Significantly Enhanced Balance of Dielectric Properties of Polyvinylidene Difluoride Three-Phase Composites by Silver Deposited on K2Ni0.93Ti7.07O16 Hollandite Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

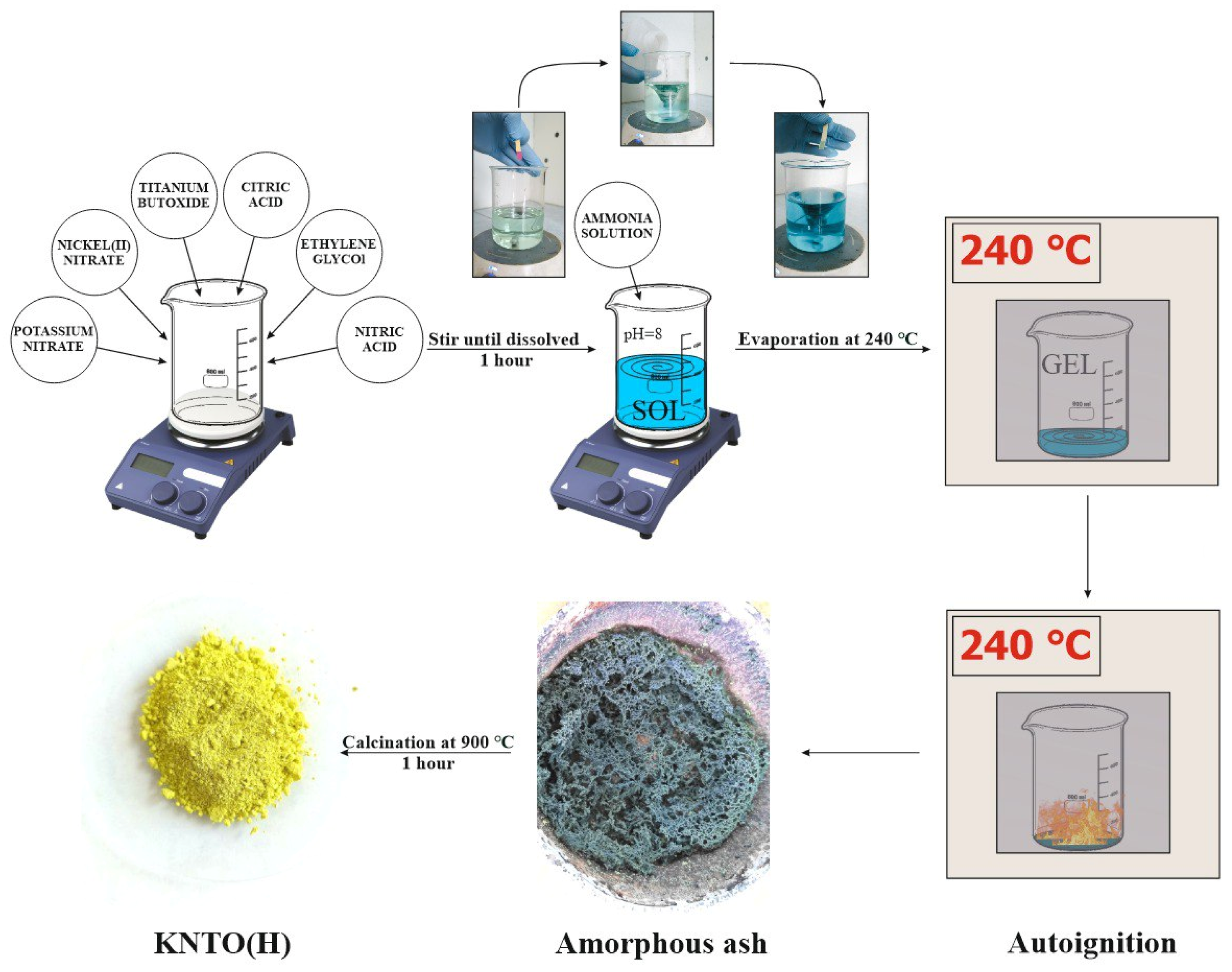

2.1. KNTO Powder Synthesis

2.2. KNTO@Ag Powder Preparation

2.3. Preparing Composites Method

2.4. Characteristic Methods

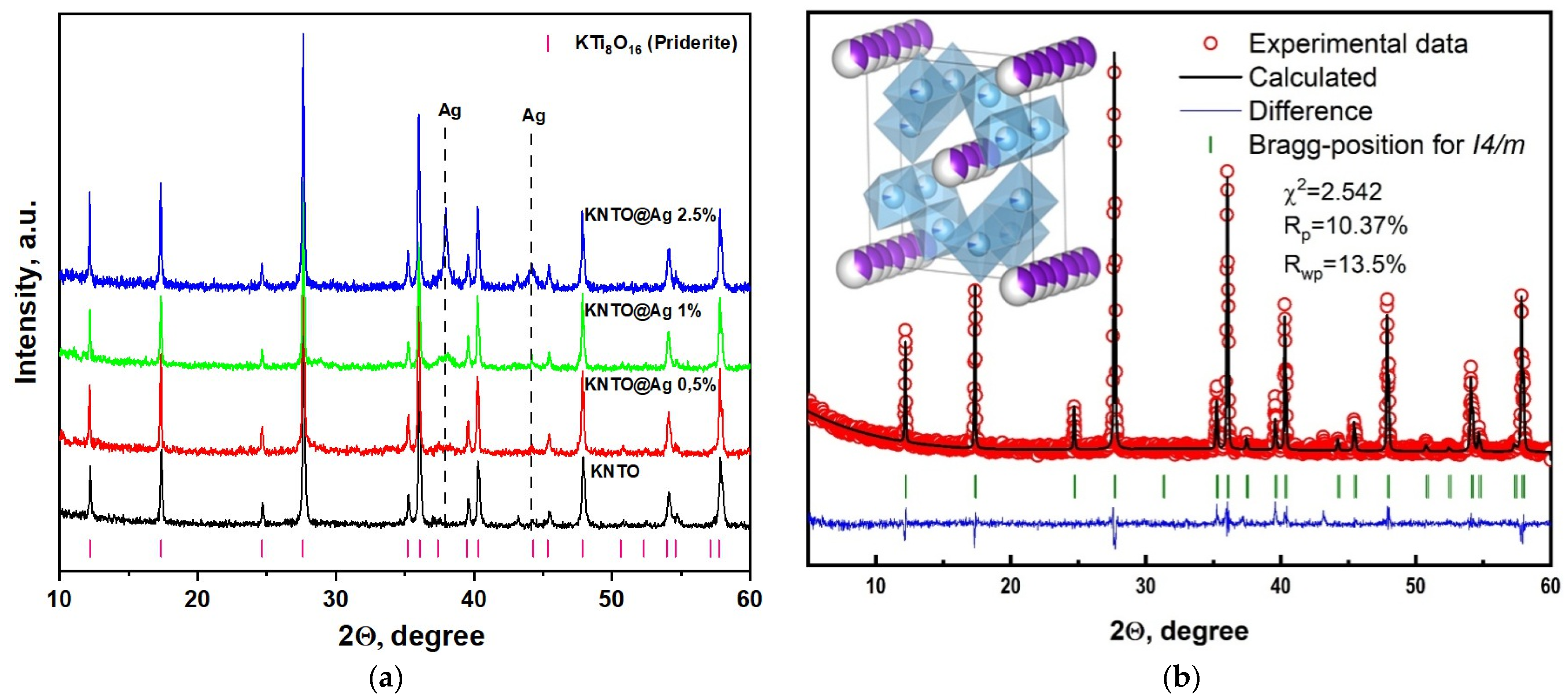

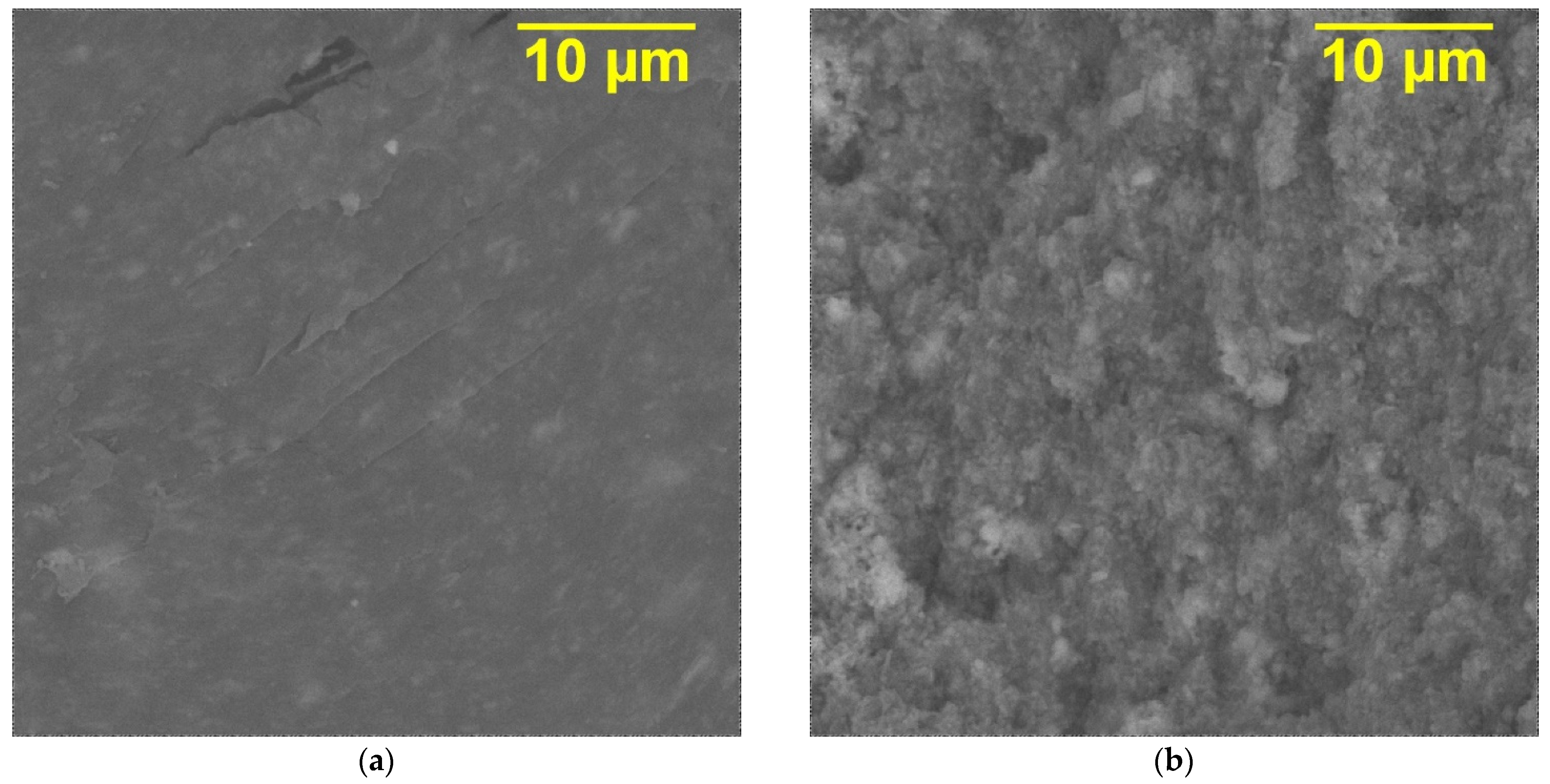

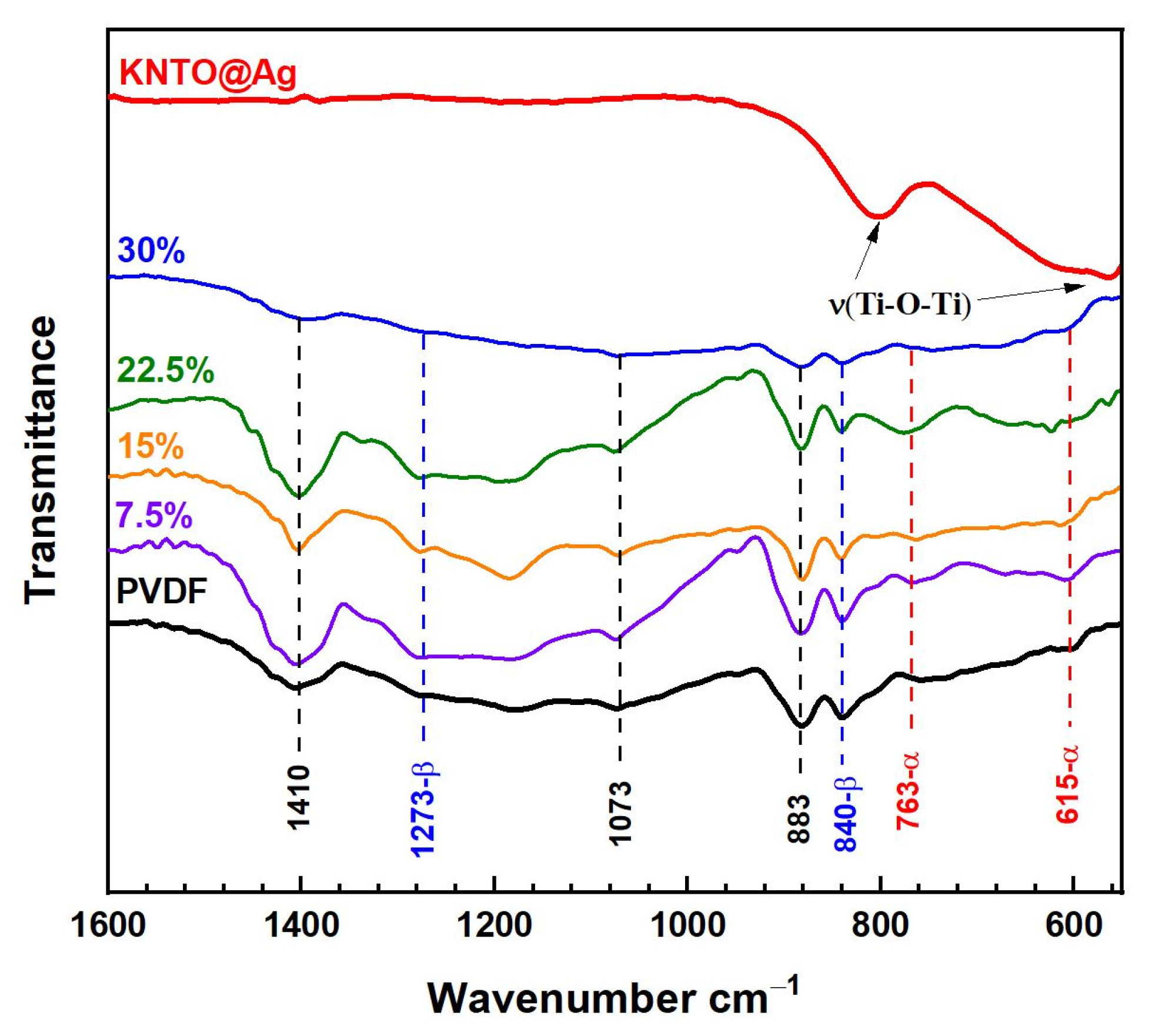

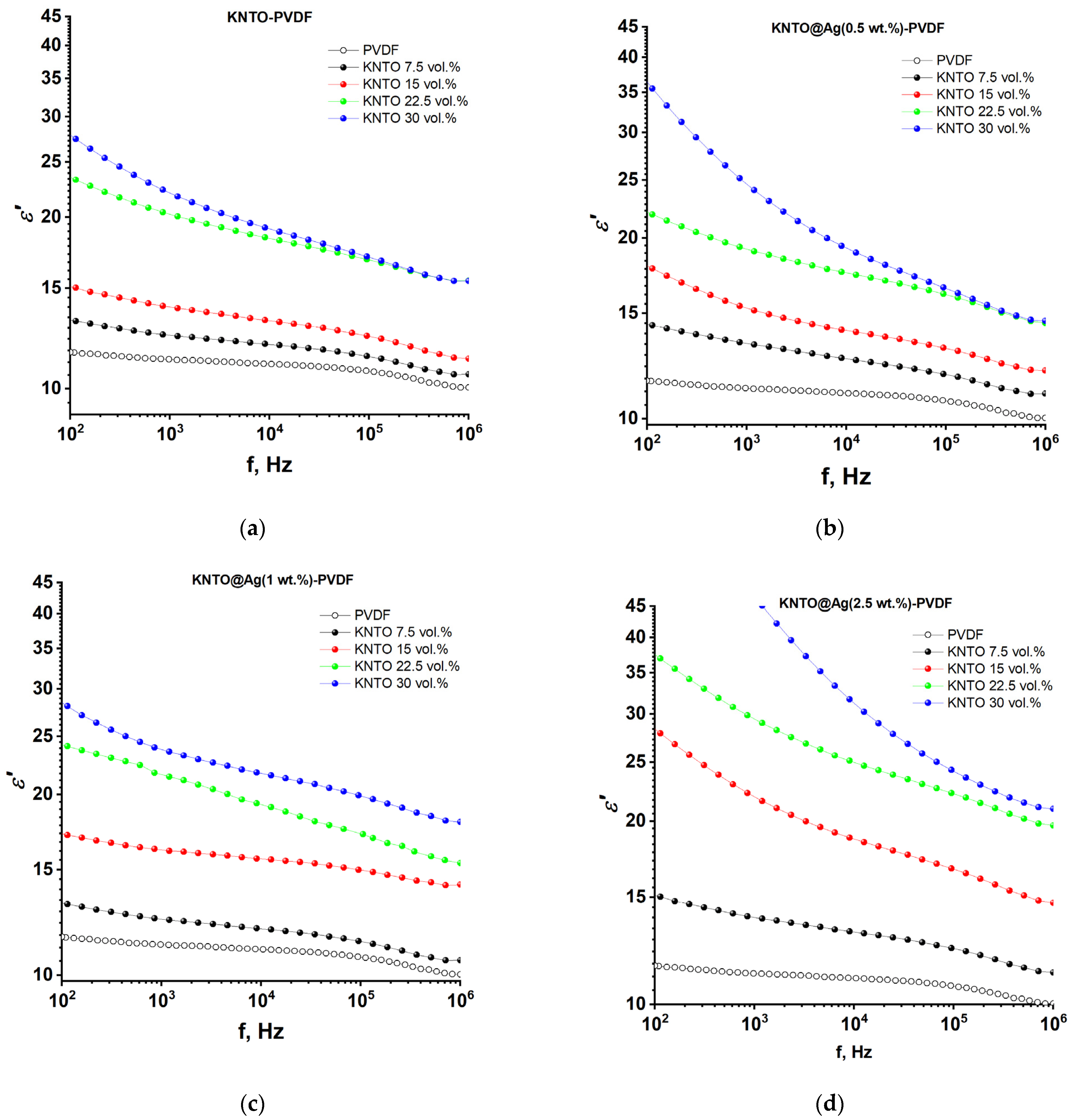

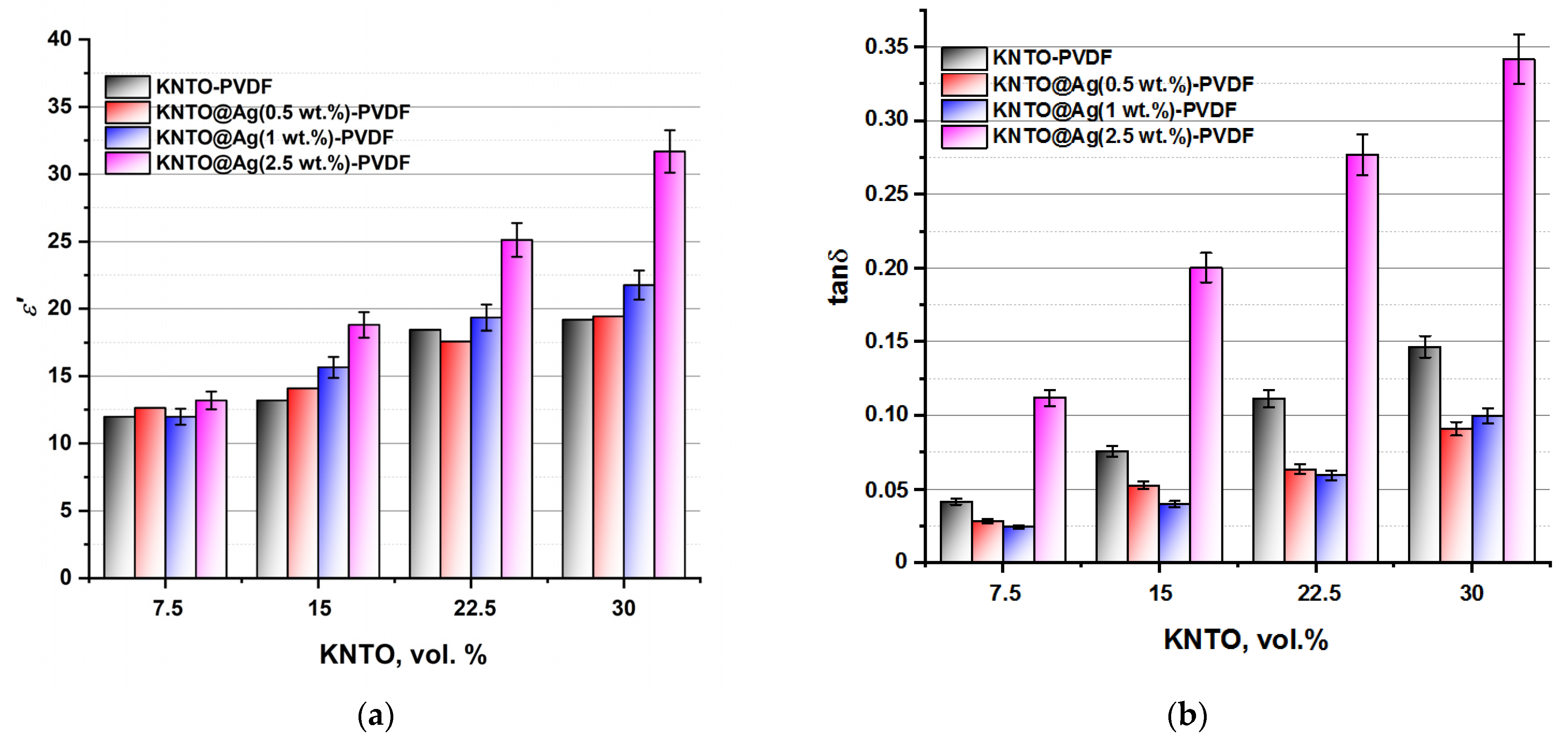

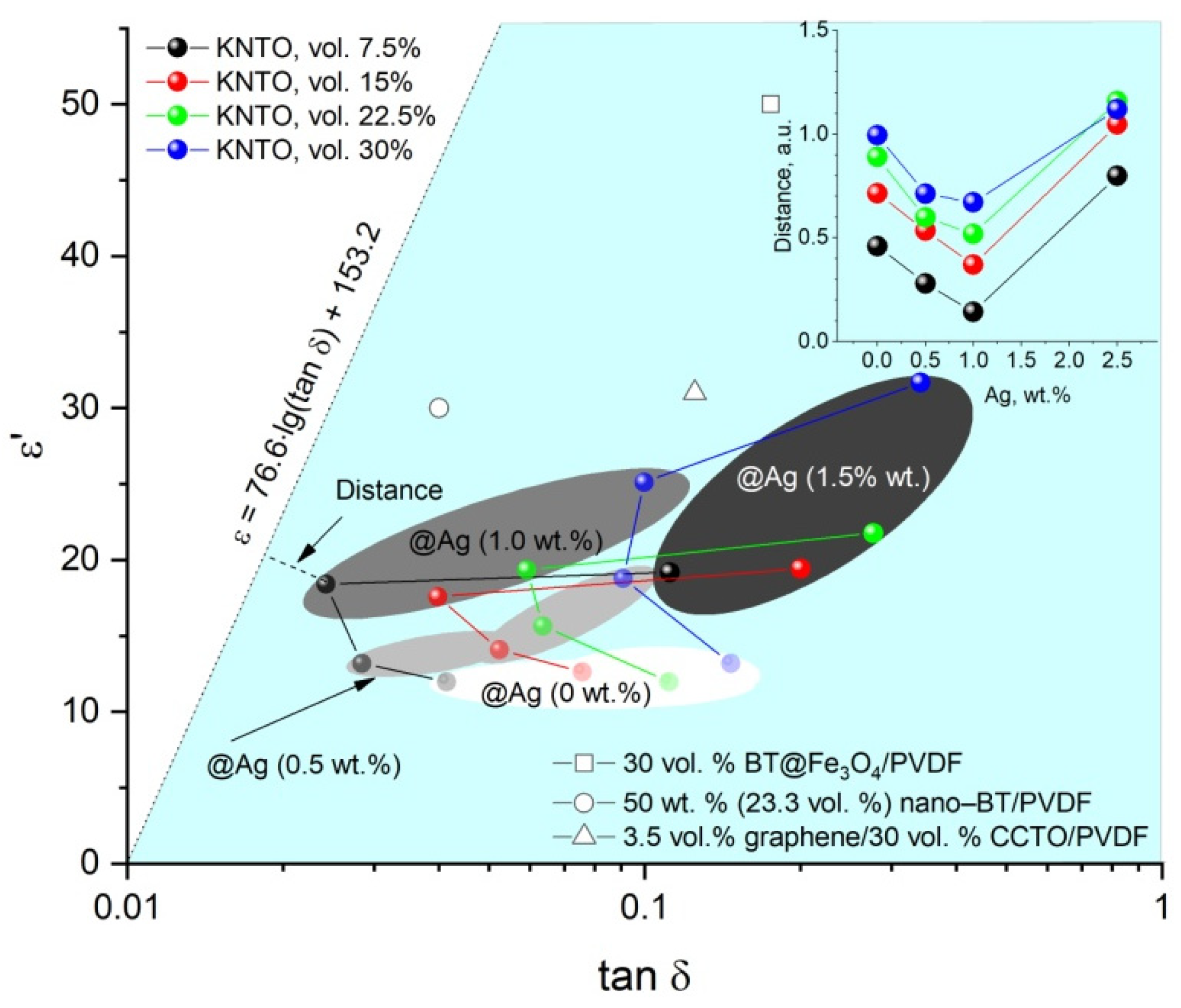

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, J.; Wong, C.P. Recent advances in high-k nanocomposite materials for embedded capacitor applications. IEEE Trans. Dielectr. Electr. Insul. 2008, 5, 11322–11328. [Google Scholar]

