Experimental Studies and Application of Fiber-Reinforced Polymers (FRPs) in Civil Infrastructure Systems: A State-of-the-Art Review

Abstract

:1. Introduction

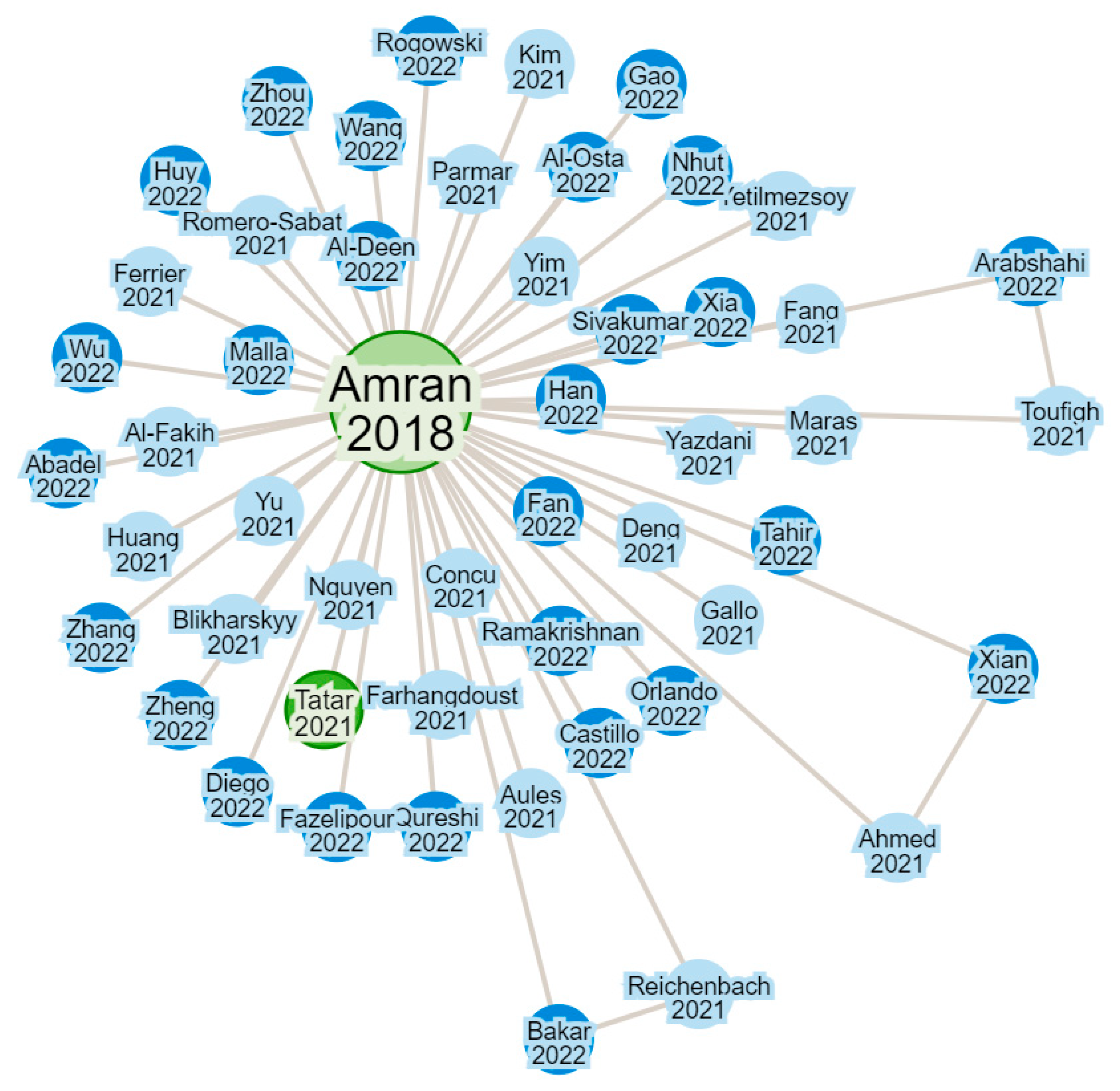

2. Methodology

3. Research Progress

3.1. Mechanical Properties of FRPs

3.1.1. Harsh Environments’ Resistance to FRPs

