Antimicrobial Coatings Based on a Photoreactive (Meth)acrylate Syrup and Ferulic Acid—The Effectiveness against Staphylococcus epidermidis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

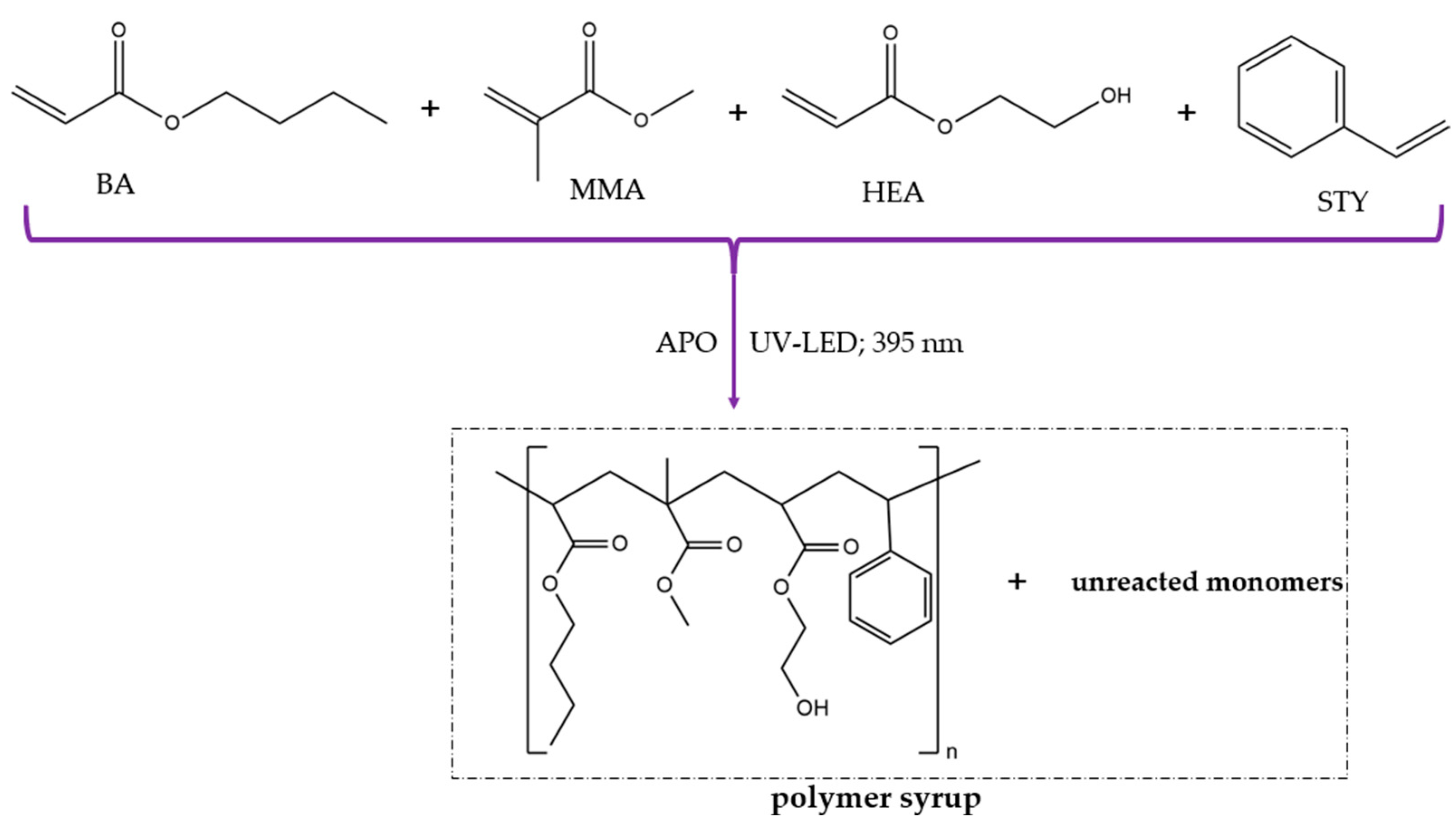

2.2. Preparation of the (Meth)acrylate Syrup

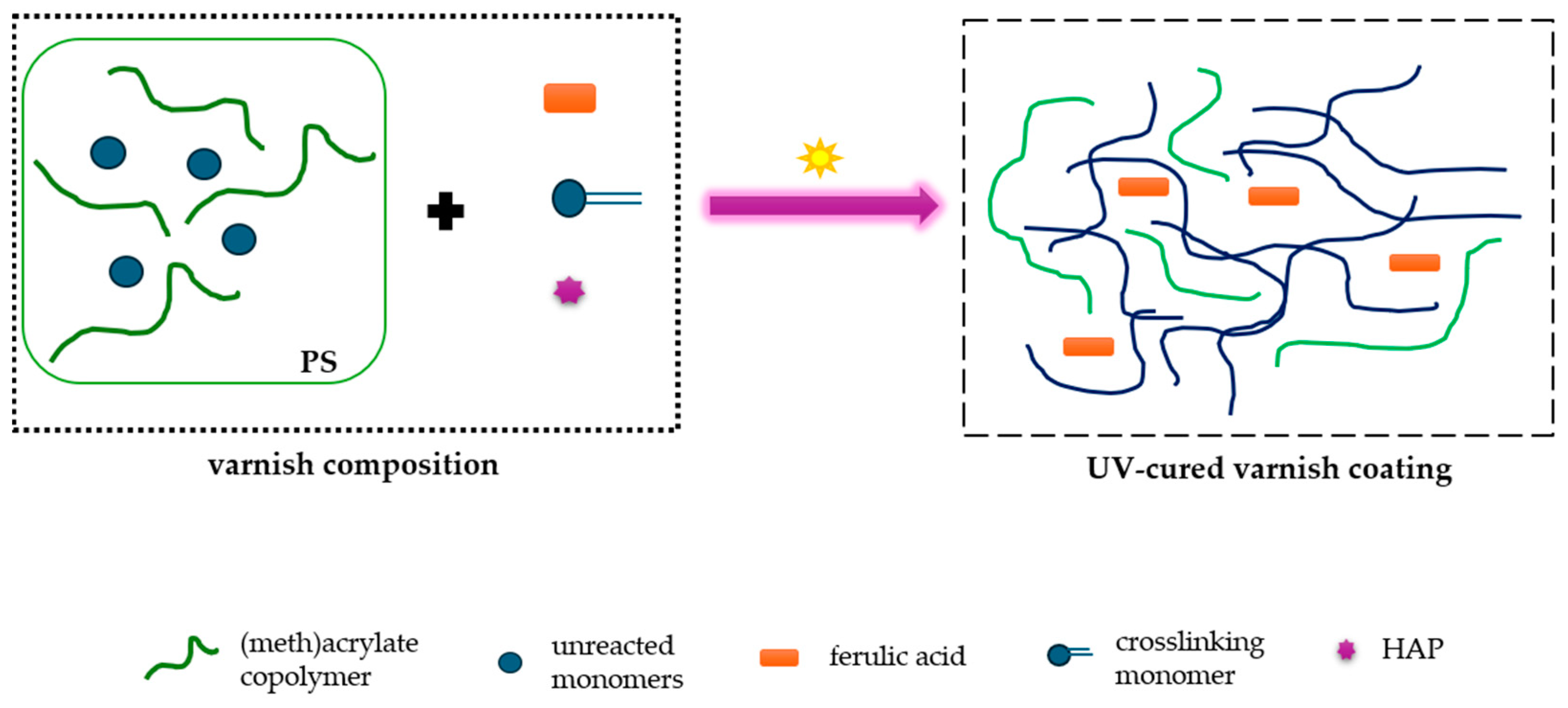

2.3. Preparation of the Varnish Compositions and Coatings

2.4. Characterization of the (Meth)acrylate Syrup

2.5. Kinetic Studies of the UV Curing Process of the Varnish Compositions

2.6. Structural Characteristics of the UV-Cured Varnish Coatings

2.7. Mechanical and Optical Characteristics of the UV-Cured Varnish Coatings

