A Comprehensive Review on the Incremental Sheet Forming of Polycarbonate

Abstract

1. Introduction

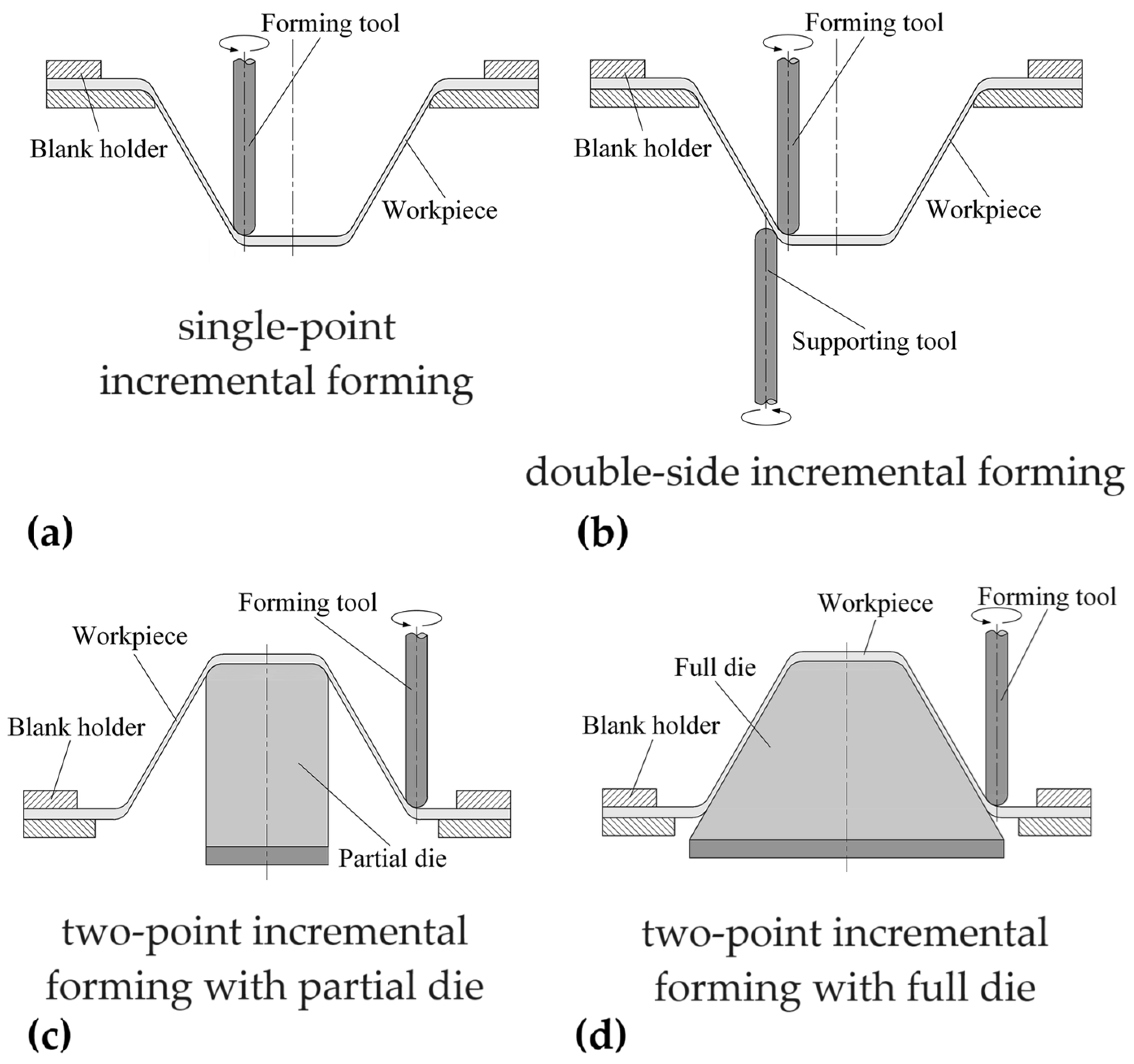

1.1. General Introduction to the Process

1.2. Incremental Forming of Polymer Sheets

2. Incremental Forming of Polycarbonate Sheets

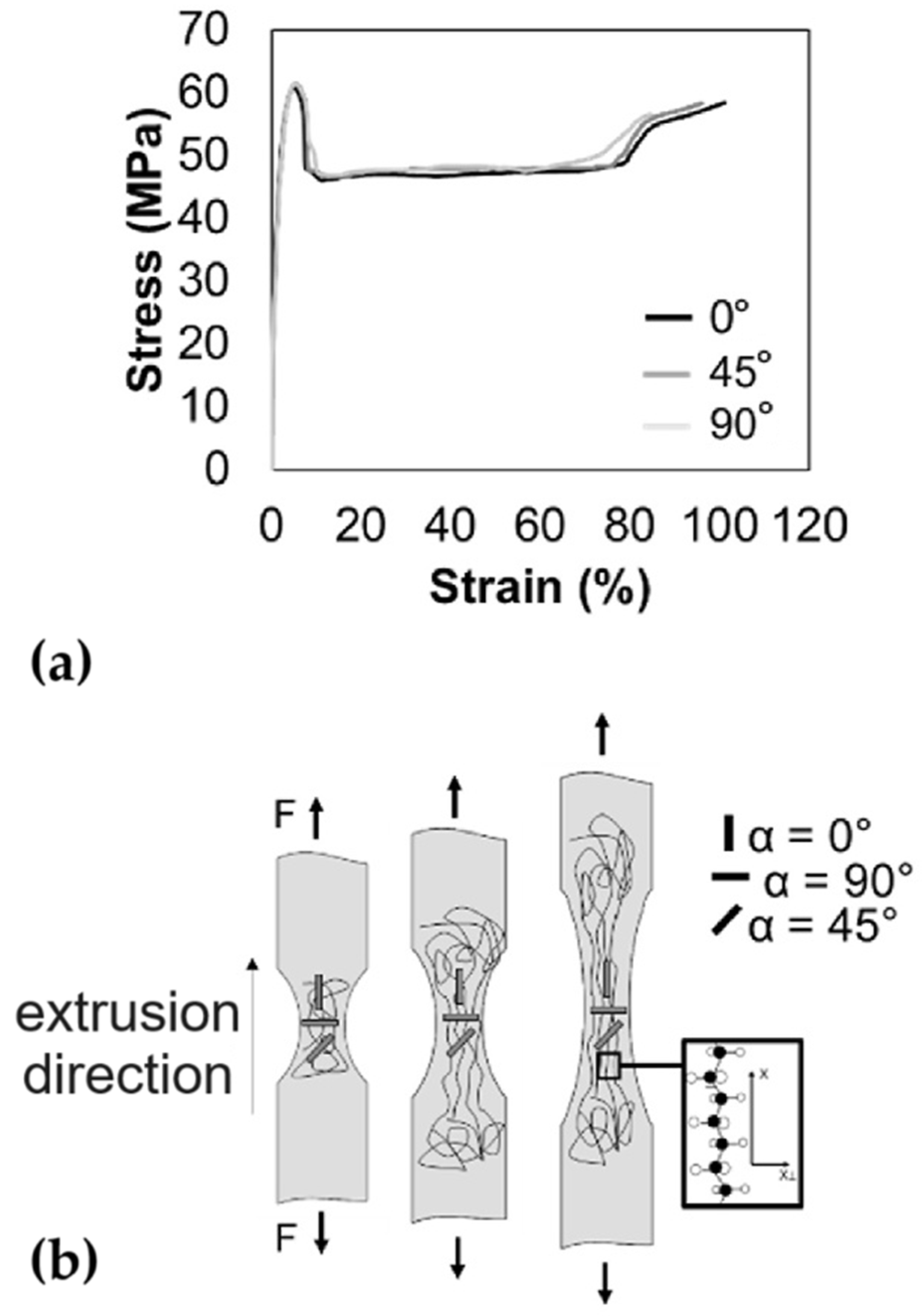

2.1. Polycarbonate: Main Properties

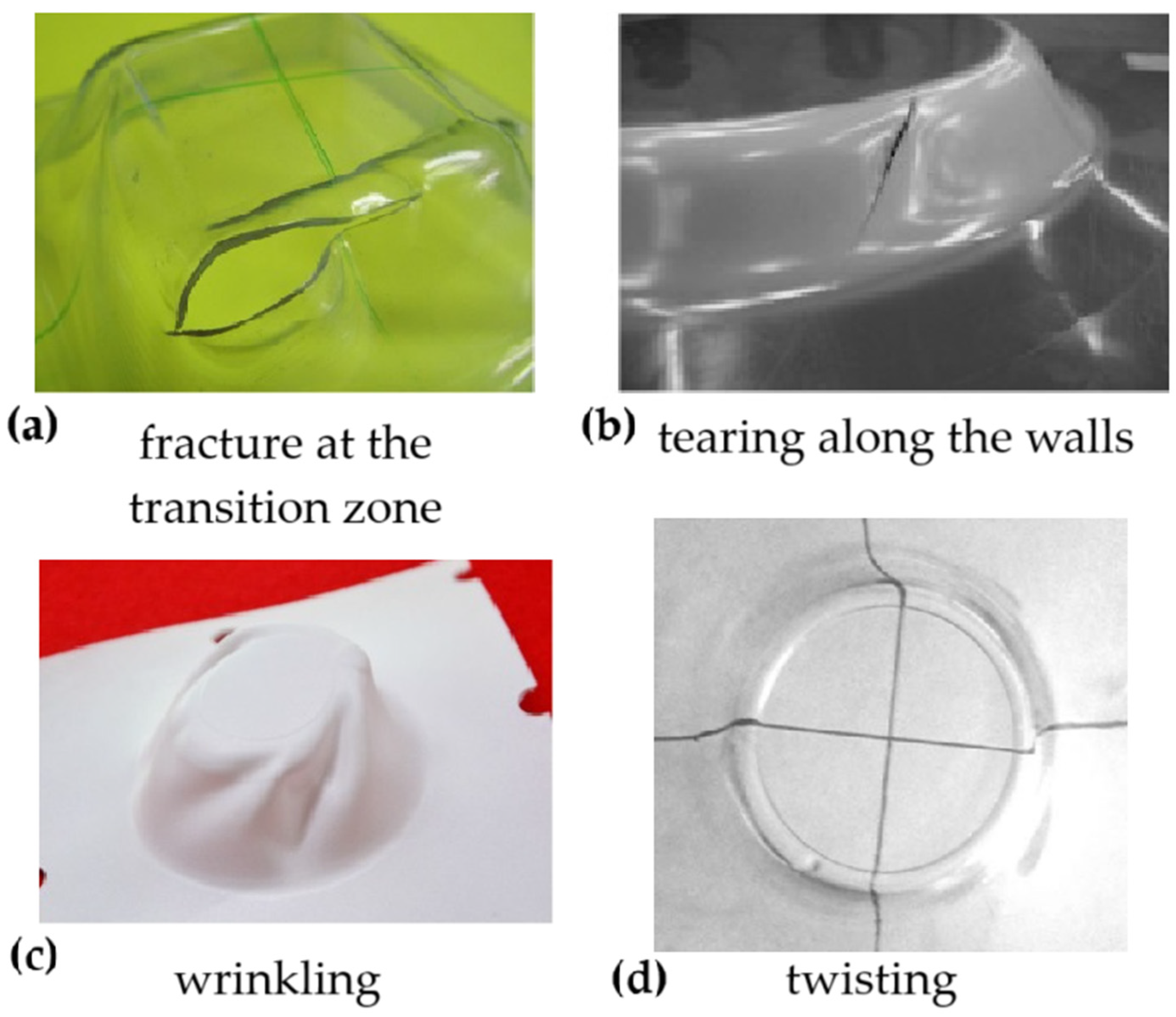

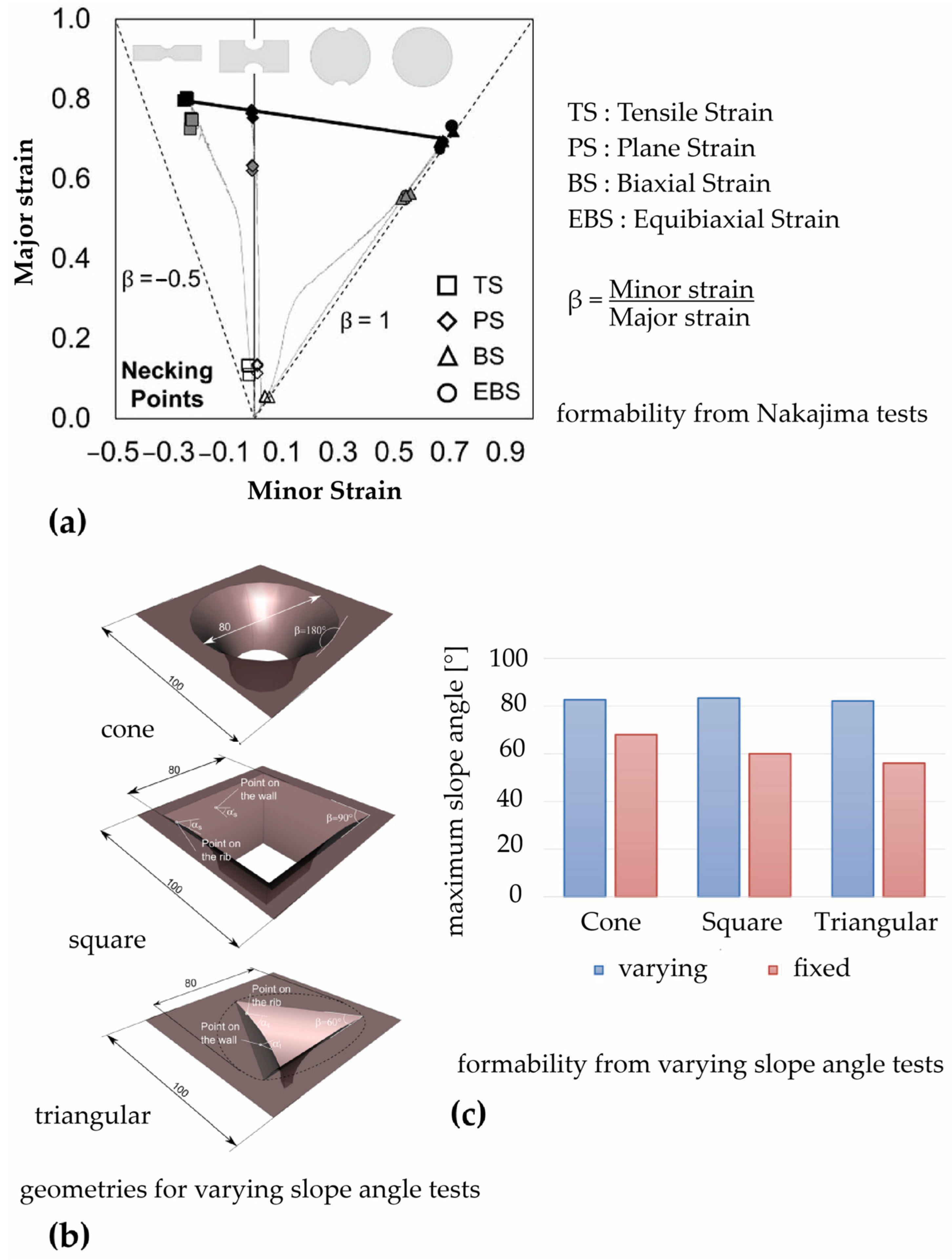

2.2. Formability of Polycarbonate Worked by ISF

3. Enhancement of Incremental Forming of Polycarbonate Sheets

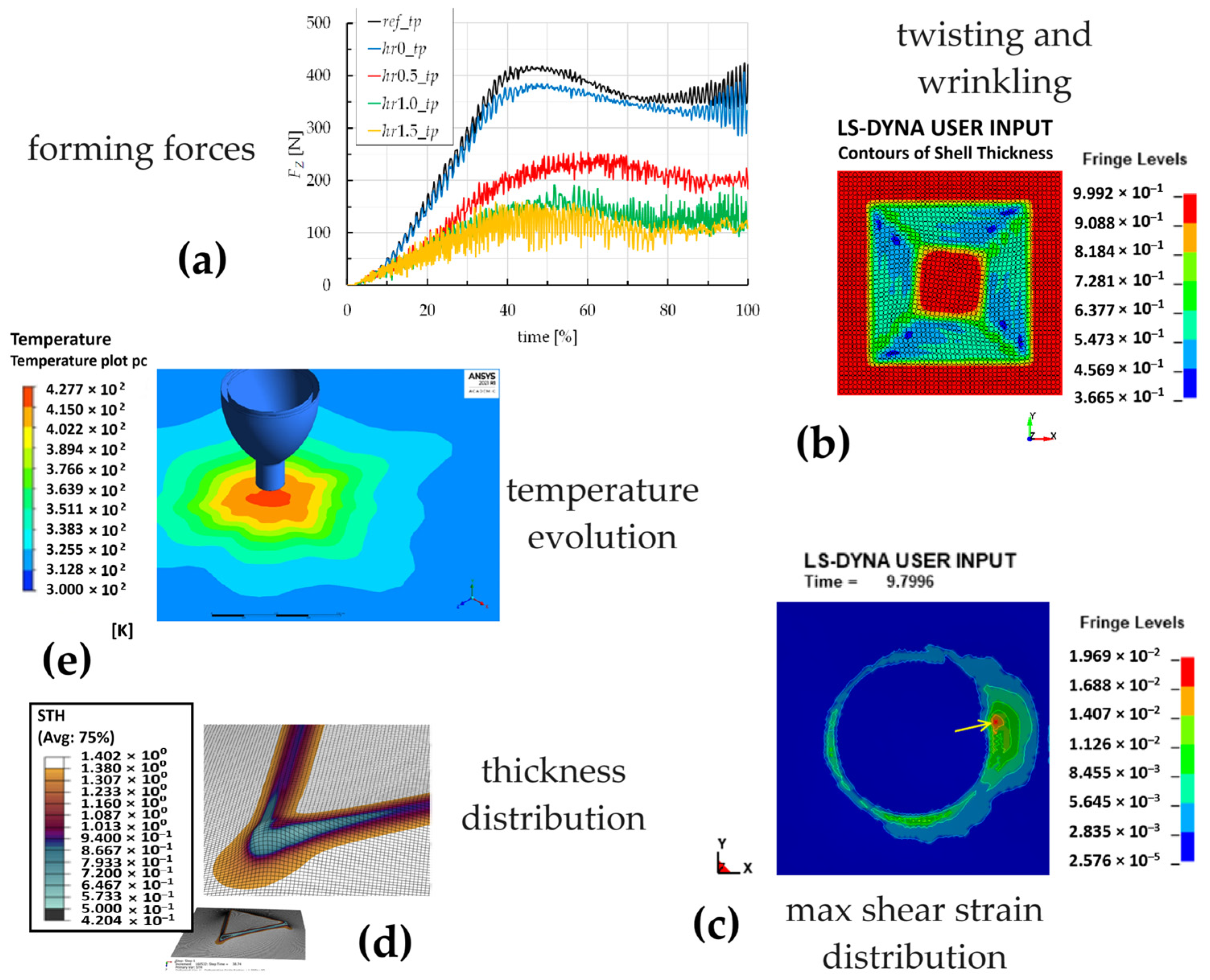

3.1. Toolpath Strategy

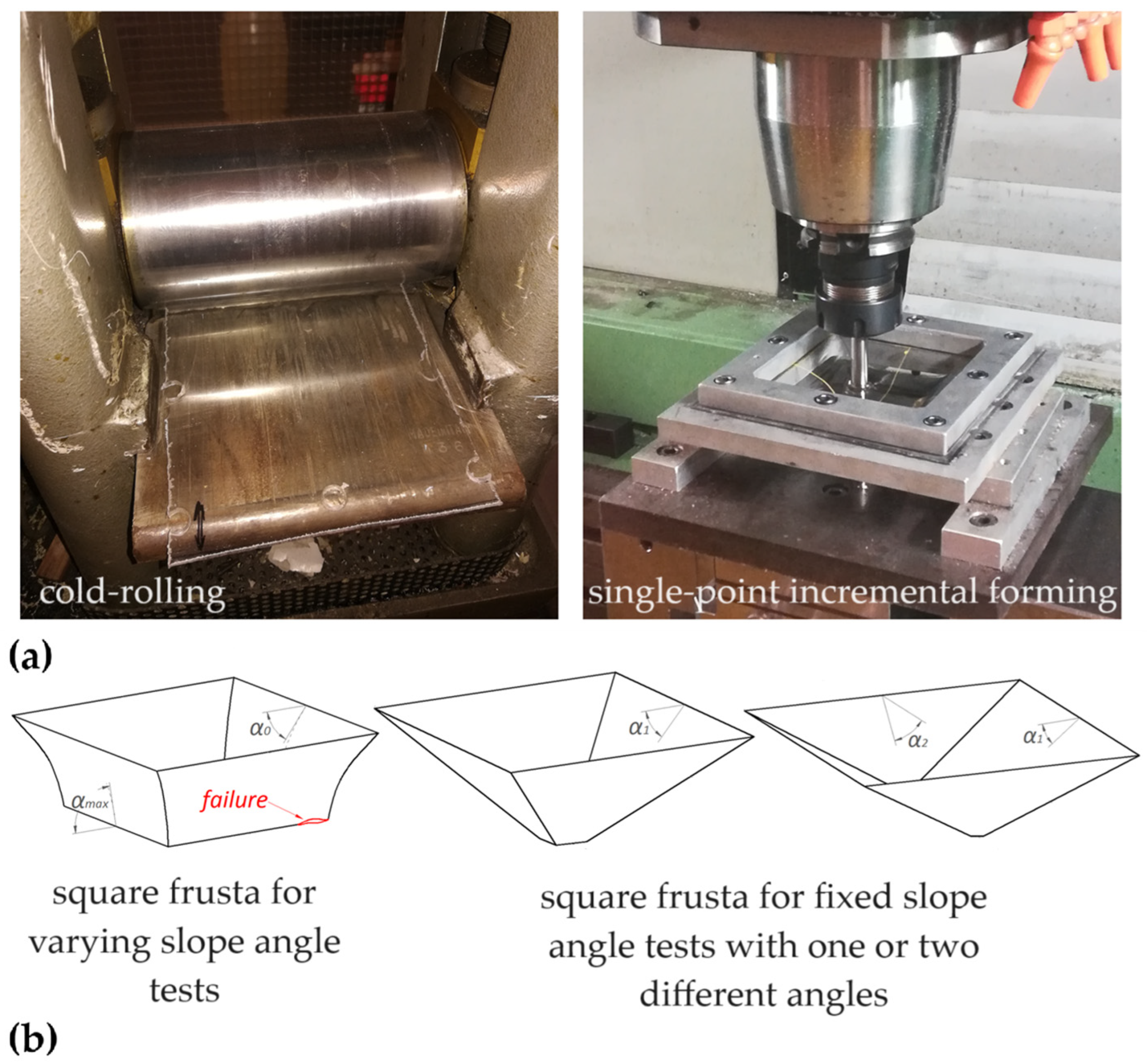

3.2. Preliminary Cold-Rolling

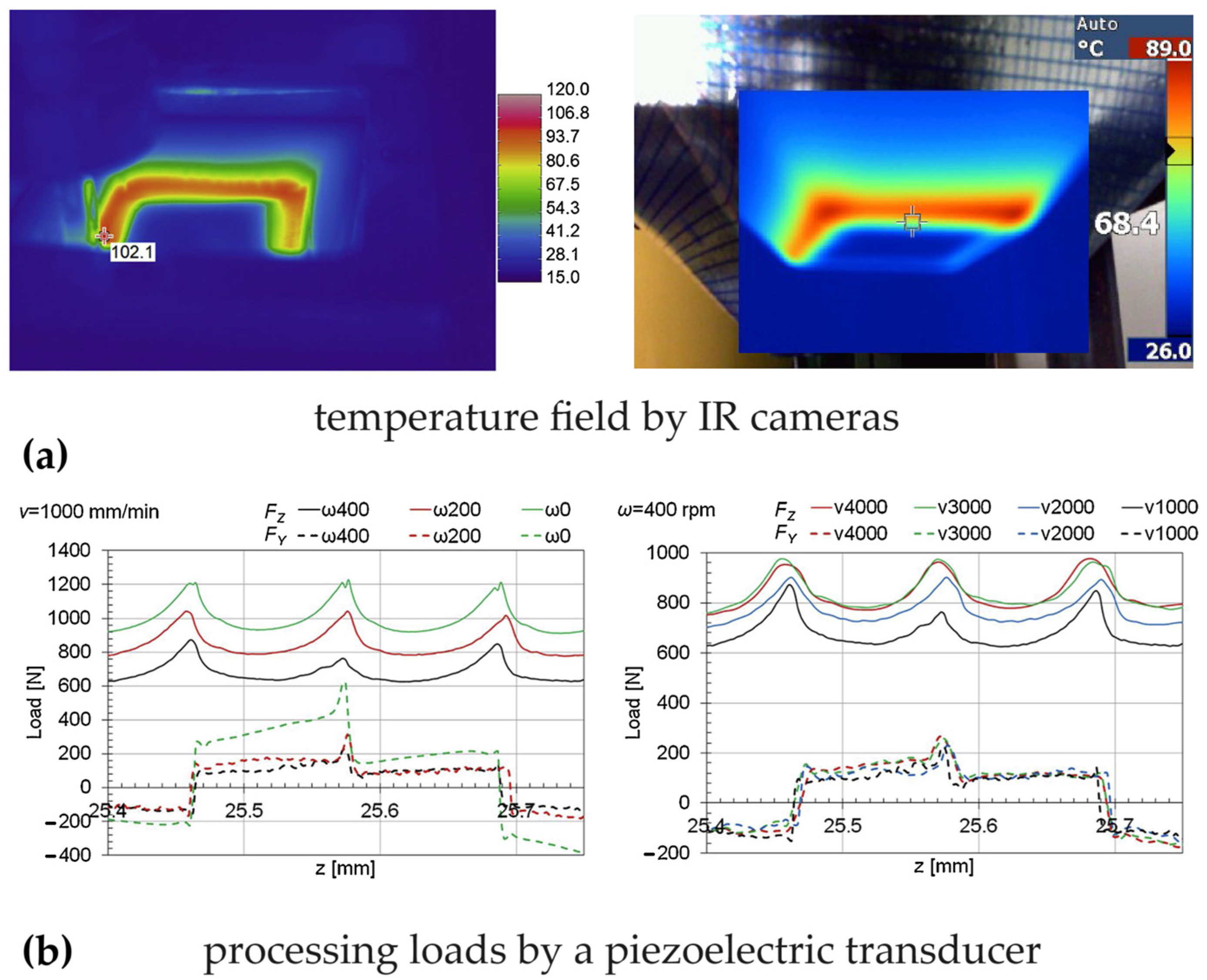

3.3. Self-Heating by Tool Rotation and Travelling Speed

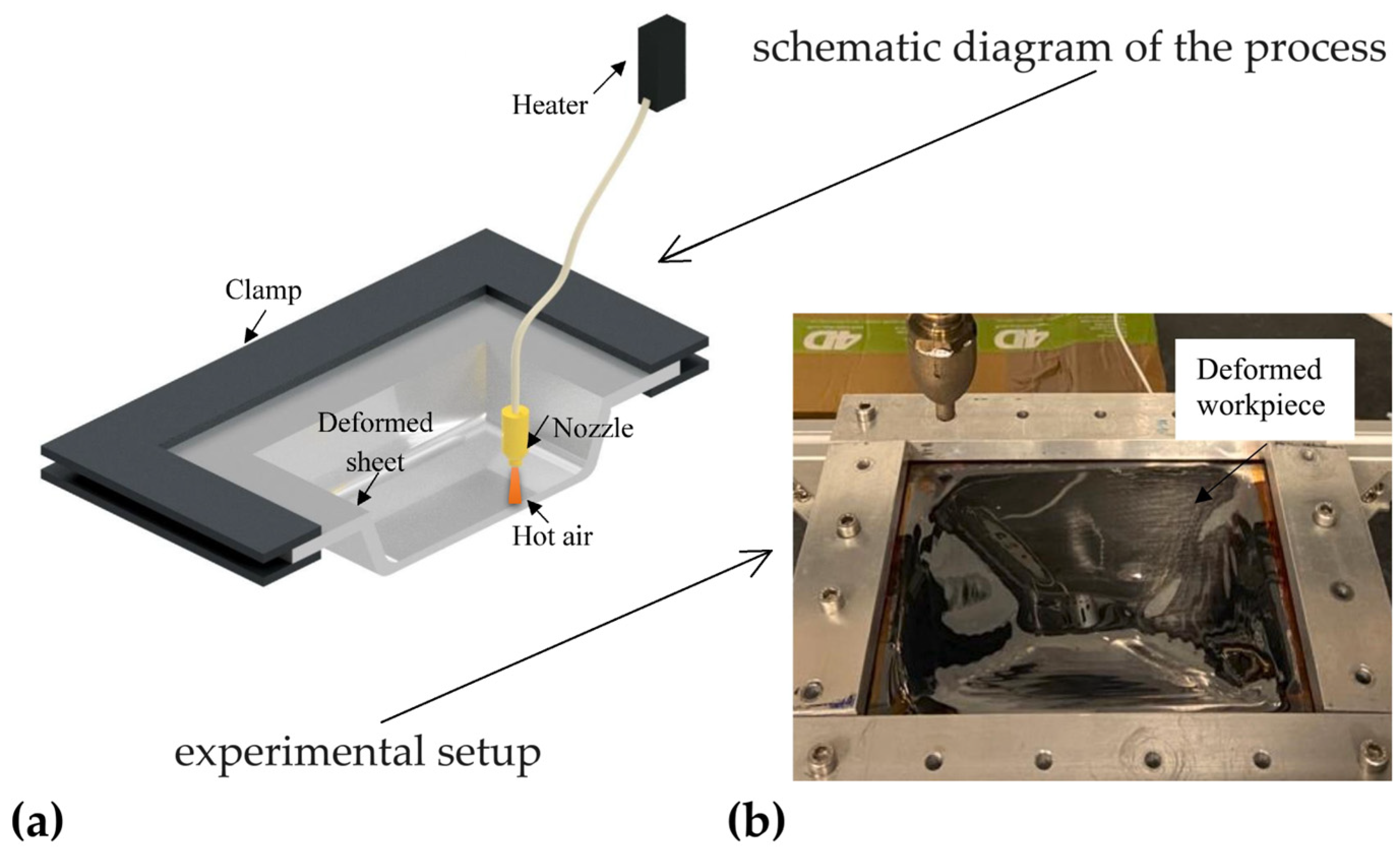

3.4. Contactless Method by Hot Air

3.5. Numerical Analyses

