Improving the Physical and Mechanical Properties of Mycelium-Based Green Composites Using Paper Waste

Abstract

1. Introduction

2. Materials and Methods

2.1. Source of Substrate and Preparation Processes

2.2. Sources of Mushroom Mycelia and Culture Conditions

2.3. Mold Designs and Mycelium-Based Green Composite Production

2.3.1. Mold Preparation and Sterilization

2.3.2. Inoculum Preparation

2.3.3. Preparation of the Substrate for Mycelial Growing

2.3.4. Green Composite Molding

2.4. Determination of Physical Properties

2.4.1. Density

2.4.2. Shrinkage

2.4.3. Water Absorption and Volumetric Swelling

2.5. Determination of Mechanical Properties

2.5.1. Compression Strength

2.5.2. Flexural Strength

2.5.3. Impact Strength

2.5.4. Tensile Strength

2.6. Statistical Analysis

3. Results and Discussion

3.1. Determination of Physical Properties

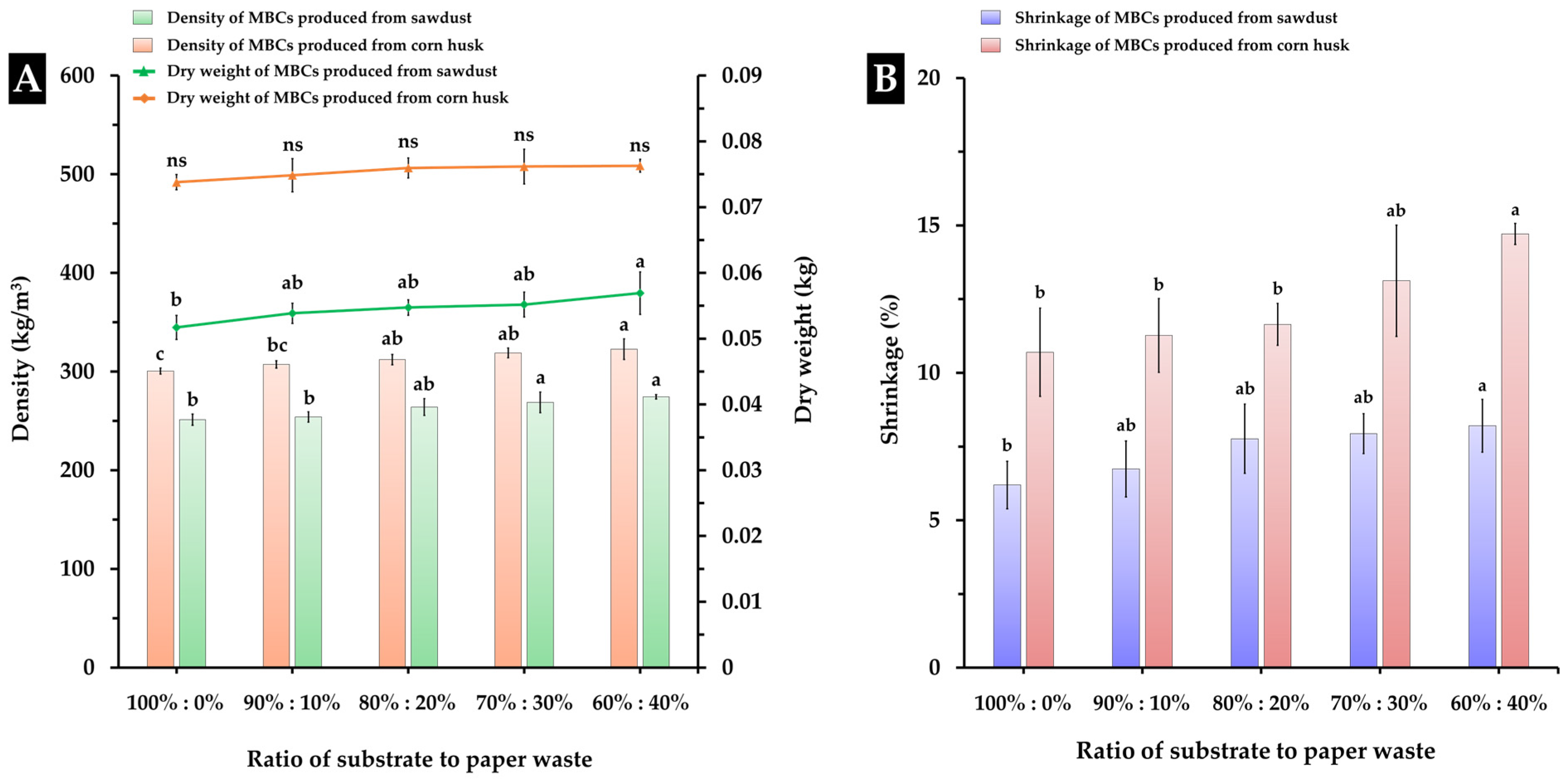

3.1.1. Density

3.1.2. Shrinkage

3.1.3. Water Absorption and Volumetric Swelling

3.2. Determination of Mechanical Properties

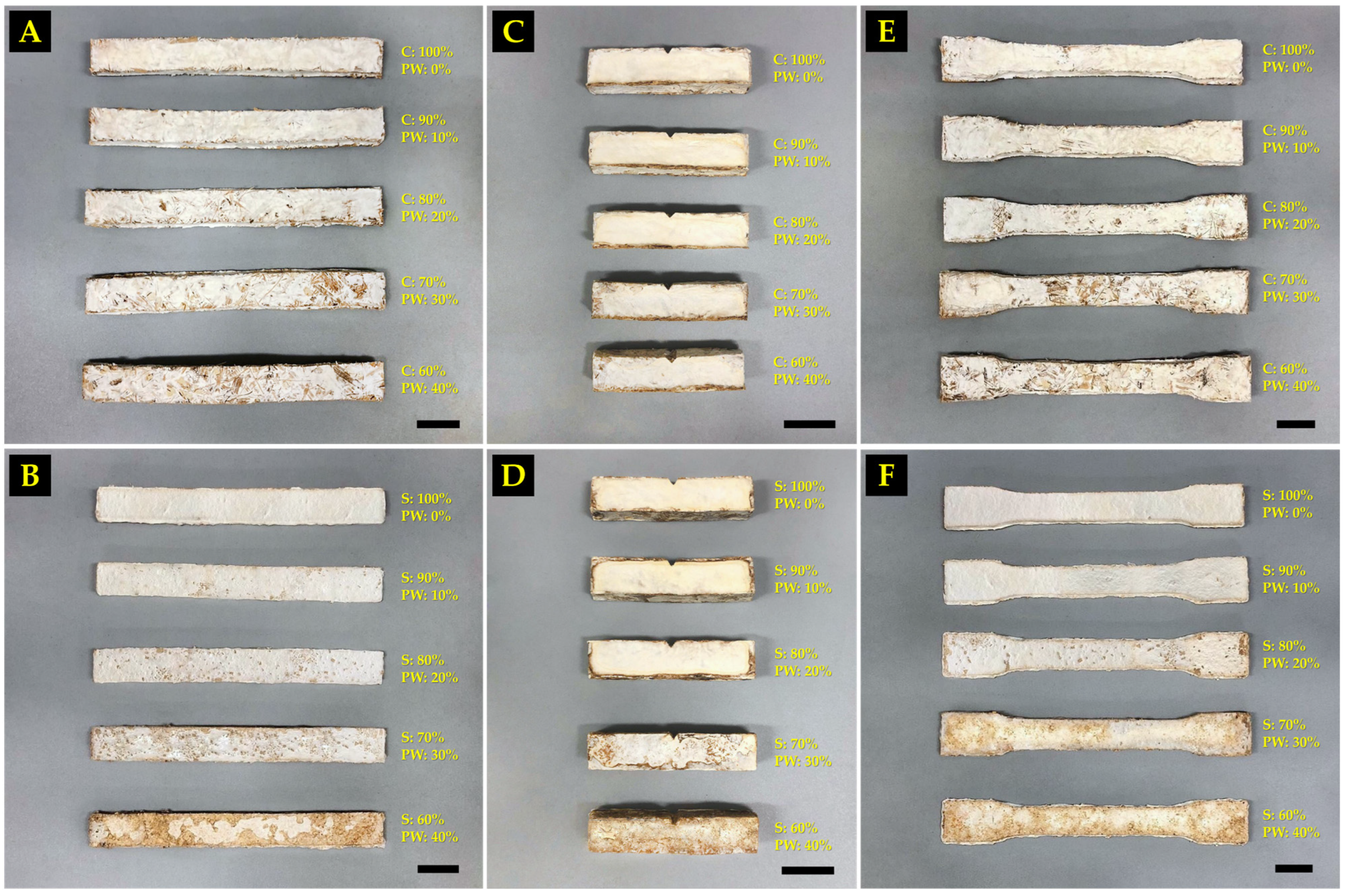

3.2.1. Compression Strength

3.2.2. Flexural Strength

3.2.3. Impact Strength

3.2.4. Tensile Strength

3.3. Challenges and Future Perspectives

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Acharjee, S.A.; Bharali, P.; Gogoi, B.; Sorhie, V.; Walling, B. Alemtoshi PHA-Based bioplastic: A potential alternative to address microplastic pollution. Water Air Soil Pollut. 2023, 234, 21. [Google Scholar] [CrossRef] [PubMed]

