-shape textured bearings via linear weighting summation. Phys. Scr. 2023, 98, 125218. [Google Scholar] [CrossRef]

- Nouali, M.; Derriche, Z.; Ghorbel, E.; Chuanqiang, L. Plastic bag waste modified bitumen a possible solution to the Algerian road pavements. Road Mater. Pavement Des. 2020, 21, 1713–1725. [Google Scholar] [CrossRef]

- Bensaada, A.; Soudani, K.; Haddadi, S. Effects of short-term aging on the physical and rheological properties of plastic waste-modified bitumen. Innov. Infrastruct. Solut. 2021, 6, 135. [Google Scholar] [CrossRef]

- Cheng, Y.; Fu, Q.; Fang, C.; Zhang, Q.; Lu, C. Preparation, Structure, and Properties of Modified Asphalt with Waste Packaging Polypropylene and Organic Rectorite. Adv. Mater. Sci. Eng. 2019, 2019, 5362795. [Google Scholar] [CrossRef]

- Dalhat, M.; Al-Abdul Wahhab, H. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2017, 18, 349–357. [Google Scholar] [CrossRef]

- Habib, N.Z.; Kamaruddin, I.; Napiah, M.; Isa, M.T. Rheological properties of polyethylene and polypropylene modified bitumen. Int. J. Civ. Environ. Eng. 2011, 3, 96–100. [Google Scholar]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Demirelli, K.; Günay, T.; Biryan, F.; Alqudah, O. Effects of waste polypropylene additive on the properties of bituminous binder. Procedia Manuf. 2015, 2, 165–170. [Google Scholar] [CrossRef]

- Sk, A.S.; Prasad, K. Utilization of waste plastic as a strength modifier in surface course of flexible and rigid pavements. Int. J. Eng. Res. Appl. 2012, 2, 185–191. [Google Scholar]

- Eldouma, I.; Xiaoming, H. Comparative study of the mechanical performance of bitumen binders and mixtures utilizing crumb rubber, tafpack super, and polypropylene. J. Civ. Environ. Eng. 2019, 9, 2. [Google Scholar]

- Sharma, S.; Sharma, P.K.; Upadhyay, N. Properties of Bituminous Binder Modified with Polyethylene. Proc. J. Phys. Conf. Ser. 2020, 1531, 012115. [Google Scholar] [CrossRef]

- Eme, D.; Nwaobakata, C. Effect of low density polyethylene as bitumen modifier on some properties of hot mix asphalt. Niger. J. Technol. 2019, 38, 1–7. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Santos, J.; Giustozzi, F. Recycling of low-value packaging films in bitumen blends: A grey-based multi criteria decision making approach considering a set of laboratory performance and environmental impact indicators. Sci. Total Environ. 2021, 778, 146187. [Google Scholar] [CrossRef]

- Joni, H.H.; Al-Rubaee, R.H.; Al-zerkani, M.A. Characteristics of asphalt binder modified with waste vegetable oil and waste plastics. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012126. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Chegenizadeh, A.; Nikraz, H.; Rezagholilou, A. Investigating the engineering properties of asphalt binder modified with waste plastic polymer. Ain Shams Eng. J. 2021, 12, 1569–1574. [Google Scholar] [CrossRef]

- Viscione, N.; Veropalumbo, R.; Oreto, C.; Biancardo, S.A.; Abbondati, F.; Russo, F. Additional procedures for characterizing the performance of recycled polymer modified asphalt mixtures. Measurement 2022, 187, 110238. [Google Scholar] [CrossRef]

- Kim, S.; Sholar, G.A.; Byron, T.; Kim, J. Performance of polymer-modified asphalt mixture with reclaimed asphalt pavement. Transp. Res. Rec. 2009, 2126, 109–114. [Google Scholar] [CrossRef]

- Ma, X.; Dong, Z.; Quan, W.; Dong, Y.; Tan, Y. Real-time assessment of asphalt pavement moduli and traffic loads using monitoring data from Built-in Sensors: Optimal sensor placement and identification algorithm. Mech. Syst. Signal Process. 2023, 187, 109930. [Google Scholar] [CrossRef]

