Application and Properties of Polyglycolic Acid as a Degradation Agent in MPU/HNBR Degradable Elastomer Composites for Dissolvable Frac Plugs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PGA@MPU/HNBR Degradable Elastomer Composites

2.3. Testing and Characterization

2.3.1. Mechanical Properties

2.3.2. Dissolution Measurements

2.3.3. Morphological Characterization

2.3.4. Thermo-Gravimetric Analysis

2.3.5. The Fourier Transform Infrared Spectroscopy and X-ray Diffraction

3. Results and Discussion

3.1. Effect of PGA on the Mechanical Properties of MPU Materials

3.2. Mechanical Properties of PGA@MPU/HNBR Composites Immersed in Water at 100 °C

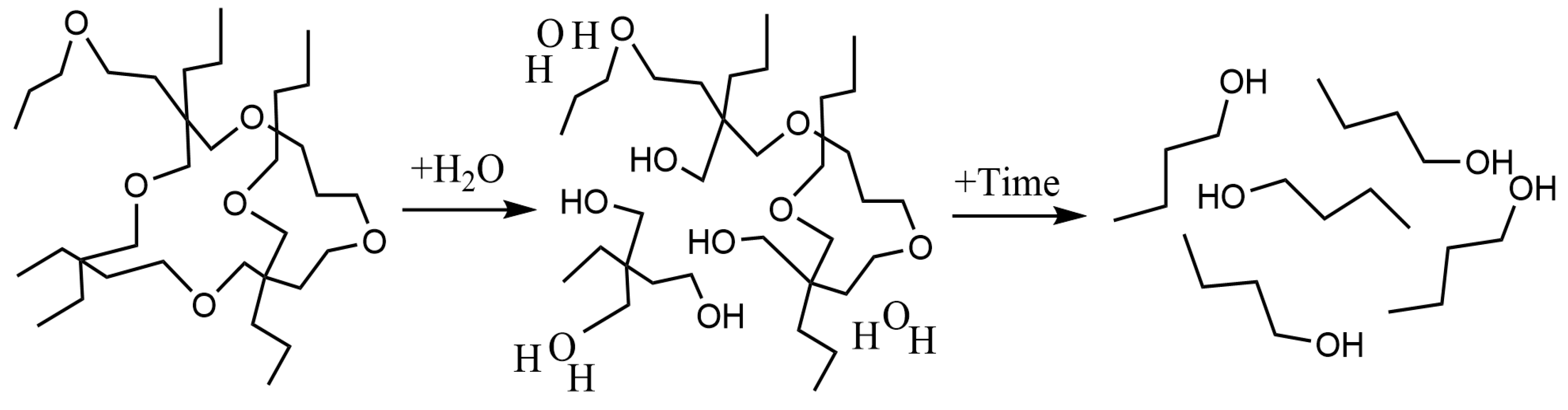

3.3. Degradation Phenomenon of PGA@MPU/HNBR Composite Material

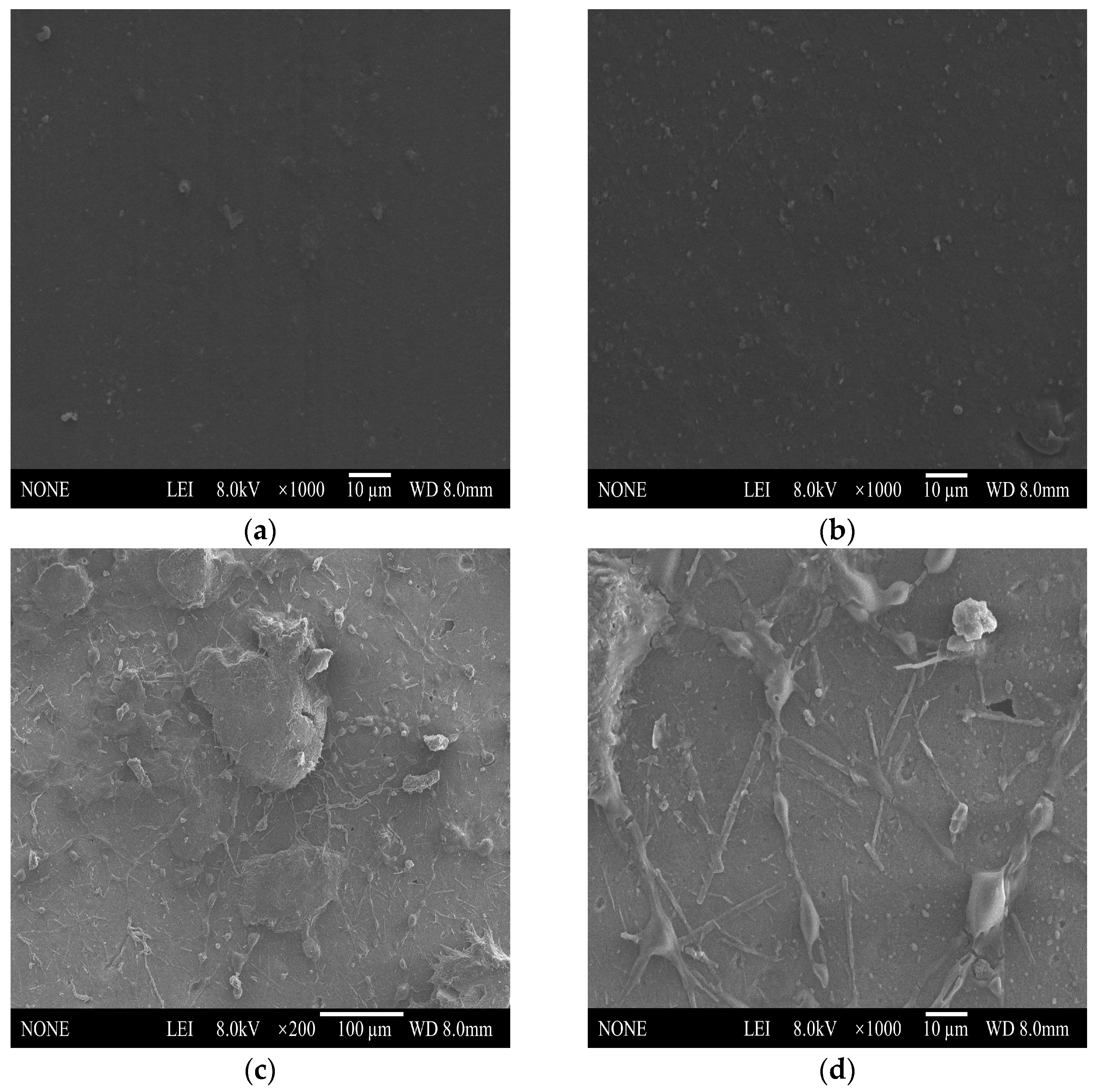

3.4. SEM Analysis of PGA@MPU/HNBR Composite Material before and after Degradation

3.5. FT-IR Analysis of PGA@MPU/HNBR Composite Materials

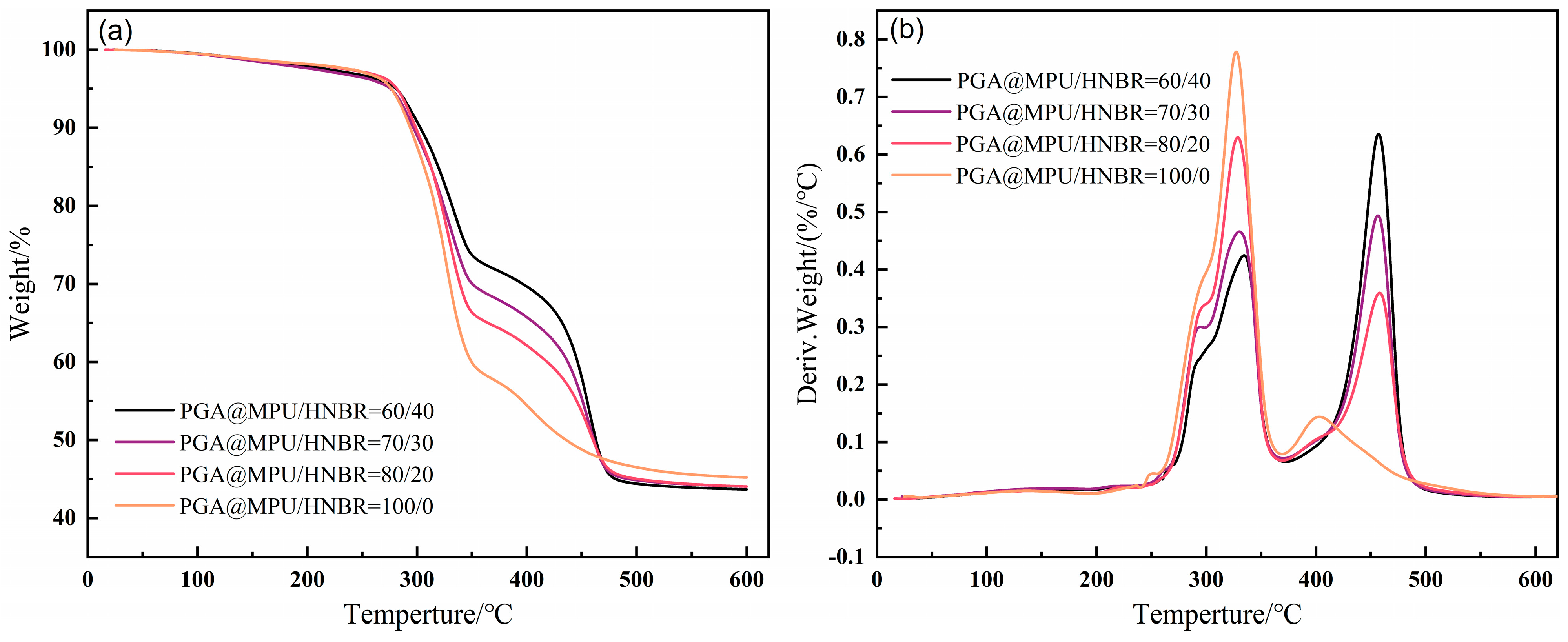

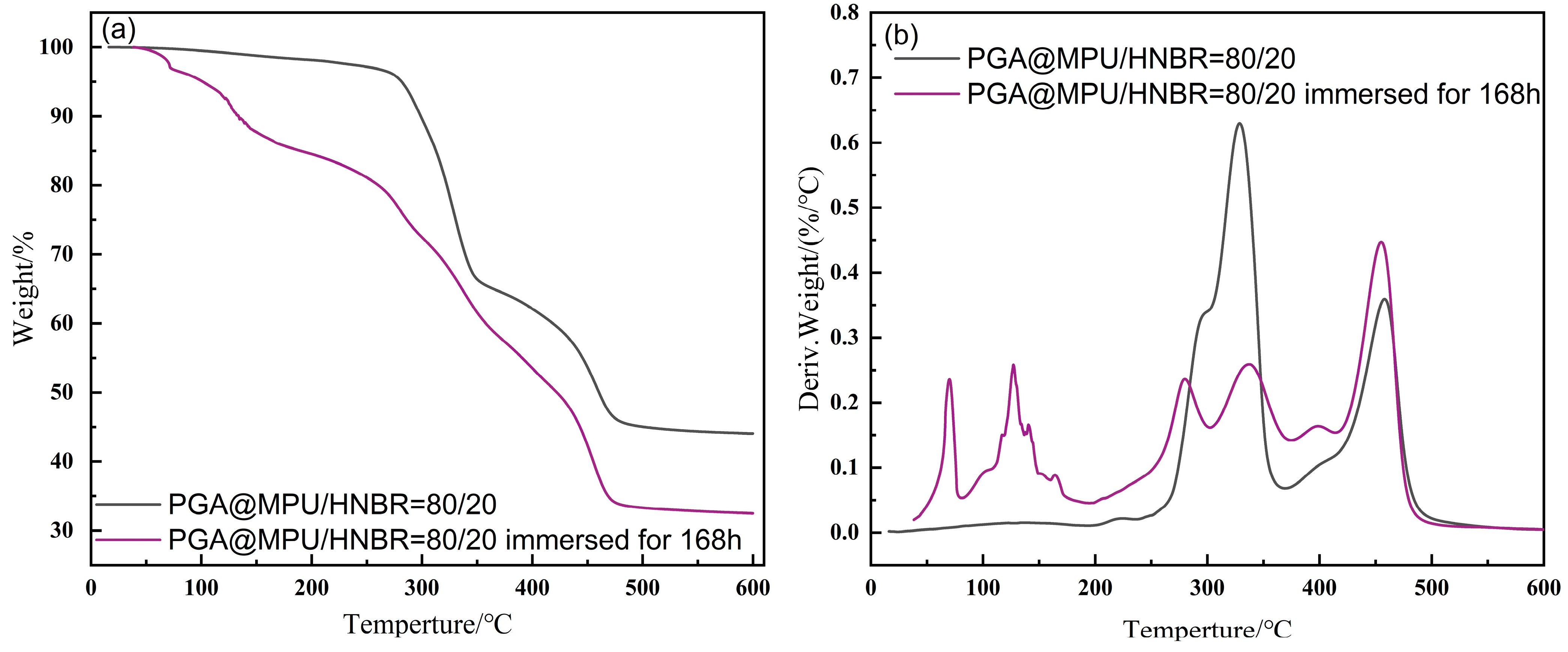

3.6. Thermal Stability of PGA@MPU/HNBR Composite Material

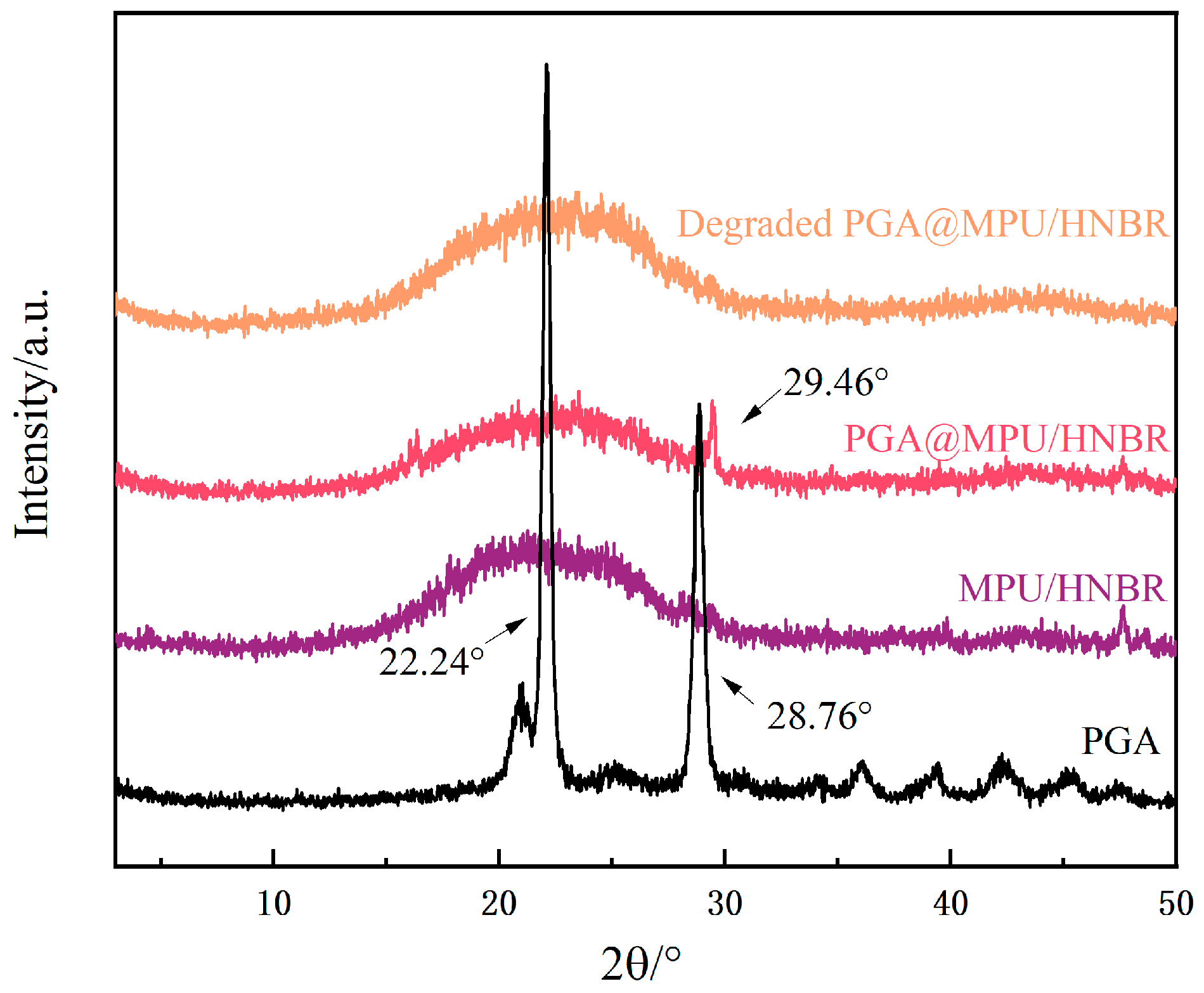

3.7. XRD Test of PGA@MPU/HNBR Composite Material

4. Conclusions

- (1)

