Development Status of Solar-Driven Interfacial Steam Generation Support Layer Based on Polymers and Biomaterials: A Review

Abstract

:1. Introduction

2. Support Layer Materials

2.1. Polymer Foam

2.1.1. Commercial Polymer Foam

2.1.2. Functional Polymer Foam

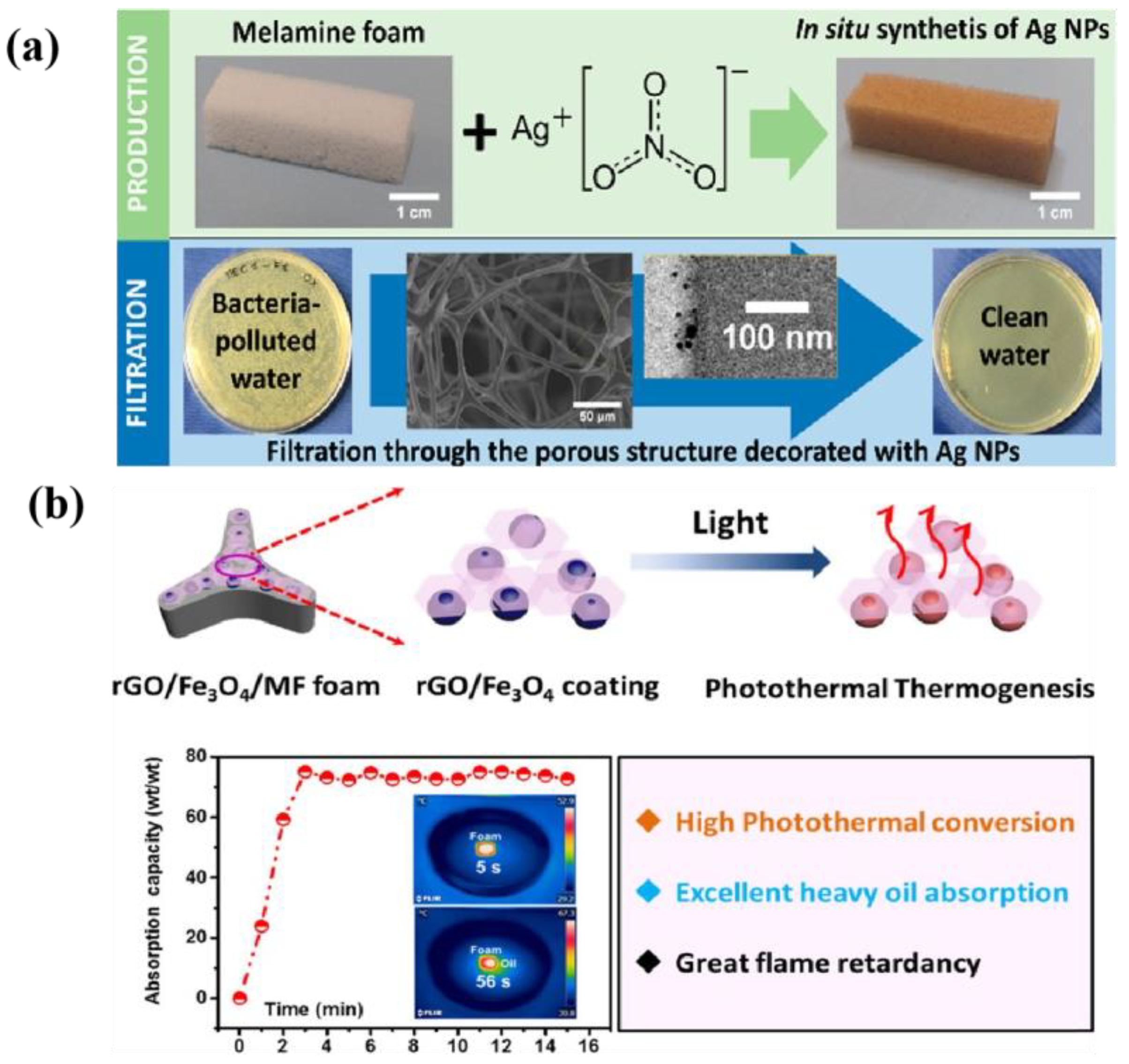

Coating Functionalized Polymer Foam

Substrate Modified Functional Polymer Foam

2.2. Gel

2.2.1. Hydrogel

2.2.2. Aerogel

2.3. Biomaterials

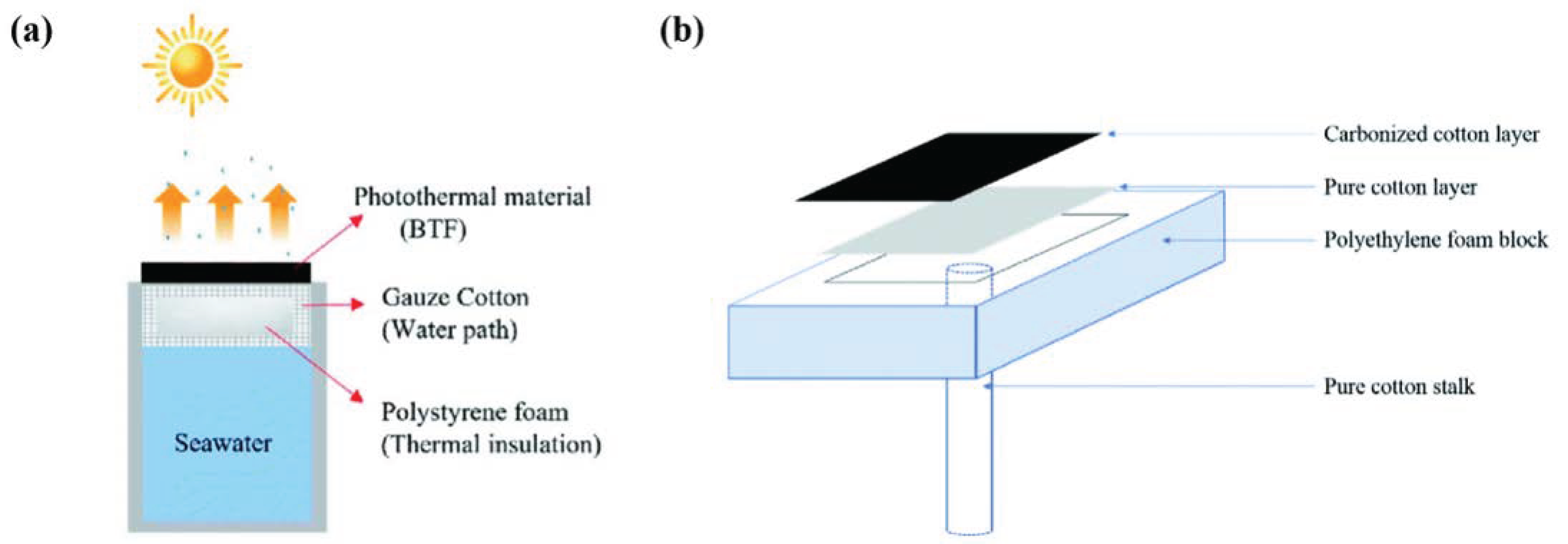

2.3.1. Natural Plants

2.3.2. Carbonized Biomaterials

2.3.3. Modified Biomaterials

3. Support Layer Structure Optimization

3.1. Cone Structure

3.2. Arch Structure

3.3. Other 3D Structures

4. Conclusions and Prospect

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tao, P.; Ni, G.; Song, C.; Shang, W.; Wu, J.; Zhu, J.; Chen, G.; Deng, T. Solar-driven interfacial evaporation. Nat. Energy 2018, 3, 1031–1041. [Google Scholar] [CrossRef]

- Kurihara, M. Seawater Reverse Osmosis Desalination. Membranes 2021, 11, 243. [Google Scholar] [CrossRef] [PubMed]

