Sustainable Transformation of Cellulose-Containing Textile Waste into Multifunctional Panels with Tailored FR-Lignocellulosic Fibres

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Synthesis

2.1.1. Materials

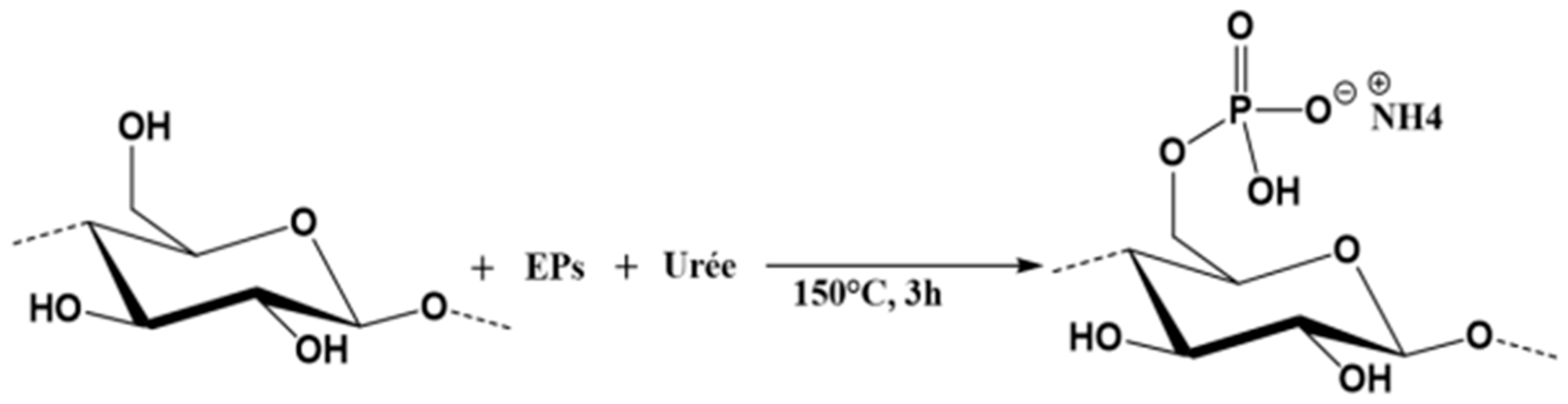

2.1.2. Synthesis

2.2. Textile Waste Panel Preparation

2.3. Fibre Length Distribution

2.4. Zeta Potential

2.5. Surface Charge

2.6. Nitrogen Content

2.7. Fibre Composition

2.8. Morphological Examination

2.9. FT-IR Spectroscopy

2.10. Thermal Conductivity

2.11. Open Porosity and Bulk Density

2.12. Tortuosity

2.13. Airflow Resistivity and Permeability

2.14. Viscous and Thermal Characteristic Lengths

2.15. Resistance to Ignition

2.16. Tensile Strength Properties

