Application of Poly(lactic Acid) Composites in the Automotive Sector: A Critical Review

Abstract

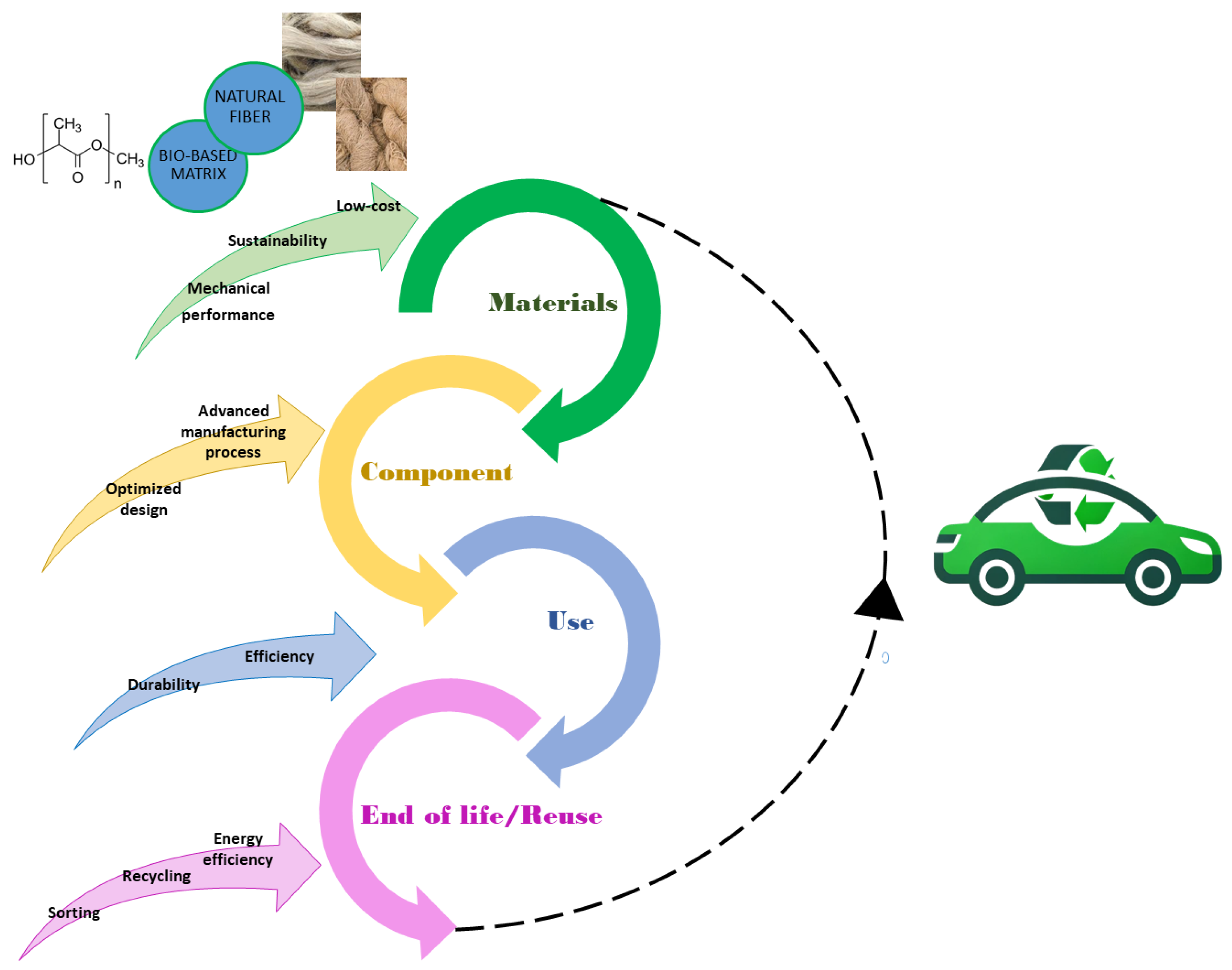

1. Introduction

2. The Use of PLA in Composites

2.1. PLA in Synthetic and Hybrid Composites

2.2. PLA in Natural Fiber Composites

3. Processing Techniques for PLA-Based Products

- Filament winding [51]: this process involves winding fibers impregnated with PLA resin onto a mandrel to create composite parts like tanks or structural components;

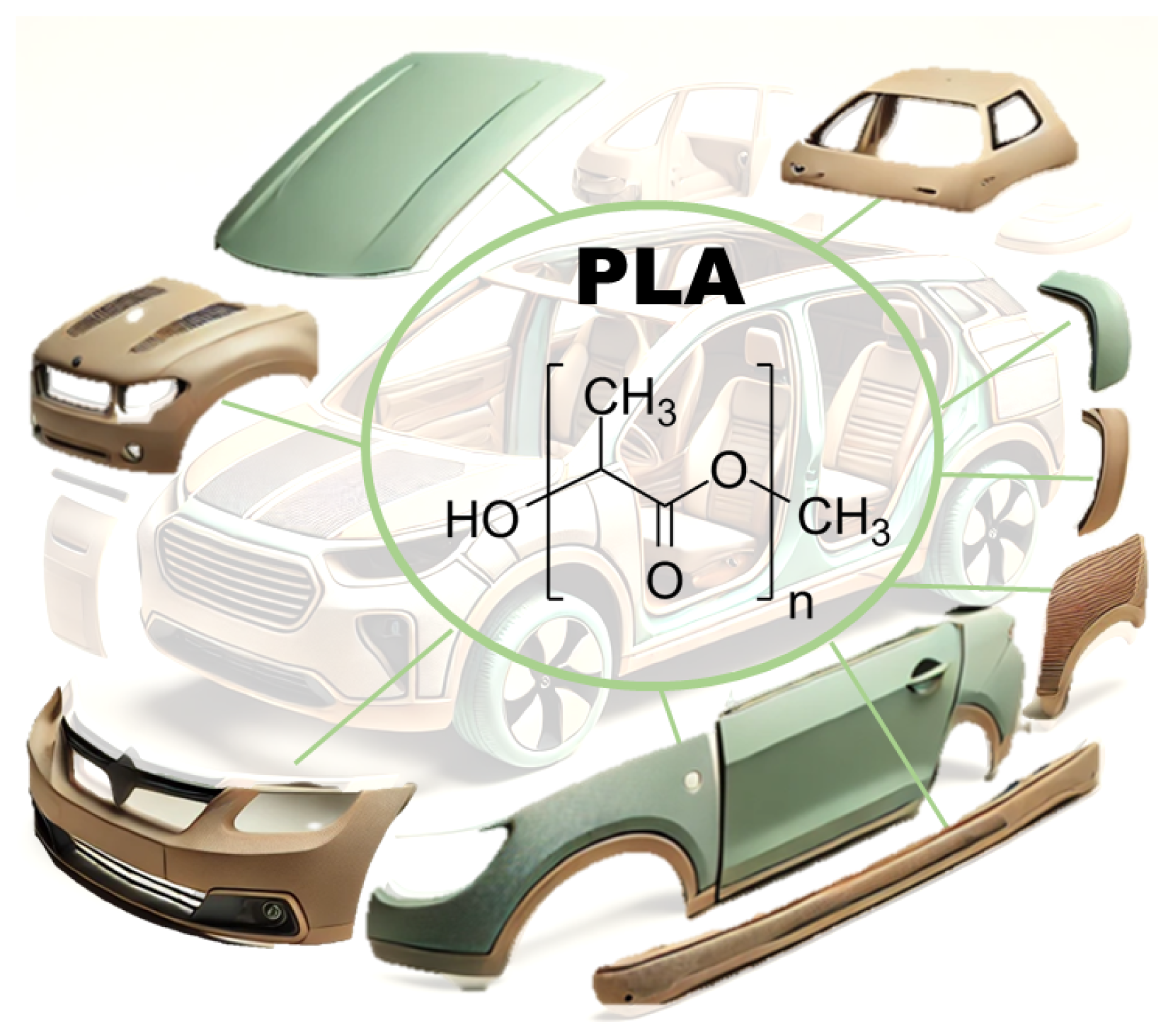

4. Automotive Components Realized Using PLA Composites

- Impurities: impurities in bio-sources can negatively affect the polymerization process and the quality of the final composites.