- Hu, D.; Li, Y.; Yang, X.; Liang, X.; Zhang, K.; Liang, X. Experiment and application of NATM tunnel deformation monitoring based on 3D laser scanning. Struct. Control Health Monit. 2023, 2023, 3341788. [Google Scholar] [CrossRef]

- He, H.; Wang, S.; Shen, W.; Zhang, W. The influence of pipe-jacking tunneling on deformation of existing tunnels in soft soils and the effectiveness of protection measures. Transp. Geotech. 2023, 42, 101061. [Google Scholar] [CrossRef]

- Sun, L.; Wang, C.; Zhang, C.; Yang, Z.; Li, C.; Qiao, P. Experimental investigation on the bond performance of sea sand coral concrete with FRP bar reinforcement for marine environments. Adv. Struct. Eng. 2023, 26, 533–546. [Google Scholar] [CrossRef]

- Huang, H.; Yuan, Y.; Zhang, W.; Zhu, L. Property assessment of high-performance concrete containing three types of fibers. Int. J. Concr. Struct. Mater. 2021, 15, 39. [Google Scholar] [CrossRef]

- Fethiza Ali, B.; Soudani, K.; Haddadi, S. Effect of waste plastic and crumb rubber on the thermal oxidative aging of modified bitumen. Road Mater. Pavement Des. 2022, 23, 222–233. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Gravina, R.; Giustozzi, F. Recycled plastic as bitumen modifier: The role of recycled linear low-density polyethylene in the modification of physical, chemical and rheological properties of bitumen. J. Clean. Prod. 2020, 266, 121988. [Google Scholar] [CrossRef]

- Al-Hadidy, A. Engineering behavior of aged polypropylene-modified asphalt pavements. Constr. Build. Mater. 2018, 191, 187–192. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, J.; Ren, J.; Chen, H. Anti-rutting performance of the damping asphalt mixtures (DAMs) made with a high content of asphalt rubber (AR). Constr. Build. Mater. 2021, 271, 121878. [Google Scholar] [CrossRef]

- Maharaj, R.; Maharaj, C. Physical properties of Low Density Polyethylene, Polyvinylchloride and Used Engine Oil Modified Asphalt. Prog. Rubber Plast. Recycl. Technol. 2015, 31, 173–187. [Google Scholar] [CrossRef]

- Punith, V.; Veeraragavan, A. Behavior of asphalt concrete mixtures with reclaimed polyethylene as additive. J. Mater. Civ. Eng. 2007, 19, 500–507. [Google Scholar] [CrossRef]

- Colbert, B.W.; You, Z. Properties of modified asphalt binders blended with electronic waste powders. J. Mater. Civ. Eng. 2012, 24, 1261–1267. [Google Scholar] [CrossRef]

- Hasan, M.R.M.; Colbert, B.; You, Z.; Jamshidi, A.; Heiden, P.A.; Hamzah, M.O. A simple treatment of electronic-waste plastics to produce asphalt binder additives with improved properties. Constr. Build. Mater. 2016, 110, 79–88. [Google Scholar] [CrossRef]

- Eisa, M.S.; Mohamady, A.; Basiouny, M.E.; Abdulhamid, A.; Kim, J.R. Laboratory Evaluation of Mechanical Properties of Modified Asphalt and Mixture Using Graphene Platelets (GnPs). Materials 2021, 14, 5599. [Google Scholar] [CrossRef] [PubMed]

- Mashaan, N.; Chegenizadeh, A.; Nikraz, H. Laboratory Properties of Waste PET Plastic-Modified Asphalt Mixes. Recycling 2021, 6, 49. [Google Scholar] [CrossRef]

