Orientation Control of Perfluorosulfonic Acid Films via Addition of 1,2,4-Triazole during Casting

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Preparation

2.3. Characterization

3. Results and Discussion

3.1. Properties of PFSA Films

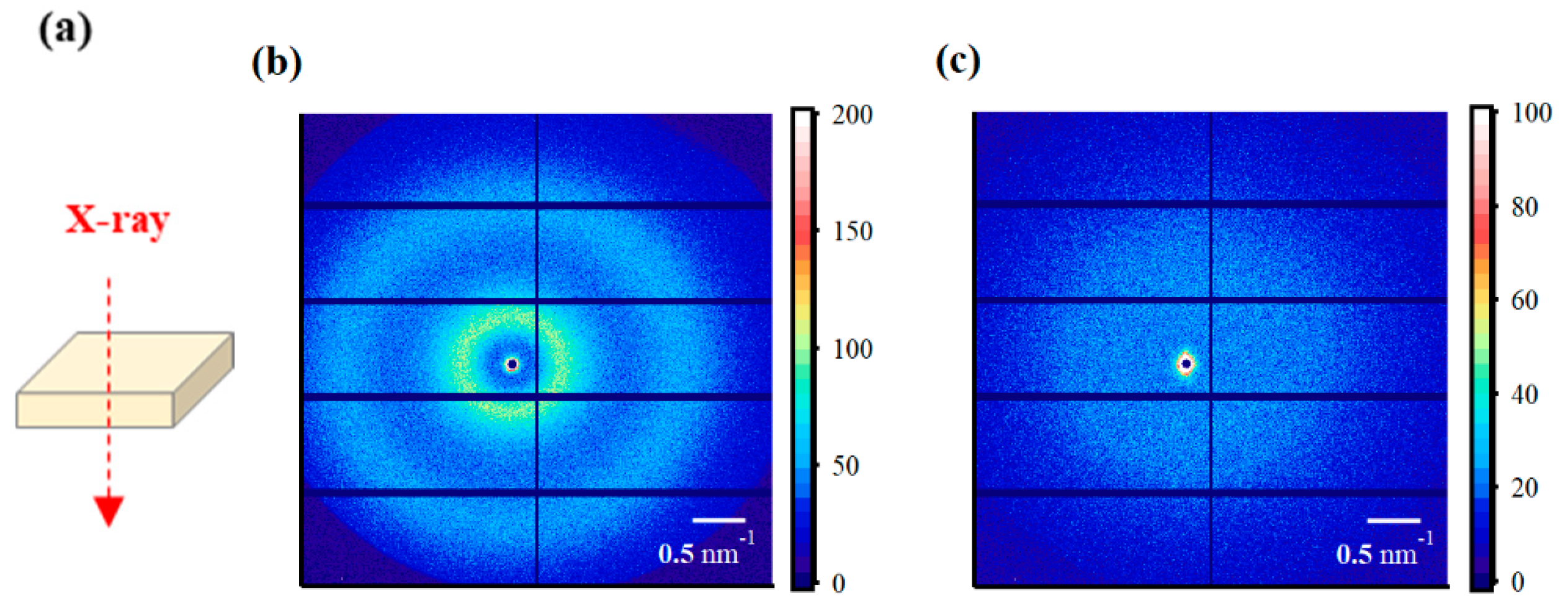

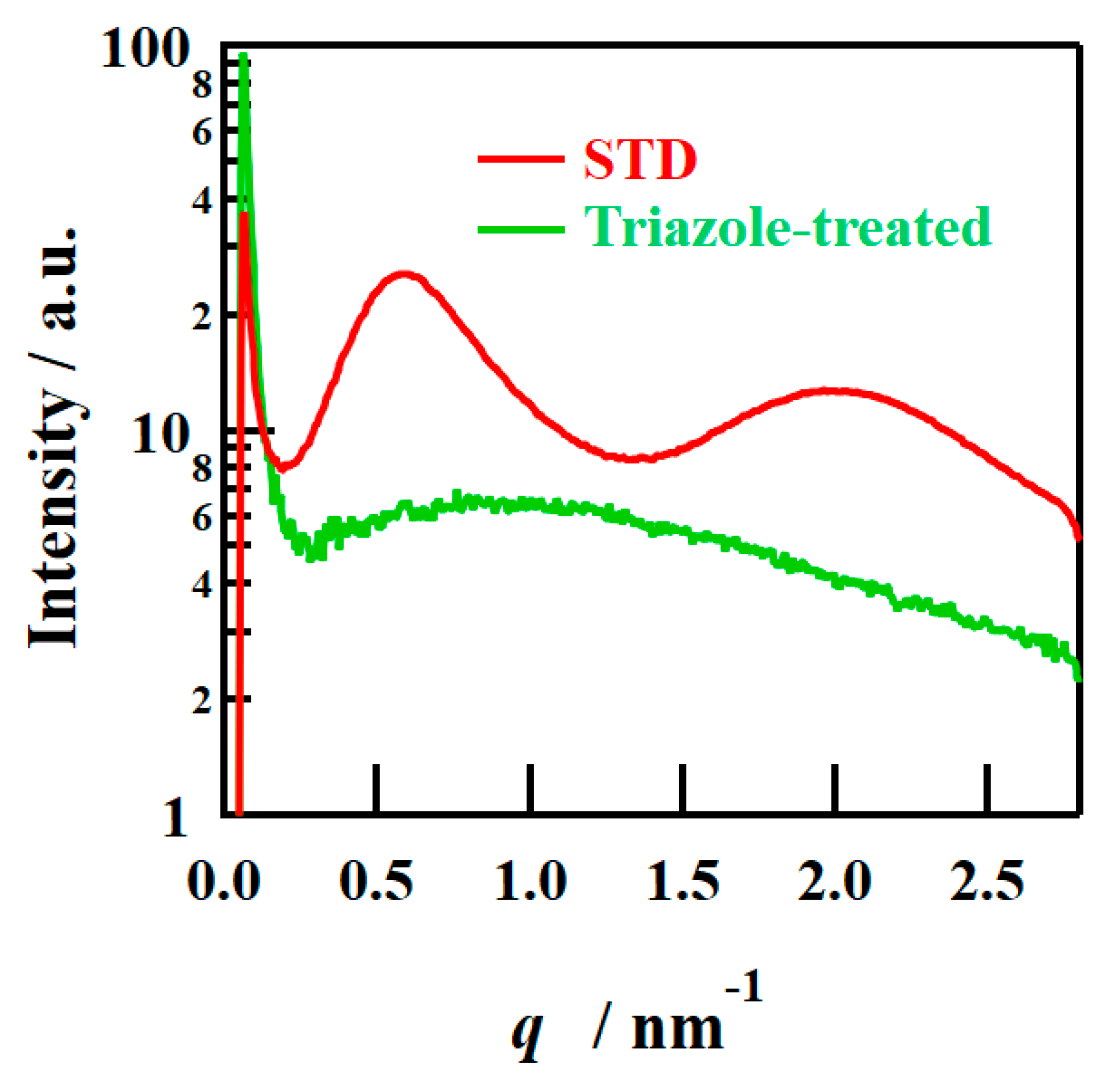

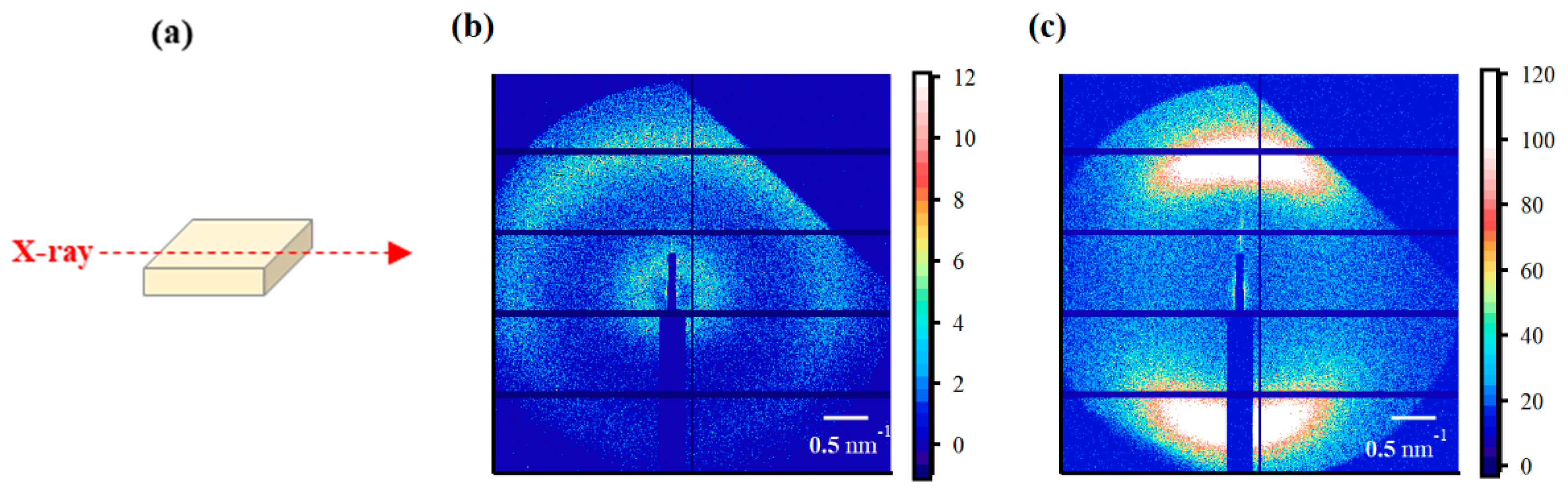

3.2. X-ray Structural Analysis

3.3. Mechanism Estimation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andújar, J.M.; Segura, F. Fuel Cells: History and Updating. A Walk along Two Centuries. Renew. Sustain. Energy Rev. 2009, 13, 2309–2322. [Google Scholar] [CrossRef]

- Cullen, D.A.; Neyerlin, K.C.; Ahluwalia, R.K.; Mukundan, R.; More, K.L.; Borup, R.L.; Weber, A.Z.; Myers, D.J.; Kusoglu, A. New Roads and Challenges for Fuel Cells in Heavy-Duty Transportation. Nat. Energy 2021, 65, 462–474. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, Z.; Zhang, J.; Tang, Y.; Song, C.; Navessin, T.; Shi, Z.; Song, D.; Wang, H.; Wilkinson, D.P.; et al. High Temperature PEM Fuel Cells. J. Power Sources 2006, 160, 872–891. [Google Scholar] [CrossRef]

- Mauritz, K.A.; Moore, R.B. State of Understanding of Nafion. Chem. Rev. 2004, 104, 4535–4585. [Google Scholar] [CrossRef]

- Kusoglu, A.; Weber, A.Z. New Insights into Perfluorinated Sulfonic-Acid Ionomers. Chem. Rev. 2017, 117, 987–1104. [Google Scholar] [CrossRef] [PubMed]

- Hinatsu, J.T.; Mizuhata, M.; Takenaka, H. Water Uptake of Perfluorosulfonic Acid Membranes from Liquid Water and Water Vapor. J. Electrochem. Soc. 1994, 141, 1493–1498. [Google Scholar] [CrossRef]

- Li, J.; Pana, M.; Tang, H. Understanding Short-Side-Chain Perfluorinated Sulfonic Acid and Its Application for High Temperature Polymer Electrolyte Membrane Fuel Cells. RSC Adv. 2014, 4, 3944–3965. [Google Scholar] [CrossRef]

- Shin, S.; Nur, P.J.; Kodir, A.; Kwak, D.; Lee, H.; Shin, D.; Bae, B. Improving the Mechanical Durability of Short-Side-Chain Perfluorinated Polymer Electrolyte Membranes by Annealing and Physical Reinforcement. ACS Omega 2019, 4, 19153–19163. [Google Scholar] [CrossRef]

- Katzenberg, A.; Chowdhury, A.; Fang, M.; Weber, A.Z.; Okamoto, Y.; Kusoglu, A.; Modestino, M.A. Highly Permeable Perfluorinated Sulfonic Acid Ionomers for Improved Electrochemical Devices: Insights into Structure–Property Relationships. J. Am. Chem. Soc. 2020, 142, 3742–3752. [Google Scholar] [CrossRef]