3. Results and Discussion

3.1. Characterisation of Fibres

3.2. Properties of Panels Made with Textile Waste Microfibres

3.2.1. Structural Properties

3.2.2. Fibre Morphology—SEM/EDX

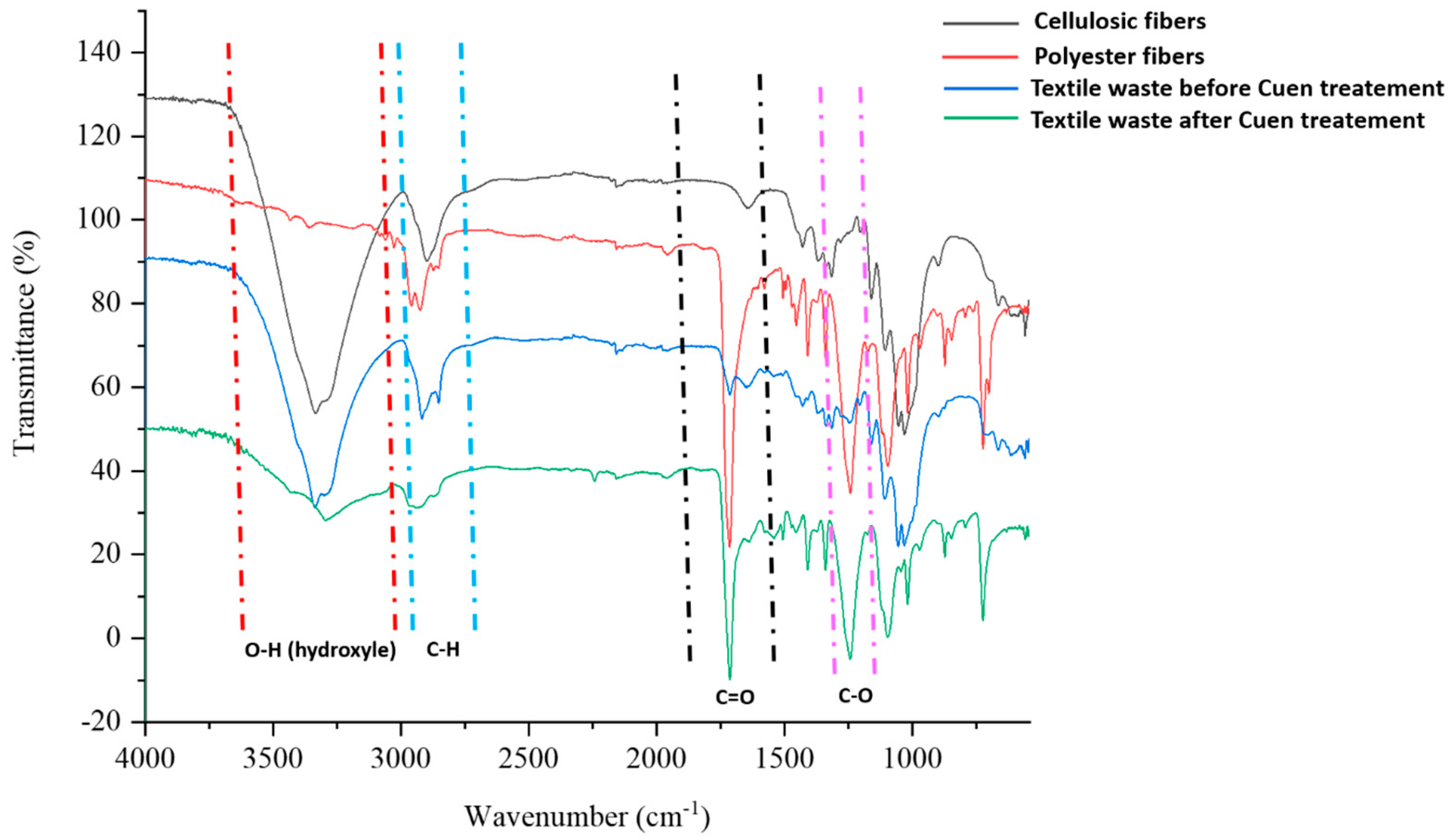

3.2.3. FTIR Spectroscopy

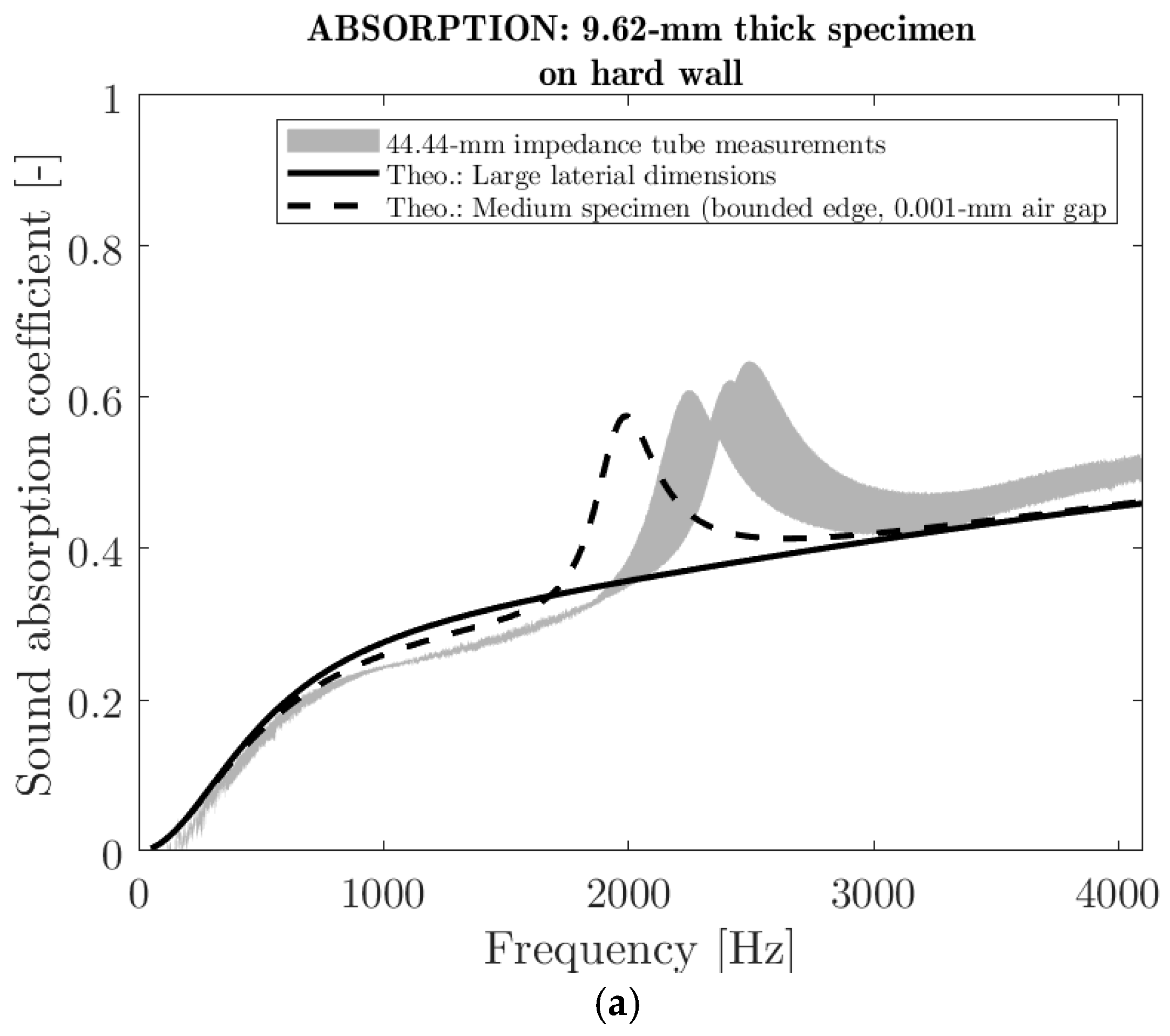

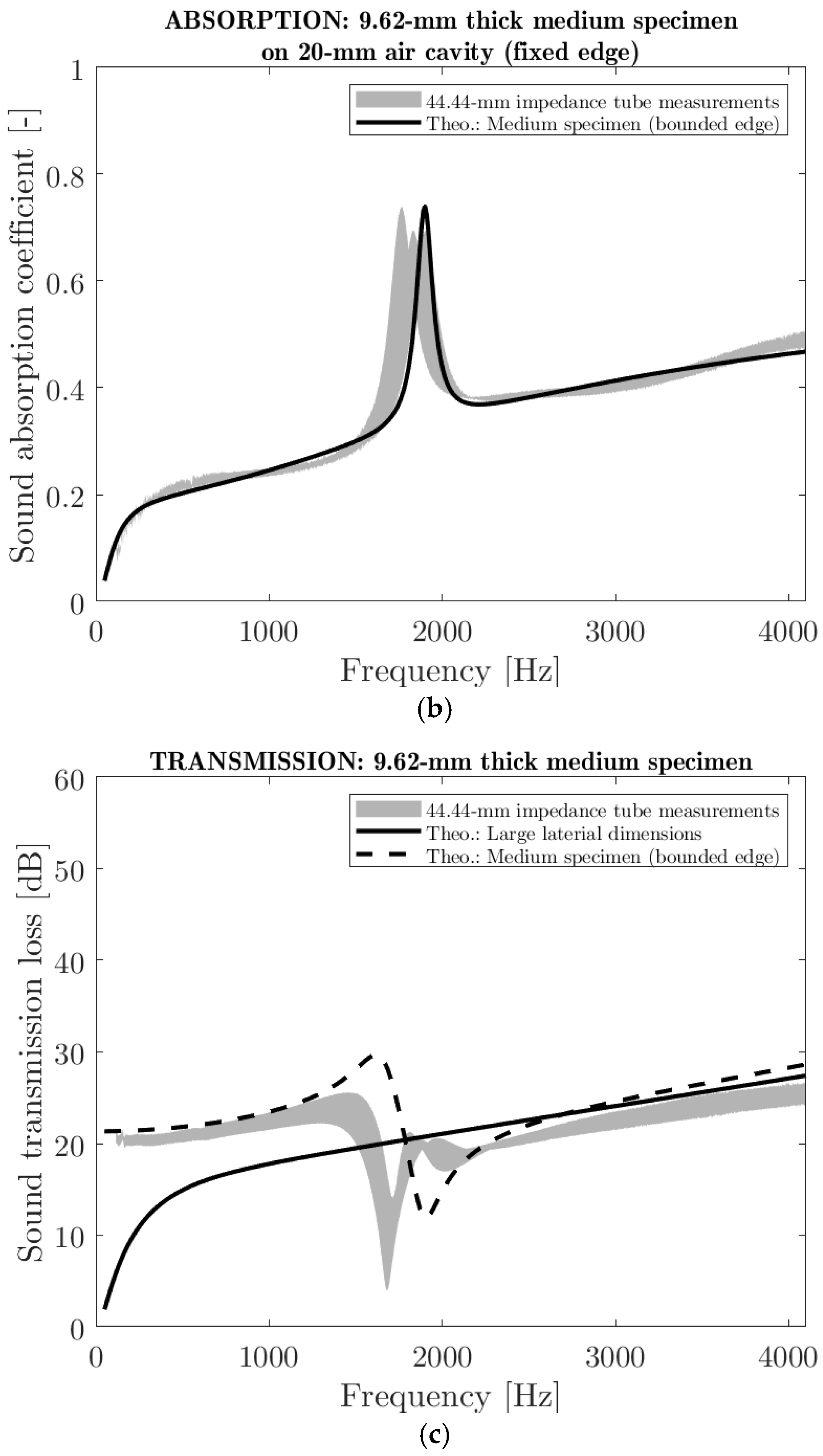

3.2.4. Acoustical Properties

3.2.5. Ignitability

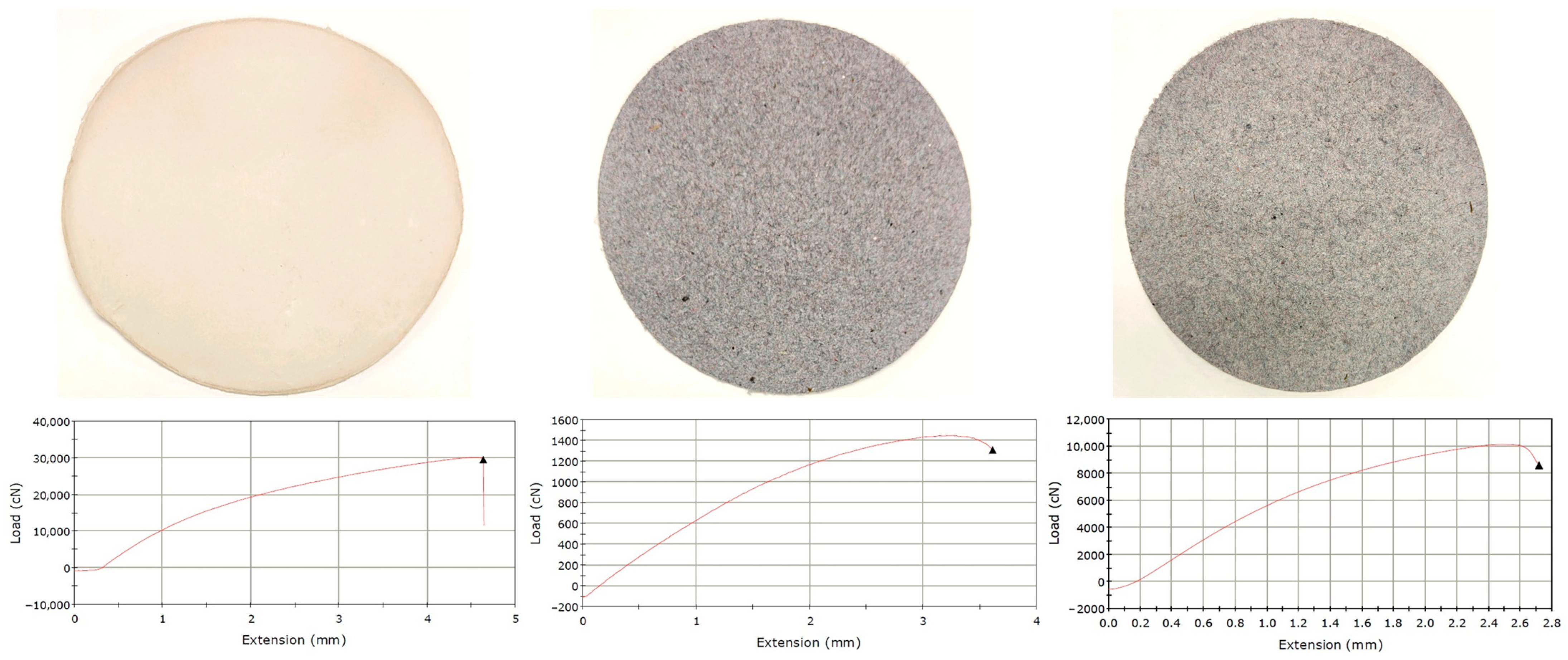

3.2.6. Tensile Strength Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.; Su, J.; Liu, T.; Ge, S.; Liew, R.K.; Zhang, H.; Naushad, M.; Lam, S.S.; Ng, H.S.; Sonne, C.; et al. A sustainable strategy to transform cotton waste into renewable cellulose fiber self-reinforcing composite paper. J. Clean. Prod. 2023, 429, 139567. [Google Scholar] [CrossRef]