- Radeef, H.R.; Hassan, N.A.; Katman, H.Y.; Mahmud, M.Z.H.; Abidin, A.R.Z.; Ismail, C.R. The Mechanical Response of Dry-Process Polymer Wastes Modified Asphalt under Ageing and Moisture damage. Case Stud. Constr. Mater. 2022, 16, e00913. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, J.; Wang, J.; Han, Y.; Yu, Z.; Wang, Q.; Zhang, P.; Yang, S. Effects of solder thickness on interface behavior and nanoindentation characteristics in Cu/Sn/Cu microbumps. Weld. World 2022, 66, 973–983. [Google Scholar] [CrossRef]

- Kuang, W.; Wang, H.; Li, X.; Zhang, J.; Zhou, Q.; Zhao, Y. Application of the thermodynamic extremal principle to diffusion-controlled phase transformations in Fe-CX alloys: Modeling and applications. Acta Mater. 2018, 159, 16–30. [Google Scholar] [CrossRef]

- Luo, Y.; Liao, P.; Pan, R.; Zou, J.; Zhou, X. Effect of bar diameter on bond performance of helically ribbed GFRP bar to UHPC. J. Build. Eng. 2024, 91, 109577. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, J.; Huang, Y.; Lin, B.; Kang, S. Temperature-dependent debonding behavior of adhesively bonded CFRP-UHPC interface. Compos. Struct. 2024, 340, 118200. [Google Scholar] [CrossRef]

- Zhou, P.; Peng, R.; Xu, M.; Wu, V.; Navarro-Alarcon, D. Path planning with automatic seam extraction over point cloud models for robotic arc welding. IEEE Robot. Autom. Lett. 2021, 6, 5002–5009. [Google Scholar] [CrossRef]

- Radhakrishnan, V.; Chowdari, G.S.; Reddy, K.S.; Chattaraj, R. Evaluation of wheel tracking and field rutting susceptibility of dense bituminous mixes. Road Mater. Pavement Des. 2019, 20, 90–109. [Google Scholar] [CrossRef]

- Özen, H.; Aksoy, A.; Tayfur, S.; Çelik, F. Laboratory performance comparison of the elastomer-modified asphalt mixtures. Build. Environ. 2008, 43, 1270–1277. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Bahia, H.U.; Tang, N.; Zhu, T. Three-stage damage evolution of asphalt mixture in the wet hamburg wheel tracking device test using X-ray computed tomography. J. Mater. Civ. Eng. 2018, 30, 04018138. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E. Comprehensive evaluation of wheel-tracking rutting performance assessment tests. Int. J. Pavement Res. Technol. 2020, 13, 334–347. [Google Scholar] [CrossRef]

- Giwa, I.S. Variability in the Hamburg Wheel-Tracking Device (Hwtd) Data And Results. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2021. [Google Scholar]

- Cook, E.; Velis, C.A.; Josh, C. Safely recovering value from plastic waste in the Global South: Opportunities and challenges for circular economy and plastic pollution mitigation. engrXiv 2021. [Google Scholar] [CrossRef]

- Rashid, S.; Khan, T.A.; Sangita; Sharma, M.B. Performance evaluation of waste plastic/polymer modified bituminous concrete mixes. J. Sci. Ind. Res. 2009, 68, 975–979. [Google Scholar]

- ASTM C-131; Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM Designation. American Society for Testing Materials Philadelphia: West Conshohocken, PA, USA, 2014.

- AASHTO T 96; Standard Method of Test for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine, Standard Specifications for Transportation Materials, and Methods for Sampling, and Testing. Part-2A: Tests.; AASHTO: Washington, DC, USA, 2004.

- ASTM-C128; Standard Test Method for Specific Gravity and Absorption of Fine Aggregate. American Society for Testing Materials Philadelphia: West Conshohocken, PA, USA, 2001.

- ASTM-C127; Standard Test Method for Relative Density (Specific Gravity) and 38 Absorption of Coarse Aggregate. American Society for Testing Materials Philadelphia: West Conshohocken, PA, USA, 2024.

- ASTM D5874; Standard Test Method for Determination of the Impact Value (IV) of a Soil. American Standard Testing Methods: West Conshohocken, PA, USA, 2007; pp. 1–9.