- Balaeș, T.; Radu, B.-M.; Tănase, C. Mycelium-composite materials—A promising alternative to plastics? J. Fungi 2023, 9, 210. [Google Scholar] [CrossRef] [PubMed]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Atta, O.M.; Yang, G. Synthesis and applications of fungal mycelium-based advanced functional materials. J. Bioresour. Bioprod. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Alemu, D.; Tafesse, M.; Mondal, A.K. Mycelium-based composite: The future sustainable biomaterial. Int. J. Biomater. 2020, 2022, 8401528. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Park, D.; Qin, Z. Material function of mycelium-based bio-composite: A review. Front. Mater. 2021, 8, 737377. [Google Scholar] [CrossRef]

- Houette, T.; Maurer, C.; Niewiarowski, R.; Gruber, P. Growth and mechanical characterization of mycelium-based composites towards future bioremediation and food production in the material manufacturing cycle. Biomimetics 2022, 7, 103. [Google Scholar] [CrossRef] [PubMed]

- Javadian, A.; Le Ferrand, H.; Hebel, D.E.; Saeidi, N. Application of mycelium-bound composite materials in construction industry: A short review. SOJ Mater. Sci. Eng. 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Aiduang, W.; Chanthaluck, A.; Kumla, J.; Jatuwong, K.; Srinuanpan, S.; Waroonkun, T.; Oranratmanee, R.; Lumyong, S.; Suwannarach, N. Amazing Fungi for Eco-Friendly Composite Materials: A Comprehensive Review. J. Fungi 2022, 8, 842. [Google Scholar] [CrossRef]