4. Conclusions and Future Perspectives

- More effective analytical mechanics—this allows for a better description of the material behaviour of thermoplastics under ISF conditions;

- The development or improvement of alternative hybrid forming and toolpath strategies—these solutions represent a viable way to improve the process in terms of the material formability and the variety and complexity of the components, among others;

- The increased use of thermo-mechanical numerical simulations—the development of accurate numerical models represents a valid tool to investigate various features, such as deformations and failure mechanisms.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Barimani-Varandi, A.; Nasrabadi, M.K.; Ravan, B.A.; Javadi, M. Rapid Prototyping of Aircraft Canopy Based on the Incremental Forming Process. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 59. [Google Scholar] [CrossRef]

- Hussain, G.; Khan, H.R.; Gao, L.; Hayat, N. Guidelines for Tool-Size Selection for Single-Point Incremental Forming of an Aerospace Alloy. Mater. Manuf. Process. 2013, 28, 324–329. [Google Scholar] [CrossRef]

- Duc-Toan, N.; Seung-Han, Y.; Dong-Won, J.; Tae-Hoon, C.; Young-Suk, K. Incremental Sheet Metal Forming: Numerical Simulation and Rapid Prototyping Process to Make an Automobile White-Body. Steel Res. Int. 2011, 82, 795–805. [Google Scholar] [CrossRef]

- Bertini, L.; Kubit, A.; Al-Sabur, R.; Gradzik, A.; Ochał, K.; Slota, J.; Korzeniowski, M. Investigating Residual Stresses in Metal-Plastic Composites Stiffening Ribs Formed Using the Single Point Incremental Forming Method. Materials 2022, 15, 8252. [Google Scholar] [CrossRef]

- Behera, A.K.; de Sousa, R.A.; Ingarao, G.; Oleksik, V. Single Point Incremental Forming: An Assessment of the Progress and Technology Trends from 2005 to 2015. J. Manuf. Process. 2017, 27, 37–62. [Google Scholar] [CrossRef]

