Fire-Resistant and Thermal Stability Properties of Fluorosilicone Adhesives by Incorporation of Surface-Modified Aluminum Trihydrate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Modification of ATH Particles

2.3. Characterization

3. Results

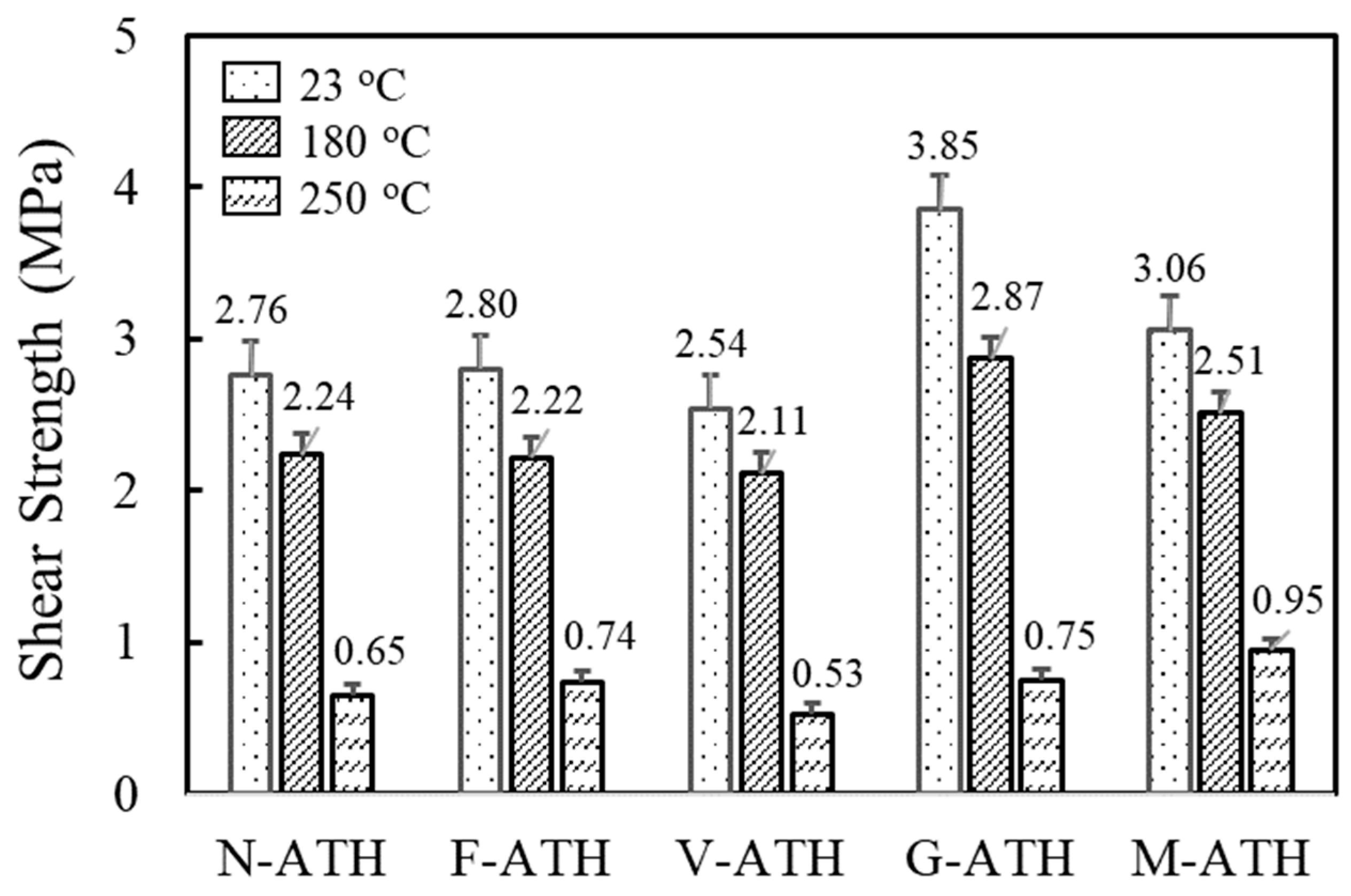

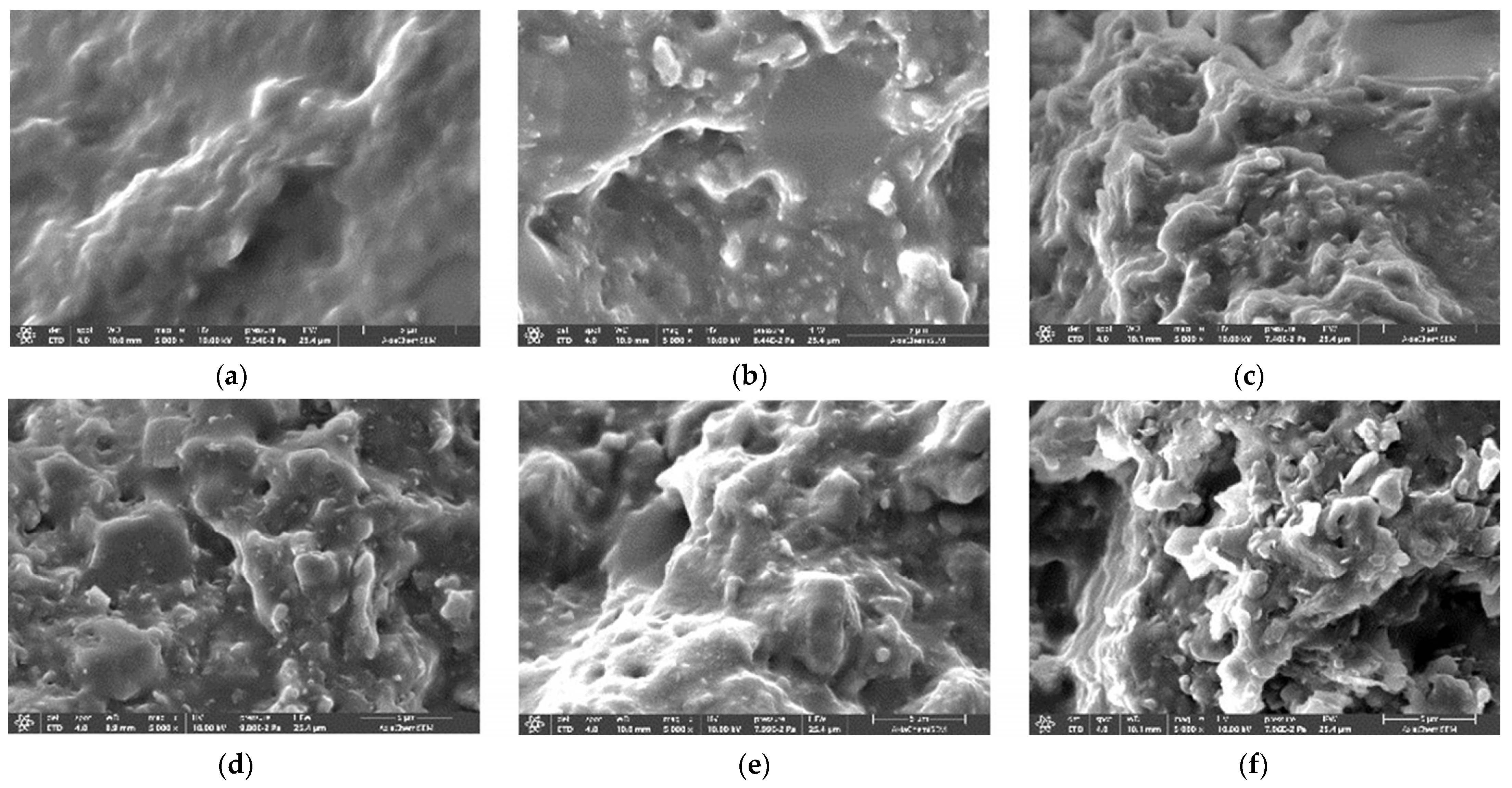

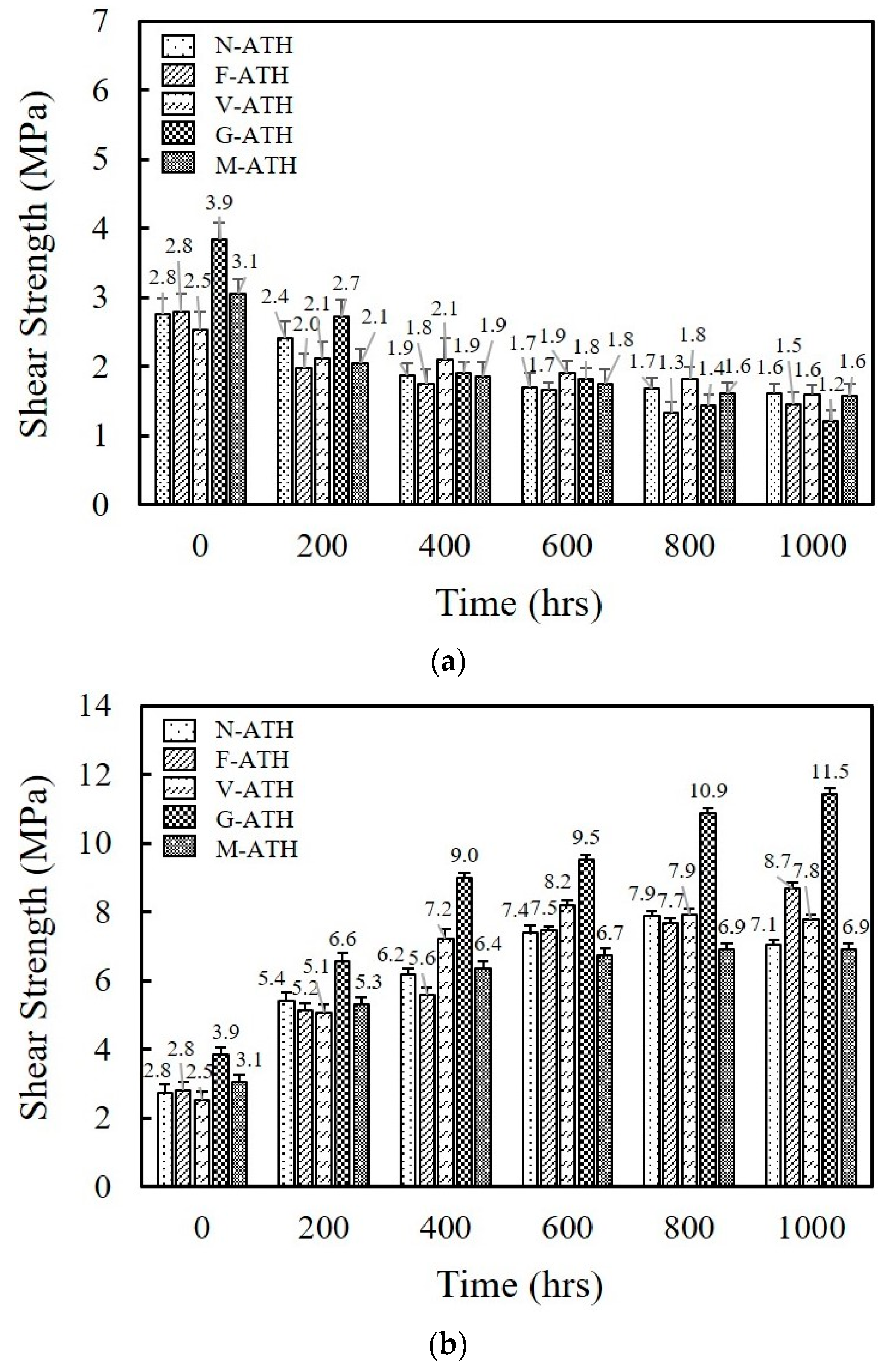

3.1. Effect of Surface Modification on Mechanical Properties

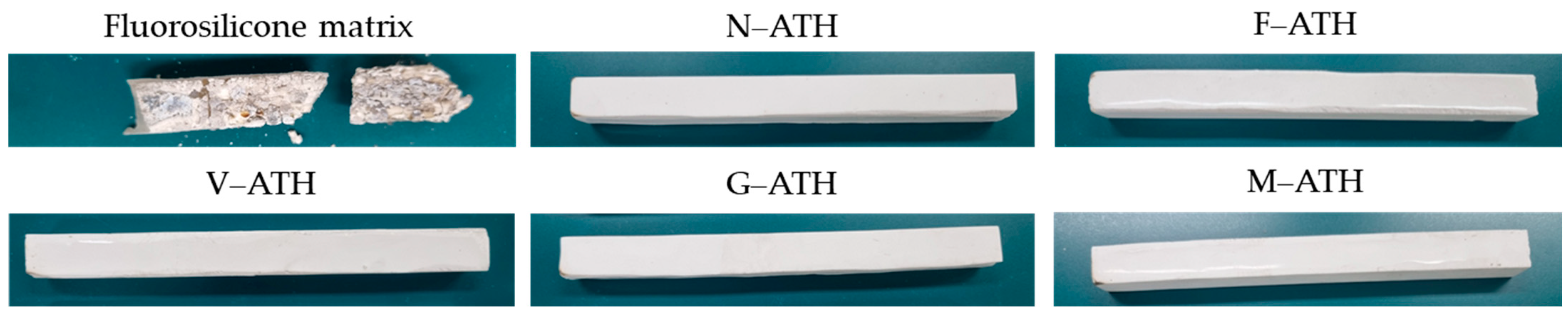

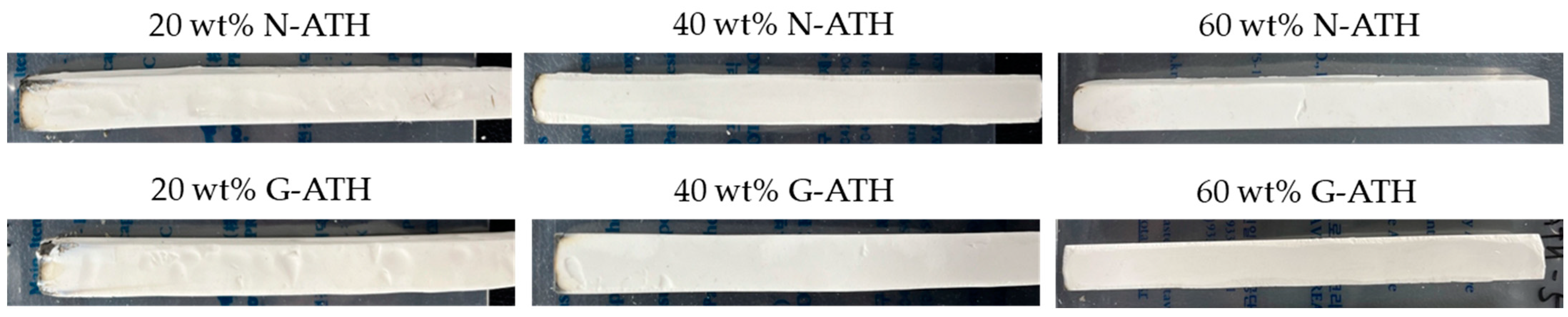

3.2. Flame Retardancy of Fluorosilicone/ATH Composites

3.3. Thermal Resistance of Fluorosilicone/ATH Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Korzeniowski, S.H.; Buck, R.C.; Newkold, R.M.; El kassmi, A.; Laganis, E.; Matsuoka, Y.; Dinelli, B.; Beauchet, S.; Adamsky, F.; Weilandt, K.; et al. A Critical Review of the Application of Polymer of Low Concern Regulatory Criteria to Fluoropolymers II: Fluoroplastics and Fluoroelastomers. Integr. Environ. Assess. Manag. 2023, 19, 326–354. [Google Scholar] [CrossRef]

