Effect of Drilling Parameters and Tool Diameter on Delamination and Thrust Force in the Drilling of High-Performance Glass/Epoxy Composites for Aerospace Structures with a New Design Drill

Abstract

1. Introduction

2. Materials and Methodology

2.1. Materials

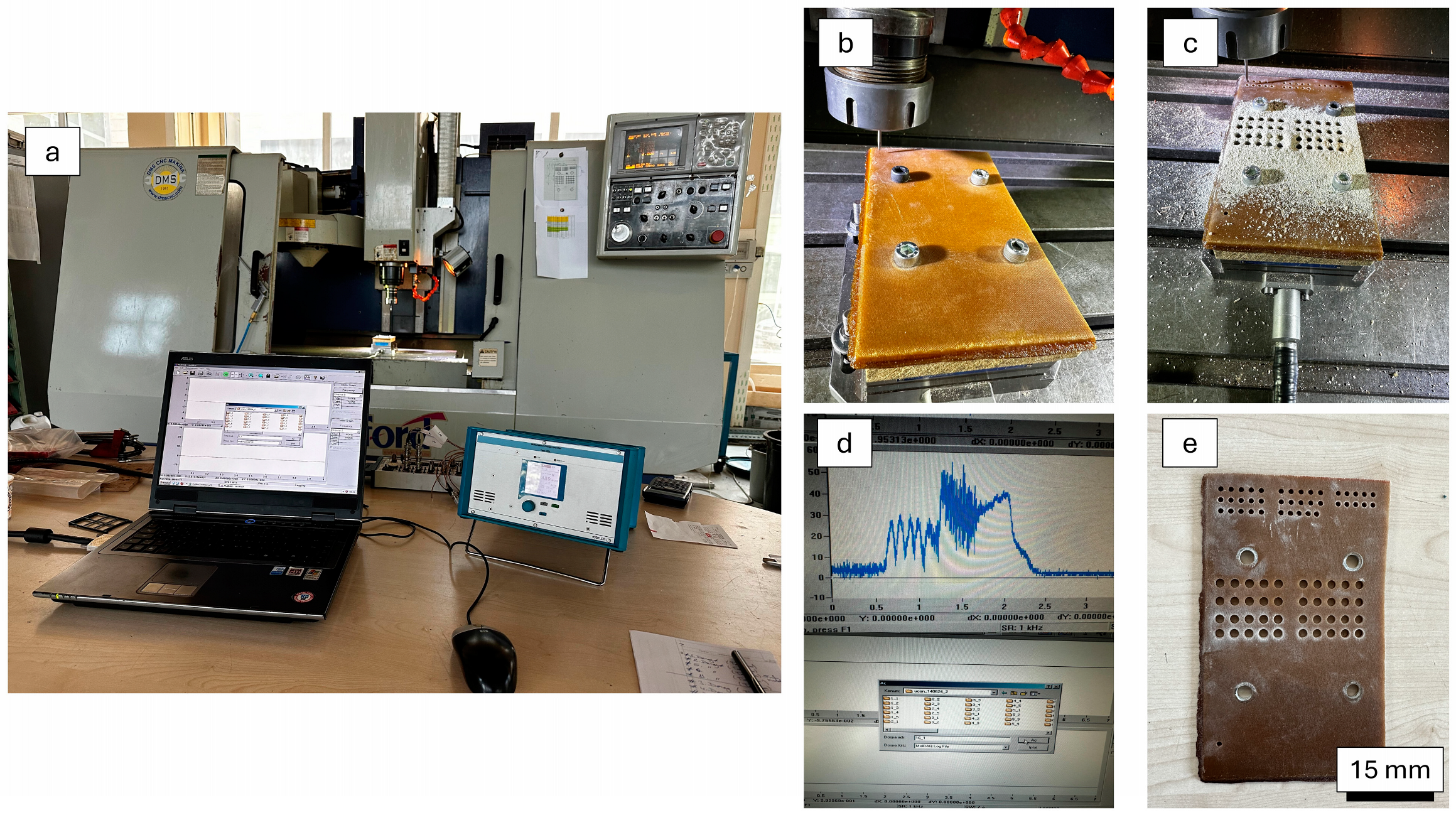

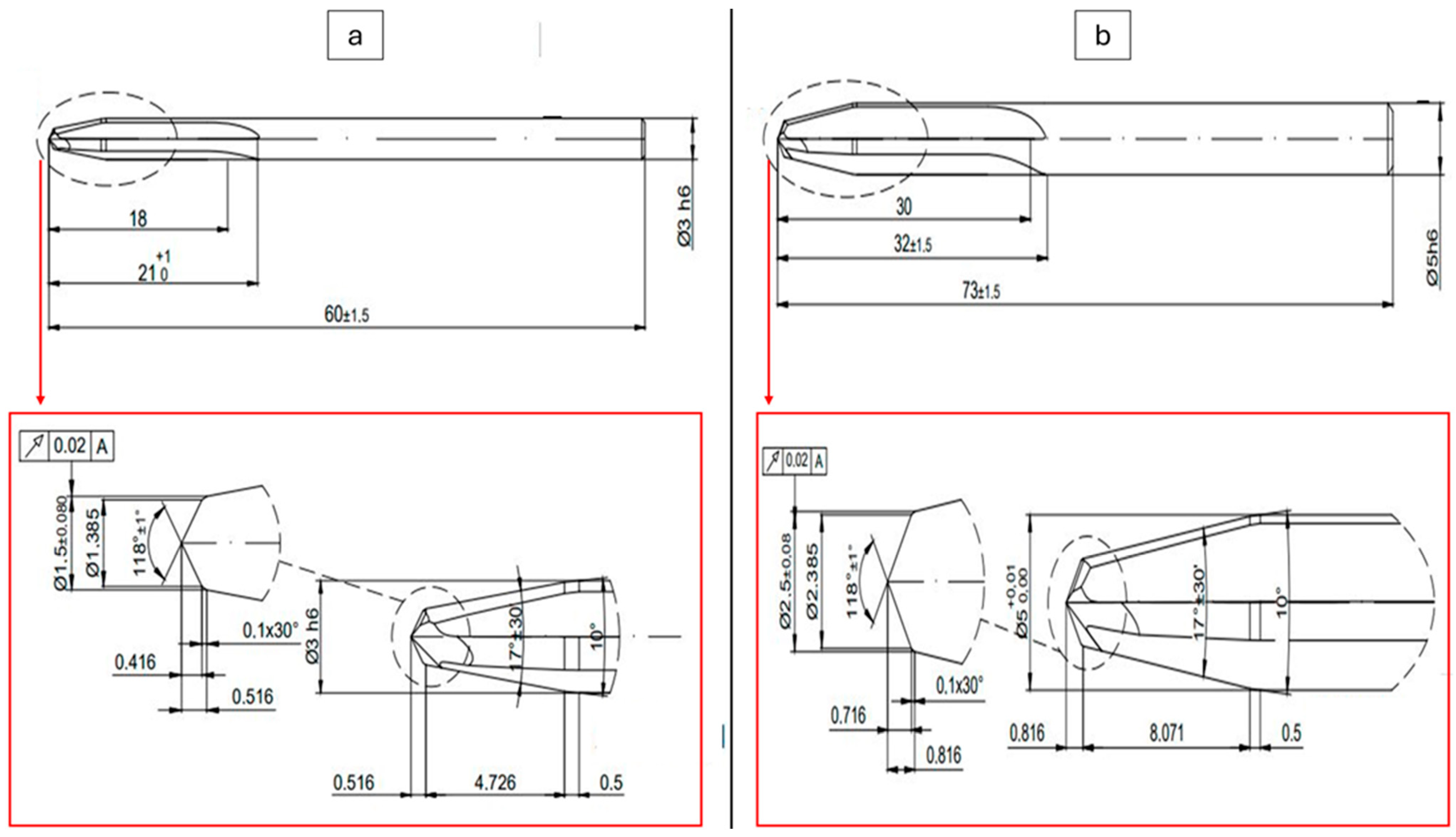

2.2. Machining Procedure and Taguchi Analyses

3. Results and Discussions

