Recyclable Thermoplastic Elastomer from Furan Functionalized Hairy Nanoparticles with Polystyrene Core and Polydimethylsiloxane Hairs

Abstract

:1. Introduction

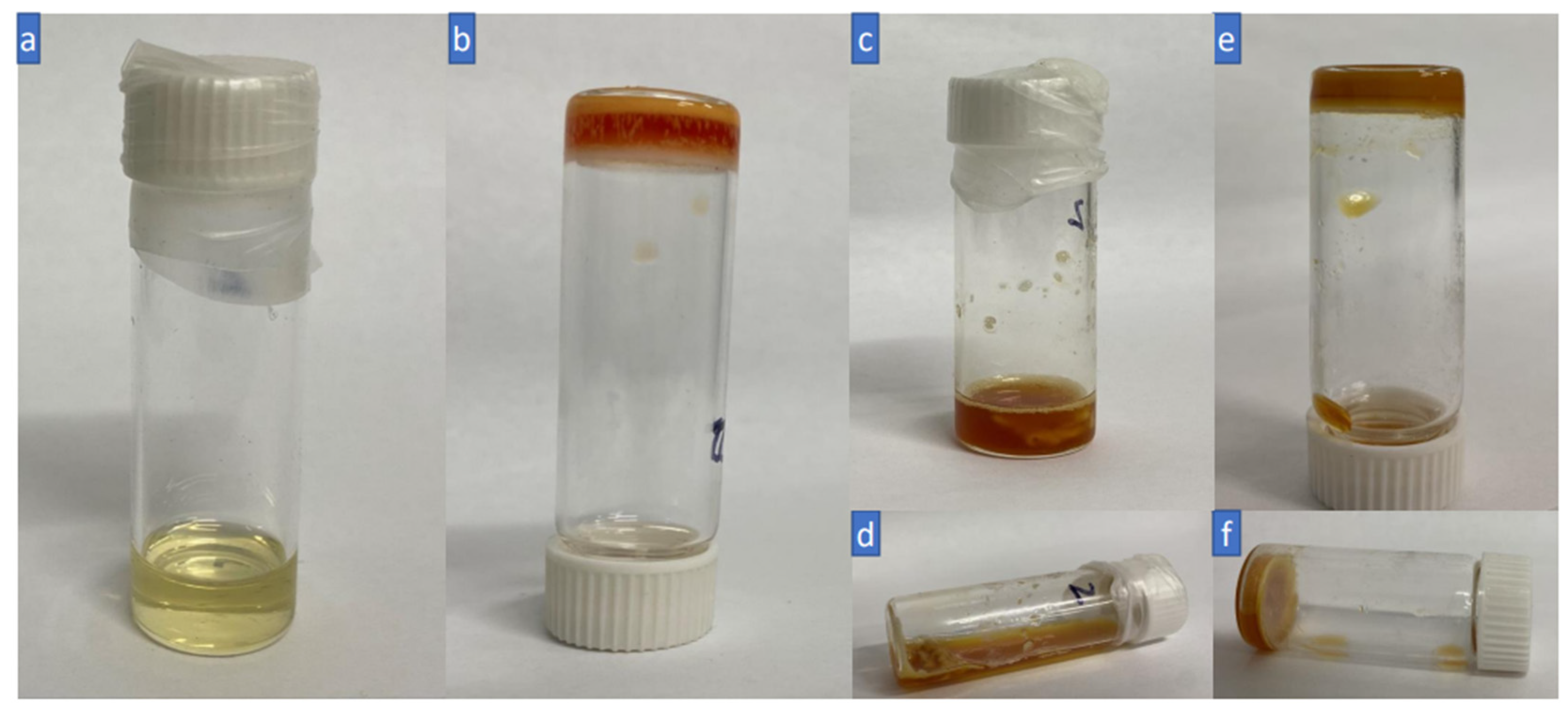

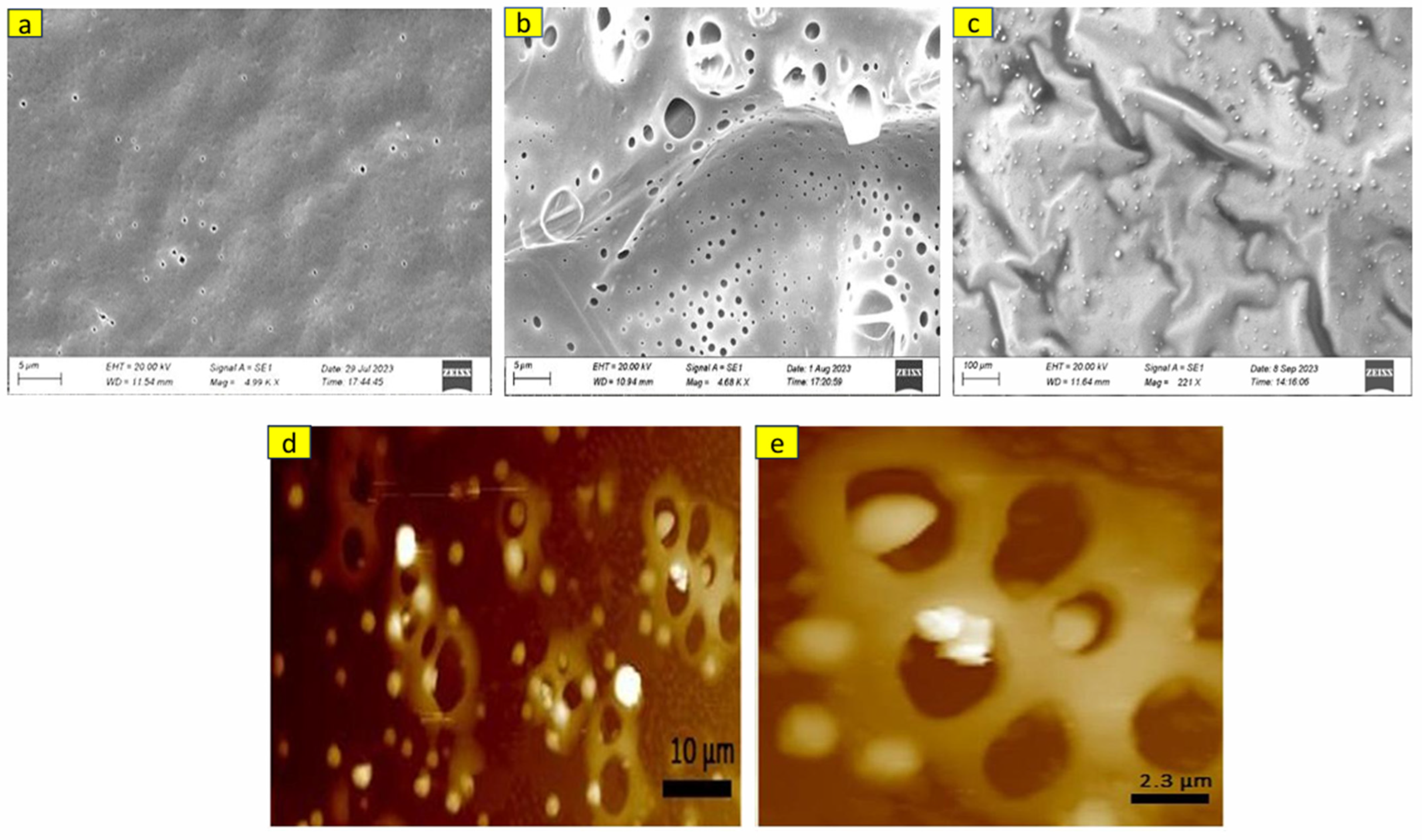

2. Materials and Methods

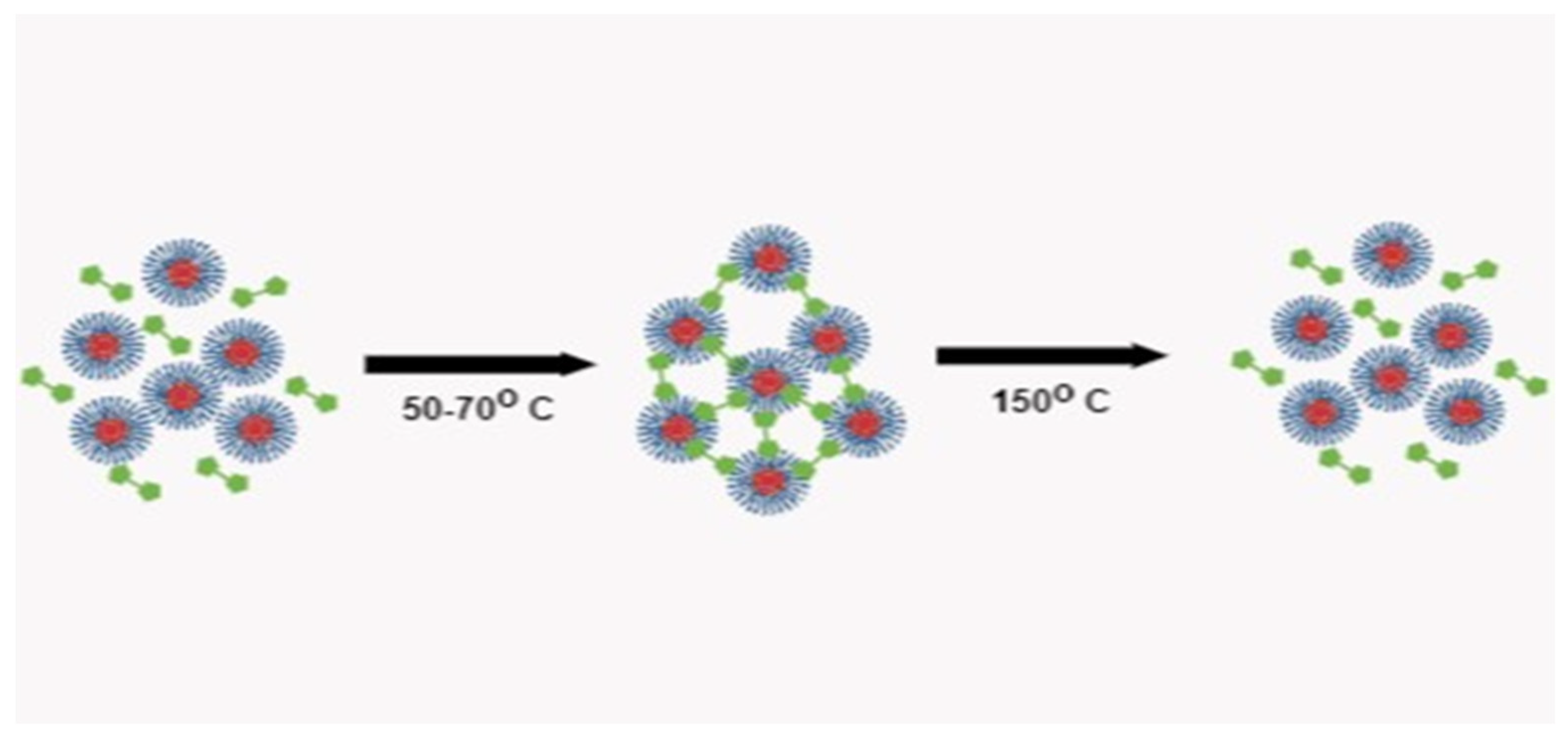