- Complex chemistry: the chemistry of bio-based materials is more complex than that of petroleum-based materials, making polymerization more challenging.

- Sensitivity to heat and humidity: bio-based materials are highly sensitive to heat and humidity, restricting the temperature and conditions for production and use.

- Degradation over time: bio-based materials tend to degrade over time, which can affect their performance and suitability for polymerization.

- Inconsistency of mechanical properties: natural fibers often exhibit large scattering in mechanical properties due to variations in growing conditions from one crop to another, and their performance is generally poorer compared to synthetic counterparts.

5. Future Developments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ABS | Acrylonitrile Butadiene Styrene |

| AE | Absorbed Energy |

| AM | Additive Manufacturing |

| BAI | Bending After Impact |

| C | Carbon |

| CCF | Continuous Carbon Fibers |

| CNF | Nanofibrillated Cellulose |

| CO2 | Carbon Dioxide |

| F | Flax |

| FDM | Fused Deposition Modeling |

| FEA | Finite Element Analysis |

| FVF | Fiber Volume Fraction |

| G | Glass |

| GHG | Greenhouse Gas |

| GFRP | Glass Fiber-Reinforced Polymer |

| GR | Graphene |

| J | Jute |

| KF | Kenaf |

| K | Kevlar |

| LCA | Life Cycle Assessment |

| LVI | Low-Velocity Impact |

| MCC | Microcrystalline Cellulose |

| MFC | Microfibrillated Cellulose |

| MWCNTs | Multiwalled Carbon Nanotubes |

| NCC | Nanocrystalline Cellulose |

| NFCs | Natural Fiber Composites |

| o-MMT | Organically Modified Montmorillonite |

| PAs | Polyamides |

| PE | Poly(ethylene) |

| PEEK | Polyetheretherketone |

| PEG | Poly(ethylene glycol) |

| PEI | Polyethyleneimine |

| PET | Poly(ethylene terephthalate) |

| PHAs | Poly(hydroxyalkanoates) |

| PI | Polyimide |

| PLA | Poly(lactic acid) |

| PP | Polypropylene |

| R | Ramie |

| SCF | Short Carbon Fibers |

| SMC | Sheet Molding Compound |

| TPS | Thermoplastic starches |

| UD | Unidirectional |

| VOCs | Volatile Organic Compounds |

| ZnO | Zinc Oxide |

References

- Rahman, M.Z.; Rahman, M.; Mahbub, T.; Ashiquzzaman, M.; Sagadevan, S.; Hoque, M.E. Advanced biopolymers for automobile and aviation engineering applications. J. Polym. Res. 2023, 30, 106. [Google Scholar] [CrossRef]

- Cywar, R.M.; Rorrer, N.A.; Hoyt, C.B.; Beckham, G.T.; Chen, E.Y.X. Bio-based polymers with performance-advantaged properties. Nat. Rev. Mater. 2022, 7, 83–103. [Google Scholar] [CrossRef]

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.T.; Shahid, M.A.; Akter, S.; Ferdous, J.; Afroz, K.; Refat, K.R.I.; Jamal, O.F.M.S.I.; Uddin, M.N.; Samad, M.A.B. Cellulose and starch-based bioplastics: A review of advances and challenges for sustainability. Polym.-Plast. Technol. Mater. 2024, 63, 1329–1349. [Google Scholar] [CrossRef]

- Musa, A.; Onwualu, A. Potential of lignocellulosic fiber reinforced polymer composites for automobile parts production: Current knowledge, research needs, and future direction. Heliyon 2024, 10, e24683. [Google Scholar] [CrossRef]

- Kaseem, M.; Hamad, K.; Deri, F. Thermoplastic starch blends: A review of recent works. Polym. Sci. Ser. A 2012, 54, 165–176. [Google Scholar] [CrossRef]

- Bouzouita, A.; Notta-Cuvier, D.; Raquez, J.M.; Lauro, F.; Dubois, P. Poly(lactic acid)-Based Materials for Automotive Applications. In Industrial Applications of Poly(Lactic Acid); Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–43. [Google Scholar] [CrossRef]

- Reddy, C.; Ghai, R.; Rashmi; Kalia, V. Polyhydroxyalkanoates: An overview. Bioresour. Technol. 2003, 87, 137–146. [Google Scholar] [CrossRef]

- Pradeep, S.A.; Deshpande, A.M.; Limaye, M.; Iyer, R.K.; Kazan, H.; Li, G.; Pilla, S. 31-A Perspective on the Evolution of Plastics and Composites in the Automotive Industry. In Applied Plastics Engineering Handbook, 3rd ed.; Kutz, M., Ed.; Plastics Design Library; William Andrew Publishing: Hoboken, NJ, USA, 2024; pp. 705–748. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2017, 38, 2553–2569. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Pinheiro, I.F.; de Souza, S.F.; Mei, L.H.I.; Lona, L.M.F. Polymer Composites Reinforced with Natural Fibers and Nanocellulose in the Automotive Industry: A Short Review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Mishra, P.; Jagadesh, T. Applications and Challenges of 3D Printed Polymer Composites in the Emerging Domain of Automotive and Aerospace: A Converged Review. J. Inst. Eng. (India) Ser. D 2022, 104, 849–866. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.; Singh, H. PLA based biocomposites for sustainable products: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Tawiah, B.; Yu, B.; Fei, B. Advances in Flame Retardant Poly(Lactic Acid). Polymers 2018, 10, 876. [Google Scholar] [CrossRef] [PubMed]

- Jagadeesh, P.; Puttegowda, M.; Boonyasopon, P.; Rangappa, S.M.; Khan, A.; Siengchin, S. Recent developments and challenges in natural fiber composites: A review. Polym. Compos. 2022, 43, 2545–2561. [Google Scholar] [CrossRef]

- Thirugnanasamabandam, A.; Subramaniyan, M.; Prabhu, B.; Ramachandran, K. Development and comprehensive investigation on PLA/carbon fiber reinforced PLA based structurally alternate layered polymer composites. J. Ind. Eng. Chem. 2024, 136, 248–257. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos. Part Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. Part Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Alkabbanie, R.; Aktas, B.; Demircan, G.; Yalcin, S. Short carbon fiber-reinforced PLA composites: Influence of 3D-printing parameters on the mechanical and structural properties. Iran. Polym. J. 2024, 33, 1065–1074. [Google Scholar] [CrossRef]

- Maqsood, N.; Rimašauskas, M. Characterization of carbon fiber reinforced PLA composites manufactured by fused deposition modeling. Compos. Part Open Access 2021, 4, 100112. [Google Scholar] [CrossRef]