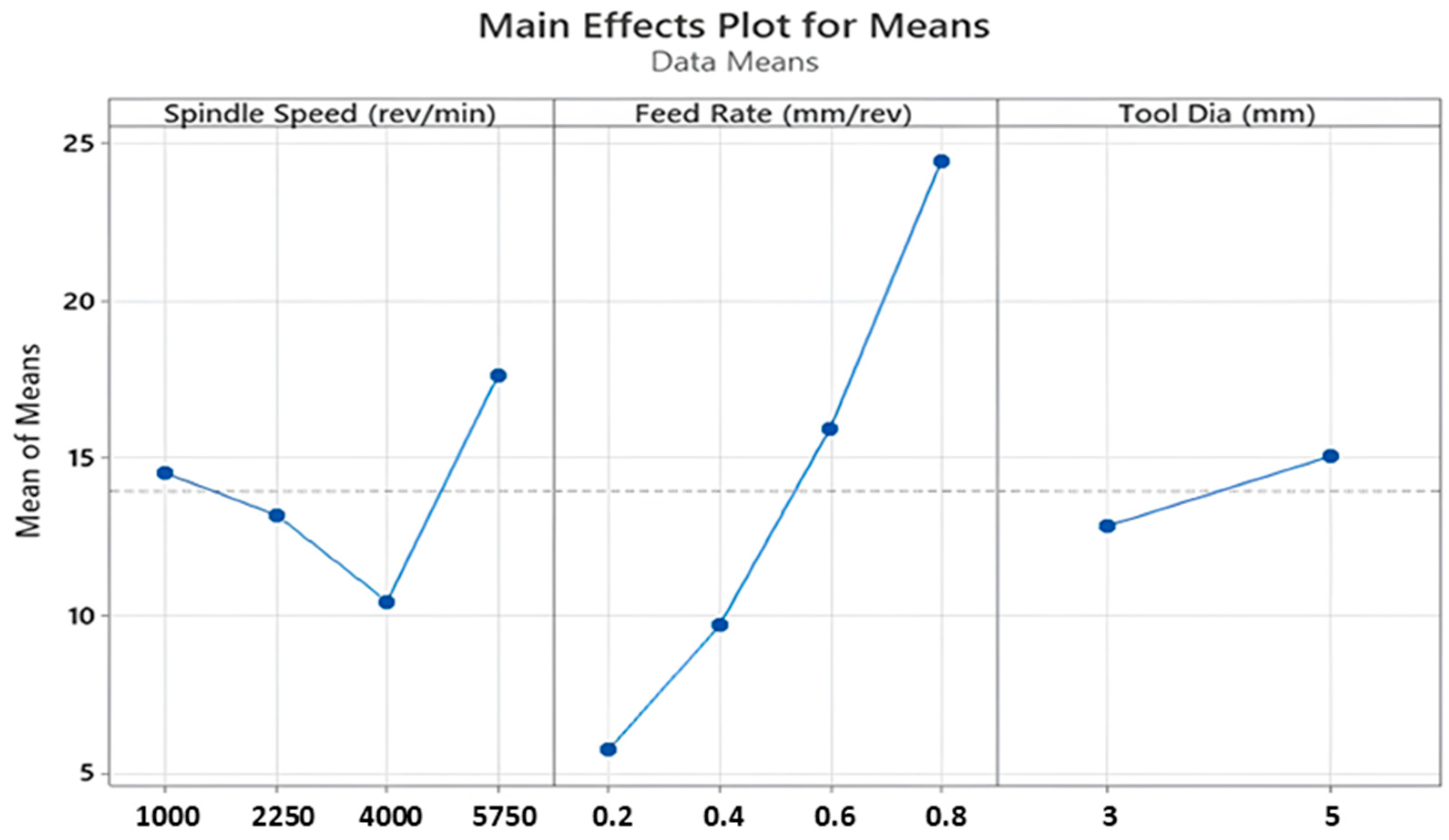

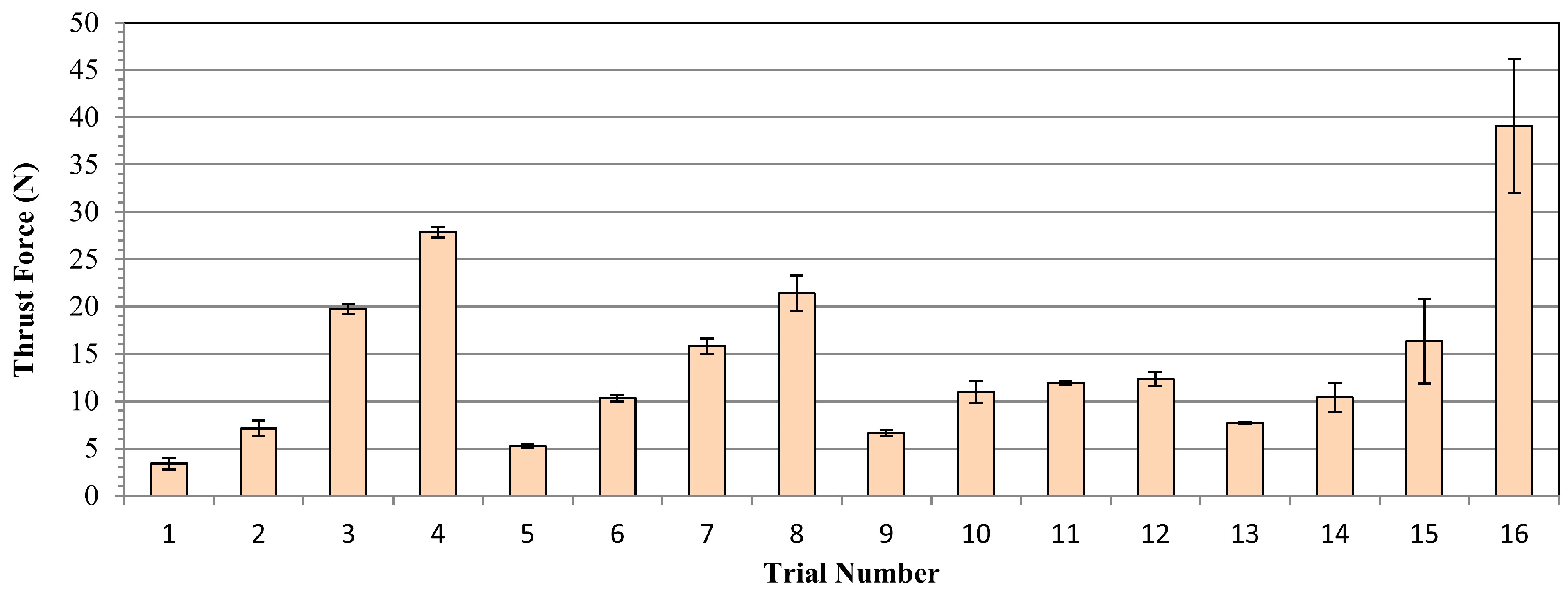

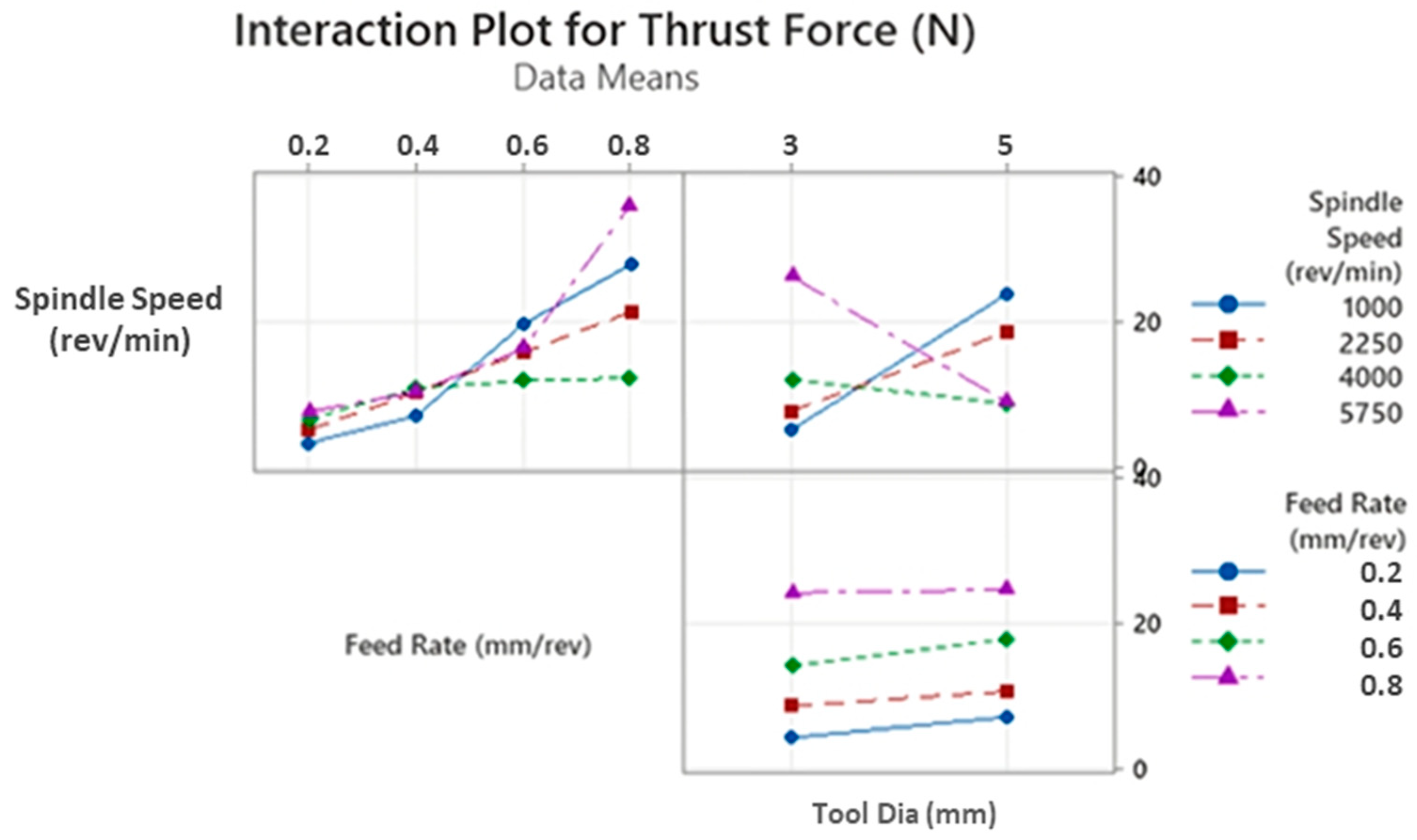

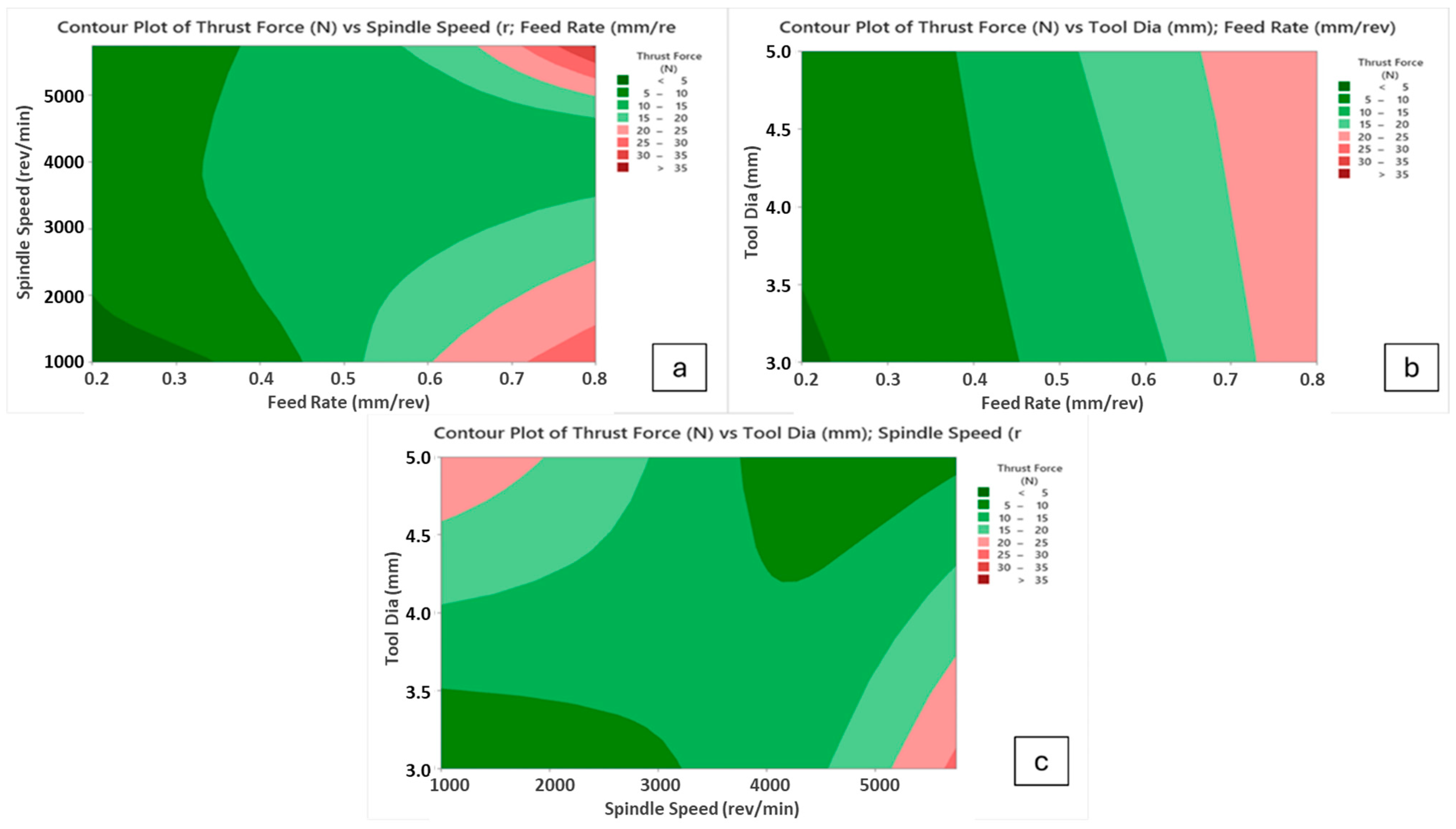

3.1. Thrust Force Analyses

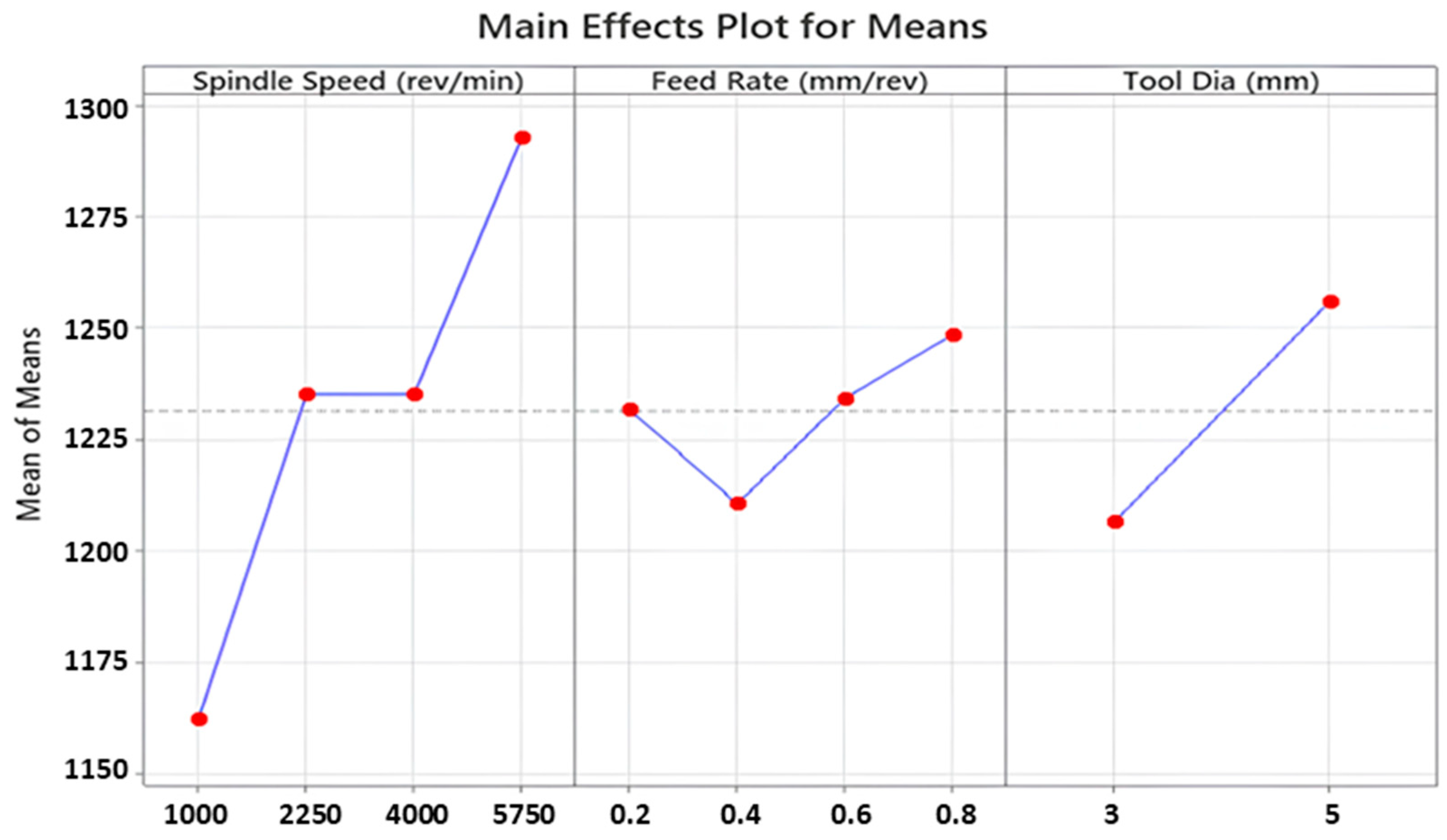