3.1.2. FRP Behavior under Seismic Loads

3.2. Novel Types of Fibers Use for Reinforce

3.3. FRP Installation Methods in Structural Elements and Their Failure Modes

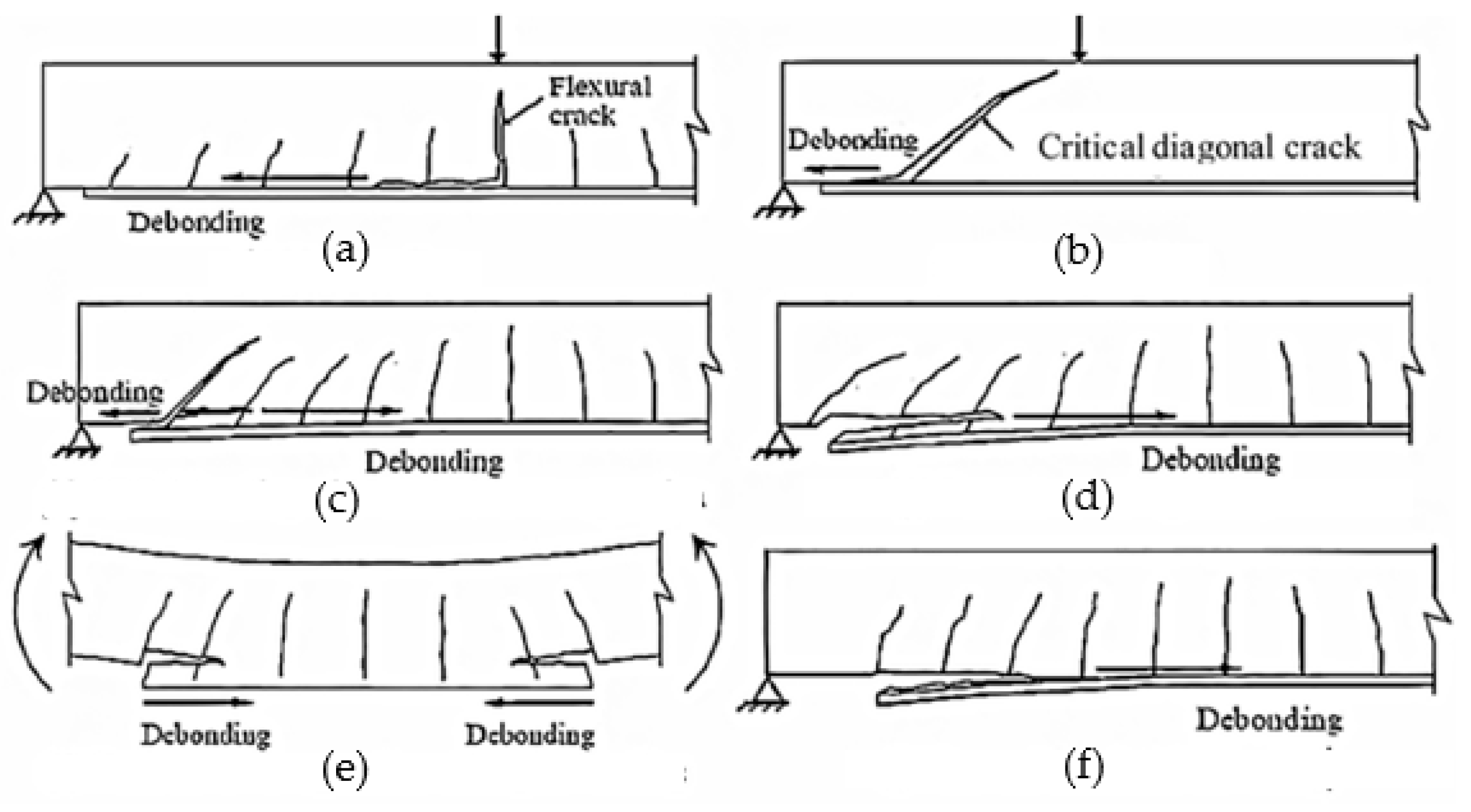

3.3.1. Mechanical Properties Using the EBR Method

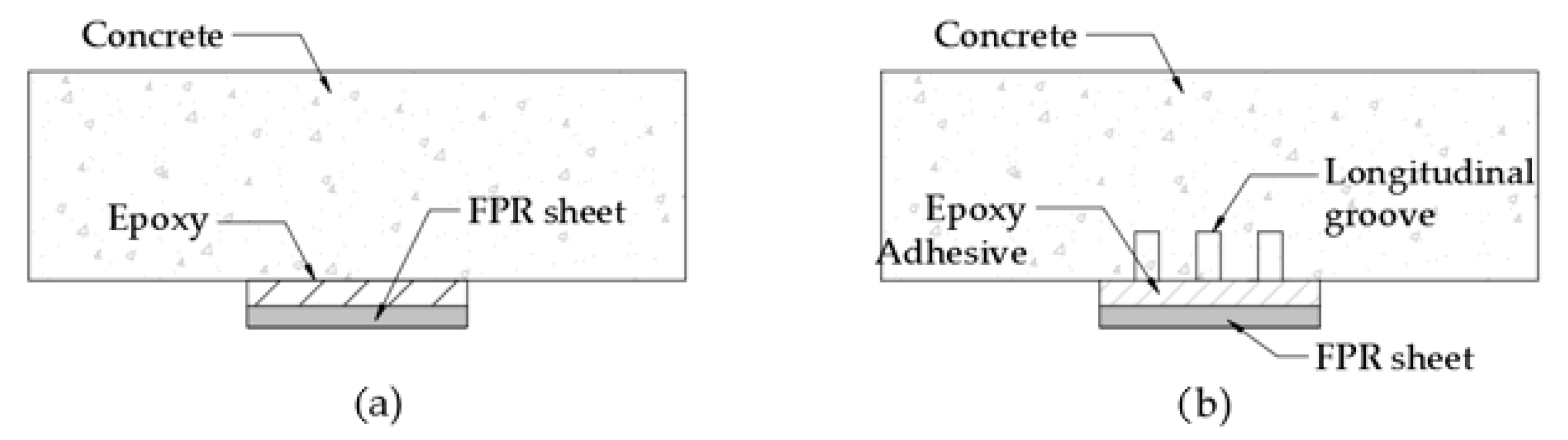

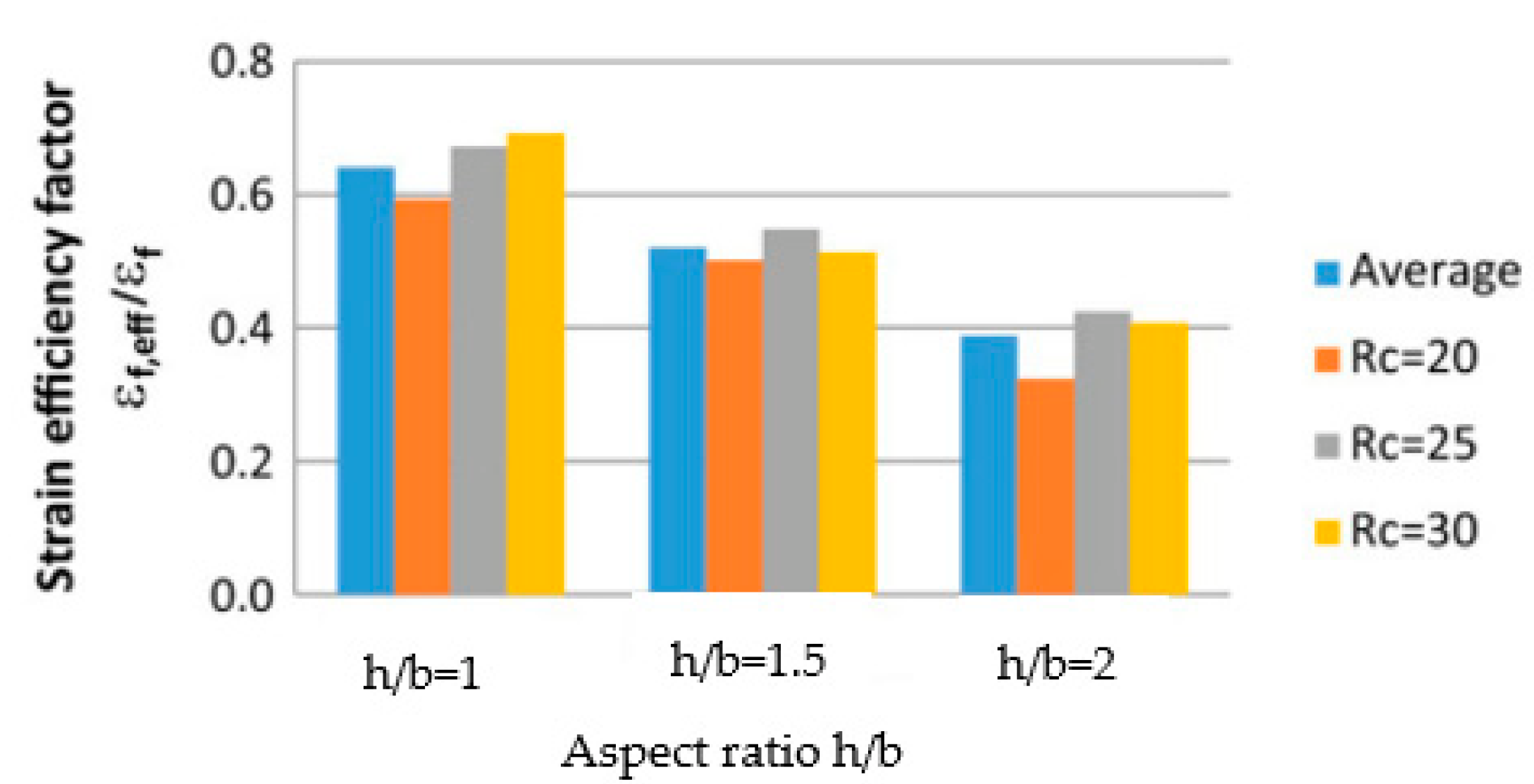