- de Moraes, E.G.; Sangiacomo, L.; Stochero, N.P.; Arcaro, S.; Barbosa, L.R.; Lenzi, A.; Siligardi, C.; de Oliveira, A.N. Innovative thermal and acoustic insulation foam by using recycled ceramic shell and expandable styrofoam (EPS) wastes. Waste Manag. 2019, 89, 336–344. [Google Scholar] [CrossRef]

- Lee, T.; Rahardianto, A.; Cohen, Y. Flexible reverse osmosis (FLERO) desalination. Desalination 2019, 452, 123–131. [Google Scholar] [CrossRef]

- Abid, M.B.; Wahab, R.A.; Salam, M.A.; Moujdin, I.A.; Gzara, L. Desalination technologies, membrane distillation, and electrospinning, an overview. Heliyon 2023, 9, e12810. [Google Scholar] [CrossRef]

- Alawad, S.M.; Khalifa, A.E. Analysis of water gap membrane distillation process for water desalination. Desalination 2019, 470, 114088. [Google Scholar] [CrossRef]

- Liu, X.; Li, L.; Wang, M.; Wang, D.; Yan, H.; Li, K.; Li, Y.; Yang, Y.; You, Y.; Yang, X.; et al. In-situ polymerization of PANI nanocone array on PEN nanofibrous membranes for solar-driven interfacial evaporation. Sep. Purif. Technol. 2024, 344, 127109. [Google Scholar] [CrossRef]

- Abdelkader, B.A.; Antar, M.A.; Khan, Z. Nanofiltration as a Pretreatment Step in Seawater Desalination: A Review. Sci. Eng. 2018, 43, 4413–4432. [Google Scholar] [CrossRef]

