The Role of Formulations in the Ageing Process of Vinyl Acetate Based Emulsion Films: A Multivariate Approach

Abstract

1. Introduction

2. Experimental

2.1. Materials and Methods

2.2. Instrumentation

2.3. Data Pre-Processing and Multivariate Statistical Analysis

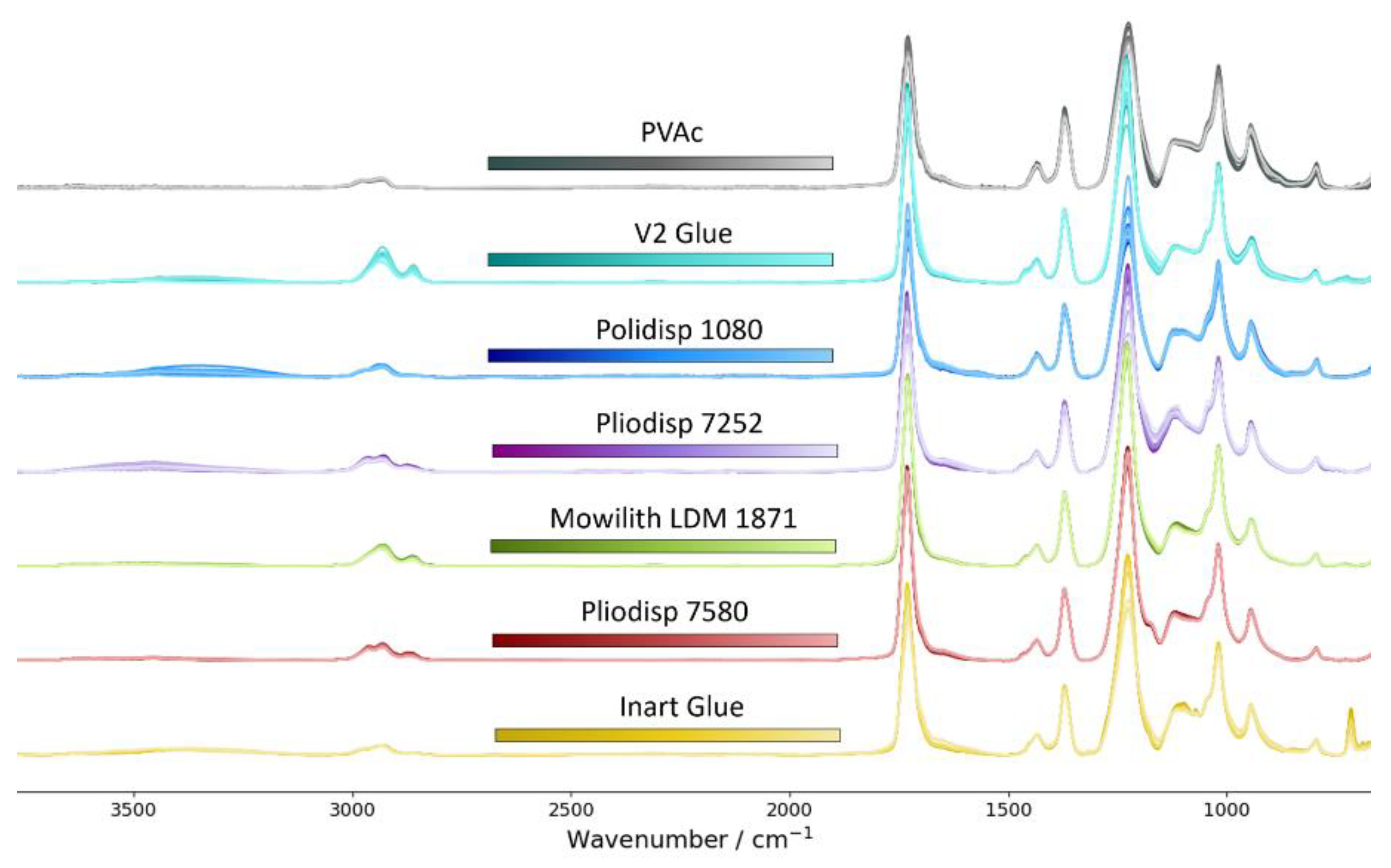