3.3.2. Mechanical Properties Using the EBROG Method

3.3.3. NSM Method

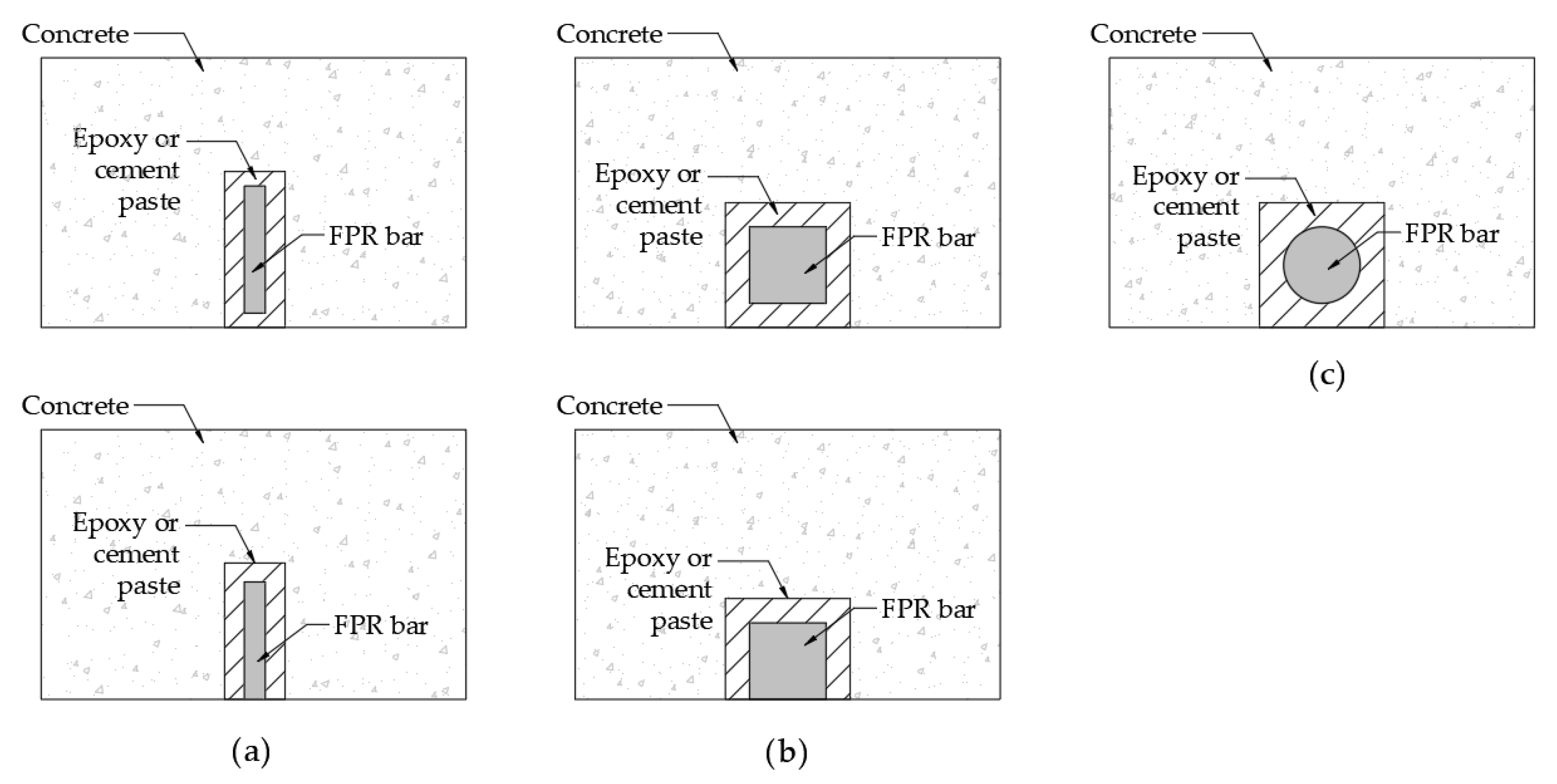

3.3.4. Scanning Electron Microscopy (SEM) Images and X-ray Diffraction Pattern Results

3.4. FRPs in Civil Infrastructure Systems

4. Future Development

5. Conclusions

- Fibers Used in FRPs

- 1.