- Huang, X.; Sun, B.; Zhu, Y.; Li, S.; Jiang, P. High-k polymer nanocomposites with 1D filler for dielectric and energy storage applications. Prog. Mater. Sci. 2019, 100, 187–225. [Google Scholar] [CrossRef]

- Thakur, V.K.; Gupta, R.K. Recent Progress on Ferroelectric Polymer-Based Nanocomposites for High Energy Density Capacitors: Synthesis, Dielectric Properties, and Future Aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar]

- Nketia-Yawson, B.; Noh, Y.Y. Recent progress on high-capacitance polymer gate dielectrics for flexible low-voltage transistors. Adv. Funct. Mater. 2018, 28, 1802201. [Google Scholar] [CrossRef]

- Malik, A.; Kandasubramanian, B. Flexible polymeric substrates for electronic applications. Polym. Rev. 2018, 58, 630667. [Google Scholar] [CrossRef]

- Ling, Q.D.; Liaw, D.J.; Zhu, C.; Chan, D.S.H.; Kang, E.T.; Neoh, K.G. Polymer electronic memories: Materials, devices and mechanisms. Prog. Polym. Sci. 2008, 33, 917–978. [Google Scholar] [CrossRef]

- Dang, Z.M.; Yuan, J.K.; Zha, J.W.; Zhou, T.; Li, S.T.; Hu, G.H. Fundamentals, processes and applications of high-permittivity polymer–matrix composites. Prog. Mater. Sci. 2012, 57, 660–723. [Google Scholar] [CrossRef]

- Dang, Z.M.; Yuan, J.K.; Yao, S.H.; Liao, R.J. Flexible nanodielectric materials with high permittivity for power energy storage. Adv. Mater. 2013, 25, 6334–6365. [Google Scholar] [CrossRef]

- Zha, J.W.; Zheng, M.S.; Fan, B.H.; Dang, Z.M. Polymer-based dielectrics with high permittivity for electric energy storage: A review. Nano Energy 2021, 89, 106438. [Google Scholar] [CrossRef]

- Wang, S.; Yang, C.; Li, X.; Jia, H.; Liu, S.; Liu, X.; Sun, Q. Polymer-based dielectrics with high permittivity and low dielectric loss for flexible electronics. J. Mater. Chem. C 2022, 10, 6196–6221. [Google Scholar] [CrossRef]

- Wang, B.; Huang, W.; Chi, L.; Al-Hashimi, M.; Marks, T.J.; Facchetti, A. High-k gate dielectrics for emerging flexible and stretchable electronics. Chem. Rev. 2018, 118, 5690–5754. [Google Scholar] [CrossRef]