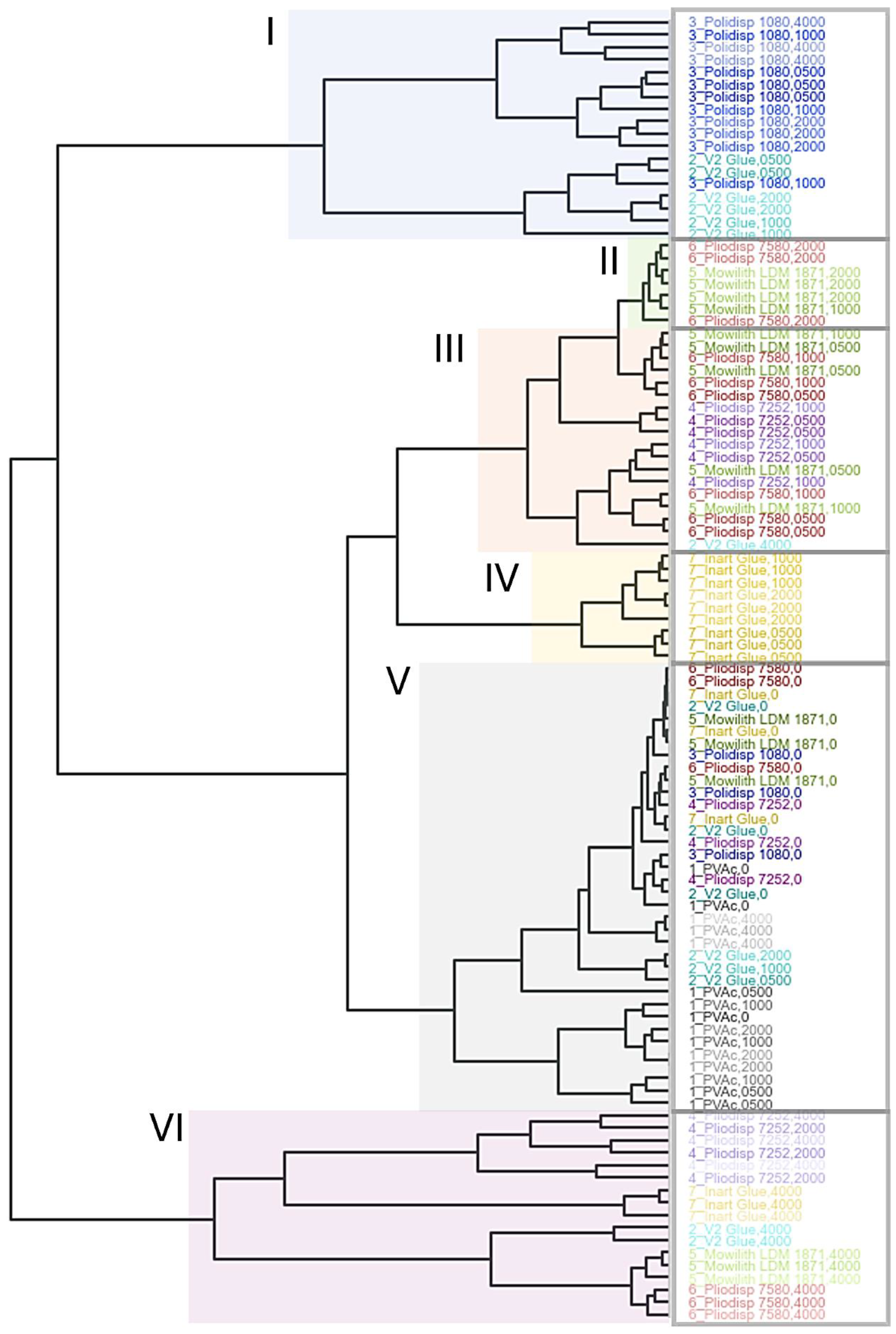

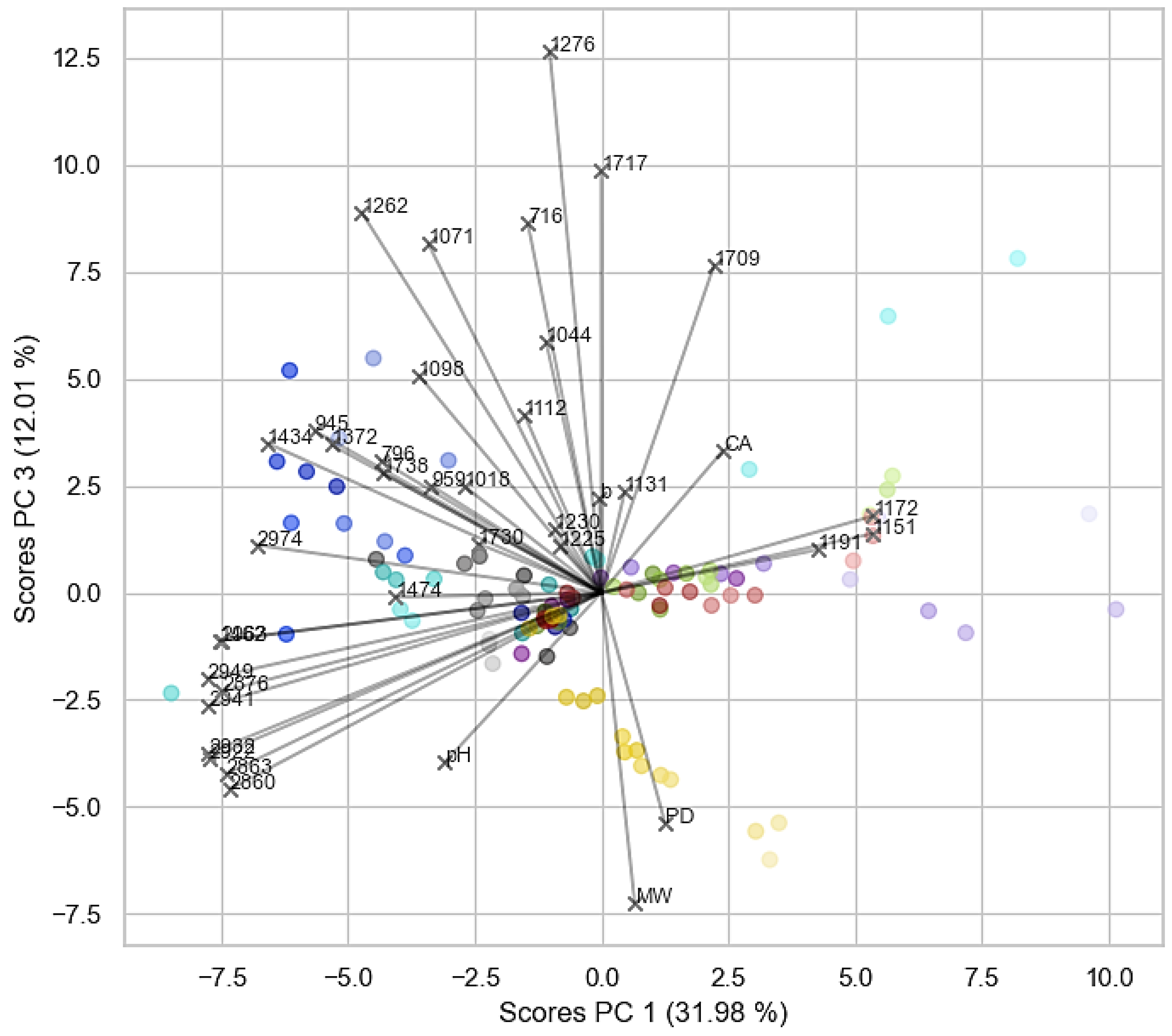

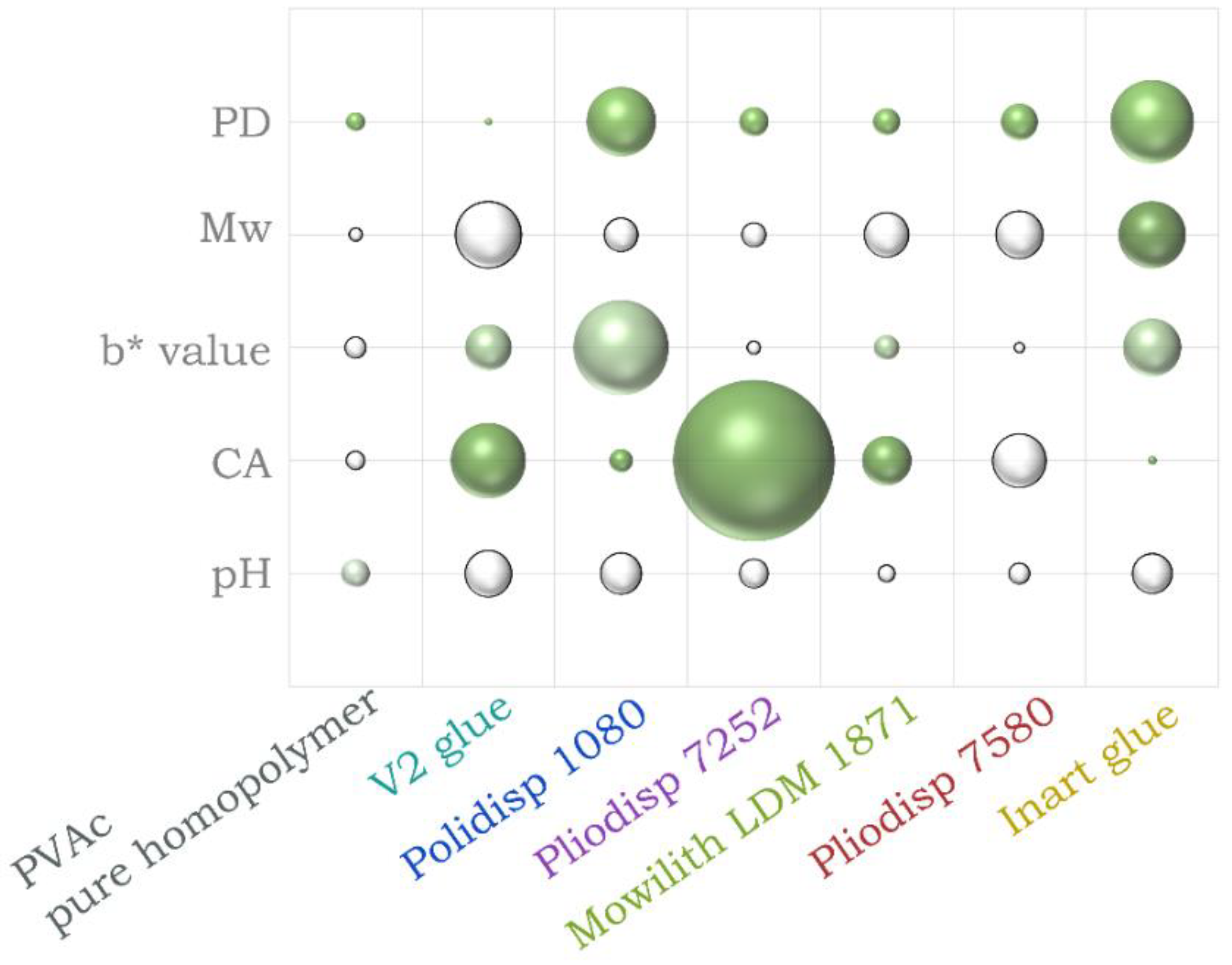

3. Results and Discussion

3.1. PVAc Pure Homopolymer

3.2. PVAc Homopolymer with Additives

3.2.1. Polidisp 1080 (PVAc + PVAl)

3.2.2. Mowilith LDM 1871 (PVAc + TEG)