- The large number of fibers used for structural reinforcement has enabled various cost–benefit solutions, as well as different responses to several objectives, to be obtained. AFRPs have demonstrated better resistance to marine environments than GFRP or BFRP, which have shown better cost–benefits, and CFRP has the best mechanical properties of all currently available fibers; however, it has a higher carbon emission factor than the others. A solution to the problem of environmental damage from manufacturing synthetic fibers could be the use of NFRP. Although they do not exhibit the same improvements as synthetic fibers, using mixed fibers is an alternative to achieve mechanical requirements in reinforced concrete structures.

- 2.

- For repairing/reinforcement structures, CFRP is the most common and effective material because it has a higher tensile strength and modulus of elasticity than other fibers. In addition, some studies have found that CFRP is more resistant to harsh environments than other materials.

- 3.

- Under SEM analysis, the impact of the fiber orientation on the composite properties was assessed using various hand lay-up techniques. Composites with the desired fiber alignment displayed superior mechanical performance compared to those with a random fiber orientation. Moreover, a unidirectional fiber alignment resulted in the highest tensile and flexural strengths.

- Improvement in the Mechanical Properties

- 4.

- Many investigations aimed at studying the mechanical properties affirmed that FRPs have a high modulus of elasticity, high tensile strength, good fatigue resistance, high dimensional stability, low coefficient of thermal expansion, and low abrasion. Most investigations concluded that the flexural and shear capacities could improve by 20–80% and 14–20%, respectively. These percentages could increase with a better configuration of FRP as a U-jacket or by including anchors, which could enhance the epoxy properties and the quality of the concrete surface.

- 5.

- The combination of types of FRPs according to the fiber, such as GFRP-CFRP or AFRP-GFRP, could increase the flexural capacity of a structural element by more than 100% and could enhance the load capacity, consequently increasing the elastic modulus between 10% and 14%.

- Different Types of Installation

- 6.

- The EBR method has five failure modes: (i) FRP rupture, (ii) adhesive failure, (iii) debonding of the adhesive FRP, (iv) debonding of the adhesive concrete, and (v) concrete substrate failure. The main issue with the EBR method is the debonding failure before the ultimate load. Many studies have concluded that anchoring the slips/sheet of FRP applied in the EBR method improves the failure mode and increases the flexure and shear strength. However, the NMS method could be considered as the best and safest method, in terms of failure, and constructors prefer EBR due to the easiness of the install.

- 7.

- The FRP jacket can change the mode of failure from brittle shear failure to bending shear failure and can also enhance the ductility capacity of columns; consequently, this novel method can reduce the effects of seismic loads. Similarly, FRPs improve the mechanical properties of damaged structural elements for corrosion, wet–dry cycles, fire, and chemical substances.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, Q.Q.; Zhao, Y.Z.; Wu, H.; Wang, Z.; Zhu, Z.Y. Experimental study on AFRP-to-concrete bond behavior subjected to underground water. Compos. Struct. 2023, 306, 116565. [Google Scholar] [CrossRef]

- Ramadan, A.S.; Elgendi, E.O. A review of optimization techniques and algorithms used for FRP applications in civil engineering. J. Eng. Appl. Sci. 2023, 70, 61. [Google Scholar] [CrossRef]

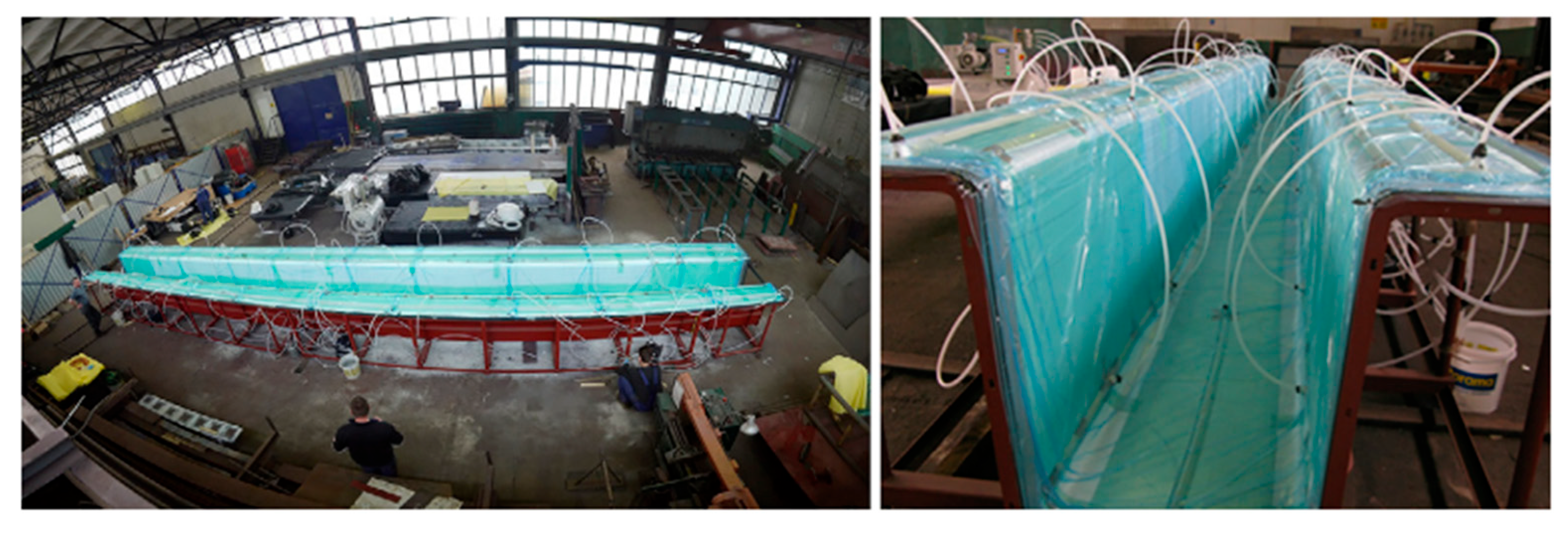

- Siwowski, T.; Kulpa, M.; Rajchel, M.; Poneta, P. Design, manufacturing and structural testing of all-composite FRP bridge girder. Compos. Struct. 2018, 206, 814–827. [Google Scholar] [CrossRef]