- Mordor Intelligence. Apparel Market (2020–2025)|Growth|Trends|Forecasts. Available online: https://www.mordorintelligence.com/industry-reports/apparel-market (accessed on 15 June 2024).

- Global Apparel Industry Statistics Statistics: Market Data Report 2024. Available online: https://www.gitnux.org/global-apparel-industry-statistics/ (accessed on 30 September 2024).

- Oberlo. Apparel Industry Statistics (2012–2025)|Oberlo. Available online: https://www.oberlo.com/statistics/apparel-industry-statistics (accessed on 15 June 2024).

- Igini, M. 10 concerning Fast Fashion Waste Statistics. Available online: https://earth.org/statistics-about-fast-fashion-waste/ (accessed on 20 September 2024).

- Huang, X.; Tan, Y.; Huang, J.; Zhu, G.; Yin, R.; Tao, X.; Tian, X. Industrialization of Open-and Closed-Loop Waste Textiles Recycling towards Sustainability: A Review. J. Clean. Prod. 2024, 436, 140676. [Google Scholar] [CrossRef]

- Ütebay, B.; Çelik, P.; Çay, A. Textile Wastes: Status and Perspectives. In Waste in Textile and Leather Sectors; IntechOpen Limited: Londan, UK, 2020. [Google Scholar] [CrossRef]

- Ruiz, A. 17 Most Worrying Textile Waste Statistics & Facts. Available online: https://theroundup.org/textile-waste-statistics/ (accessed on 30 September 2024).

- Bartl, A. End-of-Life Textiles; Waste: Somerset, UK, 2019; pp. 323–336. [Google Scholar] [CrossRef]

- Teixeira França Alves, P.H.; Clarke-Sather, A.; Carlson, S.; Martini, A. Theoretical Method for Characterizing Textile Failure Mechanics in Mechanical Recycling with Carded Drums; American Society of Mechanical Engineers: New York, NY, USA, 2023. [Google Scholar] [CrossRef]

- Ribul, M.; Lanot, A.; Tommencioni Pisapia, C.; Purnell, P.; McQueen-Mason, S.J.; Baurley, S. Mechanical, Chemical, Biological: Moving towards Closed-Loop Bio-Based Recycling in a Circular Economy of Sustainable Textiles. J. Clean. Prod. 2021, 326, 129325. [Google Scholar] [CrossRef]

- Lawson, L.; Degenstein, L.M.; Bates, B.; Chute, W.; King, D.; Dolez, P.I. Cellulose Textiles from Hemp Biomass: Opportunities and Challenges. Sustainability. Sustainability 2022, 14, 15337. [Google Scholar] [CrossRef]