2.8. Antibacterial Properties of the UV-Cured Varnish Coatings

3. Results and Discussion

3.1. The Physicochemical Properties of the (Meth)acrylate Syrup and Copolymer

3.2. Kinetic Studies of UV Curing of the Varnish Composition

3.3. Structural Characterization of UV-Cured Varnish Coatings

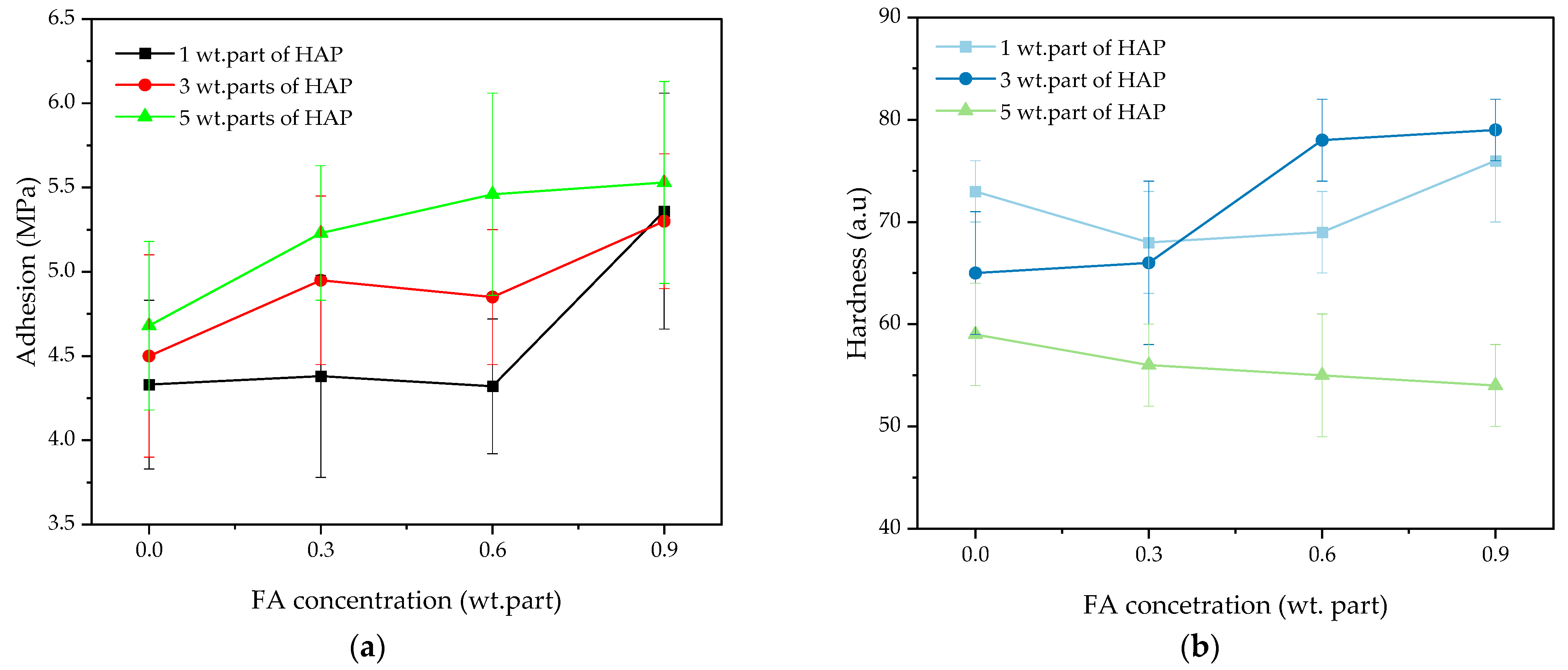

3.4. Mechanical and Optical Properties of the UV-Cured Varnish Coatings

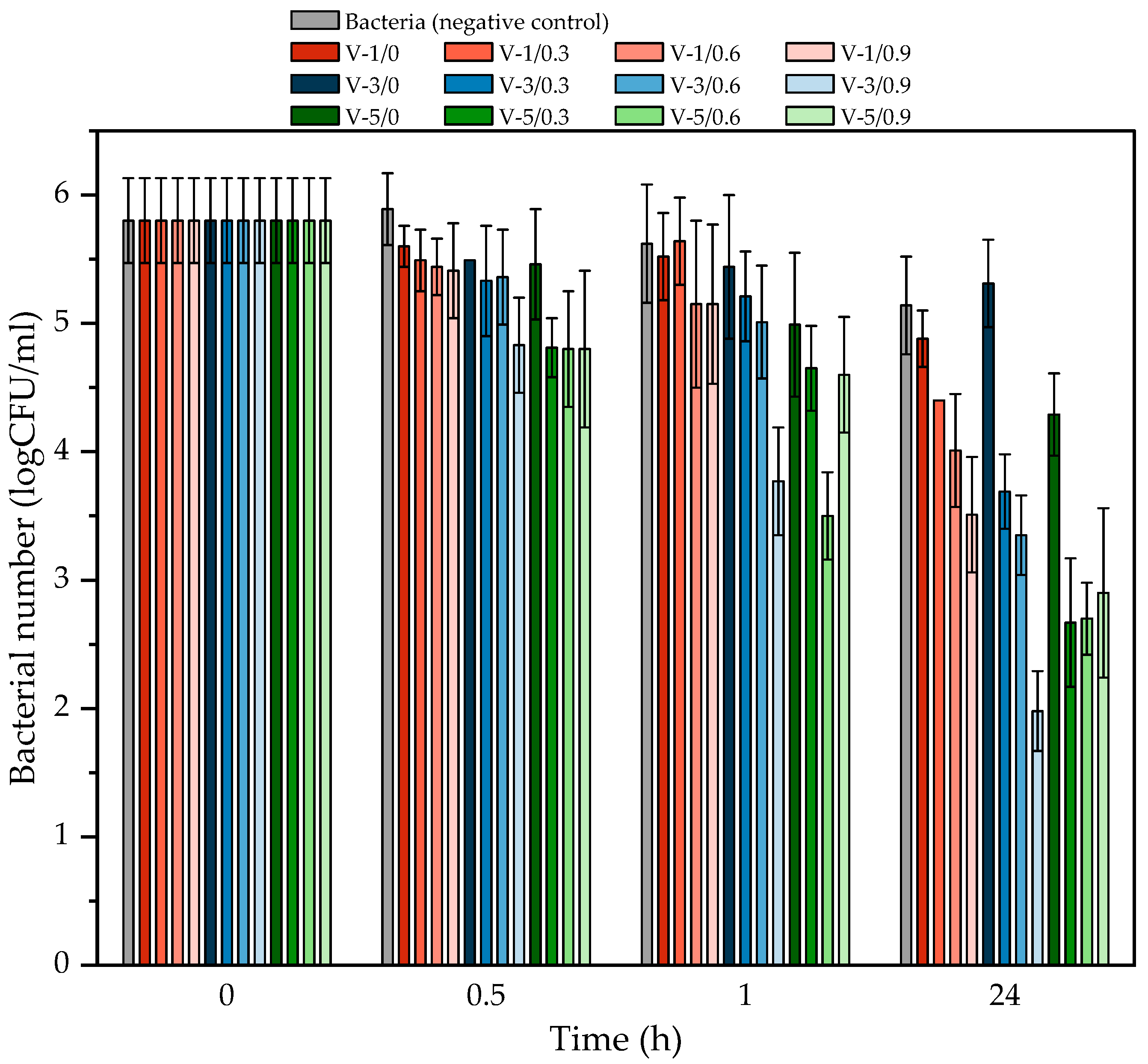

3.5. Antimicrobial Properties of the UV-Cured Varnish Coatings

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Donskey, C.J. Does improving surface cleaning and disinfection reduce health care-associated infections? Am. J. Infect. Control 2013, 41, 12–19. [Google Scholar] [CrossRef]