- Xia, W.; Zhang, Z. PVDF-based dielectric polymers and their applications in electronic materials. IET Nanodielectrics 2018, 1, 17–31. [Google Scholar] [CrossRef]

- Chu, B.; Zhou, X.; Ren, K.; Neese, B.; Lin, M.; Wang, Q.; Zhang, Q. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef]

- Thomas, P.; Satapathy, S.; Dwarakanath, K.; Varma, K.B.R. Dielectric properties of poly (vinylidene fluoride)/CaCu3Ti4O12 nanocrystal composite thick films. arXiv 2013, arXiv:1301.4056. [Google Scholar] [CrossRef]

- Zhou, W.; Zuo, J.; Ren, W. Thermal conductivity and dielectric properties of Al/PVDF composites. Compos. Part A Appl. Sci. Manuf. 2019, 43, 658–664. [Google Scholar] [CrossRef]

- Yang, C.; Song, H.S.; Liu, D. B Effect of coupling agents on the dielectric properties of CaCu3Ti4O12/PVDF composites. Compos. B Eng. 2013, 50, 180–186. [Google Scholar] [CrossRef]

- Fu, J.; Hou, Y.; Zheng, M.; Wei, Q.; Zhu, M.; Yan, H. Improving dielectric properties of PVDF composites by employing surface modified strong polarized BaTiO3 particles derived by molten salt method. ACS Appl. Mater. Interfaces 2015, 7, 24480–24491. [Google Scholar] [CrossRef] [PubMed]

- Chi, Q.; Liu, G.; Zhang, C.; Cui, Y.; Wang, X.; Lei, Q. Microstructure and dielectric properties of BZT-BCT/PVDF nanocomposites. Results Phys. 2018, 8, 391–396. [Google Scholar] [CrossRef]

- Sang, X.; Li, X.; Zhang, D.; Zhang, X.; Wang, H.; Li, S. Improved dielectric properties and energy-storage densities of BaTiO3-doped PVDF composites by heat treatment and surface modification of BaTiO3. J. Phys. D 2022, 55, 215501. [Google Scholar] [CrossRef]

- Ma, J.; Azhar, U.; Zong, C.; Zhang, Y.; Xu, A.; Zhai, C.; Zhang, S. Core-shell structured PVDF@BT nanoparticles for dielectric materials: A novel composite to prove the dependence of dielectric properties on ferroelectric shell. Mater. Des. 2019, 164, 107556. [Google Scholar] [CrossRef]