- Macauley, N.; Lousenberg, R.D.; Spinetta, M.; Zhong, S.; Yang, F.; Judge, W.; Nikitin, V.; Perego, A.; Qi, Y.; Pedram, S.; et al. Highly Durable Fluorinated High Oxygen Permeability Ionomers for Proton Exchange Membrane Fuel Cells. Adv. Energy Mater. 2022, 12, 2201063. [Google Scholar] [CrossRef]

- Hirai, T.; Hommura, S.; Watakabe, A.; Miyajima, T.; Nakayama, S.; Tamoto, K.; Uchida, M. Effects of Humidity and Produced Water on Specific Adsorption of High Oxygen Permeability Ionomers Composed Entirely of Cyclic Monomers on Cathode Performance for Polymer Electrolyte Fuel Cells. ACS Appl. Energy Mater. 2024, 7, 3806–3823. [Google Scholar] [CrossRef]

- Gierke, T.D.; Munn, G.E.; Wilson, F.C. The Morphology in Nafion Perfluorinated Membrane Products, as Determined by Wide- and Small-Angle X-ray Studies. J. Polym. Sci. Polym. Phys. Ed. 1981, 19, 1687–1704. [Google Scholar] [CrossRef]

- Fujimura, M.; Hashimoto, T.; Kawai, H. Small-Angle X-ray Scattering Study of Perfluorinated Ionomer Membranes. 1. Origin of Two Scattering Maxima. Macromolecules 1981, 14, 1309–1315. [Google Scholar] [CrossRef]

- Moore, R.B.; Martin, C.R. Morphology and Chemical Properties of the Dow Perfluorosulfonate Ionomers. Macromolecules 1989, 22, 3594–3599. [Google Scholar] [CrossRef]

- Gebel, G. Structural Evolution of Water Swollen Perfluorosulfonated Ionomers from Dry Membrane to Solution. Polymer 2000, 41, 5829–5838. [Google Scholar] [CrossRef]

- Rubatat, L.; Rollet, A.L.; Gebel, G.; Diat, O. Evidence of Elongated Polymeric Aggregates in Nafion. Macromolecules 2002, 35, 4050–4055. [Google Scholar] [CrossRef]

- Liu, Y.; Horan, J.L.; Schlichting, G.J.; Caire, B.R.; Liberatore, M.W.; Hamrock, S.J.; Haugen, G.M.; Yandrasits, M.A.; Seifert, S.; Herring, A.M. A Small-Angle X-ray Scattering Study of the Development of Morphology in Films Formed from the 3M Perfluorinated Sulfonic Acid Ionomer. Macromolecules 2012, 45, 7495–7503. [Google Scholar] [CrossRef]

- Schmidt-Rohr, K.; Chen, Q. Parallel Cylindrical Water Nanochannels in Nafion Fuel Cell Membranes. Nat. Mater. 2008, 7, 75–83. [Google Scholar] [CrossRef]

- Mendil-Jakani, H.; Pouget, S.; Gebel, G.; Pintauro, P. Insight into the Multiscale Structure of Pre-stretched Recast Nafion Membranes: Focus on the Crystallinity Features. Polymer 2015, 63, 99–107. [Google Scholar] [CrossRef]

- Miyajima, T.; Okuyama, T.; Saito, S.; Watabe, H.; Morita, C.; Hirai, T.; Shimohira, T.; Matsuba, G. Relationship between Polymer Structure and Dry-Wet Cycling Resistance of Perfluorosulfonic Acid Membranes. Polymer 2024, 296, 126789. [Google Scholar] [CrossRef]

- Cable, K.M.; Mauritz, K.A.; Moore, R.B. Anisotropic Ionic Conductivity in Uniaxially Oriented Perfluorosulfonate Ionomers. Chem. Mater. 1995, 7, 1601–1603. [Google Scholar] [CrossRef]

- Park, M.K.; Li, J.; Divoux, G.M.; Madsen, L.A.; Moor, R.B. Oriented Morphology and Anisotropic Transport in Uniaxially Stretched Perfluorosulfonate Ionomer Membranes. Macromolecules 2011, 44, 5701–5710. [Google Scholar] [CrossRef]

