Influence of Recycling and UV Exposure on the Properties of 3D Printing Polymer Materials

Abstract

:1. Introduction

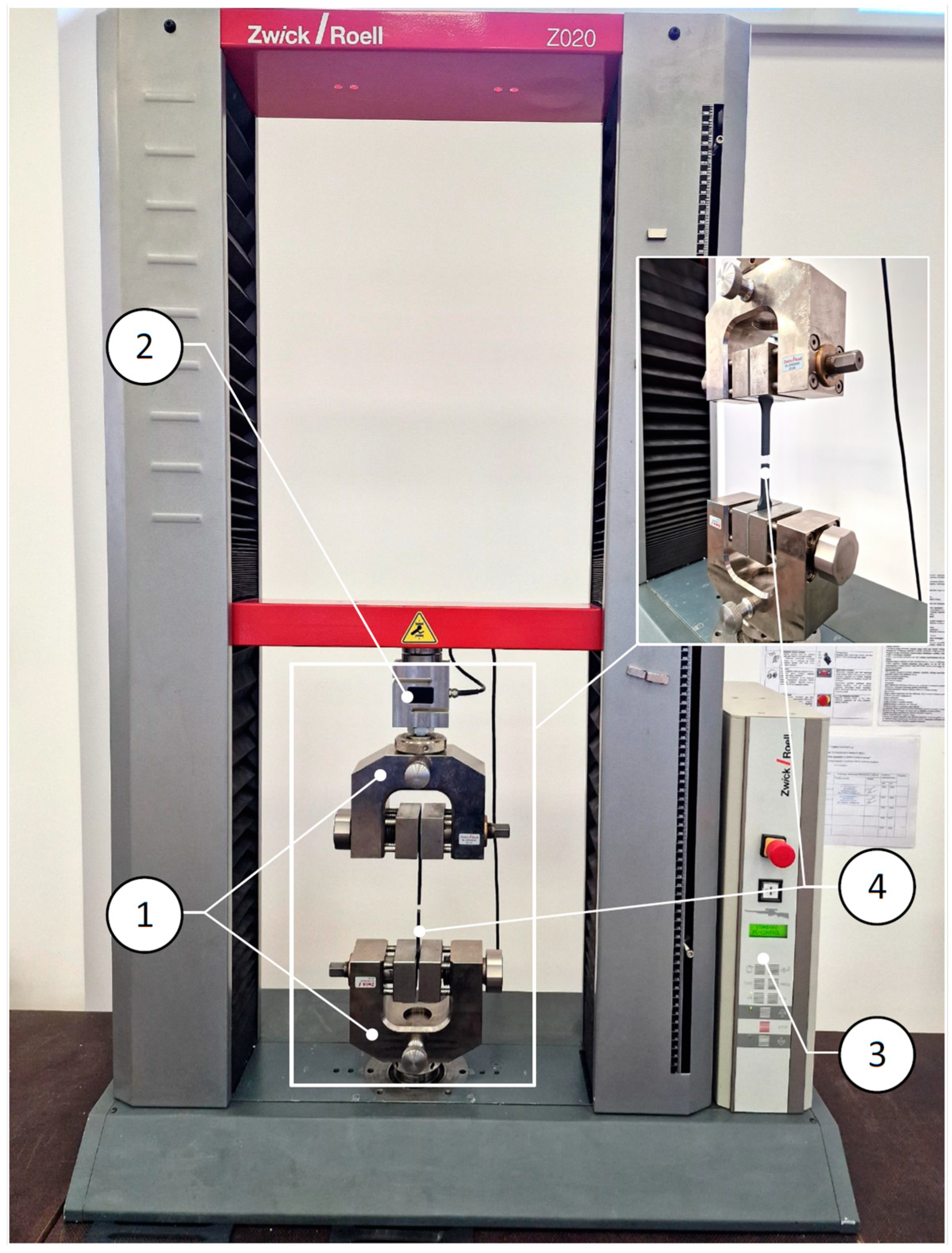

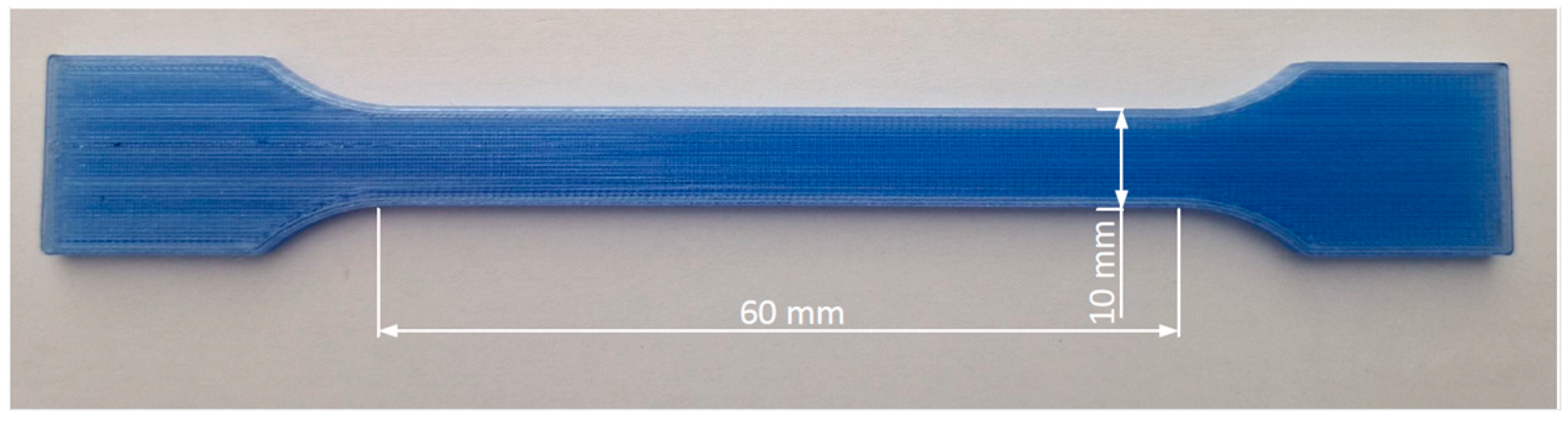

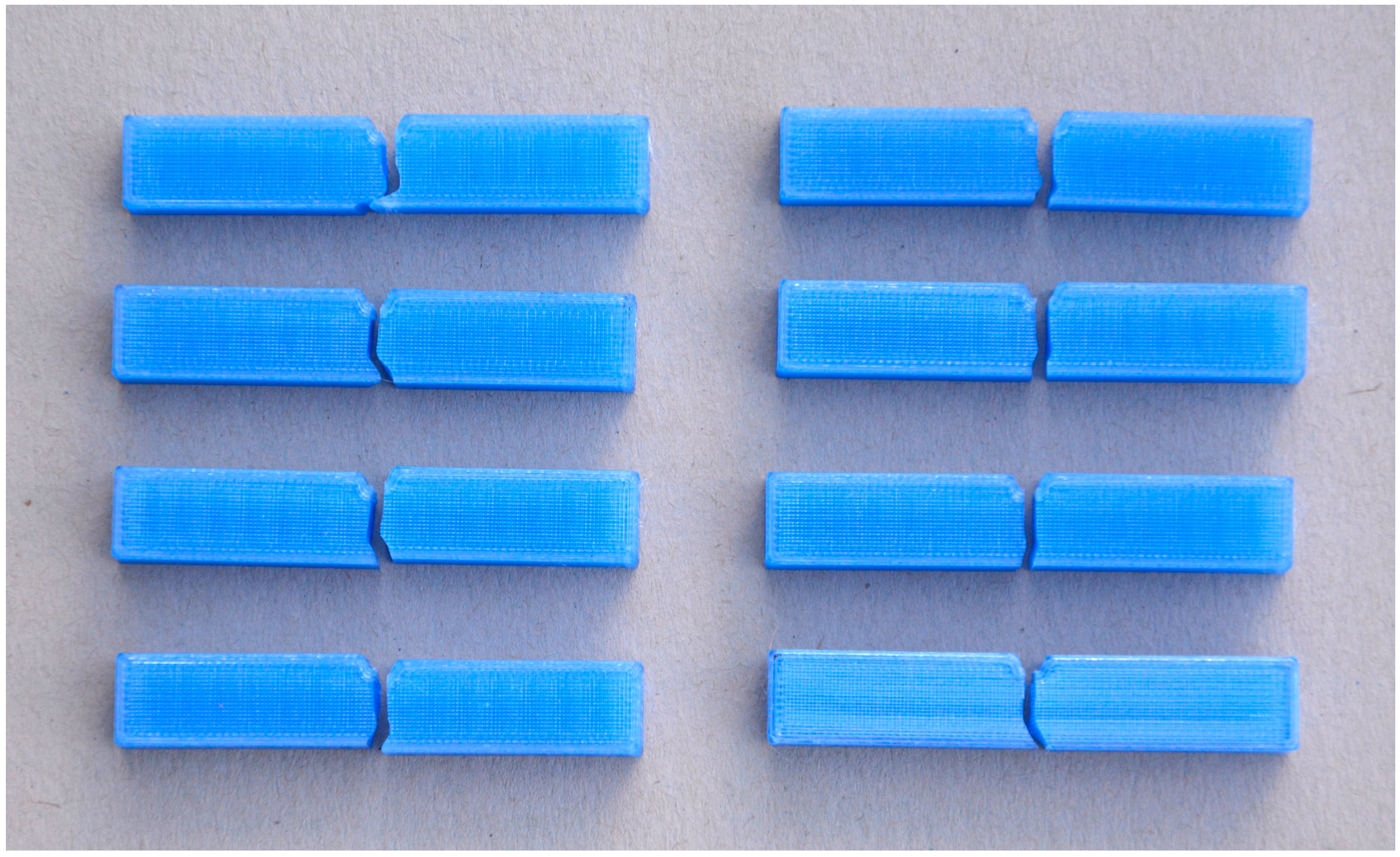

2. Materials and Methods

3. Results and Discussion

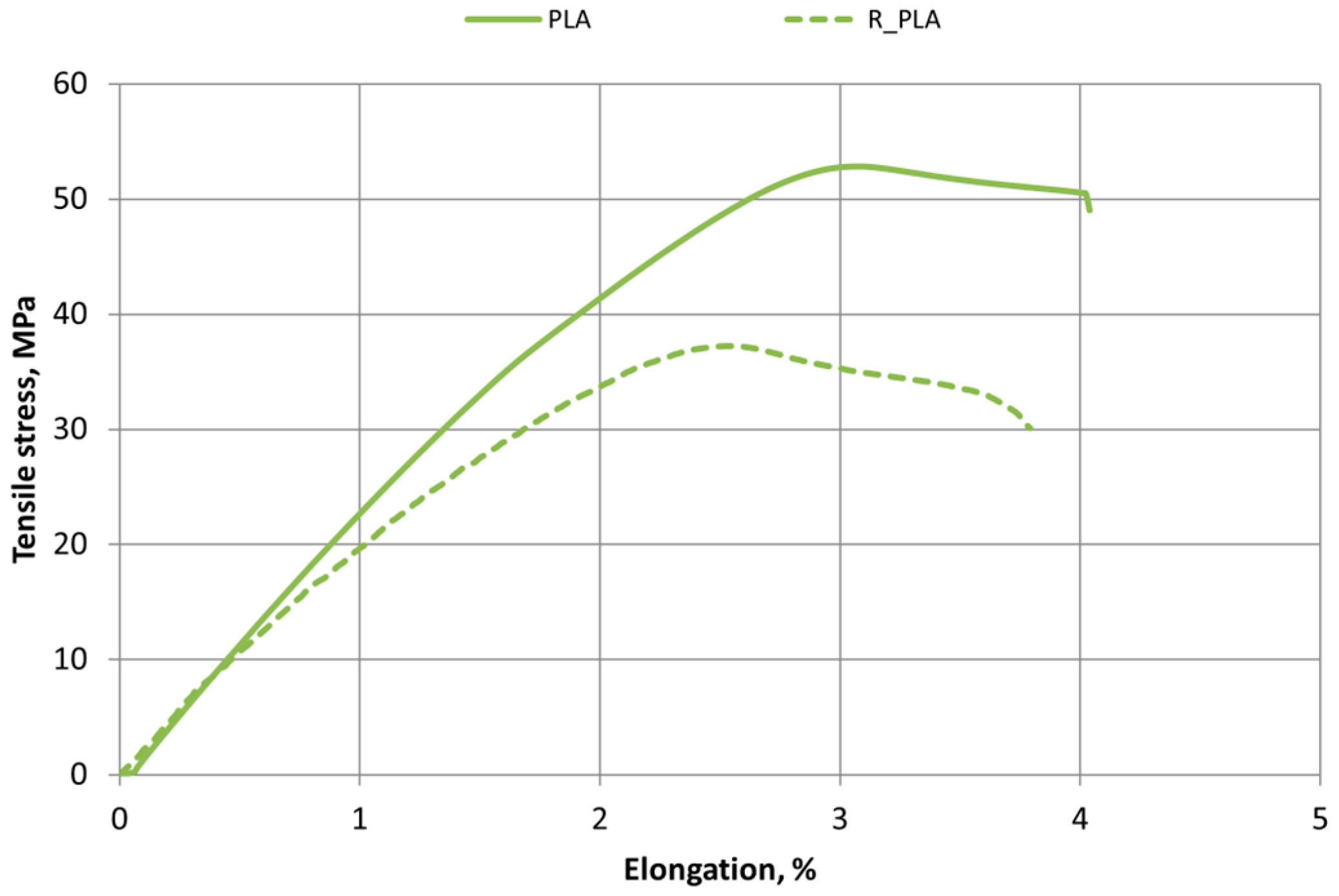

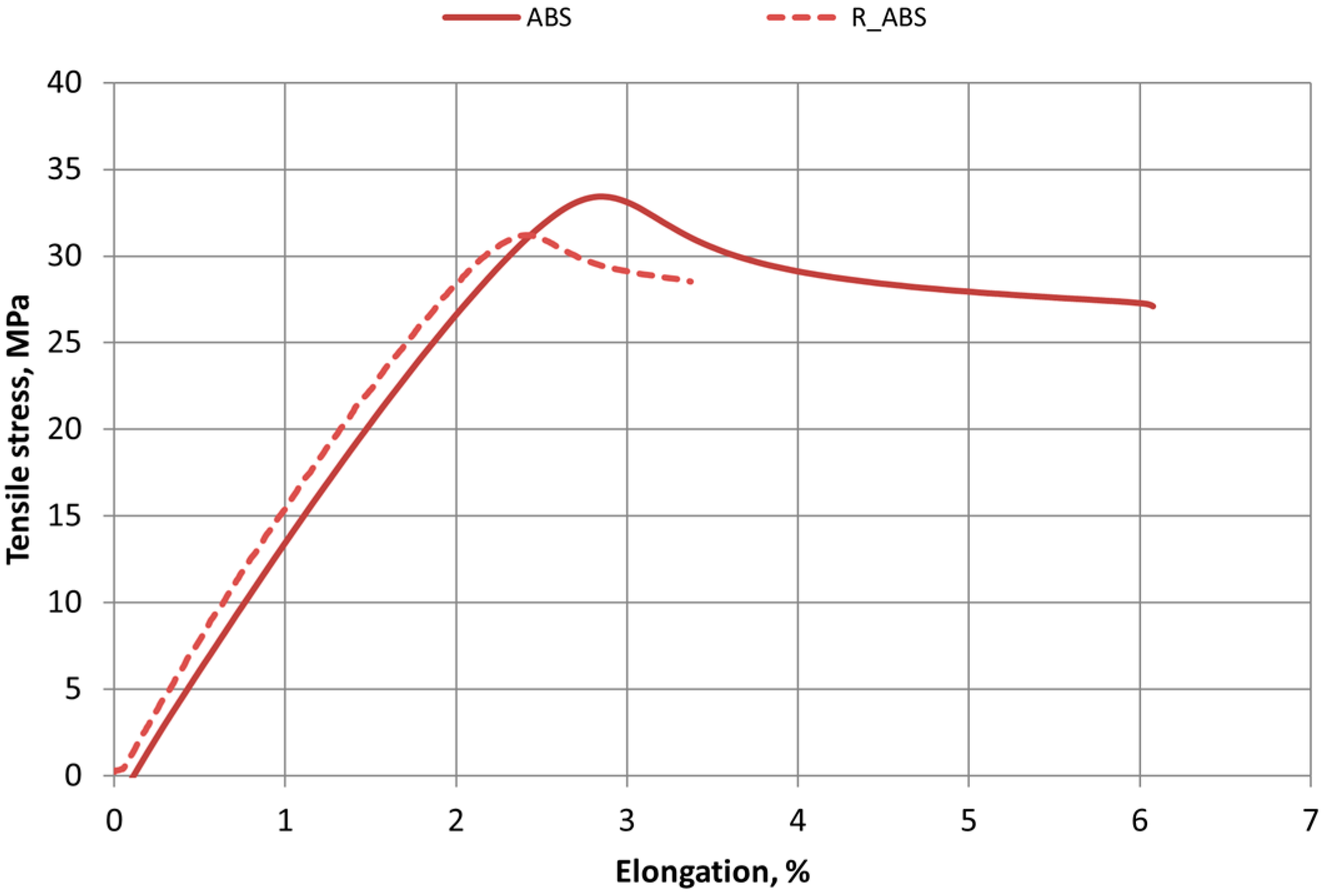

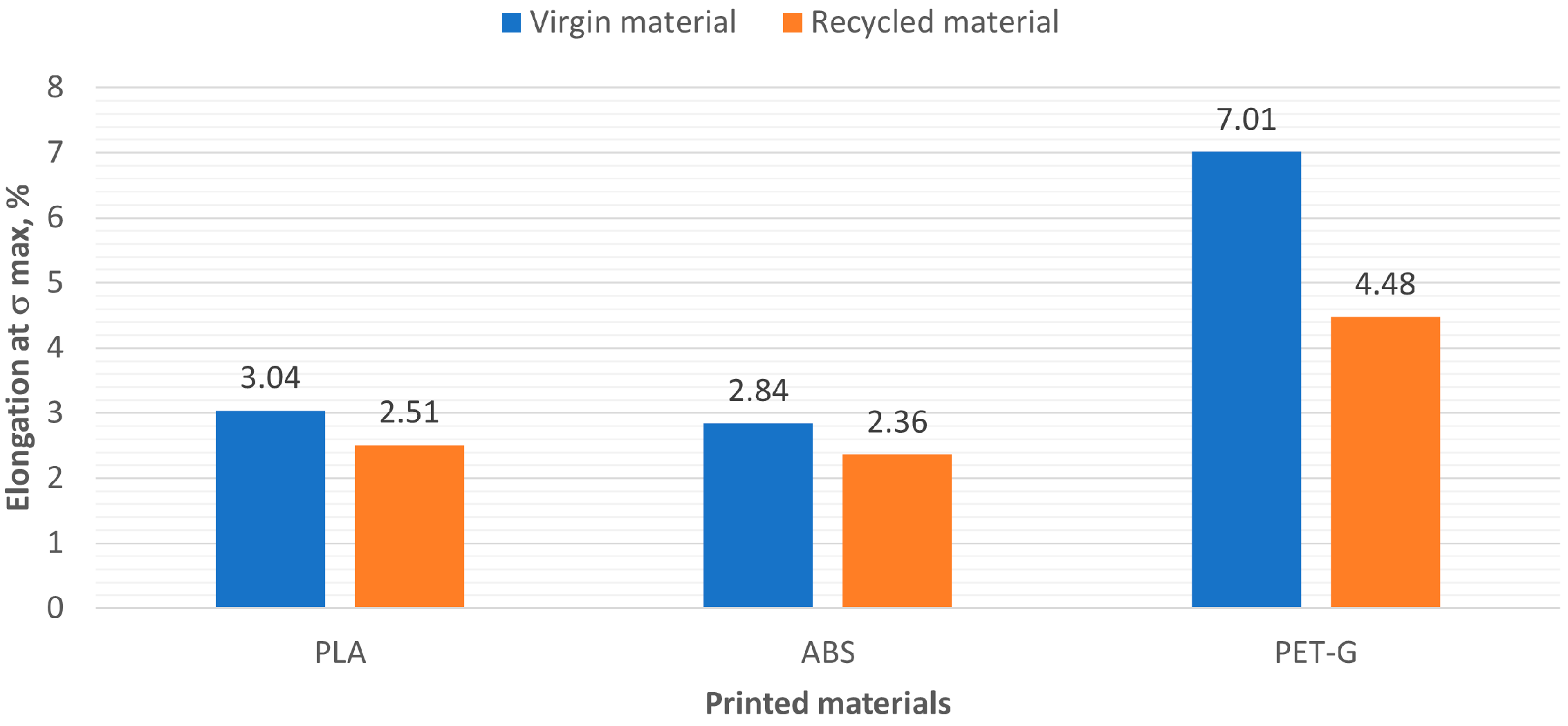

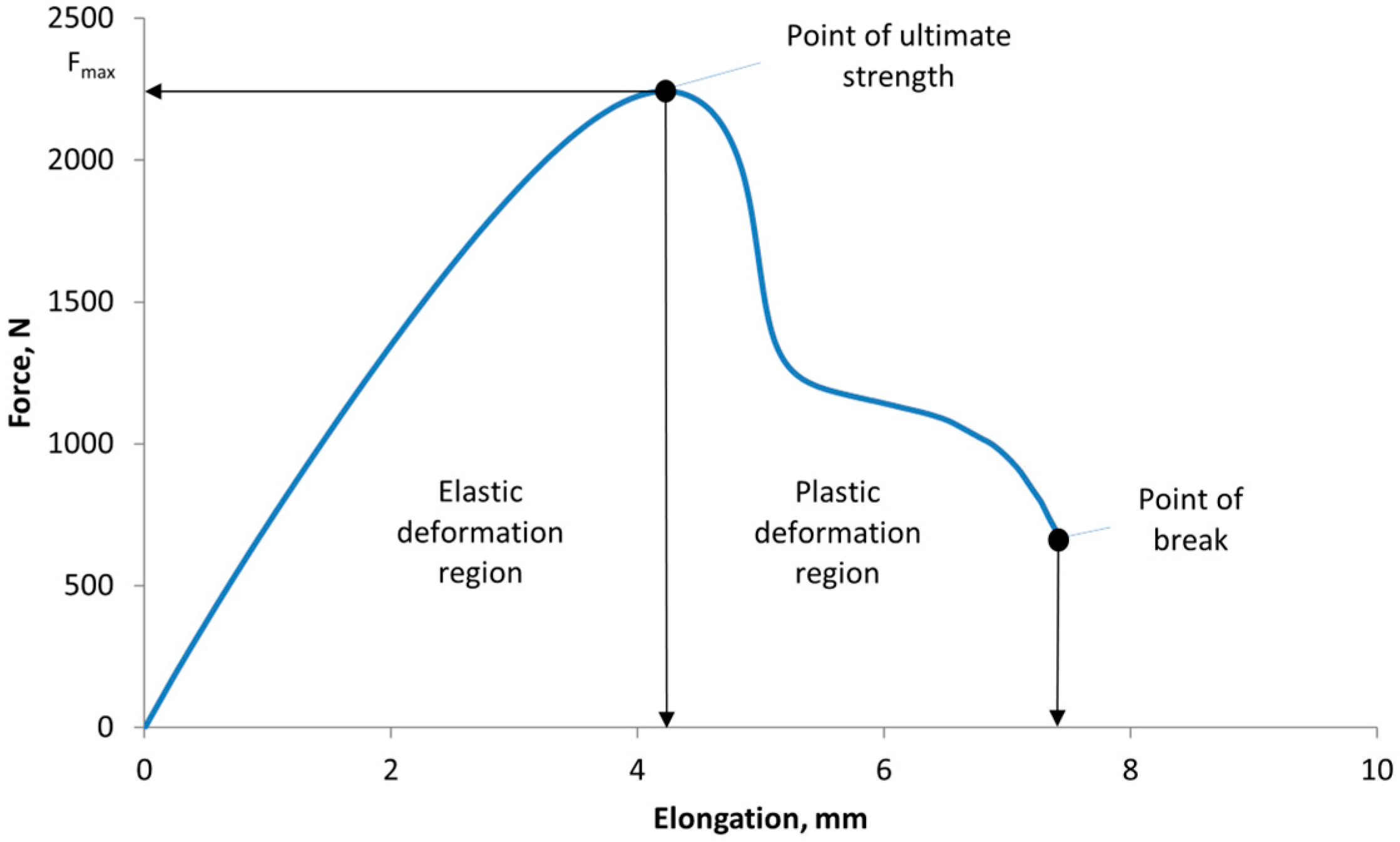

3.1. Mechanical Properties of 3D Printed Recycled Polymer Materials