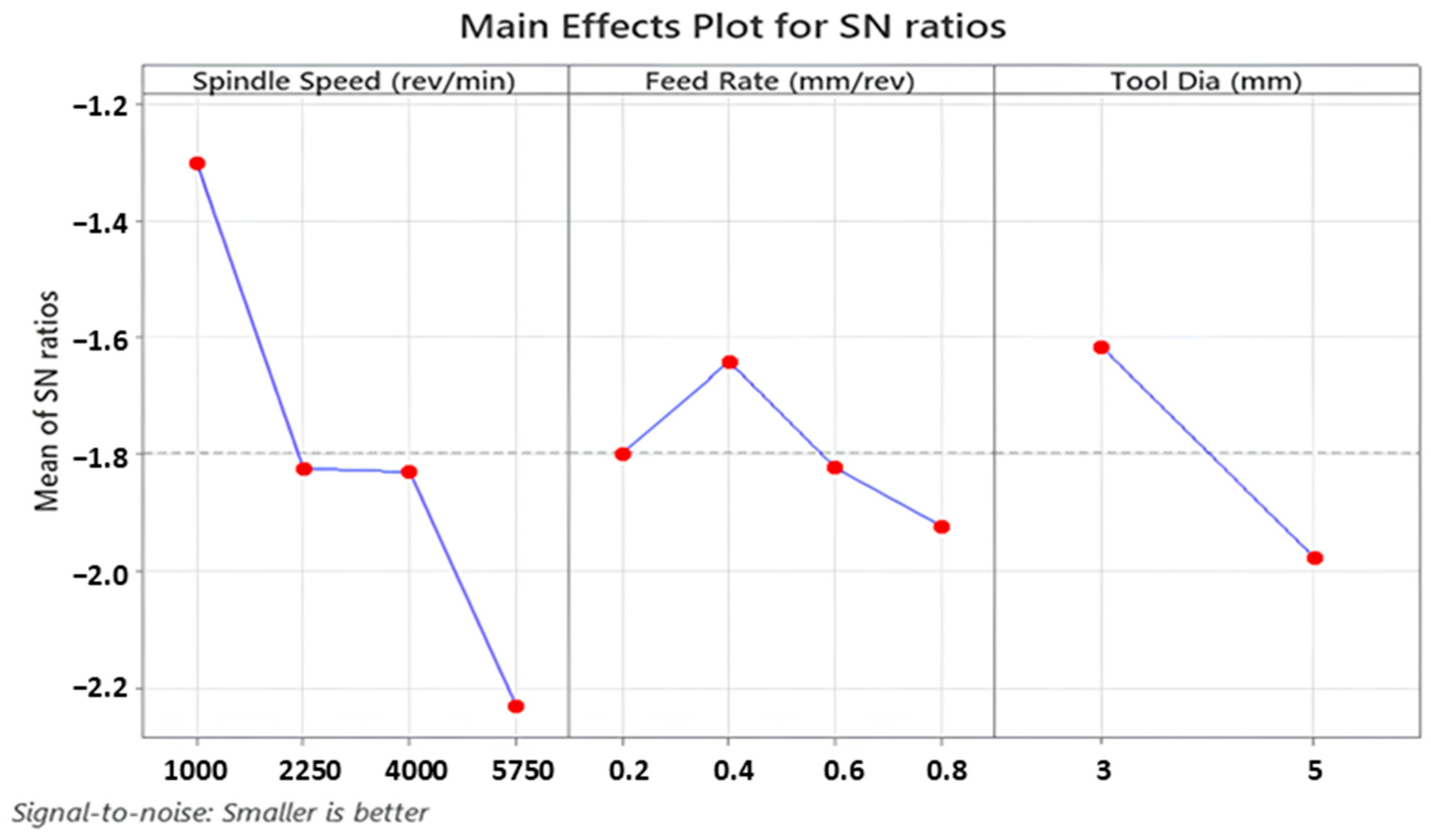

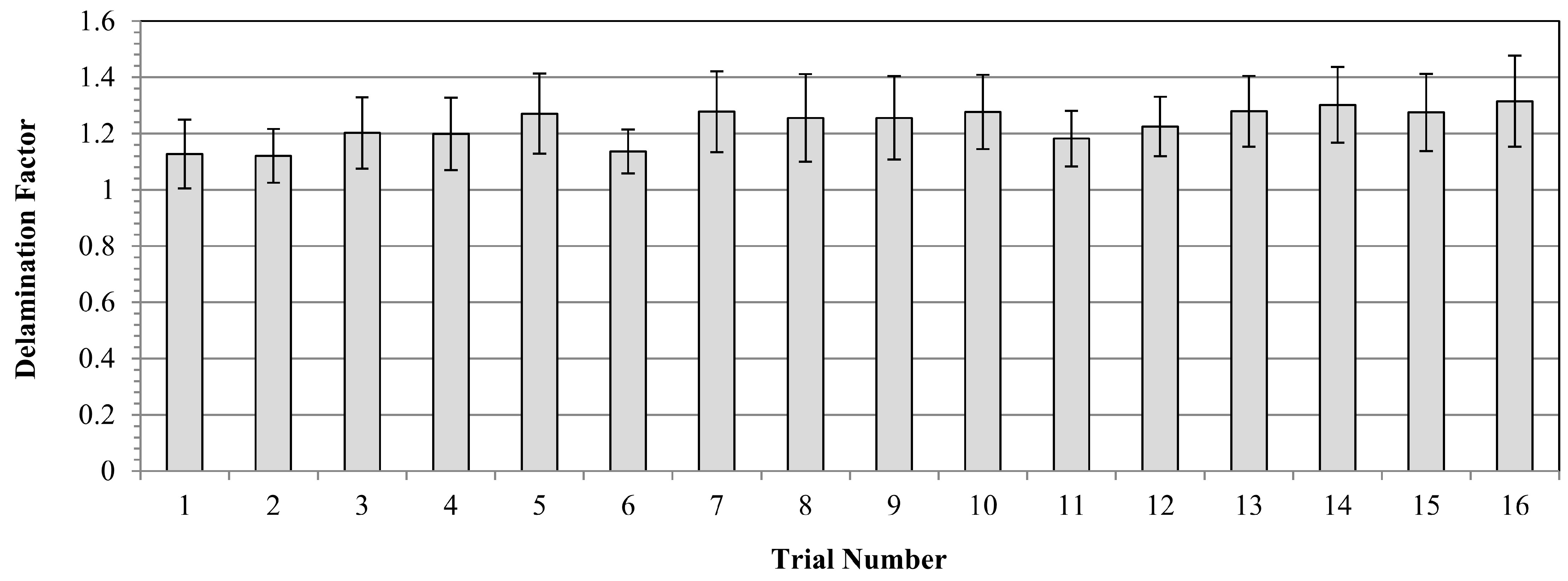

3.2. Delamination Factor Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Selvaraj, R.; Maneengam, A.; Sathiyamoorthy, M. Characterization of mechanical and dynamic properties of natural fiber reinforced laminated composite multiple-core sandwich plates. Compos. Struct. 2022, 284, 115141. [Google Scholar] [CrossRef]

