Optimal Conversion of Food Packaging Waste to Liquid Fuel via Nonthermal Plasma Treatment: A Model-Centric Approach

Abstract

1. Introduction

2. Modelling and Experiments

2.1. Model Development

2.2. Model Hybridisation

- The energy variables and discharge qualities are considered to change solely in the direction that was perpendicular to the electrodes, allowing for a 0-dimensional simulation;

- The drift/diffusion approximation describes the flux of charged particles;

- This 0-dimensional model assumes that every component possesses a high diffusivity and diffuses through the discharge zone after their formation, resulting in an even distribution of spatial variables within the plasma reactor;

- The electron energy distribution function (EEDF) is believed to be Maxwellian, and the electron temperature equation could be solved;

- It is assumed that the gas temperature is the same as that of the ions and excited neutral species.

2.3. Optimisation Model

2.3.1. Equations Developed for the Experimental Design

2.3.2. Calculating the Regression Coefficients

2.3.3. Optimum Value Calculation Method

2.4. Model Equations Developed to Calculate the Impact of the Variables via the Response Surface Method (RSM)

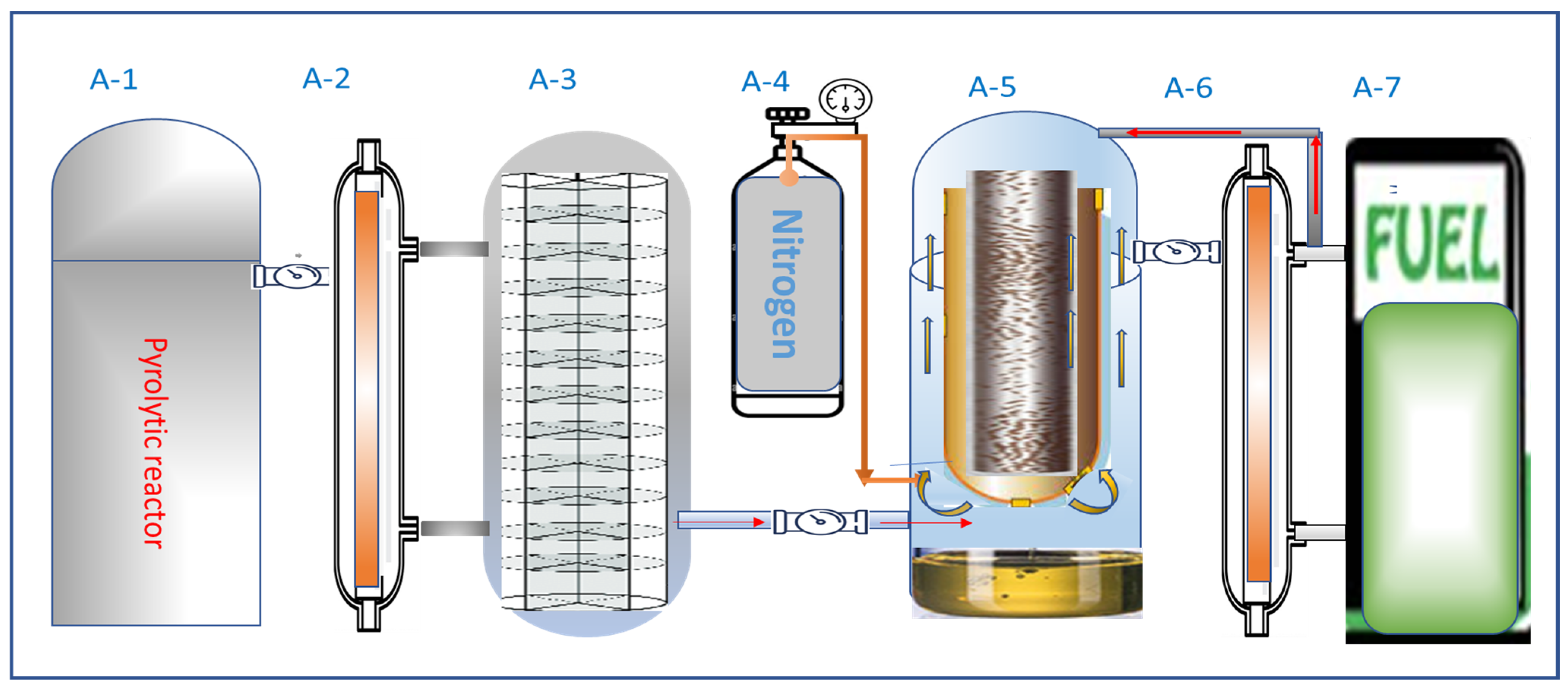

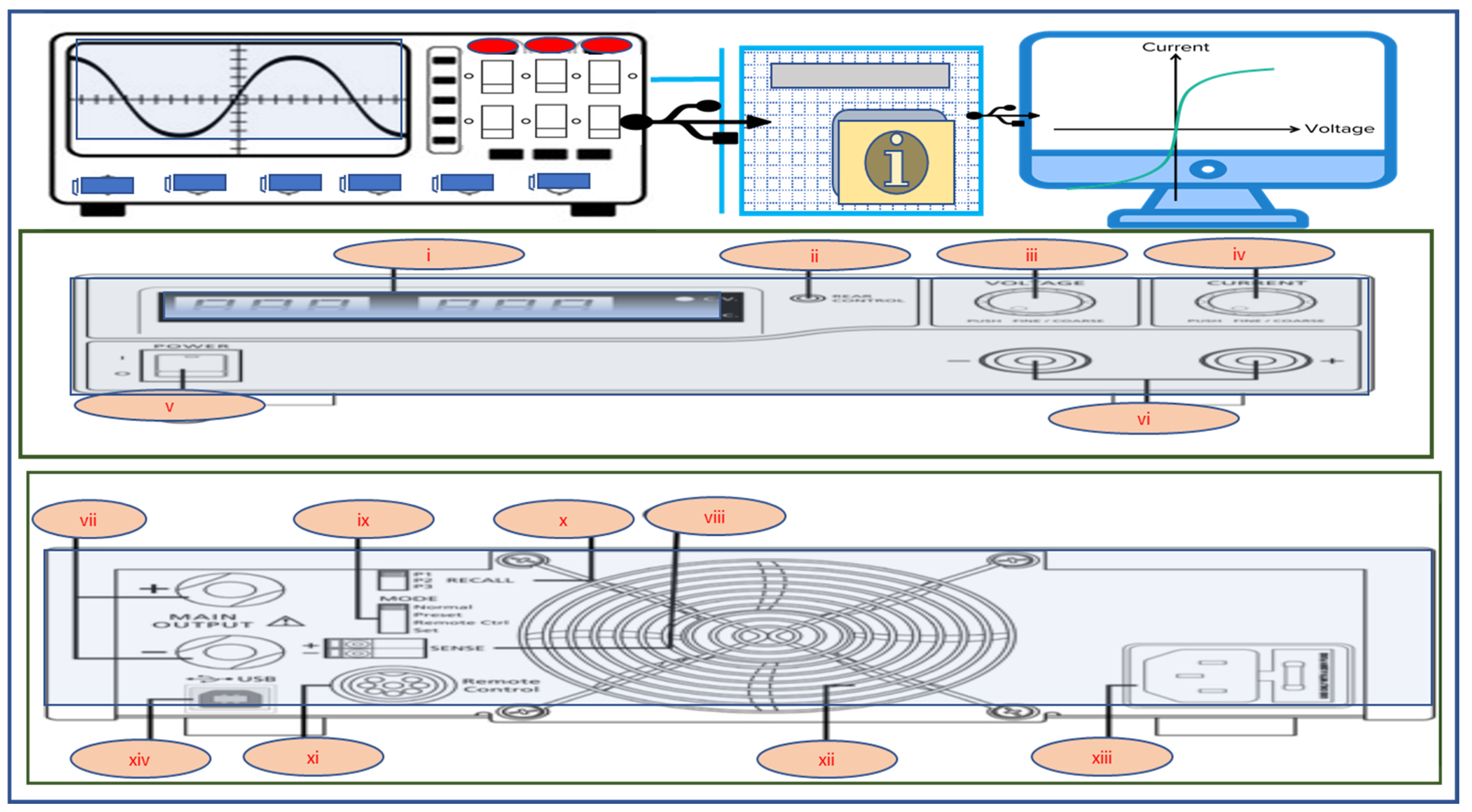

2.5. Experimental Set-Up

3. Results and Discussion

3.1. Verifying the Model

3.2. Model Explanation and Parametric Effect Analysis via the Integrated Response Surface Method (IRSM)

