Study on the Storage Stability and Rheological Property of Bio-Oil/Lignin Composite-Modified Asphalt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials and Preparation of Sample

2.1.1. Materials

2.1.2. Sample Preparation

2.2. Thermal Storage Stability Test

2.3. Physical Properties Characterization

2.3.1. Softening Point Test

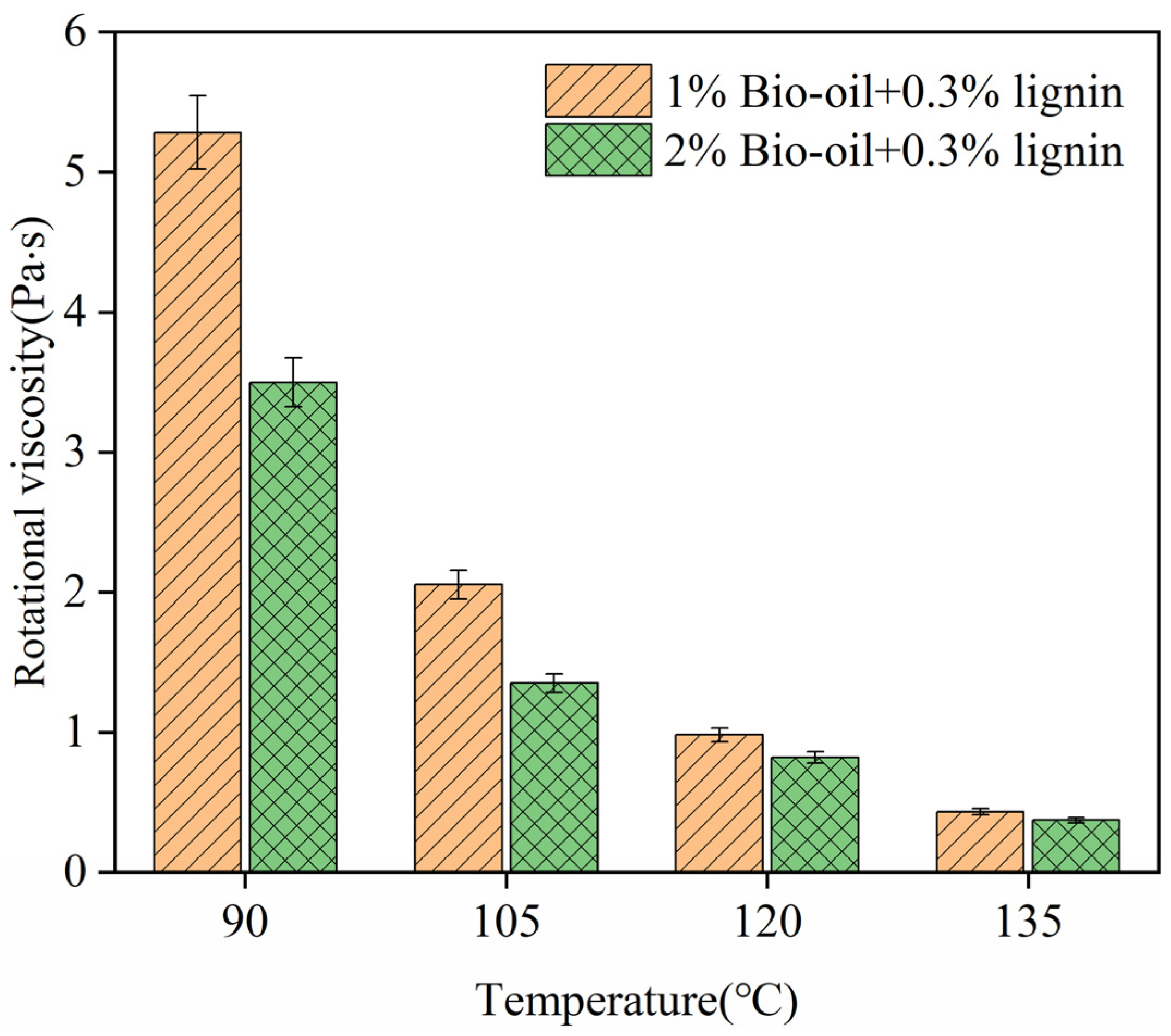

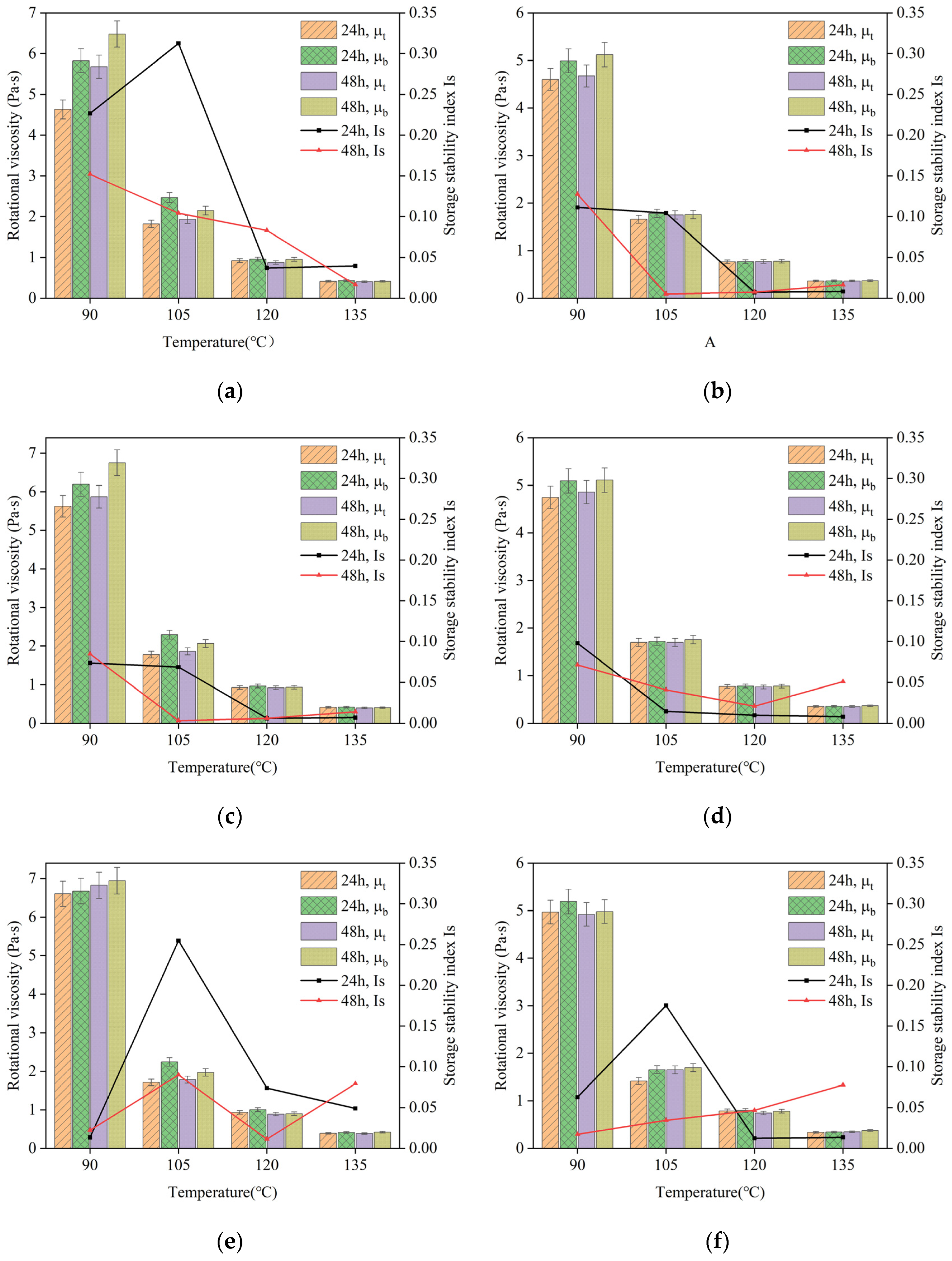

2.3.2. Rotational Viscosity Test