- Otter, J.A.; Yezli, S.; Salkeld, J.A.; French, G.L. Evidence that contaminated surfaces contribute to the transmission of hospital pathogens and an overview of strategies to address contaminated surfaces in hospital settings. Am. J. Infect. Control 2013, 41, 6–11. [Google Scholar] [CrossRef]

- Martínez-Santos, V.I.; Torres-Añorve, D.A.; Echániz-Aviles, G.; Parra-Rojas, I.; Ramírez-Peralta, A.; Castro-Alarcón, N. Characterization of Staphylococcus epidermidis Clinical Isolates from Hospitalized Patients with Bloodstream Infection Obtained in Two Time Periods. Peer J. 2022, 10, 1–17. [Google Scholar] [CrossRef]

- Steinka, I. The role of abiogenic factors in the transmission of microflora in hospital settings. Ann. Acad. Med. Gedan. 2013, 43, 165–174. [Google Scholar]

- Noskin, G.A.; Bednarz, P.; Suriano, T.; Reiner, S.; Peterson, L.R. Persistent contamination of fabric-covered furniture by vancomycin-resistant enterococci: Implications for upholstery selection in hospitals. Am. J. Infect. Control 2000, 28, 311. [Google Scholar] [CrossRef]

- Akbar, M.U.; Haque, A.; Liaquat, S.; Schierack, P.; Ali, A. Biofilm Formation by Staphylococcus epidermidis and Its Inhibition Using Carvacrol, 2-Aminobenzemidazole, and 3-Indole Acetonitrile. ACS Omega 2023, 8, 682–687. [Google Scholar] [CrossRef]

