Preparation and Utilization of a Highly Discriminative Absorbent Imprinted with Fetal Hemoglobin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Protein Samples

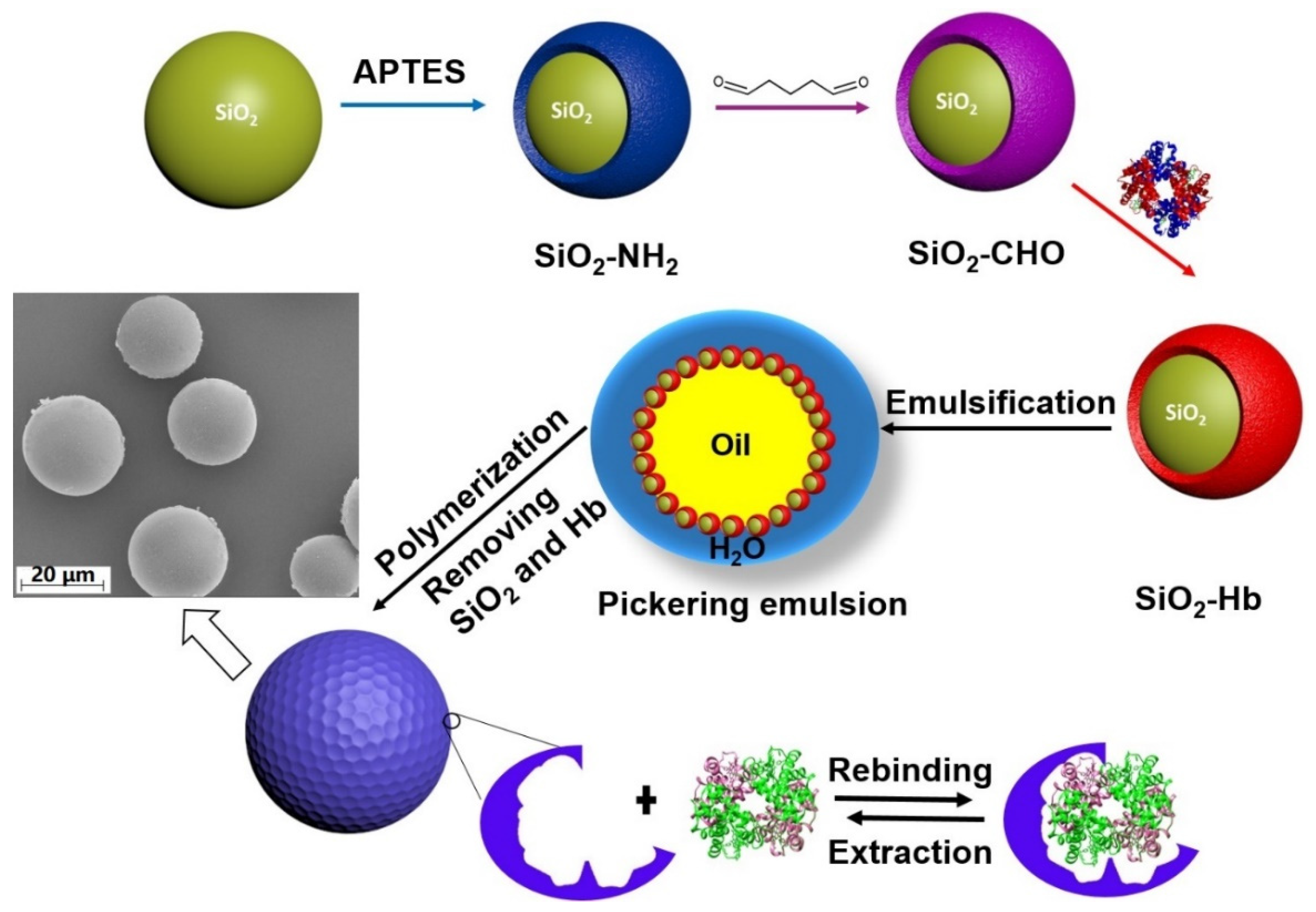

2.3. Preparation of HbF-Imprinted Polymers Using Immobilized Templates

2.4. Surface Characterization of the MIP Beads

2.5. Competitive Protein-Binding Assay

2.6. Selective Capture of Hb from Recombinant HbA and HbF Complex Samples

2.7. Chromatographic Analysis

3. Results