2.4. Rheological Property Evaluation

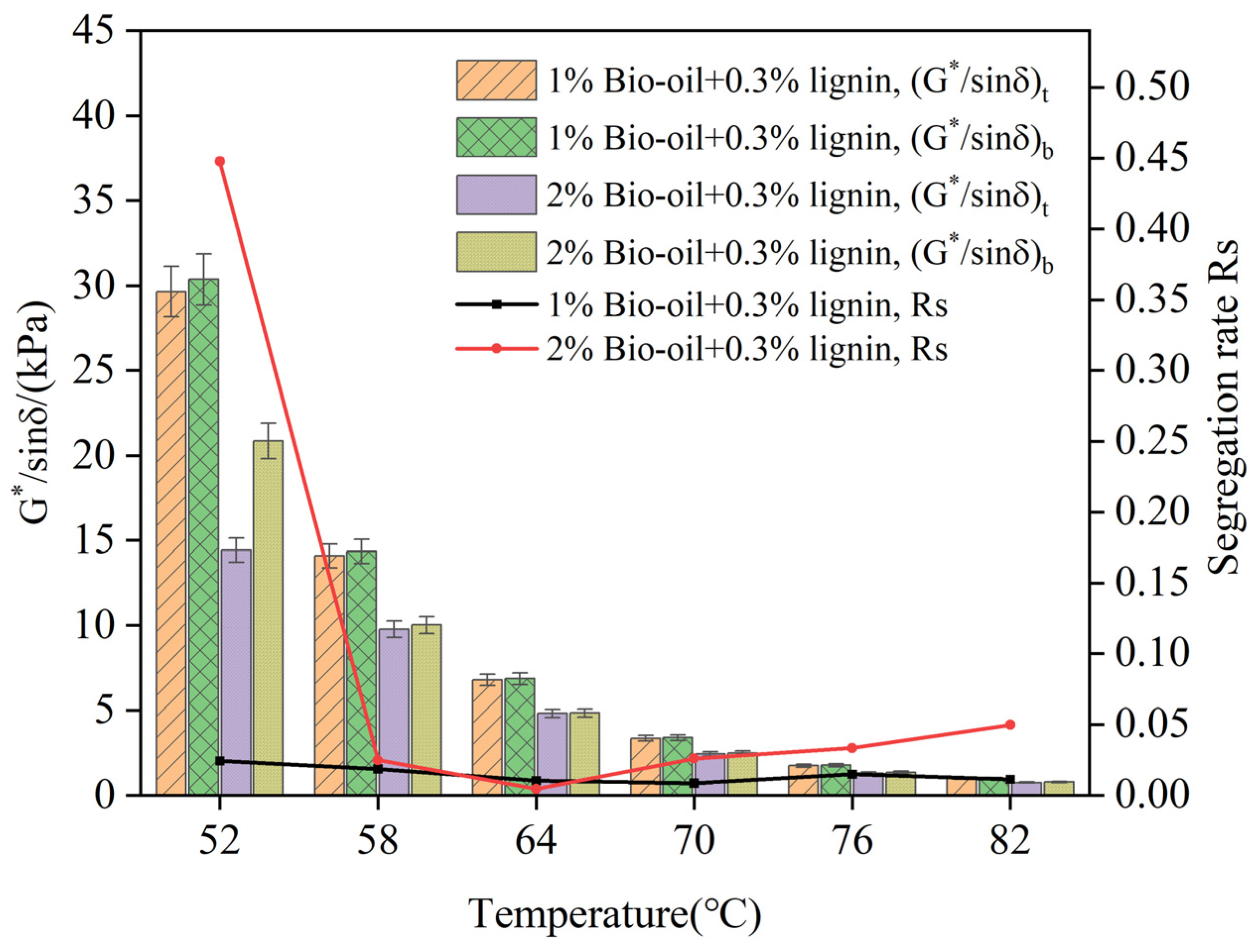

2.4.1. Temperature Sweep Test

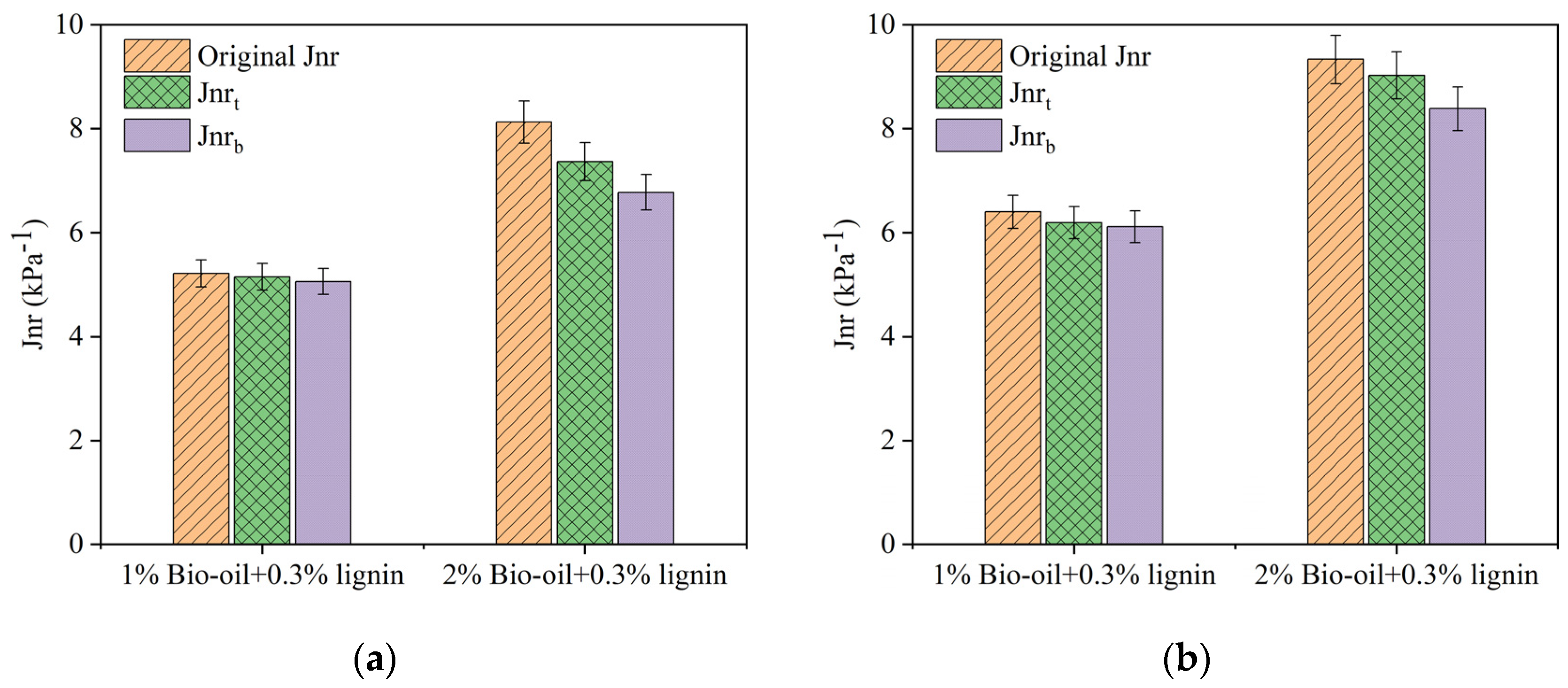

2.4.2. Multiple Stress Creep Recovery (MSCR) Test

2.5. Fourier-Transform Infrared (FTIR) Spectroscopy

2.6. Scanning Electron Microscopy (SEM)

3. Results

3.1. Softening Point Difference

3.2. Rotational Viscosity and Is

3.3. Temperature Sweep Test and Rs

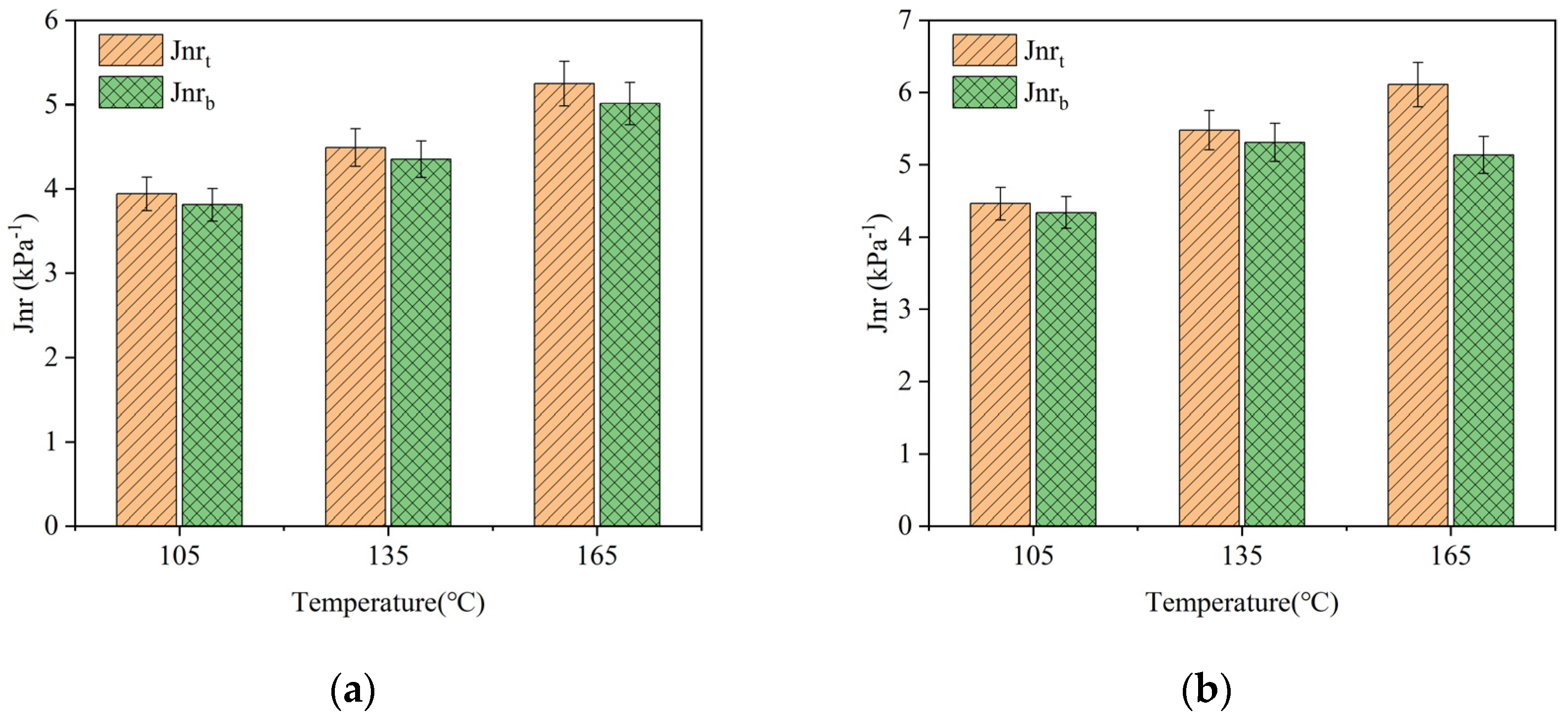