- Uşun, A.; Gümrük, R. The mechanical performance of the 3D printed composites produced with continuous carbon fiber reinforced filaments obtained via melt impregnation. Addit. Manuf. 2021, 46, 102112. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, X.; Mao, J.; Zhao, M.; Liu, G. Experimental analysis of 3D printed continuous carbon/glass hybrid fiber reinforced PLA composites: Revealing synergistic mechanical properties and failure mechanisms. Polym. Compos. 2024, 45, 10888–10897. [Google Scholar] [CrossRef]

- Varsavas, S.D.; Kaynak, C. Effects of glass fiber reinforcement and thermoplastic elastomer blending on the mechanical performance of polylactide. Compos. Commun. 2018, 8, 24–30. [Google Scholar] [CrossRef]

- Sun, Y.; Zheng, Z.; Wang, Y.; Yang, B.; Wang, J.; Mu, W. PLA composites reinforced with rice residues or glass fiber—A review of mechanical properties, thermal properties, and biodegradation properties. J. Polym. Res. 2022, 29, 422. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Wan, G.; Li, B.; Zhao, G. Glass fiber reinforced PLA composite with enhanced mechanical properties, thermal behavior, and foaming ability. Polymer 2019, 181, 121803. [Google Scholar] [CrossRef]

- Yang, J.; Guo, Y.; Yao, L.; Ni, Q.; Qiu, Y. Effects of Kevlar volume fraction and fabric structures on the mechanical properties of 3D orthogonal woven ramie/Kevlar reinforced poly (lactic acid) composites. J. Ind. Text. 2018, 47, 2074–2091. [Google Scholar] [CrossRef]

- Akonda, M.; Alimuzzaman, S.; Shah, D.U.; Rahman, A.M. Physico-Mechanical, Thermal and Biodegradation Performance of Random Flax/Polylactic Acid and Unidirectional Flax/Polylactic Acid Biocomposites. Fibers 2018, 6, 98. [Google Scholar] [CrossRef]

- Couture, A.; Lebrun, G.; Laperrière, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers. Compos. Struct. 2016, 154, 286–295. [Google Scholar] [CrossRef]

- Charca, S.; Jiao-Wang, L.; Loya, J.; Martínez, M.A.; Santiuste, C. High cycle fatigue life analysis of unidirectional flax/PLA composites through infrared thermography. Compos. Struct. 2024, 344, 118370. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.M.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.; Sanjay, M.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites – A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Manral, A.; Ahmad, F.; Chaudhary, V. Static and dynamic mechanical properties of PLA bio-composite with hybrid reinforcement of flax and jute. Mater. Today Proc. 2020, 25, 577–580. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Development and characterization of PLA-based green composites: A review. J. Thermoplast. Compos. Mater. 2014, 27, 52–81. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wan, H.; Wang, B.; Wang, B.; Chen, K.; Tan, H.; Sun, C.; Zhang, Y. Preparation and properties of bamboo fiber/polylactic acid composite modified with polycarbodiimide. Ind. Crop. Prod. 2024, 218, 118829. [Google Scholar] [CrossRef]

- Fang, X.; Li, Y.; Zhao, J.; Xu, J.; Li, C.; Liu, J.; Liu, Y.; Guo, H. Improved interfacial performance of bamboo fibers/polylactic acid composites enabled by a self-supplied bio-coupling agent strategy. J. Clean. Prod. 2022, 380, 134719. [Google Scholar] [CrossRef]

- Swetha, T.A.; Bora, A.; Mohanrasu, K.; Balaji, P.; Raja, R.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A comprehensive review on polylactic acid (PLA)—Synthesis, processing and application in food packaging. Int. J. Biol. Macromol. 2023, 234, 123715. [Google Scholar] [CrossRef]

- Zibaei, R.; Ebrahimi, B.; Rouhi, M.; Hashami, Z.; Roshandel, Z.; Hasanvand, S.; De Toledo Guimarães, J.; Goharifar, M.; Mohammadi, R. Development of packaging based on PLA/POE/SeNPs nanocomposites by blown film extrusion method: Physicochemical, structural, morphological and antioxidant properties. Food Packag. Shelf Life 2023, 38, 101104. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, M.; Ju, Z.; Tam, P.Y.; Hua, T.; Younas, M.W.; Kamrul, H.; Hu, H. Poly(lactic acid) fibers, yarns and fabrics: Manufacturing, properties and applications. Text. Res. J. 2021, 91, 1641–1669. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Harussani, M.; Hakimi, M.; Haziq, M.; Atikah, M.; Asyraf, M.; Ishak, M.; Razman, M.; Nurazzi, N.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Dejene, B.K.; Gudayu, A.D. Eco-Friendly Packaging Innovations: Integrating Natural Fibers and ZnO Nanofillers in Polylactic Acid (PLA) Based Green Composites–A Review. Polym.-Plast. Technol. Mater. 2024, 63, 1645–1681. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kourinou, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.; Tzounis, L. Additive manufacturing of multifunctional polylactic acid (PLA)—Multiwalled carbon nanotubes (MWCNTs) nanocomposites. Nanocomposites 2021, 7, 184–199. [Google Scholar] [CrossRef]

- Cailloux, J.; Hakim, R.; Santana, O.; Bou, J.; Abt, T.; Sánchez-Soto, M.; Carrasco, F.; Maspoch, M. Reactive extrusion: A useful process to manufacture structurally modified PLA/o-MMT composites. Compos. Part Appl. Sci. Manuf. 2016, 88, 106–115. [Google Scholar] [CrossRef]

- Abdalla, A.; Hamzah, H.; Keattch, O.; Covill, D.; Patel, B. Augmentation of conductive pathways in carbon black/PLA 3D-printed electrodes achieved through varying printing parameters. Electrochim. Acta 2020, 354, 136618. [Google Scholar] [CrossRef]

- Ma, X.; Hu, Q.; Dai, Y.; He, P.; Zhang, X. Disposable sensors based on biodegradable polylactic acid piezoelectret films and their application in wearable electronics. Sens. Actuators Phys. 2022, 346, 113834. [Google Scholar] [CrossRef]

- Yan, T.; Ye, X.; He, E.; Gao, Q.; Wang, Y.; Ye, Y.; Wu, H. GR-Fe3O4/PLA 3D printing composite materials with excellent microwave absorption properties. J. Alloys Compd. 2024, 972, 172799. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Odent, J.; Delille, R.; Murariu, M.; Lauro, F.; Raquez, J.; Bennani, B.; Dubois, P. Tailoring polylactide (PLA) properties for automotive applications: Effect of addition of designed additives on main mechanical properties. Polym. Test. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- Benini, K.C.C.D.C.; Bomfim, A.S.C.D.; Voorwald, H.J.C. Cellulose-Reinforced Polylactic Acid Composites for Three-Dimensional Printing Using Polyethylene Glycol as an Additive: A Comprehensive Review. Polymers 2023, 15, 3960. [Google Scholar] [CrossRef]

- Aumnate, C.; Soatthiyanon, N.; Makmoon, T.; Potiyaraj, P. Polylactic acid/kenaf cellulose biocomposite filaments for melt extrusion based-3D printing. Cellulose 2021, 28, 8509–8525. [Google Scholar] [CrossRef]

- Moscoso-Sánchez, F.J.; Alvarad, A.; Martínez-Chávez, L.; Hernández-Montelongo, R.; Escamilla, V.V.F.; Escamilla, G.C. The effects of henequen cellulose treated with polyethylene glycol on properties of polylactic acid composites. BioResources 2019, 14, 2707–2726. [Google Scholar] [CrossRef]