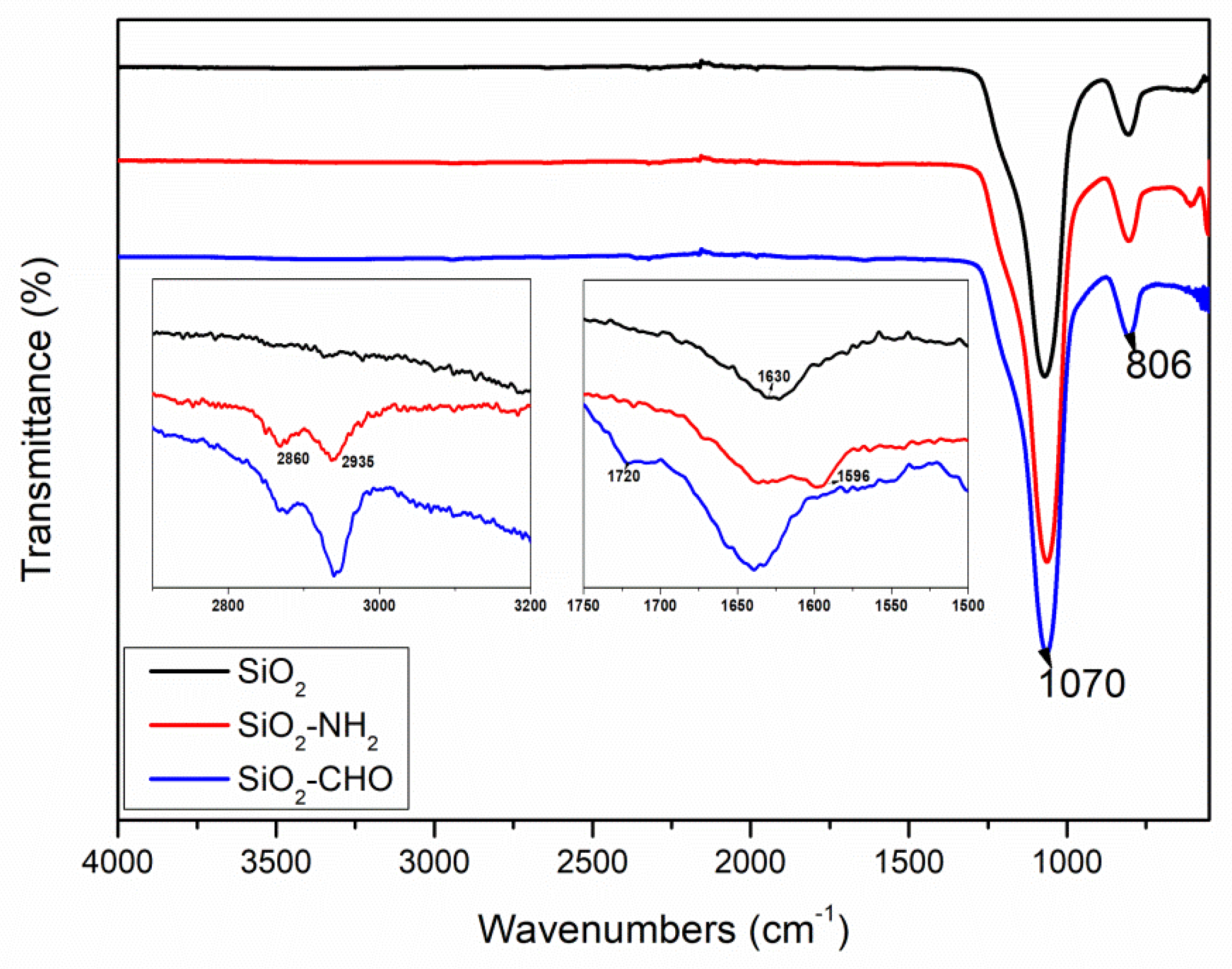

3.1. Preparation and Characterization of HbF-MIPs

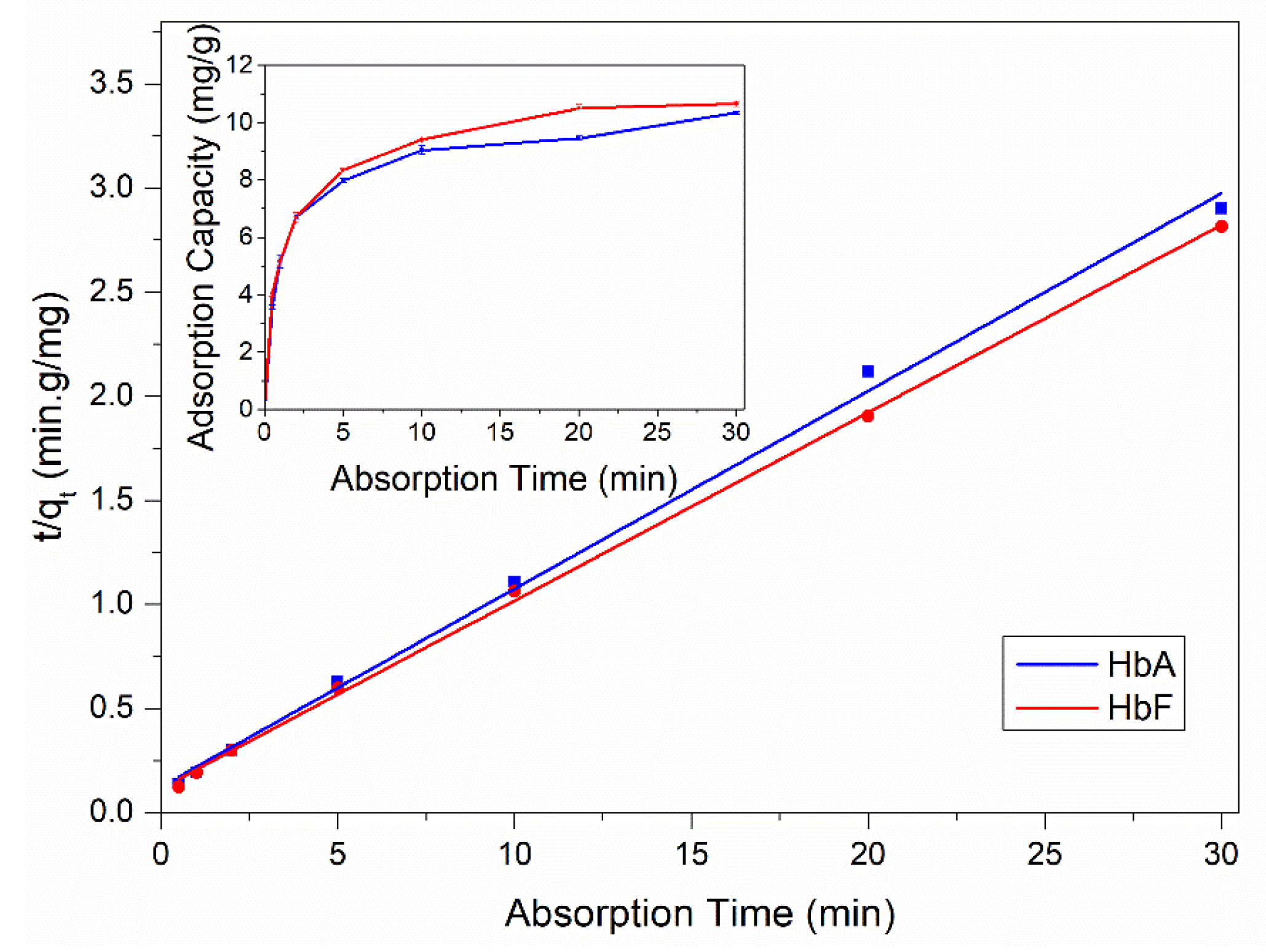

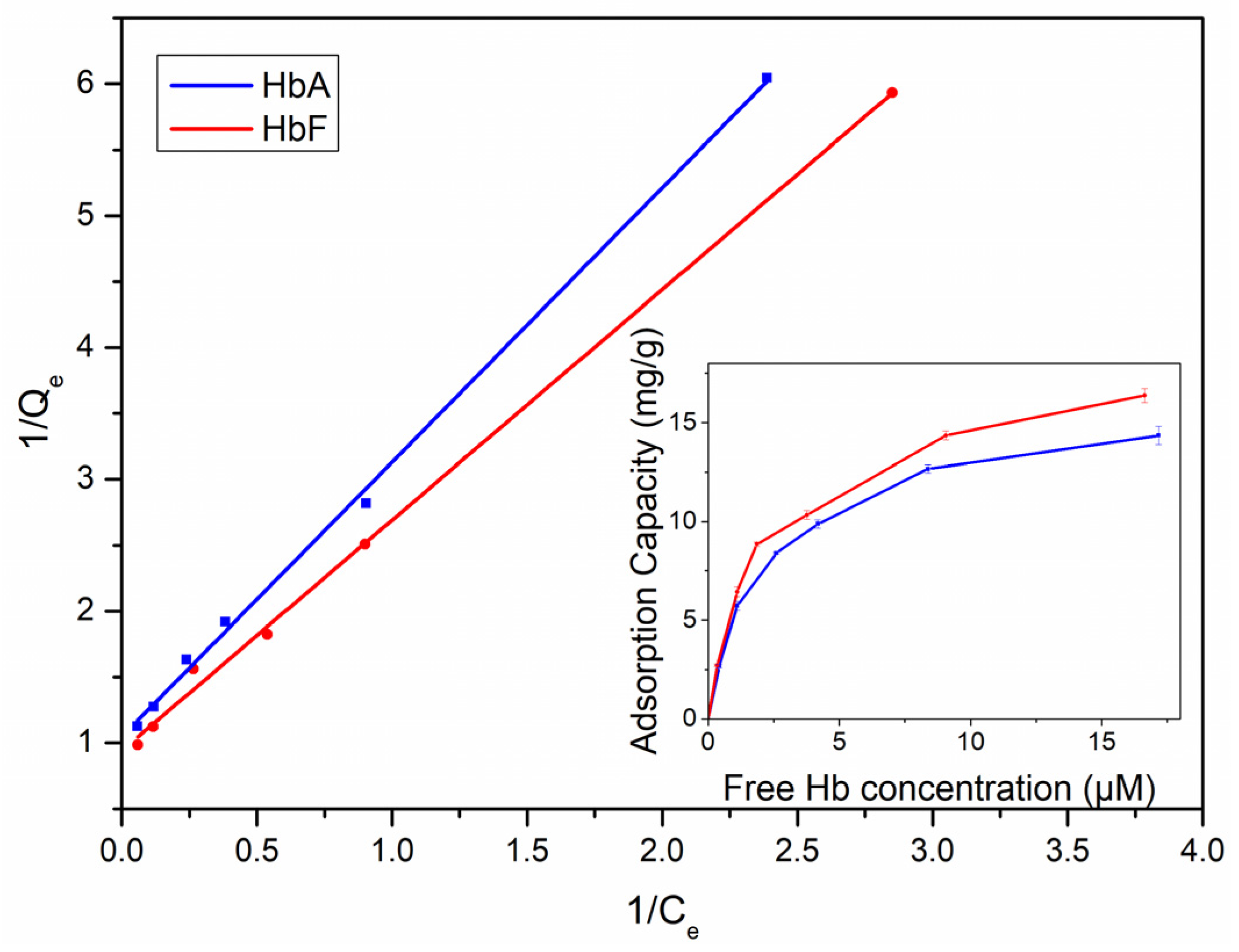

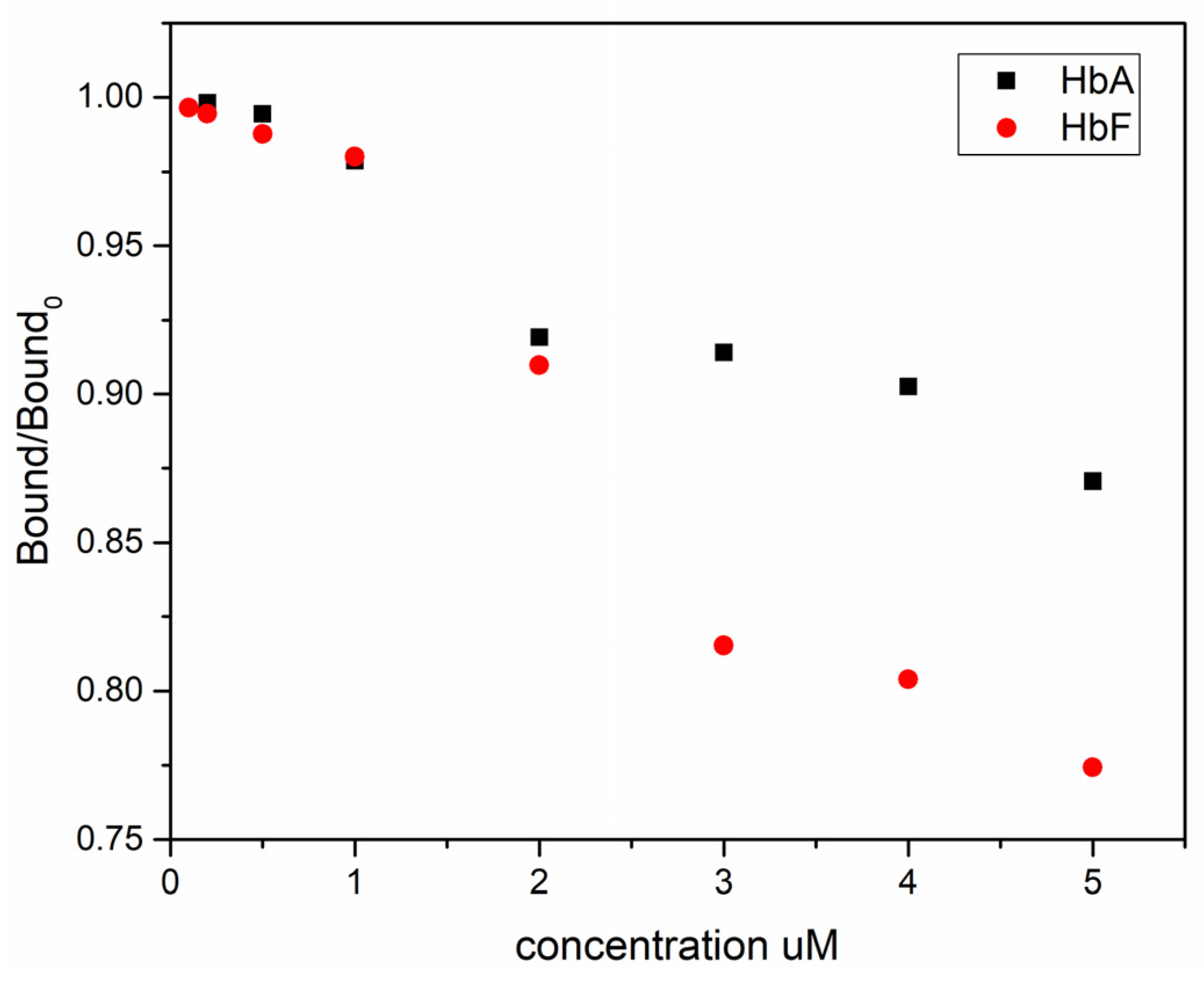

3.2. Molecular Recognition Property of HbF-MIPs

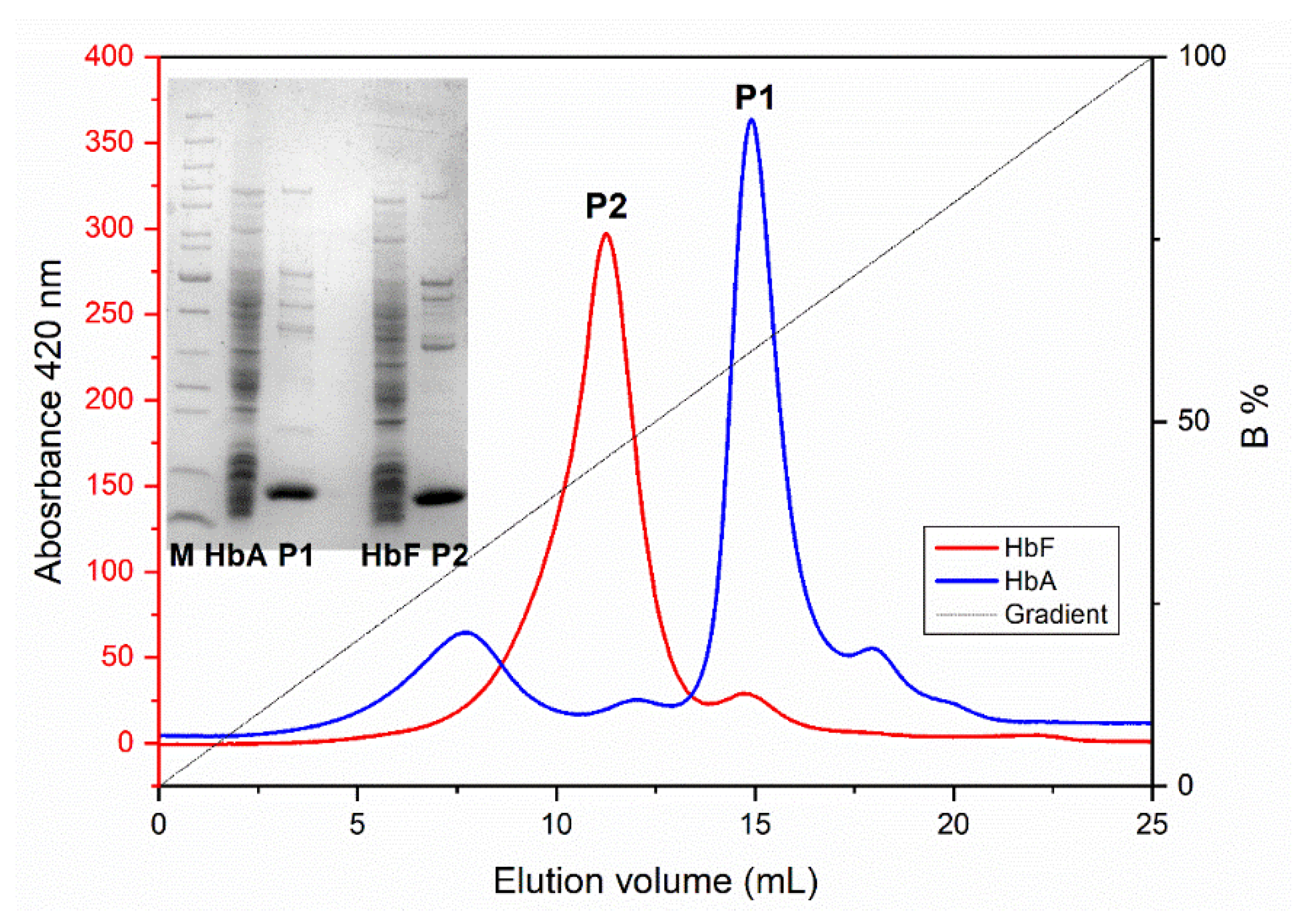

3.3. Selective Capture of Intact Hb in Complex Samples

3.4. Chromatographic Separation of HbA and HbF from E. coli Crude Cell Extracts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moreno-Bondi, M.C.; Benito-Pena, M.E.; Urraca, J.L.; Orellana, G. Immuno-like