Abstract

New carriers for protein immobilization are objects of interest in various fields of biomedicine. Immobilization is a technique used to stabilize and provide physical support for biological micro- and macromolecules and whole cells. Special efforts have been made to develop new materials for protein immobilization that are non-toxic to both the body and the environment, inexpensive, readily available, and easy to modify. Currently, biodegradable and non-toxic polymers, including cellulose, are widely used for protein immobilization. Bacterial cellulose (BC) is a natural polymer with excellent biocompatibility, purity, high porosity, high water uptake capacity, non-immunogenicity, and ease of production and modification. BC is composed of glucose units and does not contain lignin or hemicellulose, which is an advantage allowing the avoidance of the chemical purification step before use. Recently, BC–protein composites have been developed as wound dressings, tissue engineering scaffolds, three-dimensional (3D) cell culture systems, drug delivery systems, and enzyme immobilization matrices. Proteins or peptides are often added to polymeric scaffolds to improve their biocompatibility and biological, physical–chemical, and mechanical properties. To broaden BC applications, various ex situ and in situ modifications of native BC are used to improve its properties for a specific application. In vivo studies showed that several BC–protein composites exhibited excellent biocompatibility, demonstrated prolonged treatment time, and increased the survival of animals. Today, there are several patents and commercial BC-based composites for wounds and vascular grafts. Therefore, further research on BC–protein composites has great prospects. This review focuses on the major advances in protein immobilization on BC for biomedical applications.

1. Introduction

Protein immobilization is a biotechnological technique in which a protein is fixed in a suitable matrix to limit mobility, increase stability, and, in the case of an enzyme protein, allow reuse while retaining the immobilized protein activity [1]. The immobilized proteins and enzymes have been used in biomedicine, including the detection and treatment of many diseases. The immobilization process allows protein functionality to be optimized for specific tasks. For example, immobilized antibodies, receptors, or enzymes are used in biosensors and ELISA to detect various bioactive substances in disease diagnosis. Immobilized enzymes are also used in bioreactors to remove waste metabolites and correct congenital metabolic deficiencies. Today, artificial cells are being developed and controlled-release drug delivery systems based on the release of encapsulated enzymes or proteins are being created [2,3]. Immobilization of the protein improves its stability by preventing environmentally induced structural denaturation, allowing it to remain active under various conditions [4,5]. The incorporation of proteins into polymer biomaterials enables the acquisition of pro-adhesive properties, a modification of the biomaterial’s hydrophilicity, the introduction of supplementary functional groups that facilitate cellular activity, an alteration of the surface stiffness, and a modification of the biomaterial’s degradation rate [6].

The matrix for protein immobilization should be inert, stable, accessible, resistant to mechanical stress, and biocompatible without disrupting the protein structure. Among the matrixes, natural polymers as carriers have attracted considerable attention [7]. Polysaccharides, cellulose, chitosan, alginate, and their derivatives are widely used in protein immobilization [8]. Recently, cellulose materials have been studied and used due to their good renewability, availability, biodegradability, and biocompatibility [9]. Cellulose is a robust, dual hydrophilic/hydrophobic, non-toxic, and chemically inert material under physiological conditions [10]. Cellulose is a versatile material that can be used as a reinforcement material or as a matrix, depending on the specific requirements of the task at hand. Its well-organized fibrous network structure allows it to enclose nanoparticles, acting as a matrix. Similarly, cellulose nanofibers can be used to reinforce other materials, cells, and tissues [11]. BC has similar chemistry and superior physical properties to plant cellulose, making it an ideal choice for manufacturing a range of composite materials for diverse applications [12]. The composite BC with protein can utilize the dual properties of both materials [13]. In addition, several BC-based composites were created that showed high protein immobilization efficiency compared to other materials [14,15,16].

BC is produced by gram-positive bacteria such as Sarcina and gram-negative bacteria strains the Acetobacter, Rhizobium, Agrobacterium, Aerobacter, Achromobacter, Azotobacter, Salmonella, Escherichia [17,18]. Moreover, BC can be synthesized in a cell-free system [19]. BC is a biopolymer consisting of linear chains of covalently linked glucose residues between carbon 1 and 4—β (1,4)-bound d-glucopyranosyl [20]. BC does not contain lignin and hemicellulose, rendering it more pure than plant cellulose [21]. BC has high porosity, water-holding capacity biocompatibility, low toxicity, and non-immunogenicity and can be readily and safely sterilized [22]. Moreover, BC has enhanced mechanical strength, biodegradability, and high crystallinity [14] and increased the surface-to-volume ratio [23,24].

BC composites are prepared to adapt their characteristics for a specific application [25] and overcome the disadvantages of native BC. By in situ modification, different structures can be formed during fermentation to produce materials for various applications. In addition, BC can be modified ex situ by adding a functional compound or polymer coating [26]. Previously has been demonstrated that the combination of nanoparticles (Ag, ZnO, etc.) and polymers (e.g., polyaniline, chitosan, polyethylene glycol) can be used to create BC composites with bactericidal and conductive properties [12], enhance antimicrobial, antiviral and anticancer activities [27]. BC-based nanocomposites were used for phage immobilization to detect live S. aureus [28], incorporation of probiotic bacteria Lactobacillus acidophilus 016 [29], and yeast immobilization [30]. BC is utilized in the development of drug delivery systems, scaffolds, tissue and organ regeneration, and wound healing [31].

The latest drug delivery research has further demonstrated various advantages of BC, including its promising effects on controlling drug release, biocompatibility, low immunogenicity, and ease of production and handling [32]. BC films have been successfully used for the immobilization of antibiotics (amoxicillin [33], tetracycline [34], levofloxacin [35], ciprofloxacin [36], gentamycin [37]), anesthetics (lidocaine [38]), anticancer drugs (doxorubicin [39], curcumin [40], paclitaxel [41], immune checkpoint blocking antibodies [32]). The porous structure and increased surface area of BC make it useful for the immobilization of enzymes and bioactive compounds [42]. Various types of BC and activation methods have been investigated to immobilize glucoamylase [43,44], glutamate decarboxylase [45], and laccase [14].

The commercialization of BC has increased markedly recently, driven by its growing applications in a range of fields. The global BC market was valued at approximately USD 426.7 million in 2022 [46] and is projected to reach approximately USD 777 million by 2027 [47]. Among the major trends in the BC market today, the main interest is in the creation of BC-based composites for wound care products, dental treatment, organ regeneration, and BC for drug delivery [46]. Soon, BC can potentially be widely applied in bioprinting techniques [48]. Furthermore, as regulatory agencies promote the use of xeno-free biomaterials in human care and medicine delivery, BC has gained popularity due to its animal- and human-free origin [49]. Currently, an increasing number of studies [50] have been dedicated to the utilization of BC in the development of protein composites for wound healing, tissue engineering, three-dimensional (3D) cell culture systems, drug delivery systems, and enzyme immobilization matrices. This review concentrates on the employment of BC for protein immobilization in biomedical applications, the diverse forms of protein immobilization and the modifications of BC for protein immobilization, and the advantages and disadvantages of employing BC as a carrier.

2. Structure of Bacterial Cellulose

BC is a linear glucose biopolymer produced primarily by the bacterium Gluconacetobacter xylinus (G. xylinus) in both synthetic and non-synthetic environments via oxidative fermentation. This non-photosynthetic organism can obtain sugars, glycerol, glucose, and various other organic molecules before converting them to pure cellulose [51,52]. Bacteria strains typically produce and use BC as a protective envelope against harsh environmental conditions or as a component of their cell walls. The bacteria release nanofibrils that self-assemble into larger fibers that interconnect to form a BC matrix of increasing volume and density. The BC matrix forms a visible hydrogel called a pellicle at the air–liquid interface of the working culture [53].

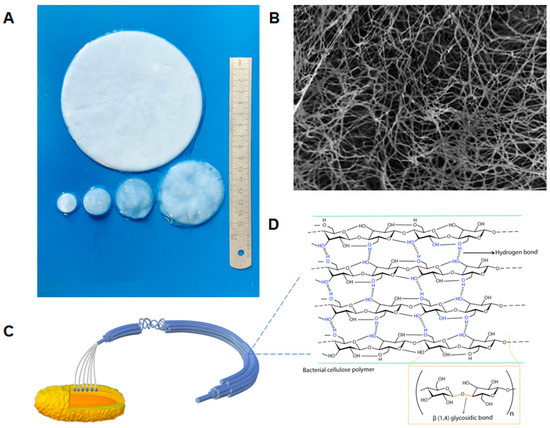

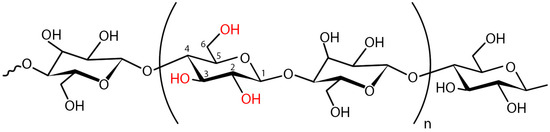

BC is composed of β-(1 → 4) glucan chains with fiber widths of 25–100 nm and lengths of several microns. It is predominantly twisted to the left. BC is the “gold standard” for nanocellulose because one of its dimensions is on the nanometer scale, and it is released in a controlled environment by bacteria. The monomer unit has a cyclic structure with reactive primary and secondary hydroxyl groups (Figure 1). The β-D-glucopyranose ring and all -OH groups are free and play an important role in intermolecular hydrogen bonding between adjacent chains [20]. Each monomer unit is rotated 180° relative to its neighbor. These chains first form nanofibrils, then microfibrils, and finally macrofibrils (Figure 1) [54]. The microfibrils exhibit distinctive characteristics, including unidirectional polarity and variable thickness [55].