- Pilz, M.; Staats, K.; Tobudic, S.; Assadian, O.; Presterl, E.; Windhager, R.; Holinka, J. Zirconium Nitride Coating Reduced Staphylococcus epidermidis Biofilm Formation on Orthopaedic Implant Surfaces: An In Vitro Study. Clin. Orthop. Relat. Res. 2019, 477, 461–466. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Chen, M.; Jones, J.E.; Ritts, A.C.; Yu, Q.; Sun, H. Inhibition of Staphylococcus epidermidis Biofilm by Trimethylsilane Plasma Coating. Antimicrob. Agents Chemother. 2012, 56, 5923–5937. [Google Scholar] [CrossRef] [PubMed]

- Skovdal, S.; Jørgensen, N.P.; Petersen, E.; Jensen-Fangel, S.; Ogaki, R.; Zeng, G.; Johansen, M.I.; Wang, M.; Rohde, H.; Meyer, R.L. Ultra-dense polymer brush coating reduces Staphylococcus epidermidis biofilms on medical implants and improves antibiotic treatment outcome. Acta Biomater. 2018, 76, 46–55. [Google Scholar] [CrossRef]

- Kazemzadeh-Narbat, M.; Cheng, H.; Chabok, R.; Alvarez, M.M.; de la Fuente-Nunez, C.; Phillips, K.S.; Khademhosseini, A. Strategies for Antimicrobial Peptide Coatings on Medical Devices: A Review and Regulatory Science Perspective. Crit. Rev. Biotechnol. 2021, 41, 94–120. [Google Scholar] [CrossRef]

- Musa, N.H.; Chang, Z.H.; Teow, Y.H.; Rosli, N.A.; Mohammad, A.W. A Review on Polymer Based Antimicrobial Coating. J. Biochem. Microbiol. Biotechnol. 2022, 10, 1–8. [Google Scholar] [CrossRef]

- Ganguly, S.; Margel, S. Chapter 1—Introduction to Coatings and Surface Preparation. In Polymer-Based Nanoscale Materials for Surface Coatings; Thomas, S., George, J.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–18. [Google Scholar]

- Gan, Y.X. A Brief Summary of Publications in the Special Issue: Advances in Corrosion Resistant Coatings. Coatings 2022, 12, 996. [Google Scholar] [CrossRef]

- Xue, J.; Wang, J.; Cao, Y.; Zhang, X.; Zhang, L.; Chen, K.; Huang, C. Corrosion Protection Mechanism Study of Nitrite-Modified CaAl-LDH in Epoxy Coatings. Coatings 2023, 13, 1166. [Google Scholar] [CrossRef]

- Kotlík, P.; Doubravová, K.; Horálek, J.; Kubáč, L.; Akrman, J. Acrylic Copolymer Coatings for Protection against UV Rays. J. Cult. Herit. 2014, 15, 44–48. [Google Scholar] [CrossRef]

- Schwalm, R. UV Coatings: Basic, Recent Developments and New Application; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Ligon-Auer, S.C.; Schwentenwein, M.; Gorsche, C.; Stampfl, J.; Liska, R. Toughening of Photo-Curable Polymer Networks: A Review. Polym. Chem. 2016, 7, 257–286. [Google Scholar] [CrossRef]

- Patil, R.S.; Thomas, J.; Patil, M.; John, J. To Shed Light on the UV Curable Coating Technology: Current State of the Art and Perspectives. J. Compos. Sci. 2023, 7, 513. [Google Scholar] [CrossRef]

- Sheel Wali, A.; Kumar, S.; Khan, D. A Review on Recent Development and Application of Radiation Curing. Mater. Today Proc. 2023, 82, 68–74. [Google Scholar] [CrossRef]

- Mendes-Felipe, C.; Oliveira, J.; Etxebarria, I.; Vilas-Vilela, J.L.; Lanceros-Mendez, S. State-of-the-Art and Future Challenges of UV Curable Polymer-Based Smart Materials for Printing Technologies. Adv. Mater. Technol. 2019, 4, 1800618. [Google Scholar] [CrossRef]

- Liu, F.; Liu, A.; Tao, W.; Yang, Y. Preparation of UV Curable Organic/Inorganic Hybrid Coatings-a Review. Prog. Org. Coat. 2020, 145, 105685. [Google Scholar] [CrossRef]