assays and biomimetic microchips. Top. Curr. Chem. 2012, 325, 111–164. [Google Scholar]

- Takeuchi, T.; Hishiya, T. Molecular imprinting of proteins emerging as a tool for protein recognition. Org. Biomol. Chem. 2008, 6, 2459–2467. [Google Scholar] [CrossRef] [PubMed]

- Bossi, A.; Bonini, F.; Turner, A.P.F.; Piletsky, S.A. Molecularly imprinted polymers for the recognition of proteins: The state of the art. Biosens. Bioelectron. 2007, 22, 1131–1137. [Google Scholar] [CrossRef] [PubMed]

- Alexander, C.; Davidson, L.; Hayes, W. Imprinted polymers: Artificial molecular recognition materials with applications in synthesis and catalysis. Tetrahedron 2003, 59, 2025–2057. [Google Scholar] [CrossRef]

- Andersson, L.I. Molecular imprinting for drug bioanalysis: A review on the application of imprinted polymers to solid-phase extraction and binding assay. J. Chromatogr. B Biomed. Sci. Appl. 2000, 739, 163–173. [Google Scholar] [CrossRef] [PubMed]

- White, C.J.; Byrne, M.E. Molecularly imprinted therapeutic contact lenses. Expert Opin. Drug Deliv. 2010, 7, 765–780. [Google Scholar] [CrossRef] [PubMed]

- Resmini, M. Molecularly imprinted polymers as biomimetic catalysts. Anal. Bioanal. Chem. 2012, 402, 3021–3026. [Google Scholar] [CrossRef]

- Ge, Y.; Turner Anthony, P.F. Molecularly imprinted sorbent assays: Recent developments and applications. Chem. Eur. J. 2009, 15, 8100–8107. [Google Scholar] [CrossRef] [PubMed]