- The addition of PGA to MPU leads to a decline in the initial mechanical properties of the PGA@MPU composites. The optimal PGA content for balancing the degradation rate and mechanical properties was determined to be 6 phr.

- (2)

- PGA contributed to enhanced hydrolytic degradation and a reduction in material hardness. Hydrolysis primarily affected the ester groups in both PGA and MPU, with complete degradation of MPU ester groups within 24 h and PGA ester groups degrading over approximately 72 h.

- (3)

- The PGA@MPU/HNBR composites exhibited a marked decrease in mechanical properties within the first 24 h of immersion, stabilizing after that—a higher HNBR content correlated with a better retention of mechanical properties.

- (4)

- Following initial degradation, the PGA@MPU/HNBR composites underwent late-stage colloidal hardening, maintaining sufficient strength for potential use in dissolvable frac plugs designed for controlled fragmentation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- McGlade, C.; Speirs, J.; Sorrell, S. Unconventional Gas—A Review of Regional and Global Resource Estimates. Energy 2013, 55, 571–584. [Google Scholar] [CrossRef]

- Davies, R.J.; Almond, S.; Ward, R.S.; Jackson, R.B.; Adams, C.; Worrall, F.; Herringshaw, L.G.; Gluyas, J.G.; Whitehead, M.A. Oil and Gas Wells and Their Integrity: Implications for Shale and Unconventional Resource Exploitation. Mar. Pet. Geol. 2014, 56, 239–254. [Google Scholar] [CrossRef]

- Jia, C. Breakthrough and Significance of Unconventional Oil and Gas to Classical Petroleum Geology Theory. Pet. Explor. Dev. 2017, 44, 1–10. [Google Scholar] [CrossRef]

- Zou, C.; Qiu, Z.; Zhang, J.; Li, Z.; Wei, H.; Liu, B.; Zhao, J.; Yang, T.; Zhu, S.; Tao, H.; et al. Unconventional Petroleum Sedimentology: A Key to Understanding Unconventional Hydrocarbon Accumulation. Engineering 2022, 18, 62–78. [Google Scholar] [CrossRef]