- Sarfraz, M.H.; Hayat, S.; Siddique, M.H.; Aslam, B.; Ashraf, A.; Saqalein, M.; Khurshid, M.; Sarfraz, M.F.; Afzal, M.; Muzammil, S. Chitosan Based Coatings and Films: A Perspective on Antimicrobial, Antioxidant, and Intelligent Food Packaging. Prog. Org. Coat. 2024, 188, 108235. [Google Scholar] [CrossRef]

- Staneva, A.D.; Dimitrov, D.K.; Gospodinova, D.N.; Vladkova, T.G. Antibiofouling Activity of Graphene Materials and Graphene-Based Antimicrobial Coatings. Microorganisms 2021, 9, 1839. [Google Scholar] [CrossRef]

- Kędziora, A.; Speruda, M.; Krzyżewska, E.; Rybka, J.; Łukowiak, A.; Bugla-Płoskońska, G. Similarities and Differences between Silver Ions and Silver in Nanoforms as Antibacterial Agents. Int. J. Mol. Sci. 2018, 19, 444. [Google Scholar] [CrossRef] [PubMed]

- Sathiyaraj, S.; Suriyakala, G.; Dhanesh Gandhi, A.; Babujanarthanam, R.; Almaary, K.S.; Chen, T.-W.; Kaviyarasu, K. Biosynthesis, Characterization, and Antibacterial Activity of Gold Nanoparticles. J. Infect. Public Health 2021, 14, 1842–1847. [Google Scholar] [CrossRef] [PubMed]

- Vijayakumar, S.; Krishnakumar, C.; Arulmozhi, P.; Mahadevan, S.; Parameswari, N. Biosynthesis, Characterization and Antimicrobial Activities of Zinc Oxide Nanoparticles from Leaf Extract of Glycosmis Pentaphylla (Retz.) DC. Microb. Pathog. 2018, 116, 44–48. [Google Scholar] [CrossRef]

- Mitra, D.; Kang, E.T.; Neoh, K.G. Antimicrobial Copper-Based Materials and Coatings: Potential Multifaceted Biomedical Applications. ACS Appl. Mater. Interfaces 2020, 12, 21159–21182. [Google Scholar] [CrossRef] [PubMed]

- Kumaravel, V.; Nair, K.M.; Mathew, S.; Bartlett, J.; Kennedy, J.E.; Manning, H.G.; Whelan, B.J.; Leyland, N.S.; Pillai, S.C. Antimicrobial TiO2 Nanocomposite Coatings for Surfaces, Dental and Orthopaedic Implants. Chem. Eng. J. 2021, 416, 129071. [Google Scholar] [CrossRef]

- Boz, H. Ferulic Acid in Cereals—A Review. Czech. J. Food Sci. 2015, 33, 1–7. [Google Scholar] [CrossRef]

- Puligundla, P.; Mok, C. Valorization of Sugar Beet Pulp through Biotechnological Approaches: Recent Developments. Biotechnol. Lett. 2021, 43, 1253–1263. [Google Scholar] [CrossRef]

- Ferreira-Santos, P.; Zanuso, E.; Genisheva, Z.; Rocha, C.M.R.; Teixeira, J.A. Green and Sustainable Valorization of Bioactive Phenolic Compounds from Pinus By-Products. Molecules 2020, 25, 2931. [Google Scholar] [CrossRef]

- Kroon, P.A.; Garcia Cones, M.T.; Fillingham, I.J.; Williamson, G. Release of ferulic acid dehydrodimers from plant cell walls by feruloyl esterases. J. Sci. Food Agric. 1999, 79, 428–434. [Google Scholar] [CrossRef]

- Balasubashini, M.S.; Rukkumani, R.; Viswanathan, P.; Menon, V.P. Ferulic Acid Alleviates Lipid Peroxidation in Diabetic Rats. Phytother. Res. 2004, 18, 310–314. [Google Scholar] [CrossRef] [PubMed]

- Brenelli de Paiva, L.; Goldbeck, R.; Dantas dos Santos, W.; Squina, F.M. Ferulic acid and derivatives: Molecules with potential appli-cation in the pharmaceutical field. Braz. J. Pharm. Sci. 2013, 49, 395–411. [Google Scholar] [CrossRef]

- Dędek, K.; Rosicka-Kaczmarek, J.; Nebesny, E.; Kowalska, G. Characteristics and biological properties of ferulic acid. Biotechnol. Food Sci. 2019, 83, 71–85. [Google Scholar]