3.2.3. Pliodisp 7580 (PVAc + DEHP + DEP + DiBP + DNOP + 2-EHB)

3.2.4. Inart Glue (PVAc + Diacetin + DEGDB + DPGDB)

3.3. VAc Copolymers with Additives

3.3.1. V2 Glue (E-co-VAc + Diacetin + PVAl)

3.3.2. Pliodisp 7252 (VAc-co-VeoVa + Isonox 132®)

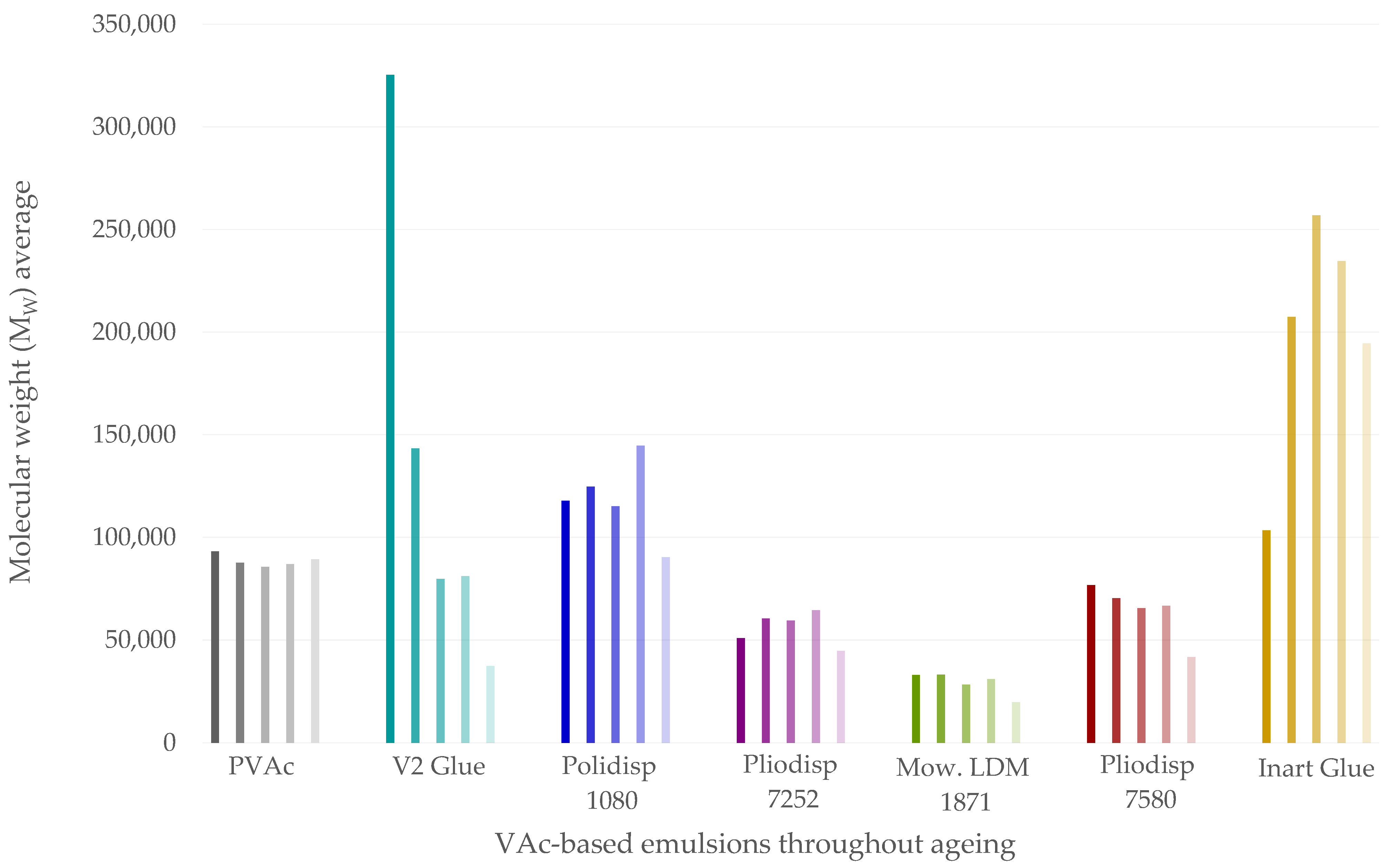

3.4. A Closer Look at MW

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ferreira, J.L. Liaisons Dangereuses, Conservation of Modern and Contemporary Art: A Study of the Synthetic Binding Media in Portugal. Ph.D. Thesis, NOVA University of Lisbon, Lisbon, Portugal, 2011. [Google Scholar]