- Arafat, Y.; Uddin, A.J. Recycled Fibers from Pre- and Post-Consumer Textile Waste as Blend Constituents in Manufacturing 100% Cotton Yarns in Ring Spinning: A Sustainable and Eco-Friendly Approach. Heliyon 2022, 8, e11275. [Google Scholar] [CrossRef]

- Subramanian, K.; Chopra, S.S.; Cakin, E.; Li, X.; Lin, C.S.K. Environmental Life Cycle Assessment of Textile Bio-Recycling—Valorizing Cotton-Polyester Textile Waste to Pet Fiber and Glucose Syrup. Resour. Conserv. Recycl. 2020, 161, 104989. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Strategies of Recovery and Organic Recycling Used in Textile Waste Management. Int. J. Environ. Res. Public Health 2022, 19, 5859. [Google Scholar] [CrossRef]

- Thomas, J.; Patil, R.S.; Patil, M.; John, J. Navigating the Labyrinth of Polymer Sustainability in the Context of Carbon Footprint. Coatings. 2024, 14, 774. [Google Scholar] [CrossRef]

- Eppinger, E. Recycling Technologies for Enabling Sustainability Transitions of the Fashion Industry: Status Quo and Avenues for Increasing Post-Consumer Waste Recycling. Sustain.Sci. Pract. Policy 2022, 18, 114–128. [Google Scholar] [CrossRef]

- Harmsen, P.; Scheffer, M.; Bos, H. Textiles for Circular Fashion: The Logic behind Recycling Options. Sustainability 2021, 13, 9714. [Google Scholar] [CrossRef]

- Costa, C.; Viana, A.; Silva, C.; Marques, E.F.; Azoia, N.G. Recycling of Textile Wastes, by Acid Hydrolysis, into New Cellulosic Raw Materials. Waste Manag. 2022, 153, 99–109. [Google Scholar] [CrossRef] [PubMed]

- Sanchis-Sebastiá, M.; Ruuth, E.; Stigsson, L.; Galbe, M.; Wallberg, O. Novel Sustainable Alternatives for the Fashion Industry: A Method of Chemically Recycling Waste Textiles via Acid Hydrolysis. Waste Manag. 2021, 121, 248–254. [Google Scholar] [CrossRef] [PubMed]

- Palme, A.; Peterson, A.; de la Motte, H.; Theliander, H.; Brelid, H. Development of an Efficient Route for Combined Recycling of PET and Cotton from Mixed Fabrics. Text. Cloth. Sustain. 2017, 3, 4. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A. Textile Recycling Processes, State of the Art and Current Developments: A Mini Review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef]

- Clarke, C.J.; Tu, W.-C.; Levers, O.; Bröhl, A.; Hallett, J.P. Green and Sustainable Solvents in Chemical Processes. Chem. Rev. 2018, 118, 747–800. [Google Scholar] [CrossRef] [PubMed]

- Lamoudan, H.; Brouillette, F. fabrication of high strength paper from different types of phosphorylated fibers using hot pressing and forming agents. Cellul. Chem. Technol. 2024, 58, 313–322. [Google Scholar] [CrossRef]

- Shi, Y.; Belosinschi, D.; Brouillette, F.; Belfkira, A.; Chabot, B. The Properties of Phosphorylated Kraft Fibers. BioResources 2015, 10, 4375–4390. [Google Scholar] [CrossRef]

- Bobu, E.; Belosinschi, D. Effects of coagulants on the dcs accumulation in process water of papermaking. Environ. Eng. Manag. J. 2008, 7, 269–276. [Google Scholar] [CrossRef]

- Lamoudan, H.; Abenghal, L.; Brouillette, F. Improving the Mechanical Strength of Paper Sheets Made from Phosphorylated Fibers through the Use of Forming Agents. J. Nat. Fibers 2024, 21, 2332705. [Google Scholar] [CrossRef]

- Bradstreet, R.B. Kjeldahl Method for Organic Nitrogen. Anal. Chem. 1954, 26, 185–187. [Google Scholar] [CrossRef]

- ASTM D7984-21; Standard Test Method for Measurement of Thermal Effusivity of Fabrics Using a Modified Transient Plane Source (MTPS) Instrument. ASTM: West Conshohocken, PA, USA, 2021.