Figure 1.

Schematic of bacterial cellulose structure: (A) Photograph of purified BC films. (B) SEM image of films grown for 72 h. Magnification 10,000×; (C) Schematic of the structure of BC microfibrils. BC are arranged in parallel chains (10–15) via hydrogen bonds to form subfibrils, then aggregated into microfibrils, and finally into microfibril bundles that form a ribbon composed of about 1000 individual glucan chains [56]; (D) Chemical structure of the BC polymer and inter- and intra-hydrogen bonding of BC. Intramolecular hydrogen bonds form in the C3–OH group and oxygen on the pyranose ring.

Although both BC and plant cellulose have structural similarities, their distinct nanofibrous structures give them different physical and chemical properties [57]. BC is classified as a cellulose subtype Iα, while plant cellulose is mainly classified as Iβ, which differ in their crystalline structure [54], molecular conformation, and hydrogen bonding, and these differences may influence the physical properties of the cellulose [56]. In contrast to plant cellulose, BC comprises a fully crystalline core encased in a less crystalline zone interposed by the amorphous form of cellulose, along with fibers arranged in a 3D lattice. Due to the robust intermolecular interactions and the presence of hydroxyl groups, the fibers exhibit a proclivity for self-assembly. These fibers give rise to a network structure interconnected by intramolecular hydrogen bonds, resulting in the formation of sheets with a high surface area and porosity [20].

BC exhibits ultrafine fibers (width 50–80 nm and thickness 3–8 nm) [14], and BC is thinner than plant cellulose [23,24]. Furthermore, in contrast to plant cellulose, which typically consists of fibers with 10,000–15,000 degrees of polymerization, BC fibers consist of the pure form of the polymer with a degree of polymerization of 2000–8000. Such structural characteristics render microbial cellulose with improved mechanical properties, such as strength and toughness, compared to plant cellulose with a similar chemical structure [53]. Different morphologies of BC have a direct effect on its mechanical properties and cell attachment to the material. Tang et al. [58] produced BC mats with different aperture sizes and porosities when the fermentation conditions and post-treatment interventions were changed. Backdahl et al. [59] invented a novel approach to introduce microporosity in BC tubes, which are intended to be used as scaffolds for tissue-engineered blood vessels [51]. BC, like plant cellulose, contains reactive hydroxyl groups that can be modified [25]. The increased surface area-to-volume ratio allows for greater interaction with the components of BC-derived composites, making them ideal for medical applications.

3. Biomedical Application of Bacterial Cellulose

The use of BC for biomedical applications has attracted considerable interest over the past decade [60]. BC is a promising biomaterial due to its physical and chemical properties [24,25,61]. Various surface functionalizations by biosynthetic or chemical modification can enhance the functionality of BC and broaden their potential applications [62].

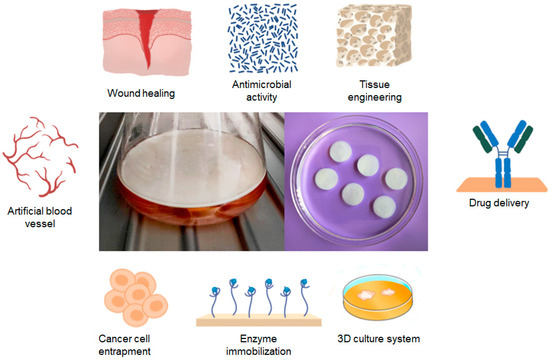

Both native and modified BC have been used in various applications, including tissue engineering, the fabrication of artificial organs, and the development of scaffolds and drug delivery systems (Figure 2) [63]. Previously, the most diversified application of BC in biomedicine has been the creation of drug delivery systems. A significant number of published research studies have attempted to develop an effective BC-based system for delivering specific drugs to the wound or diseased tissue [64]. The majority of BC carrier research focuses on loading cellulose (often a dressing) with small molecules, including analgesics and anti-inflammatory drugs, bacteriostatic agents such as metal ions, antibiotics, or other chemicals [65].

Figure 2.

The primary areas of application for BC in the biomedical industry.

The latest developments in the field of BC focus on new carrier materials for cell culture, cell encapsulation or enzyme immobilization, medical device coating, and the production of BC materials with soft tissue implants and materials for bone regeneration [66]. To achieve this, it is important to immobilize larger molecules such as proteins (e.g., albumin, lysozyme, lipase, or phospholipase) and growth factors in the membrane after changing the porosity of the cellulose nanostructure. In recent times, BC-based materials have been employed in the field of cancer therapeutics [24,61]. BC-based materials are also suitable for the delivery of proteins and nucleic acids [67,68].

3.1. Wound Healing and Antibacterial Wound Dressings

A wound is a break in the continuity of the skin. Microbial infection and inflammation are the most common wound-related conditions [69]. Wound healing requires the coordinated and balanced activity of inflammation and vascularization of connective tissue and epithelial cells. All of these stages require an extracellular matrix (ECM) and various growth factors to support the healing process [70]. The primary proteins of the ECM are collagen, non-collagen fractions, and proteoglycans [71]. These proteins serve as scaffolds and mediate cell attachment, cellular proliferation, differentiation, and migration. Each organ has a unique ECMs [20].

ECM proteins, a plethora of growth factors, and antidiabetic wound-healing agents (insulin) play a pivotal role in the process of tissue regeneration [72]. Proteins and growth factors are used to create nanopreparations with wound healing and regenerative effects to help reduce inflammation, cell proliferation, and remodeling. These formulations release proteins over time, increasing the efficacy and impact on the wound area, promoting targeted drug delivery, improving solubility and biocompatibility, and helping wounds heal without complications [72]. Enzymatic wound treatment with proteases is already used in surgical practice [73]. Proteolytic enzymes (serine proteases, metalloproteinases, cysteine proteases, and aspartate proteases) contribute positively to tissue regeneration processes [74].

Despite the advances in wound healing management, the treatment of the majority of skin lesions remains a significant challenge for the biomedical and pharmaceutical industries [75,76,77]. Alternative approaches, such as the use of hydrogels as wound dressings, can be used when surgery is not feasible due to patient circumstances or when there is insufficient necrotic tissue [78]. Wound healing materials must be able to keep the wound moist, absorb wound fluid, promote new skin growth, let in oxygen and other gases, and fight infection. They must also be safe for the body [79]. In addition, the material must act as a suitable interphase to support the complex interactions that occur during wound healing involving various cells, soluble substances, and ECM components. Therefore, the aforementioned properties of BC make it ideal for this purpose [25,80].

For the first time, BC was used in medicine as a wound dressing to promote tissue regeneration [81]. A moist environment, non-toxicity and non-allergy, promotion of thermal insulation, and ease of gas transfer are the primary requirements for effective wound dressings [82]. The use of constructed BC composite scaffolds can extend cell adhesion, proliferation, and transplantation of scaffold-seeded cells, enhancing their biocompatibility [81]. It has been shown that BC and BC-composites are biocompatible with skin tissues [83]. BC is appropriate for skin care applications because it can relieve discomfort, speed healing, and fit the body well [82]. Water-holding is an important factor in the healing process because dry wounds need more moisture to promote tissue regeneration and prevent necrosis [84,85]. BC has a 30% higher water absorption capacity and a 33% longer drying time than cotton gauze [86]. In terms of maintaining a moist wound environment, reducing discomfort, accelerating tissue re-epithelialization, and minimizing scarring, BC-based wound dressings outperformed conventional wound dressings [31,87]. By retaining liquid, a hydrogel can be used to load liquid medications and physiologically active substances close to the dressing material [88].

In vivo studies have proved that BC wound dressings in porous form outperform compacted form in terms of wound healing performance [13,89]. Long-term clinical trials have shown that BC-based dressings are more cost-effective than standard fiber dressings (surgical pads, tulle grass, and saline-impregnated gas), synthetic foams, and alginate dressings. The high surface area and porosity of BC allow for the integration of additional wound-healing-promoting agents [12,90]. A number of commercial BC-based dressings have been developed, including BioFill®, Bioprocess®, Gengiflex® (BioFill Produtos Biotecnológicos, Curitiba, Brazil), Xcell® (Xylos Corporation, Langhorne, PA, USA), Dermafill® (Seven Indústria de Produtos Biotecnológicos Ltda, Londrina, Brazil), and Epiprotect® (Royal Wootton Bassett, UK). The efficacy of BC-based dressings has been investigated in clinical trials, with the results demonstrating that the BC membrane can significantly reduce pain and facilitate the healing of a range of wounds [83,91]. The dressings based on BC can vary considerably in composition, from relatively simple films to highly complex constructions. They often incorporate various biomolecules, pharmaceutical agents, and polymers [92].

There are several limitations to the use of BC-based dressings. Due to the slow degradation of BC, several attempts have been made to improve the degradability of BC for wound healing. Several approaches have been used: oxidation with periodate, γ-irradiation, or incorporation of the enzyme cellulase into BC [93]. Compared to more expensive protein-based materials, BC shows limited cell attachment and proliferation, especially in fibroblast cells in the wound. Several modification strategies have been developed to improve the cellular response of fibroblasts to various materials. Techniques include biopolymer/protein adsorption, gas plasma surface modification, and self-assembled monolayers [94].