- Viana, C. Are All Vinyl Paints The Same? The Impact of Paint Formulations on Their Stability and the State of Conservation of Ângelo De Sousa’s Paintings. Master’s Thesis, NOVA School of Science and Technology, Lisbon, Portugal, 2022. [Google Scholar]

- Toja, F.; Saviello, D.; Nevin, A.; Comelli, D.; Lazzari, M.; Levi, M.; Toniolo, L. The Degradation of Poly(Vinyl Acetate) as a Material for Design Objects: A Multi-Analytical Study of the Effect of Dibutyl Phthalate Plasticizer. Part 1. Polym. Degrad. Stab. 2012, 97, 2441–2448. [Google Scholar] [CrossRef]

- Ferreira, J.L.; Melo, M.J.; Ramos, A.M. Poly(Vinyl Acetate) Paints in Works of Art: A Photochemical Approach. Part 1. Polym. Degrad. Stab. 2010, 95, 453–461. [Google Scholar] [CrossRef]

- Novak, M.; Ormsby, B. Poly(Vinyl Acetate) Paints: A Literature Review of Material Properties, Ageing Characteristics, and Conservation Challenges. Polymers 2023, 15, 4348. [Google Scholar] [CrossRef] [PubMed]

- Pintus, V.; Viana, C.; Angelin, E.M.; França de Sá, S.; Wienland, K.; Sterflinger, K.; Ferreira, J.L. Applicability of Single-Shot and Double-Shot of Py-GC/MS for the Detection of Components in Vinyl Acetate-Based Emulsions Used in Modern-Contemporary Art. J. Anal. Appl. Pyrolysis 2022, 168, 105782. [Google Scholar] [CrossRef]

- Malea, E.; Papageorgiou, E.; Panagiaris, G. Investigation of the Degradation Mechanisms of Organic Materials: From Accelerated Ageing to Chemometric Studies. In Proceedings of the International Conference on Integrated Information (IC-ININFO 2011), Kos Island, Greece, 28 October–3 November; 2011; pp. 280–284. [Google Scholar]

- Pintus, V.; Wei, S.; Schreiner, M. Accelerated UV Ageing Studies of Acrylic, Alkyd and Polyvinyl Acetate Paints: Influence of Inorganic Pigments. Microchem. J. 2016, 124, 949–961. [Google Scholar] [CrossRef]

- Wei, S.; Pintus, V.; Schreiner, M. Photochemical Degradation Study of Polyvinyl Acetate Paints Used in Artworks by Py-GC/MS. J. Anal. Appl. Pyrolysis 2012, 97, 158–163. [Google Scholar] [CrossRef]

- Doménech-Carbó, M.; Bitossi, G.; Osete-Cortina, L.; Cruz-Cañizares, J.; Yusá-Marco, D. Characterization of Polyvinyl Resins Used as Binding Media in Paintings by Pyrolysis–Silylation–Gas Chromatography—Mass Spectrometry. Anal. Bioanal. Chem. 2008, 391, 1371–1379. [Google Scholar] [CrossRef]

- Izzo, F.C.; Balliana, E.; Perra, E.; Zendri, E. Accelerated Ageing Procedures to Assess the Stability of an Unconventional Acrylic-Wax Polymeric Emulsion for Contemporary Art. Polymers 2020, 12, 1925. [Google Scholar] [CrossRef]

- Lazzari, M.; López-Morán, T. Aging of a Poly(Vinyl Acetate)-Based White Glue and Its Durability in Contemporary Artworks. Polymers 2024, 16, 1712. [Google Scholar] [CrossRef]

- Fardi, T.; Pintus, V.; Kampasakali, E.; Pavlidou, E.; Schreiner, M. Analytical Characterization of Artist’s Paint Systems Based on Emulsion Polymers and Synthetic Organic Pigments. J. Anal. Appl. Pyrolysis 2018, 135, 231–241. [Google Scholar] [CrossRef]

- França de Sá, S.; Viana, C.; Ferreira, J.L. Tracing Poly(Vinyl Acetate) Emulsions by Infrared and Raman Spectroscopies: Identification of Spectral Markers. Polymers 2021, 13, 3609. [Google Scholar] [CrossRef] [PubMed]

- Carlesi, S.; Picollo, M.; Ricci, M.; Becucci, M. Vibrational Spectroscopy The Ageing of Model Pigment/Linseed Oil Systems Studied by Means of Vibrational Spectroscopies and Chemometrics. Vib. Spectrosc. 2018, 99, 86–92. [Google Scholar] [CrossRef]