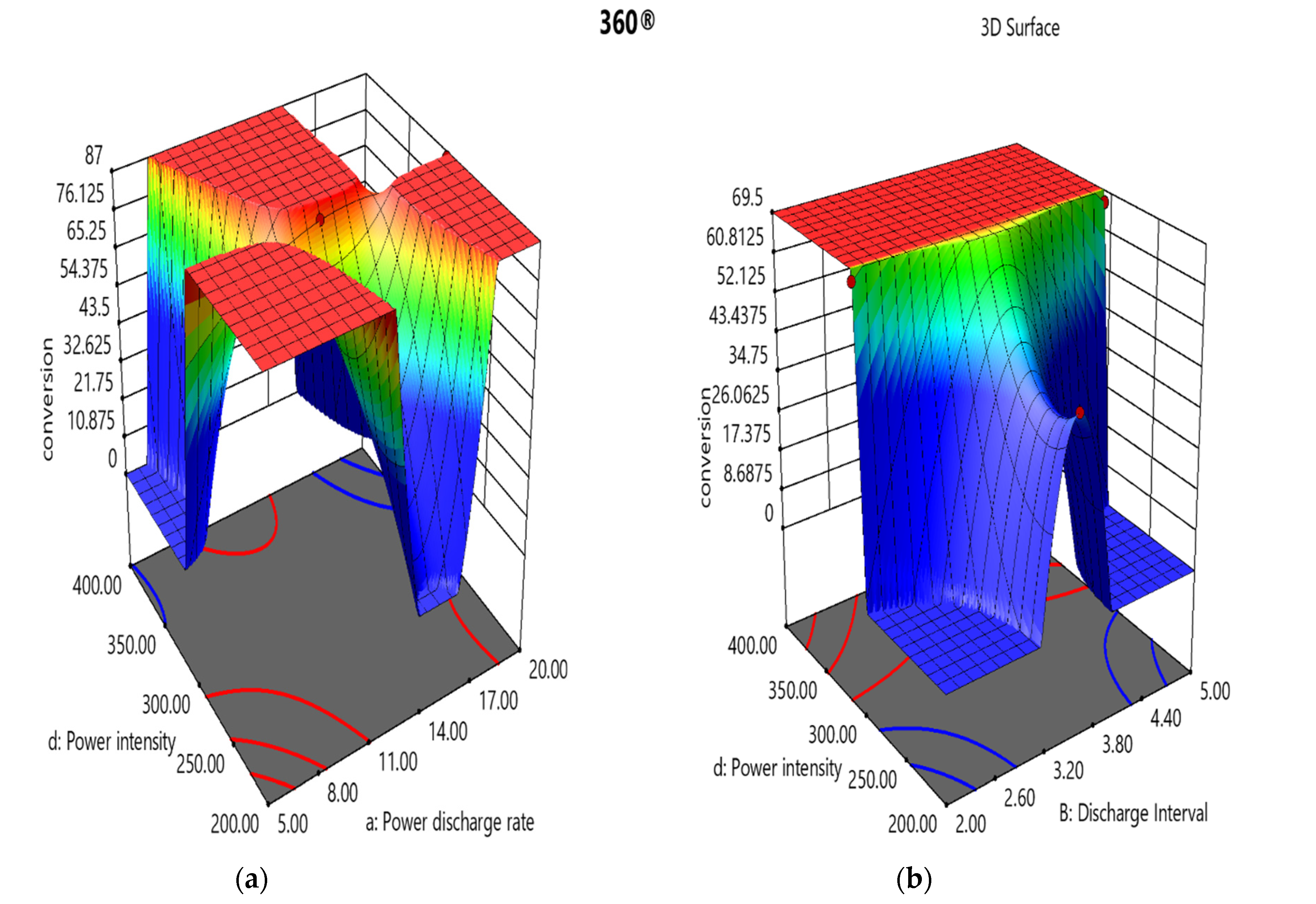

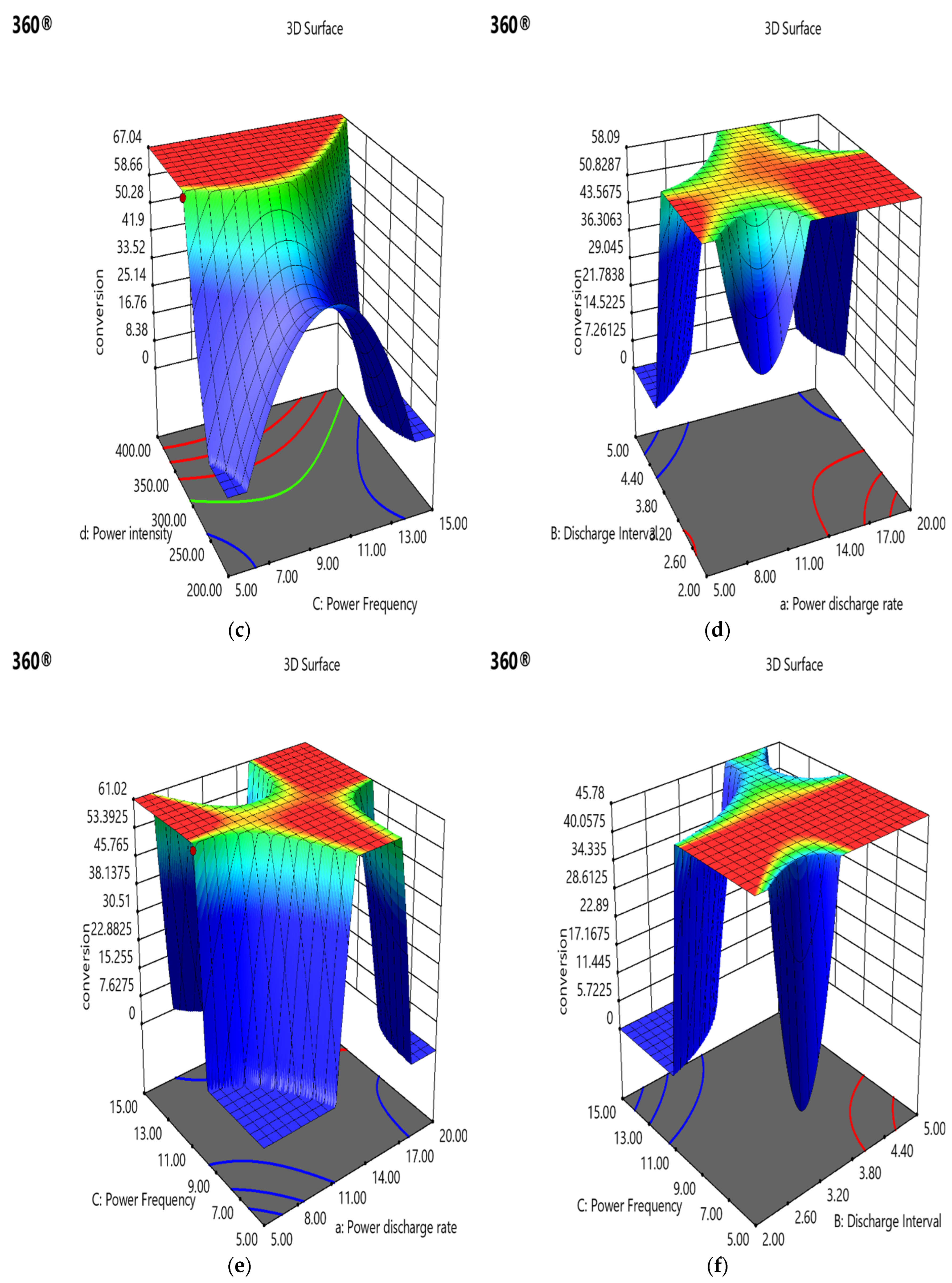

3.2.1. Multifactor Impact Analysis

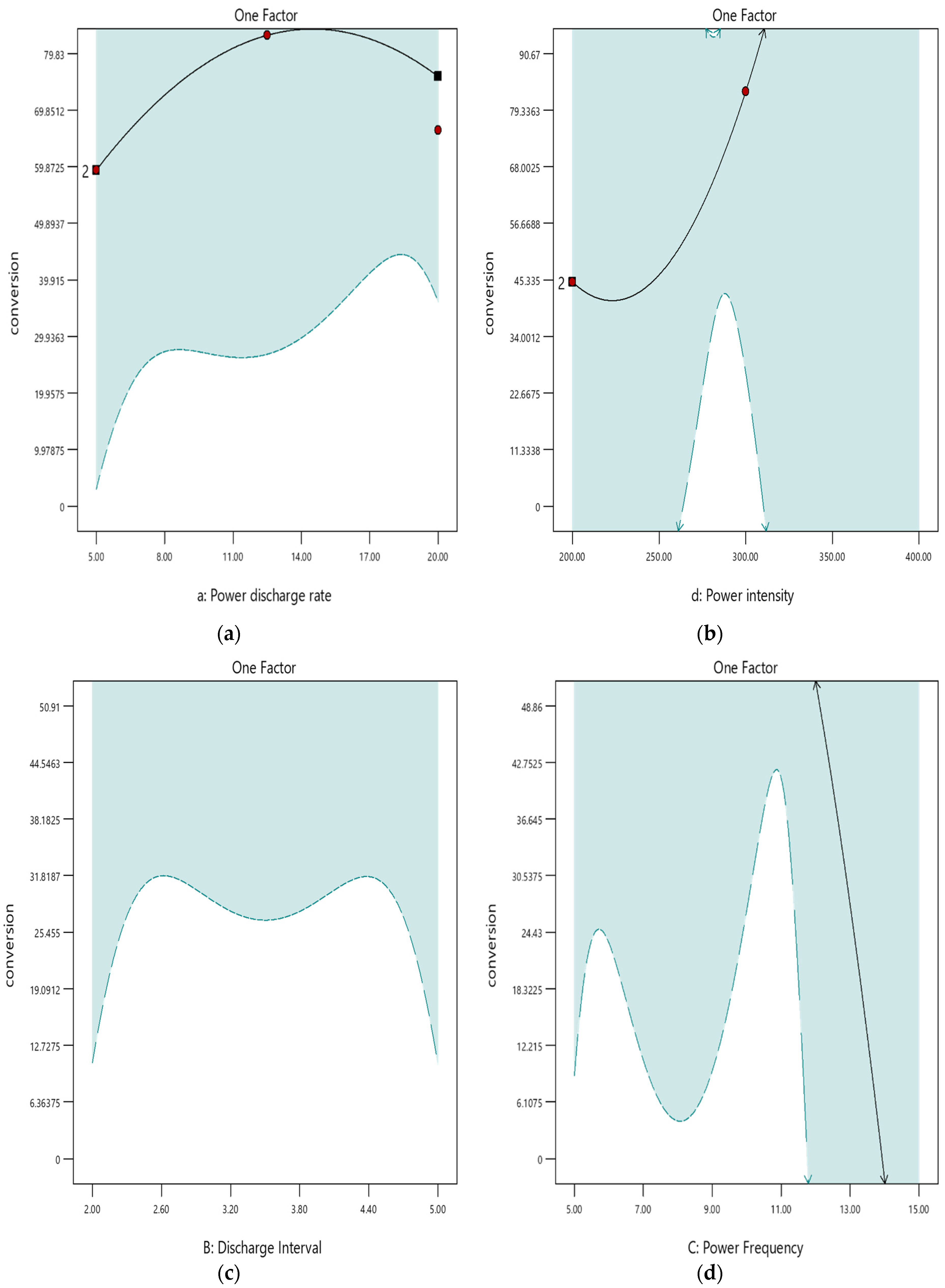

3.2.2. One-Factor Effect (OFE) Analysis

- i—Point of interest determined by Factors Tool settings and selected treatment on graph;

- j—Arbitrary reference IDs for each displayed prediction point;

- k—Total number of displayed prediction points;

- t—Student’s t critical value;

- α—alpha risk = 1 − confidence level;

- residual df—residual degrees of freedom found on the ANOVA;

- —Expanded point vector for the point of interest or the displayed prediction point;

- X—The expanded model matrix;

- V—The variance matrix.