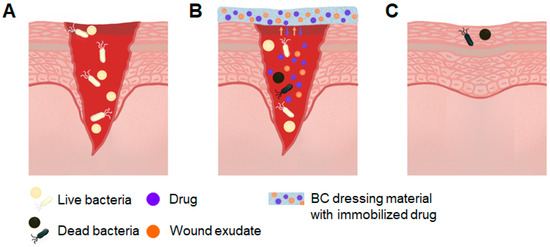

Regarding passive wound healing, BC can be combined with various compounds, including antimicrobial polymers, photosensitizers, metallic nanoparticles, antibiotics, antimicrobial peptides, and antiseptics to accelerate wound healing. Researchers often use BC doped with conductive chemicals to locate wound healing sites. This allows the circuit to be carried over a large area and stimulates skin cell behavior, resulting in faster healing [81,91]. BC-based composites can help retain and slowly release antibiotics (Figure 3); however, the issue of antibiotic resistance is still being investigated [95]. Antibacterial nanomaterials may replace antibiotics, but nanoparticles have drawbacks such as easy aggregation, an unpredictable tendency to release ions, and potential cytotoxicity that limit their use [96]. Due to the large number of active functional groups, BC and its modified derivatives can be used as a template or immobilization material for antibacterial nanoparticles, which helps to reduce nanoparticle agglomeration and control the release rate. As a result, there is no defect-free BC-based wound dressing material, and the development of multifunctional BC-based composites is an important area of future research [97].

Figure 3.

Schematic of wound treatment with antibacterial BC-based composites. (A) Infection of open wound; (B) wound treatment with BC composite. The BC absorbs wound exudate and is loaded with an antibacterial agent that is released into the wound; (C) healed wound.

There are a number of techniques that can be employed to modify BC in order to address the shortcomings of the native material while simultaneously optimizing its biocompatibility, water uptake and release, and antibacterial activity [97]. Given that BC lacks intrinsic antimicrobial properties [78], it is modified by incorporating other polymers or inorganic materials. Modification of BC has several goals, including improving mechanical properties, changing some physical parameters such as water-holding capacity, water retention rate, and water vapor transmission rate, or even imparting antimicrobial activity [98]. Various techniques, including microbial fermentation, physical modification, chemical modification, and combination modification, have been used to enhance the biocompatibility and antibacterial activity of BC to ensure better use in wound healing [25,83]. For dental and drug delivery applications, the degradability of BC mediated by oxidation is very important [25], as BC is slow to degrade in the human body [99,100]. Also, composites are created with collagen [101,102,103,104] and sericin [105]. These polymers strengthen the BC structure, improve its mechanical properties, and accelerate wound healing [78,106]. β-keratose [107], ECMs (collagen, elastin, and hyaluronan) and growth factors (B-FGF, H-EGF, and KGF) [70], laccase [108], soybean protein isolate [13], involucrin antibody SY5 [109], papain [110] have been used for the development of BC-based wound dressings. The BC with antibacterial activity was obtained with lysozyme [111,112] and such peptides as nisin [113], ε-poly-l-Lysine [79], and bacteriocins from Lactobacillus sakei [114,115].

3.2. Tissue Engineering

Tissue engineering involves developing scaffolds and growth factors that influence the regeneration or replacement of damaged tissue [106,116,117]. The scaffold material plays a pivotal role in providing the biological and physical environment essential for tissue growth, including the ECM. This is achieved by facilitating cell adhesion, development, and differentiation [71,118]. The replacement of natural ECMs is becoming an increasingly crucial and promising aspect of tissue engineering, as they facilitate the localization and transportation of cells to specific regions of the body [119].

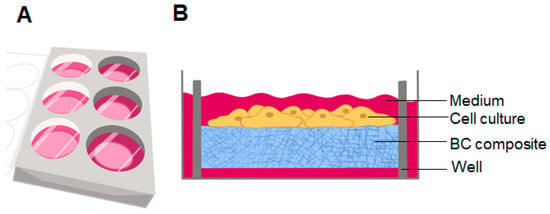

BC structurally resembles natural ECM [120], therefore, BC has been believed to be a promising material for tissue engineering scaffolds [121]. The BC products have been approved by the FDA for use as tissue replacement due to their low endotoxin levels (less than 20 EU per device) [122]. BC scaffolds (Figure 4) have been shown to have the potential to serve as a viable material for chondrogenesis applications due to their ability to successfully regenerate cartilage using human mesenchymal stem cells [123]. In vivo studies consistently demonstrate that BC membranes or scaffolds are typically well tolerated by host tissues after implantation, with no significant adverse effects [124]. Several studies have shown good in vivo biocompatibility of BC-based scaffolds, giving the material potential for use as a scaffold in tissue engineering [21,117,125,126,127].

Figure 4.

(A) Culture plate with BC hydrogel placed in a black well; (B) diagram of a monolayer of cell culture grown on BC.

While the suitability of BC as a raw material for the fabrication of tissue engineering grafts has been demonstrated, the native form of BC is deficient in certain fundamental characteristics that are essential for its utilization in tissue engineering. These include limited biocompatibility, which is a prerequisite for effective tissue regeneration, and inadequate mechanical strength, which is a prerequisite for high-strength applications such as bone and cartilage tissue engineering [128]. Moreover, there is currently no research available that investigates the potential for BC to calcify in vivo over a long-term period [129]. The lack of macropores in native BC also limits its widespread use in tissue engineering [117], as calcification is largely dependent on the porosity of the material and the length of exposure. It should be emphasized that while calcification is undesirable, the degree of calcification will vary depending on the tissue into which the biomaterial is to be incorporated. Appropriate porosity can prevent calcification processes by ensuring angiogenesis and adequate nutrient supply to the cells [129]. In addition, BC has strong mechanical properties, although the presence of many pores limits its stress-bearing capacity [12]. Furthermore, there is a possibility of immunological rejection [106]. To overcome these limitations, the most commonly studied strategies include the production of BC-based nanocomposites with bioactive components, such as polymers and nanomaterials [128].

The majority of research studies have focused on modifying the microporosity of BC to produce materials with the desired properties for replacement or regeneration applications [118,130,131]. Collagen was primarily employed in the development of composite materials with BC for tissue engineering [132,133,134,135,136]. In comparison to the use of collagen composites alone, it has been demonstrated that BC-collagen composites facilitate enhanced cell adhesion and proliferation [132]. In addition, modification BC by proteins such as osteopontin and bone morphogenetic protein 2 (BMP-2) can provide a novel alternative to collagen in the guided bone regeneration field [120,137,138]. In several studies, BC–gelatin composite scaffolds were fabricated for bone tissue engineering applications [117,118,139,140]. BC-keratin composite scaffolds [141] were created for skin tissue engineering. In one study, BC was functionalized by recombinant IKVAV peptide for nerve tissue engineering. BC has also been used for nerve regeneration. BC functionalized with recombinant proteins IKVAV-CBM3 (Ile-Lys-Val-Ala-Val fused with cellulose-binding module) and (19)IKVAV-CBM3 increased mesenchymal stem cell adhesion, cell survival, and neurotrophin expression, which promoted neuronal regeneration [142]. A soy protein isolate (SPI) has been compounded on a double-modified BC to provide a new material for urethral reconstruction [143].

3.3. Artificial Blood Vessels

The limited availability of veins in the human body and the potential for severe rejection caused by allografts necessitates the development of artificial veins as a replacement. The most commonly employed clinical artificial vessels are currently constructed of expanded polytetrafluoroethylene (ePTEE, Gore-Tex), polyglycolic acid (PGA), and poly-l-lactic acid (PLLA). However, these materials exhibit several inadequacies that facilitate the formation of thrombi and intimal thickening, which must be addressed in the design of new artificial vein models [144]. In addition, when the procoagulant properties of PET (polyethylene terephthalate, Dacron®, DuPont de Nemours, Inc., Wilmington, DE, USA) and ePTFE (Gore-Tex®, W. L. Gore & Associates, Newark, NJ, USA) vascular graft materials were compared with BC grafts, BC was shown not to significantly induce plasma coagulation. Compared to PET and ePTFE, BC was found to induce the least and slowest activation of the coagulation cascade and is, therefore, considered a potential vascular graft material [145].

BC and its composites are great options for artificial blood vessels [100,144] by promoting neovascularization. A major problem that can arise in the construction of tubular tissue engineering constructs is the attempt to seed the construct with cells in a tubular state, whereas cells in culture adhere much more readily to a flat scaffold [25]. In hemocompatibility tests, BC typically exhibits a low hemolysis rate, and the mechanical properties of BC-based artificial vessels frequently necessitate enhancement. Modifications of the BC surface through chemical functionalization, in addition to alterations in the manufacturing process, can influence the optimization of BC properties. BC has been functionalized with several macromolecules, including peptides, proteins, and polysaccharides, to improve its hemostatic characteristics. Amino acids have varying electrostatic and hydrophobic characteristics, allowing them to interact with platelets and other blood components via physical and chemical mechanisms to induce hemostasis [146]. To solve this challenge, researchers have mostly focused on making artificial blood vessels with the desired properties and have examined the fermentation procedures and conditions that influence the production of BC tubes [144].