- Pagnin, L.; Brunnbauer, L.; Wiesinger, R.; Limbeck, A.; Schreiner, M. Multivariate Analysis and Laser-Induced Breakdown Spectroscopy ( LIBS ): A New Approach for the Spatially Resolved Classification of Modern Art Materials. Anal. Bioanal. Chem. 2020, 412, 3187–3198. [Google Scholar] [CrossRef] [PubMed]

- Sciutto, G.; Oliveri, P.; Prati, S.; Catelli, E.; Bonacini, I.; Mazzeo, R. A Multivariate Methodological Workflow for the Analysis of FTIR Chemical Mapping Applied on Historic Paint Stratigraphies. Int. J. Anal. Chem. 2017, 2017, 4938145. [Google Scholar] [CrossRef] [PubMed]

- Miguel, C.; Lopes, J.A.; Clarke, M.; João, M. Chemometrics and Intelligent Laboratory Systems Combining Infrared Spectroscopy with Chemometric Analysis for the Characterization of Proteinaceous Binders in Medieval Paints. Chemom. Intell. Lab. Syst. 2012, 119, 32–38. [Google Scholar] [CrossRef]

- Rygula, A.; Miskowiec, P. Chemometric Analysis of Raman and IR Spectra of Natural Dyes. In Optical Spectroscopy and Computational Methods in Biology and Medicine; Baranska, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 279–308. ISBN 9789400778320. [Google Scholar]

- Pintus, V.; Szab, F.; Noel, T.; Wieland, K.; Csuti, P.; Anghelone, M.; Santorelli, O.; Salvadori, C.; Haisch, C.; Sterflinger, K.; et al. A Multi-Analytical Approach for Studying the Effect of New LED Lighting Systems on Modern Paints: Chemical Stability Investigations. Polymers 2021, 13, 4441. [Google Scholar] [CrossRef]

- Rijavec, T.; Ribar, D.; Markelj, J.; Strlič, M.; Cigić, I.K. Machine Learning—Assisted Non—Destructive Plasticizer Identification and Quantification in Historical PVC Objects Based on IR Spectroscopy. Sci. Rep. 2022, 12, 5017. [Google Scholar] [CrossRef]

- Jolliffe, I.; Cadima, J. Principal Component Analysis: A Review and Recent Developments. Philos. Trans. R. Soc. A 2016, 374, 20150202. [Google Scholar] [CrossRef]

- Hou, K. Principal Component Analysis and Prediction of Students’ Physical Health Standard Test Results Based on Recurrent Convolution Neural Network. Wirel. Commun. Mob. Comput. 2021, 2021, 2438656. [Google Scholar] [CrossRef]

- Granato, D.; Santos, J.S.; Escher, G.B.; Ferreira, B.L.; Maggio, R.M. Use of Principal Component Analysis (PCA) and Hierarchical Cluster Analysis (HCA) for Multivariate Association between Bioactive Compounds and Functional Properties in Foods: A Critical Perspective. Trends Food Sci. Technol. 2018, 72, 83–90. [Google Scholar] [CrossRef]

- Liu, L.; Delnevo, G.; Mirri, S. Hierarchical Clustering as an Unsurpervised Machine Learning Algorithm for Hyperspectral Image Segmentation of Films. In Proceedings of the 2022 ACM Conference on Information Technology for Social Good (GoodIT’22), Limassol, Cyprus, 7–9 September 2022; ACM: New York, NY, USA, 2022; pp. 397–402. [Google Scholar]

- Capobianco, G.; Bracciale, M.P.; Sali, D.; Sbardella, F.; Belloni, P.; Bonifazi, G.; Serranti, S.; Santarelli, M.L.; Guidi, M.C. Chemometrics Approach to FT-IR Hyperspectral Imaging Analysis of Degradation Products in Artwork Cross-Section. Microchem. J. 2017, 132, 69–76. [Google Scholar] [CrossRef]

- Sarmiento, A.; Olivares, M.; Castro, K. Classification and Identification of Organic Binding Media in Artworks by Means of Fourier Transform Infrared Spectroscopy and Principal Component Analysis. Anal. Bioanal. Chem. 2011, 399, 3601–3611. [Google Scholar] [CrossRef]

- Gajarska, Z.; Brunnbauer, L.; Lohninger, H.; Limbeck, A. Identification of 20 Polymer Types by Means of Laser-Induced Breakdown Spectroscopy (LIBS) and Chemometrics. Anal. Bioanal. Chem. 2021, 413, 6581–6594. [Google Scholar] [CrossRef]

- Haghighi, Z.; Karimy, A.; Karami, F.; Bagheri, A.; Khanmohammadi, M. Infrared Spectroscopic and Chemometric Approach for Identifying Binding Medium in Sukias Mansion’ s Wall Paintings. Nat. Prod. Res. 2019, 33, 1052–1060. [Google Scholar] [CrossRef]