- Kumar, S.S.; Kumaran, T.S.; Velmurugan, G.; Perumal, A.; Sekar, S.; Uthayakumar, M. Physical and mechanical properties of various metal matrix composites: A review. Mater. Today Proc. 2022, 50, 1022–1031. [Google Scholar] [CrossRef]

- Ghazvinian, A.; Farrokhsiar, P.; Vieira, F.; Pecchia, J.; Gursoy, B. Mycelium-based bio-composites for architecture: Assessing the effects of cultivation factors on compressive strength. Mater. Res. Innov. 2019, 2, 505–514. [Google Scholar]

- Yang, L.; Qin, Z. Mycelium-based wood composites for light weight and high strength by experiment and machine learning. Cell Rep. Phys. Sci. 2023, 4, 1–17. [Google Scholar] [CrossRef]

- Ghazvinian, A. A sustainable alternative to architectural materials: Mycelium-based bio-composites. In Proceedings of the Conference Divergence in Architectural Research, Atlanta, GA, USA, 5–6 March 2021; pp. 159–167. [Google Scholar]

- Andersson, F. Mycelium: Growing Materials Experience: A Study on Improving the Appearance of Mycelium-Composites through a Material Driven Design Process. Bachelor’s Thesis, Malmö University, Malmö, Sweden, 11 October 2022. [Google Scholar]

- Li, K.; Jia, J.; Wu, N.; Xu, Q. Recent advances in the construction of biocomposites based on fungal mycelia. Front. Bioeng. Biotechnol. 2022, 10, 1067869. [Google Scholar] [CrossRef]

- Sydor, M.; Cofta, G.; Doczekalska, B.; Bonenberg, A. Fungi in mycelium-based composites: Usage and recommendations. Materials 2022, 15, 6283. [Google Scholar] [CrossRef] [PubMed]