- Salissou, Y.; Panneton, R. Pressure/Mass Method to Measure Open Porosity of Porous Solids. J. Appl. Phys. 2007, 101, 124913. [Google Scholar] [CrossRef]

- Allard, J.F.; Castagnède, B.; Henry, M.; Lauriks, W. Evaluation of Tortuosity in Acoustic Porous Materials Saturated by Air. Rev. Sci. Instrum. 1994, 65, 754–755. [Google Scholar] [CrossRef]

- ISO 9053-1; Acoustics—Determination of Airflow Resistance. Part 1: Static Airflow Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- Allard, J.F.; Atalla, N. Propagation of Sound in Porous Media; John Wiley and Sons: Hoboken, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Verdiere, K.; Panneton, R.; Atalla, N.; Elkoun, S. Inverse Poroelastic Characterization of Open-Cell Porous Materials Using an Impedance Tube; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- CEN ISO 11925-2; Reaction to Fire Tests. Ignitability of Products Subjected to Direct Impingement of Flame. Single-Flame Source Test. European Committee for Standardization: Brussels, Belgium; International Organization for Standardization: Geneva, Switzerland, 2010.

- CEN 13501-1; Fire Classification of Construction Products and Building Elements. Classification Using Test Data from Reaction to Fire Tests. Standard European Committee for Standardization: Brussels, Belgium, 2007.

- TAPPI/ANSI T 494; Tensile Properties of Paper and Paperboard (Using Constant Rate of Elongation Apparatus). TAPPI Press: Atlanta, GA, USA, 2022.

- Smook, G.A. Chapter 2—Characteristics of Wood and Wood Pulp Fibers. In Handbook for Pulp & Paper Technologists, 3rd ed.; TAPPI PRESS: Atlanta, GA, USA, 2002. [Google Scholar]

- Behrens, S.H.; Borkovec, M. Electrostatic Interaction of Colloidal Surfaces with Variable Charge. J. Phys. Chem. B 1999, 103, 2918–2928. [Google Scholar] [CrossRef]

- Hunter, R.J. Zeta Potential in Colloid Science: Principles and Applications; Academic Press: London, UK, 1981. [Google Scholar]

- Lindman, B.; Medronho, B.; Alves, L.; Costa, C.; Edlund, H.; Norgren, M. The Relevance of Structural Features of Cellulose and Its Interactions to Dissolution, Regeneration, Gelation and Plasticization Phenomena. Phys. Chem. Chem. Phys. 2017, 19, 23704–23718. [Google Scholar] [CrossRef]

- Belosinschi, D.; Brouillette, F.; Shi, Y.; Paradis, J.; Doucet, J. Phosphorylated Lignocellulosic Fibers, Uses and Processes of Preparation Thereof. International Patent Application WO 2017/214719A1, 21 December 2017. [Google Scholar]

- Islam, R.; Golovin, K.; Dolez, P.I. Thermal Effusivity Assessment of Sportswear Fabrics in the Dry State: Stacked and Air-Hoop Methods. J. Test. Eval. 2024, 52, 2468–2482. [Google Scholar] [CrossRef]

- Tran, Q.V.; Perrot, C.; Panneton, R.; Hoang, M.T.; Dejaeger, L.; Marcel, V.; Jouve, M. Effect of Polydispersity on the Transport and Sound Absorbing Properties of Three-Dimensional Random Fibrous Structures. Int. J. Solids Struct. 2024, 296, 112840. [Google Scholar] [CrossRef]

- Dipietro, J.; Stepniczka, H.; Nametz, R.C. A Study of Flammability of Cotton, Polyester, and Their Blends. Text. Res. J. 1971, 41, 593–599. [Google Scholar] [CrossRef]