The team of Dieter Klemm was the first research organization to investigate and apply artificial vascular substitute obtained with biomaterials from BC [147] and described a clinical product named BActerial SYnthesized Cellulose (BASYC®, Jena, Germany) [100,147,148,149]. The use of BC for the creation of vascular grafts has also been the subject of other studies. Various ECM proteins are used to improve the biofunctional properties of BC membranes and to create a functional endothelial layer [146]. BC/fibrin composites have been developed for the fabrication of artificial blood vessels. However, an investigation of BC/fibrin composites revealed only a slight increase in mechanical properties over those of native BC [150]. In another study, Andrade et al. used BC modified with a recombinant CBM-2 protein and an adhesion peptide tripeptide Arg-Gly-Asp (RGD) to create hemocompatible material [151]. The incorporation of functional peptides usually facilitates protein interaction of ECM by acting as docking sites [152]. In a study conducted by Leitão et al., a novel graft material was created from unmodified, small-caliber, minimally processed BC. The graft’s luminal surface had a similar topography to native vessels. Neovascularization and endothelialization of the graft resulted in the restoration of patency within one month [153].

3.4. Cell Culture System

Three-dimensional culture systems are gaining increasing popularity due to their capacity to more effectively mimic tissue-like structures than monolayer cultures [154]. Three-dimensional cell culture models are employed in the prediction of responses to anticancer treatments. In order to accurately and successfully predict treatment options, 3D cell culture must be capable of mimicking the ECM of cancer cells in an artificial environment [155]. Early studies have shown that using commercial hydrophobic proteins enables the hydrophobization of cellulosic cotton fiber [156], and impregnating zein [157] into BC can increase the hydrophobicity of BC surface as well as enhance cell attachment and proliferation when it is used as cell culture scaffold (Figure 4).

Today, natural and synthetic polymers and their composites are employed in the fabrication of 3D scaffolds for tissue engineering and even 3D cancer cell cultures. Cancer cells within a solid tumor maintain close and continual contact with the ECM [158]. Currently, 3D systems used to research tumor behavior, such as MatrigelVR and GeltrexVR, are based on natural ECM components. However, chemical variability resulting from the presence of numerous growth factors and proteins, in addition to batch-to-batch variability in these matrices, may interfere with signaling pathway biological reasoning or drug-induced effect outcomes. Consequently, the development of new biomaterials is essential to overcome the limitations of natural ECM [159].

Many researchers have conducted studies to explore the application of BC as a scaffold for 3D in vitro cancer cell models [160,161]. To mimic the characteristics of the tumor microenvironment, BC-based scaffolds were synthesized and evaluated in vitro for their ability to support cancer cell growth [162]. Modifying the pore structure of the BC scaffold can influence the behavior of cancer cells, thereby representing an effective approach for the design and fabrication of in vitro models for the study of cancer biology, potential application in cancer diagnosis, and the development of cancer treatments [121,163,164]. Some molecules, such as hyaluronic acid, chitosan, and gelatin, have been incorporated into the BC network to enhance the mechanical strength, cell adhesion, and cell growth properties of composite scaffolds [155,164,165,166,167].

One of the drawbacks of using BC to make small 3D spheroids is the millimeter scale and low precision of manual fabrication. To produce smaller or more precise shapes from BC-based engineered living materials, it is proposed to use molds or recently developed 3D printing methods for bacterial cultures, such as the «functional living ink» (FLINK) method or a hybrid approach in which a 3D printer is programmed to dispense BC spheroids precisely with different functionalizations [168]. Another challenge of using BC for 3D culture is that it is an uneven three-dimensional substrate for cell attachment with limited integrin binding sites, and cells did not adhere well to BC without surface modification. This can affect cell motility and migration on the surface, as cells migrate toward each other and form huge aggregates that spread in three planes, in contrast to cells cultured on conventional cell plastic, which spread evenly across the surface with no evidence of migration. Morphological variations of individual cells were also observed. To improve cell adhesion and cell proliferation, BC can be modified with the use of different porogens [169] or biodegradable polymers [170] to develop 3D biomimetic scaffolds with interconnected macropores and nanofibrous structure, mimicking the physical structure of ECM. The development of simple, effective physicochemical techniques for surface modification of BC with alternative ECM, growth factors, or other materials could enhance its biocompatibility and biodegradability in vivo [128].

In order to model the tumor microenvironment, it was synthesized and studied BC/gelatin hydrogels as scaffolds for the human breast cancer cell line MDA-MB-231 in vitro culture [171]. BC hydrogel was used for the immobilization of a laminin peptide (IKVAV) to mimic human melanoma cells’ microenvironment and to evaluate the influence of the microstructure and modified chemical surface properties of the resulting matrix [159]. Recently, the BC matrix has been proposed as a tool for trapping and localizing tumor cells within a predetermined region that can be targeted with therapy. The BC scaffold is placed at the tumor site after excision to attract and trap residual cancer cells. Once the cells are immobilized on the BC scaffold, they can be killed by targeted treatment. For example, the chemoattractant human serum albumin (HSA) has been used to capture cancer cells [25]. Biofunctionalized BC scaffold was created for cell replacement therapies in Parkinson’s disease. Human embryonic stem cell-derived progenitor cells were cultured on BC with growth factors and laminin that were covalently functionalized to the surface via silanization [172].

3.5. Targeted Drug Delivery System

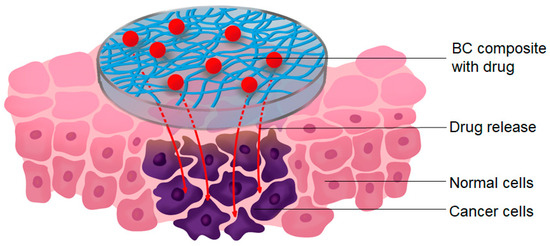

The development of a targeted drug delivery system has the potential to markedly enhance the therapeutic efficacy of drugs. Antibodies represent one of the most commonly utilized targeting molecules [173]. BC-based drug delivery systems have been a subject of considerable interest recently [32,174]. BC is often mixed with other materials to provide controlled drug release mechanisms. It has been shown that the properties of BC composites can be changed [175], allowing these composites to be tuned for use in a wide range of biomedical applications requiring varying drug release rates. BC has been shown to be a viable substance for long-term drug release, making it an excellent carrier for cancer therapy [174]. A key advantage of using a drug carrier such as BC is that it allows for controlled and localized treatment, which can increase drug concentrations at the tumor site [25] (Figure 5).

Figure 5.

Schematic of the local treatment of cancer cells with a BC loaded with a drug.

Two transdermal delivery systems for immune checkpoints (anti-CTLA-4 antibody [32], 131I-αPD-L1 antibody [176]) to treat melanoma cells have been developed based on BC. These novel approaches offer distinct advantages that can be leveraged to enhance the efficacy of immunotherapy. The controlled release of antibodies via delivery systems such as BC represents a highly attractive strategy for reducing the systemic dissemination of antibodies and potentially mitigating the adverse effects associated with checkpoint therapy [32].

A recent study has indicated that the BC may be an appropriate nanocarrier for developing vaccines for aquatic animals. The use of carboxylated BC by 2,2,6,6-tetramethyl-1-piperidinoxyl (TEMPO) oxidization was employed to conjugate ribavirin to the NbE4 nanobody, with the objective of developing a drug system against the largemouth bass virus [173]. In another study, a system for delivering cyano-phycocyanin to the gastrointestinal tract was developed based on BC nanocrystals (BCNC). This system has been shown to protect phycocyanin release from degradation by gastric fluid until phycocyanin reaches target sites [177].

Although researchers have reported encouraging results with the use of BC-based materials for drug delivery, most studies are still in their early stages. Some research focuses solely on in vitro drug release [98], while others primarily use animal models. As a result, more clinical trials are needed to ensure the safety and efficacy of BC-based materials before they can be commercialized. In addition, most of the drugs used in BC-based drug delivery systems are model drugs. More sophisticated drugs used to treat specific diseases are unlikely to be useful due to uncertain interactions between BC and other treatments. To improve the efficiency of drug delivery, ensure biocompatibility, and adjust the hydrophilicity/hydrophobicity of BC, it is necessary to optimize the composite formula based on BC; some drugs need additional research and integration of 3D printing [174].

3.6. Enzyme Immobilization

Enzyme immobilization reduces operating costs, extends enzyme life, increases enzyme stability, and facilitates recovery and reuse [178]. The immobilization of the enzyme on BC ensures high contact between the substrate and the immobilized enzyme due to the fast diffusion of substrates and products into the aqueous solution through the network of BC nanofibrils, which ensures high turnover of the enzyme [179].

The most common and most effective way to immobilize enzymes is to attach them to highly activated supports. The enzyme’s primary amino groups are good at reacting with activated supports, and they do not need to be activated [180]. The primary amino groups in enzymes can be classified as either highly reactive at neutral pH or low reactive at neutral pH due to the high pK (10.5) of lysine residues. Although the less reactive lysine residues in this area are 1000 times less reactive than the single N-terminus, immobilization of the enzyme through this region is necessary to achieve the best multipoint immobilization [180].

One of the disadvantages of utilizing both BC and the majority of carriers is the necessity to activate them prior to immobilization, as well as the relatively low efficiency of immobilization, especially with BC [14]. Furthermore, immobilization may result in enzyme inactivation or a low initial activity of the immobilized enzyme. This may be due to limited diffusion of the substrate and products through the cellulose matrix in which the hybrid protein is embedded. The enzyme activity may also be affected by the method of BC drying. This may affect the access of water to the enzymes bound in the inner parts of the membrane, thereby changing their hydrolytic activity [178].