- Ou, S.; Kwok, K.C. Ferulic acid: Pharmaceutical functions, preparation and application in food. J. Sci. Food Agric. 2004, 84, 1261–1269. [Google Scholar] [CrossRef]

- Pinheiro, P.G.; Santiago, G.M.P.; Freitas da Silva, F.E.; Justino de Araújo, A.C.; Tavares de Oliveira, C.R.; Ramos Freitas, P.; Rocha, J.E.; Bezerra de Araújo Neto, J.; Costa da Silva, M.M.; Tintino, S.R.; et al. Ferulic acid derivatives inhibiting Staphylococcus aureus tetK and MsrA efflux pumps. Biotechnol. Rep. 2022, 34, e00717. [Google Scholar] [CrossRef]

- Zduńska, K.; Dana, A.; Kolodziejczak, A.; Rotsztejn, H. Antioxidant Properties of Ferulic Acid and Its Possible Application. Ski. Pharmacol. Physiol. 2018, 31, 332–336. [Google Scholar] [CrossRef]

- Janus, E.; Pinheiro, L.R.; Nowak, A.; Kucharska, E.; Świątek, E.; Podolak, N.; Perużyńska, M.; Piotrowska, K.; Duchnik, W.; Kucharski, Ł.; et al. New Ferulic Acid and Amino Acid Derivatives with Increased Cosmeceutical and Pharmaceutical Potential. Pharmaceutics 2023, 15, 117. [Google Scholar] [CrossRef]

- Mialon, L.; Pemba, A.G.; Miller, S.A. Biorenewable polyethylene terephthalate mimics derived from lignin and acetic acid. Green Chem. 2010, 12, 1704–1706. [Google Scholar] [CrossRef]

- Llevot, A.; Grau, E.; Carlotti, S.; Grelier, S.; Cramail, H. From Lignin-derived Aromatic Compounds to Novel Biobased Pol-ymers. Macromol. Rapid Commun. 2016, 37, 9–28. [Google Scholar] [CrossRef]

- Pezzana, L.; Mousa, M.; Malmström, E.; Johansson, M.; Sangermano, M. Bio-Based Monomers for UV-Curable Coatings: Al-lylation of Ferulic Acid and Investigation of Photocured Thiol-Ene Network. Prog. Org. Coat. 2021, 150, 105986. [Google Scholar] [CrossRef]

- Iemma, F.; Puoci, F.; Curcio, M.; Parisi, O.I.; Cirillo, G.; Spizzirri, U.G.; Picci, N. Ferulic acid as a comonomer in the synthesis of a novel polymeric chain with biological properties. J. Appl. Polym. Sci. 2010, 115, 784–789. [Google Scholar] [CrossRef]

- Clark, S.C.; Hill, D.J.T.; Hoyle, C.E.; Miller, C.W.; Shao, L.Y. N-Substituent effect of maleimides on acrylate polymerization initiated by three-component systems. Polym. Int. 2003, 52, 1701–1710. [Google Scholar] [CrossRef]

- Sebastian, S.; Sundaraganesan, N.; Manoharan, S. Molecular structure, spectroscopic studies and first-order molecular hyperpolarizabilities of ferulic acid by density functional study. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2009, 74, 312–323. [Google Scholar] [CrossRef]

- ISO 1522:2022; Paints and Varnishes—Pendulum Damping Test. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 4624:2023; Paints and Varnishes—Pull-Off Test for Adhesion. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 2813:2014; Paints and Varnishes—Determination of Gloss Value at 20°, 60° and 85°. International Organization for Standardization: Geneva, Switzerland, 2014.

- ASTM D5767-18; Standard Test Method for Instrumental Measurement of Distinctness-of-Image (DOI) Gloss of Coated Surfaces. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM E2149-20; Standard Test Method for Determining the Antimicrobial Activity of Antimicrobial Agents under Dynamic Contact Conditions. ASTM International: West Conshohocken, PA, USA, 2020. Available online: www.astm.org (accessed on 20 October 2021).