- Kusoglu, A.; Hexemer, A.; Jiang, R.; Gittleman, C.S.; Weber, A. Effect of Compression on PFSA-Ionomer Morphology and Predicted Conductivity Changes. J. Membr. Sci. 2012, 421–422, 283–291. [Google Scholar] [CrossRef]

- Modestino, M.A.; Kusoglu, A.; Hexemer, A.; Weber, A.Z.; Segalman, R.A. Controlling Nafion Structure and Properties via Wetting Interactions. Macromolecules 2012, 45, 4681–4688. [Google Scholar] [CrossRef]

- Kusoglu, A.; Kushner, D.; Paul, D.K.; Karan, K.; Hickner, M.A.; Weber, A.Z. Impact of Substrate and Processing on Confinement of Nafion Thin Films. Adv. Funct. Mater. 2014, 24, 4763–4774. [Google Scholar] [CrossRef]

- Kusoglu, A.; Dursch, T.J.; Weber, A.Z. Nanostructure/Swelling Relationships of Bulk and Thin-Film PFSA Ionomers. Adv. Funct. Mater. 2016, 26, 4961–4975. [Google Scholar] [CrossRef]

- Dudenas, P.J.; Kusoglu, A. Evolution of Ionomer Morphology from Dispersion to Film: An In-situ X-ray Study. Macromolecules 2019, 52, 7779–7785. [Google Scholar] [CrossRef]

- Karan, K. Interesting Facets of Surface, Interfacial, and Bulk Characteristics of Perfluorinated Ionomer Films. Langmuir 2019, 35, 13489–13520. [Google Scholar] [CrossRef]

- Gao, X.; Yamamoto, K.; Hirai, T.; Uchiyama, T.; Ohta, N.; Takao, N.; Matsumoto, M.; Imai, H.; Sugawara, S.; Shinohara, K.; et al. Morphology Changes in Perfluorosulfonated Ionomer from Thickness and Thermal Treatment Conditions. Langmuir 2020, 36, 3871–3878. [Google Scholar] [CrossRef]

- Gao, X.; Yamamoto, K.; Hirai, T.; Ohta, N.; Uchiyama, T.; Watanabe, T.; Takahashi, M.; Takao, N.; Imai, H.; Sugawara, S.; et al. Substrate-Dependent Proton Transport and Nanostructural Orientation of Perfluorosulfonic Acid Polymer Thin Films on Pt and Carbon Substrate. Solid State Ion. 2020, 357, 115456. [Google Scholar] [CrossRef]

- Kim, J.-D.; Oba, Y.; Ohnuma, M.; Mori, T.; Nishimura, C.; Honma, I. Physico-chemical Properties of Temperature Tolerant Anhydrous Nafion-Benzimidazole Blend Membrane. Solid State Ion. 2010, 181, 1098–1102. [Google Scholar] [CrossRef]

- Kim, J.-D.; Mori, T.; Hayashi, S.; Honma, I. Anhydrous Proton-Conducting Properties of Nafion–1,2,4-Triazole and Nafion–Benzimidazole Membranes for Polymer Electrolyte Fuel Cells. J. Electrochem. Soc. 2007, 154, A290–A294. [Google Scholar] [CrossRef]

- Kim, J.-D.; Ohnuma, M.; Nishimura, C.; Mori, T.; Kucernak, A. Small-Angle X-ray Scattering and Proton Conductivity of Anhydrous Nafion–Benzimidazole Blend Membrane. J. Electrochem. Soc. 2009, 156, B729–B734. [Google Scholar] [CrossRef]

- Kim, J.-D.; Jun, M.-S.; Nishimura, C.; Choi, Y.-W. Highly Flexible Temperature Tolerant Anhydrous Nafion-1,2,3-Triazole Blend Membranes Synthesized by Autoclave Solution Processing. ECS Trans. 2011, 35, 241–250. [Google Scholar] [CrossRef]

- Kim, J.-D.; Jun, M.-S.; Divona, M.L. Nafion-1,2,3-Triazole Blend Membranes for High Temperature PEMFCs. Fuel Cells 2013, 13, 65–71. [Google Scholar] [CrossRef]