One way to alter the BC matrix used for enzyme immobilization is to add substances such as carboxymethylcellulose (CMC), chitosan, alginate, and lignin derivatives to the culture medium. Similarly, modifying the drying conditions of BC membranes can change the physical and chemical characteristics of BC, as it impacts the membrane’s porosity and its capacity to adsorb enzymes [13,14,15,16]. These treatments significantly enhance the potential for using BC as a carrier of enzymes or other active compounds [181].

To date, both unmodified and modified BC have been successfully employed for the immobilization of numerous enzymes, including papain [110], lysozyme [111], lipase [14,182,183,184], β-galactosidase [178], horseradish peroxidase (HRP) [185], superoxide dismutase (SOD) [4], glutamate decarboxylase (GAD) [45], laccase [108,186], lecitase [181], urease [187], L-asparaginase [188], and others. The enzymes were immobilized using unmodified BC and modified by chitosan BC hydrogel beads, as well as preactivated BC with glutaraldehyde or oxidized BC with sodium periodate.

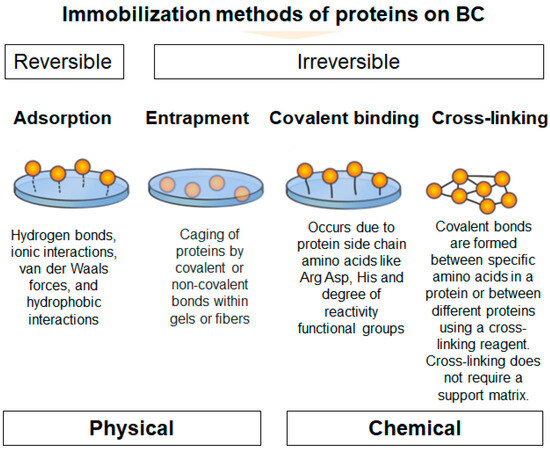

4. Methods of Protein Immobilization on Bacterial Cellulose

The latest advances in nanostructured carrier material and immobilization technique development now allow for precise protein immobilization, including on BC [189]. Protein immobilization on BC can be achieved through a number of different methods, including covalent binding, adsorption, crosslinking, and entrapment (Figure 6).

Figure 6.

Schematic illustrating protein immobilization methods on BC. Physical methods include adsorption and entrapment. Chemical methods include covalent binding and crosslinking.

Physical immobilization techniques utilize physical interactions to stabilize proteins and enzymes onto cellulose substrates. This approach frequently results in only minor alterations to the protein [10,178]. Compared to other immobilization techniques, physical immobilization methods are relatively straightforward and cost-effective. The primary physical immobilization methods are entrapment and adsorption [10].

Among protein and enzyme immobilization methods, adsorption is the simplest. Adsorption is usually accomplished by hydrophobic interactions and salt bridges, and protein function is largely preserved because the bond between the support and the protein or enzyme is minimal [190]. The degree of protein adsorption on BC depends on the characteristics of the native form of BC, such as the porosity, the degree of cross-linking of the nanofibrils, and other material properties, depending on the culture time and the composition of the medium [191]. The efficiency of protein immobilization on BC can reach over 93,5% with physical adsorption [14]. Recently, a protein imprinted material based on a BC composite carrier and a metal–organic framework, zeolite imidazolate framework-67 (ZIF-67), was developed for the isolation of bovine serum albumin. This material exhibited ultra-high adsorption capacity (1017.0 mg/g), excellent recognition (IF = 5.98), and fast adsorption equilibrium time (50 min) [16].

The cellulose matrix is one of the most optimal substrates for the immobilization of enzymes by entrapment [178]. Entrapment methods do not place proteins directly on the surface of their supports, in contrast to adsorption approaches. Instead, they are physically entrapped within the polymer matrix. Entrapment protects proteins and enzymes from hostile conditions and improves their stability [192]. Nevertheless, due to the weak interactions involved, physical methods often result in enzyme degradation during washing, which can lead to loss of functionality. It is, therefore, essential to employ enzyme purification as a preliminary step in such cases [178].

Protein immobilization by crosslinking is the process of chemically joining two or more molecules by a covalent bond [193]. The protein is typically adsorbed to the nanocarrier and then cross-linked using a bifunctional agent like glutaraldehyde [194]. The combination of two groups in a single protein results in intramolecular cross-links, which reinforce the protein’s tertiary or quaternary structure. Intermolecular cross-links are formed when groups of two distinct proteins bind together, creating a stable protein-protein connection [193]. This method improves enzyme stability and reduces leakage, which is common with non-covalently attached enzymes on supports [194].

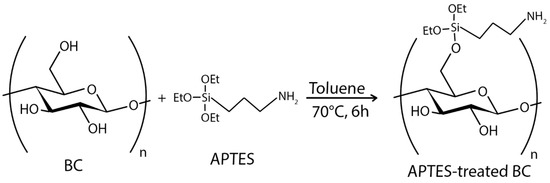

Covalent bonds between protein functional groups and support materials are often used for immobilization [192]. In this approach, proteins are securely attached to the surface by covalent bonds [195]. In addition, covalent bonding has a high loading efficiency [196], which is not possible with other methods [8]. The covalent attachment process involves the binding of amino acid residues (i.e., –NH2, –COOH, –SH) to support matrices [48]. Hydroxyl groups on a cellulose surface may interact with proteins, but this is not sufficient for the covalent immobilization process. Therefore, additional functionalization procedures must be conducted to achieve a robust covalent immobilization. The incorporation of functional groups into cellulose surfaces that may react with amino acid residues was accomplished through modification of the cellulose matrix [10].

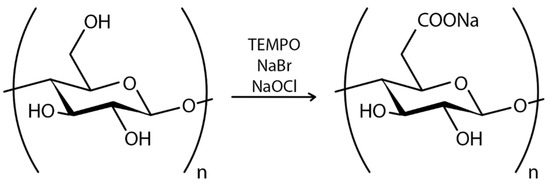

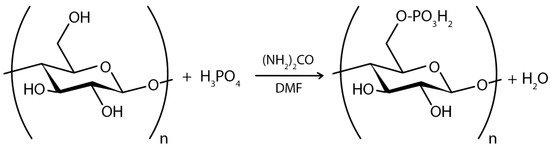

There are two methods for functionalizing cellulose. The first method entails the addition of amino groups to the surface of cellulose, thereby enabling the formation of a reactive complex with the carboxylic acid groups of amino acids. The second approach involves the introduction of an aldehyde, carboxyl, or epoxide moiety that can engage in a reaction with the amino (–NH₂) group. Another strategy for immobilizing proteins and enzymes on cellulose is to use protein carboxyl groups to react with matrix functionality, including the amino groups present in the cellulose matrix. Activated groups like carboxyl and aldehyde can attach to protein amino groups. To produce aldehyde or carboxyl groups, several chemical methods were employed to oxidize the hydroxyl groups of cellulose [10].

Covalent binding is the most stable approach for enzyme immobilization on cellulosic supports, which can increase the activity and thermal stability of the immobilized enzyme [63,197]. However, protein immobilization by covalent coupling to polymeric materials offers several outstanding advantages for a wide variety of applications, yet coupling techniques are typically limited by their high cost or complexity [198]. The efficiency of protein immobilization by covalent binding to BC may vary depending on the method used. The immobilization efficiency of conjugated recombinant human osteopontin, coupled with the poly(acrylic acid) (PAA)-grafted BC, has been determined to be 97% [15]. However, the strong binding has implications as the enzymes are chemically modified and lose some of their catalytic activity [8]. The use of chemical coupling agents can potentially inactivate the protein or enzyme [10,178]. In some cases, chemical modification of BC (for instance, by diphenyltetrazole) may lead to ineffective protein conjugation [178,199]. Examples of BC modification for protein immobilization in biomedicine will be discussed in detail in the next chapter.

5. Ex Situ and In Situ Modifications of Bacterial Cellulose for Protein Immobilization

Despite the development of new BC-based composites, there are still obstacles to overcome before BC can be fully utilized as a biomedical material. The main issues that need to be addressed are optimizing culture conditions to control the porosity of the BC scaffold, incorporating functional groups into the BC matrix, and increasing the degradation rate of BC to suit specific applications [99,200]. Furthermore, the utilization of native BC presents a challenge in the form of dehydration during the drying process. To prevent dehydration, BC can be modified by various methods to achieve the desired properties [201]. Although BC has a high degree of crystallinity and a single functional hydroxyl group, providing low solubility and limiting its application, BC contains a high concentration of hydroxyl groups on its surface that can be modified. The focus is on modified BC with multiple functional groups that exhibit diverse surface properties, such as lipophilic-hydrophilic properties and magnetic and optical capabilities, along with a regulated specified functionalization pattern [62].

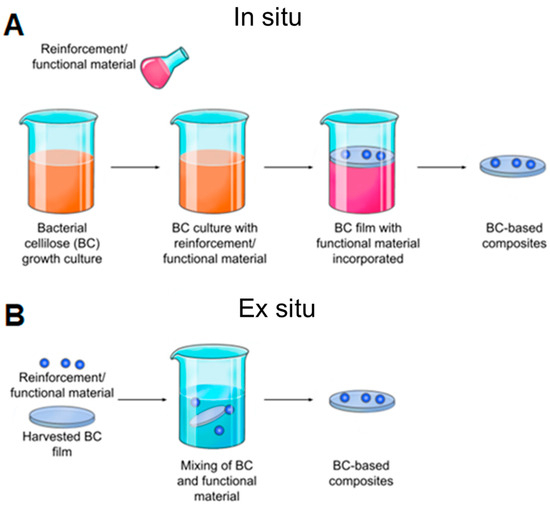

To achieve these goals, BC has been modified in a variety of ways, including chemical modifications (changes in chemical structure and functionality) and physical modifications (changes in porosity, crystallinity, and fiber density). In general, there are two main approaches to implementing these changes: ex situ and in situ [202] (Figure 7).