- Carbone, C.; Benwadih, M.; D’Ambrogio, G.; Le, M.Q.; Capsal, J.F.; Cottinet, P.J. Influence of matrix and surfactant on piezoelectric and dielectric properties of screen-printed BaTiO3/PVDF composites. Polymers 2021, 13, 2166. [Google Scholar] [CrossRef]

- Uddin, A.S.M.I.; Lee, D.; Cho, C.; Kim, B. Impact of multi-walled CNT incorporation on dielectric properties of PVDF-BaTiO3 nanocomposites and their energy harvesting possibilities. Coatings 2022, 12, 77. [Google Scholar] [CrossRef]

- Yadav, N.P.; Sahu, B.B.; Yadav, T.; Kumar, R.; Pathak, A.; Pandey, G.N.; Moharana, S. Enhanced dielectric and electrical properties of polystyrene-2% divinyl benzene (PDB) embedded in SrTiO3–Poly (vinylidene fluoride) three phase composite films. Optik 2022, 270, 170001. [Google Scholar] [CrossRef]

- Kaur, S.; Singh, D.P. On the structural, dielectric and energy storage behaviour of PVDF-CaCu3Ti4O12 nanocomposite films. Mater. Chem. Phys. 2020, 239, 122301. [Google Scholar] [CrossRef]

- Wang, J.J.; Deng, Q.J.; He, Y.Y.; Feng, Y.N.; Kang, M.P.; Duan, X.L.; Yang, Y.L. Fabrications and dielectric performances of novel composites: Calcium copper titanate/Polyvinylidene fluoride. Curr. Appl. Phys. 2022, 39, 25–29. [Google Scholar] [CrossRef]

- Ngongang, R.T.; Nwanya, A.C.; Onoh, E.U.; Nwachukwu, I.M.; Ugwuoke, C.; Atawa, B.; Ezema, F.I. Studies of the Dielectric Properties of Pvdf-CaCu3Ti4O12 Composite Thin Film: Experimental and Theoretical. SSRN 2023, 4347544. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4347544 (accessed on 3 February 2023).

- Ou, J.; Chen, Y.; Zhao, J.; Luo, S.; Wong, K.W.; Ng, K.M. Nano-Sized Calcium Copper Titanate for the Fabrication of High Dielectric Constant Functional Ceramic–Polymer Composites. Polymers 2022, 14, 4328. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, M.; Huang, Z.X.; Qu, J.P. Synergistic effect based on enhanced local shear forces in PVDF/TiO2/CNT ternary composites. Ind. Eng. Chem. Res. 2022, 59, 18887–18897. [Google Scholar] [CrossRef]

- Dai, J.; Meng, S.; Yang, C.; Lü, W.; Chen, X.; Yin, Y.; Liang, F. Effect of nano silver modification on the dielectric properties of Ag@ TiO2/PVDF Composites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2021, 36, 303–310. [Google Scholar] [CrossRef]

- Kum-Onsa, P.; Chanlek, N.; Thongbai, P. Largely enhanced dielectric properties of TiO2-nanorods/poly (vinylidene fluoride) nanocomposites driven by enhanced interfacial areas. Nanocomposites 2021, 7, 123–131. [Google Scholar] [CrossRef]

- Kum-Onsa, P.; Thongbai, P. Dielectric properties of poly (vinylidene fluoride)-based nanocomposites containing a LaFeO3 nanoparticle filler. J. Mater. Sci. Mater. Electron. 2021, 32, 13985–13993. [Google Scholar] [CrossRef]

- Kum-Onsa, P.; Putasaeng, B.; Manyam, J.; Thongbai, P. Significantly improved dielectric properties of poly (vinylidene fluoride) polymer nanocomposites by the addition of nAu−LaFeO3 hybrid particles. Mater. Res. Bull. 2021, 146, 111603. [Google Scholar] [CrossRef]

- Chen, C.; Wang, L.; Liu, X.; Yang, W.; Lin, J.; Chen, G.; Yang, X. K0.5Na0.5NbO3-SrTiO3/PVDF polymer composite film with low remnant polarization and high discharge energy storage density. Polymers 2019, 11, 310. [Google Scholar] [CrossRef] [PubMed]

- Jain, A.; Prashanth, K.J.; Sharma, A.K.; Jain, A.; Rashmi, P.N. Dielectric and piezoelectric properties of PVDF/PZT composites: A review. Polym. Eng. Sci. 2015, 55, 1589–1616. [Google Scholar] [CrossRef]

- Feng, M.; Feng, Y.; Zhang, T.; Li, J.; Chen, Q.; Chi, Q.; Lei, Q. Recent advances in multilayer-structure dielectrics for energy storage application. Adv. Sci. 2021, 8, 2102221. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Xia, S.; Wei, Y.; Lv, X.; Sun, S.; Li, Q. Fluoro-polymer-coated carbon nanotubes for improved interfacial interactions and dielectric properties in MWCNTs/PVDF composites. J. Mater. Sci. 2020, 55, 3212–3227. [Google Scholar] [CrossRef]

- Liu, P.; Yao, Z.; Zhou, J. Mechanical, thermal and dielectric properties of graphene oxide/polyimide resin composite. High Perform. Polym. 2016, 28, 1033–1042. [Google Scholar] [CrossRef]

- Dang, Z.M.; Shen, Y.; Nan, C.W. Dielectric behavior of three-phase percolative Ni–BaTiO3/polyvinylidene fluoride composites. Appl. Phys. Lett. 2002, 81, 4814–4816. [Google Scholar] [CrossRef]

- Qi, L.; Lee, B.I.; Chen, S.; Samuels, W.D.; Exarhos, G.J. High-dielectric-constant silver–epoxy composites as embedded dielectrics. Adv. Mater. 2005, 17, 1777–1781. [Google Scholar] [CrossRef]

- Lu, J.; Moon, K.S.; Xu, J.; Wong, C.P. Synthesis and dielectric properties of novel high-K polymer composites containing in-situ formed silver nanoparticles for embedded capacitor applications. J. Mater. Chem. 2006, 16, 1543–1548. [Google Scholar] [CrossRef]

- Dang, Z.M.; Peng, B.; Xie, D.; Yao, S.H.; Jiang, M.J.; Bai, J. High dielectric permittivity silver/polyimide composite films with excellent thermal stability. Appl. Phys. Lett. 2008, 92, 112910. [Google Scholar] [CrossRef]

- Gong, K.; Zhou, K.; Qian, X.; Shi, C.; Yu, B. MXene as emerging nanofillers for high-performance polymer composites: A review. Compos. B Eng. 2021, 217, 108867. [Google Scholar] [CrossRef]