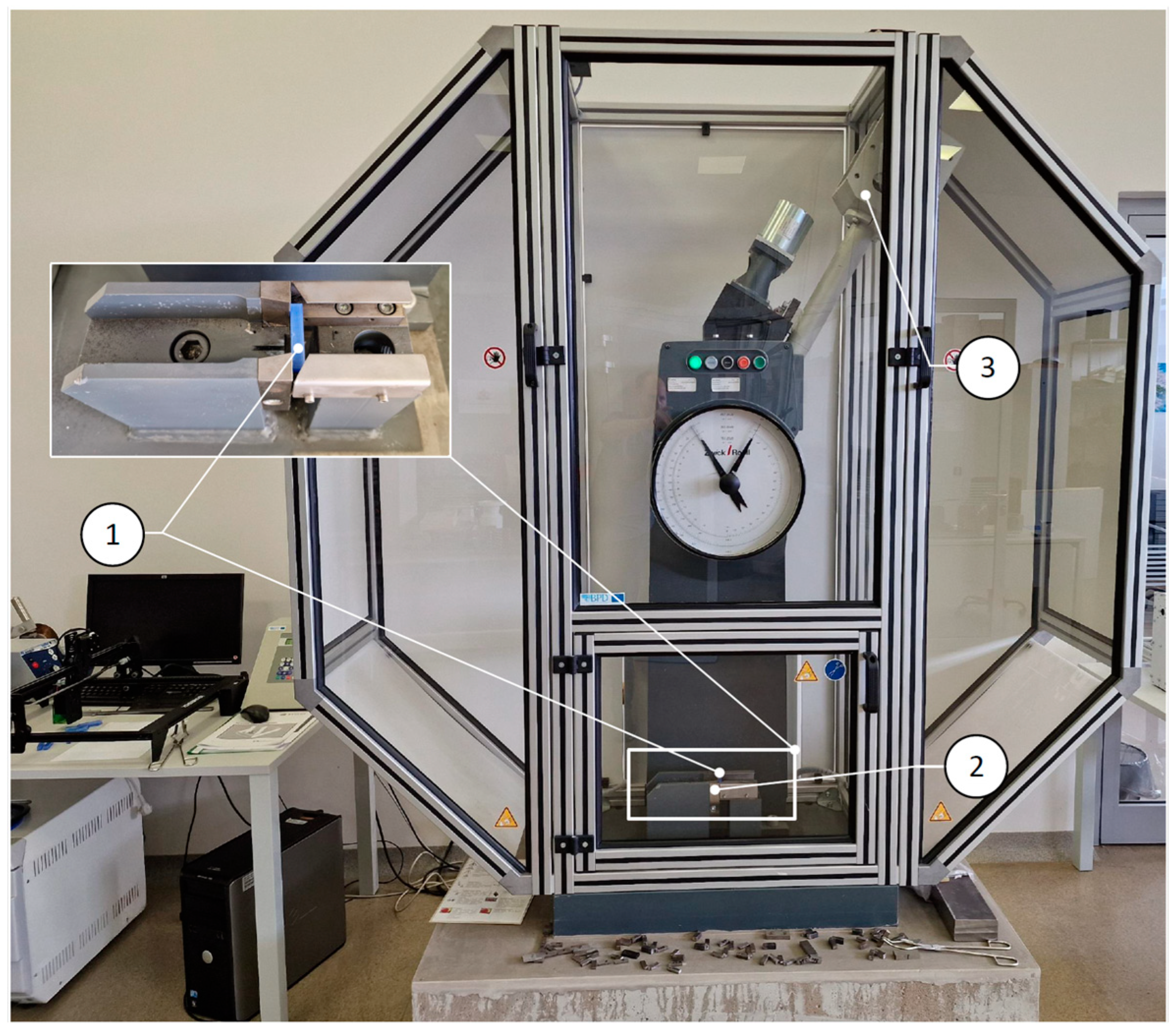

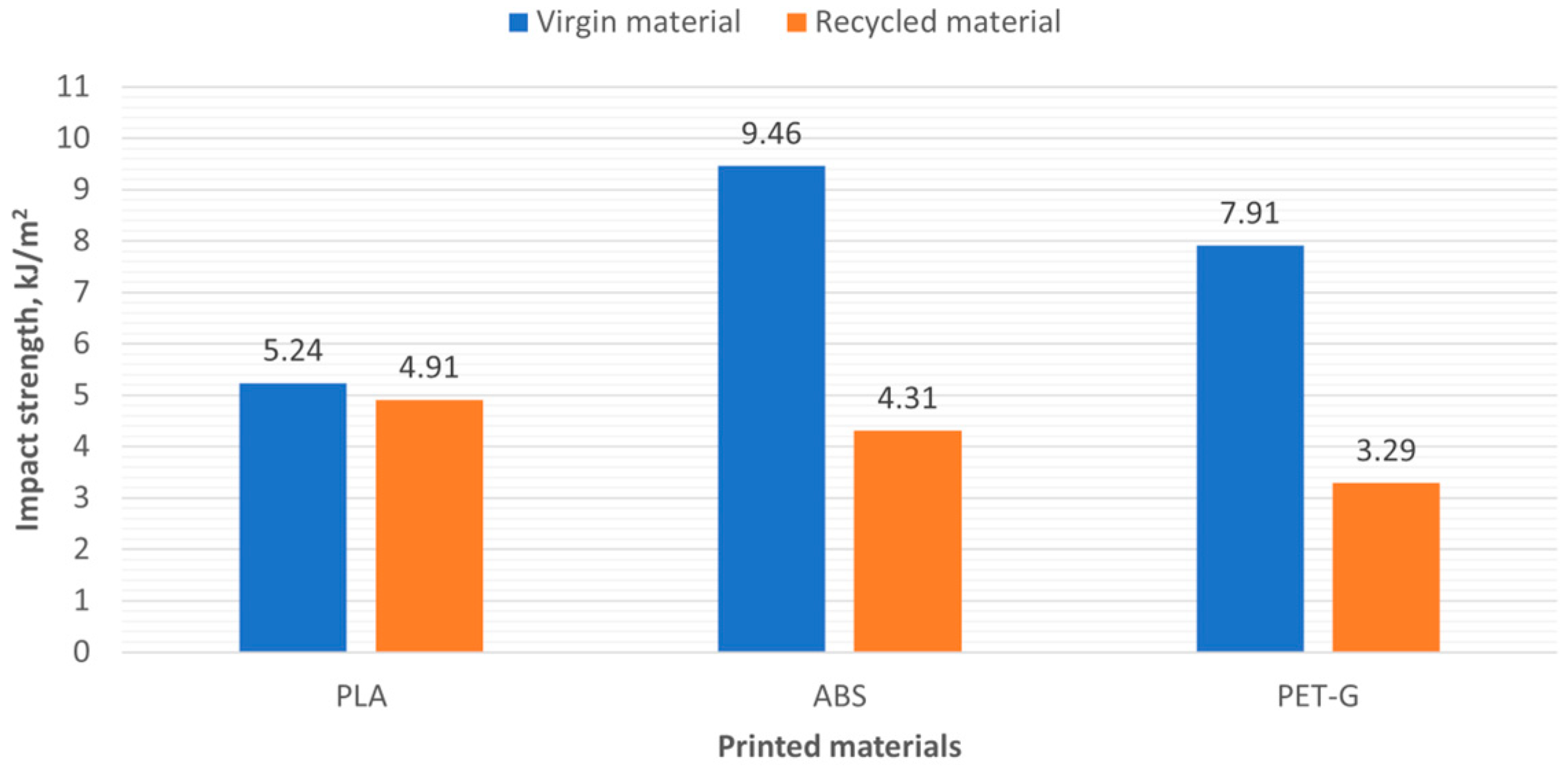

3.2. Impact Test

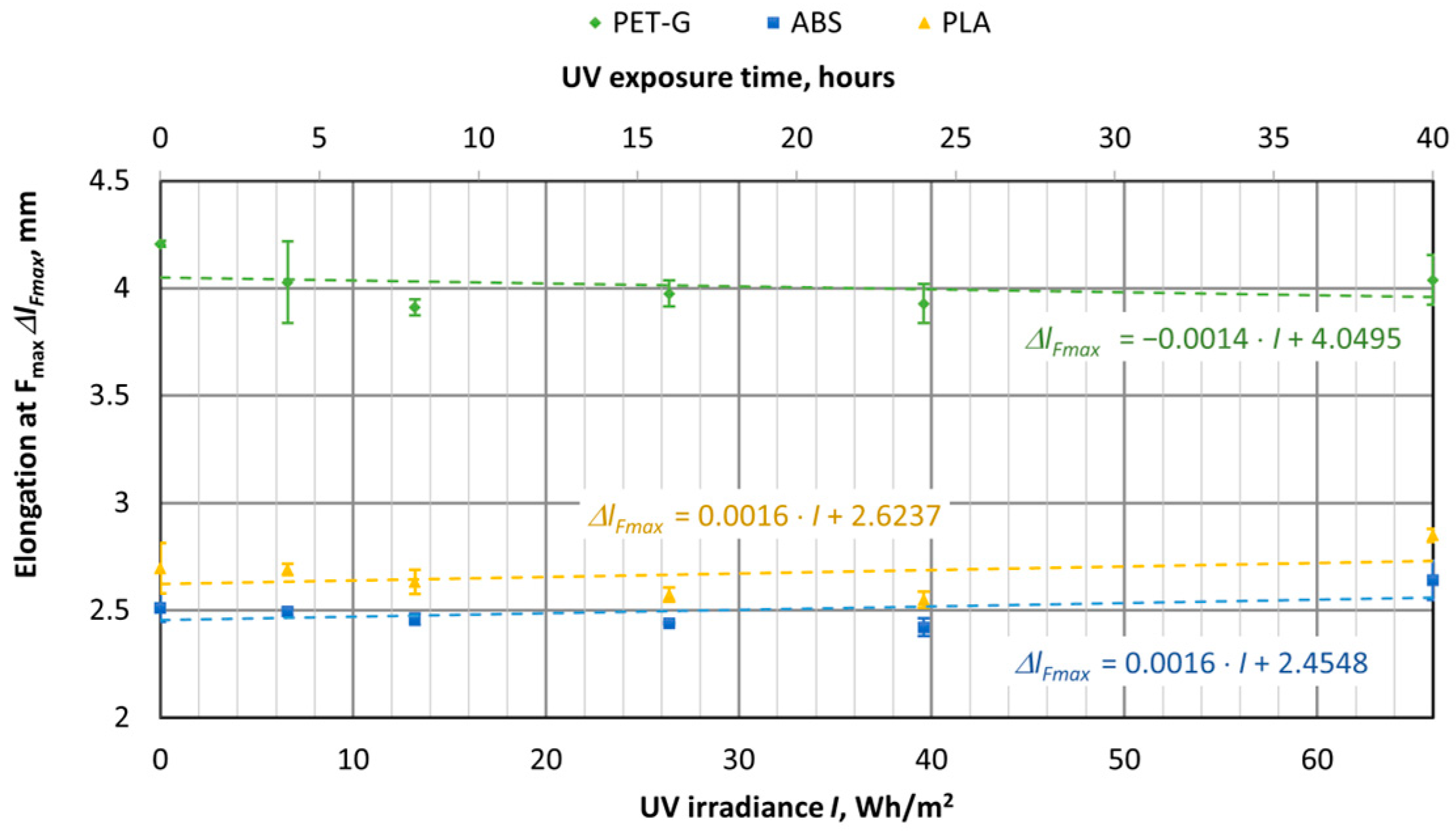

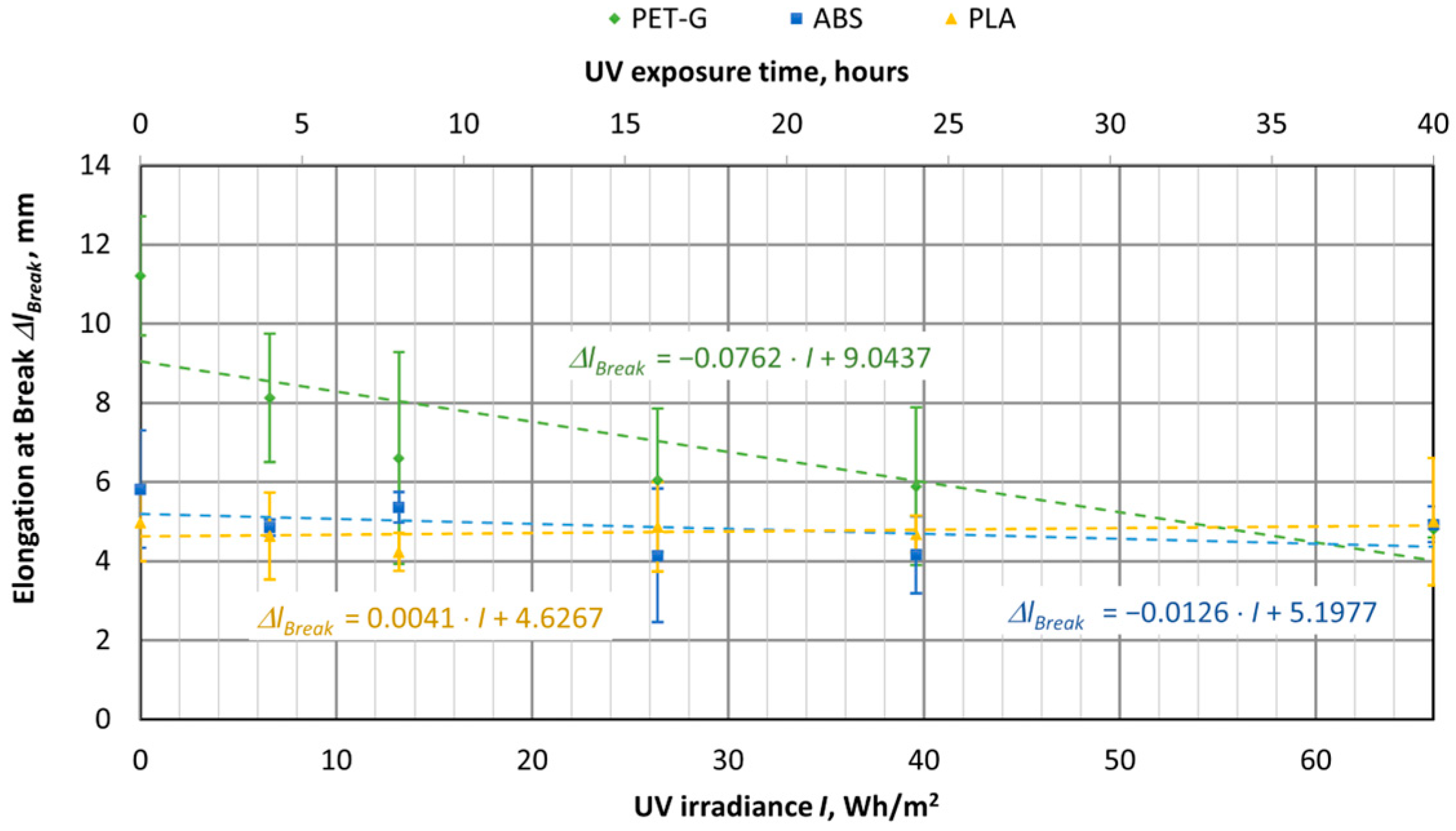

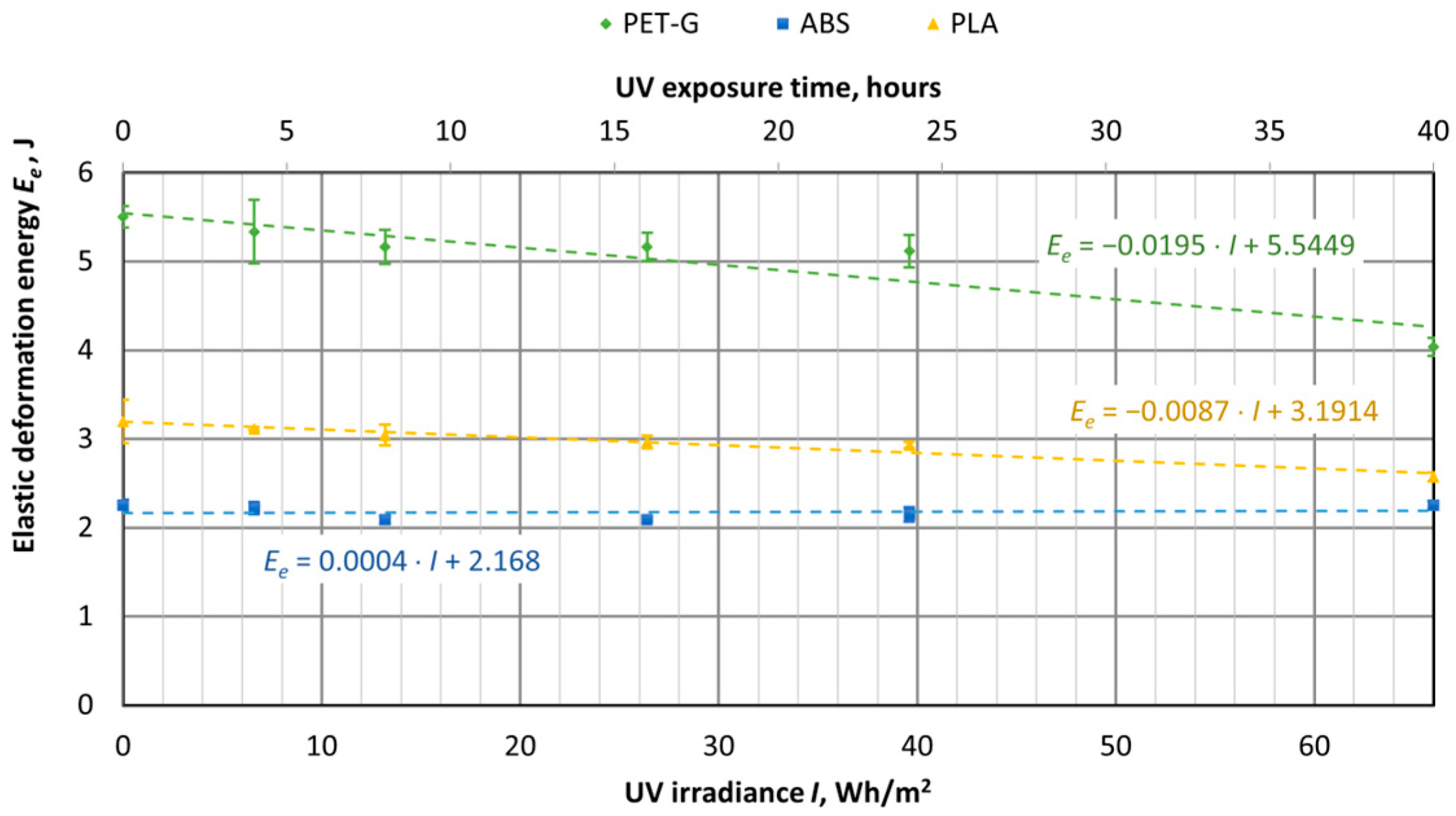

3.3. UV Effects on the Mechanical Properties of 3D Printed Polymer Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development: A/RES/71/1. 2015. Available online: https://undocs.org/A/RES/71/1 (accessed on 6 June 2024).