- Solouki, S.; Karrabi, M.; Eftekhari, M. Application of a functionalized thin-film composite nanofiltration membrane in water desalination. J. Mol. Liq. 2024, 399, 124399. [Google Scholar] [CrossRef]

- Sharshir, S.W.; Algazzar, A.M.; Elmaadawy, K.A.; Kandeal, A.W.; Elkadeem, M.R.; Arunkumar, T.; Zang, J.; Yang, N. New hydrogel materials for improving solar water evaporation, desalination and wastewater treatment: A review. Desalination 2020, 491, 114564. [Google Scholar] [CrossRef]

- Wang, J.; Kong, Y.; Liu, Z.; Wang, H. Solar-driven interfacial evaporation: Design and application progress of structural evaporators and functional distillers. Nano Energy 2023, 108, 108115. [Google Scholar] [CrossRef]

- Zhao, Q.; Yang, Y.; Pan, C.; Zhu, B.; Sha, Z.; Wei, Y.; Que, W. Integrated strategy of solar evaporator and steam collector configurations for interfacial evaporation water purification. Sol. Energy 2023, 266, 112187. [Google Scholar] [CrossRef]

- Lu, X.; Mu, C.; Liu, Y.; Wu, L.; Tong, Z.; Huang, K. Recent advances in solar-driven interfacial evaporation coupling systems: Energy conversion, water purification, and seawater resource extraction. Nano Energy 2024, 120, 109180. [Google Scholar] [CrossRef]

- Han, H.; Huang, K.; Meng, X. Review on solar-driven evaporator: Development and applications. J. Ind. Eng. Chem. 2023, 119, 77–89. [Google Scholar] [CrossRef]

- Chen, C.; Kuang, Y.; Hu, L. Challenges and Opportunities for Solar Evaporation. Joule 2019, 3, 683–718. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, W.; Wang, X. Carbon nanocomposites with high photothermal conversion efficiency. Sci. China Mater. 2018, 61, 905–914. [Google Scholar] [CrossRef]

- Zhu, H.; Jiang, X. Development of a General Fabrication Strategy for Carbonaceous Noble Metal Nanocomposites with Photothermal Property. Nanoscale Res. Lett. 2020, 15, 17. [Google Scholar] [CrossRef]

- Huang, J.; Fu, J.; Li, L.; Ma, J. Mg-based metallic glass nanowires with excellent photothermal effect. Scr. Mater. 2023, 222, 115036. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Lee, P.C.; Park, C.B. A review of the state-of-the-art on thermal insulation performance of polymeric foams. Therm. Sci. Eng. Prog. 2023, 41, 101808. [Google Scholar] [CrossRef]

- Sakhadeo, N.N.; Patro, T.U. Exploring the Multifunctional Applications of Surface-Coated Polymeric Foams—A Review. Ind. Eng. Chem. Res. 2022, 61, 5366–5387. [Google Scholar] [CrossRef]

- Hu, X.; Yang, J.; Tu, Y.; Su, Z.; Guan, Q.; Ma, Z. Hydrogel-Based Interfacial Solar-Driven Evaporation: Essentials and Trails. Gels 2024, 10, 371. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liu, Q.; He, J.; Zhang, Y.; Mu, L.; Zhu, X.; Yao, Y.; Sun, C.-L.; Qu, M. Aerogel-based solar interface evaporation: Current research progress and future challenges. Desalination 2024, 569, 117068. [Google Scholar] [CrossRef]

- Liu, X.; Tian, Y.; Caratenuto, A.; Chen, F.; Zheng, Y. Biomass-Based Materials for Sustainably Sourced Solar-Driven Interfacial Steam Generation. Adv. Energy Mater. 2023, 25, 2300778. [Google Scholar] [CrossRef]

- Wang, S.-X.; Zhao, H.-B.; Rao, W.-H.; Huang, S.-C.; Wang, T.; Liao, W.; Wang, Y.-Z. Inherently flame-retardant rigid polyurethane foams with excellent thermal insulation and mechanical properties. Polymer 2018, 153, 616–625. [Google Scholar] [CrossRef]

- Kirpluks, M.; Kalnbunde, D.; Benes, H.; Cabulis, U. Natural oil based highly functional polyols as feedstock for rigid polyurethane foam thermal insulation. Ind. Crop. Prod. 2018, 122, 627–636. [Google Scholar] [CrossRef]

- An, W.; Sun, J.; Liew, K.M.; Zhu, G. Flammability and safety design of thermal insulation materials comprising PS foams and fire barrier materials. Mater. Des. 2016, 99, 500–508. [Google Scholar] [CrossRef]

- Shi, L.; Wang, Y.; Zhang, L.; Wang, P. Rational design of a bi-layered reduced graphene oxide film on polystyrene foam for solar-driven interfacial water evaporation. J. Mater. Chem. A 2017, 5, 16212–16219. [Google Scholar] [CrossRef]