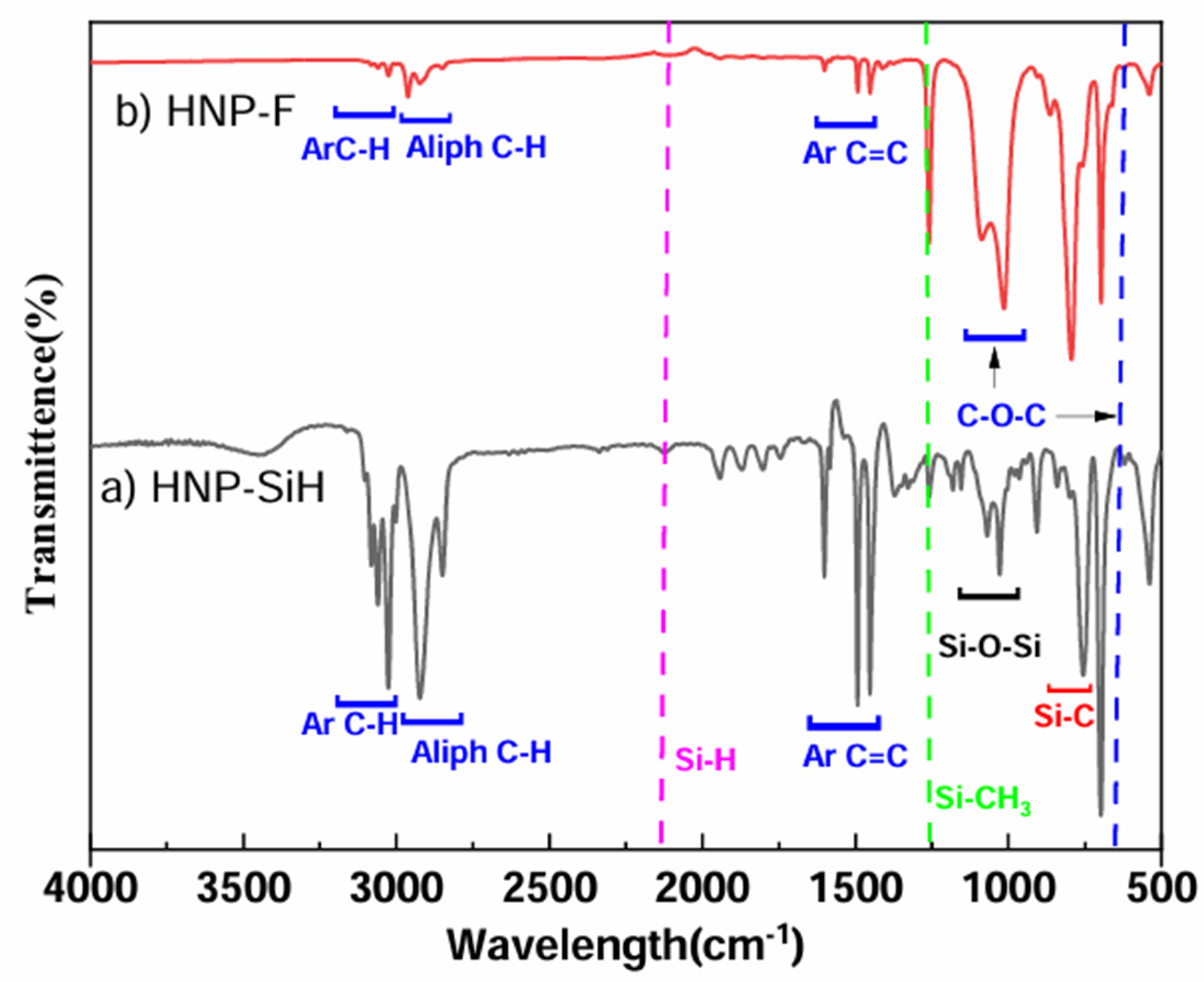

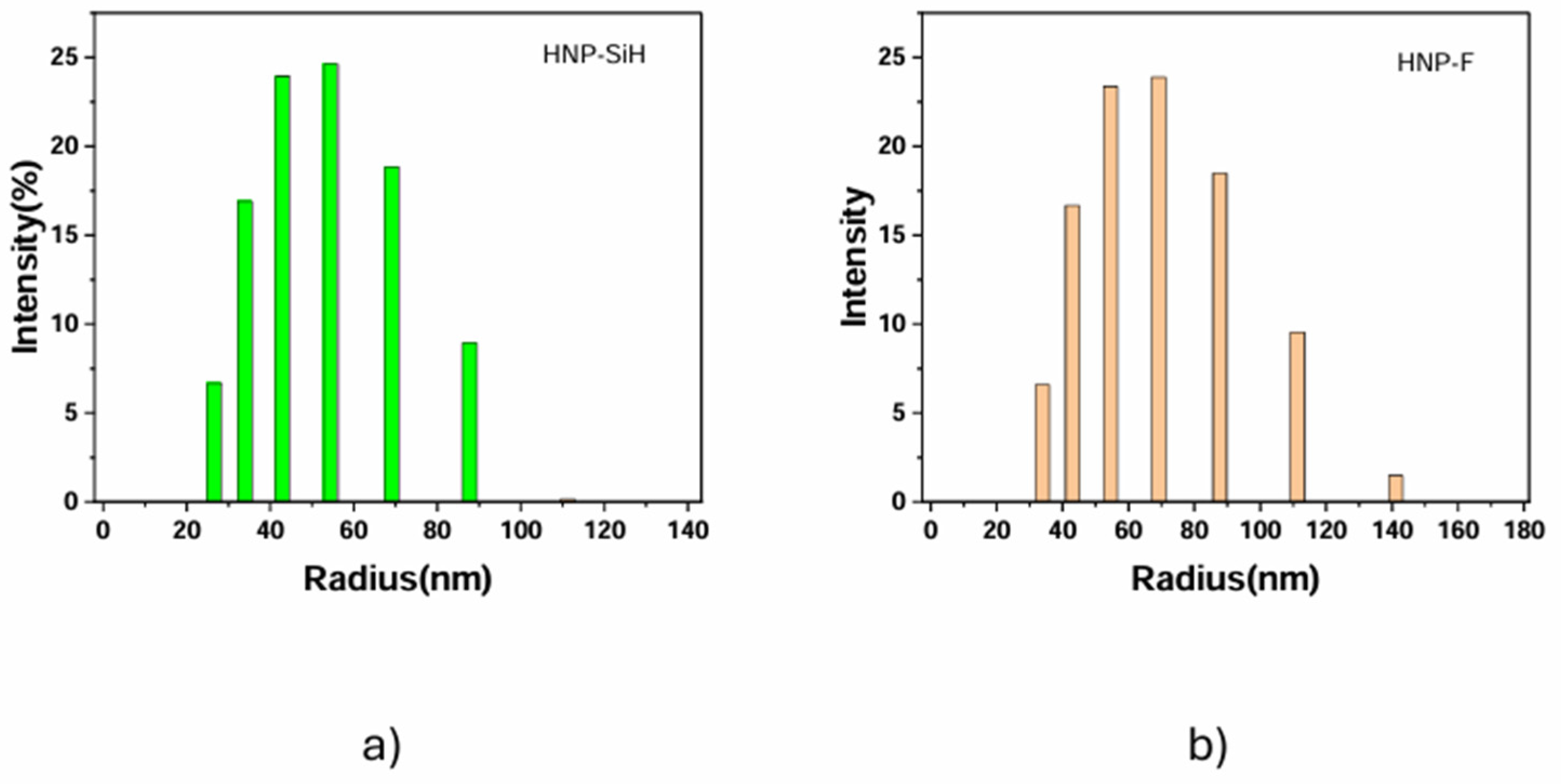

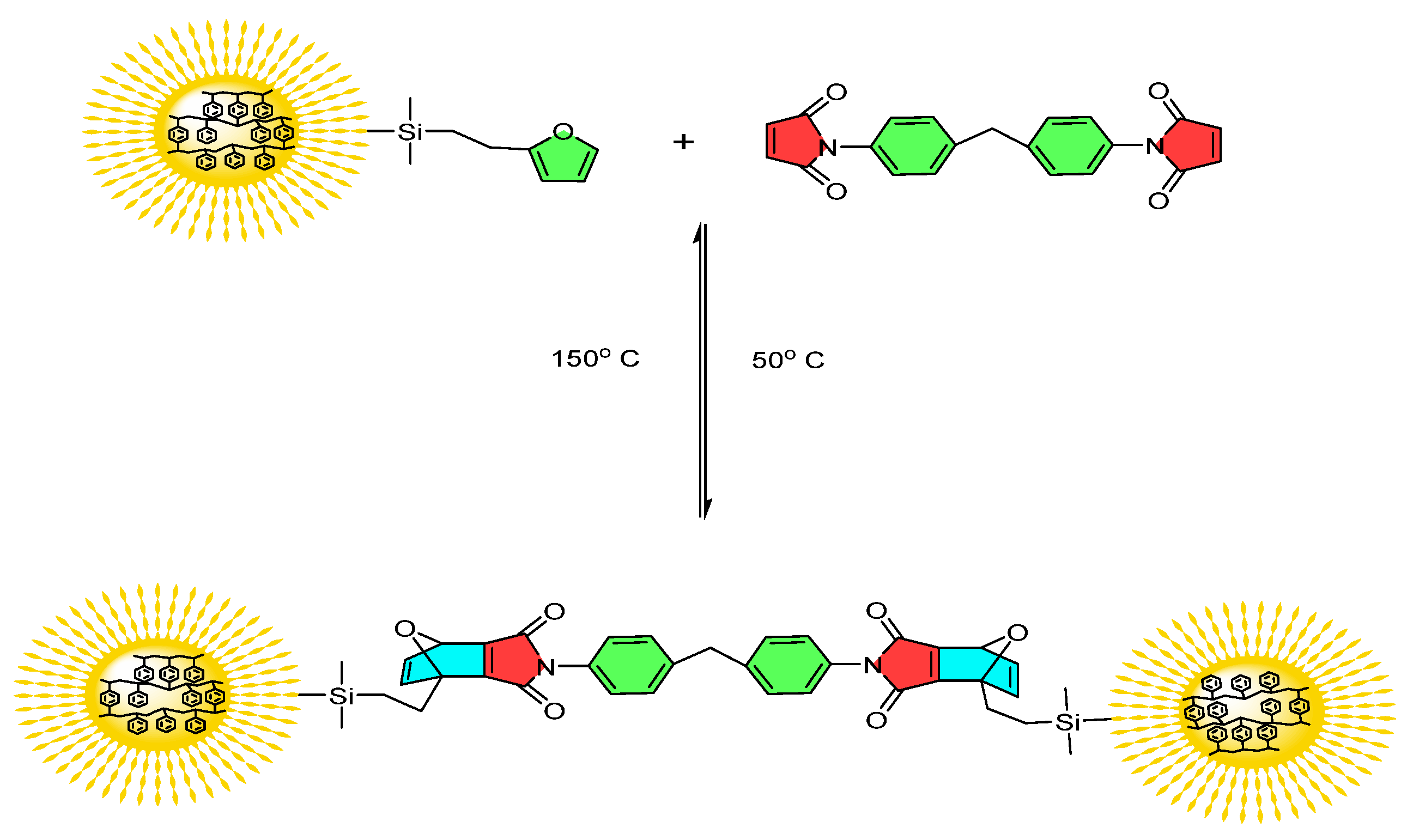

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Foundation, E.M. The New Plastics Economy: Rethinking the Future of Plastics; Ellen MacArthur Found: The Isle of Wight, UK, 2016; p. 120. [Google Scholar]