- Van, L.; Einde, D.; Zhao, L.; Seible, F. Use of FRP composites in civil structural applications. Constr. Build. Mater. 2003, 17, 389–403. [Google Scholar] [CrossRef]

- Kavitha, S.S.; Joseph, L.; Madhavan, M.K.; Jayanarayanan, K. Comparative study of carbon and glass fiber reinforced polymer composites for the confinement of concrete columns. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J.A. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Ramezani, M.; Kim, Y.H.; Sun, Z. Mechanical properties of carbon-nanotube-reinforced cementitious materials: Database and statistical analysis. Mag. Concr. Res. 2020, 72, 1047–1071. [Google Scholar] [CrossRef]

- Cosenza, E.; Iervolino, I. Case Study: Seismic Retrofitting of a Medieval Bell Tower with FRP. J. Compos. Constr. 2007, 11, 319–327. [Google Scholar] [CrossRef]

- Sivaraja, S.S.; Thandavamoorthy, T.S.; Vijayakumar, S.; Aranganathan, S.M.; Dasarathy, A.K. Preservation of historical monumental structures using fibre reinforced polymer (FRP)—Case studies. Procedia Eng. 2013, 54, 472–479. [Google Scholar] [CrossRef]

- Ramezani, M. Performance of composite connections strengthened with CFRP laminate. Mag. Civ. Eng. 2021, 106, 10614. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Y.; Yu, J.; Yu, J.; Tan, H.; Sui, L.; Zhou, Y. Eco-friendly and mechanically reliable alternative to synthetic FRP in externally bonded strengthening of RC beams: Natural FRP. Compos. Struct. 2020, 241, 112081. [Google Scholar] [CrossRef]

- Navaratnam, S.; Selvaranjan, K.; Jayasooriya, D.; Rajeev, P.; Sanjayan, J. Applications of natural and synthetic fiber reinforced polymer in infrastructure: A suitability assessment. J. Build. Eng. 2023, 66, 105835. [Google Scholar] [CrossRef]

- Bouzid, H.; Rabia, B.; Daouadji, T.H. Ultimate behavior of RC beams strengthened in flexure using FRP material. Eng. Struct. 2023, 289, 116300. [Google Scholar] [CrossRef]

- Mhanna, H.H.; Hawileh, R.A.; Abdalla, J.A. Comparative analysis of design guidelines for FRP contribution to shear capacity of strengthened RC beams. Procedia Struct. Integr. 2022, 37, 359–366. [Google Scholar] [CrossRef]

- Saribiyik, A.; Al-dhabir, W.; Akbalik, H.H. Experimental and FE studies on the bonding performance of basalt FRP bonded to notched concrete beams and improving with anchorage. Eng. Sci. Technol. Int. J. 2023, 46, 101507. [Google Scholar] [CrossRef]

- Zou, X.; Feng, Y.; Zhong, R.; Fang, T.; Wang, J. An experimental study of FRP truss side plate joint. Constr. Build. Mater. 2023, 365, 130012. [Google Scholar] [CrossRef]

- Chen, G.M.; Fu, M.Q.; Zhang, J.J.; Lin, G.; Chen, J.P.; Jiang, T. FRP spiral strip-confined concrete columns: Stress-strain behavior and size effect. Structures 2023, 57, 105223. [Google Scholar] [CrossRef]

- Liao, J.; Lin, X.C.; Zhu, D.H.; Zheng, Y.; Zeng, J.J.; Ma, C.L.; Zhao, H.C. Behavior of FRP grid-reinforced ultra-high performance concrete (UHPC) pipes under lateral compression. Case Stud. Constr. Mater. 2023, 19, e02189. [Google Scholar] [CrossRef]

- Yuan, F.; Song, J.; Wu, Y. Effect of compression casting method on the axial compressive behavior of FRP-confined seawater sea-sand concrete columns. Eng. Struct. 2023, 290, 116311. [Google Scholar] [CrossRef]

- Koushfar, K.; Rahman, A.B.; Hosseini, S.J.; Kim, S.H.; Soufia, L.; Ahmad, Y.; Kang, S.M.; Zhou, Y.; Lee, J.M.; Hwang, H.J. Behavior of grouted splice sleeve connection using FRP sheet. Eng. Struct. 2023, 296, 116898. [Google Scholar] [CrossRef]

- de Diego, A.; Martínez, S.; Castro, V.J.; Echevarría, L.; Barroso, F.J.; Gutiérrez, J.P. Experimental investigation on the compressive behaviour of FRP-confined rectangular concrete columns. Arch. Civ. Mech. Eng. 2022, 131, 116285. [Google Scholar] [CrossRef]

- Kalyani, G.; Pannirselvam, N. Experimental and numerical investigations on RC beams flexurally strengthened utilizing hybrid FRP sheets. Results Eng. 2023, 19, 101337. [Google Scholar] [CrossRef]

- Kalyani, V.J.; Joshi, D.D.; Patel, P.V. Study of the behaviour of FRP materials and epoxy adhesives under elevated temperature. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Wang, B.; Bachtiar, E.V.; Yan, L.; Kasal, B.; Fiore, V. Flax, basalt, E-glass FRP and their hybrid FRP strengthened wood beams: An experimental study. Polymers 2019, 11, 1255. [Google Scholar] [CrossRef]

- Halicka, A.; Ślósarz, S. Strengthening of timber beams with pretensioned CFRP strips. Structures 2021, 34, 2912–2921. [Google Scholar] [CrossRef]

- Prakash, A.; Priyadharshani, S.A.; Rao, S.V. A comparative study of concrete columns reinforced with steel and GFRP bars. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Toufigh, V.; Haghighi, S.; Kosarimovahhed, M. An experimental study on bond behavior of tensile lap spliced FRP in aggressive environments. Structures 2021, 32, 342–354. [Google Scholar] [CrossRef]