- Gholami, P.; Farsi, M.A.; Kouchakzadeh, M.A. Stochastic fatigue life prediction of Fiber-Reinforced laminated composites by continuum damage Mechanics-based damage plastic model. Int. J. Fatigue 2021, 152, 106456. [Google Scholar] [CrossRef]

- Kosmachev, P.V.; Alexenko, V.O.; Bochkareva, S.A.; Panin, S.V. Deformation behavior and fracture patterns of laminated PEEK-and PI-based composites with various carbon-fiber reinforcement. Polymers 2021, 13, 2268. [Google Scholar] [CrossRef]

- Ercetin, A.; Özgün, Ö.; Aslantaş, K.; Der, O.; Yalçın, B.; Şimşir, E.; Aamir, M. Microstructural and Mechanical Behavior Investigations of Nb-Reinforced Mg–Sn–Al–Zn–Mn Matrix Magnesium Composites. Metals 2023, 13, 1097. [Google Scholar] [CrossRef]

- Bolat, Ç.; Karakılınç, U.; Yalçın, B.; Öz, Y.; Yavaş, Ç.; Ergene, B.; Ercetin, A.; Akkoyun, F. Effect of Drilling Parameters and Tool Geometry on the Thrust Force and Surface Roughness of Aerospace Grade Laminate Composites. Micromachines 2023, 14, 1427. [Google Scholar] [CrossRef]

- Yalçın, B.; Yüksel, A.; Aslantaş, K.; Der, O.; Ercetin, A. Optimization of Micro-Drilling of Laminated Aluminum Composite Panel (Al–PE) Using Taguchi Orthogonal Array Design. Materials 2023, 16, 4528. [Google Scholar] [CrossRef]

- Shi, Z.; Zou, C.; Zhou, F.; Zhao, J. Analysis of the mechanical properties and damage mechanism of carbon fiber/epoxy composites under UV aging. Materials 2022, 15, 2919. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, X.; Wang, Z. Effect of isothermal heat treatment on crystallinity, tensile strength and failure mode of CF/PPS laminate. High Perform. Polym. 2021, 33, 497–508. [Google Scholar] [CrossRef]

- Ergene, B.; Bolat, C.; Karakilinc, U.; Irez, A.B. A comprehensive investigation of drilling performance of anisotropic stacked glass-carbon fiber reinforced hybrid laminate composites. Polym. Compos. 2023, 44, 2656–2670. [Google Scholar] [CrossRef]

- Xu, Y.; Gao, Y.; Wu, C.; Fang, J.; Sun, G.; Steven, G.P.; Li, Q. On design of carbon fiber reinforced plastic (CFRP) laminated structure with different failure criteria. Int. J. Mech. Sci. 2021, 196, 106251. [Google Scholar] [CrossRef]

- Khandelwal, S.; Rhee, K.Y. Recent advances in basalt-fiber-reinforced composites: Tailoring the fiber-matrix interface. Compos. Part B Eng. 2020, 192, 108011. [Google Scholar] [CrossRef]

- Patel, R.V.; Yadav, A.; Winczek, J. Physical, mechanical, and thermal properties of natural fiber-reinforced epoxy composites for construction and automotive applications. Appl. Sci. 2023, 13, 5126. [Google Scholar] [CrossRef]

- Senthilnathan, K.; Ravi, R.; Leon, J.S.; Suresh, G.; Manikandan, K.; Lavanya, R. Analysing the effect of mechanical properties of various proportions of filler material on jute fibre/epoxy reinforced composites. J. Phys. Conf. Ser. 2021, 1921, 012089. [Google Scholar] [CrossRef]

- Thakur, R.K.; Singh, K.K. Influence of fillers on polymeric composite during conventional machining processes: A review. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 94. [Google Scholar] [CrossRef]

- Ogunleye, R.O.; Rusnakova, S.; Zaludek, M.; Emebu, S. The influence of ply stacking sequence on mechanical properties of carbon/epoxy composite laminates. Polymers 2022, 14, 5566. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Taheri, F. Mechanical performance of a novel environmentally friendly basalt-elium® thermoplastic composite and its stainless steel-based fiber metal laminate. Polym. Compos. 2021, 42, 4660–4672. [Google Scholar] [CrossRef]

- Boddeti, N.; Tang, Y.; Maute, K.; Rosen, D.W.; Dunn, M.L. Optimal design and manufacture of variable stiffness laminated continuous fiber reinforced composites. Sci. Rep. 2020, 10, 16507. [Google Scholar] [CrossRef]

- Cutolo, A.; Carotenuto, A.R.; Palumbo, S.; Esposito, L.; Minutolo, V.; Fraldi, M.; Ruocco, E. Stacking sequences in composite laminates through design optimization. Meccanica 2021, 56, 1555–1574. [Google Scholar] [CrossRef]

- Cadieu, L.; Kopp, J.B.; Jumel, J.; Bega, J.; Froustey, C. Temperature effect on the mechanical properties and damage mechanisms of a glass/thermoplastic laminate. J. Compos. Mater. 2020, 54, 2271–2282. [Google Scholar] [CrossRef]

- Saeed, K.; McIlhagger, A.; Harkin-Jones, E.; Kelly, J.; Archer, E. Predication of the in-plane mechanical properties of continuous carbon fibre reinforced 3D printed polymer composites using classical laminated-plate theory. Compos. Struct. 2021, 259, 113226. [Google Scholar] [CrossRef]

- Kumar, P.A.V.; Dean, A.; Reinoso, J.; Paggi, M. A multi phase-field-cohesive zone model for laminated composites: Application to delamination migration. Compos. Struct. 2021, 276, 114471. [Google Scholar] [CrossRef]

- Kumar, A.; Sain, T. Phase field-based cohesive zone approach to model delamination in fiber-reinforced polymer composites. Compos. Struct. 2024, 329, 117751. [Google Scholar] [CrossRef]

- Ng, L.F.; Yahya, M.Y.; Leong, H.Y.; Parameswaranpillai, J.; Muthukumar, C.; Syed Hamzah, S.M.S.A.; Dhar Malingam, S. State-of-the-art review on developing lightweight fiber-metal laminates based on synthetic/natural fibers. Polym. Compos. 2023, 44, 6275–6303. [Google Scholar] [CrossRef]