- Jeswiet, J.; Micari, F.; Hirt, G.; Bramley, A.; Duflou, J.; Allwood, J. Asymmetric Single Point Incremental Forming of Sheet Metal. CIRP Ann. 2005, 54, 88–114. [Google Scholar] [CrossRef]

- Martins, P.A.F.; Bay, N.; Skjoedt, M.; Silva, M.B. Theory of Single Point Incremental Forming. CIRP Ann. Manuf. Technol. 2008, 57, 247–252. [Google Scholar] [CrossRef]

- Peng, W.; Ou, H.; Becker, A. Double-Sided Incremental Forming: A Review. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 50802. [Google Scholar] [CrossRef]

- Silva, M.B.; Martins, P.A.F. Two-Point Incremental Forming with Partial Die: Theory and Experimentation. J. Mater. Eng. Perform. 2013, 22, 1018–1027. [Google Scholar] [CrossRef]

- Xu, P.; Li, X.; Feng, F.; Li, X.; Yang, Y. Experimental and Numerical Studies on Two-Point Incremental Forming of Woven Fabric Composite Sheet. J. Manuf. Process. 2023, 85, 205–215. [Google Scholar] [CrossRef]

- Gatea, S.; Ou, H.; McCartney, G. Review on the Influence of Process Parameters in Incremental Sheet Forming. Int. J. Adv. Manuf. Technol. 2016, 87, 479–499. [Google Scholar] [CrossRef]

- Echrif, S.B.M.; Hrairi, M. Research and Progress in Incremental Sheet Forming Processes. Mater. Manuf. Process. 2011, 26, 1404–1414. [Google Scholar] [CrossRef]

- Emmens, W.C.; Sebastiani, G.; van den Boogaard, A.H. The Technology of Incremental Sheet Forming-A Brief Review of the History. J. Mater. Process. Technol. 2010, 210, 981–997. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Oleksik, V.; Pepelnjak, T.; Najm, S.M.; Paniti, I.; Maji, K. Emerging Trends in Single Point Incremental Sheet Forming of Lightweight Metals. Metals 2021, 11, 1188. [Google Scholar] [CrossRef]