- Manzano, E.; García-atero, J.; Dominguez-vidal, A.; Ayora-cañada, M.J.; Capitán-vallvey, F. Discrimination of Aged Mixtures of Lipidic Paint Binders by Raman Spectroscopy and Chemometrics. J. Raman Spectrosc. 2011, 43, 781–786. [Google Scholar] [CrossRef]

- Musumarra, G.; Fichera, M. Chemometrics and Cultural Heritage. Chemom. Intell. Lab. Syst. 1998, 44, 363–372. [Google Scholar] [CrossRef]

- Manfredi, M.; Barberis, E.; Marengo, E. Prediction and Classification of the Degradation State of Plastic Materials Used in Modern and Contemporary Art. Appl. Phys. A 2017, 123, 35. [Google Scholar] [CrossRef]

- Abdel-maksoud, G.; Ibrahim, M.; Issa, Y.M.; Magdy, M. Investigation of Painting Technique of Coptic Icon by Integrated Analytical Methods: Imaging, Spectroscopic and Chemometric Methods. J. Archaeol. Sci. Rep. 2020, 29, 102085. [Google Scholar] [CrossRef]

- Peris-Vicente, J.; Lerma-García, M.J.; Simó-Alfonso, E.; Gimeno-Adelantado, J.V.; Teresa Doménech Carbó, M. Use of Linear Discriminant Analysis Applied to Vibrational Spectroscopy Data to Characterize Commercial Varnishes Employed for Art Purposes. Anal. Chim. Acta 2007, 589, 208–215. [Google Scholar] [CrossRef]

- Pagnin, L.; Calvini, R.; Sterflinger, K.; Izzo, F. Data Fusion Approach to Simultaneously Evaluate the Degradation Process Caused by Ozone and Humidity on Modern Paint Materials. Polymers 2022, 14, 1787. [Google Scholar] [CrossRef]

- Ortiz-Herrero, L.; Cardaba, I.; Setien, S.; Bartolomé, L.; Alonso, M.L.; Maguregui, M.I. OPLS Multivariate Regression of FTIR-ATR Spectra of Acrylic Paints for Age Estimation in Contemporary Artworks. Talanta 2019, 205, 120114. [Google Scholar] [CrossRef] [PubMed]

- Doménech, A.; Doménech-Carbó, M.T.; Edwards, H.G.M. Identification of Earth Pigments by Applying Hierarchical Cluster Analysis to Solid State Voltammetry. Application to Severely Damaged Frescoes. Electroanalysis 2007, 19, 1890–1900. [Google Scholar] [CrossRef]

- Pujari, J.; Pushpalatha, S.N.; Desai, P.D. Content-Based Image Retrieval Using Color and Shape Descriptors. In Proceedings of the 2010 International Conference on Signal and Image Processing, Chennai, India, 15–17 December 2010; pp. 239–242. [Google Scholar]

- McKinney, W. Data Structures for Statistical Computing in Python. In Proceedings of the 9th Python in Science Conference, Austin, TX, USA, 28 June–3 July 2010; pp. 51–56. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V. Scikit-Learn: Machine Learning in Python. J. Mach. Lear. Res. 2011, 12, 2825–2830. [Google Scholar]

- Virtanen, P.; Gommers, R.; Oliphant, T.E.; Haberland, M.; Reddy, T.; Cornapeau, D.; Burovski, E.; Peterson, P.; Weckesser, W.; Bright, J. SciPy 1.0: Fundamental Algorithms for Scientific Computing in Python. Nat. Methods 2020, 17, 261–272. [Google Scholar] [CrossRef] [PubMed]

- Harris, C.R.; Millman, K.J.; van der Walt, S.J.; Gommers, R.; Virtanen, P.; Cournapeau, D.; Wieser, E.; Taylor, J.; Berg, S.; Smith, N.J. Array Programming with NumPy. Nature 2020, 585, 357–362. [Google Scholar] [CrossRef]

- Hunter, J.D. Matplotlib: A 2D Graphics Environment. Comput. Sci. Eng. 2007, 9, 90–95. [Google Scholar] [CrossRef]

- Eilers, P.H.; Boelens, H.F.M. Baseline Correction with Asymmetric Least Squares Smoothing; Leiden University Medical Centre Report: Leiden, The Netherlands, 2005. [Google Scholar]

- Down, J.L.; Macdonald, M.A.; Tétreault, J.; Williams, R.S. Adhesive Testing at the Canadian Conservation Institute-an Evaluation of Selected Poly(Vinyl Acetate) and Acrylic Adhesives. Stud. Conserv. 1996, 41, 19–44. [Google Scholar] [CrossRef]

- Vaidergorin, E.; Marcondes, M.; Toscano, V. Photodegradation of Poly(Vinyl Acetate). Polym. Degrad. Stab. 1987, 18, 329–339. [Google Scholar] [CrossRef]

- Hexion VeoVaTM Vinyl Esters. Available online: https://www.hexion.com/our-products/products-by-chemistry/versatic-acids-and-derivatives/veova-vinyl-esters (accessed on 7 July 2024).