- Wenbin, C.; Zhaomin, L.; Xialin, Z.; Bo, Z.; Qi, Z. Horizontal Well Fracturing Technology for Reservoirs with Low Permeability. Pet. Explor. Dev. 2009, 36, 80–85. [Google Scholar] [CrossRef]

- Li, G.; Sheng, M.; Tian, S.; Huang, Z.; Li, Y.; Yuan, X. Multistage Hydraulic Jet Acid Fracturing Technique for Horizontal Wells. Pet. Explor. Dev. 2012, 39, 107–112. [Google Scholar] [CrossRef]

- Baki, S.; Alzamil, A.; Habiballah, Z.; Shariff, E.; Alowaid, A.; Alnakhli, W.; Alshammari, H.; Mahfouz, M. Frac Plug Evaluation to Improve Operations Efficiency. In Proceedings of the SPE Middle East Oil, Gas and Geosciences Show, Manama, Bahrain, 19–21 February 2023. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Jin, Z.; Li, Z.; Liu, Q.; Zhang, K. Oil and Gas Pathway to Net-Zero: Review and Outlook. Energy Strategy Rev. 2023, 45, 101048. [Google Scholar] [CrossRef]

- Cao, X.; Wang, M.; Kang, J.; Wang, S.; Liang, Y. Fracturing Technologies of Deep Shale Gas Horizontal Wells in the Weirong Block, Southern Sichuan Basin. Nat. Gas Ind. B 2020, 7, 64–70. [Google Scholar] [CrossRef]

- Zhao, C.; Xu, Z. CFD Simulation of Flow Interference between Multi-Stage Fractures along a Horizontal Wellbore. Geoenergy Sci. Eng. 2023, 226, 211763. [Google Scholar] [CrossRef]

- Trabelsi, H.; Seibi, A.; Liu, N.; Boukadi, F.; Trabelsi, R. Bridge Plug Drillouts Cleaning Practices—An Overview. Nat. Resour. 2021, 12, 19–33. [Google Scholar] [CrossRef]

- Chen, L.; Wei, R.; Wei, S.; Wang, X. Application of Bionic Technologies on the Fracturing Plug. Biomimetics 2019, 4, 78. [Google Scholar] [CrossRef] [PubMed]

- Cheng, K.; Shang, L.; Li, H.; Peng, B.; Li, Z. A Novel Degradable Sealing Material for the Preparation of Dissolvable Packer Rubber Barrel. J. Macromol. Sci. Part A 2023, 60, 207–216. [Google Scholar] [CrossRef]

- Zhao, J.; Ren, L.; Jiang, T.; Hu, D.; Wu, L.; Wu, J.; Yin, C.; Li, Y.; Hu, Y.; Lin, R.; et al. Ten Years of Gas Shale Fracturing in China: Review and Prospect. Nat. Gas Ind. B 2022, 9, 158–175. [Google Scholar] [CrossRef]

- Fripp, M.; Walton, Z. Fully Dissolvable Frac Plug Using Dissolvable Elastomeric Elements. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 6–9 March 2017. [Google Scholar] [CrossRef]

- Yue, W.; Ren, J.; Yue, J.; Cheng, P.; Dunne, T.; Zhao, L.; Patsy, M.; Nettles, D.; Liu, Y.; Liu, H. High Temperature Dissolvable Materials Development for High Temperature Dissolvable Plug Applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–5 October 2022. [Google Scholar] [CrossRef]

- Geng, Z.; Xiao, D.; Chen, L. Microstructure, Mechanical Properties, and Corrosion Behavior of Degradable Mg-Al-Cu-Zn-Gd Alloys. J. Alloys Compd. 2016, 686, 145–152. [Google Scholar] [CrossRef]

- Liu, L.; Yu, S.; Niu, Y.; Liu, E. Preparation and Properties of Hollow Glass Microspheres Reinforced Mg Alloy Degradable Composites. J. Alloys Compd. 2020, 835, 155198. [Google Scholar] [CrossRef]