- Mandaloi, G.; Nagargoje, A.; Gupta, A.K.; Banerjee, G.; Shahare, H.Y.; Tandon, P. A Comprehensive Review on Experimental Conditions, Strategies, Performance, and Applications of Incremental Forming for Deformation Machining. J. Manuf. Sci. Eng. 2022, 144, 1–15. [Google Scholar] [CrossRef]

- Agrawal, M.K.; Singh, P.; Mishra, P.; Deb, R.K.; Mohammed, K.A.; Kumar, S.; Kumar, G. A Brief Review on the Perspective of a Newer Incremental Sheet Forming Technique and Its Usefulness. Adv. Mater. Process. Technol. 2024, 10, 506–516. [Google Scholar] [CrossRef]

- McAnulty, T.; Jeswiet, J.; Doolan, M. Formability in Single Point Incremental Forming: A Comparative Analysis of the State of the Art. CIRP J. Manuf. Sci. Technol. 2017, 16, 43–54. [Google Scholar] [CrossRef]

- Emmens, W.C.; van den Boogaard, A.H. An Overview of Stabilizing Deformation Mechanisms in Incremental Sheet Forming. J. Mater. Process. Technol. 2009, 209, 3688–3695. [Google Scholar] [CrossRef]

- Ai, S.; Long, H. A Review on Material Fracture Mechanism in Incremental Sheet Forming. Int. J. Adv. Manuf. Technol. 2019, 104, 33–61. [Google Scholar] [CrossRef]

- Kumar, A.; Gulati, V.; Kumar, P.; Singh, H. Forming Force in Incremental Sheet Forming: A Comparative Analysis of the State of the Art; Springer: Berlin/Heidelberg, Germany, 2019; Volume 41, ISBN 0123456789. [Google Scholar]

- Hirt, G.; Bambach, M.; Bleck, W.; Prahl, U.; Stollenwerk, J. The Development of Incremental Sheet Forming from Flexible Forming to Fully Integrated Production of Sheet Metal Parts; Springer: Berlin/Heidelberg, Germany, 2015; pp. 117–129. [Google Scholar] [CrossRef]

- Scheffler, S.; Pierer, A.; Scholz, P.; Melzer, S.; Weise, D.; Rambousek, Z. Incremental Sheet Metal Forming on the Example of Car Exterior Skin Parts. Procedia Manuf. 2019, 29, 105–111. [Google Scholar] [CrossRef]

- Lu, B.; Ou, H.; Shi, S.Q.; Long, H.; Chen, J. Titanium Based Cranial Reconstruction Using Incremental Sheet Forming. Int. J. Mater. Form. 2016, 9, 361–370. [Google Scholar] [CrossRef]

- Mohan, S.R.; Dewang, Y.; Sharma, V. Tool Path Planning for Hole-Flanging Process Using Single Point Incremental Forming. MATEC Web Conf. 2024, 393, 01003. [Google Scholar] [CrossRef]

- Chen, X.; Wen, T.; Qin, J.; Hu, J.; Zhang, M.; Zhang, Z. Deformation Feature of Sheet Metals During Inclined Hole-Flanging by Two-Point Incremental Forming. Int. J. Precis. Eng. Manuf. 2020, 21, 169–176. [Google Scholar] [CrossRef]

- Zhu, H.; Ou, H.; Popov, A. Incremental Sheet Forming of Thermoplastics: A Review. Int. J. Adv. Manuf. Technol. 2020, 111, 565–587. [Google Scholar] [CrossRef]

- Jackson, K.P.; Allwood, J.M.; Landert, M. Incremental Forming of Sandwich Panels. J. Mater. Process. Technol. 2008, 204, 290–303. [Google Scholar] [CrossRef]

- Fiorotto, M.; Sorgente, M.; Lucchetta, G. Preliminary Studies on Single Point Incremental Forming for Composite Materials. Int. J. Mater. Form. 2010, 3, 951–954. [Google Scholar] [CrossRef]

- Conte, R.; Ambrogio, G.; Pulice, D.; Gagliardi, F.; Filice, L. Incremental Sheet Forming of a Composite Made of Thermoplastic Matrix and Glass-Fiber Reinforcement. Procedia Eng. 2017, 207, 819–824. [Google Scholar] [CrossRef]

- AL-Obaidi, A.; Kunke, A.; Kräusel, V. Hot Single-Point Incremental Forming of Glass-Fiber-Reinforced Polymer (PA6GF47) Supported by Hot Air. J. Manuf. Process. 2019, 43, 17–25. [Google Scholar] [CrossRef]

- Okada, M.; Kato, T.; Otsu, M.; Tanaka, H.; Miura, T. Development of Optical-Heating-Assisted Incremental Forming Method for Carbon Fiber Reinforced Thermoplastic Sheet—Forming Characteristics in Simple Spot-Forming and Two-Dimensional Sheet-Fed Forming. J. Mater. Process. Technol. 2018, 256, 145–153. [Google Scholar] [CrossRef]

- Borić, A.; Kalendová, A.; Urbanek, M.; Pepelnjak, T. Characterisation of Polyamide (PA)12 Nanocomposites Withmontmorillonite (MMT) Filler Clay Used for the Incremental Forming of Sheets. Polymers 2019, 11, 1248. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Vanhove, H.; Attisano, M.; Ambrogio, G.; Duflou, J.R. Single Point Incremental Forming of Shape Memory Polymer Foam. In Proceedings of the MATEC Web of Conferences, Zürich, Switzerland, 19–21 October 2015; Volume 21, p. 4007. [Google Scholar]

- Rosa-Sainz, A.; Centeno, G.; Silva, M.B.; Vallellano, C. Experimental Failure Analysis in Polycarbonate Sheet Deformed by Spif. J. Manuf. Process. 2021, 64, 1153–1168. [Google Scholar] [CrossRef]

- Rosa-Sainz, A.; Centeno, G.; Silva, M.B.; Andrés López-Fernández, J.; Jesus Martínez-Donaire, A.; Vallellano, C. On the Determination of Forming Limits in Polycarbonate Sheets. Materials 2020, 13, 928. [Google Scholar] [CrossRef] [PubMed]

- Bagudanch, I.; Centeno, G.; Vallellano, C.; Garcia-Romeu, M.L. Revisiting Formability and Failure of Polymeric Sheets Deformed by Single Point Incremental Forming. Polym. Degrad. Stab. 2017, 144, 366–377. [Google Scholar] [CrossRef]

- Alkas Yonan, S.; Silva, M.B.; Martins, P.A.F.; Tekkaya, A.E. Plastic Flow and Failure in Single Point Incremental Forming of PVC Sheets. Express Polym. Lett. 2014, 8, 301–311. [Google Scholar] [CrossRef]

- Le, V.S.; Ghiotti, A.; Lucchetta, G. Preliminary Studies on Single Point Incremental Forming for Thermoplastic Materials. Int. J. Mater. Form. 2008, 1, 1179–1182. [Google Scholar] [CrossRef]

- Rajenthirakumar, D.; Sridhar, R. Single Point Incremental Sheet Forming of Polymer on Computer Numerically Controlled (CNC) Milling Machine Tool. Key Eng. Mater. 2014, 622, 420–426. [Google Scholar] [CrossRef]

