Extrusion 3D Printing of Intrinsically Fluorescent Thermoplastic Polyimide: Revealing an Undisclosed Potential

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

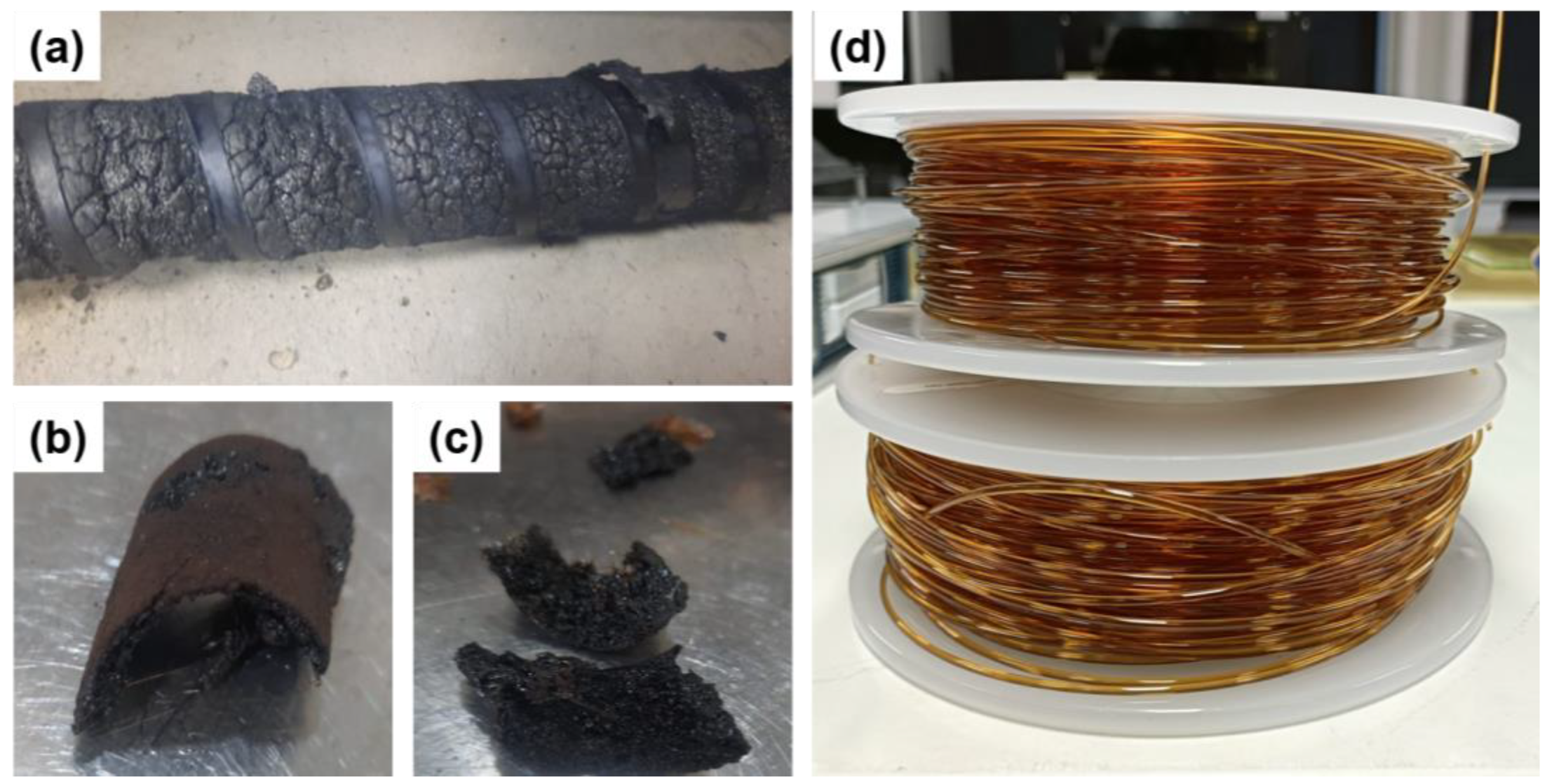

2.2. Preparation of TPI Filaments

2.2.1. Pellet Drying