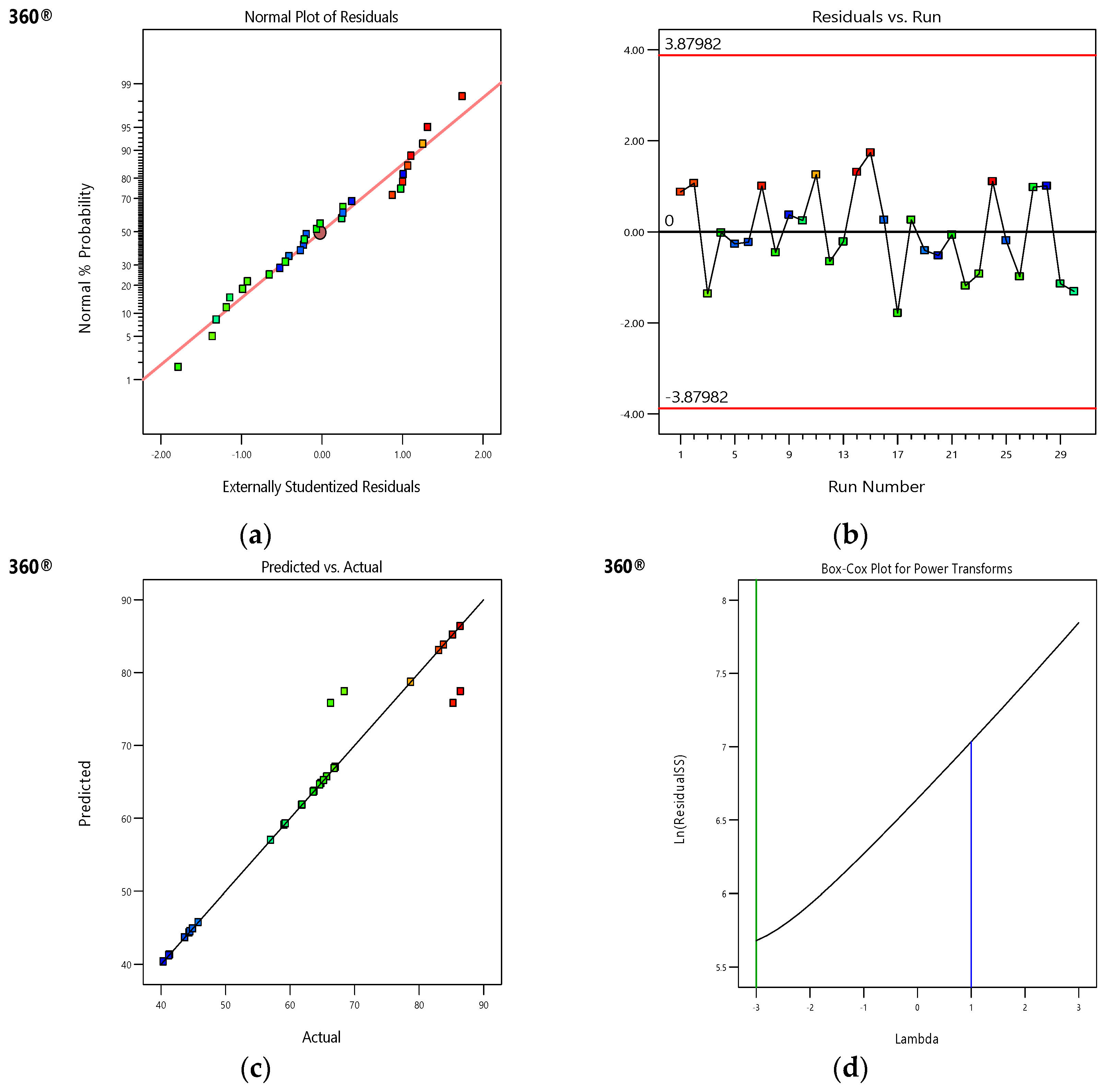

3.3. Analysing Model Accuracy

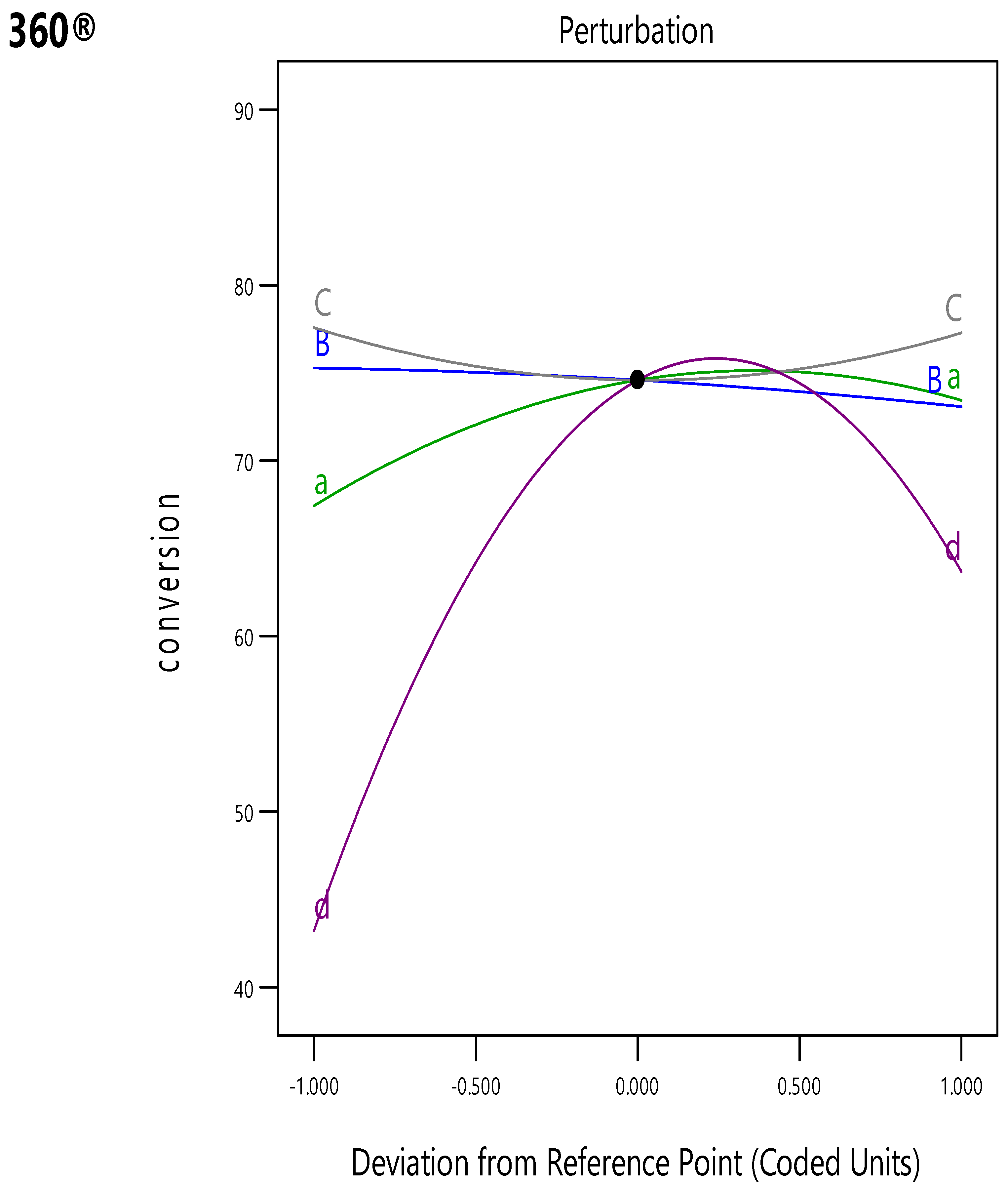

3.4. Perturbation Graph

3.5. Characterisation of Fuel by Calorific Value

3.6. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ghasemlou, M.; Barrow, C.J.; Adhikari, B. The future of bioplastics in food packaging: An industrial perspective. Food Packag. Shelf Life 2024, 43, 101279. [Google Scholar] [CrossRef]

- Singh, P.; Wani, A.A.; Saengerlaub, S.; Langowski, H.-C. Understanding critical factors for the quality and shelf life of MAP fresh meat: A review. Crit. Rev. Food Sci. Nutr. 2011, 51, 146–177. [Google Scholar] [CrossRef] [PubMed]

- Ganeson, K.; Mouriya, G.K.; Bhubalan, K.; Razifah, M.R.; Jasmine, R.; Sowmiya, S.; Amirul, A.-A.A.; Vigneswari, S.; Ramakrishna, S. Smart packaging—A pragmatic solution to approach sustainable food waste management. Food Packag. Shelf Life 2023, 36, 101044. [Google Scholar] [CrossRef]

- Arnold, M. Recycling Food Packaging: Discussion Paper; Discussion Paper No. VTT-CR-00139-22; VTT Technical Research Centre of Finland: Espoo, Finland, 2022; Available online: https://cris.vtt.fi/ws/portalfiles/portal/58598713/VTT_CR_00139_22.pdf (accessed on 24 July 2024).