- Poma, A.; Turner, A.P.F.; Piletsky, S.A. Advances in the manufacture of MIP nanoparticles. Trends Biotechnol. 2010, 28, 629–637. [Google Scholar] [CrossRef]

- Chen, L.; Xu, S.; Li, J. Recent advances in molecular imprinting technology: Current status, challenges and highlighted applications. Chem. Soc. Rev. 2011, 40, 2922–2942. [Google Scholar] [CrossRef] [PubMed]

- Verheyen, E.; Schillemans, J.P.; van Wijk, M.; Demeniex, M.-A.; Hennink, W.E.; van Nostrum, C.F. Challenges for the effective molecular imprinting of proteins. Biomaterials 2011, 32, 3008–3020. [Google Scholar] [CrossRef] [PubMed]

- Kryscio, D.R.; Peppas, N.A. Critical review and perspective of macromolecularly imprinted polymers. Acta Biomater. 2012, 8, 461–473. [Google Scholar] [CrossRef]

- Turner, N.W.; Jeans, C.W.; Brain, K.R.; Allender, C.J.; Hlady, V.; Britt, D.W. From 3D to 2D: A review of the molecular imprinting of proteins. Biotechnol. Prog. 2006, 22, 1474–1489. [Google Scholar] [CrossRef] [PubMed]

- He, Y.T.; Lin, Z.A. Recent advances in protein-imprinted polymers: Synthesis, applications and challenges. J. Mat. Chem. B 2022, 10, 6571–6589. [Google Scholar] [CrossRef] [PubMed]

- Resina, L.; Ferreira, F.C.; Esteves, T. Protein-imprinted polymers: How far have “plastic antibodies” come? Biotechnol. Adv. 2023, 68, 108220. [Google Scholar] [CrossRef] [PubMed]

- Bossi, A.; Piletsky, S.A.; Piletska, E.V.; Righetti, P.G.; Turner, A.P. Surface-grafted molecularly imprinted polymers for protein recognition. Anal. Chem. 2001, 73, 5281–5286. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.-H.; You, Q.-H.; Zhuang, Z.-X.; Wang, X.-R. Protein recognition via surface molecularly imprinted polymer nanowires. Anal. Chem. 2006, 78, 317–320. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Tsai, W.-B.; Garrison, M.D.; Ferrari, S.; Ratner, B.D. Template-imprinted nanostructured surfaces for protein recognition. Nature 1999, 398, 593–597. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, K.; Kamra, T.; Bulow, L.; Ye, L. Preparation of protein imprinted polymer beads by Pickering emulsion polymerization. J. Mater. Chem. B 2015, 3, 1254–1260. [Google Scholar] [CrossRef]

- Pickering, S.U. CXCVI.-Emulsions. J. Chem. Soc. 1907, 91, 2001–2021. [Google Scholar] [CrossRef]

- He, Y.; Yu, X. Preparation of silica nanoparticle-armored polyaniline microspheres in a Pickering emulsion. Mater. Lett. 2007, 61, 2071–2074. [Google Scholar] [CrossRef]

- Chen, T.; Colver, P.J.; Bon, S.A. Organic–inorganic hybrid hollow spheres prepared from TiO2-stabilized Pickering emulsion polymerization. Adv. Mater. 2007, 19, 2286–2289. [Google Scholar] [CrossRef]

- Wang, Z.; van Oers Matthijs, C.M.; Rutjes Floris, P.J.T.; van Hest Jan, C.M. Polymersome colloidosomes for enzyme catalysis in a biphasic system. Angew. Chem. Int. Ed. Engl. 2012, 124, 10904–10908. [Google Scholar] [CrossRef]

- Yang, J.; Li, Y.; Wang, J.; Sun, X.; Cao, R.; Sun, H.; Huang, C.; Chen, J. Molecularly imprinted polymer microspheres prepared by Pickering emulsion polymerization for selective solid-phase extraction of eight bisphenols from human urine samples. Anal. Chim. Acta 2015, 872, 35–45. [Google Scholar] [CrossRef] [PubMed]

- Pan, J.; Li, L.; Hang, H.; Wu, R.; Dai, X.; Shi, W.; Yan, Y. Fabrication and evaluation of magnetic/hollow double-shelled imprinted sorbents formed by Pickering emulsion polymerization. Langmuir 2013, 29, 8170–8178. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Svensson Bonde, J.; Kamra, T.; Bülow, L.; Leo, J.C.; Linke, D.; Ye, L. Bacterial imprinting at Pickering emulsion interfaces. Angew. Chem. Int. Ed. Engl. 2014, 53, 10687–10690. [Google Scholar] [CrossRef] [PubMed]

- Shen, X.; Zhou, T.; Ye, L. Molecular imprinting of protein in Pickering emulsion. Chem. Commun. 2012, 48, 8198–8200. [Google Scholar] [CrossRef]

- Shen, X.; Ye, L. Molecular imprinting in Pickering emulsions: A new insight into molecular recognition in water. Chem. Commun. 2011, 47, 10359–10361. [Google Scholar] [CrossRef]