- Ma, Q.; Ge, J.; Rejab, M.; Sun, B.; Ding, Y.; Nie, X.; Pang, H. Fabrication of the carbon fiber reinforced plastic (CFRP) cone tube through the laboratory-scale 3-axis winding machine. Mater. Today Proc. 2021, 46, 1645–1651. [Google Scholar] [CrossRef]

- Li, P.; Ma, J.; He, L.; Wu, S.; Yang, P.; Zhao, L.; Zhang, Y.; Zhu, Y.; Tan, H. Pultrusion preparation and properties of continuous glass fiber reinforced polylactic acid thermoplastic composites. J. Appl. Polym. Sci. 2023, 140, e54292. [Google Scholar] [CrossRef]

- Linganiso, L.Z.; Bezerra, R.; Bhat, S.; John, M.; Braeuning, R.; Anandjiwala, R.D. Pultrusion of flax/poly(lactic acid) commingled yarns and nonwoven fabrics. J. Thermoplast. Compos. Mater. 2014, 27, 1553–1572. [Google Scholar] [CrossRef]

- Memon, A.; Nakai, A. The Processing Design of Jute Spun Yarn/PLA Braided Composite by Pultrusion Molding. Adv. Mech. Eng. 2013, 5, 816513. [Google Scholar] [CrossRef]

- Milenkovic, S.; Slavkovic, V.; Fragassa, C.; Grujovic, N.; Palic, N.; Zivic, F. Effect of the raster orientation on strength of the continuous fiber reinforced PVDF/PLA composites, fabricated by hand-layup and fused deposition modeling. Compos. Struct. 2021, 270, 114063. [Google Scholar] [CrossRef]

- Li, Y.; Ding, Q.; Zhao, H.; Wu, T.; Zhang, M.; Zhang, Y. Anisotropic Properties of Polylactic acid–carbon Fiber Composites Prepared by Droplet spray Additive Manufacturing. Materials 2019, 12, 669. [Google Scholar] [CrossRef] [PubMed]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Anuar, H.; Zuraida, A.; Kovacs, J.G.; Tabi, T. Improvement of Mechanical Properties of Injection-Molded Polylactic Acid–Kenaf Fiber Biocomposite. J. Thermoplast. Compos. Mater. 2012, 25, 153–164. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M. Characterisation of polylactic acid biocomposites made from prepregs composed of woven polylactic acid/hemp–Lyocell hybrid yarn fabrics. Compos. Part Appl. Sci. Manuf. 2016, 81, 139–144. [Google Scholar] [CrossRef]

- Rubio-López, A.; Olmedo, A.; Díaz-Álvarez, A.; Santiuste, C. Manufacture of compression moulded PLA based biocomposites: A parametric study. Compos. Struct. 2015, 131, 995–1000. [Google Scholar] [CrossRef]

- Almeida, V.H.M.; Jesus, R.M.; Santana, G.M.; Pereira, T.B. Polylactic Acid Polymer Matrix (Pla) Biocomposites with Plant Fibers for Manufacturing 3D Printing Filaments: A Review. J. Compos. Sci. 2024, 8, 67. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Reverte, J.M.; Caminero, M.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Becar, J.P. Mechanical and Geometric Performance of PLA-Based Polymer Composites Processed by the Fused Filament Fabrication Additive Manufacturing Technique. Materials 2020, 13, 1924. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Q.; Kang, Y.; Wang, Y.; Liu, J. An investigation of preparation of continuous carbon fiber reinforced PLA prepreg filament. Compos. Commun. 2023, 39, 101530. [Google Scholar] [CrossRef]

- Ying, Z.; Wu, D.; Zhang, M.; Qiu, Y. Polylactide/basalt fiber composites with tailorable mechanical properties: Effect of surface treatment of fibers and annealing. Compos. Struct. 2017, 176, 1020–1027. [Google Scholar] [CrossRef]

- Gong, K.; Liu, H.; Huang, C.; Jiang, Q.; Xu, H.; Cao, Z.; Fuenmayor, E.; Major, I. Mass Customization of Polylactic Acid (PLA) Parts via a Hybrid Manufacturing Process. Polymers 2022, 14, 5413. [Google Scholar] [CrossRef]

- Mushtaq, R.T.; Iqbal, A.; Wang, Y.; Khan, A.M.; Petra, M.I. Advancing PLA 3D Printing with Laser Polishing: Improving Mechanical Strength, Sustainability, and Surface Quality. Crystals 2023, 13, 626. [Google Scholar] [CrossRef]

- Chen, K.; Yu, L.; Cui, Y.; Jia, M.; Pan, K. Optimization of printing parameters of 3D-printed continuous glass fiber reinforced polylactic acid composites. Thin-Walled Struct. 2021, 164, 107717. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Berto, F.; Ayatollahi, M.R.; Reinicke, T. Characterization of 3D-printed PLA parts with different raster orientations and printing speeds. Sci. Rep. 2022, 12, 1016. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of Print Orientation on Surface Roughness in Fused Deposition Modeling (FDM) Processes. Materials 2019, 12, 3834. [Google Scholar] [CrossRef]

- Kaščak, J.; Gašpár, Š.; Paško, J.; Husár, J.; Knapčíková, L. Polylactic Acid and Its Cellulose Based Composite as a Significant Tool for the Production of Optimized Models Modified for Additive Manufacturing. Sustainability 2021, 13, 1256. [Google Scholar] [CrossRef]

- Matsumoto, K.; Takemura, K.; Kitamura, R.; Katogi, H.; Tanaka, T.; Takagi, H. Cellulose nanofiber-introduced continuous-ramie yarn-reinforced polylactic acid filament for 3D printing: Novel fabrication process and mechanical properties. Compos. Part Appl. Sci. Manuf. 2024, 176, 107836. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three-dimensional printing of poly(lactic acid) bio-based composites with sugarcane bagasse fiber: Effect of printing orientation on tensile performance. Polym. Adv. Technol. 2019, 30, 910–922. [Google Scholar] [CrossRef]

- Murphy, C.A.; Collins, M.N. Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym. Compos. 2018, 39, 1311–1320. [Google Scholar] [CrossRef]

- Molinari, G.; Gigante, V.; Fiori, S.; Aliotta, L.; Lazzeri, A. Dispersion of Micro Fibrillated Cellulose (MFC) in Poly(lactic acid) (PLA) from Lab-Scale to Semi-Industrial Processing Using Biobased Plasticizers as Dispersing Aids. Chemistry 2021, 3, 896–915. [Google Scholar] [CrossRef]

- Ahmad, N.D.; Kusmono; Wildan, M.W.; Herianto. Preparation and properties of cellulose nanocrystals-reinforced Poly (lactic acid) composite filaments for 3D printing applications. Results Eng. 2023, 17, 100842. [Google Scholar] [CrossRef]

- Agbakoba, V.C.; Mokhena, T.C.; Ferg, E.E.; Hlangothi, S.P.; John, M.J. PLA bio-nanocomposites reinforced with cellulose nanofibrils (CNFs) for 3D printing applications. Cellulose 2023, 30, 11537–11559. [Google Scholar] [CrossRef]

- Gauss, C.; Pickering, K.L. A new method for producing polylactic acid biocomposites for 3D printing with improved tensile and thermo-mechanical performance using grafted nanofibrillated cellulose. Addit. Manuf. 2023, 61, 103346. [Google Scholar] [CrossRef]