3.4. MSCR Test

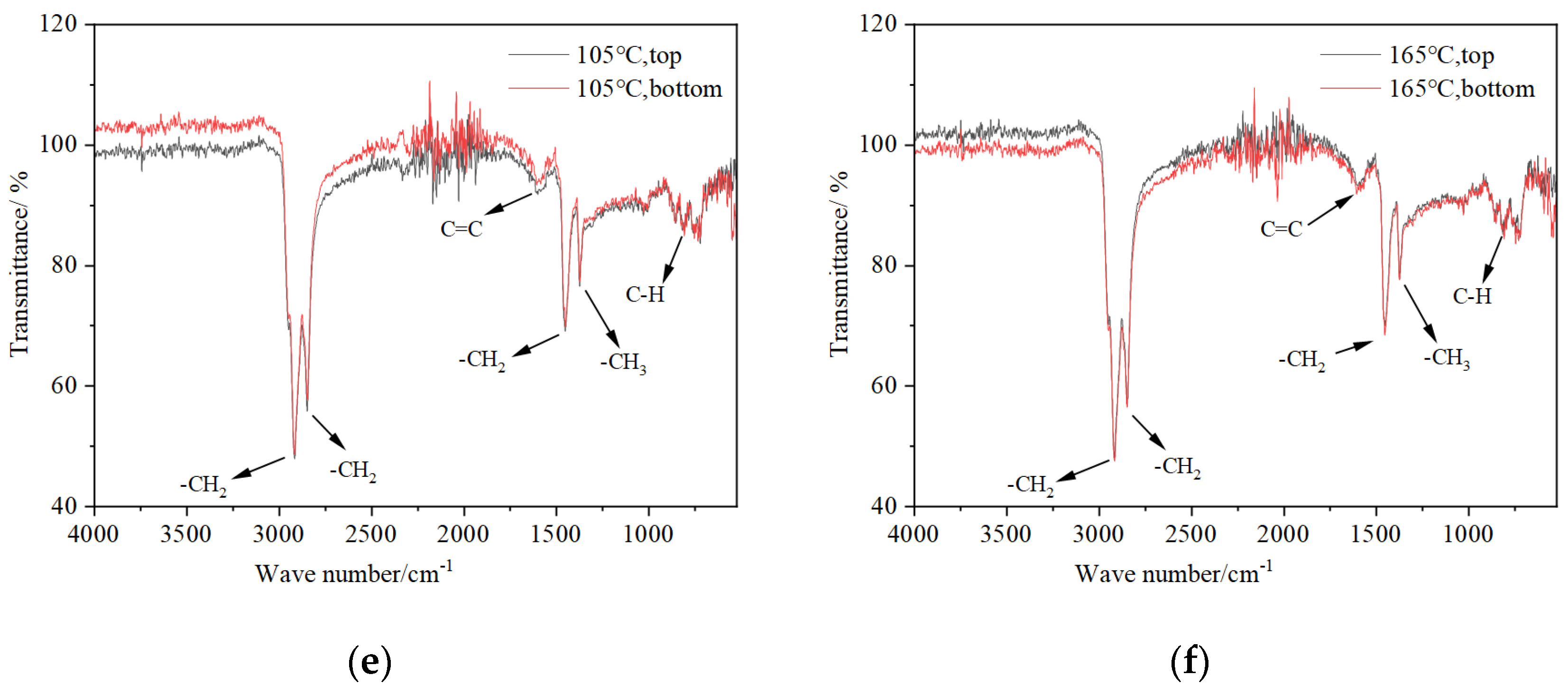

3.5. Functional Group Composition Characterization

3.6. SEM Test

4. Conclusions

- Based on the softening point difference, storage stability index Is, segregation rate Rs, and Jnr, it was found that the composite-modified asphalt had excellent storage stability;

- The high-temperature performance of the composite-modified asphalt after thermal storage has been improved, and the high-temperature performance index of the bottom of the composite-modified asphalt is slightly better than that of the top, which may be caused by the downward migration of heavy components in the asphalt during storage;

- Based on FTIR spectroscopy, it was found that no new functional groups were produced during thermal storage, and no chemical reaction occurred during thermal storage. The results of scanning electron microscopy showed that the longer storage time would make the storage effect of composite-modified asphalt better, which was consistent with the results of softening spread, storage stability index Is, and Rs.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Carrión, A.J.D.; Subhy, A.; Rodriguez, M.A.I.; Lo Presti, D. Optimisation of liquid rubber modified bitumen for road pavements and roofing applications. Constr. Build. Mater. 2020, 249, 118630. [Google Scholar] [CrossRef]