- Kim, J.-D.; Ghil, L.-J.; Jun, M.-S.; Choi, J.-K.; Chang, H.-J.; Kim, Y.-C.; Rhee, H.-W. Nafion-Propyl-1,2,3-Triazole Composite Membrane for Fuel Cells. J. Electrochem. Soc. 2014, 161, F724–F728. [Google Scholar] [CrossRef]

- Kim, J.-D.; Ghil, L.-J.; Ohira, A. Annealing Effect of Nafion-Propyl-1,2,3-Triazole Membrane by Autoclave Solution Processing. ECS Trans. 2018, 85, 943–959. [Google Scholar] [CrossRef]

- Kim, J.-D.; Ohira, A.; Nakao, H. High-Performance Nafion Membrane Modified Using a 1,2,4-Triazole Derivative. 2019. ECSarXiv preprint. [Google Scholar] [CrossRef]

- Tanuma, T. Innovative Hydrophilic Microporous Layers for Cathode Gas Diffusion Media. J. Electrochemical. Soc. 2010, 157, B1809–B1813. [Google Scholar] [CrossRef]

- So, S.; Cha, M.S.; Jo, S.-W.; Kim, T.-H.; Lee, J.Y.; Hong, Y.T. Hydrophilic Channel Alignment of Perfluoronated Sulfonic-AcidIonomers for Vanadium Redox Flow Batteries. ACS Appl. Mater. Interfaces 2018, 10, 19689–19696. [Google Scholar] [CrossRef]

- Rubatat, L.; Diat, O. Stretching Effect on Nafion Fibrillar Nanostructure. Macromolecules 2007, 40, 9455–9462. [Google Scholar] [CrossRef]

- Al-Hussein, M.; Séréro, Y.; Konovalov, O.; Mourran, A.; Möller, M.; de Jeu, W.H. Nanoordering of Fluorinated Side-Chain Liquid Crystalline/Amorphous Diblock Copolymers. Macromolecules 2005, 38, 9610–9616. [Google Scholar] [CrossRef]