- Jarvis, C.W.; Barker, R.H. Flammability of Cotton-Polyester Blend Fabrics. In Flame—Retardant Polymeric Materials; Lewin, M., Atlas, S.M., Pearce, E.M., Eds.; Springer: Boston, MA, USA, 1978. [Google Scholar] [CrossRef]

| Fibre Size | Electrostatic Properties in Water | Composition | ||||||

|---|---|---|---|---|---|---|---|---|

| Length (mm) | Width (µm) | Fines (%) | Surface Charge (µeq/g) | Zeta Potential (mV) | Kjeldahl Nitrogen (%) | Synthetic/Cellulosic (%) | Ash at 525 °C (%) | |

| PKF | 1.99 ± 0.03 | 31.9 ± 0.6 | 0.2 | 350 ± 15 | −55 to −30 | 5.3 | 0/100 | 45 * |

| Textile waste fibres | 0.81 ± 0.02 | 24.6 ± 0.1 | 5.6 | 30 ± 5 | −25 to −10 | 1.6 | 33/67 | 0.8 |

| Criteria | Value |

|---|---|

| Composition, % textile waste microfibres/% PKF | 45/55 |

| Mass per unit area, g/m2 | 1864 ± 103 |

| Thickness, mm | 9.62 ± 1.02 |

| Density, kg/m3 | 183.3 ± 4.9 |

| Open porosity, % | 86 ± 1 |

| Viscous characteristic length, µm | 5.4 ± 0.3 |

| Tortuosity | 2 ± 1 |

| Thermal conductivity, W/m∗K | 0.047 ± 0.003 |

| Thermal characteristic length, µm | 60.8 ± 4.8 |

| Airflow resistivity at 0.5 mm/s, N∗s/m4 | 896,260 ± 57,266 |

| Samples | %C | %O | %N | %P |

|---|---|---|---|---|

| Phosphorylated fibres (PKF) | 43.5 | 44.3 | 7.8 | 4.4 |

| Textile waste | 65.8 | 33.4 | 0.5 | N.D * |

| Mixture of textile waste microfibres and PKF (45/55%) | 53.9 | 40 | 3.1 | 2.7 |

| Sample | Basis Weight, g/m2 | Thickness, mm | Load at Break, N | Energy at Break, J | Tensile Strain at Break, % | Tensile Stress at Break, MPa | E-Modulus, MPa |

|---|---|---|---|---|---|---|---|

| Phosphorylated fibres (100%) | 500 ± 10 | 1.15 ± 0.02 | 292.3 ± 14.6 | 0.95 ± 0.04 | 4.67 ± 0.2 | 26.38 ± 1.31 | 922.3 ± 46.1 |

| Textile waste (100%) | 500 ± 10 | 2.81 ± 0.11 | 12.4 ± 0.9 | 0.03 ± 0.002 | 3.27 ± 0.21 | 0.44 ± 0.03 | 29.2 ± 2.3 |

| Mix of phosphorylated fibres and textile waste (55/45%) | 500 ± 10 | 2.26 ± 0.06 | 81.1 ± 4.8 | 0.19 ± 0.01 | 3.18 ± 0.18 | 3.59 ± 0.28 | 198.8 ± 15.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lamoudan, H.; Abenghal, L.; Belosinschi, D.; Brouillette, F.; Dolez, P.; Panneton, R.; Fonrouge, C. Sustainable Transformation of Cellulose-Containing Textile Waste into Multifunctional Panels with Tailored FR-Lignocellulosic Fibres. Polymers 2024, 16, 3242. https://doi.org/10.3390/polym16233242

Lamoudan H, Abenghal L, Belosinschi D, Brouillette F, Dolez P, Panneton R, Fonrouge C. Sustainable Transformation of Cellulose-Containing Textile Waste into Multifunctional Panels with Tailored FR-Lignocellulosic Fibres. Polymers. 2024; 16(23):3242. https://doi.org/10.3390/polym16233242

Chicago/Turabian StyleLamoudan, Hamid, Lahbib Abenghal, Dan Belosinschi, François Brouillette, Patricia Dolez, Raymond Panneton, and Cécile Fonrouge. 2024. "Sustainable Transformation of Cellulose-Containing Textile Waste into Multifunctional Panels with Tailored FR-Lignocellulosic Fibres" Polymers 16, no. 23: 3242. https://doi.org/10.3390/polym16233242

APA StyleLamoudan, H., Abenghal, L., Belosinschi, D., Brouillette, F., Dolez, P., Panneton, R., & Fonrouge, C. (2024). Sustainable Transformation of Cellulose-Containing Textile Waste into Multifunctional Panels with Tailored FR-Lignocellulosic Fibres. Polymers, 16(23), 3242. https://doi.org/10.3390/polym16233242