- Rathinamoorthy, R.; Bharathi, T.S.; Snehaa, M.; Swetha, C. Mycelium as sustainable textile material—Review on recent research and future prospective. Int. J. Cloth. Sci. Technol. 2023, 35, 454–476. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Gou, L.; Li, S.; Yin, J.; Li, T.; Liu, X. Morphological and physico-mechanical properties of mycelium biocomposites with natural reinforcement particles. Constr. Build. Mater. 2021, 304, 124656. [Google Scholar] [CrossRef]

- Gou, L.; Li, S. Dynamic shear modulus and damping of lightweight sand-mycelium soil. Acta Geotech. 2023, 1–15. [Google Scholar] [CrossRef]

- Elsacker, E.; De Laet, L.; Peeters, E. Functional grading of mycelium materials with inorganic particles: The effect of nanoclay on the biological, chemical and mechanical properties. Biomimetics 2022, 7, 57. [Google Scholar] [CrossRef]

- Lim, A.; Henzi, P.; Arvin, O. Comparison of Pleurotus ostreatus and Phizopus oligosporus fungi for loose sand improvement. J. GeoEngin. 2023, 18, 1–10. [Google Scholar]

- Irfan, T.M.; George, T.S.; Abidh, K.S.; Prakash, S.; Kanoth, B.P.; George, N.; Balachandrakurup, V.; Dominic, C.M.; Nair, A.B. Waste paper as a viable sustainable source for cellulosic extraction by chlorine free bleaching and acid hydrolysis method for the production of PVA-starch/cellulose based biocomposites. Mater. Today Proc. 2023, 1–17. [Google Scholar] [CrossRef]

- Liu, M.; Tong, S.; Tong, Z.; Guan, Y.; Sun, Y.A. Strong, biodegradable and transparent cellulose-based bioplastic stemmed from waste paper. J. Appl. Polym. Sci. 2023, 140, e53671. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent re-search. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Stănescu, M.M.; Bolcu, D. A study of some mechanical properties of composite materials with a Dammar-based hybrid matrix and reinforced by waste paper. Polymers 2020, 12, 1688. [Google Scholar] [CrossRef]

- Solahuddin, B.A.; Yahaya, F.M. Inclusion of waste paper on concrete properties: A review. Civ. Eng. J. 2022, 7, 94–113. [Google Scholar] [CrossRef]

- De Oliveira, D.M.; de Bomfim, A.S.C.; Benini, K.C.C.d.C.; Cioffi, M.O.H.; Voorwald, H.J.C.; Rodrigue, D. Waste Paper as a Valuable Resource: An Overview of Recent Trends in the Polymeric Composites Field. Polymers 2023, 15, 426. [Google Scholar] [CrossRef] [PubMed]

- Aiduang, W.; Kumla, J.; Srinuanpan, S.; Thamjaree, W.; Lumyong, S.; Suwannarach, N. Mechanical, physical, and chemical properties of mycelium-based composites produced from various lignocellulosic residues and fungal species. J. Fungi 2022, 8, 1125. [Google Scholar] [CrossRef] [PubMed]

- Sabry, A.A.; Salih, N.A. Physical Characteristics for Biocomposite Material Using to Jawbones Compensation. J. Phys. Conf. Ser. 2021, 1879, 032057. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTMD256; Standard Test Method for Determining the Izod Pendulum Impact Resistence of Plastics. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D638-14:2014; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D570-98; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, physical and chemical characterisation of mycelium-based composites with different types of lignocellulosic substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef]

- McGowan, M.J.; Shimoda, L.M.; Woolsey, G.D. Effects of sodium hypochlorite on denture base metals during immersion for short-term sterilization. J. Prosthet. Dent. 1988, 60, 212–218. [Google Scholar] [CrossRef]

- Kupradi, C.; Khongla, C.; Musika, S.; Ranok, A.; Tamaruay, K.; Woraratphoka, J.; Mangkalanan, S. Cultivation of Lentinus squarrosulus and Pleurotus ostreatus on cassava bagasse based substrates. Int. J. Agric. Technol. 2017, 13, 883–892. [Google Scholar]

- ISO 9427:2003; Wood-Based Panels Determination of Density. International Organization for Standardization: Geneva, Switzerland, 2003.