- Berg, J.M.; Tymoczko, J.L.; Stryer, L. Biochemistry, 7th ed.; W. H. Freeman: New York, NY, USA, 2010. [Google Scholar]

- Manning, L.R.; Russell, J.E.; Padovan, J.C.; Chait, B.T.; Popowicz, A.; Manning, R.S.; Manning, J.M. Human embryonic, fetal, and adult hemoglobins have different subunit interface strengths. Correlation with lifespan in the red cell. Protein Sci. 2007, 16, 1641–1658. [Google Scholar] [CrossRef]

- Hartwell, S.K.; Srisawang, B.; Kongtawelert, P.; Christian, G.D.; Grudpan, K. Review on screening and analysis techniques for hemoglobin variants and thalassemia. Talanta 2005, 65, 1149–1161. [Google Scholar] [CrossRef]

- Wild, B.J.; Bain, B.J. Detection and quantitation of normal and variant haemoglobins: An analytical review. Ann. Clin. Biochem. 2004, 41, 355–369. [Google Scholar] [CrossRef] [PubMed]

- Alayash, A.I. Blood substitutes: Why haven’t we been more successful? Trends Biotechnol. 2014, 32, 177–185. [Google Scholar] [CrossRef] [PubMed]

- Palmer, A.F.; Intaglietta, M. Blood Substitutes. Annu. Rev. Biomed. Eng. 2014, 16, 77–101. [Google Scholar] [CrossRef] [PubMed]

- Moradi, S.; Jahanian-Najafabadi, A.; Roudkenar, M.H. Artificial Blood Substitutes: First Steps on the Long Route to Clinical Utility. Clin. Med. Insights Blood Disord. 2016, 9, 33–41. [Google Scholar] [CrossRef] [PubMed]

- Francisca, L.; Gomes, F.L.; Jeong, S.-H.; Shin, S.R.; Leijten, J.; Jonkheijm, P. Engineering Synthetic Erythrocytes as Next-Generation Blood Substitutes. Adv. Funct. Mat. 2024, 34, 2315879. [Google Scholar]

- Alayash, A.I. Mechanisms of toxicity and modulation of hemoglobin-based oxygen carriers (HBOCs). Shock 2017, 52, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Mackenzie, C.F.; Pitman, A.N.; Hodgson, R.E.; Sussman, M.J.; Levien, L.J.; Jahr, J.S.; Greenburg, A.G. Are hemoglobin-based oxygen carriers being withheld because of regulatory requirement for equivalence to packed red blood cells? Am. J. Ther. 2015, 22, e115–e121. [Google Scholar] [CrossRef] [PubMed]

- Ratanasopa, K.; Cedervall, T.; Bülow, L. Possibilities of using fetal hemoglobin as a platform for producing hemoglobin-based oxygen carriers (HBOCs). Adv. Exp. Med. Biol. 2016, 876, 445–453. [Google Scholar]

- Weiskopf, R.B. Hemoglobin-based oxygen carriers: Disclosed history and the way ahead: The relativity of safety. Anesth. Analg. 2014, 119, 758–760. [Google Scholar] [CrossRef]

- Alayash, A.I. Hemoglobin-based blood substitutes and the treatment of sickle cell disease: More harm than help? Biomolecules 2017, 7, 2. [Google Scholar] [CrossRef]

- Reeder, B.J.; Grey, M.; Silaghi-Dumitrescu, R.L.; Svistunenko, D.A.; Bulow, L.; Cooper, C.E.; Wilson, M.T. Tyrosine residues as redox cofactors in human hemoglobin: Implications for engineering nontoxic blood substitutes. J. Biol. Chem. 2008, 283, 30780–30787. [Google Scholar] [CrossRef] [PubMed]

- Ratanasopa, K.; Strader, M.B.; Alayash, A.I.; Bulow, L. Dissection of the radical reactions linked to fetal hemoglobin reveals enhanced pseudoperoxidase activity. Front. Physiol. 2015, 6, 39. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Zhou, T.; Ye, L.; Bülow, L. Characterization of protein-protein interactions in recombinant hemoglobin producing Escherichia coli cells using molecularly imprinted polymers. Adv. Exp. Med. Biol. 2017, 977, 367–373. [Google Scholar] [PubMed]

- Lu, Y.-K.; Yan, X.-P. An imprinted organic-inorganic hybrid sorbent for selective separation of cadmium from aqueous solution. Anal. Chem. 2004, 76, 453–457. [Google Scholar] [CrossRef]

- Jackson, N.; Ortiz, A.C.; Jerez, A.; Morales, J.; Arriagada, F. Kinetics and mechanism of camptothecin release from transferrin-gated mesoporous silica nanoparticles through a pH-responsive surface linker. Pharmaceutics 2023, 15, 1590. [Google Scholar] [CrossRef]

- Perutz, M.F. Mechanism of denaturation of haemoglobin by alkali. Nature 1974, 247, 341–344. [Google Scholar] [CrossRef] [PubMed]

- Blood, A.B.; Tiso, M.; Verma, S.T.; Lo, J.; Joshi, M.S.; Azarov, I.; Longo, L.D.; Gladwin, M.T.; Kim-Shapiro, D.B.; Power, G.G. Increased nitrite reductase activity of fetal versus adult ovine hemoglobin. Am. J. Physiol.-Heart Circ. Physiol. 2009, 296, H237–H246. [Google Scholar] [CrossRef]