| Proton Conductivity (S/cm) | |

|---|---|

| STD film | 0.055 |

| Triazole-treated film | 0.083 |

| D for Matrix (nm) | D for Ion Cluster (nm) | |

|---|---|---|

| STD film | 10.6 | 3.14 |

| Triazole-treated cast film | – | 6.8 * |

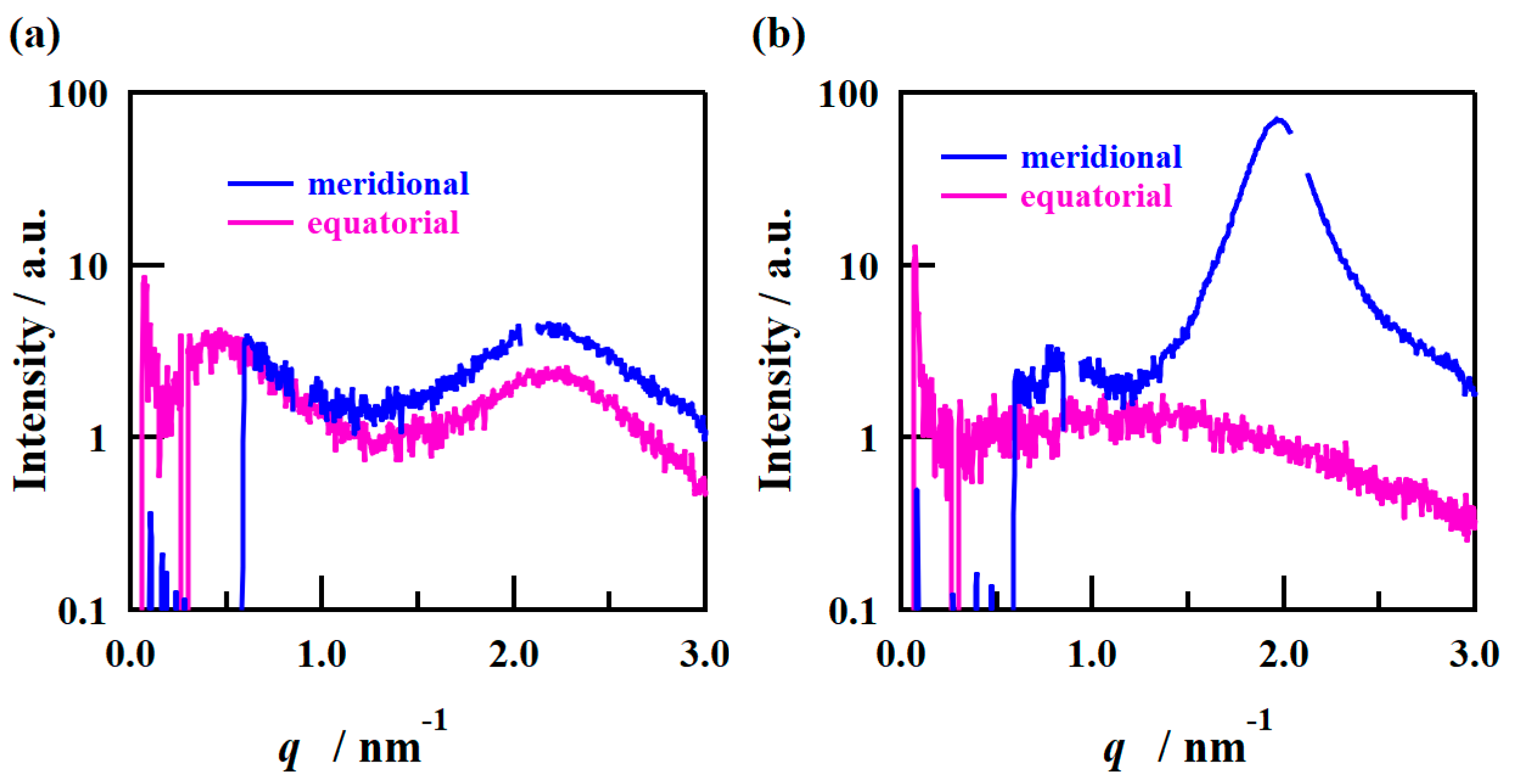

| D for Matrix in Equatorial Direction (nm) | D for Matrix in Meridional Direction (nm) | D for Ion Cluster in Equatorial Direction (nm) | D for Ion Cluster in Meridional Direction (nm) | |