- Miller, L.; Soulliere, K.; Sawyer-Beaulieu, S.; Tseng, S.; Tam, E.C. Challenges and Alternatives to Plastics Recycling in the Automotive Sector. Materials 2014, 7, 5883–5902. [Google Scholar] [CrossRef] [PubMed]

- Duflou, J.R.; de Moor, J.; Verpoest, I.; Dewulf, W. Environmental Impact Analysis of Composite use in Car Manufacturing. CIRP Ann. 2009, 58, 9–12. [Google Scholar] [CrossRef]

- Yuan, C.; Zhang, M.Q.; Rong, M.Z. Application of Alkoxyamine in Self-Healing of Epoxy. J. Mater. 2014, 2, 6558–6566. [Google Scholar] [CrossRef]

- Toncelli, C.; de Reus, D.C.; Picchioni, F.; Broekhuis, A.A. Properties of Reversible Diels-Alder Furan/Maleimide Polymer Networks as Function of Crosslink Density. Macromol. Chem. 2012, 213, 157–165. [Google Scholar] [CrossRef]

- Goiti, E.; Huglin, M.B.; Rego, J.M. Thermal Breakdown by the Retro Diels-Alder Reaction of Crosslinking in Poly [Styrene-Co-(Furfuryl Methacrylate)]. Macromol Rapid Commun. 2003, 24, 692–696. [Google Scholar] [CrossRef]

- Gheneim, R.; Perez-Berumen, C.; Gandini, A. Diels-Alder Reactions with Novel Polymeric Dienes and Dienophiles: Synthesis of Reversibly Cross-Linked Elastomers. Macromolecules 2002, 35, 7246–7253. [Google Scholar] [CrossRef]

- Franc, G.; Kakkar, A.K. Diels-Alder “Click” Chemistry in Designing Dendritic Macromolecules. Chem.–A Eur. J. 2009, 15, 5630–5639. [Google Scholar] [CrossRef]

- Gandini, A.; Silvestre, A.; Coelho, D. Reversible Click Chemistry at the Service of Macromolecular Materials. Polym. Chem. 2011, 2, 1713–1719. [Google Scholar] [CrossRef]

- Nandivada, H.; Jiang, X.; Lahann, J. Click Chemistry: Versatility and Control in the Hands of Materials Scientists. Adv. Mater. 2007, 19, 2197–2208. [Google Scholar] [CrossRef]

- Chen, X.; Dam, M.A.; Ono, K.; Mal, A.; Shen, H.; Nutt, S.R.; Sheran, K.; Wudl, F. A Thermally Re-Mendable Cross-Linked Polymeric Material. Science 2002, 295, 1698–1702. [Google Scholar] [CrossRef]

- Stevens, M.P.; Jenkins, A.D. Crosslinking of polystyrene via pendant maleimide groups. J. Polym. Sci. Polym. Chem. Ed. 1979, 17, 3675–3685. [Google Scholar] [CrossRef]

- Canary, S.A.; Stevens, M.P. Thermally Reversible Crosslinking of Polystyrene via the Furan-Maleimide Diels-Alder Reaction. J. Polym. Sci. 1992, 30, 1755–1760. [Google Scholar] [CrossRef]

- Bapat, A.P.; Ray, J.G.; Savin, D.A.; Hoff, E.A.; Patton, D.L.; Sumerlin, B.S. Dynamic-Covalent Nanostructures Prepared by Diels-Alder Reactions of Styrene-Maleic Anhydride-Derived Copolymers Obtained by One-Step Cascade Block Copolymerization. Polym. Chem. 2012, 3, 3112–3120. [Google Scholar] [CrossRef]

- Barthel, M.J.; Rudolph, T.; Crotty, S.; Schacher, F.H.; Schubert, U.S. Homo- and Diblock Copolymers of Poly (furfuryl glycidyl ether) by Living Anionic Polymerization: Toward Reversibly Core-Crosslinked Micelles. J. Polym. Sci. 2012, 50, 4958–4965. [Google Scholar] [CrossRef]

- Kuang, X.; Liu, G.; Dong, X.; Liu, X.; Xu, J.; Wang, D. Facile Fabrication of Fast Recyclable and Multiple Self-Healing Epoxy Materials through Diels-Alder Adduct Cross-Linker. J. Polym. Sci. 2015, 53, 2094–2103. [Google Scholar] [CrossRef]

- Kang, B.G.; Pramanik, N.B.; Singha, N.K.; Lee, J.S.; Mays, J. Precise Synthesis of Thermoreversible Block Copolymers Containing Reactive Furfuryl Groups via Living Anionic Polymerization: The Countercation Effect on Block Copolymerization Behavior. Polym. Chem. 2015, 6, 6732–6738. [Google Scholar] [CrossRef]

- Das, S.; Samitsu, S.; Nakamura, Y.; Yamauchi, Y.; Payra, D.; Kato, K.; Naito, M. Thermo-Resettable Cross-Linked Polymers for Reusable/Removable Adhesives. Polym. Chem. 2018, 9, 5559–5565. [Google Scholar] [CrossRef]

- Buonerba, A.; Speranza, V.; Capacchione, C.; Milione, S.; Grassi, A. Improvement of Tensile Properties, Self-Healing and Recycle of Thermoset Styrene/2-Vinylfuran Copolymers via Thermal Triggered Rearrangement of Covalent Crosslink. Eur. Polym. J. 2018, 99, 368–377. [Google Scholar] [CrossRef]

- Liang, C.; Li, J.; Xia, M.; Li, G.; Luo, Y.P. Performance and Kinetics Study of Self-Repairing Hydroxyl-Terminated Polybutadiene Binders Based on the Diels–Alder Reaction. Polymers 2017, 9, 6. [Google Scholar] [CrossRef]