- Nguyen, T.K.T.; Dao, Q.K.; Tanaka, D.; Nghiem, L.H.T.; Nguyen, M.V.; Nguyen, Z.H.; Pham, T.T. Flexible, affordable and environmentally sustainable solar vapor generation based on ferric tannate/bacterial cellulose composite for efficient desalination solutions. RSC Adv. 2021, 11, 31641–31649. [Google Scholar] [CrossRef] [PubMed]

- Kiriarachchi, H.D.; Hassan, A.A.; Awad, F.S.; El-Shall, M.S. Metal-free functionalized carbonized cotton for efficient solar steam generation and wastewater treatment. RSC Adv. 2021, 12, 1043–1050. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, L.; Zhang, F.; Yu, K.; Yang, C.; Jia, J.; Guo, W.; Zhao, J.; Qu, F. Synthesis of a Co-Sn Alloy-Deposited PTFE Film for Enhanced Solar-Driven Water Evaporation via a Super-Absorbent Polymer-Based “Water Pump” Design. ACS Appl. Mater. 2021, 13, 26879–26890. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, X.; Li, C.; Peng, H.; Zhang, T.; Ye, M. A salt-rejecting solar evaporator for continuous steam generation. J. Eeviron. Chem. Eng. 2021, 9, 105010. [Google Scholar] [CrossRef]

- Chang, C.; Liu, M.; Li, L.; Chen, G.; Pei, L.; Wang, Z.; Ji, Y. Salt-rejecting rGO-coated melamine foams for high-efficiency solar desalination. J. Mater. Res. 2021, 37, 294–303. [Google Scholar] [CrossRef]

- Lal, S.; Batabyal, S.K. Activated carbon-cement composite coated polyurethane foam as a cost-efficient solar steam generator. J. Clean. Prod. 2022, 379, 134302. [Google Scholar] [CrossRef]

- Chen, J.; Li, B.; Hu, G.; Aleisa, R.; Lei, S.; Yang, F.; Liu, D.; Lyu, F.; Wang, M.; Ge, X.; et al. Integrated Evaporator for Efficient Solar-Driven Interfacial Steam Generation. Nano Lett. 2020, 20, 6051–6058. [Google Scholar] [CrossRef] [PubMed]

- Lin, B.; Yuen, A.C.Y.; Oliver, S.; Liu, J.; Yu, B.; Yang, W.; Wu, S.; Yeoh, G.H.; Wang, C.H. Dual functionalisation of polyurethane foam for unprecedented flame retardancy and antibacterial properties using layer-by-layer assembly of MXene chitosan with antibacterial metal particles. Compos. Part B Eng. 2022, 244, 110147. [Google Scholar] [CrossRef]

- Pinto, J.; Magrì, D.; Valentini, P.; Palazon, F.; Heredia-Guerrero, J.A.; Lauciello, S.; Barroso-Solares, S.; Ceseracciu, L.; Pompa, P.P.; Athanassiou, A.; et al. Antibacterial Melamine Foams Decorated with in Situ Synthesized Silver Nanoparticles. ACS Appl. Mater. Interfaces 2018, 10, 16095–16104. [Google Scholar] [CrossRef]

- Wang, J.; Yang, W.; He, F.; Xie, C.; Fan, J.; Wu, J.; Zhang, K. Superhydrophobic Melamine-formaldehyde Foam Prepared by In-situ Coprecipitation. Chem. Lett. 2018, 47, 414–416. [Google Scholar] [CrossRef]

- Shi, H.-G.; Li, S.-L.; Cheng, J.-B.; Zhao, H.-B.; Wang, Y.-Z. Multifunctional Photothermal Conversion Nanocoatings Toward Highly Efficient and Safe High-Viscosity Oil Cleanup Absorption. ACS Appl. Mater. Interfaces 2021, 13, 11948–11957. [Google Scholar] [CrossRef]

- Wang, Z.; Niu, J.; Wang, J.; Zhang, Y.; Wu, G.; Liu, X.; Liu, Q. Rational Design of Photothermal and Anti-Bacterial Foam With Macroporous Structure for Efficient Desalination of Water. Front. Chem. 2022, 10, 912489. [Google Scholar] [CrossRef] [PubMed]

- Gnanasekaran, A.; Rajaram, K. Rational design of different interfacial evaporators for solar steam generation: Recent development, fabrication, challenges and applications. Renew. Sust. Enegr. Rev. 2024, 192, 114202. [Google Scholar] [CrossRef]

- Ullah, F.; Othman, M.B.H.; Javed, F.; Ahmad, Z.; Akil, H.M. Classification, processing and application of hydrogels: A review. Mater. Sci. Eng. C 2015, 57, 414–433. [Google Scholar] [CrossRef]