- Jozinović, A.; Kovač, M.; Ocelić Bulatović, V.; Kučić Grgić, D.; Miloloža, M.; Šubarić, D.; Ačkar, Đ.J.P. Biopolymeric Blends of Thermoplastic Starch and Polylactide as Sustainable Packaging Materials. Polymers 2024, 16, 1268. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Thermal degradation of waste plastics under non-sweeping atmosphere: Part 1—Effect of temperature, product optimization, and degradation mechanism. J. Environ. Manag. 2019, 239, 395–406. [Google Scholar] [CrossRef]

- Antelava, A.; Damilos, S.; Hafeez, S.; Manos, G.; Al-Salem, S.M.; Sharma, B.K.; Kohli, K.; Constantinou, A. Plastic Solid Waste (PSW) in the Context of Life Cycle Assessment (LCA) and Sustainable Management. Environ. Manag. 2019, 64, 230–244. [Google Scholar] [CrossRef]

- Uzoejinwa, B.B.; Xiuhua, H.; Wang, S.; Abomohra, A.E.-F.; Hu, Y.; Wang, Q. Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: Recent progress and future directions elsewhere worldwide. Energy Convers. Manag. 2018, 163, 468–492. [Google Scholar] [CrossRef]

- Butler, E.; Devlin, G.; McDonnell, K. Waste polyolefins to liquid fuels via pyrolysis: Review of commercial state-of-the-art and recent laboratory research. Waste Biomass Valorization 2011, 2, 227–255. [Google Scholar] [CrossRef]

- Sharma, B.K.; Moser, B.R.; Vermillion, K.E.; Doll, K.M.; Rajagopalan, N. Production, characterization and fuel properties of alternative diesel fuel from pyrolysis of waste plastic grocery bags. Fuel Process. Technol. 2014, 122, 7990. [Google Scholar] [CrossRef]