- Nandal, M.; Sood, H.; Gupta, P.K. A review study on sustainable utilisation of waste in bituminous layers of flexible pavement. Case Stud. Constr. Mater. 2023, 19, e02525. [Google Scholar] [CrossRef]

- Meng, Y.; Zhan, L.; Hu, C.; Tang, Y.; Großegger, D.; Ye, X. Research on modification mechanism and performance of an innovative bio-based polyurethane modified asphalt: A sustainable way to reducing dependence on petroleum asphalt. Constr. Build. Mater. 2022, 350, 128830. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Gnatowski, P.; Malus, M.; Grzegórska, A.; Ipakchi, H.; Jouyandeh, M.; Kucinska-Lipka, J.; Navarro, F.J.; Saeb, M.R. Eco-friendly modification of bitumen: The effects of rubber wastes and castor oil on the microstructure, processability and properties. J. Clean. Prod. 2024, 447, 141524. [Google Scholar] [CrossRef]

- Jin, D.; Yin, L.; Nedrich, S.; Boateng, K.A.; You, Z. Resurface of rubber modified asphalt mixture with stress absorbing membrane interlayer: From laboratory to field application. Constr. Build. Mater. 2024, 441, 137452. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, H.; Chen, Y.; Ji, J.; You, Z.; Zhang, Y. A review on compatibility between crumb rubber and asphalt binder. Constr. Build. Mater. 2021, 297, 123820. [Google Scholar] [CrossRef]

- Xu, G.; Kong, P.P.; Yu, Y.H.; Yang, J.Y.; Zhu, M.H.; Chen, X.H. Rheological properties of rubber modified asphalt as function of waste tire rubber reclaiming degree. J. Clean. Prod. 2022, 332, 130113. [Google Scholar] [CrossRef]

- Yu, H.Y.; Deng, G.S.; Wang, D.Y.; Zhang, Z.Y.; Oeser, M. Warm asphalt rubber: A sustainable way for waste tire rubber recycling. J. Cent. South Univ. 2020, 27, 3477–3498. [Google Scholar] [CrossRef]

- Jin, D.; Mohammadi, S.; Xin, K.; Yin, L.; You, Z. Laboratory performance and field demonstration of asphalt overlay with recycled rubber and tire fabric fiber. Constr. Build. Mater. 2024, 438, 136941. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.P.; Ji, J.; Shi, Q.W.; Suo, Z. A Review of Characteristics of Bio-Oils and Their Utilization as Additives of Asphalts. Molecules 2021, 26, 5049. [Google Scholar] [CrossRef]

- Gao, J.F.; Wang, H.N.; You, Z.P.; Hasan, M.R.M.; Lei, Y.; Irfan, M. Rheological Behavior and Sensitivity of Wood-Derived Bio-Oil Modified Asphalt Binders. Appl. Sci. 2018, 8, 919. [Google Scholar] [CrossRef]

- He, L.; Tao, M.Z.; Liu, Z.; Cao, Z.; Zhu, J.Q.; Gao, J.; van den Bergh, W.; Chailleux, E.; Huang, Y.; Vasconcelos, K.; et al. Biomass valorization toward sustainable asphalt pavements: Progress and prospects. Waste Manag. 2023, 165, 159–178. [Google Scholar] [CrossRef] [PubMed]

- Lv, S.T.; Ju, Z.H.; Peng, X.H.; Cabrera, M.B.; Wang, Z.H.; Yuan, J.; Hu, L. Preparation and Performance of Polyphosphoric Acid/Bio-Oil Composite-Modified Asphalt Containing a High Content Bio-Oil. J. Mater. Civ. Eng. 2022, 34, 04021484. [Google Scholar] [CrossRef]

- Wang, H.; Jing, Y.F.; Zhang, J.P.; Cao, Y.B.; Lyu, L. Preparation and performance evaluation of swine manure bio-oil modified rubber asphalt binder. Constr. Build. Mater. 2021, 294, 123584. [Google Scholar] [CrossRef]

- Luo, Y.F.; Zhang, K. Review on Performance of Asphalt and Asphalt Mixture with Waste Cooking Oil. Materials 2023, 16, 1341. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.Y.; Ren, S.S.; Jing, R.X.; Lin, P.; Apostolidis, P.; Erkens, S.; Wang, X.C.; Scarpas, T. Effect of Bio-oil on Rheology and Chemistry of Organosolv Lignin-Modified Bitumen. J. Mater. Civ. Eng. 2022, 34, 04022009. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q.; Mills-Beale, J. Mechanical performance of asphalt mixtures modified by bio-oils derived from waste wood resources. Constr. Build. Mater. 2014, 51, 424–431. [Google Scholar] [CrossRef]