- Jing, X.; Liu, F.; Abdiryim, T.; Liu, X. Hydrogels as promising platforms for solar-driven water evaporators. Chem. Eng. J. 2024, 479, 147519. [Google Scholar] [CrossRef]

- Zhao, Q.; Wen, H.; Wu, J.; Wen, X.; Xu, Z.; Duan, J. Galactomannan/graphene oxide/Fe3O4 hydrogel evaporator for solar water evaporation for synergistic photothermal power generation. Desalination 2024, 570, 117064. [Google Scholar] [CrossRef]

- Wang, J.; Guo, Z.; Xiao, B.; Xiong, X.; Liu, G.; Wang, X. Reduced graphene oxide/Cu7·2S4 composite hydrogels for highly efficient solar steam generation. Mater. Today. Sustain. 2022, 18, 100121. [Google Scholar] [CrossRef]

- Xiong, Y.; Hu, D.; Huang, L.; Fang, Z.; Jiang, H.; Mao, Q.; Wang, H.; Tang, P.; Li, J.; Wang, G.; et al. Ultra-high strength sodium alginate/PVA/PHMB double-network hydrogels for marine antifouling. Prog. Org. Coat. 2024, 187, 108175. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, H.; Shutes, B. Multi-strategy coupling of custom hydrogel evaporators for sustained, high-efficiency clean water production and anti-pollution. Nano Today 2024, 57, 102370. [Google Scholar] [CrossRef]

- Chu, A.; Yang, M.; Chen, J.; Zhao, J.; Fang, J.; Yang, Z.; Li, H. Biomass-enhanced Janus sponge-like hydrogel with salt resistance and high strength for efficient solar desalination. Green. Energy Environ. 2023, in press. [Google Scholar] [CrossRef]

- Zhao, J.; Chu, A.; Chen, J.; Qiao, P.; Fang, J.; Yang, Z.; Duan, Z.; Li, H. Spongy polyelectolyte hydrogel for efficient Solar-Driven interfacial evaporation with high salt resistance and compression resistance. Chem. Eng. J. 2024, 485, 150118. [Google Scholar] [CrossRef]

- Peng, B.; Lyu, Q.; Gao, Y.; Li, M.; Xie, G.; Xie, Z.; Zhang, H.; Ren, J.; Zhu, J.; Zhang, L.; et al. Composite Polyelectrolyte Photothermal Hydrogel with Anti-biofouling and Antibacterial Properties for the Real-World Application of Solar Steam Generation. ACS Appl. Mater. Interfaces 2022, 14, 16546–16557. [Google Scholar] [CrossRef]

- Peng, B.; Gao, Y.; Lyu, Q.; Xie, Z.; Li, M.; Zhang, L.; Zhu, J. Cationic Photothermal Hydrogels with Bacteria-Inhibiting Capability for Freshwater Production via Solar-Driven Steam Generation. ACS Appl. Mater. Interfaces 2021, 13, 37724–37733. [Google Scholar] [CrossRef]

- Garg, S.; Singh, S.; Shehata, N.; Sharma, H.; Samuel, J.; Khan, N.A.; Ramamurthy, P.C.; Singh, J.; Mubashir, M.; Bokhari, A.; et al. Aerogels in wastewater treatment: A review. J. Taiwan Inst. Chem. E 2023, 105299. [Google Scholar] [CrossRef]

- Rai, N.; Chauhan, I. Multifunctional Aerogels: A comprehensive review on types, synthesis and applications of aerogels. J. Sol-Gel. Sci. Technol. 2023, 105, 324–336. [Google Scholar] [CrossRef]

- Wu, J.; Yang, X.; Jia, X.; Yang, J.; Miao, X.; Shao, D.; Song, H.; Li, Y. Full biomass-derived multifunctional aerogel for solar-driven interfacial evaporation. Chem. Eng. J. 2023, 471, 144684. [Google Scholar] [CrossRef]

- Storer, D.P.; Phelps, J.L.; Wu, X.; Owens, G.; Khan, N.I.; Xu, H. Graphene and Rice-Straw-Fiber-Based 3D Photothermal Aerogels for Highly Efficient Solar Evaporation. ACS Appl. Mater. Interfaces 2020, 12, 15279–15287. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.-K.; Gong, J.-Z.; Dai, M.; Zhang, Y.-F.; Wang, S.-G.; Lin, Z.-D.; Du, F.-P.; Fu, P. Reduced graphene oxide/Ag nanoparticle aerogel for efficient solar water evaporation. J. Alloy. Compd. 2023, 930, 167404. [Google Scholar] [CrossRef]

- Jian, H.; Wang, Y.; Li, W.; Ma, Y.; Wang, W.; Yu, D. Reduced graphene oxide aerogel with the dual-cross-linked framework for efficient solar steam evaporation. Colloid. Surface A 2021, 629, 127440. [Google Scholar] [CrossRef]