- Wang, Y.L.; Guo, X.Y.; Shu, S.Y.H.; Guo, Y.C.; Qin, X.M. Effect of salt solution wet-dry cycling on the bond behavior of FRP-concrete interface. Constr. Build. Mater. 2020, 254, 119317. [Google Scholar] [CrossRef]

- Yeboah, D.; Gkantou, M. Investigation of flexural behaviour of structural timber beams strengthened with NSM basalt and glass FRP bars. Structures 2021, 33, 390–405. [Google Scholar] [CrossRef]

- Abadel, A.; Abbas, H.; Albidah, A.; Almusallam, T.; Al-Salloum, Y. Effectiveness of GFRP strengthening of normal and high strength fiber reinforced concrete after exposure to heating and cooling. Eng. Sci. Technol. Int. J. 2022, 36, 101147. [Google Scholar] [CrossRef]

- Mahdavipour, M.A.; Eslami, A.; Jehel, P. Seismic evaluation of ordinary RC buildings retrofitted with externally bonded FRPs using a reliability-based approach. Compos. Struct. 2020, 232, 111567. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, T.; Zhang, Z.; Tan, W.; Liang, Z. Near-surface-mounted retrofitting of adobe walls using different materials: Evaluation of seismic performance. Structures 2023, 54, 1149–1163. [Google Scholar] [CrossRef]

- Zhou, C.; Cao, J.; Zhang, Z.; Zhu, Y. Effect of fiber reinforcement on bond behavior between coral aggregate concrete and GFRP bar. Constr. Build. Mater. 2023, 403, 133201. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Hashim, M.H.M.; Alyousef, R.; Mutafi, A.; Sabah, S.H.A.; Tafsirojjaman, T. Cracking behavior of sea sand RC beam bonded externally with CFRP plate. Structures 2021, 33, 1578–1589. [Google Scholar] [CrossRef]

- Liu, D.; Qin, F.; Di, J.; Zhang, Z. Flexural behavior of reinforced concrete (RC) beams strengthened with carbon fiber reinforced polymer (CFRP) and ECC. Case Stud. Constr. Mater. 2023, 19, e02270. [Google Scholar] [CrossRef]

- Shen, D.; Yang, Q.; Huang, C.; Cui, Z.; Zhang, J. Tests on seismic performance of corroded reinforced concrete shear walls repaired with basalt fiber-reinforced polymers. Constr. Build. Mater. 2019, 209, 508–521. [Google Scholar] [CrossRef]

- Li, M.; Shen, D.; Yang, Q.; Cao, X.; Liu, C.; Kang, J. Rehabilitation of seismic-damaged reinforced concrete beam-column joints with different corrosion rates using basalt fiber-reinforced polymer sheets. Compos. Struct. 2022, 289, 115397. [Google Scholar] [CrossRef]

- Gao, D.; Wei, D.; Gu, Z.; Qin, D. Compressive behavior of GFRP partially strengthened corroded RC columns subjected to freeze-thaw erosion. J. Build. Eng. 2022, 57, 104883. [Google Scholar] [CrossRef]

- del Rey Castillo, E.; Griffith, M.; Ingham, J. Seismic behavior of RC columns flexurally strengthened with FRP sheets and FRP anchors. Compos. Struct. 2018, 203, 382–395. [Google Scholar] [CrossRef]

- Gattesco, N.; Rizzi, E.; Boem, I.; Facconi, L.; Minelli, F.; Dudine, A.; Gams, M. Full-scale cyclic tests on a stone masonry building to investigate the effectiveness of a one-side application of the composite reinforced mortar system. Eng. Struct. 2023, 296, 116967. [Google Scholar] [CrossRef]

- Siha, A.; Zhou, C. Experimental study on hysteretic behavior of circular timber columns strengthened with wrapped CFRP strips and near surface mounted steel bars. Eng. Struct. 2022, 263, 114416. [Google Scholar] [CrossRef]

- Wu, M.; Yuan, F.; Guo, S.; Li, W.; Chen, G.; Zhou, Y.; Huang, Z.; Yang, X. Experimental investigation of the shear behaviour of concrete beams with CFRP strip stirrups under static and fatigue loading. Structures 2022, 41, 1602–1615. [Google Scholar] [CrossRef]

- Mei, S.J.; Bai, Y.L.; Dai, J.G.; Han, Q. Seismic behaviour of shear critical square RC columns strengthened by large rupture strain FRP. Eng. Struct. 2023, 280, 115679. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, J.; Zhang, J.; Zhang, M.; Yan, Q.; Zhao, Y.; Yang, Y.; Shao, F. Experimental study and finite element analysis on impact resistance of large-rupture-strain FRP reinforced civil air defense wall. Structures 2022, 41, 511–524. [Google Scholar] [CrossRef]

- Ma, C.; Li, K.; Gao, H.; Lu, D.; Wang, G.; Du, X. Seismic performance of underground structures improved by using PET FRP retrofitting central columns. Tunn. Undergr. Space Technol. 2023, 142, 105435. [Google Scholar] [CrossRef]

- Yazdani, N.; Aljaafreh, T.; Beneberu, E. Concrete beam flexural strengthening with anchored pre-saturated CFRP laminates. Compos. Struct. 2020, 235, 111733. [Google Scholar] [CrossRef]

- Hamrat, M.; Bouziadi, F.; Boulekbache, B.; Daouadji, T.H.; Chergui, S.; Labed, A.; Amziane, S. Experimental and numerical investigation on the deflection behavior of pre-cracked and repaired reinforced concrete beams with fiber-reinforced polymer. Constr. Build. Mater. 2020, 249, 118745. [Google Scholar] [CrossRef]

- Dong, K.; Gao, Y.; Yang, S.; Yang, Z.; Jiang, J. Experimental investigation and analytical prediction on bond behaviour of CFRP-to-concrete interface with FRP anchors. Case Stud. Constr. Mater. 2023, 19, e02510. [Google Scholar] [CrossRef]

- Berardi, V.P. Fracture failure modes in fiber-reinforced polymer systems used for strengthening existing structures. Appl. Sci. 2021, 11, 6344. [Google Scholar] [CrossRef]