- Hofmann, O.; Brittain, T. Ligand binding kinetics and dissociation of the human embryonic haemoglobins. Biochem. J. 1996, 315, 65–70. [Google Scholar] [CrossRef]

- Chakane, S.; Matos, T.; Kettisen, K.; Bulow, L. Fetal hemoglobin is much less prone to DNA cleavage compared to the adult protein. Redox Biol. 2017, 12, 114–120. [Google Scholar] [CrossRef]

- Simons, M.; Gretton, S.; Silkstone, G.G.A.; Rajagopal, B.S.; Allen-Baume, V.; Syrett, N.; Shaik, T.; Eriksson, N.; Ronda, L.; Mozzarelli, A.; et al. Comparison of the oxidative reactivity of recombinant fetal and adult human hemoglobin: Implications for the design of hemoglobin-based oxygen carriers. Biosci. Rep. 2018, 38, BSR20180370. [Google Scholar] [CrossRef]

- Graves, P.E.; Henderson, D.P.; Horstman, M.J.; Solomon, B.J.; Olson, J.S. Enhancing stability and expression of recombinant human hemoglobin in E. coli: Progress in the development of a recombinant HBOC source. Biochim. Biophys. Acta 2008, 1784, 1471–1479. [Google Scholar] [CrossRef] [PubMed]

- Thompson, J.D.; Higgins, D.G.; Gibson, T.J. CLUSTAL W: Improving the sensitivity of progressive multiple sequence alignment through sequence weighting, position-specific gap penalties and weight matrix choice. Nucleic Acids Res. 1994, 22, 4673–4680. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.-L.; Yao, H.-F.; Li, X.-Y.; Wang, X.; Huang, Y.-P.; Liu, Z.-S. pH/temperature-sensitive hydrogel-based molecularly imprinted polymers (hydroMIPs) for drug delivery by frontal polymerization. RSC Adv. 2016, 6, 94038–94047. [Google Scholar] [CrossRef]

- Fan, H.; Wang, J.; Meng, Q.; Xu, X.; Fan, T.; Jin, Z. Preparation of photoirradiation molecular imprinting polymer for selective separation of branched cyclodextrins. Molecules 2017, 22, 288. [Google Scholar] [CrossRef]

- Tsien, R.Y. The Green Fluorescent Protein. Annu. Rev. Biochem. 1998, 67, 509–544. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, C.; Jiang, X.; Fago, A.; Weber, R.E.; Moriyama, H.; Storz, J.F. Expression and purification of recombinant hemoglobin in Escherichia coli. PLoS ONE 2011, 6, e20176. [Google Scholar] [CrossRef] [PubMed]

- Silkstone, G.G.; Silkstone, R.S.; Wilson, M.T.; Simons, M.; Bulow, L.; Kallberg, K.; Ratanasopa, K.; Ronda, L.; Mozzarelli, A.; Reeder, B.J.; et al. Engineering tyrosine electron transfer pathways decreases oxidative toxicity in hemoglobin: Implications for blood substitute design. Biochem. J. 2016, 473, 3371–3383. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Chaudhuri, T.K. Revisiting Escherichia coli as microbial factory for enhanced production of human serum albumin. Microb. Cell Fact. 2017, 16, 173. [Google Scholar] [CrossRef]

| Equation | Qe (mg g−1) | V0 (mg g−1 min−1) | R2 | |

|---|---|---|---|---|

| HbA | y = 0.0950x + 0.1253 | 10.53 | 7.98 | 0.997 |

| HbF | y = 0.0902x + 0.1168 | 11.08 | 8.56 | 0.999 |

| Equation | Ka (×105 M−1) | Qmax (mg/g) | R2 | |

|---|---|---|---|---|

| HbA | y = 2.0820x + 1.0477 | 5.03 | 15.4 | 0.998 |

| HbF | y = 1.7495x + 0.9413 | 5.38 | 17.1 | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Zhou, T.; Dicko, C.; Ye, L.; Bülow, L. Preparation and Utilization of a Highly Discriminative Absorbent Imprinted with Fetal Hemoglobin. Polymers 2024, 16, 2734. https://doi.org/10.3390/polym16192734

Zhang K, Zhou T, Dicko C, Ye L, Bülow L. Preparation and Utilization of a Highly Discriminative Absorbent Imprinted with Fetal Hemoglobin. Polymers. 2024; 16(19):2734. https://doi.org/10.3390/polym16192734

Chicago/Turabian StyleZhang, Ka, Tongchang Zhou, Cedric Dicko, Lei Ye, and Leif Bülow. 2024. "Preparation and Utilization of a Highly Discriminative Absorbent Imprinted with Fetal Hemoglobin" Polymers 16, no. 19: 2734. https://doi.org/10.3390/polym16192734

APA StyleZhang, K., Zhou, T., Dicko, C., Ye, L., & Bülow, L. (2024). Preparation and Utilization of a Highly Discriminative Absorbent Imprinted with Fetal Hemoglobin. Polymers, 16(19), 2734. https://doi.org/10.3390/polym16192734