- Zimele, Z.; Irbe, I.; Grinins, J.; Bikovens, O.; Verovkins, A.; Bajare, D. Novel mycelium-based biocomposites (MBB) as building materials. J. Renew. Mater. 2020, 8, 1067–1076. [Google Scholar] [CrossRef]

- ASTM D3501-05; Standard Test Methods for Wood-Based Structural Panels in Compression. ASTM International: West Conshohocken, PA, USA, 2005.

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wosten, H.A.B. Fabrication factors influencing mechanical, moisture and water related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Zweben, C.H.; Beaumont, P.W.; Gdutos, E.; Talreja, R.; Poursartip, A.; Clyne, T.W.; Ruggles-Wrenn, M.B.; Peijs, T.; Thostenson, E.T.; Crane, R.; et al. Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; Volume 6. [Google Scholar]

- Bhatia, S.; Angra, S.; Khan, S. Mechanical and wear properties of epoxy matrix composite reinforced with varying ratios of solid glass microspheres. J. Phys. Conf. Ser. 2019, 1240, 012080. [Google Scholar] [CrossRef]

- Tacer-Caba, Z.; Varis, J.J.; Lankinen, P.; Mikkonen, K.S. Comparison of novel fungal mycelia strains and sustainable growth substrates to produce humidity-resistant biocomposites. Mater. Des. 2020, 192, 108728. [Google Scholar] [CrossRef]

- Kar, K.K. Handbook of Fly Ash; Butterworth-Heinemann: Oxford, UK, 2021; pp. 1–868. [Google Scholar]

- Martijanti, M.; Sutarno, S.; Juwono, A.L. Polymer composite fabrication reinforced with bamboo fiber for particle board product raw material application. Polymers 2021, 13, 4377. [Google Scholar] [CrossRef] [PubMed]

- Butu, A.; Rodino, S.; Miu, B.; Butu, M. Mycelium-based materials for the ecodesign of bioeconomy. Dig. J. Nanomater. Biostruct. 2020, 15, 1129–1140. [Google Scholar] [CrossRef]

- Bozkurt, F.; Avci, B.; Mengeloğlu, F. Utilization of melamine impregnated paper waste as a filler in thermoplastic composites. Bioresources 2021, 16, 3159. [Google Scholar] [CrossRef]

- Chan, X.Y.; Saeidi, N.; Javadian, A.; Hebel, D.E.; Gupta, M. Mechanical properties of dense mycelium-bound composites under accelerated tropical weathering conditions. Sci. Rep. 2021, 11, 22112. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Odusote, J.K.; Onowuma, S.A.; Fodeke, E.A. Production of paperboard briquette using waste paper and sawdust. J. Eng. Res. 2016, 15, 80–88. [Google Scholar] [CrossRef]

- Aryal, G.M.; Kandel, K.P.; Bhattarai, R.K.; Giri, B.; Adhikari, M.; Ware, A.; Han, S.; George, G.; Luo, Z.; Gautam, B.R.; et al. Material Properties of Traditional Handmade Paper Samples Fabricated from Cellulosic Fiber of Lokta Bushes. ACS Omega 2022, 7, 32717–32726. [Google Scholar] [CrossRef]

- Łątka, J.F.; Jasiołek, A.; Karolak, A.; Niewiadomski, P.; Noszczyk, P.; Klimek, A.; Zielińska, S.; Misiurka, S.; Jezierska, D. Properties of paper-based products as a building material in architecture—An interdisciplinary review. J. Build. Eng. 2022, 50, 104135. [Google Scholar] [CrossRef]

- Felba, J. Thermally conductive adhesives in electronics. In Advanced Adhesives in Electronics; Alam, M.O., Bailey, C., Eds.; Woodhead Publishing: Sawston, CA, USA, 2011; pp. 15–52. [Google Scholar]

- Beushausen, H.; Chilwesa, M. Assessment and prediction of drying shrinkage cracking in bonded mortar overlays. Cem. Concr. Res. 2013, 53, 256–266. [Google Scholar] [CrossRef]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: Evaluation study of select blends of cotton byproducts. J. Biobased Mater. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Tran, N.P.; Gunasekara, C.; Law, D.W.; Houshyar, S.; Setunge, S.; Cwirzen, A. A critical review on drying shrinkage mitigation strategies in cement-based materials. J. Build. Eng. 2021, 38, 102210. [Google Scholar] [CrossRef]