- Rett, J.P.; Traone, Y.L.; Ho, E.A. Sustainable Materials for Fused Deposition Modeling 3D Printing Applications. Adv. Eng. Mater. 2021, 23, 2001472. [Google Scholar] [CrossRef]

- Subramani, R.; Mustafa, M.A.; Ghadir, G.K.; Al-Tmimi, H.M.; Alani, Z.K.; Rusho, M.A.; Rajeswari, N.; Haridas, D.; Rajan, A.J.; Kumar, A.P. Exploring the use of Biodegradable Polymer Materials in Sustainable 3D Printing. Appl. Chem. Eng. 2024, 7, 3870. [Google Scholar] [CrossRef]

- Sanchez-Rexach, E.; Jonston, T.G.; Jehanno, C.; Sardon, H.; Nelson, A. Sustainable Materials and Chemical Processes for Additive Manufacturing. Chem. Mater. 2020, 32, 7105–7119. [Google Scholar] [CrossRef]

- Lodha, S.; Song, B.; Park, S.I.; Choi, H.J.; Lee, S.W.; Park, H.W.; Choi, S.K. Sustainable 3D printing with recycled materials: A review. J. Mech. Sci. Technol. 2023, 37, 5481–5507. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, Q.; Zhang, Y.; Li, T.; Zhang, H.Z. Sustainability of 3D Printing: A Critical Review and Recommendations. In Proceedings of the