- Ding, Y.; Shan, B.; Cao, X.; Liu, Y.; Huang, M.; Tang, B. Development of bio oil and bio asphalt by hydrothermal liquefaction using lignocellulose. J. Clean. Prod. 2021, 288, 125586. [Google Scholar] [CrossRef]

- Batista, K.B.; Padilha, R.P.L.; Castro, T.O.; Silva, C.; Araújo, M.; Leite, L.F.M.; Pasa, V.M.D.; Lins, V.F.C. High-temperature, low-temperature and weathering aging performance of lignin modified asphalt binders. Ind. Crops Prod. 2018, 111, 107–116. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2020, 230, 117063. [Google Scholar] [CrossRef]

- Yu, J.; Vaidya, M.; Su, G.; Adhikari, S.; Korolev, E.; Shekhovtsova, S. Experimental study of soda lignin powder as an asphalt modifier for a sustainable pavement material. Constr. Build. Mater. 2021, 298, 123884. [Google Scholar] [CrossRef]

- Zhang, Y.; Si, C.; Fan, T.; Zhu, Y.; Li, S.; Ren, S.; Lin, P. Research on the optimal dosage of Bio-Oil/Lignin composite modified asphalt based on rheological and Anti-Aging properties. Constr. Build. Mater. 2023, 389, 131796. [Google Scholar] [CrossRef]

- Xue, X.; Gao, J.; Wang, J.; Chen, Y. Evaluation of High-Temperature and Low-Temperature Performances of Lignin-Waste Engine Oil Modified Asphalt Binder and Its Mixture. Materials 2021, 15, 52. [Google Scholar] [CrossRef]

- Fakhri, M.; Norouzi, M.A. Rheological and ageing properties of asphalt bio-binders containing lignin and waste engine oil. Constr. Build. Mater. 2022, 321, 126364. [Google Scholar] [CrossRef]

- Sheng, X.H.; Wang, M.; Xu, T.; Chen, J. Preparation, properties and modification mechanism of polyurethane modified emulsified asphalt. Constr. Build. Mater. 2018, 189, 375–383. [Google Scholar] [CrossRef]

- Liang, M.; Chen, L.; Jiao, Y.P.; Wang, J.J.; Xin, X.; Chen, Z.C.; Zhang, Y.F.; Luan, X.H.; Su, L.P.; Yao, Z.Y. Research on microscopic process and mechanism of modified asphalt based on phase field theory. Constr. Build. Mater. 2024, 421, 135619. [Google Scholar] [CrossRef]

- Penki, R.; Rout, S.K. Next-generation bitumen: A review on challenges and recent developments in bio-bitumen preparation and usage. Biomass Convers. Biorefinery 2023, 13, 9583–9600. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, Q.; Chen, L.; Pei, J.Z.; Zhang, J.P.; Li, R. Review and comparison of methods to assess the storage stability of terminal blend rubberized asphalt binders. Constr. Build. Mater. 2020, 258, 119586. [Google Scholar] [CrossRef]

- Gong, X.; Liu, Q.; Liu, X.; Wan, P.; Jiang, P.; Chen, S.; Wang, H.; Wu, S. Green synthesis of end-capped polyurethane prepolymer with high storage stability and its effects on bitumen properties. Constr. Build. Mater. 2023, 401, 132860. [Google Scholar] [CrossRef]

- Li, H.; Dong, B.; Zhao, D.; Guo, P.; Zhang, J. Physical, Rheological and Stability Properties of Desulfurized Rubber Asphalt and Crumb Rubber Asphalt. Arab. J. Sci. Eng. 2019, 44, 5043–5056. [Google Scholar] [CrossRef]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar] [CrossRef]

- Mehta, D.; Saboo, N. Performance of bio-asphalts: State of the art review. Environ. Sci. Pollut. Res. 2023, 30, 119772–119795. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.; Wang, H.N.; Chen, X.; Yang, X.; You, Z.P.; Dong, S.; Gao, J.F. Shear property, high-temperature rheological performance and low-temperature flexibility of asphalt mastics modified with bio-oil. Constr. Build. Mater. 2018, 174, 30–37. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering, Engineering; Transport Industry, Standard. Institute of Highway Science, M.o.T: Beijing, China, 2011.