- Okafor, C.E.; Iweriolor, S.; Ani, O.I.; Ahmad, S.; Mehfuz, S.; Ekwueme, G.O.; Chukwumuanya, O.E.; Abonyi, S.E.; Ekengwu, I.E.; Chikelu, O.P. Advances in machine learning-aided design of reinforced polymer composite and hybrid material systems. Hybrid Adv. 2023, 2, 100026. [Google Scholar] [CrossRef]

- Masannan, V.; Anbalagan, C.; Lakshmaiya, N.; Kumar, P. Experimental Investigation on the Drilling Characteristics of Kenaf/PLA-Based Laminates. Eng. Proc. 2024, 61, 9. [Google Scholar] [CrossRef]

- Shetty, S.; Shetty, R.; Nayak, R.; Hegde, A.; Uday Kumar Shetty, S.V.; Sudheer, M. DOE coupled MLP-ANN for optimization of thrust force and torque during drilling of CCFRP composite laminates. Cogent. Eng. 2024, 11, 2319397. [Google Scholar] [CrossRef]

- Prakash, C.; Selvakumar, A.A.; Sekar, K.V. 3D finite element investigation in high speed drilling of unidirectional glass fiber reinforced polymer composite. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Ze, G.K.; Pramanik, A.; Basak, A.K.; Prakash, C.; Shankar, S.; Radhika, N. Challenges associated with drilling of carbon fiber reinforced polymer (CFRP) composites—A review. Compos. Part C Open Access 2023, 11, 100356. [Google Scholar] [CrossRef]

- Rao, V.D.P.; Ali, S.R.M.; Ali, S.M.; Santhoshi, B.S. Analysis Of Delamination During Drilling Process of Aramid Fibre Reinforced Polymers. J. Phys. Conf. Ser. 2024, 2765, 012016. [Google Scholar]

- Lukács, T.; Pereszlai, C.; Geier, N. Delamination measurement in glass fibre reinforced polymer (GFRP) composite based on image differencing. Compos. Part B Eng. 2023, 248, 110381. [Google Scholar] [CrossRef]

- Biruk-Urban, K.; Bere, P.; Józwik, J. Machine Learning Models in Drilling of Different Types of Glass-Fiber-Reinforced Polymer Composites. Polymers 2023, 15, 4609. [Google Scholar] [CrossRef]

- Arhamnamazi, S.A.; Aymerich, F.; Buonadonna, P.; Mehtedi, M.E. Assessment of drilling-induced delamination and tool wear in carbon fibre reinforced laminates. Polym. Polym. Compos. 2021, 29 (Suppl. S9), S729–S740. [Google Scholar] [CrossRef]

- Thakur, R.K.; Singh, K.K. Evaluation of drilling characteristics to explore the effect of graphene nanoplatelets on glass fiber reinforced polymer composite. Measurement 2023, 219, 113233. [Google Scholar] [CrossRef]

- Demirsöz, R.; Yaşar, N.; Korkmaz, M.E.; Günay, M.; Giasin, K.; Pimenov, D.Y.; Aamir, M.; Unal, H. Evaluation of the mechanical properties and drilling of glass bead/fiber-reinforced polyamide 66 (PA66)-based hybrid polymer composites. Materials 2022, 15, 2765. [Google Scholar] [CrossRef]

- Upputuri, H.B.; Nimmagadda, V.S.; Duraisamy, E. Optimization of drilling parameters on carbon fiber reinforced polymer composites using fuzzy logic. Mater. Today Proc. 2020, 23, 528–535. [Google Scholar] [CrossRef]

- Mathew, S.; Shunmugesh, K. Application of grey-fuzzy logic for the optimization of drilling parameters for coir fibre reinforced composite. Mater. Today Proc. 2023, 72, 2082–2088. [Google Scholar] [CrossRef]

- Babu, U.H.; Sai, N.V.; Sahu, R.K. Artificial intelligence system approach for optimization of drilling parameters of glass-carbon fiber/polymer composites. Silicon 2021, 13, 2943–2957. [Google Scholar] [CrossRef]

- Zhilyaev, I.; Chigrinets, E.; Shevtsov, S.; Chotchaeva, S.; Snezhina, N. ANN-based estimation of the defect severity in the drilling of GFRP/Ti multilayered composite structure. J. Compos. Sci. 2022, 6, 370. [Google Scholar] [CrossRef]

- Xu, J.; Lin, T.; Davim, J.P.; Chen, M.; El Mansori, M. Wear behavior of special tools in the drilling of CFRP composite laminates. Wear 2021, 476, 203738. [Google Scholar] [CrossRef]

- Xu, J.; Lin, T.; Davim, J.P. On the machining temperature and hole quality of CFRP laminates when using diamond-coated special drills. J. Compos. Sci. 2022, 6, 45. [Google Scholar] [CrossRef]

- Capello, E. Workpiece damping and its effect on delamination damage in drilling thin composite laminates. J. Mater. Process. Technol. 2004, 148, 186–195. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Effects of exit back-up on delamination in drilling composite materials using a saw drill and a core drill. Int. J. Mach. Tools Manuf. 2005, 45, 1261–1270. [Google Scholar] [CrossRef]

- Tan, C.L.; Azmi, A.I.; Muhammad, N. Delamination and surface roughness analyses in drilling hybrid carbon/glass composite. Mater. Manuf. Process. 2016, 31, 1366–1376. [Google Scholar] [CrossRef]

- Gupta, A.; Vaishya, R.; Kumar, R.; Khan, K.L.A.; Chhabra, S.; Verma, A.S.; Bharadwaj, A. Effect of drilling process parameters on delamination factor in drilling of pultruded glass fiber reinforced polymer composite. Mater. Today Proc. 2022, 64, 1290–1294. [Google Scholar] [CrossRef]

- Mohan, N.S.; Kulkarni, S.M.; Ramachandra, A. Delamination analysis in drilling process of glass fiber reinforced plastic (GFRP) composite materials. J. Mater. Process. Technol. 2007, 186, 265–271. [Google Scholar] [CrossRef]

- Chadha, V.; Gupta, S.; Singari, R.M. Optimization of cutting parameters on delamination using Taguchi method during drilling of GFRP composites. In Proceedings of the International Multi Conference of Engineers and Computer Scientists, Kowloon, Hong Kong, 15–17 March 2017; Volume 2. [Google Scholar]