- Jimmy, J.; Kandasubramanian, B. Mxene functionalized polymer composites: Synthesis and applications. Eur. Polym. J. 2020, 122, 109367. [Google Scholar] [CrossRef]

- Tsyganov, A.; Vikulova, M.; Artyukhov, D.; Zheleznov, D.; Gorokhovsky, A.; Gorshkov, N. Intercalation Effects on the Dielectric Properties of PVDF/Ti3C2Tx MXene Nanocomposites. Nanomaterials 2023, 13, 1337. [Google Scholar] [CrossRef] [PubMed]

- Silakaew, K.; Thongbai, P. Significantly improved dielectric properties of multiwall carbon nanotube-BaTiO3/PVDF polymer composites by tuning the particle size of the ceramic filler. RSC Adv. 2019, 9, 23498–23507. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Rao, S.; Xiong, C.; Du, G.; Fan, Z.; Chen, N. Enhanced dielectric and mechanical properties of CaCu3Ti4O12/Ti3C2Tx MXene/silicone rubber ternary composites. Ceram. Int. 2022, 48, 6116–6123. [Google Scholar] [CrossRef]

- Feng, Y.; Deng, Q.; Peng, C.; Wu, Q. High dielectric and breakdown properties achieved in ternary BaTiO3/MXene/PVDF nanocomposites with low-concentration fillers from enhanced interface polarization. Ceram. Int. 2019, 45, 7923–7930. [Google Scholar] [CrossRef]

- Wang, H.Y.; You, Y.B.; Zha, J.W.; Dang, Z.M. Fabrication of BaTiO3@ super short MWCNTs core-shell particles reinforced PVDF composite films with improved dielectric properties and high thermal conductivity. Compos. Sci. Technol. 2020, 200, 108405. [Google Scholar] [CrossRef]

- Chi, Q.G.; Gao, L.; Wang, X.; Chen, Y.; Dong, J.F.; Cui, Y.; Lei, Q.Q. Effects of magnetic field treatment on dielectric properties of CCTO@ Ni/PVDF composite with low concentration of ceramic fillers. AIP Adv. 2015, 5, 117103. [Google Scholar] [CrossRef]

- Su, Y.; Gu, Y.; Li, H.; Geng, F. Ag-NBCTO-PVDF composites with enhanced dielectric properties. Mater. Lett. 2016, 185, 208–210. [Google Scholar] [CrossRef]

- Huang, X.; Jiang, P.; Xie, L. Ferroelectric polymer/silver nanocomposites with high dielectric constant and high thermal conductivity. Appl. Phys. Lett. 2009, 95, 242901. [Google Scholar] [CrossRef]

- Khan, M.M.; Kumar, S.; Ahmed, J.; Ahamed, M.; Kumar, A. Influence of silver doping on the structure, optical and photocatalytic properties of Ag-doped BaTiO3 ceramics. Mater. Chem. Phys. 2021, 259, 124058. [Google Scholar] [CrossRef]

- Luo, S.; Yu, S.; Sun, R.; Wong, C.P. Nano Ag-deposited BaTiO3 hybrid particles as fillers for polymeric dielectric composites: Toward high dielectric constant and suppressed loss. ACS Appl. Mater. Interfaces 2014, 6, 176–182. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Kong, X.; Ni, Y.; Xu, Y.; Huang, S.; Shang, G.; Zhang, L. Enhancement of dielectric performance of polymer composites via constructing BaTiO3–Poly (dopamine)–Ag nanoparticles through mussel-inspired surface functionalization. ACS Omega 2018, 3, 14087–14096. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.S.; Wang, M.; Yang, C.; Shao, Y.W.; Qi, X.D.; Yang, J.H.; Wang, Y. Heterogeneous BaTiO3@ Ag core-shell fibers as fillers for polymer dielectric composites with simultaneously improved dielectric constant and breakdown strength. Compos. Commun. 2021, 27, 100874. [Google Scholar] [CrossRef]

- Tumurugoti, P.; Betal, S.; Sundaram, S.K. Hollandites’ crystal chemistry, properties, and processing: A review. Int. Mater. Rev. 2021, 66, 141–159. [Google Scholar] [CrossRef]

- Besprozvannykh, N.V.; Sinel’shchikova, O.Y.; Morozov, N.A.; Kuchaeva, S.K.; Galankina, O.L. Combustion synthesis and electrophysical properties of hollandites of the system K2O–MeO–TiO2 (Me = Mg, Ni, Cu). Ceram. Int. 2022, 48, 24283–24289. [Google Scholar] [CrossRef]

- Fort, A.; Addabbo, T.; Vignoli, V.; Bertocci, F.; Mugnaini, M.; Atrei, A.; Gregorkiewitz, M. Gas-sensing properties and modeling of silver doped potassium hollandite. Sens. Actuators B Chem. 2014, 194, 427–439. [Google Scholar] [CrossRef]

- Sakao, M.; Kijima, N.; Akimoto, J.; Okutani, T. Lithium insertion and extraction properties of hollandite-type KxTiO2 with different K content in the tunnel space. Solid State Ion. 2013, 243, 22–29. [Google Scholar] [CrossRef]

- Sakao, M.; Kijima, N.; Akimoto, J.; Okutani, T. Synthesis, crystal structure, and electrochemical properties of hollandite-type K0.008TiO2. Solid State Ion. 2012, 225, 502–505. [Google Scholar] [CrossRef]

- Gorokhovsky, A.V.; Tsiganov, A.R.; Nikityuk, T.V.; Escalante-Garcia, J.I.; Burmistrov, I.N.; Goffman, V.G. Synthesis and properties of nanocomposites in the system of potassium polytitanate-layered double hydroxide. J. Mater. Res. Technol. 2020, 9, 3924–3934. [Google Scholar] [CrossRef]

- Tsyganov, A.; Artyukhov, D.; Vikulova, M.; Morozova, N.; Zotov, I.; Brudnik, S.; Asmolova, A.; Zheleznov, D.; Gorokhovsky, A.; Gorshkov, N. Synthesis and Dielectric Relaxation Studies of KxFeyTi8-yO16 (x = 1.4–1.8 and y = 1.4–1.6) Ceramics with Hollandite Structure. Ceramics 2023, 6, 619–629. [Google Scholar] [CrossRef]

- Vikulova, M.; Nikityuk, T.; Artyukhov, D.; Tsyganov, A.; Bainyashev, A.; Burmistrov, I.; Gorshkov, N. High-k Three-phase epoxy/K1.6(Ni0.8Ti7.2)O16/CNT composites with synergetic effect. Polymers 2022, 14, 448. [Google Scholar] [CrossRef] [PubMed]