- Cruz, R.; Correia, L.; Cabral-Fonseca, S.; Sena-Cruz, J. Durability of bond of EBR CFRP laminates to concrete under real-time field exposure and laboratory accelerated ageing. Constr. Build. Mater. 2023, 377, 131047. [Google Scholar] [CrossRef]

- Xue, Y.J.; Wang, W.W.; Tian, J.; Wu, Z.H. Experimental study and analysis of RC beams shear strengthened with FRP/SMA composites. Structures 2023, 55, 1936–1948. [Google Scholar] [CrossRef]

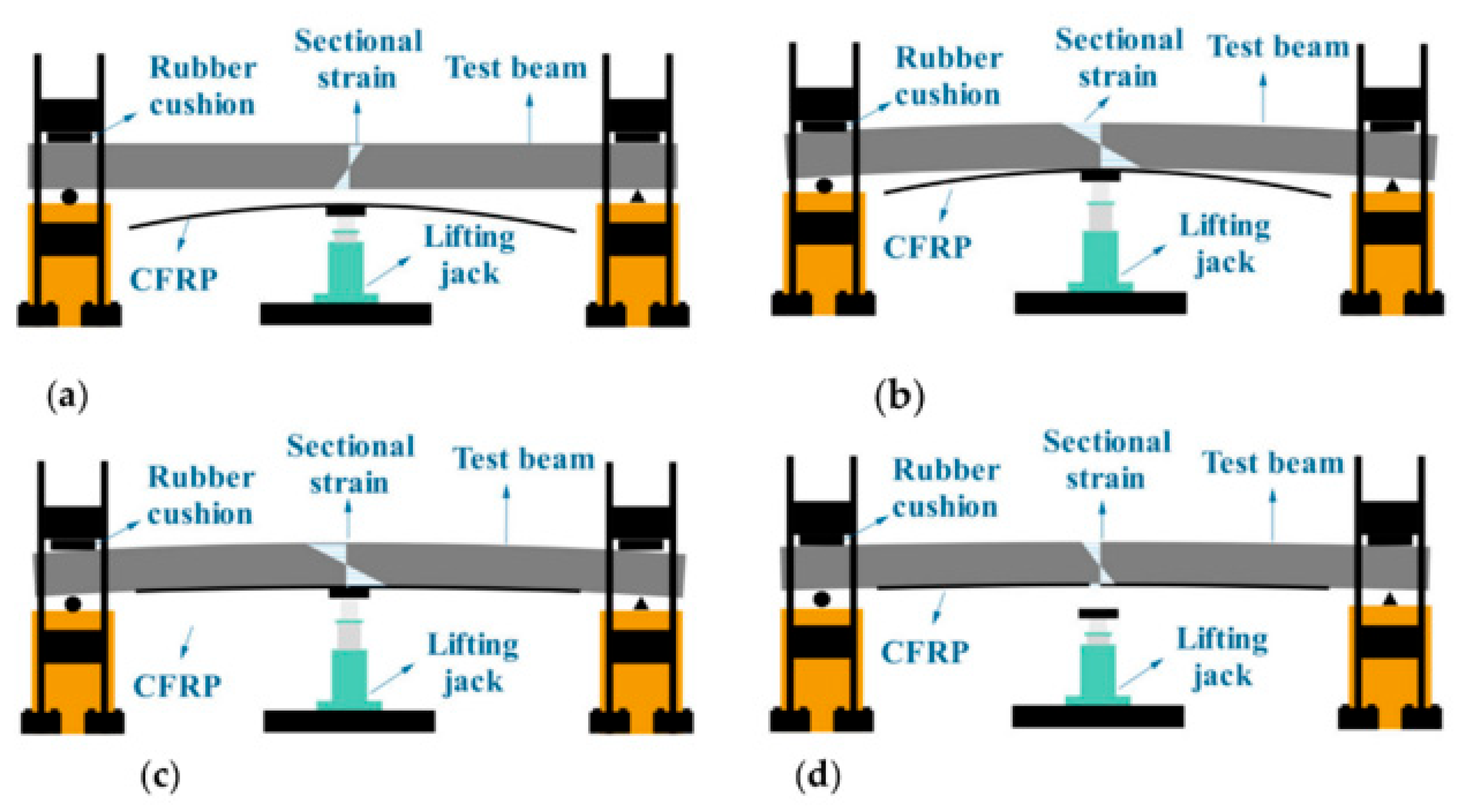

- Yu, T.; Sun, Q.; Li, C.; Liu, Y. Experimental research on the flexural performance of rc rectangular beams strengthened by reverse-arch method. Symmetry 2021, 13, 1666. [Google Scholar] [CrossRef]

- Bouyahyaoui, A.; Elmalyh, S.; Cherradi, T. Behaviour of masonry walls reinforced by fiber reinforced polymers. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Moghaddas, A.; Mostofinejad, D.; Saljoughian, A.; Ilia, E. An empirical FRP-concrete bond-slip model for externally-bonded reinforcement on grooves. Constr. Build. Mater. 2021, 281, 122575. [Google Scholar] [CrossRef]

- Moshiri, N.; Czaderski, C.; Mostofinejad, D.; Hosseini, A.; Sanginabadi, K.; Breveglieri, M.; Motavalli, M. Flexural strengthening of RC slabs with nonprestressed and prestressed CFRP strips using EBROG method. Compos. B Eng. 2020, 201, 108359. [Google Scholar] [CrossRef]

- Zolfaghari, S.; Mostofinejad, D.; Fantuzzi, N.; Luciano, R.; Fabbrocino, F. Experimental evaluation of FRP-concrete bond using externally-bonded reinforcement on grooves (EBROG) method. Compos. Struct. 2023, 310, 116693. [Google Scholar] [CrossRef]

- Qiu, Q.; Lau, D. Defect detection of FRP-bonded civil structures under vehicle-induced airborne noise. Mech. Syst. Signal Process. 2021, 146, 106992. [Google Scholar] [CrossRef]