- Rosca, N.; Oleksik, M.; Rosca, L.; Avrigean, E.; Trzepieciński, T.; Najm, S.M.; Oleksik, V. Minimizing the Main Strains and Thickness Reduction in the Single Point Incremental Forming Process of Polyamide and High-Density Polyethylene Sheets. Materials 2023, 16, 1644. [Google Scholar] [CrossRef]

- Centeno, G.; Bagudanch, I.; Morales-Palma, D.; García-Romeu, M.L.; Gonzalez-Perez-Somarriba, B.; Martinez-Donaire, A.J.; Gonzalez-Perez, L.M.; Vallellano, C. Recent Approaches for the Manufacturing of Polymeric Cranial Prostheses by Incremental Sheet Forming. Procedia Eng. 2017, 183, 180–187. [Google Scholar] [CrossRef]

- Bagudanch, I.; García-Romeu, M.L.; Ferrer, I.; Ciurana, J. Customized Cranial Implant Manufactured by Incremental Sheet Forming Using a Biocompatible Polymer. Rapid Prototyp. J. 2018, 24, 120–129. [Google Scholar] [CrossRef]

- Centeno, G.; Morales-Palma, D.; Gonzalez-Perez-Somarriba, B.; Bagudanch, I.; Egea-Guerrero, J.J.; Gonzalez-Perez, L.M.; García-Romeu, M.L.; Vallellano, C. A Functional Methodology on the Manufacturing of Customized Polymeric Cranial Prostheses from CAT Using SPIF. Rapid Prototyp. J. 2017, 23, 771–780. [Google Scholar] [CrossRef]

- Franzen, V.; Kwiatkowski, L.; Martins, P.A.F.; Tekkaya, A.E. Single Point Incremental Forming of PVC. J. Mater. Process. Technol. 2009, 209, 462–469. [Google Scholar] [CrossRef]

- Hernández-Ávila, M.; Lozano-Sánchez, L.M.; Perales-Martínez, I.A.; Elías-Zúñiga, A.; Bagudanch, I.; García-Romeu, M.L.; Elizalde, L.E.; Barrera, E.V. Single Point Incremental Forming of Bilayer Sheets Made of Two Different Thermoplastics. J. Appl. Polym. Sci. 2019, 136, 47093. [Google Scholar] [CrossRef]

- Marques, T.A.; Silva, M.B.; Martins, P.A.F. On the Potential of Single Point Incremental Forming of Sheet Polymer Parts. Int. J. Adv. Manuf. Technol. 2012, 60, 75–86. [Google Scholar] [CrossRef]

- Bagudanch, I.; Garcia-Romeu, M.L.; Centeno, G.; Elías-Zúñiga, A.; Ciurana, J. Forming Force and Temperature Effects on Single Point Incremental Forming of Polyvinylchloride. J. Mater. Process. Technol. 2015, 219, 221–229. [Google Scholar] [CrossRef]

- Davarpanah, M.A.; Mirkouei, A.; Yu, X.; Malhotra, R.; Pilla, S. Effects of Incremental Depth and Tool Rotation on Failure Modes and Microstructural Properties in Single Point Incremental Forming of Polymers. J. Mater. Process. Technol. 2015, 222, 287–300. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Lambiase, F. Incremental Forming of Polycarbonate Sheets. J. Mater. Process. Technol. 2018, 253, 57–63. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Lambiase, F. Formability of Polycarbonate Sheets in Single-Point Incremental Forming. Int. J. Adv. Manuf. Technol. 2019, 102, 2049–2062. [Google Scholar] [CrossRef]

- Chang, Z.; Chen, J. Mechanism of the Twisting in Incremental Sheet Forming Process. J. Mater. Process. Technol. 2019, 276, 116396. [Google Scholar] [CrossRef]

- Duflou, J.R.; Vanhove, H.; Verbert, J.; Gu, J.; Vasilakos, I.; Eyckens, P. Twist Revisited: Twist Phenomena in Single Point Incremental Forming. CIRP Ann. Manuf. Technol. 2010, 59, 307–310. [Google Scholar] [CrossRef]

- Asghar, J.; Lingam, R.; Shibin, E.; Reddy, N.V. Tool Path Design for Enhancement of Accuracy in Single-Point Incremental Forming. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1027–1035. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; Capece Minutolo, F.; Carrino, L.; Durante, M.; Langella, A. Negative and Positive Incremental Forming: Comparison by Geometrical, Experimental, and FEM Considerations. Mater. Manuf. Process. 2017, 32, 530–536. [Google Scholar] [CrossRef]

- Peng, H.; Li, M.; Liu, C.; Fu, W.; Cao, J. Numerical Simulation of Multi-Point Forming Accuracy for Polycarbonate Sheet. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2014, 228, 87–96. [Google Scholar] [CrossRef]

- Lambiase, F.; Paoletti, A.; Grossi, V.; Di Ilio, A. Analysis of Loads, Temperatures and Welds Morphology in FSW of Polycarbonate. J. Mater. Process. Technol. 2019, 266, 639–650. [Google Scholar] [CrossRef]

- Hou, Z.X.; Wu, J.; Wang, Z.R. A Study of the Bulge-Forming of Polycarbonate (PC) Sheet. J. Mater. Process. Technol. 2004, 151, 312–315. [Google Scholar] [CrossRef]

- Beşliu, I.; Tamaşag, I.; Slătineanu, L. An Experimental Study on Incremental Forming Process of Polycarbonate Sheets. Macromol. Symp. 2021, 395, 2000282. [Google Scholar] [CrossRef]

- Kyriacos, D. Polycarbonates. In Brydson’s Plastics Materials, 8th ed.; Elsevier: Amsterdam, The Netherlands, 2017; Chapter 17; pp. 457–485. ISBN 978-0-323-35824-8. [Google Scholar]

- Rey Calderón, A.A.; Díaz Díaz, A. New Aspects in the Mechanical Behavior of a Polycarbonate Found by an Experimental Study. Adv. Mater. Sci. Eng. 2018, 2018, 1540919. [Google Scholar] [CrossRef]

- Gedde, U.W. Polymer Physics; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Rosa-Sainz, A.; Magrinho, J.P.; Vaz, M.F.; Silva, M.B.; Centeno, G.; Vallellano, C. Analysing the Mechanisms of Failure in Polycarbonate Sheets Deformed by SPIF. J. Mater. Res. Technol. 2024, 31, 2156–2168. [Google Scholar] [CrossRef]

- ASTM D638; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Lampman, S. Characterization and Failure Analysis of Plastics; ASM International: Novelty, OH, USA, 2004; ISBN 978 0 87170 789 5. [Google Scholar]

- Hussain, G.; Gao, L.; Zhang, Z.Y. Formability Evaluation of a Pure Titanium Sheet in the Cold Incremental Forming Process. Int. J. Adv. Manuf. Technol. 2008, 37, 920–926. [Google Scholar] [CrossRef]

- Formisano, A.; Durante, M.; Boccarusso, L.; Astarita, A. The Influence of Thermal Oxidation and Tool-Sheet Contact Conditions on the Formability and the Surface Quality of Incrementally Formed Grade 1 Titanium Thin Sheets. Int. J. Adv. Manuf. Technol. 2017, 93, 3723–3732. [Google Scholar] [CrossRef]

- ISO12004-2; Metallic Materials-Sheet and Strip-Determination of Forming Limit Curves Part 2: Determination of Forming Limit Curves in Laboratory. ISO: Geneva, Switzerland, 2008.