- Jiang, X.; Zhao, B.; Zhong, G.; Jin, N.; Horton, J.M.; Zhu, L.; Hafner, R.S.; Lodge, T.P. Microphase Separation of High Grafting Density Asymmetric Mixed Homopolymer Brushes on Silica Particles. Macromolecules 2010, 43, 8209–8217. [Google Scholar] [CrossRef]

- Min Ke Gao, H.; Yoon, J.A.; Wu, W.; Kowalewski, T.; Matyjaszewski, K. One-Pot Synthesis of Hairy Nanoparticles by Emulsion ATRP. Macromolecules 2009, 42, 1597–1603. [Google Scholar]

- Wang, X.; Hall, E.; Warren, J.; Krom, J.; Magistrelli, J.M.; Rackaitis, M.; Bohm, G.G.A. Characterization, and Application of Novel Polymeric Nanoparticles. Macromolecules 2007, 40, 499–508. [Google Scholar] [CrossRef]

- Helms, B.; Guillaudeu, S.J.; Xie, Y.; McMurdo, M.; Hawker, C.J.; Fréchet, J.M. One-Pot Reaction Cascades Using Star Polymers with Core-Confined Catalysts. Angew. Chem. Int. Ed. 2005, 44, 6384–6387. [Google Scholar] [CrossRef]

- Klos, J.; Pakula, T. Interaction of a spherical particle with linear chains. II. Chains end-grafted at the particle surface. J. Chem. Phys. 2003, 118, 7682–7689. [Google Scholar]

- Yezek, L.; Schartl, W.; Chen, Y.; Gohr, K.; Schmidt, M. Influence of Hair Density and Hair Length on Interparticle Interactions of Spherical Polymer Brushes in a Homopolymer Matrix. Macromolecules 2003, 36, 4226–4235. [Google Scholar] [CrossRef]

- Kalra, V.; Escobedo, F.; Joo, Y.L. Effect of shear on nanoparticle dispersion in polymer melts: A coarse-grained molecular dynamics study. J. Chem. Phys. 2010, 132, 024901. [Google Scholar] [CrossRef] [PubMed]

- Siegwart, D.J.; Whitehead, K.A.; Nuhn, L.; Sahay, G.; Cheng, H.; Jiang, S.; Ma, M.; Lytton-Jean, A.; Vegas, A.; Fenton, P.; et al. Combinatorial Synthesis of Chemically Diverse Core-Shell Nanoparticles for Intracellular Delivery. Proc. Natl. Acad. Sci. USA 2011, 108, 12996–13001. [Google Scholar] [CrossRef]

- Werne, V.; Patten, T.E. Preparation of Structurally Well-Defined Polymer-Nanoparticle Hybrids with Controlled/Living Radical Polymerizations. J. Am. Chem. Soc. 1999, 121, 7409–7410. [Google Scholar] [CrossRef]

- Ueda, K.; Hirao, A.; Nakahama, S. Synthesis of Polymers with Amino End Groups. 3. Reactions of Anionic Living Polymers with α-Halo-ι-Aminoalkanes with a Protected Amino Functionality. Macromolecules 1990, 23, 939–945. [Google Scholar] [CrossRef]

- Takenaka, K.; Hirao, A.; Nakahama, S. Synthesis of end-functionalized polymers by means of living anionic polymerization, 3a) Synthesis of polystyrene and polyisoprene with 1,3-butadienyl termini by reaction of their anionic living polymers with 6-bromo-3-methylene-1-hexene. Macromol. Chem. Phys. 1995, 196, 1687–1696. [Google Scholar] [CrossRef]

- Quirk, R.P.; Zhuo, Q.; Jang, S.H.; Lee, Y.; Lizarraga, G. Principles of Anionic Polymerization: An Introduction. ACS Symp. Ser. 1998, 696, 2–27. [Google Scholar] [CrossRef]

- Zheng, L.; Xie, A.F.; Lean, J.T. Polystyrene Nanoparticles with Anionically Polymerized Polybutadiene Brushes. Macromolecules 2004, 37, 9954–9962. [Google Scholar] [CrossRef]

- Zhou, G.; Person, V.; Khan, I.M. Hairy Nanoparticles with Hard Polystyrene Cores and Soft Polydimethylsiloxane Shells: One-Pot Synthesis by Living Anionic Polymerization and Characterization. Macromol. Chem. Phys. 2016, 217, 2601–2610. [Google Scholar] [CrossRef]

- Polgar, L.M.; Duin, M.; van Broekhuis, A.A.; Picchioni, F. Use of Diels−Alder Chemistry for Thermoreversible Cross-Linking of Rubbers: The Next Step toward Recycling of Rubber Products? Macromolecules 2015, 48, 7096–7105. [Google Scholar] [CrossRef]

- Liu, X.; Du, P.; Liu, L.; Zheng, Z. Kinetic Study of Diels—Alder Reaction Involving Maleimide—Furan Compounds and Linear Polyurethane. Polym. Bull. 2013, 70, 2319–2335. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, Y.; Wang, X.; Lin, T. Thermally Healable Polyhedral Oligomeric Silsesquioxane (POSS) Nanocomposite Based on Diels—Alder Chemistry. Chem. Commun. 2013, 49, 6755–6757. [Google Scholar] [CrossRef]

- Goussé, C.; Gandini, A.; Hodge, P. Application of the Diels—Alder Reaction to Polymers Bearing Furan Moieties. 2. Diels—Alder and Retro-Diels—Alder Reactions Involving Furan Rings in Some Styrene Copolymers. Macromolecules 1998, 1, 314–321. [Google Scholar] [CrossRef]

- Liu, S.; Liu, X.; He, Z.; Liu, L.; Niu, H. Thermoreversible Cross-Linking of Ethylene/Propylene Copolymers Based on Diels-Alder Chemistry: The Cross-Linking Reaction Kinetics. Polym. Chem. 2020, 11, 5851–5860. [Google Scholar] [CrossRef]