Figure 7.

Schematic representation of BC modification methods. (A) In situ modification involves changing the composition of the culture medium, typically through the addition of other materials. (B) Ex situ modification is a process whereby BC is treated with chemicals or absorbed by other materials after the BC membrane has been formed in culture.

An ex situ modification is the most common modification of BC [203]. Ex situ modification of BC occurs when an exogenous macromolecule interacts primarily with the BC surface and can penetrate through membrane pores. Changes in the physical-chemical parameters of the BC composite are determined by the degree of exogenous molecule incorporation into the membrane [98]. The key benefits of ex situ modification of BC include a wide range of composite synthesis techniques, the ability to utilize liquefied and suspended materials [204], the maintenance of BC’s primary structural characteristics [11], and the avoidance of issues associated with the incorporation of antimicrobial materials [205].

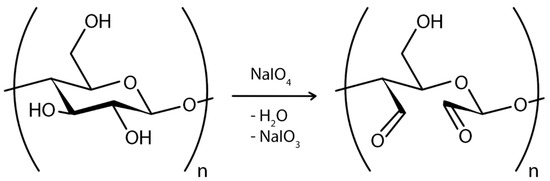

However, the size and nature of the exogenous molecule (reinforcing material) pose the greatest challenge to ex situ composite synthesis. Only submicron to nanoscale materials can be implanted into the BC matrix. This is because larger particles cannot pass through the BC pores, and hydrophobic materials cannot combine with BC. In addition, the structural arrangement of the BC fibrils is not always regular, so penetrating materials may not be uniformly distributed throughout the BC matrix [12]. In addition, unless a covalent chemical modification is performed, the interaction between the BC membrane and the exogenous molecule is weaker compared to the in situ process [98]. The influence of many modifications on environmental and host physiological conditions is still not fully known and, therefore, requires further investigation [174]. For example, treatment of cells with NaIO4 has been shown to result in the formation of free surface aldehydes that lead to cross-linking between cells via a Schiff base and cause cytotoxicity [206].

There are two forms of ex situ modification: chemical and physical. Physical ex situ modification is usually achieved by physical absorption—a porous BC matrix can be filled with solutions or particle suspensions—the presence of hydroxyl groups on the cellulose chains often results in strong hydrogen bonding between the BC molecules and the absorbed molecules to achieve modification [80,202,207].

In the case of chemical ex situ modification, a reaction with chemicals to change BC’s chemical composition takes place. Since the chemical nature of BC is cellulose, it can be phosphorylated and then modified by graft copolymerization or crosslinking [208]. Carboxymethylation [209], acetylation [203], phosphorylation [210], esterification [211], and other graft copolymerization and crosslinking processes on the BC surface have produced a wide range of BC derivatives with unique structures and properties.

Chemical modification of the BC structure disrupts the ordered crystal-forming hydrogen bonds and increases the water solubility of even hydrophobic derivatives [25]. Incorporation of additional functional groups into the BC structure can impart to BC hydrophobicity, ion adsorption capacity, and optical properties while retaining the characteristic three-dimensional nanostructure and superior mechanical properties of BC. For example, oxidation under moderate aqueous conditions can preserve the crystallinity and size of BC. Recently, acetylation of BC via a non-swelling reaction mechanism has been reported to increase its dispersibility and compatibility in various solvents or matrices suitable for nanocomposite fabrication [212]. The hydrophobicity of the acetylated surface is beneficial for maintaining a large surface area after drying from water and also makes the microfibrils compatible with other hydrophobic materials [62]. The surface modification of BC matrices can improve drug loading and release capabilities. The results indicated that surface modification of BC matrices can alter the surface properties [207]. Most BC modifications are aimed at improving its applicability and performance in a variety of applications (Table S1 in Supplementary Materials).

Biosynthetic (in situ) modification of BC represents an environmentally friendly method that is also simple and cost-effective. This process can be combined with various different chemical additives present in the culture solution to create scalable nanocomposites [213]. In contrast to ex situ modification, in situ modification is relatively straightforward to perform and exhibits uniformity in modification effect. The application of in situ modification of BC presents certain challenges, including the precipitation of additional compounds, the inability to successfully incorporate reinforcement materials into the pellicle [214], and the stringent conditions required for bacterial growth [203]. Although in situ BC modification is commonly used in tissue engineering applications, the stringent microbial fermentation conditions limit the entry of a wider range of additives. Other concerns with the in situ modification process, such as interactions between externally added additives and BC fibril formation, as well as structure controls of BC nanofibers, need to be addressed [202]. In addition, there are limitations in the synthesis of BC composites with antimicrobials [215], the use of BC composites produced by the agitation technique [216], and the disturbance of the main structural features of BC [217]. By incorporating liquid and nanoparticles into the structural matrix of the prepared BC, some problems associated with the in situ synthesis of BC composites can be solved [12].

5.1. Ex Situ Bacterial Cellulose Modification

5.1.1. Native Bacterial Cellulose

Native BC (Figure 8) exhibits superior mechanical strength and stability [150] and high water absorption capacity [218] in the wet state. Implants created from native BC exhibit gradual, non-enzymatic hydrolysis, which is determined by the chemical composition of the main chain and side groups, aggregation state and shape, hydrophilic-hydrophobic balance, surface, and other variables. This process is of utility in certain applications [219], for example drug delivery or tissue engineering. It was shown that unmodified BC did not affect the antibody binding efficacy [32]. Furthermore, unmodified BC membranes do not possess any inflammatory or immunogenic properties [20,32,65,220]. A grafted, native BC membrane serves as a physical barrier, reducing pain and the risk of infection, and allows drug delivery to the wound [221]. In contrast, unmodified BCs are characterized by the immediate release of drugs, regardless of the solubility of drugs in water and the dose [207].

Figure 8.

The structure of repeating dimer units of the native (unmodified) BC. The dimer demonstrates the intra-chain interactions in cellulose. The numbers indicate the positions of carbon atoms in the glucose molecule. Hydroxyl groups are shown in red. The two most accessible hydroxyl groups on cellulose for substitution are OH-C6 and OH-C2, while OH-C3 is less accessible. n = degree of polymerization.

There are several studies on the use of native BC as a carrier for proteins. A macroporous BC hydrogel was developed for wound healing through a process of physical punching with a stainless mold to generate uniform holes with a size of 0.5 mm in diameter, separated by a constant distance of 2 mm. The generation of the macroporous BC hydrogel was achieved by direct layering of the BC hydrogel on top of an alginate solution, with CaCl2 promoting the integration of the alginate into the BC. Then, BC hydrogel was immersed in ECMs (collagen, elastin, and hyaluronan) and growth factors (B-FGF, H-EGF, and KGF). The modified BC hydrogels were shown to be biodegradable under physiological conditions, and growth factors were gradually released. The H-EGF and collagen-modified BCHG were found to support the growth of human skin fibroblasts [70].

A BC–sericin composite was developed for wound healing. For this purpose, BC was impregnated with a sericin solution for 24 h with stirring. The resulting composites exhibited a homogeneous, highly porous structure, a smaller pore size, and a high swelling capacity when compared to BC. However, no significant difference was observed between the effect of BC and the BC–sericin composite on the behavior of keratinocyte cells during cultivation. Additionally, no significant changes were noted in the thermal and mechanical stability of the BC network after the addition of sericin [105].

Modification of native BC with soybean isolate protein was utilized for wound healing treatment. The surface roughness and hydrophilicity of BC–soy protein composites are reduced compared to native BC, and soy protein could be stably released. The resulting composites promoted improved adhesion and proliferation of normal human dermal fibroblast culture and type I collagen expression in vitro compared to the control. At the same time, cell viability increased by almost 50% compared to BC. The composites promoted accelerated wound healing (17 days versus 21 days for wound treatment by control). In addition, BC–soy protein composites stimulated collagen deposition (five times higher than the control), enhanced angiogenesis and hair follicle regeneration, and helped reduce scarring and skin inflammation in rats [13].

Nisin-loaded BC membranes were developed to preserve food quality and inhibit the growth of microbial contaminants. When the antimicrobial activity of the resulting membranes was evaluated by minimum inhibitory concentration and agar diffusion assay using Staphylococcus aureus (S. aureus), Escherichia coli (E. coli), and Pseudomonas aeruginosa (P. aeruginosa), it was shown that nisin in combination with EDTA exhibited significant antimicrobial and antioxidant activity against S. aureus (MIC was 15.63 μg/mL) and E. coli (MIC was 31.25 μg/mL). No antimicrobial activity was observed against P. aeruginosa [113].

Two distinct methodologies were employed to functionalize BC with the antimicrobial peptide ε-poly-l-lysine. The first strategy involved adding ε-PLL to CMC-functionalized BC membranes using EDC (N-(3-dimethylaminopropyl)-N’-ethylcarbodiimide hydrochloride) and NHS (N-hydroxysuccinimide) to form the amide bond [190]. The second strategy involved directly crosslinking ε-PLL with the BC structure using carbodiimide chemistry to form a stable interpenetrating network. Both techniques yielded membranes that were biocompatible with human fibroblasts and capable of inhibiting S. epidermidis development upon contact [222].