- Fillet, R.; Nicolas, V.; Fierro, V.; Celzard, A. A review of natural materials for solar evaporation. Sol. Energ. Mater. Sol. C 2021, 219, 110814. [Google Scholar] [CrossRef]

- Zhang, P.; Xie, M.; Jin, Y.; Jin, C.; Wang, Z. A Bamboo-Based Photothermal Conversion Device for Efficient Solar Steam Generation. ACS Appl. Mater. Interfaces 2022, 4, 2393–2400. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, P.; Ni, F.; Yan, L.; Liu, Q.; Zhang, D.; Gu, J.; Wang, W.; Chen, T. Converting Pomelo Peel into Eco-friendly and Low-Consumption Photothermic Biomass Sponge toward Multifunctioal Solar-to-Heat Conversion. ACS Sustain. Chem. Eng. 2020, 8, 5328–5337. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Song, J.; Yang, Z.; Kuang, Y.; Hitz, E.; Jia, C.; Gong, A.; Jiang, F.; Zhu, J.Y.; et al. Highly Flexible and Efficient Solar Steam Generation Device. Adv. Mater. 2017, 29, 1701756. [Google Scholar] [CrossRef]

- Song, D.; Zheng, D.; Li, Z.; Wang, C.; Li, J.; Zhang, M. Research Advances in Wood Composites in Applications of Industrial Wastewater Purification and Solar-Driven Seawater Desalination. Polymers 2023, 15, 4712. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, Q.; Qiu, Y.; Feng, H. High-efficiency wood-based evaporators for solar-driven interfacial evaporation. Sol. Energy 2022, 244, 322–330. [Google Scholar] [CrossRef]

- Li, W.; Li, F.; Zhang, D.; Bian, F.; Sun, Z. Porous wood-carbonized solar steam evaporator. Wood Sci. Technol. 2021, 55, 625–637. [Google Scholar] [CrossRef]

- Chen, T.; Wu, Z.; Liu, Z.; Aladejana, J.T.; Wang, X.; Niu, M.; Wei, Q.; Xie, Y. Hierarchical Porous Aluminophosphate-Treated Wood for High-Efficiency Solar Steam Generation. ACS Appl. Mater. Interfaces 2020, 12, 19511–19518. [Google Scholar] [CrossRef]

- Fang, Q.; Li, T.; Chen, Z.; Lin, H.; Wang, P.; Liu, F. Full Biomass-Derived Solar Stills for Robust and Stable Evaporation To Collect Clean Water from Various Water-Bearing Media. ACS Appl. Mater. Interfaces 2019, 11, 10672–10679. [Google Scholar] [CrossRef]

- Huang, W.; Hu, G.; Tian, C.; Wang, X.; Tu, J.; Cao, Y.; Zhang, K. Nature-inspired salt resistant polypyrrole–wood for highly efficient solar steam generation. Ssutain. Energ. Fuels 2019, 3, 3000–3008. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, M.; Du, X.; Liu, B.; Li, S.; An, C. In situ polymerization of pyrrole on elastic wood for high efficiency seawater desalination and oily water purification. J. Mater. Sci. 2022, 57, 16317–16332. [Google Scholar] [CrossRef]

- Pham, T.T.; Nguyen, T.H.; Nguyen, T.A.H.; Pham, D.D.; Nguyen, D.C.; Do, D.B.; Nguyen, H.V.; Ha, M.H.; Nguyen, Z.H. Durable, scalable and affordable iron (III) based coconut husk photothermal material for highly efficient solar steam generation. Desalination 2021, 518, 115280. [Google Scholar] [CrossRef]

- Long, Y.; Huang, S.; Yi, H.; Chen, J.; Wu, J.; Liao, Q.; Liang, H.; Cui, H.; Ruan, S.; Zeng, Y.-J. Liu, Carrot-inspired solar thermal evaporator. J. Mater. Chem. A 2019, 7, 26911. [Google Scholar] [CrossRef]

- Jia, X.; Liu, X.; Guan, H.; Fan, T.; Chen, Y.; Long, Y.-Z. A loofah-based photothermal biomass material with high salt-resistance for efficient solar water evaporation. Compos. Commun. 2023, 37, 101430. [Google Scholar] [CrossRef]

- Chen, T.; Xie, H.; Qiao, X.; Hao, S.; Wu, Z.; Sun, D.; Liu, Z.; Cao, F.; Wu, B.; Fang, X. Highly Anisotropic Corncob as an Efficient Solar Steam-Generation Device with Heat Localization and Rapid Water Transportation. ACS Appl. Mater. Interfaces 2020, 12, 50397–50405. [Google Scholar] [CrossRef]