2.2.2. Extrusion Process

2.3. FDM 3D Printing of TPI Filaments

2.4. Characterisation Methods

2.4.1. Moisture Analysis

2.4.2. Rheological Characterisations

2.4.3. Mechanical Characterisations

2.4.4. Fluorescence Measurements

2.4.5. Differential Scanning Calorimetry and Thermogravimetric Analysis

2.4.6. Field-Emission Scanning Electron Microscopy

2.4.7. X-Ray Micro-Computed Tomography Imaging

3. Results and Discussion

3.1. Moisture Content Analysis and Processing of TPI for Filament Production

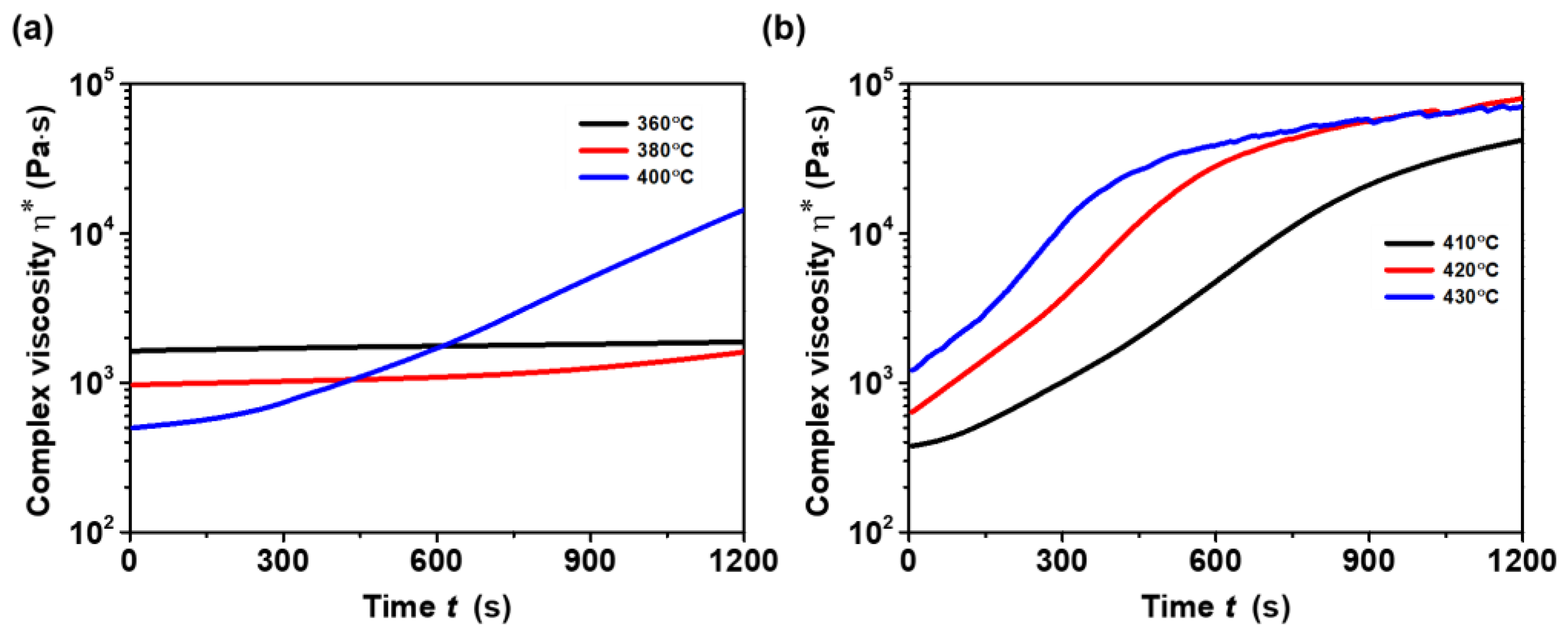

3.2. Rheological Characterisation

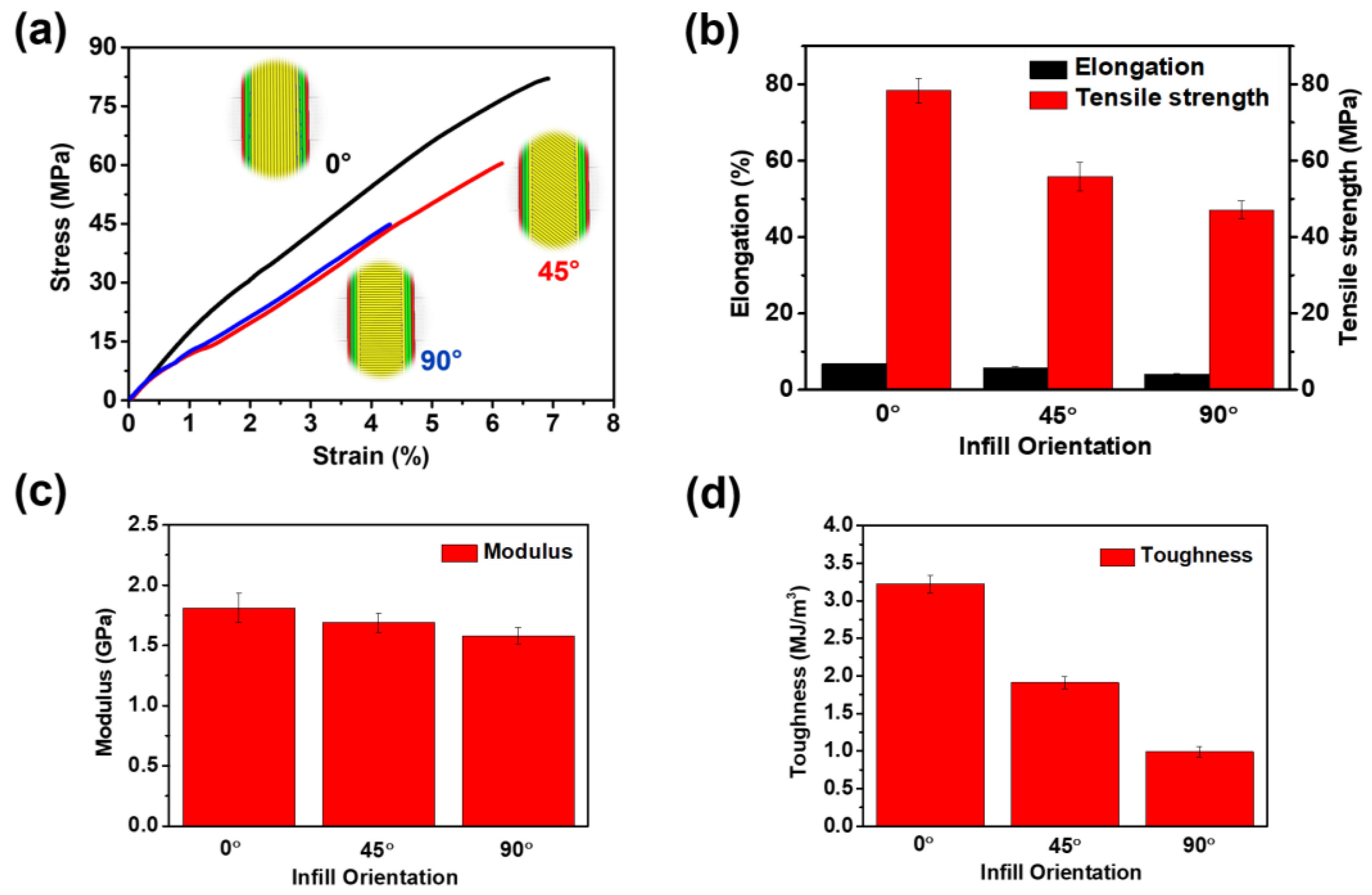

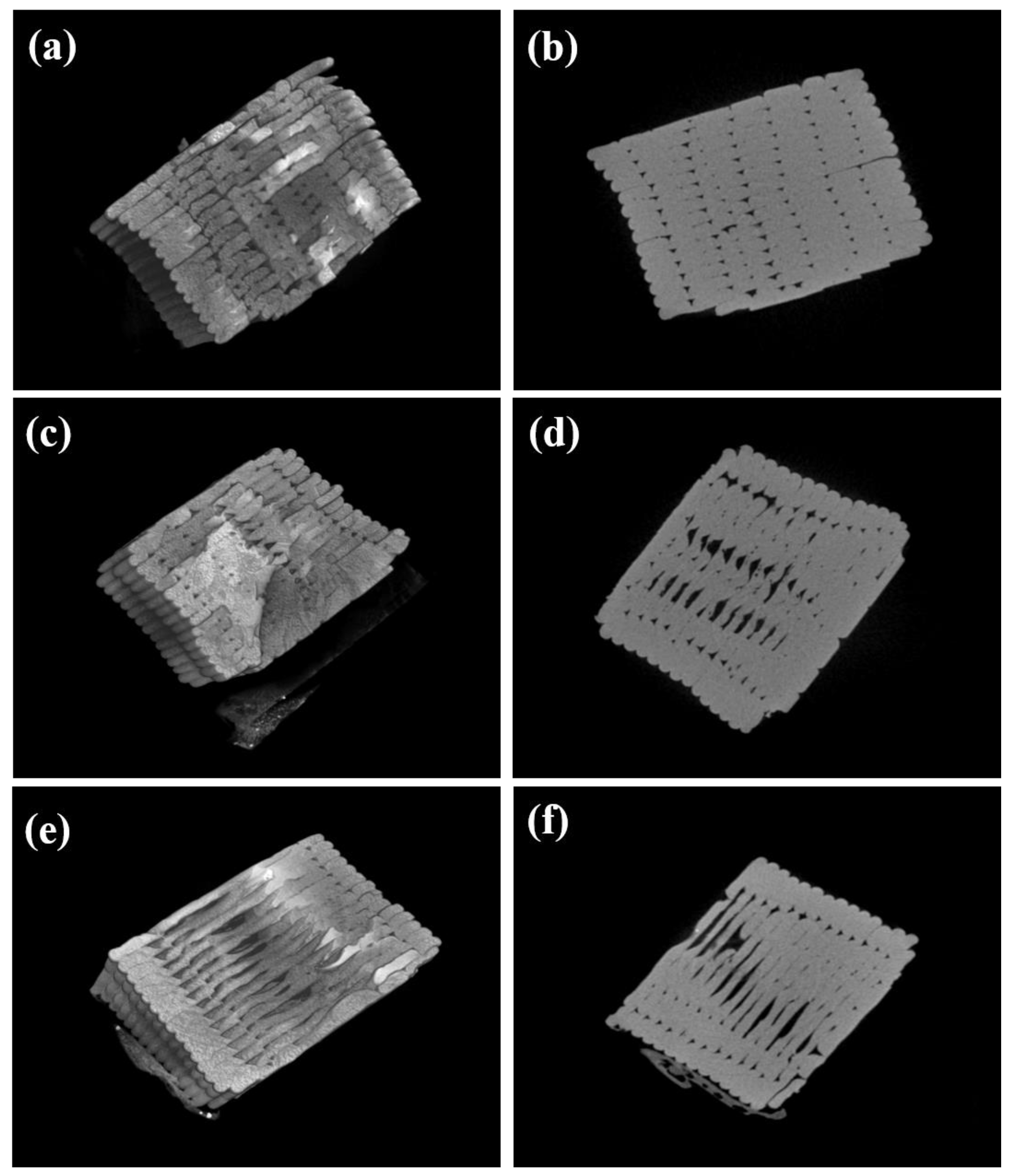

3.3. 3D Printing of TPI in Different Infill Directions and Their Mechanical Characterisation