Bacteriocins from Lactobacillus sakei subsp. sakei 2a (Lb. sakei 2a) strains were immobilized on BC membranes to enhance their antimicrobial activity against Listeria monocytogenes (L. monocytogenes, foodborne pathogen). Immobilized bacteriocins were significantly (p < 0.05) more effective in controlling pathogen growth than the free bacteriocins throughout the study period [115]. In another study, commercial laccase and silver nanoparticles were physically adsorbed onto BC for wound dressings. The specific activities of immobilized and free laccase were similar. However, the value of the Michaelis–Menten constant (Km) for immobilized laccase (0.77 mM) was almost twice that of the free enzyme. The antimicrobial effect of laccase on medically relevant strains was 92% (S. aureus) and 26% (E. coli), while the composite had no cytotoxicity on fibroblasts [108].

To enhance the biocompatibility and osteoinductivity of BC, Huang et al. developed a porous BC scaffold modified with gelatin and coated with hydroxyapatite. Gelatin was introduced into the surfaces of BC nanofibres by physical adsorption or via the procyanidins crosslinking technique. The results demonstrated that procyanidine crosslinking led to a greater improvement in Young’s modulus and maximum load of BC scaffolds compared to physical crosslinking. A notable increase in mechanical properties was observed in the order of BC, BC/gelatin, BC/procyanidine/gelatin, and BC/procyanidine/gelatin/hydroxyapatite scaffolds. The BC/procyanidine/gelatin/hydroxyapatite scaffold exhibited superior adhesion, viability, proliferation, and osteogenic differentiation of human bone marrow stromal cells. In vivo studies in nude mice and rabbits demonstrated that the BC/procyanidine/gelatin/hydroxyapatite composite exhibited the most favorable osteogenic properties [117].

A recent study demonstrated that BC could serve as a carrier of BMP-2 (an osteoinductive cytokine) for bone regeneration. The rabbits treated with the BC/BMP-2 composite exhibited significantly more newly formed bone than the other groups. The new bone was found to have a markedly higher number of PCNA-positive cells compared to sites away from the composite. After eight weeks, the composite exhibited continuous release of BMP-2. Additionally, no rabbits showed any noticeable inflammation, and no capsules developed around the BC or the BC/BMP-2 combination [138].

A novel keratin-containing BC nanocomposite with the potential to enhance skin fibroblast adherence to the BC surface was developed and characterized by Lin et al. The BC-containing keratin composites were obtained through both in situ and ex situ modification. In comparison to native BC and in situ modified BC/keratin, the viability of keratinocytes and fibroblasts on post-modified BC/keratin nanocomposites was found to be higher. In vitro cell culture studies have demonstrated that cutaneous fibroblasts have good attachment and proliferation on post-modified BC/keratin nanocomposites [141].

Different recombinant bioactive peptides IKVAV, (19)IKVAV, and RGD were fused to a CBM3 to functionalize BC surfaces to promote neuronal and mesenchymal stem cell (MSC) adhesion. It was demonstrated that there was an improvement of almost 100% in cell adhesion for PC12 cells and 30% for MSCs. The RGD-CBM3 protein also exhibited the capacity to enhance the adhesion of N1E-115 and mesenchymal cells. Additionally, the IKVAV-CBM3 facilitated the release of neurotrophic factor (NGF) secreted by MSCs into the culture medium [142].

One study utilized native BC, which was dissolved in N-methylmorpholine N-oxide (NMMO), followed by the addition of porogen (sodium chloride) and then gelatin to create a composite that can be applied in tissue engineering. The resulting composite had high porosity and rapid swelling. In vitro biological tests demonstrated that animal fibroblast cells (NIH 3T3) adhered well and proliferated well on the BC–gelatin composite scaffolds. Increased expression of metalloproteases indicated that long-term incubation of cells can lead to the formation of ECM within the resulting 3D scaffolds [118].

Surface modification of native BC was performed with tripeptide Arg-Gly-Asp (RGD) fused to a cellulose-binding module for the development of hemocompatible material. The RGD is found in many adhesive plasma and ECM proteins and has been shown to improve cell adhesion. The plasma recalcification time and whole blood clotting results demonstrated that BC did not interfere with the coagulation process. A significant amount of plasma protein was adsorbed to BC fibers, and the adsorption of plasma proteins to the BC fiber surface did not affect its protein structure. Human microvascular endothelial cells grown on RGD-modified BC developed a confluent cell layer, which inhibited platelet attachment [151].

Human serum albumin (HSA) was chosen as a model protein to study the loading of chemoattractants onto and released from BC membranes in the F98 rat glioma model. The BC membrane was found to confine F98 tumor cells, preventing their migration once attached to the membrane surface (even in the presence of an attractive medium in the environment). F98 cells trapped on BC remained viable and retained the ability to grow, adopting a spheroid pattern of growth [223,224].

BC was studied as a carrier for antibody delivery. To investigate the release of antibodies in vitro and in vivo, BC was loaded with a model IgG antibody and an anti-CTLA-4 antibody. In vitro experiments demonstrated that IgG was released within 24–48 h. Experiments on cell cultures indicated that BC did not have a cytotoxic effect on the M39 cell line and did not cause activation of dendritic cells. In vivo investigations in serum demonstrated that BC hydrogels significantly reduced the levels of IgG and anti-CTLA-4 antibodies when compared to the levels of antibodies in PBS. The antibodies loaded in the BC retained their binding capacity, as compared to antibodies from a stock solution, after 14 days of implantation [32]. Additionally, BC films were utilized to facilitate the delivery of L-asparaginase to melanoma cells. L-asparaginase was immobilized via physical adsorption. The maximum adsorption of L-asparaginase was observed among BC films grown for 96 h, reaching 84.5 ± 5.7%. Uveal melanoma cells (A875) demonstrated sensitivity to L-asparaginase, with an IC50 value of 0.03. L-asparaginase immobilized on BC caused the death of over 90% of tumor cells after 72 h [188].

BC has also been used to immobilize superoxide dismutase (SOD) to increase its stability at high temperatures and protect fibroblasts against oxidative damage. The results demonstrated that the immobilized SOD was stable at pH levels ranging from 4 to 8, with approximately 70% of the remaining activity. In contrast, the free SOD lost 70% of its initial activity. At temperatures ranging from 25 to 40 °C, the immobilized SOD retained more than 80% of its residual activity. The residual activity of immobilized SOD exhibited a gradual decline from 40 to 45 °C, reaching 30% of the initial activity at 50 °C. In comparison, the activity of free SOD demonstrated a precipitous decline at temperatures above 40 °C. The fibroblast cells that were incubated with BC/SOD and subsequently treated with hydrogen peroxide demonstrated a cell viability of 78.46%, which was higher than that observed in the induced fibroblast cells [4].

Unmodified or dry BC membranes were used to immobilize wild-type β-galactosidase and β-galactosidase with a thermostable module CBM2 (TmLac). The CBM2 domain allows direct immobilization of cellulose substrates with high specificity. The binding efficiency of the TmLac-CBM2 hybrid was similar to hydrated BC and freeze-dried BC. The TmLac-CBM2 protein bound to BC more strongly at pH 6.5 than at pH 8.5 and with high specificity compared to the wild-type enzyme. The CBM2 module fused to the enzyme provided a stable attachment to cellulose at 75 °C. The efficiency of lactose hydrolysis was similar between the three forms of β-galactosidase. Enzyme recycling was limited by the instability of the β-galactosidase module, whereas the attachment of CBM2 to cellulose was stable even at 75 °C for 3 h [178].

5.1.2. Bacterial Cellulose Nanoparticles

BC has a wide range of applications in the biomedical field. However, the usage of BC in the form of films or membranes, which is produced by static culture fermentation, limits its applicability [225]. Furthermore, BC scaffolds have some other drawbacks, such as a lack of antimicrobial properties (for use as dressings) and modest mechanical strength [62,226].

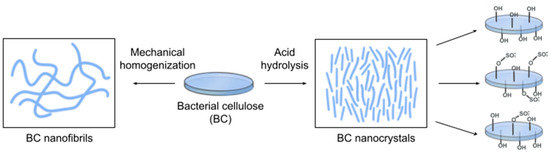

Nanoparticles derived from BC can be classified into two categories: BCNCs and BCNFs (Figure 9) [227]. BCNC and BCNF can be obtained from BC using acid hydrolysis and mechanical homogenization, respectively [228,229,230]. Unlike the hydrogel structure of BC in its natural form, BCNC, and BCNF can be dispersed in an aqueous solution and easily incorporated into polymer networks that act as reinforcing agents [231]. These nanoparticles have different sizes, shapes, and properties [227].

Figure 9.

Schematic of methods for obtaining BC nanofibrils (BCNF) and BC nanocrystals (BCNC) from BC for protein immobilization: BCNF production from BC by homogenization (left); BCNCs production from BC by acid hydrolysis with different types of acid surface modification (right). The most commonly used acids are hydrochloric acid (HCl), sulfuric acid (H2SO4), and a mixture of HCl and H2SO4.