- Praburaj, T.; Paul, M.; Murty, C.N.; Rao, G.V. Dimensional stability-factors for consideration with special reference to bagasse paper making. IPPTA 2003, 15, 127–132. [Google Scholar]

- Larsson, P.A. Dimensional stability of paper: Influence of Fibre-Fibre Joints and Fibre Wall Oxidation. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2008. [Google Scholar]

- Kuribayashi, T.; Lankinen, P.; Hietala, S.; Mikkonen, K.S. Dense and continuous networks of aerial hyphae improve flexi-bility and shape retention of mycelium composite in the wet state. Compos. Part A Appl. Sci. Manuf. 2022, 152, 106688. [Google Scholar] [CrossRef]

- Shakir, M.A.; Azahari, B.; Yusup, Y.; Yhaya, M.F.; Salehabadi, A.; Ahmad, M.I. Preparation and characterization of mycelium as a bio-matrix in fabrication of bio-composite. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 65, 253–263. [Google Scholar]

- Haneef, M.; Ceseracciu, L.; Canale, C.; Bayer, I.S.; Heredia-Guerrero, J.A.; Athanassiou, A. Advanced Materials from Fungal Mycelium: Fabrication and Tuning of Physical Properties. Sci. Rep. 2017, 7, srep41292. [Google Scholar] [CrossRef]

- De Lima, G.G.; Schoenherr, Z.C.P.; Magalhães, W.L.E.; Tavares, L.B.B.; Helm, C.V. Enzymatic activities and analysis of a mycelium-based composite formation using peach palm (Bactris gasipaes) residues on Lentinula edodes. Bioresour. Bioprocess. 2020, 7, 1–17. [Google Scholar] [CrossRef]

- Onyekwere, O.S.; Oladeinde, M.H.; Edokpia, R.O. Optimization of parameter settings to achieve improved moisture absorption properties of Bamboo fibre composites. J. Appl. Res. Ind. 2021, 8, 213–235. [Google Scholar]

- Charpentier-Alfaro, C.; Benavides-Hernández, J.; Poggerini, M.; Crisci, A.; Mele, G.; Della Rocca, G.; Emiliani, G.; Frascella, A.; Torrigiani, T.; Palanti, S. Wood-Decaying Fungi: From Timber Degradation to Sustainable Insulating Biomaterials Production. Materials 2023, 16, 3547. [Google Scholar] [CrossRef] [PubMed]

- Solahuddin, B.A.; Yahaya, F.M. A Review Paper on The Effect of Waste Paper on Mechanical Properties of Concrete. In Proceeding of the IOP Conference Series: Materials Science and Engineering, Pekan Pahang, Malaysia, 22–23 December 2020. [Google Scholar]

- Samadam, A.; Vallepalli, R.; Kumar, K.N.; Sreekanth, M.; Goud, R.R. Mechanical properties evaluation and behaviour of cellulose-HDPE composite. Mater. Today Proc. 2022, 62, 3405–3410. [Google Scholar] [CrossRef]

- Giwa, A.S.; Ali, N.; Akhter, M.S. Cellulose Degradation Enzymes in Filamentous Fungi, A Bioprocessing Approach Towards Biorefinery. Mol. Biotechnol. 2023, 2023, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Shaaban, A.; Se, S.-M.; Mitan, N.M.M.; Dimin, M. Characterization of biochar derived from rubber wood sawdust through slow pyrolysis on surface porosities and functional groups. Procedia Eng. 2013, 68, 365–371. [Google Scholar] [CrossRef]

- Kampeerapappun, P. Extraction and characterization of cellulose nanocrystals produced by acid hydrolysis from corn husk. J. Met. Mater. Miner. 2015, 25, 1–8. [Google Scholar]

- Pattanayak, S.S.; Laskar, S.H.; Sahoo, S. Investigation of organic corn husk-based flat microwave absorber. Int. J. Microw. Wirel. Technol. 2021, 13, 779–788. [Google Scholar] [CrossRef]

- Bruscato, C.; Malvessi, E.; Brandalise, R.N.; Camassola, M. High performance of macrofungi in the production of myceli-um-based biofoams using sawdust—Sustainable technology for waste reduction. J. Clean. Prod. 2019, 234, 225–232. [Google Scholar] [CrossRef]