- Pourkarimi, S.; Hallajisani, A.; Alizadehdakhel, A.; Nouralishahi, A. Biofuel production through micro- and macroalgae pyrolysis—A review of pyrolysis methods and process parameters. J. Anal. Appl. Pyrolysis 2019, 142, 19. [Google Scholar] [CrossRef]

- Bridgewater, T. Challenges and Opportunities in Fast Pyrolysis of Biomass: Part I. Johns. Matthey Technol. Rev. 2018, 62, 118–130. [Google Scholar] [CrossRef]

- Erdogan, S. Recycling of Waste Plastics into Pyrolytic Fuels and Their Use in IC Engines. In Sustainable Mobility; Llamas, B., Romero, M.F.O., Sillero, E., Eds.; Intechopen: London, UK, 2020; Chapter 5. [Google Scholar] [CrossRef]

- Ordaz-Quintero, A.; Monroy-Alonso, A.; Saldivar-Guerra, E. Thermal Pyrolysis of Polystyrene Aided by a Nitroxide EndFunctionality. Experiments and Modeling. Processes 2020, 8, 432. [Google Scholar] [CrossRef]

- Ratnasari, D.K.; Nahil, M.A.; Williams, P.T. Catalytic pyrolysis of waste plastics using staged catalysis for production of gasoline range hydrocarbon oils. J. Anal. Appl. Pyrolysis 2017, 124, 631–637. [Google Scholar] [CrossRef]

- Kumar, S.; Panda, A.K.; Singh, R.K. A review on tertiary recycling of high-density polyethylene to fuel. Resour. Conserv. Recycl. 2011, 55, 893–910. [Google Scholar] [CrossRef]

- Rehan, M.; Miandad, R.; Barakat, M.A.; Ismail, I.M.I.; Almeelbi, T.; Gardy, J.; Hassanpour, A.; Khan, M.Z.; Demirbas, A.; Nizami, A.S. Effect of zeolite catalysts on pyrolysis liquid oil. Int. Biodeterior. Biodegrad. 2017, 119, 162. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Ismail, I.M.I.; Nizami, A.S. Effect of plastic waste types on pyrolysis liquid oil. Int. Biodeterior. Biodegrad. 2017, 119, 239. [Google Scholar] [CrossRef]

- Jin, Z.; Chen, D.; Yin, L.; Hu, Y.; Zhu, J.; Hong, L. Molten waste plastic pyrolysis in a vertical fallingfilm reactor and the influence of temperature on the pyrolysis products. Chin. J. Chem. Eng. 2018, 26, 400–406. [Google Scholar] [CrossRef]

- Faussone, G.C.; Seljak, T.; Jasiukaitytė-Grojzdek, E.; Baškovič, U.Ž.; Katrašnik, T.; Grilc, M. Pyrolysis oil from post-consumer packaging and its ageing: Physical and chemical properties and drop-in performance in a power generating unit. Energy Rep. 2023, 10, 613–627. [Google Scholar] [CrossRef]

- Hasan, M.M.; Rasul, M.G.; Jahirul, M.I.; Khan, M.M.K. Characterization of pyrolysis oil produced from organic and plastic wastes using an auger reactor. Energy Convers. Manag. 2023, 278, 116723. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. The effect of slow pyrolysis on the conversion of packaging waste plastics (PE and PP) into fuel. Waste Manag. 2018, 79, 615–624. [Google Scholar] [CrossRef]

- Lee, X.J.; Ong, H.C.; Gan, Y.Y.; Chen, W.-H.; Indra Mahlia, T.M. State of art review on conventional and advanced pyrolysis of macroalgae and microalgae for biochar, bio-oil, and bio-syngas production. Energy Convers. Manag. 2020, 210, 11270. [Google Scholar] [CrossRef]

- Lim, M.T.; Tan, E.S.; Chai, Y.H.; Chin, B.L.F.; Juwono, F.H.; Hisham, D.H.B.; Mohamed Anuar, M.A. Pilot-scale flue gas pyrolysis system for organic and plastic wastes with improved liquid properties in a non-thermal plasma reactor. J. Anal. Appl. Pyrolysis 2023, 173, 106062. [Google Scholar] [CrossRef]

- Khosravanipour Mostafazadeh, A.; Solomatnikova, O.; Drogui, P.; Tyagi, R.D. A review of recent re-search and developments in fast pyrolysis and bio-oil upgrading. Biomass Convers. Biorefinery 2018, 8, 739–773. [Google Scholar] [CrossRef]

- Mo, L.; Leong, K.K.M.; Kawi, S. A highly dispersed and anti-coking Ni–La2O3/SiO2 catalyst for syngas production from dry carbon dioxide reforming of methane. Catal. Sci. Technol. 2014, 4, 2107–2114. [Google Scholar] [CrossRef]

- Mudassir, M.A.; Batool, M.; Kousar, S.; Makarem, M.A.; Razia, E.T.; Meshksar, M.; Murtaza, M.; Tariq, K.; Ud Din, M.A.; Bodlah, M.A.; et al. Plasma-assisted hydrodeoxygenation of bio-oils. Fuel Process. Technol. 2023, 250, 107872. [Google Scholar] [CrossRef]

- Mortazavi, M.; Amato, L.; Manivannan, N.; Balachandran, W. Modelling of Electric Field Distribution in a Non-thermal Plasma Reactor using COMSOL Multiphysics®; Technical Papers and Presentations; COMSOL: Stockholm, Sweden, 2020; Available online: https://www.comsol.com/paper/modelling-of-electric-field-distribution-in-a-non-thermal-plasma-reactor-using-c-95241 (accessed on 24 July 2024).