- Améduri, B. The Promising Future of Fluoropolymers. Macromol. Chem. Phys. 2020, 221, 1900573. [Google Scholar] [CrossRef]

- Améduri, B. Fluoropolymers: The Right Material for the Right Applications. Chem. Eur. J. 2018, 24, 18830–18841. [Google Scholar] [CrossRef]

- Henry, B.J.; Carlin, J.P.; Hammerschmidt, J.A.; Buck, R.C.; Buxton, L.W.; Fiedler, H.; Seed, J.; Hernandez, O. A Critical Review of the Application of Polymer of Low Concern and Regulatory Criteria to Fluoropolymers. Integr. Environ. Assess. Manag. 2018, 14, 316–334. [Google Scholar] [CrossRef]

- Bhairamadgi, N.S.; Pujari, S.P.; van Rijn, C.J.M.; Zuilhof, H. Adhesion and Friction Properties of Fluoropolymer Brushes: On the Tribological Inertness of Fluorine. Langmuir 2014, 30, 12532–12540. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Peng, C.; Liu, C.; Yuan, C.; Hong, J.; Chen, G.; Xu, Y.; Dai, L. Modification of Epoxy Resin with a Phosphorus, Nitrogen, and Fluorine Containing Polymer to Improve the Flame Retardant and Hydrophobic Properties. Macromol. Mater. Eng. 2019, 304, 1800498. [Google Scholar] [CrossRef]

- Wehbi, M.; Mehdi, A.; Negrell, C.; David, G.; Alaaeddine, A.; Améduri, B. Phosphorus-Containing Fluoropolymers: State of the Art and Applications. ACS Appl. Mater. Interfaces 2020, 12, 38–59. [Google Scholar] [CrossRef] [PubMed]

- Speight, J. Properties of Atoms, Radicals, and Bonds. In Lange’s Handbook of Chemistry, 16th ed.; Speight, J., Ed.; McGRAW-HILL: New York, NY, USA, 2004; pp. 4.41–4.53. [Google Scholar]

- Fan, X.; Li, S.; Wang, C.; Deng, Y.; Zhang, C.; Wang, Z. Research on Fluoropyridine-Based Benzoxazine with High Thermal Stability and Excellent Flame Retardancy for Its Application in Coatings. Eur. Polym. J. 2023, 187, 111884. [Google Scholar] [CrossRef]

- Xiong, K.; Zhang, W.; Wang, Y.; Liu, R.; Yang, S.; Nie, H.; Yan, Q.-L. The Effects of Fluoropolymers with Optimized Contents on Reactivity and Combustion Behavior of Al/MxOy Nanocomposites. Combust. Flame 2023, 249, 112606. [Google Scholar] [CrossRef]

- Beaugendre, A.; Saidi, S.; Degoutin, S.; Bellayer, S.; Pierlot, C.; Duquesne, S.; Casetta, M.; Jimenez, M. One Pot Flame Retardant and Weathering Resistant Coatings for Plastics: A Novel Approach. RSC Adv. 2017, 7, 40682–40694. [Google Scholar] [CrossRef]

- Teng, H. Overview of the Development of the Fluoropolymer Industry. Appl. Sci. 2012, 2, 496–512. [Google Scholar] [CrossRef]

- Apostolo, M.; Triulzi, F. Properties of Fluoroelastomer/Semicrystalline Perfluoropolymer Nano-Blends. J. Fluor. Chem. 2004, 125, 303–314. [Google Scholar] [CrossRef]

- Drobny, J.G. Blends and Composites Based on Fluoropolymers. Macromol. Symp. 2001, 170, 149–156. [Google Scholar] [CrossRef]