- Baptista, R.; Guedes, M.; Pereira, M.; Maurício, A.; Carrelo, H.; Cidade, T. On the effect of design and fabrication parameters on mechanical performance of 3D printed PLA scaffolds. Bioprinting 2020, 20, e00096. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Andrzejewski, J.; Matykiewicz, D.; Skórczewska, K.; Lewandowski, K.; Jakubowicz, M.; Aniśko, J.; Gapiński, B.; Sałasińska, K.; et al. bioXpul™-technology for manufacturing PLA-based biocomposites with increased thermomechanical stability. Manuf. Lett. 2023, 35, 43–47. [Google Scholar] [CrossRef]

- Gigante, V.; Coltelli, M.B.; Vannozzi, A.; Panariello, L.; Fusco, A.; Trombi, L.; Donnarumma, G.; Danti, S.; Lazzeri, A. Flat Die Extruded Biocompatible Poly(Lactic Acid) (PLA)/Poly(Butylene Succinate) (PBS) Based Films. Polymers 2019, 11, 1857. [Google Scholar] [CrossRef]

- Mallegni, N.; Phuong, T.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Poly(lactic acid) (PLA) Based Tear Resistant and Biodegradable Flexible Films by Blown Film Extrusion. Materials 2018, 11, 148. [Google Scholar] [CrossRef] [PubMed]

- Harris, A.M.; Lee, E.C. Heat and humidity performance of injection molded PLA for durable applications. J. Appl. Polym. Sci. 2010, 115, 1380–1389. [Google Scholar] [CrossRef]

- European Commission. Determining the Environmental Impacts of Conventional and Alternatively Fuelled Vehicles through LCA; Technical Report; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Subic, A.; Schiavone, F.; Leary, M.; Manning, J. Comparative Life Cycle Assessment (LCA) of passenger seats and their impact on different vehicle models. Int. J. Veh. Des. 2010, 53, 89–109. [Google Scholar] [CrossRef]

- Ridge, L. EUCAR-Automotive LCA Guidelines-Phase 2; SAE: Warrendale, PA, USA, 1998; Volume 11. [Google Scholar] [CrossRef]

- Gibson, T. Life Cycle Assessment of Advanced Materials for Automotive Applications. SAE Trans. 2000, 1, 1932–1941. [Google Scholar] [CrossRef]

- Guide, G.V. Greenhouse Gas Emissions from a Typical Passenger Vehicle. Available online: https://www.epa.gov/greenvehicles/greenhouse-gas-emissions-typical-passenger-vehicle (accessed on 27 October 2024).

- Pero, F.D.; Delogu, M.; Pierini, M. Life Cycle Assessment in the automotive sector: A comparative case study of Internal Combustion Engine (ICE) and electric car. Procedia Struct. Integr. 2018, 12, 521–537. [Google Scholar] [CrossRef]

- Verma, S.; Dwivedi, G.; Verma, P. Life cycle assessment of electric vehicles in comparison to combustion engine vehicles: A review. Mater. Today Proc. 2022, 49, 217–222. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of composite materials in automobile applications–A review. J. Eng. Res. 2024, in press. [Google Scholar] [CrossRef]

- Jeyaguru, S.; Thiagamani, S.M.K.; Rangappa, S.M.; Siengchin, S.; Krishnasamy, S.; Muthukumar, C. 8-Lightweight and sustainable materials for automotive applications. In Lightweight and Sustainable Composite Materials; Rangappa, S.M., Doddamani, S.M., Siengchin, S., Doddamani, M., Eds.; Woodhead Publishing: Sawston, UK, 2023; pp. 143–156. [Google Scholar] [CrossRef]

- Busarac, N.; Adamovic, D.; Grujovic, N.; Zivic, F. Lightweight Materials for Automobiles. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1271, 012010. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar] [CrossRef]

- AL-Oqla, F.; Omari, M. Sustainable Biocomposites: Challenges, Potential and Barriers for Development. Green Biocompos. Manuf. Prop. 2017, 2, 13–29. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, P.; Li, Y.; Li, J.; Li, X.; Yang, J.; Ji, M.; Li, F.; Zhang, C. Recent advances and future challenges of the starch-based bio-composites for engineering applications. Carbohydr. Polym. 2023, 307, 120627. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef] [PubMed]

- Murawski, A.; Diaz, R.; Inglesby, S.; Delabar-Monroe, K.; Quirino, R. Synthesis of Bio-based Polymer Composites: Fabrication, Fillers, Properties, and Challenges. In Polymer Nanocomposites in Biomedical Engineering; Springer: Cham, Switzerland, 2019; pp. 29–55. [Google Scholar] [CrossRef]

- Abdul Malek, N.S.; Faizuwan, M.; Khusaimi, Z.; Bonnia, N.; Rusop, M.; Asli, N. Preparation and Characterization of Biodegradable Polylactic Acid (PLA) Film for Food Packaging Application: A Review. J. Phys. Conf. Ser. 2021, 1892, 012037. [Google Scholar] [CrossRef]

- De Luca, S.; Milanese, D.; Gallichi-Nottiani, D.; Cavazza, A.; Sciancalepore, C. Poly(lactic acid) and Its Blends for Packaging Application: A Review. Clean Technol. 2023, 5, 1304–1343. [Google Scholar] [CrossRef]

- Ramezani Dana, H.; Ebrahimi, F. Synthesis, properties, and applications of polylactic acid-based polymers. Polym. Eng. Sci. 2023, 63, 22–43. [Google Scholar] [CrossRef]

- Díaz, C.A.; Pao, H.Y.; Kim, S. Film Performance of Poly(lactic acid) Blends for Packaging Applications. J. Appl. Poult. Res. 2016, 8, 4. [Google Scholar]

- ADAPT, A.P.T. History Of Bioplastics In The Automotive Industry. Available online: https://adapt.mx/history-of-bioplastics-in-the-automotive-industry/ (accessed on 27 October 2024).

- Mitsubishi Motors Develops Plant-Based Green Plastic Floor Mat; Green Car Congress; 2006. Available online: https://www.greencarcongress.com/2006/06/mitsubishi_moto.html (accessed on 27 October 2024).

- Nadda, A.; Sharma, S.; Bhat, R.; Singh, H. Biopolymers Recent Updates, Challenges and Opportunities; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Rusu, D.; Boyer, S.; Lacrampe, M.F.; Krawczak, P. Bioplastics in automotive applications. In Proceedings of the Handbook of Bioplastics and Biocomposites Engineering Applications; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Bledzki, A.K.; Faruk, O.; Jaszkiewicz, A. Cars from Renewable Materials. Kompoz. Compos. 2010, 10, 282–288. [Google Scholar]

- Jung, J.W.; Kim, S.H.; Kim, S.H.; Park, J.K.; Lee, W.I. Research on the development of the properties of PLA composites for automotive interior parts. Compos. Res. 2011, 24, 1–5. [Google Scholar] [CrossRef][Green Version]