3.4. Fluorescence Characterisation

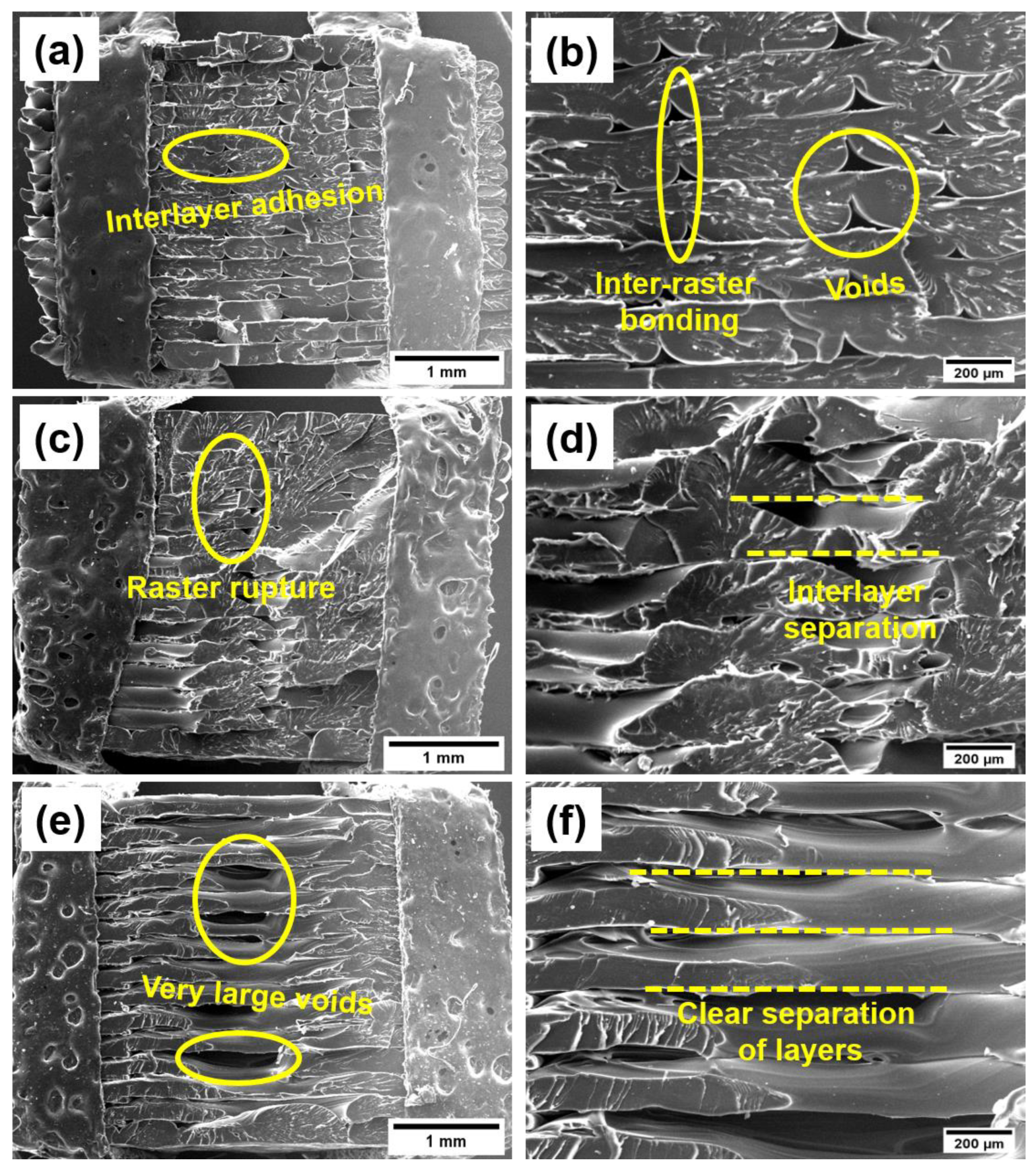

3.5. Morphological Characterisation

3.6. Thermal Characterisation

3.7. 3D-Printed Functional Impeller

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- García, J.M.; García, F.C.; Serna, F.; de la Peña, J.L. High-Performance Aromatic Polyamides. Prog. Polym. Sci. 2010, 35, 623–686. [Google Scholar] [CrossRef]

- Gouzman, I.; Grossman, E.; Verker, R.; Atar, N.; Bolker, A.; Eliaz, N. Advances in Polyimide-Based Materials for Space Applications. Adv. Mater. 2019, 31, 1807738. [Google Scholar] [CrossRef] [PubMed]

- Benzait, Z.; Trabzon, L. A Review of Recent Research on Materials Used in Polymer–Matrix Composites for Body Armor Application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Feng, X.; Liu, J. Thermoplastic Polyimide (TPI). In High Performance Polymers and Their Nanocomposites; Wiley: Hoboken, NJ, USA, 2018; pp. 149–219. [Google Scholar] [CrossRef]

- Margolis, J.M. (Ed.) Thermoplastic Polyimide (TPI). In Engineering Plastics Handbook; McGraw-Hill Education: New York, NY, USA, 2006. [Google Scholar]

- Fraivillig, J. The Evolution of Thermoplastic Polyimide Adhesive Technology; Fraivillig Technologies Company: Boston, MA, USA, 2022. [Google Scholar]

- Liu, J.; Li, J.; Wang, T.; Huang, D.; Li, Z.; Zhong, A.; Liu, W.; Sui, Y.; Liu, Q.; Niu, F.; et al. Organosoluble Thermoplastic Polyimide with Improved Thermal Stability and UV Absorption for Temporary Bonding and Debonding in Ultra-Thin Chip Package. Polymer 2022, 244, 124660. [Google Scholar] [CrossRef]