- Singh, B.; Kumar, L.; Gupta, M.; Chauhan, G.S. Polymer-modified bitumen of recycled LDPE and maleated bitumen. J. Appl. Polym. Sci. 2013, 127, 67–78. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Jiang, X.; You, Z.; Yang, X.; Ye, M. Thermal Storage Stability of Bio-Oil Modified Asphalt. J. Mater. Civ. Eng. 2018, 30. [Google Scholar] [CrossRef]

- Goli, A.; Ziari, H.; Amini, A. Influence of Carbon Nanotubes on Performance Properties and Storage Stability of SBS Modified Asphalt Binders. J. Mater. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Dong, R.K.; Zhao, M.Z.; Tang, N.P. Characterization of crumb tire rubber lightly pyrolyzed in waste cooking oil and the properties of its modified bitumen. Constr. Build. Mater. 2019, 195, 10–18. [Google Scholar] [CrossRef]

- Meng, Y.J.; Wei, X.Z.; Lei, J.C.; Liao, Y.J.; Huang, K.Z.; Lai, J.; Yang, X.L. Effect of bio-asphalt as additive on macro and micro properties of TLA modified asphalt and its modification mechanism. Constr. Build. Mater. 2023, 365, 130079. [Google Scholar] [CrossRef]

- Sun, H.G.; Hu, Y.T.; Wang, H.T.; Xing, Z.F. Properties and low-temperature performance of biomass heavy oil used in road applications. Case Stud. Constr. Mater. 2024, 20, e02872. [Google Scholar] [CrossRef]

- Dong, W.; Ma, F.; Li, C.; Fu, Z.; Huang, Y.; Liu, J. Evaluation of Anti-Aging Performance of Biochar Modified Asphalt Binder. Coatings 2020, 10, 1037. [Google Scholar] [CrossRef]

- Walubita, L.F.; Ling, M.; Pianeta, L.M.R.; Fuentes, L.; Komba, J.J.; Mabrouk, G.M. Correlating the Asphalt-Binder MSCR Test Results to the HMA HWTT and Field Rutting Performance. J. Transp. Eng. Part B Pavements 2022, 148, 04022047. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Wu, S.P.; Xie, J.; Yang, C.; Yang, X.K.; Chen, S.C.; Liu, Q.T. Recycle of waste tire rubber powder in a novel asphalt rubber pellets for asphalt performance enhancement. Constr. Build. Mater. 2023, 399, 132572. [Google Scholar] [CrossRef]

| Item | Units | Test Results | Standard |

|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s) | 0.1 mm | 67 | JTG-T0604-2011 [35] |

| Softening temperature | °C | 51.0 | JTG-T0606-2011 [35] |

| Ductility (15 °C, 5 cm/min) | cm | >100 | JTG-T0605-2011 [35] |

| RTFO treated at 163 °C, for 85 min | |||

| Quality change | % | 0.2 | JTG-T0610-1-2011 [35] |

| Residual penetration ratio (25 °C) | % | 62.7 | JTG-T0610-2-2011 [35] |

| Residual ductility (5 °C) | cm | 11.2 | JTG-T0605-2011 [35] |

| Modified Asphalt with Different Bio-Oil Content (%) | Storage Time (h) | Evaluation Index | Softening Point (°C) | ||

|---|---|---|---|---|---|

| 105 | 135 | 165 | |||

| 1 | 0 | - | 46.8 | ||

| 2 | 44.4 | ||||

| 1 | 24 | TR&Bt | 46.3 | 47.3 | 47.5 |

| TR&Bb | 47.1 | 46.9 | 47.4 | ||

| ΔTR&B | 0.8 | 0.4 | 0.1 | ||

| 2 | TR&Bt | 43.9 | 44.5 | 45.1 | |

| TR&Bb | 44.8 | 44.8 | 44.9 | ||

| ΔTR&B | 0.9 | 0.3 | 0.2 | ||

| 1 | 48 | TR&Bt | 47.1 | 47.6 | 47.6 |

| TR&Bb | 47.5 | 48.0 | 47.9 | ||

| ΔTR&B | 0.4 | 0.4 | 0.3 | ||

| 2 | TR&Bt | 45.2 | 44.7 | 45.0 | |

| TR&Bb | 45.4 | 45.0 | 44.9 | ||

| ΔTR&B | 0.2 | 0.3 | 0.1 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, G.; Gao, J.; Jin, D.; Wang, X.; Bi, Y.; Guo, P. Study on the Storage Stability and Rheological Property of Bio-Oil/Lignin Composite-Modified Asphalt. Polymers 2024, 16, 2484. https://doi.org/10.3390/polym16172484

Guo G, Gao J, Jin D, Wang X, Bi Y, Guo P. Study on the Storage Stability and Rheological Property of Bio-Oil/Lignin Composite-Modified Asphalt. Polymers. 2024; 16(17):2484. https://doi.org/10.3390/polym16172484

Chicago/Turabian StyleGuo, Guixiu, Junfeng Gao, Dongzhao Jin, Xuan Wang, Yanqiu Bi, and Peng Guo. 2024. "Study on the Storage Stability and Rheological Property of Bio-Oil/Lignin Composite-Modified Asphalt" Polymers 16, no. 17: 2484. https://doi.org/10.3390/polym16172484