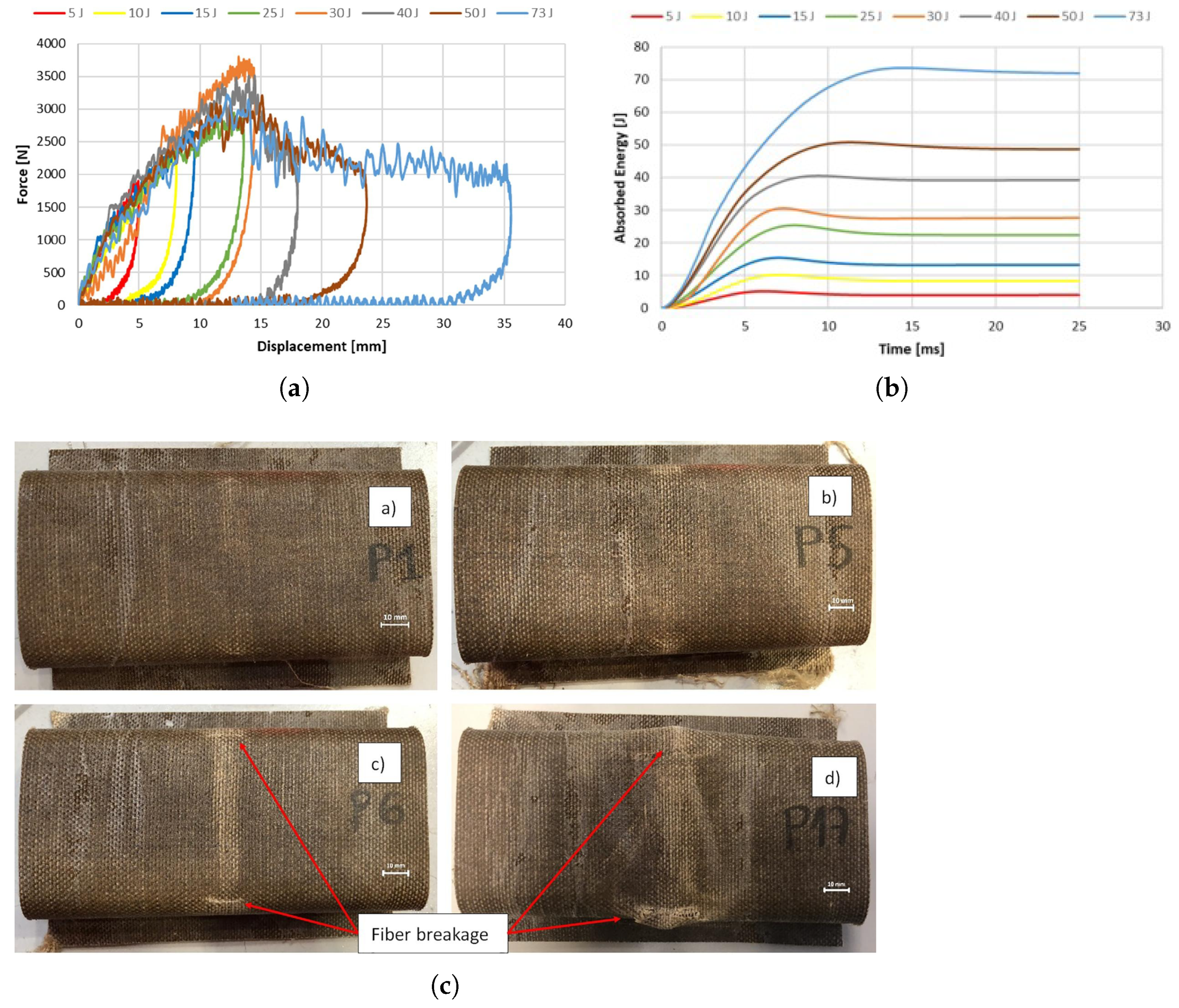

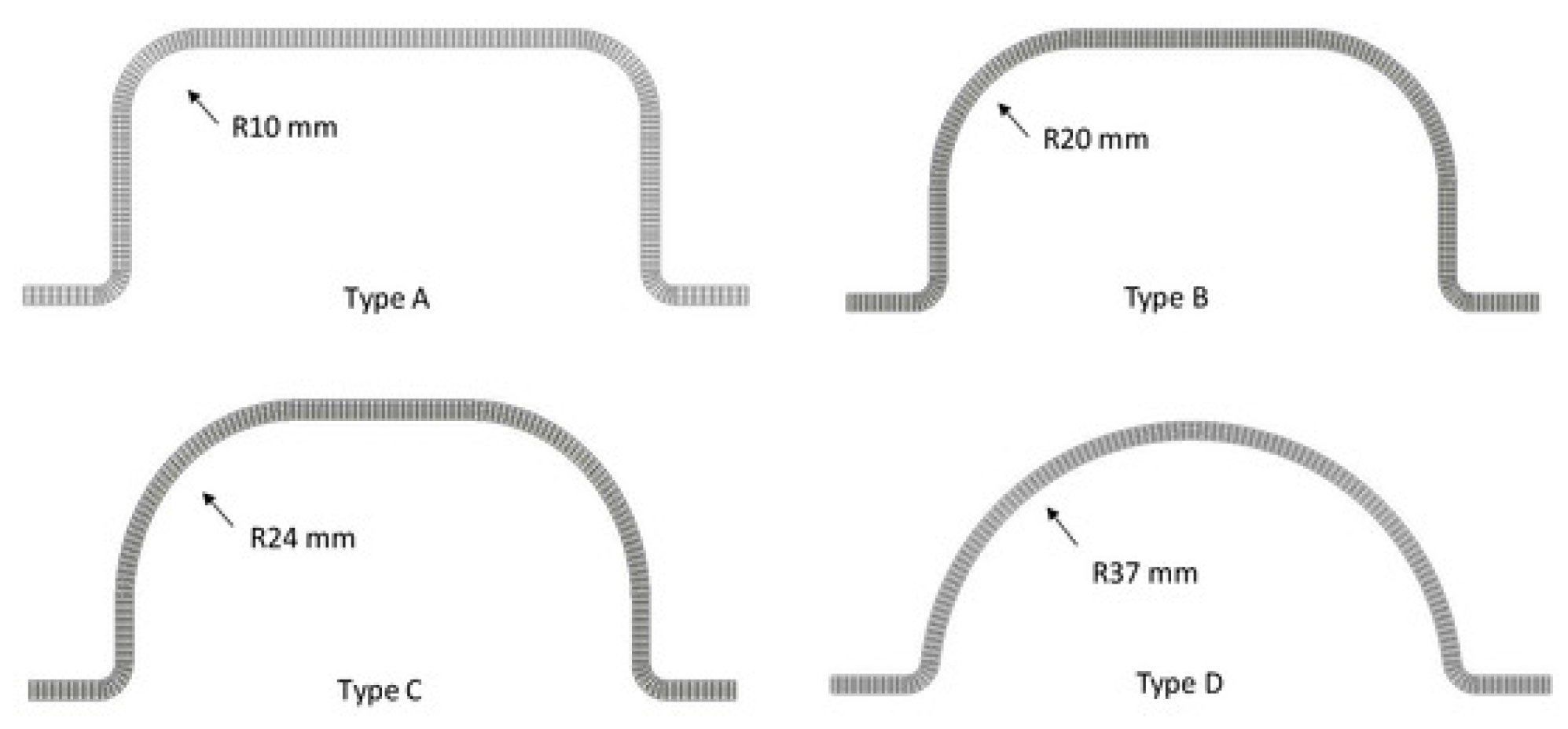

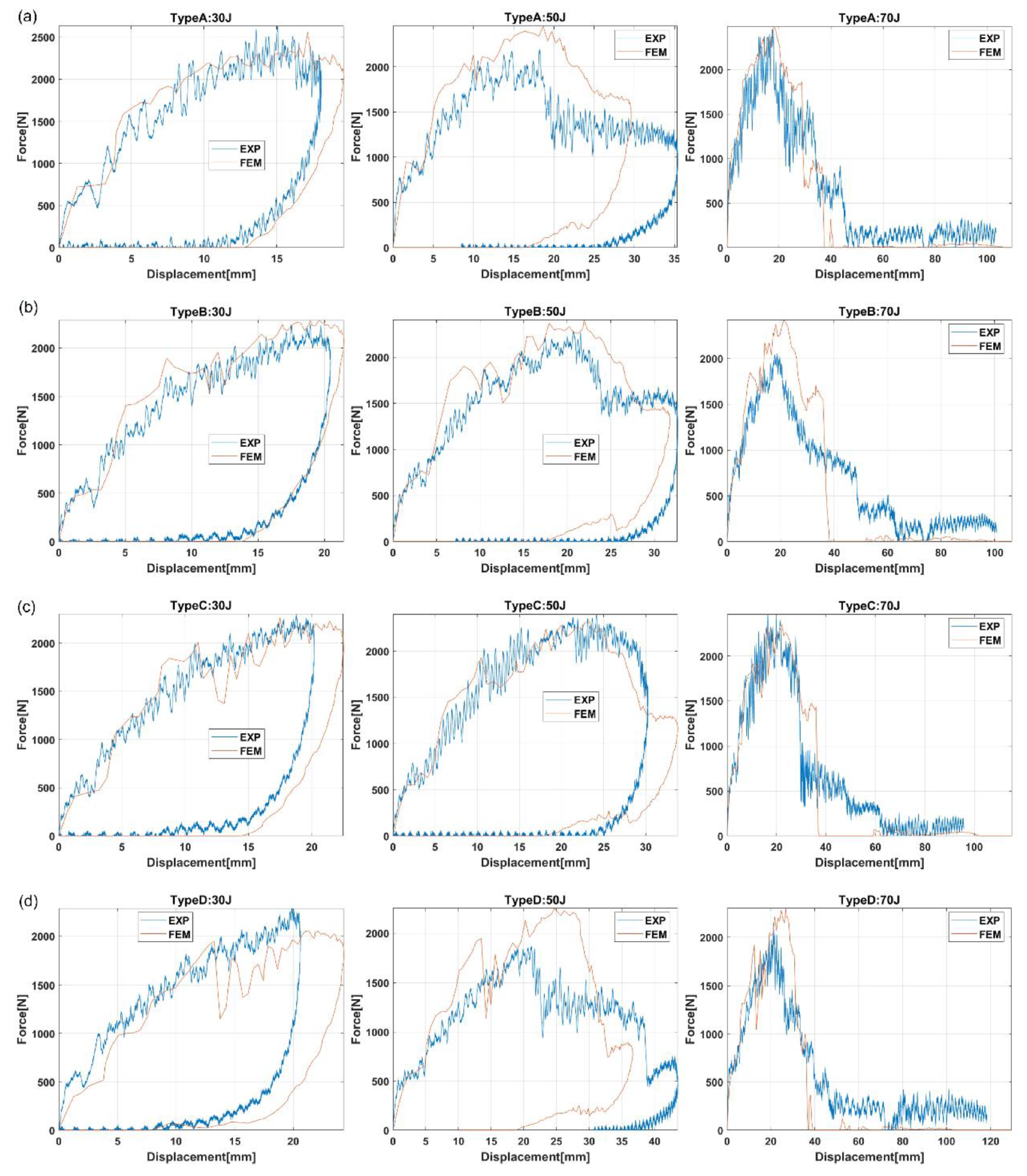

- Díaz-Álvarez, A.; Jiao-Wang, L.; Feng, C.; Santiuste, C. Energy absorption and residual bending behavior of biocomposites bumper beams. Compos. Struct. 2020, 245, 112343. [Google Scholar] [CrossRef]

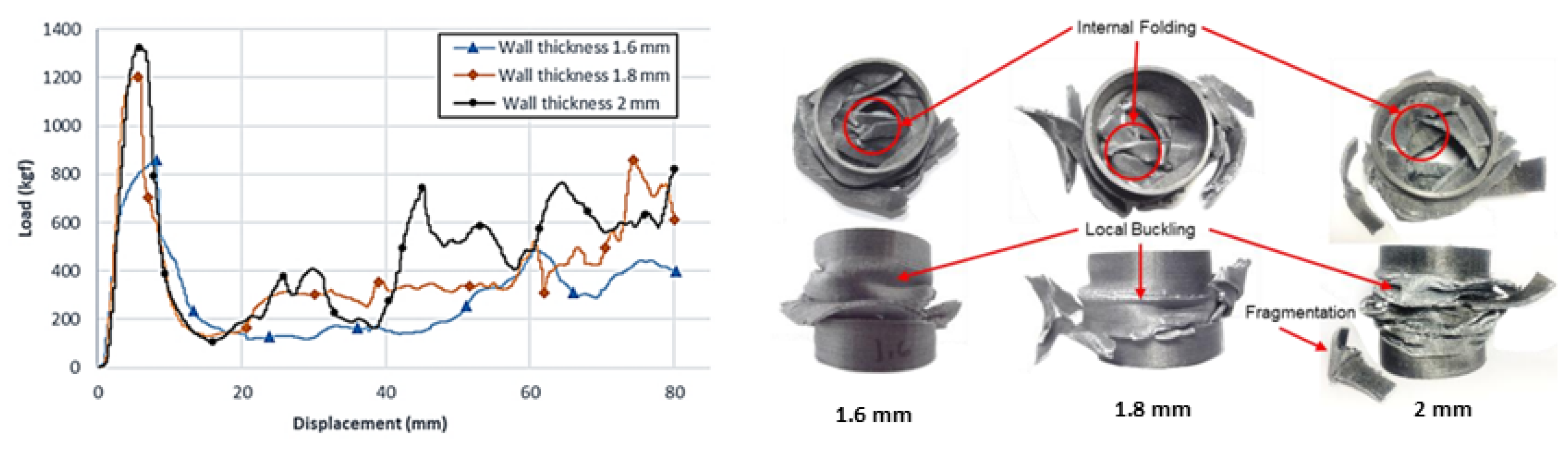

- Bintara, R.; Choiron, M. Deformation pattern and energy absorption of polylactic acid (PLA) carbon crash box under quasi static loading. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1034, 012011. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Hamada, H.; Maekawa, Z.; Sato, H. Energy absorption behavior of carbon-fiber-reinforced thermoplastic composite tubes. J. Thermoplast. Compos. Mater. 1995, 8, 323–344. [Google Scholar] [CrossRef]

- MatWeb. Overview of Materials for Polyetheretherketone, Unreinforced. Available online: https://www.matweb.com/search/datasheet_print.aspx?matguid=2164cacabcde4391a596640d553b2ebe (accessed on 27 October 2024).

- MatWeb. Overview of Materials for Polylactic Acid (PLA) Biopolymer. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=ab96a4c0655c4018a8785ac4031b9278 (accessed on 27 October 2024).