- Ozcelik, G.; Elcin, O.; Guney, S.; Erdem, A.; Hacioglu, F.; Dogan, M. Flame-Retardant Features of Various Boron Compounds in Thermoplastic Polyurethane and Performance Comparison with Aluminum Trihydroxide and Magnesium Hydroxide. Fire Mater. 2022, 46, 1020–1033. [Google Scholar] [CrossRef]

- Chai, G.; Zhu, G.; Gao, S.; Zhou, J.; Gao, Y.; Wang, Y. On Improving Flame Retardant and Smoke Suppression Efficiency of Epoxy Resin Doped with Aluminum Tri-Hydroxide. Adv. Compos. Lett. 2019, 28, 1–12. [Google Scholar] [CrossRef]

- Hoffendahl, C.; Duquesne, S.; Fontaine, G.; Taschner, F.; Mezger, M.; Bourbigot, S. Decomposition Mechanism of Fire Retarded Ethylene Vinyl Acetate Elastomer (EVA) Containing Aluminum Trihydroxide and Melamine. Polym. Degrad. Stab. 2015, 113, 168–179. [Google Scholar] [CrossRef]

- Unlu, S.M.; Dogan, S.D.; Dogan, M. Comparative Study of Boron Compounds and Aluminum Trihydroxide as Flame Retardant Additives in Epoxy Resin. Polym. Adv. Technol. 2014, 25, 769–776. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, Z.; Zhu, J. Synergistic Flame Retardant Effect of Aluminum Hydroxide and Ammonium Polyphosphate on Epoxy Resin. J. Appl. Polym. Sci. 2022, 139, e53168. [Google Scholar] [CrossRef]

- Zhang, L.; Bian, Y.; Kuai, D. Preparation and Flame Retardant Property of Nano-Aluminum Hydroxide Foam for Preventing Spontaneous Coal Combustion. Fuel 2021, 304, 121494. [Google Scholar] [CrossRef]

- Elbasuney, S. Novel Multi-Component Flame Retardant System Based on Nanoscopic Aluminium-trihydroxide (ATH). Powder Technol. 2017, 305, 538–545. [Google Scholar] [CrossRef]

- Pan, Y.; Han, L.; Guo, Z.; Fang, Z. Improving the Flame-Retardant Efficiency of Aluminum Hydroxide with Fullerene for High-Density Polyethylene. J. Appl. Polym. Sci. 2017, 134, 44551. [Google Scholar] [CrossRef]

- Rudawska, A.; Sikora, J.W.; Müller, M.; Valášek, P. The Effect of Environmental Ageing at Lower and Sub-Zero Temperatures on the Adhesive Joint Strength. Int. J. Adhes. Adhes. 2020, 97, 102487. [Google Scholar] [CrossRef]

- Lahouar, M.A.; Caron, J.-F.; Pinoteau, N.; Forêt, G.; Benzarti, K. Mechanical Behavior of Adhesive Anchors under High Temperature Exposure: Experimental Investigation. Int. J. Adhes. Adhes. 2017, 78, 200–211. [Google Scholar] [CrossRef]

- MIL-STD-883; Die Shear Strength. Department of Defense: Portsmouth, NH, USA, 2019.

- ASTM D570; Standard Test Method for Water Absorption. ASTM International: West Conshohocken, PA, USA, 2022.

- JESD22; Solid State Device Packaging Standards. JEDEC Publication: Arlington, TX, USA, 2004.

| Element | Untreated ATH | Trifluoro-ATH | Vinyl-ATH | 3-Glycidoxy-ATH | Methyl-ATH | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Atomic (%) | Weight (%) | Atomic (%) | Weight (%) | Atomic (%) | Weight (%) | Atomic (%) | Weight (%) | Atomic (%) | Weight (%) | |

| C | 6.4 | 4.2 | 6.1 | 4.1 | 6.5 | 4.3 | 5.2 | 3.4 | 8.3 | 5.6 |

| O | 71.8 | 63.3 | 72.0 | 63.4 | 71.3 | 62.8 | 74.1 | 65.7 | 71.1 | 63.4 |

| F | - | - | 0.2 | 0.2 | - | - | - | - | - | - |

| Al | 21.8 | 32.5 | 21.6 | 32.2 | 22.1 | 32.8 | 20.6 | 30.8 | 20.5 | 30.9 |

| Si | - | - | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Shear Rate (rpm) | N-ATH | F-ATH | V-ATH | G-ATH | M-ATH |