- Yalçın, B. Surface roughness and cutting forces in turning of tool steel with mixed ceramic and cubic boron nitride cutting tools. Trans. Can. Soc. Mech. Eng. 2015, 39, 323–336. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Y.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Malik, K.; Ahmad, F.; Keong, W.T.; Gunister, E. The effects of drilling parameters on thrust force, temperature and hole quality of glass fiber reinforced polymer composites. Polym. Polym. Compos. 2022, 30, 09673911221131113. [Google Scholar] [CrossRef]

- Mudhukrishnan, M.; Hariharan, P.; Palanikumar, K. Measurement and analysis of thrust force and delamination in drilling glass fiber reinforced polypropylene composites using different drills. Measurement 2020, 149, 106973. [Google Scholar] [CrossRef]

- Latha, B.; Senthilkumar, V.S.; Palanikumar, K. Influence of drill geometry on thrust force in drilling GFRP composites. J. Reinf. Plast. Compos. 2011, 30, 463–472. [Google Scholar] [CrossRef]

- El-Sonbaty, I.; Khashaba, U.A.; Machaly, T. Factors affecting the machinability of GFR/epoxy composites. Compos. Struct. 2004, 63, 329–338. [Google Scholar] [CrossRef]

- Mohan, N.S.; Ramachandra, A.; Kulkarni, S.M. Machining of fiber-reinforced thermoplastics: Influence of feed and drill size on thrust force and torque during drilling. J. Reinf. Plast. Compos. 2005, 24, 1247–1257. [Google Scholar] [CrossRef]

- Rajamurugan, T.V.; Shanmugam, K.; Rajakumar, S.; Palanikumar, K. Modelling and analysis of thrust force in drilling of GFRP composites using response surface methodology (RSM). Procedia Eng. 2012, 38, 3757–3768. [Google Scholar] [CrossRef]

- Abhishek, K.; Datta, S.; Mahapatra, S.S. Optimization of thrust, torque, entry, and exist delamination factor during drilling of CFRP composites. Int. J. Adv. Manuf. Technol. 2015, 76, 401–416. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P. Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos. Struct. 2003, 59, 481–487. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Kumar, M.S.; Zitoune, R.; Davim, J.P. Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos. Part B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Palanikumar, K. Experimental investigation and optimisation in drilling of GFRP composites. Measurement 2011, 44, 2138–2148. [Google Scholar] [CrossRef]

- Tsao, C.C. Investigation into the effects of drilling parameters on delamination by various step-core drills. J. Mater. Process. Technol. 2008, 206, 405–411. [Google Scholar] [CrossRef]

- Abrao, A.M.; Rubio, J.C.; Faria, P.E.; Davim, J.P. The effect of cutting tool geometry on thrust force and delamination when drilling glass fibre reinforced plastic composite. Mater. Des. 2008, 29, 508–513. [Google Scholar] [CrossRef]

- Shyha, I.S.; Aspinwall, D.K.; Soo, S.L.; Bradley, S. Drill geometry and operating effects when cutting small diameter holes in CFRP. Int. J. Mach. Tools Manuf. 2009, 49, 1008–1014. [Google Scholar] [CrossRef]

- Melentiev, R.; Priarone, P.C.; Robiglio, M.; Settineri, L. Effects of tool geometry and process parameters on delamination in CFRP drilling: An overview. Procedia CIRP 2016, 45, 31–34. [Google Scholar] [CrossRef]

- Rahmani, H.; Najafi, S.H.M.; Saffarzadeh-affar, S.; Ashori, A. Mechanical properties of carbon fiber/epoxy composites: Effects of number of plies, fiber contents, and angle-ply layers. Polym. Eng. Sci. 2014, 54, 2676–2682. [Google Scholar] [CrossRef]

- Hadăr, A.; Baciu, F.; Voicu, A.D.; Vlăsceanu, D.; Tudose, D.I.; Adetu, C. Mechanical characteristics evaluation of a single ply and multi-ply carbon fiber-reinforced plastic subjected to tensile and bending loads. Polymers 2022, 14, 3213. [Google Scholar] [CrossRef] [PubMed]

- Subagia, I.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

| Trial No. | Spindle Speed (rev/min) | Feed Rate (mm/rev) | Tool Diameter |

|---|---|---|---|

| 1 | 1000 | 0.2 | 3 |

| 2 | 1000 | 0.4 | 3 |

| 3 | 1000 | 0.6 | 5 |

| 4 | 1000 | 0.8 | 5 |

| 5 | 2250 | 0.2 | 3 |

| 6 | 2250 | 0.4 | 3 |

| 7 | 2250 | 0.6 | 5 |

| 8 | 2250 | 0.8 | 5 |

| 9 | 4000 | 0.2 | 5 |

| 10 | 4000 | 0.4 | 5 |

| 11 | 4000 | 0.6 | 3 |

| 12 | 4000 | 0.8 | 3 |

| 13 | 5750 | 0.2 | 5 |

| 14 | 5750 | 0.4 | 5 |

| 15 | 5750 | 0.6 | 3 |

| 16 | 5750 | 0.8 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yalçın, B.; Bolat, Ç.; Ergene, B.; Karakılınç, U.; Yavaş, Ç.; Öz, Y.; Ercetin, A.; Maraş, S.; Der, O. Effect of Drilling Parameters and Tool Diameter on Delamination and Thrust Force in the Drilling of High-Performance Glass/Epoxy Composites for Aerospace Structures with a New Design Drill. Polymers 2024, 16, 3011. https://doi.org/10.3390/polym16213011

Yalçın B, Bolat Ç, Ergene B, Karakılınç U, Yavaş Ç, Öz Y, Ercetin A, Maraş S, Der O. Effect of Drilling Parameters and Tool Diameter on Delamination and Thrust Force in the Drilling of High-Performance Glass/Epoxy Composites for Aerospace Structures with a New Design Drill. Polymers. 2024; 16(21):3011. https://doi.org/10.3390/polym16213011

Chicago/Turabian StyleYalçın, Bekir, Çağın Bolat, Berkay Ergene, Uçan Karakılınç, Çağlar Yavaş, Yahya Öz, Ali Ercetin, Sinan Maraş, and Oguzhan Der. 2024. "Effect of Drilling Parameters and Tool Diameter on Delamination and Thrust Force in the Drilling of High-Performance Glass/Epoxy Composites for Aerospace Structures with a New Design Drill" Polymers 16, no. 21: 3011. https://doi.org/10.3390/polym16213011

APA StyleYalçın, B., Bolat, Ç., Ergene, B., Karakılınç, U., Yavaş, Ç., Öz, Y., Ercetin, A., Maraş, S., & Der, O. (2024). Effect of Drilling Parameters and Tool Diameter on Delamination and Thrust Force in the Drilling of High-Performance Glass/Epoxy Composites for Aerospace Structures with a New Design Drill. Polymers, 16(21), 3011. https://doi.org/10.3390/polym16213011