- Martínez-Donaire, A.J.; García-Lomas, F.J.; Vallellano, C. New Approaches to Detect the Onset of Localised Necking in Sheets under Through-Thickness Strain Gradients. Mater. Des. 2014, 57, 135–145. [Google Scholar] [CrossRef]

- Liu, Z. Heat-Assisted Incremental Sheet Forming: A State-of-the-Art Review. Int. J. Adv. Manuf. Technol. 2018, 98, 2987–3003. [Google Scholar] [CrossRef]

- Araghi, B.T.; Göttmann, A.; Bambach, M.; Hirt, G.; Bergweiler, G.; Diettrich, J.; Steiners, M.; Saeed-Akbari, A. Review on the Development of a Hybrid Incremental Sheet Forming System for Small Batch Sizes and Individualized Production. Prod. Eng. 2011, 5, 393–404. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; De Fazio, D.; Durante, M. Effects of Toolpath on Defect Phenomena in the Incremental Forming of Thin Polycarbonate Sheets. Int. J. Adv. Manuf. Technol. 2024, 133, 4957–4966. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; De Fazio, D.; Durante, M. Experimental Evidence on Incremental Formed Polymer Sheets Using a Stair Toolpath Strategy. J. Manuf. Mater. Process. 2024, 8, 105. [Google Scholar] [CrossRef]

- Wang, J.; Nair, M.; Zhang, Y. An Efficient Force Prediction Strategy for Single Point Incremental Sheet Forming. Int. J. Adv. Manuf. Technol. 2017, 92, 3931–3939. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Boccarusso, L.; Langella, A. Influence of Cold-Rolling on Incremental Sheet Forming of Polycarbonate. Mater. Manuf. Process. 2020, 35, 328–336. [Google Scholar] [CrossRef]

- Durante, M.; Formisano, A.; Boccarusso, L.; Astarita, A.; Langella, A. Single Point Incremental Forming of Cold-Rolled Polycarbonate Sheets. AIP Publ. 2019, 2113, 060007. [Google Scholar]

- Formisano, A.; Lambiase, F.; Durante, M. Polymer Self-Heating during Incremental Forming. J. Manuf. Process. 2020, 58, 1189–1199. [Google Scholar] [CrossRef]

- Formisano, A.; Durante, M.; Langella, A.; Minutolo, F.M.C. Localized Heat Assisted Incremental Forming of Polycarbonate Sheets by Tool Rotation. AIP Conf. Proc. 2019, 2113, 110002. [Google Scholar] [CrossRef]

- Almadani, M.; Guner, A.; Hassanin, H.; Essa, K. Hot-Air Contactless Single-Point Incremental Forming. J. Manuf. Mater. Process. 2023, 7, 179. [Google Scholar] [CrossRef]

- Almadani, M.; Guner, A.; Hassanin, H.; Essa, K. Optimisation of a Novel Hot Air Contactless Single Incremental Point Forming of Polymers. J. Manuf. Process. 2024, 117, 302–314. [Google Scholar] [CrossRef]

- Nagargoje, A.; Kankar, P.K.; Jain, P.K.; Tandon, P. Application of Artificial Intelligence Techniques in Incremental Forming: A State-of-the-Art Review. J. Intell. Manuf. 2023, 34, 985–1002. [Google Scholar] [CrossRef]

- Gómez-López, L.M.; Miguel, V.; Martínez, A.; Coello, J.; Calatayud, A. Simulation and Modeling of Single Point Incremental Forming Processes within a Solidworks Environment. Procedia Eng. 2013, 63, 632–641. [Google Scholar] [CrossRef]

- Medina-Sanchez, G.; Garcia-Collado, A.; Carou, D.; Dorado-Vicente, R. Force Prediction for Incremental Forming of Polymer Sheets. Materials 2018, 11, 1597. [Google Scholar] [CrossRef]

- Ostasevicius, V.; Eidukynas, D.; Grigaliunas, V.; Jurenas, V.; Paleviciute, I.; Gudauskis, M. Investigation of Advanced Robotized Polymer Sheet Incremental Forming Process. Sensors 2021, 21, 7459. [Google Scholar] [CrossRef]

- Formisano, A.; Durante, M.; Boccarusso, L.; Memola Capece, F. A Numerical Approach to Optimize the Toolpath Strategy for Polymers Forming. Mater. Res. Proc. 2023, 28, 1697–1702. [Google Scholar] [CrossRef]

- Formisano, A.; Boccarusso, L.; Durante, M. Optimization of Single-Point Incremental Forming of Polymer Sheets through FEM. Materials 2023, 16, 451. [Google Scholar] [CrossRef]

- Suresh, K.; Bagade, S.D.; Regalla, S.P. Deformation Behavior of Extra Deep Drawing Steel in Single-Point Incremental Forming. Mater. Manuf. Process. 2015, 30, 1202–1209. [Google Scholar] [CrossRef]

- Formisano, A.; Durante, M.; Formisano, A.; Durante, M. A Numerical-Experimental Investigation of the Wrinkling Defect in Incremental Forming of Thin Polycarbonate Sheets. Int. Rev. Model. Simul. 2019, 12, 206–211. [Google Scholar] [CrossRef]

- Almadani, M.; Guner, A.; Hassanin, H.; De Lisi, M.; Essa, K. Contactless Single Point Incremental Forming: Experimental and Numerical Simulation. Int. J. Adv. Manuf. Technol. 2023, 129, 5167–5179. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, C.; Gao, M.; Liu, C. Emergy-Based Sustainability Measurement and Evaluation of Industrial Production Systems. Environ. Sci. Pollut. Res. 2022, 1, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Bagudanch, I.; Garcia-Romeu, M.L.; Sabater, M. Incremental Forming of Polymers: Process Parameters Selection from the Perspective of Electric Energy Consumption and Cost. J. Clean. Prod. 2016, 112, 1013–1024. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Formisano, A.; Durante, M. A Comprehensive Review on the Incremental Sheet Forming of Polycarbonate. Polymers 2024, 16, 3098. https://doi.org/10.3390/polym16213098

Formisano A, Durante M. A Comprehensive Review on the Incremental Sheet Forming of Polycarbonate. Polymers. 2024; 16(21):3098. https://doi.org/10.3390/polym16213098

Chicago/Turabian StyleFormisano, Antonio, and Massimo Durante. 2024. "A Comprehensive Review on the Incremental Sheet Forming of Polycarbonate" Polymers 16, no. 21: 3098. https://doi.org/10.3390/polym16213098

APA StyleFormisano, A., & Durante, M. (2024). A Comprehensive Review on the Incremental Sheet Forming of Polycarbonate. Polymers, 16(21), 3098. https://doi.org/10.3390/polym16213098