- Zeng, H.; Pei, X.; Chen, G.; Cao, L.; Chen, L.; Fang, X. Comparative Studies on Melt Processable Polyimides Derived from 2,3,3′,4′-Oxydiphthalic Anhydride and 2,3,3′,4′-Thioetherdiphthalic Anhydride. High Perform. Polym. 2013, 25, 454–463. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, S.; Li, X.; Zhu, S.; Jiang, Z. Synthesis of Poly(Ether Ether Ketone)-Block-Polyimide Copolymer and Its Compatibilization for Poly(Ether Ether Ketone)/Thermoplastic Polyimide Blends. Polymer 2014, 55, 119–125. [Google Scholar] [CrossRef]

- Rivera Nicholls, A.; Pellisier, M.; Perez, Y.; Stock, J.A.; Kull, K.; Julien, T.; Eubank, J.; Harmon, J.P. Thermomechanical Characterization of Thermoplastic Polyimide–Polyurea to Improve the Chain Interaction via Internal Hydrogen Bonds. Polym. Eng. Sci. 2019, 59, 1948–1959. [Google Scholar] [CrossRef]

- Xia, J.; Liu, S.; Pallathadka, P.K.; Chng, M.L.; Chung, T.-S. Structural Determination of Extem XH 1015 and Its Gas Permeability Comparison with Polysulfone and Ultem via Molecular Simulation. Ind. Eng. Chem. Res. 2010, 49, 12014–12021. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; McLouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of Processing and Orientation Print Effects on the Mechanical and Thermal Behavior of 3D-Printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Cicala, G.; Ognibene, G.; Portuesi, S.; Blanco, I.; Rapisarda, M.; Pergolizzi, E.; Recca, G. Comparison of Ultem 9085 Used in Fused Deposition Modelling (FDM) with Polytherimide Blends. Materials 2018, 11, 285. [Google Scholar] [CrossRef]

- Wu, W.; Ye, W.; Geng, P.; Wang, Y.; Li, G.; Hu, X.; Zhao, J. 3D Printing of Thermoplastic PI and Interlayer Bonding Evaluation. Mater. Lett. 2018, 229, 206–209. [Google Scholar] [CrossRef]

- Ye, W.; Wu, W.; Hu, X.; Lin, G.; Guo, J.; Qu, H.; Zhao, J. 3D Printing of Carbon Nanotubes Reinforced Thermoplastic Polyimide Composites with Controllable Mechanical and Electrical Performance. Compos. Sci. Technol. 2019, 182, 107671. [Google Scholar] [CrossRef]

- Ye, W.; Lin, G.; Wu, W.; Geng, P.; Hu, X.; Gao, Z.; Zhao, J. Separated 3D Printing of Continuous Carbon Fiber Reinforced Thermoplastic Polyimide. Compos. Part A Appl. Sci. Manuf. 2019, 121, 457–464. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing–General Principles–Terminology. ASTM International: West Conshohocken, PA, USA, 2021.

- 2023 Guide to 3D Printing with Polymers. Available online: https://nexa3d.com/blog/3d-printing-with-polymers/ (accessed on 25 January 2024).

- Sheth, M.; Kumar, R.A.; Davé, V.; Gross, R.A.; McCarthy, S.P. Biodegradable Polymer Blends of Poly(Lactic Acid) and Poly(Ethylene Glycol). J. Appl. Polym. Sci. 1997, 66, 1495–1505. [Google Scholar] [CrossRef]

- Chueca de Bruijn, A.; Gómez-Gras, G.; Pérez, M.A. Mechanical Study on the Impact of an Effective Solvent Support-Removal Methodology for FDM Ultem 9085 Parts. Polym. Test. 2020, 85, 106433. [Google Scholar] [CrossRef]

- Kothavade, P.; Yadav, P.; Gopal, A.; Pol, H.; Kafi, A.; Bateman, S.; Shanmuganathan, K. Enhancing the Crystallization Kinetics and Mechanical Properties of Poly(Lactic Acid) Blends for 3D Printing Application. ACS Appl. Polym. Mater. 2024, 6, 5754–5762. [Google Scholar] [CrossRef]

- Caldona, E.B.; Dizon, J.R.C.; Viers, R.A.; Garcia, V.J.; Smith, Z.J.; Advincula, R.C. Additively Manufactured High-Performance Polymeric Materials and Their Potential Use in the Oil and Gas Industry. MRS Commun. 2021, 11, 701–715. [Google Scholar] [CrossRef]

- Chyr, G.; DeSimone, J.M. Review of High-Performance Sustainable Polymers in Additive Manufacturing. Green Chem. 2023, 25, 453–466. [Google Scholar] [CrossRef]