- Xu, N.; Hu, X.; Xu, W.; Li, X.; Zhou, L.; Zhu, S.; Zhu, J. Mushrooms as Efficient Solar Steam-Generation Devices. Adv. Mater. 2017, 29, 1606762. [Google Scholar] [CrossRef]

- Zeng, L.; Deng, D.; Zhu, L.; Wang, H.; Zhang, Z.; Yao, Y. Biomass photothermal structures with carbonized durian for efficient solar-driven water evaporation. Energy 2023, 273, 127170. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Deng, H.; Zhang, Y.; Hu, J.; Tian, R. Carbonized sugarcane as interfacial photothermal evaporator for vapor generation. Desalination 2022, 526, 115544. [Google Scholar] [CrossRef]

- Roy, A.; Tariq, M.Z.; La, M.; Choi, D.; Park, S.J. 3D carbonized orange peel: A self-floating solar absorber for efficient water evaporation. Desalination 2024, 573, 117191. [Google Scholar] [CrossRef]

- Li, Z.; Wei, S.; Ge, Y.; Zhang, Z.; Li, Z. Biomass-based materials for solar-powered seawater evaporation. Sci. Total Environ. 2023, 858, 160003. [Google Scholar] [CrossRef]

- Zhu, M.; Yu, J.; Ma, C.; Zhang, C.; Wu, D.; Zhu, H. Carbonized daikon for high efficient solar steam generation. Sol. Energ. Mater. Sol. C 2019, 191, 83–90. [Google Scholar] [CrossRef]

- Guo, M.X.; Wu, J.B.; Zhao, H.Y.; Li, F.H.; Min, F.Q. Carbonized loofah and MOF-801 of synergistic effect for efficient solar steam generation. Int. J. Energ. Res. 2021, 45, 10599–10608. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, L.; Li, T.; Wu, D.; Zhang, C.; Zhu, H. Efficient solar-driven interfacial water evaporation enabled wastewater remediation by carbonized sugarcane. J. Water. Process Eng. 2022, 49, 102991. [Google Scholar] [CrossRef]

- Cao, N.; Lu, S.; Yao, R.; Liu, C.; Xiong, Q.; Qin, W.; Wu, X. A self-regenerating air-laid paper wrapped ASA 3D cone-shaped Janus evaporator for efficient and stable solar desalination. Chem. Eng. J. 2020, 397, 125522. [Google Scholar] [CrossRef]

- Zou, M.; Zhang, Y.; Cai, Z.; Li, C.; Sun, Z.; Yu, C.; Dong, Z.; Wu, L.; Song, Y. 3D Printing a Biomimetic Bridge-Arch Solar Evaporator for Eliminating Salt Accumulation with Desalination and Agricultural Applications. Adv. Mater. 2021, 33, e2102443. [Google Scholar] [CrossRef] [PubMed]

- Chaule, S.; Hwang, J.; Ha, S.J.; Kang, J.; Yoon, J.C.; Jang, J.H. Rational Design of a High Performance and Robust Solar Evaporator via 3D-Printing Technology. Adv. Mater. 2021, 33, 2102649. [Google Scholar] [CrossRef] [PubMed]

- Khalil, A.; Ahmed, F.E.; Hilal, N. The emerging role of 3D printing in water desalination. Sci. Total. Environ. 2021, 790, 148238. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, C.; Song, X.; Huang, M.; Megarajan, S.K.; Shaukat, S.F.; Jiang, H. Improved light-harvesting and thermal management for efficient solar-driven water evaporation using 3D photothermal cones. J. Mater. Chem. A 2018, 6, 9874–9881. [Google Scholar] [CrossRef]

- Lv, F.; Miao, J.; Hu, J.; Orejon, D. 3D Solar Evaporation Enhancement by Superhydrophilic Copper Foam Inverted Cone and Graphene Oxide Functionalization Synergistic Cooperation. Small 2023, 19, e2208137. [Google Scholar] [CrossRef] [PubMed]

- Xie, M.; Zhang, P.; Cao, Y.; Yan, Y.; Wang, Z.; Jin, C. A three-dimensional antifungal wooden cone evaporator for highly efficient solar steam generation. NPJ Clean Water 2023, 6, 12. [Google Scholar] [CrossRef]

- Bu, Y.; Zhou, Y.; Lei, W.; Ren, L.; Xiao, J.; Yang, H.; Xu, W.; Li, J. A bioinspired 3D solar evaporator with balanced water supply and evaporation for highly efficient photothermal steam generation. J. Mater. Chem. A 2022, 10, 2856–2866. [Google Scholar] [CrossRef]

- Xu, Z.; Ran, X.; Zhang, Z.; Zhong, M.; Wang, D.; Li, P.; Fan, Z. Designing a solar interfacial evaporator based on tree structures for great coordination of water transport and salt rejection. Mater. Horiz. 2023, 10, 1737–1744. [Google Scholar] [CrossRef]