- Kerr, D.E. Physics of Fully Ionized Gases. J. Am. Chem. Soc. 1956, 78, 5133–5134. [Google Scholar] [CrossRef]

- Haas, F. Kinetic theory derivation of exchange-correlation in quantum plasma hydrodynamics. Plasma Phys. Control. Fusion 2019, 61, 044001. [Google Scholar] [CrossRef]

- Maitre, P.-A.; Bieniek, M.S.; Kechagiopoulos, P.N. Plasma-enhanced catalysis for the upgrading of methane: A review of modelling and simulation methods. React. Chem. Eng. 2020, 5, 814–837. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z.; Guo, Y.; Liu, J.; Wang, K.; Luo, H.; Fu, Y. Kinetic model of grating-like DBD fed with flowing humid air. Plasma Sources Sci. Technol. 2024, 33, 025001. [Google Scholar] [CrossRef]

- Sanjaya, E.; Weihs, G.F.; Manaf, N.A.; Abbas, A. Reaction kinetic modelling of tar cracking in a non-thermal plasma reactor: Model evaluation and reaction mechanism investigation. Chem. Eng. J. 2024, 479, 147649. [Google Scholar] [CrossRef]

- Ban, Y.; Zhong, S.; Zhu, J.; Zhang, F. Effects of non-equilibrium plasma and equilibrium discharge on low-temperature combustion in lean propane/air mixtures. Fuel 2023, 339, 127353. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, Y.; Pan, D.; Cheng, X. Characterization of a Gliding Arc Igniter from an Equilibrium Stage to a Non–Equilibrium Stage Using a Coupled 3D–0D Approach. Processes 2023, 11, 873. [Google Scholar] [CrossRef]

- Khan, M.J.H.; Hussain, M.A.; Mansourpour, Z.; Mostoufi, N.; Ghasem, N.M.; Abdullah, E.C. CFD simulation of fluidized bed reactors for polyolefin production—A review. J. Ind. Eng. Chem. 2014, 20, 3919–3946. [Google Scholar] [CrossRef]

- Khan, M.J.H.; Hussain, M.A.; Mujtaba, I.M. Polypropylene Production Optimization in Fluidized Bed Catalytic Reactor (FBCR): Statistical Modeling and Pilot Scale Experimental Validation. Materials 2014, 7, 2440–2458. [Google Scholar] [CrossRef]

- Khan, M.J.H.; Hussain, M.A.; Mujtaba, I.M. Developed Hybrid Model for Propylene Polymerisation at Optimum Reaction Conditions. Polymers 2016, 8, 47. [Google Scholar] [CrossRef]

- Khan, M.J.H.; Azlan Hussain, M.; Mujtaba, I.M. Multiphasic Reaction Modeling for Polypropylene Production in a Pilot-Scale Catalytic Reactor. Polymers 2016, 8, 220. [Google Scholar] [CrossRef]

- Jakubauskaite, V.; Zukauskaite, A.; Kryzevicius, Z.; Khan, M.J.H. Management, Model-centric optimisation of bio-chemical remediation of petroleum hydrocarbon contaminated soil. Soil Use Manag. 2024, 40, e12983. [Google Scholar] [CrossRef]

- El Sheikh, K.; Khan, M.J.H.; Diana Hamid, M.; Shrestha, S.; Ali, B.S.; Ryabov, G.A.; Dolgushin, L.A.; Hussain, M.A.; Bu-kharkina, T.V.; Gorelova, E.A. Advances in reduction of NOx and N2O1 emission formation in an oxy-fired fluidized bed boiler. Chin. J. Chem. Eng. 2019, 27, 426–443. [Google Scholar] [CrossRef]

- Bumajdad, A.; Khan, M.J.H.; Lukaszewicz, J.P. Nitrogen-enriched activated carbon derived from plant biomasses: A review on reaction mechanism and applications in wastewater treatment. Front. Mater. 2023, 10, 1218028. [Google Scholar] [CrossRef]

- Sedighi, M.; Keyvanloo, K.; Towfighi, J. Modeling of Thermal Cracking of Heavy Liquid Hydrocarbon: Application of Kinetic Modeling, Artificial Neural Network, and Neuro-Fuzzy Models. Ind. Eng. Chem. Res. 2011, 50, 1536–1547. [Google Scholar] [CrossRef]

- Fan, Y.; Lu, D.; Han, Y.; Yang, J.; Qian, C.; Li, B. Production of light aromatics from biomass components co-pyrolyzed with polyethylene via non-thermal plasma synergistic upgrading. Energy 2023, 265, 126427. [Google Scholar] [CrossRef]

- Adamovich, I.; Agarwal, S.; Ahedo, E.; Alves, L.L.; Baalrud, S.; Babaeva, N.; Bogaerts, A.; Bourdon, A.; Bruggeman, P.J.; Canal, C.; et al. The 2022 Plasma Roadmap: Low temperature plasma science and technology. J. Phys. D Appl. Phys. 2022, 55, 373001. [Google Scholar] [CrossRef]

- Yang, S.; Gao, X.; Yang, V.; Sun, W.; Nagaraja, S.; Lefkowitz, J.K.; Ju, Y. Power, Nanosecond pulsed plasma activated C2H4/O2/Ar mixtures in a flow reactor. J. Propuls. Power 2016, 32, 1240–1252. [Google Scholar] [CrossRef]

- Yue, W.; Lei, W.; Dong, Y.; Shi, C.; Lu, Q.; Cui, X.; Wang, X.; Chen, Y.; Zhang, J. Toluene degradation in air/H2O DBD plas-ma: A reaction mechanism investigation based on detailed kinetic modeling and emission spectrum analysis. J. Hazard. Mater. 2023, 448, 130894. [Google Scholar] [CrossRef]

- Lakshmanan, R.; Mohan Chitra, D.; Carlos, F.; Qiuming, P. Mathematical Modeling and Simulation of Nonlinear Process in Enzyme Kinetics. In Advanced Chemical Kinetics; Akhyar, F.M., Ed.; IntechOpen: Rijeka, Croatia, 2017; Chapter 2. [Google Scholar] [CrossRef]

- Hagelaar, G.; Kroesen, G.M.W.; Van Slooten, U.; Schreuders, H. Modeling of the microdischarges in plasma ad-dressed liquid crystal displays. J. Appl. Phys. 2000, 88, 2252–2262. [Google Scholar] [CrossRef]

- Koch, A.L.; Robinson, J.A.; Milliken, G.A. Mathematical Modeling in Microbial Ecology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Li, B.X.; Guan, L.; Wang, K.; Zhang, D.X.; Wang, W.C.; Liu, F. Formula and process optimization of controlled-release microcapsules prepared using a coordination assembly and the response surface methodology. J. Appl. Polym. Sci. 2016, 133, 42865. [Google Scholar] [CrossRef]

- Palanikumar, K. Introductory Chapter: Response Surface Methology in Engineering Science. In Response Surface Methology in Engineering Science, 1st ed.; IntechOpen: London, UK, 2021; Available online: https://www.doi.org/10.5772/intechopen.100484 (accessed on 24 July 2024). [CrossRef]