- ASTM D4791; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. American Standard Testing Methods: West Conshohocken, PA, USA, 2010.

- ASTM D1559-89; Standard Test Method for Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus. Annual Book of ASTM Standards USA. American Standard Testing Methods: West Conshohocken, PA, USA, 2003.

- ASTM D2041; Standard Test Method for Theoretical Maximum Specific Gravity and Density of Bituminous Paving Mixtures. American Society for Testing Materials Philadelphia: West Conshohocken, PA, USA, 2000.

- EN 12697-33; Bituminous Mixtures—Test Methods for Hot Mix Asphalt. Part 33: Specimen Prepared by Roller Compactor (EN 12697-33). European Committee for Standardization: Brussels, Belgium, 2003.

- ASTM-T49; Standard Method of Test for Penetration of Bituminous Materials. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2006.

- ASTM D5/D5M-13; Standard Test Method for Penetration of Bituminous Materials. American Society for Testing Materials Philadelphia: West Conshohocken, PA, USA, 2013.

- ASTM-D113; Standard Test Method for Ductility of Bituminous Materials. Annual Book of ASTM Standards USA. American Standard Testing Methods: West Conshohocken, PA, USA, 2007.

- Malkin, A.Y. Why does the viscosity of waxy oil decrease with the decrease in the cooling rate? A model. Thermochim. Acta 2016, 624, 82–85. [Google Scholar] [CrossRef]

- Qabur, A.; Baaj, H.; El-Hakim, M. Incorporation of the multi-layer plastic packaging in the asphalt binders: Physical, thermal, rheological, and storage properties evaluation. Polymers 2022, 14, 5396. [Google Scholar] [CrossRef]

- EN 12697-22:2020; Bituminous Mixtures. Test Methods for Hot Mix Asphalt. Part 22: Wheel Tracking. European Committee for Standardization: Brussels, Belgium, 2003.

| Sieve Size | Specification | Selected Gradation | |

|---|---|---|---|

| (mm) | NHA Class-B (%) | Percentage Passing (%) | Percentage Retained (%) |

| 19 | 100 | 100 | 0.00 |

| 12.5 | 75–90 | 82.5 | 17.5 |

| 9.5 | 60–80 | 70 | 12.5 |

| 4.75 | 40–60 | 50 | 20 |

| 2.38 | 20–40 | 30 | 20 |

| 1.18 | 5–15 | 10 | 20 |

| 0.075 | 3–8 | 5 | 5 |

| Pan | ---- | ---- | 5 |

| Sr. No. | Test Description | Test Specification | Result | Standard Limits |

|---|---|---|---|---|

| 1 | Los Angeles Abrasion Value | AASHTO T96 and ASTM C131 [57,58] | 21.46% | <30% |