International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June 2016; pp. 1–8. [Google Scholar]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2014, 67, 1191–1203. [Google Scholar] [CrossRef]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Haq, M.I.U. 3D printing—A Review of Processes, Materials and Applications in Industry. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview of 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Selvamani, S.K.; Samykano, M.; Subramaniam, S.R. 3D printing: Overview of ABS evolvement 2019. In Proceedings of the AIP Conference Proceedings, Kuantan, Malaysia, 11 January 2019; Volume 2059. [Google Scholar]

- Blanco, I. The Use of Composite Materials in 3D Printing. J. Compos. Sci. 2020, 4, 42. [Google Scholar] [CrossRef]

- Joseph, T.M.; Kallingal, A.; Suresh, A.M.; Mahapatra, D.K.; Hasanin, M.S.; Haponiuk, J.; Thomas, S. 3D printing of polylactic acid: Recent advances and opportunities. Int. J. Adv. Manuf. 2023, 125, 1015–1035. [Google Scholar] [CrossRef]

- García Plaza, E.; López, P.J.N.; Torija, M.Á.C.; Muñoz, J.M.C. Analysis of PLA geometric properties processed by FFF additive manufacturing: Effects of process parameters and plate-extruder precision motion. Polymers 2015, 11, 1581. [Google Scholar] [CrossRef]

- Naveed, N. Investigate the effects of process parameters on material properties and microstructural changes of 3D-printed specimens using fused deposition modelling (FDM). Mater. Technol. 2021, 36, 317–330. [Google Scholar] [CrossRef]