- Gziut, K.; Kowalczyk, A.; Schmidt, B.; Idzik, T.J.; Sośnicki, J.G. Influence of Methacrylate and Vinyl Monomers on Radical Bulk Photopolymerization Process and Properties of Epoxy-Acrylate Structural Adhesives. Polymers 2023, 15, 926. [Google Scholar] [CrossRef] [PubMed]

- Gziut, K.; Kowalczyk, A.; Schmidt, B.; Kowalczyk, K.; Weisbrodt, M. Epoxy-Based Structural Self-Adhesive Tapes Modified with Acrylic Syrups Prepared via a Free Radical Photopolymerization Process. Polymers 2021, 13, 189. [Google Scholar] [CrossRef]

- Kraśkiewicz, A.; Kowalczyk, A.; Kowalczyk, K.; Markowska-Szczupak, A.; Idzik, T.J.; Sośnicki, J.G. Anticorrosive and antimicrobial efficiency of photopolymerizable phosphorus (meth)acrylate oligomers-based coating materials. Prog. Org. Coat. 2024, 187, 108141. [Google Scholar] [CrossRef]

- Cho, J.-D.; Ju, H.-T.; Hong, J.-W. Photocuring kinetics of UV-initiated free-radical photopolymerizations with and without silica nanoparticles. J. Polym. Sci. A Polym. Chem. 2005, 43, 658–670. [Google Scholar] [CrossRef]

- EPA Product Performance Test Guidelines. OCSPP 810.2200: Disinfectants for Use on Hard Surfaces—Efficacy Data Recommendations. 2012. Available online: https://www.regulations.gov/document?D=EPA-HQ-OPPT-2009-0150-0021 (accessed on 4 August 2023).

- Shirai, A.; Yasutomo, Y.K. Bactericidal action of ferulic acid with ultraviolet-A light irradiation. J. Photochem. Photobiol. B Biol. 2019, 191, 52–58. [Google Scholar] [CrossRef]

| (Meth)acrylate Syrup | Monomers [wt. parts] | APO [wt. part] | |||

|---|---|---|---|---|---|

| BA | MMA | HEA | STY | ||

| MAS | 40 | 35 | 15 | 10 | 0.75 |

| Varnish Symbol | Components [wt. parts] | |||

|---|---|---|---|---|

| MAS | PETIA | HAP | FA | |

| CV-1/0 | 100 | 15 | 1 | 0 |

| CV-1/0.3 | 0.3 | |||

| CV-1/0.6 | 0.6 | |||

| CV-1/0.9 | 0.9 | |||

| CV-3/0 | 3 | 0 | ||

| CV-3/0.3 | 0.3 | |||

| CV-3/0.6 | 0.6 | |||

| CV-3/0.9 | 0.9 | |||

| CV-5/0 | 5 | 0 | ||

| CV-5/0.3 | 0.3 | |||

| CV-5/0.6 | 0.6 | |||

| CV-5/0.9 | 0.9 | |||

| Syrup | Copolymer | |||

|---|---|---|---|---|

| SC (%) | ƞ [Pa·s] | Mn [g/mol] | Mw [g/mol] | PDI [a.u.] |

| 51 | 4.6 | 15,000 | 56,000 | 3.7 |

| HAP (wt. part) | 1 | 3 | 5 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FA (wt. part) | 0 | 0.3 | 0.6 | 0.9 | 0 | 0.3 | 0.6 | 0.9 | 0 | 0.3 | 0.6 | 0.9 |

| Conversion (%) | 78 | 74 | 77 | 81 | 72 | 71 | 72 | 75 | 67 | 68 | 70 | 70 |

| tRpmax (s) | 2.8 | 6.1 | 5.7 | 9.4 | 2.1 | 4.0 | 5.5 | 7.0 | 1.8 | 3.8 | 5.6 | 6.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalczyk, A.; Kraśkiewicz, A.; Markowska-Szczupak, A.; Kowalczyk, K. Antimicrobial Coatings Based on a Photoreactive (Meth)acrylate Syrup and Ferulic Acid—The Effectiveness against Staphylococcus epidermidis. Polymers 2024, 16, 2452. https://doi.org/10.3390/polym16172452

Kowalczyk A, Kraśkiewicz A, Markowska-Szczupak A, Kowalczyk K. Antimicrobial Coatings Based on a Photoreactive (Meth)acrylate Syrup and Ferulic Acid—The Effectiveness against Staphylococcus epidermidis. Polymers. 2024; 16(17):2452. https://doi.org/10.3390/polym16172452

Chicago/Turabian StyleKowalczyk, Agnieszka, Agata Kraśkiewicz, Agata Markowska-Szczupak, and Krzysztof Kowalczyk. 2024. "Antimicrobial Coatings Based on a Photoreactive (Meth)acrylate Syrup and Ferulic Acid—The Effectiveness against Staphylococcus epidermidis" Polymers 16, no. 17: 2452. https://doi.org/10.3390/polym16172452