- Liu, B.; Yang, Y.; Zhang, Y.; Du, H.; Hou, L.; Wei, Y. Investigation of Rapidly Decomposable AZ91–RE–xCu (X = 0, 1, 2, 3, 4) Alloys for Petroleum Fracturing Balls. J. Phys. Chem. Solids 2020, 144, 109499. [Google Scholar] [CrossRef]

- Niu, H.; Deng, K.; Nie, K.; Wang, C.; Liang, W.; Wu, Y. Degradation Behavior of Mg-4Zn-2Ni Alloy with High Strength and High Degradation Rate. Mater. Chem. Phys. 2020, 249, 123131. [Google Scholar] [CrossRef]

- Sun, J. A Review on Magnesium Alloys for Application of Degradable Fracturing Tools. J. Magnes. Alloys 2022, 10, 2649–2672. [Google Scholar] [CrossRef]

- Liu, Y.H.; Zhang, Z.R.; Wang, J.; Li, Y.; Li, H.X.; Jia, L.Y.; Wang, J.H.; Zhang, J.S. A Novel Mg-Gd-Y-Zn-Cu-Ni Alloy with Excellent Combination of Strength and Dissolution via Peak-Aging Treatment. J. Magnes. Alloys 2023, 11, 720–734. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Zhang, J.; Li, Y.; Jia, L.; Liu, B.; Li, H. A Dissolvable Mg-Gd-Y-Zn-Cu Alloy Possessing the Highest Yield Strength for the Fabrication of Fracturing Plugging Tools. Mater. Lett. 2023, 338, 134053. [Google Scholar] [CrossRef]

- Duran, M.M.; Moro, G.; Zhang, Y.; Islam, A. 3D Printing of Silicone and Polyurethane Elastomers for Medical Device Application: A Review. Adv. Ind. Manuf. Eng. 2023, 7, 100125. [Google Scholar] [CrossRef]

- Hassani, F.; Faisal, N.H.; Nish, R.; Rothnie, S.; Njuguna, J. The Impact of Thermal Ageing on Sealing Performance of HNBR Packing Elements in Downhole Installations in Oilfield Wellhead Applications. J. Pet. Sci. Eng. 2022, 208, 109200. [Google Scholar] [CrossRef]

- Jiang, X.; Yuan, X.; Guo, X.; Zeng, F.; Wang, H.; Liu, G. Study on the Application of Flory–Huggins Interaction Parameters in Swelling Behavior and Crosslink Density of HNBR/EPDM Blend. Fluid Phase Equilibria 2023, 563, 113589. [Google Scholar] [CrossRef]

- Guo, J.; Xu, P.; Lv, J.; Han, X.; Sun, Y.; Hou, D.; Yuan, Z.; Li, C. Ageing Behaviour and Molecular/Network Structure Evolution of EPDM/Carbon Black Composites under Compression and in Thermal-Oxidative Environments. Polym. Degrad. Stab. 2023, 214, 110417. [Google Scholar] [CrossRef]

- Ramirez, M.; Miller, K.R.; Soucek, M.D. Linking of Oligoesters Hydrolysis to Polyurethane Coatings. J. Appl. Polym. Sci. 2014, 131, 40198. [Google Scholar] [CrossRef]

- Walton, Z.; Fripp, M.; Merron, M. Dissolvable Metal vs. Dissolvable Plastic in Downhole Hydraulic Fracturing Applications. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2016. [Google Scholar] [CrossRef]

- Burdzy, M.P. Aqueous Degradable Polyurethane Elastomers for Oil & Gas Applications. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 16–19 August 2021. [Google Scholar] [CrossRef]

- Ren, J.; Cheng, P.; Wang, X. Dissolvable Rubbers Development and Its Applications in Downhole Tools. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 28 November–1 December 2021. [Google Scholar] [CrossRef]

- Mhiri, S.; Mignard, N.; Abid, M.; Prochazka, F.; Majeste, J.-C.; Taha, M. Thermally Reversible and Biodegradable Polyglycolic-Acid-Based Networks. Eur. Polym. J. 2017, 88, 292–310. [Google Scholar] [CrossRef]