- Khan, M.J.H.; Kryzevicius, Z.; Senulis, A.; Zukauskaite, A.; Uebe, J. Modelling and Validating the Nonthermal Plasma Parameters for Producing Liquid Hydrocarbon from Solid Polyolefn Wastes. Processes 2024, 12, 2067. [Google Scholar] [CrossRef]

- Rosly, N.Z.; Abdullah, A.H.; Ahmad Kamarudin, M.; Ashari, S.E.; Alang Ahmad, S.A. Adsorption of Methylene Blue Dye by Calix [6]Arene-Modified Lead Sulphide (Pbs): Optimisation Using Response Surface Methodology. Int. J. Environ. Res. Public Health 2021, 18, 397. [Google Scholar] [CrossRef]

- Janarthanan, K.; Sivanandi, P. Extraction and characterization of waste plastic pyrolysis oil for diesel engines. J. Clean. Prod. 2022, 366, 132924. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Heydariaraghi, M.; Ghorbanian, S.; Hallajisani, A.; Heydariaraghi, A.S.M.; Ghorbanian, S.; Hallajisani, A.; Salehpour, A. Fuel properties of the oils produced from the pyrolysis of commonly-used polymers: Effect of fractionating column. J. Anal. Appl. Pyrolysis 2016, 121, 307–317. [Google Scholar] [CrossRef]

- Anderson, M.J.; Whitcomb, P.J. Practical Aspects for Disigning Statistically Optimal Experiments. J. Stat. Sci. Appl. 2014, 3, 85–92. [Google Scholar] [CrossRef]

| Factor | Name | Units | Change | Type | Subtype | Minimum | Maximum | Coded Low | Coded High |

|---|---|---|---|---|---|---|---|---|---|

| a | Power discharge rate | W | Hard | Numeric | Continuous | 5.00 | 20.00 | −1 5.00 | +1 20.00 |

| B | Discharge Interval | ms | Easy | Numeric | Continuous | 2.00 | 5.00 | −1 2.00 | +1 5.00 |

| C | Power Frequency | kHz | Easy | Numeric | Continuous | 5.00 | 15.00 | −1 5.00 | +1 15.00 |

| d | Power intensity | kV | Hard | Numeric | Continuous | 200.00 | 400.00 | −1 200.00 | +1 400.00 |

| Factor 1 | Factor 2 | Factor 3 | Factor 4 | Response 1 | |

|---|---|---|---|---|---|

| Run | a: Power Discharge Rate | B: Discharge Interval | C: Power Frequency | d: Power Intensity | Conversion |

| W | ms | kHz | kV | % | |

| 1 | 12.5 | 2 | 5 | 300 | 83.81 |

| 2 | 12.5 | 3.5 | 10 | 300 | 83.07 |

| 3 | 15 | 3.5 | 15 | 300 | 68.43 |

| 4 | 15 | 3.5 | 10 | 400 | 63.63 |

| 5 | 20 | 5 | 15 | 200 | 44.51 |

| 6 | 20 | 2 | 5 | 200 | 43.69 |

| 7 | 15 | 3.5 | 5 | 300 | 85.18 |

| 8 | 15 | 2 | 15 | 400 | 64.81 |

| 9 | 5 | 2 | 15 | 200 | 41.21 |

| 10 | 5 | 5 | 5 | 400 | 59.09 |

| 11 | 5 | 2 | 10 | 300 | 78.71 |

| 12 | 20 | 5 | 15 | 400 | 64.61 |

| 13 | 5 | 2 | 5 | 400 | 61.79 |

| 14 | 15 | 5 | 15 | 300 | 86.38 |

| 15 | 20 | 3.5 | 10 | 300 | 85.29 |

| 16 | 12.5 | 3.5 | 10 | 200 | 44.91 |

| 17 | 12.5 | 3.5 | 5 | 300 | 65.21 |

| 18 | 20 | 2 | 15 | 400 | 65.71 |

| 19 | 20 | 5 | 5 | 200 | 45.78 |

| 20 | 5 | 2 | 5 | 200 | 41.34 |

| 21 | 20 | 5 | 5 | 400 | 63.73 |

| 22 | 12.5 | 2 | 10 | 300 | 67.04 |

| 23 | 12.5 | 5 | 10 | 300 | 66.87 |

| 24 | 15 | 3.5 | 15 | 300 | 86.42 |

| 25 | 20 | 2 | 15 | 200 | 44.34 |

| 26 | 20 | 3.5 | 10 | 300 | 66.31 |

| 27 | 5 | 5 | 15 | 400 | 61.87 |

| 28 | 5 | 5 | 5 | 200 | 40.36 |

| 29 | 5 | 3.5 | 10 | 300 | 59.28 |

| 30 | 5 | 5 | 15 | 300 | 57.01 |

| 31 | 15 | 2 | 10 | 200 | 67.07 |

| 32 | 12.5 | 2 | 10 | 400 | 68.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.J.H.; Kryzevicius, Z.; Senulis, A.; Zukauskaite, A.; Rapalis, P.; Uebe, J. Optimal Conversion of Food Packaging Waste to Liquid Fuel via Nonthermal Plasma Treatment: A Model-Centric Approach. Polymers 2024, 16, 2990. https://doi.org/10.3390/polym16212990

Khan MJH, Kryzevicius Z, Senulis A, Zukauskaite A, Rapalis P, Uebe J. Optimal Conversion of Food Packaging Waste to Liquid Fuel via Nonthermal Plasma Treatment: A Model-Centric Approach. Polymers. 2024; 16(21):2990. https://doi.org/10.3390/polym16212990

Chicago/Turabian StyleKhan, Mohammad Jakir Hossain, Zilvinas Kryzevicius, Audrius Senulis, Audrone Zukauskaite, Paulius Rapalis, and Jochen Uebe. 2024. "Optimal Conversion of Food Packaging Waste to Liquid Fuel via Nonthermal Plasma Treatment: A Model-Centric Approach" Polymers 16, no. 21: 2990. https://doi.org/10.3390/polym16212990

APA StyleKhan, M. J. H., Kryzevicius, Z., Senulis, A., Zukauskaite, A., Rapalis, P., & Uebe, J. (2024). Optimal Conversion of Food Packaging Waste to Liquid Fuel via Nonthermal Plasma Treatment: A Model-Centric Approach. Polymers, 16(21), 2990. https://doi.org/10.3390/polym16212990