- Weyhrich, C.W.; Long, T.E. Additive Manufacturing of High-Performance Engineering Polymers: Present and Future. Polym. Int. 2022, 71, 532–536. [Google Scholar] [CrossRef]

- Kafi, A.; Wu, H.; Langston, J.; Atak, O.; Kim, H.; Kim, S.; Fahy, W.P.; Reber, R.; Misasi, J.; Bateman, S.; et al. Evaluation of Additively Manufactured Ultraperformance Polymers to Use as Thermal Protection Systems for Spacecraft. J. Appl. Polym. Sci. 2020, 137, 49117. [Google Scholar] [CrossRef]

- Hegde, M.; Meenakshisundaram, V.; Chartrain, N.; Sekhar, S.; Tafti, D.; Williams, C.B.; Long, T.E. 3D Printing All-Aromatic Polyimides Using Mask-Projection Stereolithography: Processing the Nonprocessable. Adv. Mater. 2017, 29, 1701240. [Google Scholar] [CrossRef] [PubMed]

- Melchels, F.P.W.; Feijen, J.; Grijpma, D.W. A Review on Stereolithography and Its Applications in Biomedical Engineering. Biomaterials 2010, 31, 6121–6130. [Google Scholar] [CrossRef] [PubMed]

- Gong, H.; Beauchamp, M.; Perry, S.; Woolley, A.T.; Nordin, G.P. Optical Approach to Resin Formulation for 3D Printed Microfluidics. RSC Adv. 2015, 5, 106621–106632. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive Manufacturing: Technology, Applications and Research Needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Kothavade, P.A.; Yadav, P.; Nidhankar, A.D.; Torris, A.; Pol, H.; Kafi, A.; Bateman, S.; Sukumaran, S.B.; Shanmuganathan, K. Luminescent 3D Printed Poly(Lactic Acid) Nanocomposites with Enhanced Mechanical Properties. Polym. Eng. Sci. 2023, 63, 2059–2072. [Google Scholar] [CrossRef]

- Tang, Y.; Liu, B.; Yuan, H.; Xin, Y.; Ren, X.; Chen, Q.; Yin, H. In Situ Synthesis of MAPbX3 Perovskite Quantum Dot-Polycaprolactone Composites for Fluorescent 3D Printing Filament. J. Alloys Compd. 2022, 916, 164961. [Google Scholar] [CrossRef]

- Yang, F.; Ye, X.; Chen, G.; Xiao, J.; Wu, Z.; Luo, Y.; Zheng, W.; Zhou, W.; Wang, L.; Lu, B.; et al. Novel AIE Luminescent Tetraphenylethene-Doped Poly (Lactic Acid) Composites for Fused Deposition Modeling and Their Application in Fluorescent Analysis of 3D Printed Products. Compos. Part B Eng. 2021, 219, 108898. [Google Scholar] [CrossRef]

- Mayer-Laigle, C.; Foulon, L.; Denoual, C.; Pernes, M.; Rondet, E.; Magueresse, A.; Barron, C.; Habrant, A.; Bourmaud, A.; Paës, G. Flax Shives-PBAT Processing into 3D Printed Fluorescent Materials with Potential Sensor Functionalities. Ind. Crops Prod. 2021, 167, 113482. [Google Scholar] [CrossRef]

- Khalid, M.A.; Zhao, Y.; Yang, Y.; Liu, X.; Garrone, E.; Dai, A.; Diao, G.; Carlini, R. Fluorescent Polyimide Films Produced with Diatomite and Mesoporous Silica as Promising High-Tech Material. J. Inorg. Organomet. Polym. Mater. 2021, 31, 3324–3333. [Google Scholar] [CrossRef]

- Wakita, J.; Sekino, H.; Sakai, K.; Urano, Y.; Ando, S. Molecular Design, Synthesis, and Properties of Highly Fluorescent Polyimides. J. Phys. Chem. B 2009, 113, 15212–15224. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Zhang, Y.; Liu, S.; Chi, Z.; Chen, X.; Xu, J. Flexible and Highly Fluorescent Aromatic Polyimide: Design, Synthesis, Properties, and Mechanism. J. Mater. Chem. C 2016, 4, 10509–10517. [Google Scholar] [CrossRef]

- Sahin, A.E. Effect of Infill Line Direction on Tensile and Flexural Properties of Poly(Lactic Acid) Samples during 3D Printing. J. Mater. Eng. Perform. 2024, 33, 1202–1209. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H. Effect of Filling Pattern on the Tensile and Flexural Mechanical Properties of FDM 3D Printed Products. Exp. Mech. 2019, 59, 883–897. [Google Scholar] [CrossRef]

- SABIC–EXTEMTM Resin. Available online: https://www.sabic.com/en/products/specialties/ultem-resin-family-of-high-heat-solutions/extem-resin (accessed on 4 December 2023).