- Feng, P.; Shen, S.; Shuai, Y.; Peng, S.; Shuai, C.; Chen, S. PLLA Grafting Draws GO from PGA Phase to the Interface in PLLA/PGA Bone Scaffold Owing Enhanced Interfacial Interaction. Sustain. Mater. Technol. 2023, 35, e00566. [Google Scholar] [CrossRef]

- Shibutani, M.; Nagahara, H.; Fukuoka, T.; Iseki, Y.; Okazaki, Y.; Hirakawa, K.; Ohira, M. Prevention of Anastomotic Leakage Using a Polyglycolic Acid Sheet in Double-Stapling Technique Anastomosis for Rectal Surgery. Ann. Med. Surg. 2021, 72, 103117. [Google Scholar] [CrossRef]

- Xu, P.; Tan, S.; Niu, D.; Wang, Q.; Liu, T.; Yang, W.; Ma, P. Effect of Temperatures on Stress-Induced Structural Evolution and Mechanical Behaviors of Polyglycolic Acid/Polycaprolactone Blends. Polymer 2023, 283, 126239. [Google Scholar] [CrossRef]

- Xu, Z.; Dong, Y.; Yang, Y.; Zhu, J. Mechanical, Barrier, and Biodegradable Properties of Poly(Butylene Adipate-Co-Terephthalate)/Polyglycolic Acid Blends Prepared by Reactive Extrusion. ACS Appl. Eng. Mater. 2023, 1, 304–315. [Google Scholar] [CrossRef]

- Kwon, H.-J.; Jang, J.; Koh, W.-G.; Lee, J.-Y.; Hwang, K. Ductile Effect of PGA/PCL Blending Plastics Using a Novel Ionic Chain Extender with Non-Covalent Bonds. Polymers 2023, 15, 3025. [Google Scholar] [CrossRef]

- Li, C.; Meng, X.; Gong, W.; Chen, S.; Xin, Z. Kinetic, Products Distribution, and Mechanism Analysis for the Pyrolysis of Polyglycolic Acid toward Carbon Cycle. Fuel 2023, 333, 126567. [Google Scholar] [CrossRef]

| PGA/phr | 0 | 3 | 6 | 9 |

|---|---|---|---|---|

| σ/MPa | 27.3 ± 0.82 | 18.3 ± 0.92 | 22.1 ± 0.99 | 19.8 ± 1.4 |

| ε/% | 220 ± 6.6 | 279 ± 10.8 | 240 ± 13.95 | 276 ± 19.32 |

| H/Shore A | 89 | 78 | 81 | 81 |

| σ2/MPa | / | / | 1.18 ± 0.04 | 7.42 ± 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, K.; Yuan, M.; Zhang, Y.; Sun, N.; Peng, B. Application and Properties of Polyglycolic Acid as a Degradation Agent in MPU/HNBR Degradable Elastomer Composites for Dissolvable Frac Plugs. Polymers 2024, 16, 181. https://doi.org/10.3390/polym16020181

Cheng K, Yuan M, Zhang Y, Sun N, Peng B. Application and Properties of Polyglycolic Acid as a Degradation Agent in MPU/HNBR Degradable Elastomer Composites for Dissolvable Frac Plugs. Polymers. 2024; 16(2):181. https://doi.org/10.3390/polym16020181

Chicago/Turabian StyleCheng, Kai, Mingyang Yuan, Yupeng Zhang, Ningjing Sun, and Bo Peng. 2024. "Application and Properties of Polyglycolic Acid as a Degradation Agent in MPU/HNBR Degradable Elastomer Composites for Dissolvable Frac Plugs" Polymers 16, no. 2: 181. https://doi.org/10.3390/polym16020181

APA StyleCheng, K., Yuan, M., Zhang, Y., Sun, N., & Peng, B. (2024). Application and Properties of Polyglycolic Acid as a Degradation Agent in MPU/HNBR Degradable Elastomer Composites for Dissolvable Frac Plugs. Polymers, 16(2), 181. https://doi.org/10.3390/polym16020181