- Ghaleh, R.Z.; Mostofinejad, D. Behaviour of EBRIG CFRP sheet-concrete joint: Comparative assessment with EBR and EBROG methods. Constr. Build. Mater. 2022, 346, 128374. [Google Scholar] [CrossRef]

- Gong, W.; Li, X.; Ge, Z.; Liu, H.; Lin, Z.; Liu, X.; Yang, G. Steel-concrete composite beams strengthened with NSM CFRP systems at the hogging-moment regions. Eng. Struct. 2023, 292, 116576. [Google Scholar] [CrossRef]

- Barris, C.; Sala, P.; Gómez, J.; Torres, L. Flexural behaviour of FRP reinforced concrete beams strengthened with NSM CFRP strips. Compos. Struct. 2020, 241, 112059. [Google Scholar] [CrossRef]

- Gao, J.; Xu, P.; Fan, L.; Terrasi, G.P. Study on Bond-Slip Behavior between Seawater Sea-Sand Concrete and Carbon Fiber-Reinforced Polymer (CFRP) Bars with Different Surface Shapes. Polymers 2022, 14, 2689. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, G.; Li, L.; Guan, Z.; Guo, M.; Yang, L.; Li, Z. Experimental Investigations on Bond Behavior between FRP Bars and Advanced Sustainable Concrete. Polymers 2022, 14, 1132. [Google Scholar] [CrossRef]

- Diab, H.M.; Sayed, A.M. An Anchorage Technique for Shear Strengthening of RC T-Beams Using NSM-BFRP Bars and BFRP Sheet. Int. J. Concr. Struct. Mater. 2020, 14, 49. [Google Scholar] [CrossRef]

- Ramezani, M. Design and Predicting Performance of Carbon Nanotube Reinforced Cementitious Materials: Mechanical Properties and Dipersion Characteristics. Ph.D. Thesis, University of Louisville, Louisville, KY, USA, 2019. [Google Scholar] [CrossRef]

- Adekomaya, O.; Adediran, A.A.; Adama, K. Characterization and morphological properties of glass fiber reinforced epoxy composites fabricated under varying degrees of hand lay-up techniques. J. Appl. Sci. Environ. Manag. 2018, 22, 110–114. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, Z.; Song, S.; Bai, Y.; Wu, D. Tensile and flexural behaviors of additively manufactured continuous carbon fiber-reinforced polymer composites. Compos. Struct. 2019, 225, 111147. [Google Scholar] [CrossRef]

- Pan, Y.; Yan, D. Study on the durability of GFRP bars and carbon/glass hybrid fiber reinforced polymer (HFRP) bars aged in alkaline solution. Compos. Struct. 2021, 261, 113285. [Google Scholar] [CrossRef]

| Parameter of Selection | Description |

|---|---|

| Publication year | Between 2019 and 2023. |

| Proposal of investigation | The aim of the investigation must be to quantify a scale and compare it with a specimen “cero” or base. |

| Method of obtaining the results | The methodology must be described on paper, and the specimens that were evaluated must be tested under a certificate test with calibrated equipment. |

| Author | Structural Element Tested | Type of FRP Used | Results Compared to a Control Element | Results Compared to Other Fibers |

|---|---|---|---|---|

| Wang et al. [28] | FRP–concrete surface | CFRP | Under WDC 0–360 days Debonding loads ↓ (less) 29.3% Bond shear stress ↓ 15.5% | Elastic modules = 231 GPa Tensile strength = 4132 MPa |

| BFRP | Debonding loads ↓ 38.3% Bond shear stress ↓ 39.7%; T = 4132 | Elastic modules = 91 GPa Tensile strength = 210 MPa | ||

| Yu et al. [1] | FRP–concrete surface | AFRP | Under WDC 0–300 days Bond shear stress ↓ 14.8–20% Bonding resistance ↓ 22.6–34.2% | - |

| Toufigh et al. [27] | Tensile lap | BFRP | Under acidic environments Bond strength ↓ 18% | - |

| CFRP | Bond strength ↓ <10% | |||

| AFRP | Bond strength ↓ <10% | |||

| Sreekumar Kavitha et al. [5] | Concrete columns | CFRP | Axial load carrying capacity ↑ 57% | - |

| GFRP | Axial load carrying capacity ↑ 23% | |||

| Shi et al. [44] | RC columns | LRS FRP (PET FRP) | Under high axial load Ductility coefficient ↑ (more) 190–310.1% Cumulative energy dissipation ↑ 2342.6–5660.4% | Under low axial load Ductility coefficient ↑ 300% compared to CFRP Cumulative energy dissipation ↑ 1962.8% compared to CFRP |

| Kalyani et al. [23] | RC beams | CFRP-GFRP (hybrid FRP) | Strength ↑ 81% Flexural capacity ↑ 102.63–202.63% | - |

| Groove Depth (mm) | Effective Groove Width (mm) |

|---|---|

| 2.5 | 5 |

| 5 | 10 |

| 10 | 5 |

| 15 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albuja-Sánchez, J.; Damián-Chalán, A.; Escobar, D. Experimental Studies and Application of Fiber-Reinforced Polymers (FRPs) in Civil Infrastructure Systems: A State-of-the-Art Review. Polymers 2024, 16, 250. https://doi.org/10.3390/polym16020250

Albuja-Sánchez J, Damián-Chalán A, Escobar D. Experimental Studies and Application of Fiber-Reinforced Polymers (FRPs) in Civil Infrastructure Systems: A State-of-the-Art Review. Polymers. 2024; 16(2):250. https://doi.org/10.3390/polym16020250

Chicago/Turabian StyleAlbuja-Sánchez, Jorge, Andreina Damián-Chalán, and Daniela Escobar. 2024. "Experimental Studies and Application of Fiber-Reinforced Polymers (FRPs) in Civil Infrastructure Systems: A State-of-the-Art Review" Polymers 16, no. 2: 250. https://doi.org/10.3390/polym16020250

APA StyleAlbuja-Sánchez, J., Damián-Chalán, A., & Escobar, D. (2024). Experimental Studies and Application of Fiber-Reinforced Polymers (FRPs) in Civil Infrastructure Systems: A State-of-the-Art Review. Polymers, 16(2), 250. https://doi.org/10.3390/polym16020250