|---|---|---|---|---|---|

| 0.1 | 86,990 | 252,700 | 107,700 | 91,130 | 149,100 |

| 0.5 | 38,110 | 72,910 | 42,250 | 38,100 | 53,850 |

| 1 | 26,100 | 42,670 | 28,580 | 27,340 | 33,970 |

| 5 | 15,660 | 18,890 | 16,650 | 16,240 | 18,890 |

| 10 | 14,000 | 15,160 | 14,500 | 14,080 | 16,200 |

| 20 | 12,700 | 12,800 | 13,070 | 12,780 | 14,310 |

| Shear Rate (rpm) | CTE (ppm/°C) 20~150 °C | Storage Modulus (MPa) | ||

|---|---|---|---|---|

| 25 °C | 150 °C | 250 °C | ||

| Fluorosilicone | 258 | - | - | - |

| N-ATH | 174 | 110 | 90 | 100 |

| F-ATH | 189 | 110 | 82 | 94 |

| V-ATH | 178 | 110 | 80 | 100 |

| G-ATH | 186 | 110 | 100 | 110 |

| M-ATH | 178 | 110 | 100 | 110 |

| Fluorosilicone/ATH | Combustion Time (s) | Dripping | Rating | |

|---|---|---|---|---|

| After 1st Ignition (t1) | After 2nd Ignition (t2) | |||

| Fluorosilicone | 176 | burned | D | No rating |

| N-ATH | 0 | 0 | N | V-0 |

| F-ATH | 0 | 0 | N | V-0 |

| V-ATH | 0 | 0 | N | V-0 |

| G-ATH | 0 | 0 | N | V-0 |

| M-ATH | 0 | 0 | N | V-0 |

| ATH Content (wt.%) | Combustion Time (s) | Dripping | Rating | ||

|---|---|---|---|---|---|

| After 1st Ignition (t1) | After 2nd Ignition (t2) | ||||

| N-ATH | 20 | 4 | 13 | N | V-0 |

| 40 | 0 | 0 | N | V-0 | |

| 60 | 0 | 0 | N | V-0 | |

| G-ATH | 20 | 8 | 11 | N | V-0 |

| 40 | 0 | 0 | N | V-0 | |

| 60 | 0 | 0 | N | V-0 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sung, K.-S.; Cho, H.-W.; Lee, D.-H.; Kim, W.; Kim, N. Fire-Resistant and Thermal Stability Properties of Fluorosilicone Adhesives by Incorporation of Surface-Modified Aluminum Trihydrate. Polymers 2024, 16, 2510. https://doi.org/10.3390/polym16172510

Sung K-S, Cho H-W, Lee D-H, Kim W, Kim N. Fire-Resistant and Thermal Stability Properties of Fluorosilicone Adhesives by Incorporation of Surface-Modified Aluminum Trihydrate. Polymers. 2024; 16(17):2510. https://doi.org/10.3390/polym16172510

Chicago/Turabian StyleSung, Kyung-Soo, Hye-Won Cho, Dae-Ho Lee, Woonjung Kim, and Namil Kim. 2024. "Fire-Resistant and Thermal Stability Properties of Fluorosilicone Adhesives by Incorporation of Surface-Modified Aluminum Trihydrate" Polymers 16, no. 17: 2510. https://doi.org/10.3390/polym16172510

APA StyleSung, K.-S., Cho, H.-W., Lee, D.-H., Kim, W., & Kim, N. (2024). Fire-Resistant and Thermal Stability Properties of Fluorosilicone Adhesives by Incorporation of Surface-Modified Aluminum Trihydrate. Polymers, 16(17), 2510. https://doi.org/10.3390/polym16172510