Bacterial Cellulose Nanofibrils

BCNFs make up over half of the research on nanocellulose and have been a European bioeconomic priority since 2008 [232]. BCNFs, like CNFs, are flexible, nanosized fibrils with a high aspect ratio. They can form strong, entangled, and disordered networks. BCNFs are long and flexible nanofibers that contain both crystalline and amorphous areas. They consist of fibrillar elements that are 10–50 nm wide and several micrometers long [227]. The BCNF solution is stable, which enhances the versatility and performance of this cellulose material [225]. BCNFs interact with other inorganic particles or biomass components (such as polyphenols, polysaccharides, or proteins) to form unique complex structures [233]. BCNFs are considered safe biomaterials in accordance with the FDA’s Generally Recognized as Safe (GRAS) standard [122].

In a recent study, BCNF was utilized to immobilize lysozyme through a process of physical absorption. After immobilization, lysozyme activity decreased by approximately 12%, but storage stability was improved, and immobilized lysozyme retained more than 70% of its original activity after nine cycles of use. Immobilized lysozyme showed enhanced antimicrobial activity against S. aureus, E. coli, L. monocytogenes, Yersinia entrocolitica, Aspergillus niger, and Saccharomyces sereviseae [111].

A BCNF–zein composite with controlled surface hydrophobicity was created for tissue engineering by Wang et al. The use of zein was based on the ability of zein to self-assemble into various microstructures upon solvent evaporation, as well as its good biodegradability and high biocompatibility. First, BCNF was immersed in zein solutions with gentle stirring, then self-assembly of zein molecules occurred under evaporation, followed by hot pressing. An increase in surface roughness and hydrophobicity of BCNF was observed with the addition of zein at low concentrations (5 mg/mL), while the opposite effect was observed with a higher zein concentration (2%). The incorporation of zein on the surface of BCNF did not significantly alter the internal structure and mechanical properties of BCNF. Compared to pure BC, BCNF–zein composites showed significantly increased adhesion and proliferation of fibroblast cells [157].

BCNFs have been used to construct a delivery system for radiotherapy and immunotherapy in the treatment of metastatic cancer. To address the challenges associated with the clinical application of immune checkpoint blockade and the nonspecific distribution of radioisotopes, an injectable suspension of 131I-labeled antibody against programmed cell death ligand 1 (αPD-L1) immobilized on BC was developed. The resulting composites were targeted specifically to the tumor and stimulated the immune response to achieve specific cancer radioimmunotherapy. The biocompatibility, long-term antibody retention, and immunostimulatory effects of 131I-αPD-L1/BC were confirmed in vitro and in vivo. After long-term treatment with 131I-αPD-L1/BC, T cells in lymph nodes were polarized to CD8+ CTL, which killed cancer cells in the tumor. Radioimmunotherapy prevented cancer from spreading in a breast cancer model [176].

BCNF-chitosan composite hydrogel beads were prepared as scaffolds for the immobilization of Candida rugosa lipase. To prepare BC-chitosan hydrogel beads, chitosan was dissolved in 1-ethyl-3-methylimidazolium acetate. BC powder was added, and the mixture was stirred and dried. The amino groups of chitosan were converted to aldehyde groups after treatment with GA. Lipase was immobilized by crosslinking GA or physical adsorption. Cross-linked lipases showed higher stability than adsorbed and free lipases. After 30 min incubation at 60 °C, the residual activity of BC2 was 76%, while free lipase retained 43% of initial activity. After 10 h incubation, the residual activity of BC2 was 44%, while that of free lipase was 15%. The half-life time of lipase adsorbed on cellulose-chitosan beads was found to be 2.7–3.7 times higher than that of free lipase. The half-life of lipase cross-linked to BC-chitosan beads at 60 °C was 22.7 times that of free lipase [183].

Bacterial Cellulose Nanocrystals

BCNCs are rod-like nanoparticles created from BC after selecting and eliminating the amorphous region. They have a high crystallinity and a rigid structure with a length of 100–1000 nm and a width of 10–50 nm [227]. BC can be hydrolyzed using strong acids such as H2SO4 and HCl to generate a stable solution of BCNC, which provides the material with new functionality [234]. However, acid hydrolysis removes the amorphous portion of cellulose, reducing yield [231]. BCNCs can be used as building blocks for a wide range of applications [234].

Sakacin-A/BCNC conjugates have been developed for use in antimicrobial food packaging. Sakacin-A is an anti-Listeria bacteriocin produced by Lb. sakei. The resulting conjugates were found to be stable when incubated in neutral and mildly acidic solutions (pH 5), but Sakacin-A completely dissociated from BCNCs in alkaline conditions (pH 11). The Sakacin-A/BCNCs conjugate-coated samples exhibited superior surface roughness and tensile strength compared to the paper substrate. The antimicrobial packaging was effective in both in vitro and cheese experiments. The paper samples coated with Sakacin-A and Sakacin-A/BCNCs conjugates had similar antimicrobial activity [114].

A 3D-printed scaffold comprising BCNC, gelatin (GEL), polycaprolactone (PCL), and hydroxyapatite (HA) was developed for use in bone tissue engineering. The 3D printing procedure was used to create four different scaffold compositions with 50%, 60%, 70%, and 80% infill rates. The 3D scaffolds with an 80% infill rate exhibited a pore size (~300 µm) that was suitable for bone tissue engineering. These scaffolds demonstrated a uniformity ratio exceeding 90%. The incorporation of BC and HA into the PCL/GEL scaffold enhanced the growth and attachment of human osteoblast cells. The 3D-printed scaffolds exhibited osteoblast cells with large cytoplasmic dendritic structures, which resembled the appearance of osteocytes [140].

In work [182], lipase was immobilized on BC and BCNC. BC and BCNC were functionalized with succinic acid as a linker [235], and the lipase was then conjugated to succinylated cellulose using EDC/NHS. After immobilization, the enzyme retained its activity in both BCNC and BC membrane, and the amount of protein immobilized on BCNC was 2.75 times higher than that in BC membrane. The BCNC was also employed for the immobilization of urease. The immobilized urease demonstrated superior tolerance to changes in pH (5.5–9) and temperature (30–80 °C) when compared to the free urease. Furthermore, the immobilized urease retained approximately 81% and 68% of its initial activity following 15 and 20 cycles of reuse, respectively. It also exhibited significantly enhanced storage stability for 20 days [187].

5.1.3. Crosslinking

Crosslinking is defined as the induction of chemical or physical links among polymer chains [236]. The crosslinking of materials can be achieved through a variety of methods, including physical processes, chemical processes, and enzymatic processes [237]. The chemical crosslinking method makes it possible to obtain an irreversible or permanent hydrogel. The physical crosslinking method can produce a hydrogel that can be reversed since the forces involved are hydrophilic interaction, electrostatic, and hydrogen bonding. Crosslinking improves the thermal and mechanical stability of the matrix and can be tailored to modify the release rate of the incorporated active agents [238].

The abundant hydroxyl functional groups in the BC molecular chains make BC an excellent candidate for modifications by crosslinking [202]. Crosslinking plays a pivotal role in the drying process [68,239], prevents the collapse of 3D network BC in the drying process [163,240,241], and improves water absorption [242]. In this sense, cross-linked samples may absorb water faster than pure samples, and their spongy structure results in a significant variation in surface shape compared to native samples [243]. The chemical structural similarities between BC and plant cellulose make it possible to utilize plant cellulose crosslinkers [163,240,241].

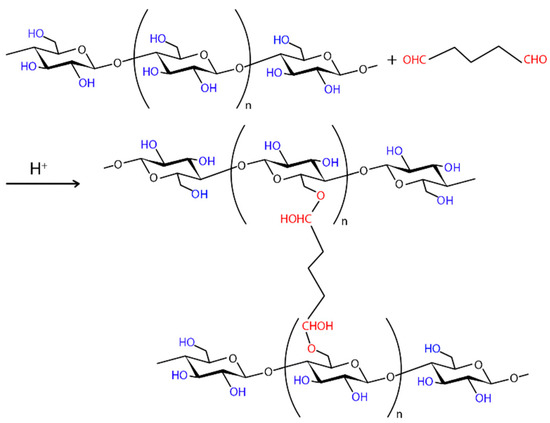

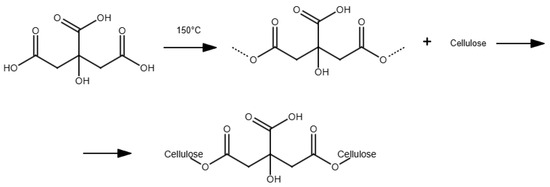

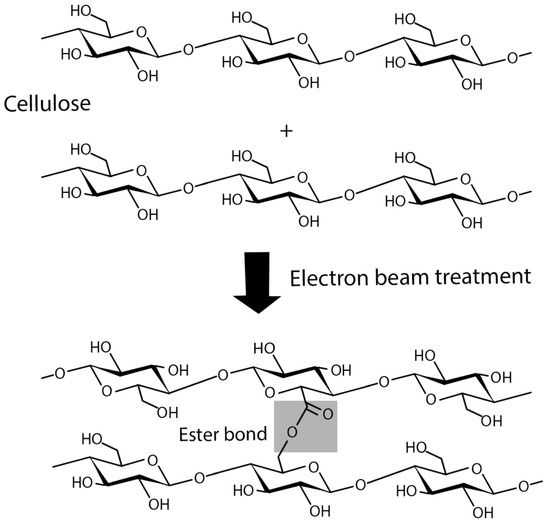

Chemical Crosslinking