- Tian, Q.; Rong, M.Z.; Zhang, M.Q.; Yuan, Y.C.S. Synthesis and Characterization of Epoxy with improved thermal remendability based on Diels-Alder reaction. Polym. Int. 2010, 59, 1339–1345. [Google Scholar] [CrossRef]

- Polgar, L.M.; Kingma, A.; Roelfs, M.; van Essen, M.; van Duin, M.; Picchioni, F. Kinetics of Cross-Linking and de-Crosslinking of EPM Rubber with Thermoreversible Diels-Alder Chemistry. Eur. Polym. J. 2017, 90, 150–161. [Google Scholar] [CrossRef]

| Furan Functionalized Samples | Weight of Polymers (mg) | Weight of BMI (mg) | DMF + THF (1:1 v/v) |

|---|---|---|---|

| HNP-F | 50 | 30 | 10 mL |

| PS-F | 25 | 10 | 7 mL |

| PDMS-F | 50 | 30 | 10 mL |

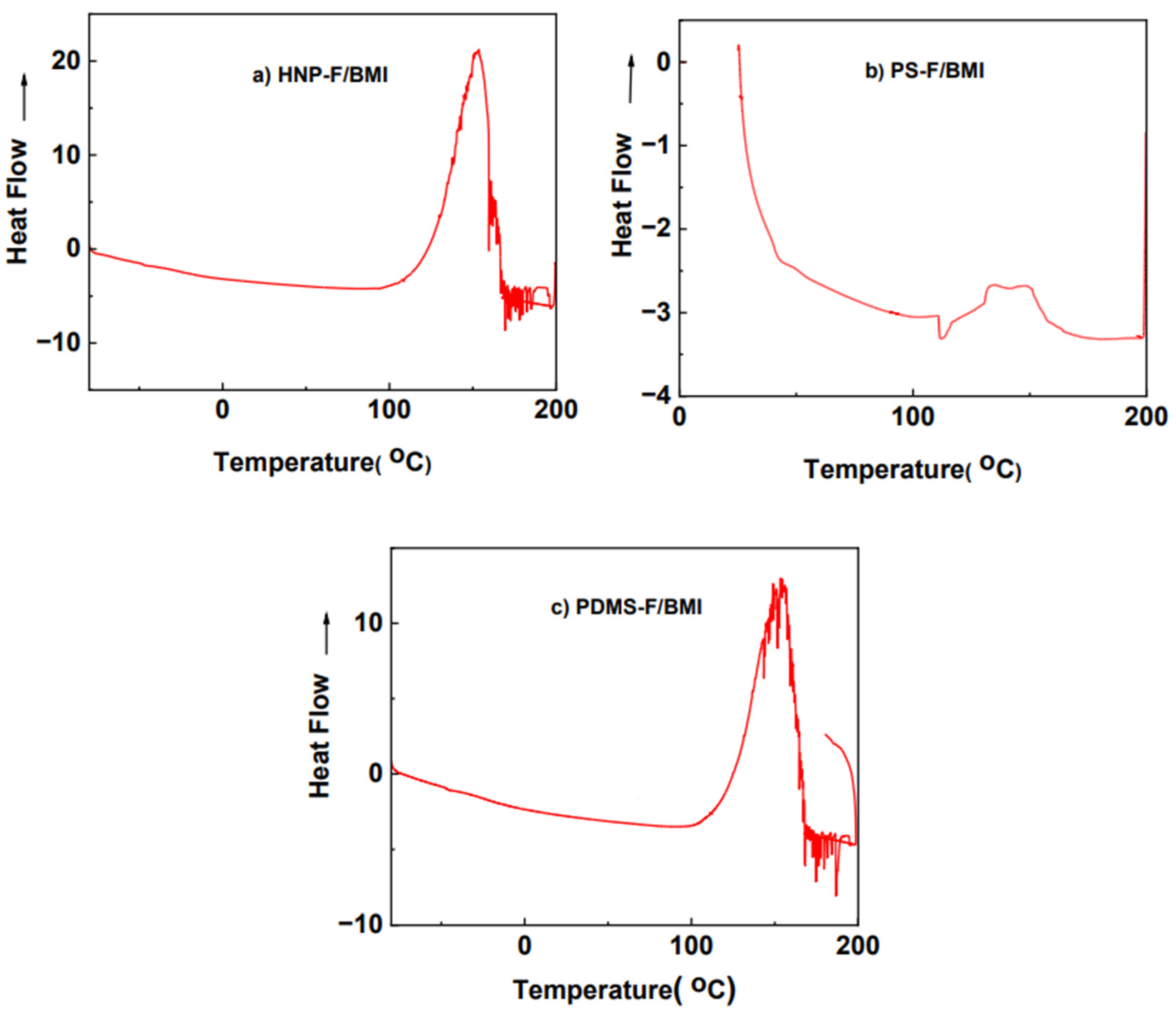

| Sample | Td (Onset) (°C) | Tmax (°C) | Char Yield at 700 °C (wt%) | Tg (°C) | Tm (°C) |