- Ratta, V.; Ayambem, A.; Young, R.; McGrath, J.E.; Wilkes, G.L. Thermal Stability, Crystallization Kinetics and Morphology of a New Semicrystalline Polyimide Based on 1,3-Bis(4-Aminophenoxy) Benzene and 3,3′,4,4′-Biphenyltetracarboxylic Dianhydride. Polymer 2000, 41, 8121–8138. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Chen, G.; Zhang, A.; Fang, X. Melt-Processable Semicrystalline Polyimides Based on 1,4-Bis(3,4-Dicarboxyphenoxy)Benzene Dianhydride (HQDPA): Synthesis, Crystallization, and Melting Behavior. Polymers 2017, 9, 420. [Google Scholar] [CrossRef]

- Ke, H.; Zhao, L.; Zhang, X.; Qiao, Y.; Wang, G.; Wang, X. Performance of High-Temperature Thermosetting Polyimide Composites Modified with Thermoplastic Polyimide. Polym. Test. 2020, 90, 106746. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced Polyimide Materials: Syntheses, Physical Properties and Applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Nazarychev, V.M.; Vaganov, G.V.; Larin, S.V.; Didenko, A.L.; Elokhovskiy, V.Y.; Svetlichnyi, V.M.; Yudin, V.E.; Lyulin, S.V. Rheological and Mechanical Properties of Thermoplastic Crystallizable Polyimide-Based Nanocomposites Filled with Carbon Nanotubes: Computer Simulations and Experiments. Polymers 2022, 14, 3154. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Davis, C.S.; Hillgartner, K.E.; Han, S.H.; Seppala, J.E. Mechanical Strength of Welding Zones Produced by Polymer Extrusion Additive Manufacturing. Addit. Manuf. 2017, 16, 162–166. [Google Scholar] [CrossRef] [PubMed]

- CAMPUSplastics|datasheet EXTEMTM Resin VH1003. Available online: https://www.campusplastics.com/campus/en/datasheet/EXTEMTM++Resin+VH1003/SABIC/658/f90ea90b (accessed on 4 December 2023).

| Parameter | Value |

|---|---|

| Printing temperature | 420 °C |

| Printing speed | 40 mm/s |

| Bed temperature | 130 °C |

| Cooling | 0% |

| Infill density | 100% |

| Infill pattern | Lines |

| Layer height | mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kothavade, P.; Kafi, A.; Dekiwadia, C.; Kumar, V.; Sukumaran, S.B.; Shanmuganathan, K.; Bateman, S. Extrusion 3D Printing of Intrinsically Fluorescent Thermoplastic Polyimide: Revealing an Undisclosed Potential. Polymers 2024, 16, 2798. https://doi.org/10.3390/polym16192798

Kothavade P, Kafi A, Dekiwadia C, Kumar V, Sukumaran SB, Shanmuganathan K, Bateman S. Extrusion 3D Printing of Intrinsically Fluorescent Thermoplastic Polyimide: Revealing an Undisclosed Potential. Polymers. 2024; 16(19):2798. https://doi.org/10.3390/polym16192798

Chicago/Turabian StyleKothavade, Premkumar, Abdullah Kafi, Chaitali Dekiwadia, Viksit Kumar, Santhosh Babu Sukumaran, Kadhiravan Shanmuganathan, and Stuart Bateman. 2024. "Extrusion 3D Printing of Intrinsically Fluorescent Thermoplastic Polyimide: Revealing an Undisclosed Potential" Polymers 16, no. 19: 2798. https://doi.org/10.3390/polym16192798

APA StyleKothavade, P., Kafi, A., Dekiwadia, C., Kumar, V., Sukumaran, S. B., Shanmuganathan, K., & Bateman, S. (2024). Extrusion 3D Printing of Intrinsically Fluorescent Thermoplastic Polyimide: Revealing an Undisclosed Potential. Polymers, 16(19), 2798. https://doi.org/10.3390/polym16192798