- Learner, T.J.S. The Characterisation of Acrylic Painting Materials and Implications for Their Use, Conservation and Stability. Ph.D. Thesis, University of London, London, UK, 1996. [Google Scholar]

- Hu, M.; Cui, H.; Yu, Z.; Xing, L.; Xiao, J. Preparation and Characterization of MMA/MAA/BA/VeoVa-10 Quaternary Co-Polymer Emulsion. In Proceedings of the 2017 International Conference on Material Science, Energy and Environmental Engineering (MSEEE 2017), Xi’an, China, 26–27 August 2017; Advances in Engineering Research Series. Volume 125. [Google Scholar] [CrossRef][Green Version]

- Rabek, J.F. Photodegradation and Photo-Oxidative Degradation of Homochain Polymers. In Polymer Photodegradation; Springer: Dordrecht, The Netherlands, 1995; pp. 67–254. [Google Scholar]

| Commercial Name | Polymer Type | Composition | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VAc | Ethylene | VeoVa | Diacetin | TEG | DEHP | DEP | DiBP | DNOP | 2-EHB | DEGDB | DPGDB | PVAl | Isonox 132® | ||

| PVAc | Homo- | x | |||||||||||||

| V2 Glue 1 | Co- | x | x | x | |||||||||||

| Polidisp 1080 1 | Homo- | x | x | ||||||||||||

| Pliodisp 7252 1 | Co- | x | x | x | |||||||||||

| Mowilith LDM 1871 3,4 | Homo | x | x | ||||||||||||

| Pliodisp 7580 2,4 | Homo | x | x | x | x | x | x | ||||||||

| Inart Glue 5 | Homo- | x | x | x | x | ||||||||||

| Label | Wavenumber/cm−1 | Tentative Band Assignment | |

|---|---|---|---|

| A | 2974 | νas (CH3) | PVAc |

| B | 2963 | ν (CH) | VeoVa |

| C | 2949 | νas (CH2) | PVAl |

| D | 2941 | ν (CH2) | PVAl/VeoVa |

| E | 2932 | νas (CH2) | PVAc |

| F | 2922 | νas (CH2) | Ethylene |

| G | 2876 | ν (CH2) | VeoVa |

| H | 2863 | νs (CH3) | PVAc |

| I | 2860 | ν (CH) | DEHP |

| a | 1738 | ν (C=O) | Diacetin |

| b | 1730 | ν (C=O) | PVAc |

| c | 1717 | ν (C=O) | PVAc |

| d | 1709 | ν (C=O) | PVAc |

| e | 1462 | CH | DEHP |

| f | 1434 | δ (CH) | PVAc |

| g | 1372 | δ (CH3) | PVAc |

| h | 1276 | ν (C-O) | Diacetin |

| i | 1262 | ν (C-O) | not assigned |

| j | 1230 | ν (C-O) | PVAc |

| k | 1225 | ν (C-O) | PVAc |

| l | 1191 | ν (C-O) | PVAc |

| m | 1172 | ν (C-O) | PVAc |

| n | 1151 | ν (C-O) | VeoVa |

| o | 1131 | CH | DEHP |

| p | 1112 | ν (C-O) | PVAc |

| q | 1098 | ν (C-O) | Benzoates |

| r | 1071 | ν (C-O) | DPGDB/DEGDB |

| s | 1044 | ν (CH) | DEHP |

| t | 1018 | ν (C-O) | PVAc |

| u | 959 | ν (C-O) | Benzoates |

| v | 945 | δ (CH) ν (C-C-O) | PVAc |

| w | 796 | δ (CH) | PVAc |

| x | 716 | δ (C=O) | DPGDB/DEGDB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Viana, C.; Wieland, K.; França de Sá, S.; Angelin, E.M.; Pintus, V.; Ferreira, J.L. The Role of Formulations in the Ageing Process of Vinyl Acetate Based Emulsion Films: A Multivariate Approach. Polymers 2024, 16, 2841. https://doi.org/10.3390/polym16192841

Viana C, Wieland K, França de Sá S, Angelin EM, Pintus V, Ferreira JL. The Role of Formulations in the Ageing Process of Vinyl Acetate Based Emulsion Films: A Multivariate Approach. Polymers. 2024; 16(19):2841. https://doi.org/10.3390/polym16192841

Chicago/Turabian StyleViana, Carolina, Karin Wieland, Susana França de Sá, Eva Mariasole Angelin, Valentina Pintus, and Joana Lia Ferreira. 2024. "The Role of Formulations in the Ageing Process of Vinyl Acetate Based Emulsion Films: A Multivariate Approach" Polymers 16, no. 19: 2841. https://doi.org/10.3390/polym16192841

APA StyleViana, C., Wieland, K., França de Sá, S., Angelin, E. M., Pintus, V., & Ferreira, J. L. (2024). The Role of Formulations in the Ageing Process of Vinyl Acetate Based Emulsion Films: A Multivariate Approach. Polymers, 16(19), 2841. https://doi.org/10.3390/polym16192841