- Pohl, C.; Schmidt, B.; Guitar, T.N.; Klemm, S.; Gusovius, H.-J.; Platzk, S.; Kruggel-Emden, H.; Klunker, A.; Völlmecke, C.; Fleck, C.; et al. Establishment of the basidiomycete Fomes fomentarius for the production of composite materials. Fungal Biol. Biotechnol. 2022, 9, 4. [Google Scholar] [CrossRef]

- Lingam, D.; Narayan, S.; Mamun, K.; Charan, D. Engineered mycelium-based composite materials: Comprehensive study of various properties and applications. Constr. Build. Mater. 2023, 391, 131841. [Google Scholar] [CrossRef]

- Pohl, A.; Fontana, M. The mechanical and thermal properties of corrugated paper honeycomb: Part 1–Experimental investi-gation. Nord. Pulp Pap. Res. J. 2010, 25, 510–518. [Google Scholar] [CrossRef]

- Stevulova, N.; Hospodarova, V.; Junak, J. Potential utilization of recycled waste paper fibres in cement composites. Chem. Technol. 2016, 67, 30–34. [Google Scholar] [CrossRef]

- Amiandamhen, S.O.; Osadolor, S.O. Recycled waste paper–cement composite panels reinforced with kenaf fibres: Durability and mechanical properties. J. Mater. Cycles Waste Manag. 2020, 22, 1492–1500. [Google Scholar] [CrossRef]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent advances in biodegradable polymers for sustainable applications. Npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- Liu, R.; Li, X.; Long, L.; Sheng, Y.; Xu, J.; Wang, Y. Improvement of mechanical properties of mycelium/cotton stalk composites by water immersion. Compos. Interfaces 2020, 27, 953–966. [Google Scholar] [CrossRef]

- Rigobello, A.; Colmo, C.; Ayres, P. Effect of Composition strategies on mycelium-based composites flexural behaviour. Biomimetics 2022, 7, 53. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Impact resistance of fiber-reinforced concrete—A review. Cem. Concr. Compos. 2019, 104, 103389. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Sendur, P. Review of the main factors controlling the fracture toughness and impact strength properties of natural composites. Mater. Res. Express 2018, 6, 022001. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Abidin, N.M.Z.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A. Charpy and Izod impact properties of natural fibre composites. In Proceedings of the 6th International Conference on Applications and Design in Mechanical Engineering, Penang Island, Malaysia, 26–27 August 2019; p. 012031. [Google Scholar]

- Sivakumar, D.; Kathiravan, S.; Ng, L.F.; Ali, M.B.; Selamat, M.Z.; Sivaraos, S.; Bapokutty, O. Experimental investigation on charpy impact response of kenaf bast fibre reinforced metal laminate system. ARPN J. Eng. Appl. Sci. 2018, 13, 822–827. [Google Scholar]

- Kusumah, S.S.; Arinana, A.; Hadi, Y.S.; Guswenrivo, I.; Yoshimura, T.; Umemura, K.; Tanaka, S.; Kanayama, K. Utilization of sweet sorghum bagasse and citric acid in the manufacturing of particleboard. III: Influence of adding sucrose on the properties of particleboard. BioResources 2017, 12, 7498–7514. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T.; Vuorinen, T. Mechanical properties of recycled polymer composites made from side-stream materials from different industries. Sustainability 2019, 11, 6054. [Google Scholar] [CrossRef]

- Abdelhady, O.; Spyridonos, E.; Dahy, H. Bio-modules: Mycelium-based composites forming a modular interlocking system through a computational design towards sustainable architecture. Designs 2023, 7, 20. [Google Scholar] [CrossRef]

- Fricker, M.D.; Bebber, D.; Boddy, L. Mycelial networks: Structure and dynamics. In British Mycological Society Symposia Series; Boddy, L., Frankland, J.C., West, P.V., Eds.; Academic Press: Amherst, MA, USA, 2021; pp. 3–18. [Google Scholar]

- Aquino, M.; Rugolo, M.; Robledo, G.; Kuhar, F. Evaluation of mycelium composite materials produced by five Patagonian fungal species. Maderas-Cienc. Tecnol. 2022, 35, 1–14. [Google Scholar] [CrossRef]