- Martin, R.; Giannis, S.; Mirza, S.; Hansen, K. Biocomposites in challenging automotive applications. Int. Conf. Compos. Mater. 2009. [Google Scholar]

- Sopher, S.; Sasaki, H. Lightweight Door Panel Made with Bio-Based Composite Material. In Proceedings of the SAE International; SAE: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Huvat, R.; Azizul, M.A.; Sulaiman, S. Characteristics of Abs and Pla Material in 3D Printing for Car Backseat Headrest Hanger/Hook Model. J. Automot. Powertrain Transp. Technol. 2021, 1, 9–24. [Google Scholar] [CrossRef]

- Guzman-Baeza, M.; Urriolagoitia-Sosa, G.; Martínez-Reyes, J.; Romero-Ángeles, B.; Soto-Barrón, F.; Torres-Yáñez, A.; Contreras-Mendoza, B.; Hernández-Patiño, O. Implementation of a Biopolymer in an Automotive Bumper. Social Science Research Network 2023. [Google Scholar] [CrossRef]

- Fatchurrohman, N.; Jun, H.X.; Muhida, R.; Adelino, M.I. Performance Simulation of Bio-Reinforced Composite Car Door Panel using Finite Element Analysis. In Proceedings of the 2021 International Conference on Computer Science and Engineering (IC2SE), Padang, Indonesia, 16–18 November 2021; Volume 1, pp. 1–5. [Google Scholar] [CrossRef]

- Jiao-Wang, L.; Loya, J.A.; Santiuste, C. On the Numerical Modeling of Flax/PLA Bumper Beams. Materials 2022, 15, 5480. [Google Scholar] [CrossRef]

- Kargar, E.; Ghasemi-Ghalebahman, A. Experimental investigation on fatigue life and tensile strength of carbon fiber-reinforced PLA composites based on fused deposition modeling. Sci. Rep. 2023, 13, 18194. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Boccarusso, L.; Langella, A.; Carrino, L. Creep behaviour of polylactic acid reinforced by woven hemp fabric. Compos. Part Eng. 2017, 124, 16–22. [Google Scholar] [CrossRef]

- Yang, X.M.; Qiu, S.; Yusuf, A.; Sun, J.; Zhai, Z.; Zhao, J.; Yin, G.Z. Recent advances in flame retardant and mechanical properties of polylactic acid: A review. Int. J. Biol. Macromol. 2023, 243, 125050. [Google Scholar] [CrossRef]

- Lyon, R.; Walters, R. Flammability of Automotive Plastics; SAE Technical Papers; SAE: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, W.; Qiu, Y.; Xu, M.; Li, B.; Liu, L. Preparation and mechanism study of a high efficiency bio-based flame retardant for simultaneously enhancing flame retardancy, toughness and crystallization rate of poly (lactic acid). Compos. Part Eng. 2022, 238, 109913. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, Y.; Luo, Q.; Tang, B.; Guan, J.; Tian, Q. Construction of carbon-based flame retardant composite with reinforced and toughened property and its application in polylactic acid. RSC Adv. 2022, 12, 22236–22243. [Google Scholar] [CrossRef]

- Zhao, P.; Liu, Z.; Wang, X.; Pan, Y.T.; Kuehnert, I.; Gehde, M.; Wang, D.Y.; Leuteritz, A. Renewable vanillin based flame retardant for poly(lactic acid): A way to enhance flame retardancy and toughness simultaneously. RSC Adv. 2018, 8, 42189–42199. [Google Scholar] [CrossRef] [PubMed]

- Kervran, M.; Shabanian, M.; Vagner, C.; Ponçot, M.; Meier-Haack, J.; Laoutid, F.; Gaan, S.; VAHABI, H. Flame retardancy of sustainable polylactic acid and polyhydroxybutyrate (PLA/PHB) blends. Int. J. Biol. Macromol. 2023, 251, 126208. [Google Scholar] [CrossRef] [PubMed]

- Mehrpouya, M.; Vahabi, H.; Janbaz, S.; Darafsheh, A.; Mazur, T.R.; Ramakrishna, S. 4D printing of shape memory polylactic acid (PLA). Polymer 2021, 230, 124080. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Ciofu, C.; Mazurchevici, S.; Maldonado-Cortes, D.; Parás, L.; Correa, D.; Nedelcu, D. Tribological behavior of PLA biodegradable materials used in the automotive industry. Int. J. Mod. Manuf. Technol. 2019, 11, 83–88. [Google Scholar]

- Yang, X.; Fan, W.; Ge, S.; Gao, X.; Wang, S.; Zhang, Y.; Foong, S.Y.; Liew, R.K.; Lam, S.S.; Xia, C. Advanced textile technology for fabrication of ramie fiber PLA composites with enhanced mechanical properties. Ind. Crop. Prod. 2021, 162, 113312. [Google Scholar] [CrossRef]

- Zhao, X.; Li, K.; Wang, Y.; Tekinalp, H.; Larsen, G.; Rasmussen, D.; Ginder, R.S.; Wang, L.; Gardner, D.J.; Tajvidi, M.; et al. High-Strength Polylactic Acid (PLA) Biocomposites Reinforced by Epoxy-Modified Pine Fibers. ACS Sustain. Chem. Eng. 2020, 8, 13236–13247. [Google Scholar] [CrossRef]

| Tensile Strength [MPa] | Tensile Modulus [GPa] | Tensile Strain [%] | Flexural Strength [MPa] | Flexural Modulus [GPa] | |

|---|---|---|---|---|---|

| CCF/PLA | 245.40 | 25.94 | 1.00 | 168.88 | 10.63 |

| SCF/PLA | 43.75 | 4.79 | 2.20 | 76.33 | 4.52 |

| FVF [%] | Tensile Strength [MPa] | Tensile Modulus [GPa] | Flexural Strength [MPa] | Flexural Modulus [GPa] |

|---|---|---|---|---|

| 22 | 338.58 | 11.31 | 256.06 | 17.85 |

| 33 | 436.94 | 12.59 | 259.23 | 22.86 |

| 40 | 543.80 | 13.64 | 309.64 | 23.18 |

| Material | FVF [%] | Tensile Strength [MPa] | Tensile Modulus [GPa] | Flexural Strength [MPa] | Flexural Modulus [GPa] | Ref. |

|---|---|---|---|---|---|---|

| Neat PLA | - | 40.0 | 3.8 | 82.0 | 4.0 | [27] |

| F/PLA | 36 | 234.4 | 20.6 | - | - | [29] |

| F/PLA | 39 | 151.0 | 18.5 | 215.0 | 18.8 | [27] |

| F/PLA | 44 | 339.0 | 20.1 | 363.0 | 26.0 | [28] |

| J/PLA | 50 | 152.0 | 5.3 | 174.0 | - | [30] |

| KF/PLA | 35 | 131.0 | 15.0 | 160.0 | - | [30] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giammaria, V.; Capretti, M.; Del Bianco, G.; Boria, S.; Santulli, C. Application of Poly(lactic Acid) Composites in the Automotive Sector: A Critical Review. Polymers 2024, 16, 3059. https://doi.org/10.3390/polym16213059

Giammaria V, Capretti M, Del Bianco G, Boria S, Santulli C. Application of Poly(lactic Acid) Composites in the Automotive Sector: A Critical Review. Polymers. 2024; 16(21):3059. https://doi.org/10.3390/polym16213059

Chicago/Turabian StyleGiammaria, Valentina, Monica Capretti, Giulia Del Bianco, Simonetta Boria, and Carlo Santulli. 2024. "Application of Poly(lactic Acid) Composites in the Automotive Sector: A Critical Review" Polymers 16, no. 21: 3059. https://doi.org/10.3390/polym16213059

APA StyleGiammaria, V., Capretti, M., Del Bianco, G., Boria, S., & Santulli, C. (2024). Application of Poly(lactic Acid) Composites in the Automotive Sector: A Critical Review. Polymers, 16(21), 3059. https://doi.org/10.3390/polym16213059