- Vikulova, M.; Tsyganov, A.; Bainyashev, A.; Artyukhov, D.; Gorokhovsky, A.; Muratov, D.; Gorshkov, N. Dielectric properties of PMMA/KCTO (H) composites for electronics components. J. Appl. Polym. Sci. 2021, 138, 51168. [Google Scholar] [CrossRef]

- Tsyganov, A.; Vikulova, M.; Artyukhov, D.; Bainyashev, A.; Goffman, V.; Gorokhovsky, A.; Gorshkov, N. Carbon Modification of K1.6Fe1.6Ti6.4O16 Nanoparticles to Optimize the Dielectric Properties of PTFE-Based Composites. Polymers 2022, 14, 4010. [Google Scholar] [CrossRef]

- Tsyganov, A.; Vikulova, M.; Artyukhov, D.; Bainyashev, A.; Goffman, V.; Gorokhovsky, A.; Boychenko, E.; Burmistrov, I.; Gorshkov, N. Permittivity and Dielectric Loss Balance of PVDF/K1.6Fe1.6Ti6.4O16 Three-Phase Composites. Polymers 2022, 14, 4609. [Google Scholar] [CrossRef] [PubMed]

- Martins, P.; Lopes, A.C.; Lanceros-Mendez, S. Electroactive phases of poly (vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Cai, X.; Lei, T.; Sun, D.; Lin, L. A critical analysis of the α, β and γ phases in poly (vinylidene fluoride) using FTIR. RSC Adv. 2017, 7, 15382–15389. [Google Scholar] [CrossRef]

- Chen, Y.; Cao, L.; Su, Y.; Feng, S. Enhancement of dielectric properties in flexible Ti3C2Tx/PVDF composite films. Ceram. Int. 2024, 50, 4323–4331. [Google Scholar] [CrossRef]

- Tsyganov, A.; Vikulova, M.; Zotov, I.; Burmistrov, I.; Gorokhovsky, A.; Gorshkov, N. Synergistic effect of CaCu3Ti4O12 ceramic and Ti3C2Tx MXene nanoflakes on the dielectric properties of poly (vinylidene fluoride) composites. Mater. Chem. Phys. 2024, 313, 128714. [Google Scholar] [CrossRef]

- Nandihalli, N.; Gregory, D.H.; Mori, T. Energy-Saving Pathways for Thermoelectric Nanomaterial Synthesis: Hydrothermal/Solvothermal, Microwave-Assisted, Solution-Based, and Powder Processing. Adv. Sci. 2022, 9, 2106052. [Google Scholar] [CrossRef]

- Rao, K.J.; Vaidhyanathan, B.; Ganguli, M.; Ramakrishnan, P.A. Synthesis of Inorganic Solids Using Microwaves. Chem. Mater. 1999, 11, 882–895. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, J.; Ni, Y. Dielectric relaxation processes in PVDF composite. Polym. Test. 2020, 91, 106801. [Google Scholar] [CrossRef]

- Zhao, X.; Li, C.; Qi, R.; Guo, H.; Peng, G. Study on relaxation behavior of all-polymer PVDF-based films containing dielectric fluoroelastomer. Polymer 2022, 252, 124933. [Google Scholar] [CrossRef]

- Zhang, C.; Chi, Q.; Dong, J.; Cui, Y.; Wang, X.; Liu, L.; Lei, Q. Enhanced dielectric properties of poly (vinylidene fluoride) composites filled with nano iron oxide-deposited barium titanate hybrid particles. Sci. Rep. 2016, 6, 33508. [Google Scholar] [CrossRef]

- Bi, X.; Yang, L.; Wang, Z.; Zhan, Y.; Wang, S.; Zhang, C.; Li, Y.; Miao, Y.; Zha, J. Construction of a Three-Dimensional BaTiO3 Network for Enhanced Permittivity and Energy Storage of PVDF Composites. Materials 2021, 14, 3585. [Google Scholar] [CrossRef]

- Wang, Y.; He, P.; Li, F. Graphene-improved dielectric property of CCTO/PVDF composite film. Ferroelectrics 2019, 540, 154–161. [Google Scholar] [CrossRef]

- Huang, Z.X.; Zhao, M.L.; Zhang, G.Z.; Song, J.; Qu, J.P. Controlled localizing multi-wall carbon nanotubes in polyvinylidene fluoride/acrylonitrile butadiene styrene blends to achieve balanced dielectric constant and dielectric loss. Compos. Sci. Technol. 2021, 212, 108874. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsyganov, A.; Vikulova, M.; Zotov, I.; Artyukhov, D.; Burmistrov, I.; Gorokhovsky, A.; Gorshkov, N. Significantly Enhanced Balance of Dielectric Properties of Polyvinylidene Difluoride Three-Phase Composites by Silver Deposited on K2Ni0.93Ti7.07O16 Hollandite Nanoparticles. Polymers 2024, 16, 223. https://doi.org/10.3390/polym16020223

Tsyganov A, Vikulova M, Zotov I, Artyukhov D, Burmistrov I, Gorokhovsky A, Gorshkov N. Significantly Enhanced Balance of Dielectric Properties of Polyvinylidene Difluoride Three-Phase Composites by Silver Deposited on K2Ni0.93Ti7.07O16 Hollandite Nanoparticles. Polymers. 2024; 16(2):223. https://doi.org/10.3390/polym16020223

Chicago/Turabian StyleTsyganov, Alexey, Maria Vikulova, Ilya Zotov, Denis Artyukhov, Igor Burmistrov, Alexander Gorokhovsky, and Nikolay Gorshkov. 2024. "Significantly Enhanced Balance of Dielectric Properties of Polyvinylidene Difluoride Three-Phase Composites by Silver Deposited on K2Ni0.93Ti7.07O16 Hollandite Nanoparticles" Polymers 16, no. 2: 223. https://doi.org/10.3390/polym16020223

APA StyleTsyganov, A., Vikulova, M., Zotov, I., Artyukhov, D., Burmistrov, I., Gorokhovsky, A., & Gorshkov, N. (2024). Significantly Enhanced Balance of Dielectric Properties of Polyvinylidene Difluoride Three-Phase Composites by Silver Deposited on K2Ni0.93Ti7.07O16 Hollandite Nanoparticles. Polymers, 16(2), 223. https://doi.org/10.3390/polym16020223