- Jensen, M.S.; Alfieri, P.V. Design and manufacture of insulation panels based on recycled lignocellulosic waste. Clean. Eng. Technol. 2021, 3, 100111. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kuzman, M.K. Properties of Honeycomb Paperboards Faced with Heat-Treated Thin Medium-Density Fiber-boards. Bioresources 2016, 11, 7803–7810. [Google Scholar] [CrossRef]

- Hult, E.-L.; Ropponen, J.; Poppius-Levlin, K.; Ohra-Aho, T.; Tamminen, T. Enhancing the barrier properties of paper board by a novel lignin coating. Ind. Crop Prod. 2013, 50, 694–700. [Google Scholar] [CrossRef]

- Lee, M.; Lee, S.-M.; Kang, E.-C.; Son, D.-W. Combustibility and characteristics of wood-fiber insulation boards prepared with four different adhesives. BioResources 2019, 14, 6316–6330. [Google Scholar] [CrossRef]

- Bahar, A.; Hamami, A.E.A.; Benmahiddine, F.; Belhabib, S.; Belarbi, R.; Guessasma, S. The thermal and mechanical behaviour of wood-pla composites processed by additive manufacturing for building insulation. Polymers 2023, 15, 3056. [Google Scholar] [CrossRef]

| Properties | MBCs in This Study | Polystyrene Foam | Polyurethane Foam | Paper Boards | Wood Insulation Board | Wood Particle Board |

|---|---|---|---|---|---|---|

| Density (kg/m3) | 251.15 ± 5.67–322.73 ± 10.44 | 11–50 | 30–100 | 200–780 | 170–430 | 600–800 |

| Shrinkage (%) | 6.19 ± 0.81–14.71 ± 0.36 | 0.2–5 | 0.6–2 | 1–12 | 18.18–30.28 | 0.3–10 |

| Water absorption (%) | 123.46 ± 8.76–197.15 ± 10.10 | 0.03–9 | 0.01–72 | 300–350 | 55–380 | 30.1–200 |

| Volumetric swelling (%) | 4.51 ± 0.66–9.41 ± 0.36 | - | - | 5–12 | 1.89–5.25 | 15–25 |

| Compression strength (kPa) | 241.58 ± 39.19–1314.75 ± 111.45 | 30–690 | 2–48,000 | 40–10,000 | 100–1210 | 1800–3400 |

| Flexural strength (kPa) | 18.23 ± 9.25–412.09 ± 36.91 | 70–700 | 210–57,000 | 3760–4200 | 2000–2500 | 1500–7000 |

| Impact strength (kJ/m2) | 0.12 ± 0.05–3.15 ± 0.20 | 0.01–0.15 | 1.0–1.2 | 2–4 | 4.2–19 | 1–3.5 |

| Tensile strength (kPa) | 4.08 ± 0.72–38.39 ± 2.96 | 80–700 | 80–103,000 | 10–3340 | 350–1380 | 10,000–100,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teeraphantuvat, T.; Jatuwong, K.; Jinanukul, P.; Thamjaree, W.; Lumyong, S.; Aiduang, W. Improving the Physical and Mechanical Properties of Mycelium-Based Green Composites Using Paper Waste. Polymers 2024, 16, 262. https://doi.org/10.3390/polym16020262

Teeraphantuvat T, Jatuwong K, Jinanukul P, Thamjaree W, Lumyong S, Aiduang W. Improving the Physical and Mechanical Properties of Mycelium-Based Green Composites Using Paper Waste. Polymers. 2024; 16(2):262. https://doi.org/10.3390/polym16020262

Chicago/Turabian StyleTeeraphantuvat, Thana, Kritsana Jatuwong, Praween Jinanukul, Wandee Thamjaree, Saisamorn Lumyong, and Worawoot Aiduang. 2024. "Improving the Physical and Mechanical Properties of Mycelium-Based Green Composites Using Paper Waste" Polymers 16, no. 2: 262. https://doi.org/10.3390/polym16020262

APA StyleTeeraphantuvat, T., Jatuwong, K., Jinanukul, P., Thamjaree, W., Lumyong, S., & Aiduang, W. (2024). Improving the Physical and Mechanical Properties of Mycelium-Based Green Composites Using Paper Waste. Polymers, 16(2), 262. https://doi.org/10.3390/polym16020262