|---|---|---|---|---|---|

| HNP-F | 382, 515 | 560 | 0 | 110 | −24 |

| PS-F | 413 | 490 | 0 | 103 | −20 |

| PDMS-F | 458 | 562 | 0 | - | −25 |

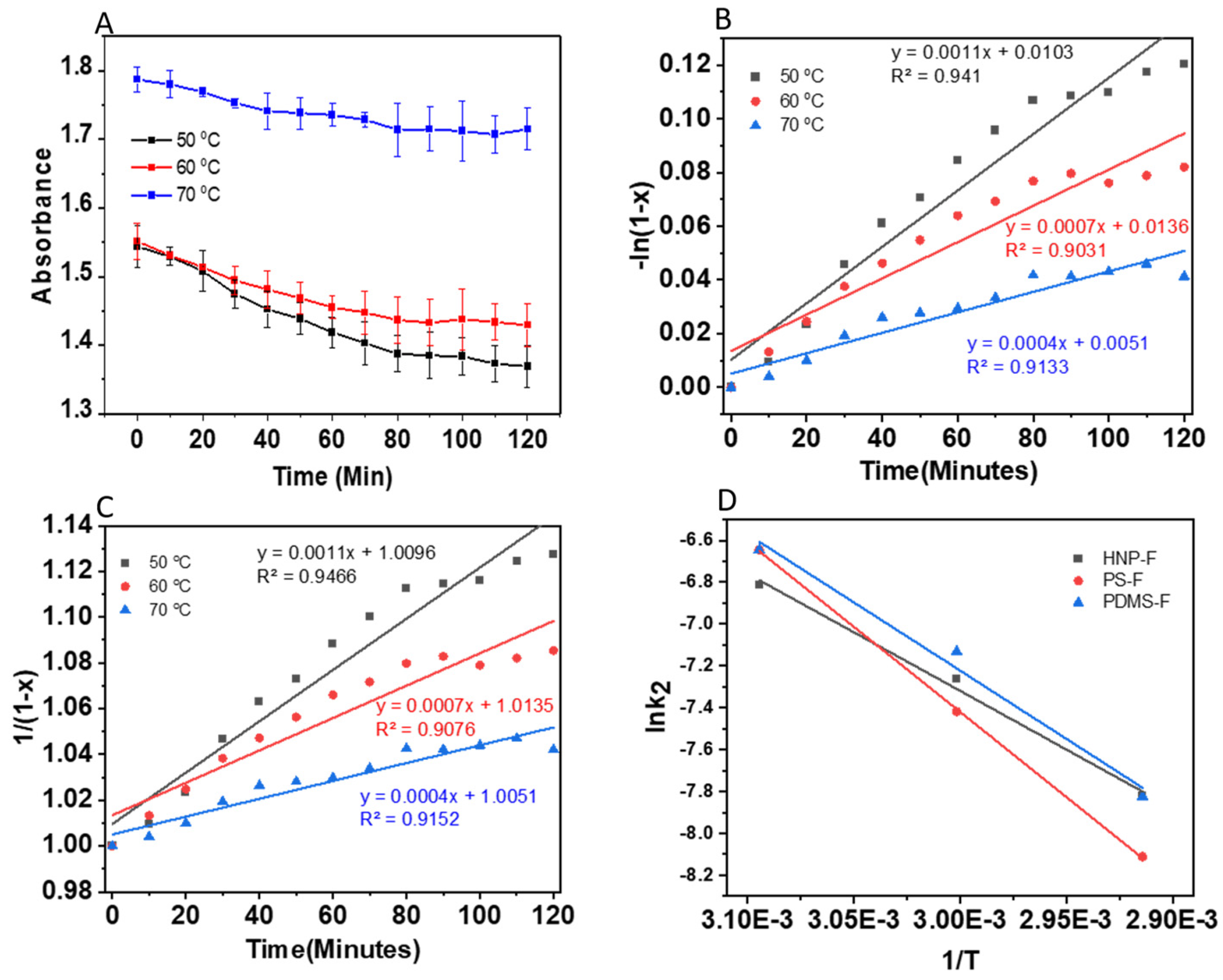

| Polymer | Kinetic Order | T/°C | 50 | 60 | 70 |

|---|---|---|---|---|---|

| HNP-F | n = 1 | k1/min−1 | 0.0011 | 0.0007 | 0.0004 |

| n = 2 | k2/(min−1 mol−1 L) | 0.0011 | 0.0007 | 0.0004 | |

| PS-F | n = 1 | k1/min−1 | 0.0012 | 0.0006 | 0.0003 |

| n = 2 | k2/(min−1 mol−1 L) | 0.0013 | 0.0006 | 0.0003 | |

| PDMS-F | n = 1 | k1/min−1 | 0.0012 | 0.0007 | 0.0004 |

| n = 2 | k2/(min−1 mol−1 L) | 0.0013 | 0.0008 | 0.0004 |

| Furan Functionalized End-Group Samples | The Activation Energy of the Crosslinking Reaction with BMI |

|---|---|

| HNP-F | 46.57 kJ mol−1 |

| PS-F | 67.61 kJ mol−1 |

| PDMS-F | 54.22 kJ mol−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uddin, M.H.; Alsahli, S.; Alqurashi, E.; Alyoubi, S.; Walters, N.; Khan, I.M. Recyclable Thermoplastic Elastomer from Furan Functionalized Hairy Nanoparticles with Polystyrene Core and Polydimethylsiloxane Hairs. Polymers 2024, 16, 3117. https://doi.org/10.3390/polym16223117

Uddin MH, Alsahli S, Alqurashi E, Alyoubi S, Walters N, Khan IM. Recyclable Thermoplastic Elastomer from Furan Functionalized Hairy Nanoparticles with Polystyrene Core and Polydimethylsiloxane Hairs. Polymers. 2024; 16(22):3117. https://doi.org/10.3390/polym16223117

Chicago/Turabian StyleUddin, Md Hanif, Sultan Alsahli, Esam Alqurashi, Saber Alyoubi, Natalia Walters, and Ishrat M. Khan. 2024. "Recyclable Thermoplastic Elastomer from Furan Functionalized Hairy Nanoparticles with Polystyrene Core and Polydimethylsiloxane Hairs" Polymers 16, no. 22: 3117. https://doi.org/10.3390/polym16223117

APA StyleUddin, M. H., Alsahli, S., Alqurashi, E., Alyoubi, S., Walters, N., & Khan, I. M. (2024). Recyclable Thermoplastic Elastomer from Furan Functionalized Hairy Nanoparticles with Polystyrene Core and Polydimethylsiloxane Hairs. Polymers, 16(22), 3117. https://doi.org/10.3390/polym16223117