| 2 | Water absorption | ASTM C128 [59] | 0.367% | <0.6% |

| 3 | Specific gravity | ASTM C127 [60] | 2.44 | 2.4–3.0 |

| 4 | Impact value test | ASTM D5874 [61] | 13.80% | <15% |

| 5 | Elongation index | ASTM D4791 [62] | 7.20% | Max 20% |

| 6 | Flakiness index | ASTM D479 [62] | 5.82% | Max 20% |

| Polymer Added in Bitumen by Weight (%) | Penetration (0.1 mm) at 25 °C | |||||

|---|---|---|---|---|---|---|

| PP | ABS | LDPE | ||||

| Mean | SE | Mean | SE | Mean | SE | |

| Neat | 67 | |||||

| 3 | 59 | ±1.851 | 60 | ±0.946 | 58 | ±1.45 |

| 5 | 46 | ±1.827 | 53 | ±1.154 | 45 | ±0.882 |

| 7 | 40 | ±1.816 | 48 | ±1.816 | 38 | ±0.577 |

| Polymer Added in Bitumen (%) | Softening Point (°C) | |||||

|---|---|---|---|---|---|---|

| PP | ABS | LDPE | ||||

| Mean | SE | Mean | SE | Mean | SE | |

| Neat | 46 | |||||

| 3 | 48 | ±1.00 | 56 | ±0.55 | 59 | ±0.42 |

| 5 | 49 | ±1.18 | 57 | ±0.34 | 62 | ±1.7 |

| 7 | 54 | ±0.57 | 61 | ±0.75 | 66 | ±0.39 |

| Polymer Added in Bitumen (%) | Ductility (cm) at 25 °C | |||||

|---|---|---|---|---|---|---|

| PP | ABS | LDPE | ||||

| Mean | SE | Mean | SE | Mean | SE | |

| Neat | 100 | |||||

| 3 | 52 | ±2.39 | 33 | ±0.88 | 39 | ±0.33 |

| 5 | 39 | ±2.33 | 28 | ±0.65 | 31 | ±0.63 |

| 7 | 25 | ±0.72 | 19 | ±0.55 | 22 | ±0.89 |

| Polymer Added in Bitumen (%) | Viscosity at 135 °C (Pa·s) | |||||

|---|---|---|---|---|---|---|

| PP | ABS | LDPE | ||||

| Mean | SE | Mean | SE | Mean | SE | |

| Neat | 0.62 ± 0.11 | |||||

| 3 | 1.17 | ±0.13 | 1.14 | ±0.08 | 1.34 | ±0.1 |

| 5 | 1.70 | ±0.09 | 1.34 | ±0.06 | 1.99 | ±0.1 |

| 7 | 2.51 | ±0.07 | 1.65 | ±0.10 | 2.26 | ±0.12 |

| Sr. No | Description | OBC (%) | Stability (kg) | Unit weight (kg/m3) | Flow (0.25 mm) |

|---|---|---|---|---|---|

| 0 | Neat | 4.33 ± 0.067 | 1030 | 2342 | 8 |

| 1 | 3% PP | 4.17 ± 0.1 | 2110 | 2290 | 7.1 |

| 2 | 5% PP | 4.03 ± 0.09 | 2125 | 2195 | 7.08 |

| 3 | 7% PP | 3.92 ± 0.06 | 2158 | 2170 | 7.1 |

| Description | Rut Depth at 10,000 Passes | Percentage Improved (w.r.t. Neat Asphalt) | |

|---|---|---|---|

| Polymer Used | Percentage Added | ||

| Neat | 0 | 4.37 mm | |

| PP | 3 | 3.86 mm | 12 |

| PP | 5 | 3.41 mm | 22 |

| PP | 7 | 3.07 mm | 30 |

| ABS | 3 | 4.01 mm | 8 |

| ABS | 5 | 3.68 mm | 16 |

| ABS | 7 | 3.37 mm | 23 |

| LDPE | 3 | 3.79 mm | 13 |

| LDPE | 5 | 3.30 mm | 24 |

| LDPE | 7 | 2.91 mm | 33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ullah, S.; Qabur, A.; Ullah, A.; Aati, K.; Abdelgiom, M.A. Enhancing High-Temperature Performance of Flexible Pavement with Plastic-Modified Asphalt. Polymers 2024, 16, 2399. https://doi.org/10.3390/polym16172399

Ullah S, Qabur A, Ullah A, Aati K, Abdelgiom MA. Enhancing High-Temperature Performance of Flexible Pavement with Plastic-Modified Asphalt. Polymers. 2024; 16(17):2399. https://doi.org/10.3390/polym16172399

Chicago/Turabian StyleUllah, Salamat, Ali Qabur, Ansar Ullah, Khaled Aati, and Mahmoud Abdelrahim Abdelgiom. 2024. "Enhancing High-Temperature Performance of Flexible Pavement with Plastic-Modified Asphalt" Polymers 16, no. 17: 2399. https://doi.org/10.3390/polym16172399

APA StyleUllah, S., Qabur, A., Ullah, A., Aati, K., & Abdelgiom, M. A. (2024). Enhancing High-Temperature Performance of Flexible Pavement with Plastic-Modified Asphalt. Polymers, 16(17), 2399. https://doi.org/10.3390/polym16172399