- Xu, Z.; Ran, X.; Wang, D.; Zhong, M.; Zhang, Z. High efficient 3D solar interfacial evaporator: Achieved by the synergy of simple material and structure. Desalination 2022, 525, 115495. [Google Scholar] [CrossRef]

- Chen, Y.; Hou, R.; Yang, L.; Chen, C.; Cui, J.; Zhou, T.; Zhao, Y.; Song, J.; Fan, Z.; Tang, Y.; et al. Elastic, Janus 3D evaporator with arch-shaped design for low-footprint and high-performance solar-driven zero-liquid discharge. Desalination 2024, 583, 117644. [Google Scholar] [CrossRef]

- Wu, L.; Dong, Z.; Cai, Z.; Ganapathy, T.; Fang, N.X.; Li, C.; Yu, C.; Zhang, Y.; Song, Y. Highly efficient three-dimensional solar evaporator for high salinity desalination by localized crystallization. Nat. Commun. 2020, 11, 521. [Google Scholar] [CrossRef]

- Zhang, Z.; Feng, Z.; Qi, H.; Chen, Y.; Chen, Y.; Deng, Q.; Wang, S. Carbonized sorghum straw derived 3D cup-shaped evaporator with enhanced evaporation rate and energy efficiency. Sustain. Mater. Technol. 2022, 32, e00414. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, B.; Hu, N.; Wang, H. Low-cost and facile fabrication of a candle soot/adsorbent cotton 3D-interfacial solar steam generation for effective water evaporation. Sol. Energ. Mater. Sol. C 2021, 221, 110876. [Google Scholar] [CrossRef]

- Sun, S.; Shi, C.; Kuang, Y.; Li, M.; Li, S.; Chan, H.; Zhang, S.; Chen, G.; Nilghaz, A.; Cao, R.; et al. 3D-printed solar evaporator with seashell ornamentation-inspired structure for zero liquid discharge desalination. Water Res. 2022, 226, 119279. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yan, Y.; Li, N.; Yang, P.; Yang, Y.; Duan, G.; Wang, X.; Xu, Y.; Li, Y. A robust and 3D-printed solar evaporator based on naturally occurring molecules. Sci. Bull. 2023, 68, 203–213. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Yang, J.; Zhang, D.; Wang, S.; Jia, X.; Li, Y.; Shao, D.; Feng, L.; Song, H.; Tang, S. A wood-inspired bimodal solar-driven evaporator for highly efficient and durable purification of high-salinity wastewater. J. Mater. Chem. A 2023, 11, 2349–2359. [Google Scholar] [CrossRef]

| Support Layer Category | Typical Materials | Main Advantages |

|---|---|---|

| Commercial polymer foam | Polyurethane (PU) foams Polystyrene (PS) foams Polydimethylsiloxane (PDMS) foam | Light weight, self-floating, low thermal, conductivity. |

| Functional polymer foam | Coating Functionalized Polymer Foam Substrate Modified Functional Polymer Foam | Light weight, self-floating, high-performance, multi-functionalization. |

| Gels | Hydrogel Aerogel | Environmentally friendly, unique transporting water structure. |

| Biomaterials | Natural plants Carbonized biomaterials Modified biomaterials | Cost-effective, rich source environmentally friendly. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Wang, P.; Li, L.; Zhao, Z.; Xiang, Y.; Guo, H.; Yang, B.; Yang, X.; Li, K.; Li, Y.; et al. Development Status of Solar-Driven Interfacial Steam Generation Support Layer Based on Polymers and Biomaterials: A Review. Polymers 2024, 16, 2427. https://doi.org/10.3390/polym16172427

Yan H, Wang P, Li L, Zhao Z, Xiang Y, Guo H, Yang B, Yang X, Li K, Li Y, et al. Development Status of Solar-Driven Interfacial Steam Generation Support Layer Based on Polymers and Biomaterials: A Review. Polymers. 2024; 16(17):2427. https://doi.org/10.3390/polym16172427

Chicago/Turabian StyleYan, Haipeng, Pan Wang, Lingsha Li, Zixin Zhao, Yang Xiang, Haoqian Guo, Boli Yang, Xulin Yang, Kui Li, Ying Li, and et al. 2024. "Development Status of Solar-Driven Interfacial Steam Generation Support Layer Based on Polymers and Biomaterials: A Review" Polymers 16, no. 17: 2427. https://doi.org/10.3390/polym16172427

APA StyleYan, H., Wang, P., Li, L., Zhao, Z., Xiang, Y., Guo, H., Yang, B., Yang, X., Li, K., Li, Y., He, X., & You, Y. (2024). Development Status of Solar-Driven Interfacial Steam Generation Support Layer Based on Polymers and Biomaterials: A Review. Polymers, 16(17), 2427. https://doi.org/10.3390/polym16172427