|---|---|---|---|---|

| STD film | 13.0 | – | 2.87 | 2.89 |

| Triazole-treated cast film | – | – | 5 * | 3.19 |

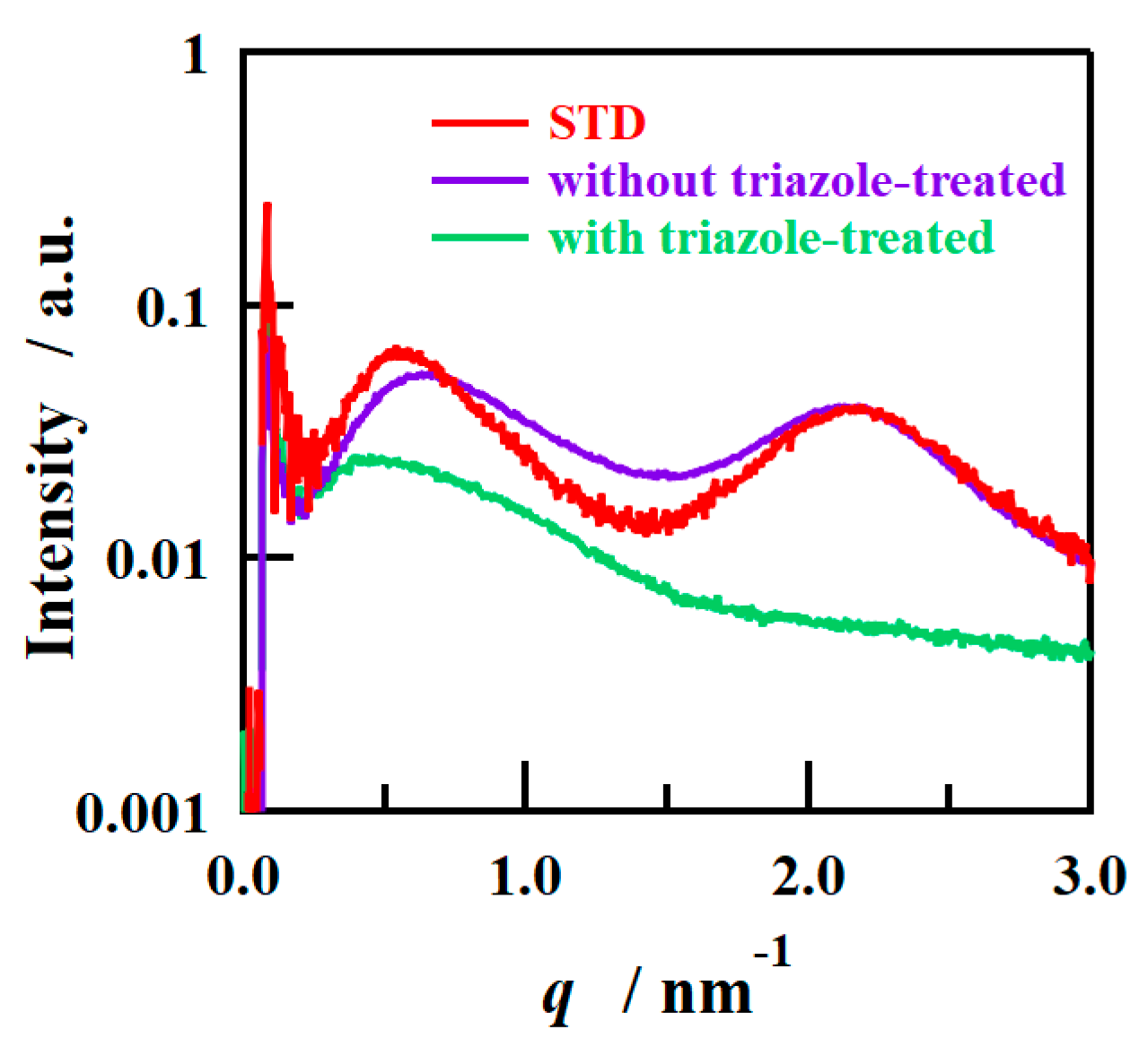

| D for Matrix (nm) | D for Ion Clusters (nm) | |

|---|---|---|

| STD film | 11.1 | 2.90 |

| Cast film treated without triazole before H2O2 treatment | 9.7 | 2.96 |

| Cast film treated with triazole before H2O2 treatment | – | 12.6 |

| S/F (Atom) | |

|---|---|

| STD film | 0.028 |

| Cast film treated without triazole before H2O2 treatment | 0.024 |

| Cast film treated with triazole before H2O2 treatment | 0.024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miyajima, T.; Saito, S.; Okuyama, T.; Matsushita, S.; Shimohira, T.; Matsuba, G. Orientation Control of Perfluorosulfonic Acid Films via Addition of 1,2,4-Triazole during Casting. Polymers 2024, 16, 2533. https://doi.org/10.3390/polym16172533

Miyajima T, Saito S, Okuyama T, Matsushita S, Shimohira T, Matsuba G. Orientation Control of Perfluorosulfonic Acid Films via Addition of 1,2,4-Triazole during Casting. Polymers. 2024; 16(17):2533. https://doi.org/10.3390/polym16172533

Chicago/Turabian StyleMiyajima, Tatsuya, Susumu Saito, Takumi Okuyama, Satoshi Matsushita, Tetsuji Shimohira, and Go Matsuba. 2024. "Orientation Control of Perfluorosulfonic Acid Films via Addition of 1,2,4-Triazole during Casting" Polymers 16, no. 17: 2533. https://doi.org/10.3390/polym16172533

APA StyleMiyajima, T., Saito, S., Okuyama, T., Matsushita, S., Shimohira, T., & Matsuba, G. (2024). Orientation Control of Perfluorosulfonic Acid Films via Addition of 1,2,4-Triazole during Casting. Polymers, 16(17), 2533. https://doi.org/10.3390/polym16172533