- Stoia, D.I.; Marsavina, L.; Linul, E. Correlations between process parameters and outcome properties of Laser-Sintered Polyamide. Polymers 2019, 11, 1850. [Google Scholar] [CrossRef] [PubMed]

- Brighenti, R.; Cosma, M.P.; Marsavina, L.; Spagnoli, A.; Terzano, M. Laser-based additively manufactured polymers: A review on processes and mechanical models. J. Mater. Sci. 2021, 56, 961–998. [Google Scholar] [CrossRef]

- Pandzic, A.; Hodzic, D.; Milovanovic, A. Influence of material colour on mechanical properties of PLA material in FDM technology. In Proceedings of the 30th DAAAM International Symposium, Zadar, Croatia, 23–26 October 2019; Volume 30, pp. 555–561. [Google Scholar]

- Gunaydin, K. The Effect of Layer Thickness to the Tensile Stress: Experimental Studies. In Proceedings of the 3rd International Congress on 3D Printing (Additive Manufacturing) Technologies and Digital Industry, Antalya, Turkey, 19–21 April 2018; pp. 667–670, ISBN 978-605-68886-6-3. [Google Scholar]

- Rifuggiato, S.; Minetola, P.; Stiuso, V.; Khandpur, M.S.; Fontana, L.; Iuliano, L. An investigation of the influence of 3d printing defects on the tensile performance of ABS material. Mater. Today Proc. 2022, 57, 851–858. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2018, 25, 122–130. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Redjala, S.; Aït Hocine, N.; Ferhoum, R.; Gratton, M.; Poirot, N.; Azem, S. UV Aging Effects on Polycarbonate Properties. J. Fail. Anal. Prev. 2020, 20, 1907–1916. [Google Scholar] [CrossRef]

- Vasylius, M.; Tadžijevas, A.; Šapalas, D.; Kartašovas, V.; Janutėnienė, J.; Mažeika, P. Degradation of Mechanical Properties of A-PET Films after UV Aging. Polymers 2023, 15, 4166. [Google Scholar] [CrossRef]

- Rockett, C. UV Degradation Effects in Materials—An Elementary Overview. UV Solut. 2019, 4, 18–22. [Google Scholar]

- Majid, F.; Zekeriti, N.; Rhanim, R.; Lahlou, M.; Rhanim, H.; Mrani, B. Mechanical behavior and crack propagation of ABS 3D printed specimens. Procedia Struct. Integr. 2020, 28, 1718–1726. [Google Scholar] [CrossRef]

- Foltut, D.; Valean, E.; Dzitac, V.; Marsavina, L. The influence of temperature on the mechanical properties of 3D printed and injection molded ABS. Mater. Today Proc. 2022, 78, 210–213. [Google Scholar] [CrossRef]

- Bakar, A.A.B.A.; Zainuddin, M.Z.B.; Adam, A.N.B.; Noor, I.S.B.M.; Tamchek, N.B.; Alauddin, M.S.B.; Ghazali, M.I.B.M. The study of mechanical properties of poly(lactic) acid PLA-based 3D printed filament under temperature and environmental conditions. Mater. Today Proc. 2022, 67, 652–658. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. Tensile, three-point bending and impact strength of 3D printed parts using PLA and recycled PLA filaments: A statistical investigation. J. Mater. Res. Technol. 2022, 18, 1542–1554. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Gupta, A.; Fidan, I. Mechanical benchmarking of additively manufactured continuous and short carbon fiber reinforced nylon. J. Compos. Mater. 2021, 55, 3629–3638. [Google Scholar] [CrossRef]

- Vălean, C.; Marșavina, L.; Mărghitaș, M.; Linul, E.; Razavi, J.; Berto, F. Effect of manufacturing parameters on tensile properties of FDM printed specimens. Procedia Struct. Integr. 2020, 26, 313–320. [Google Scholar] [CrossRef]

- Lanzotti, A.; Martonelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A comparison between mechanical properties of specimens 3D printed with virgin and recycled PLA. Proc. CIRP 2019, 79, 143–146. [Google Scholar] [CrossRef]

- Rigon, D.; Ricotta, M.; Meneghetti, G. A literature survey on structural integrity of 3D printed virgin and recycled ABS and PP compounds. Procedia Struct. Integr. 2020, 28, 1655–1663. [Google Scholar] [CrossRef]

- Drungilas, D.; Kurmis, M.; Tadžijevas, A.; Lukošius, Ž.; Martinkėnas, A.; Didžiokas, R.; Gruodė, J.; Šapalas, D.; Jankūnas, V. Evaluating the Impact of 222 nm Far-UVC Radiation on the Aesthetic and Mechanical Properties of Materials Used in Public Bus Interiors. Appl. Sci. 2023, 13, 4141. [Google Scholar] [CrossRef]

- Gomes, T.E.P.; Cadete, M.S.; Dias-de-Oliveira, J.; Neto, V. Controlling the properties of parts 3D printed from recycled thermoplastics: A review of current practices. Polym. Degrad. Stab. 2022, 196, 109850. [Google Scholar] [CrossRef]

- Budin, S.; Maideem, N.C.; Koay, M.H.; Ibrahim, D.; Yusoff, H. A comparison study on mechanical properties of virgin and recycled polylactic acid (PLA). J. Phys. Conf. Ser. 2019, 1349, 012002. [Google Scholar] [CrossRef]

- Kit, F.M.; Haq, R.H.A.; Manshoor, B.; Ghafir, M.F.A.; Rahman, M.N.R.; Hoffmann, J.; Marwah, O.M.F.; Khirotdin, R.K. Mechanical Properties of Recycled Polyethylene Terephthalate/Polycarbonate/ Methylene Diphenyl Diisocyanate (r-PET/PC/MDI) Composite. J. Adv. Res. Appl. Mech. 2024, 120, 1–13. [Google Scholar]

- Thomas, J.; Patil, R.S.; Patil, M.; John, J. Navigating the Labyrinth of Polymer Sustainability in the Context of Carbon Footprint. Coatings 2024, 14, 774. [Google Scholar] [CrossRef]

- ISO 527-2; Standard Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2012.

- Marșavina, L.; Vălean, C.; Mărghitaș, M.; Linul, E.; Razavi, S.M.J.; Berto, F.; Brighenti, F. Effect of the manufacturing parameters on the tensile and fracture properties of FDM 3D-printed PLA specimens. Mater. Today Proc. 2022, 274, 108766. [Google Scholar] [CrossRef]

| Description | PLA | R_PLA | ABS | R_ABS | PET-G | R_PET-G |

|---|---|---|---|---|---|---|

| Initial layer nozzle temperature, ° | 215 | 215 | 255 | 255 | 235 | 235 |

| Nozzle temperature, ° | 210 | 210 | 250 | 250 | 230 | 230 |

| Printing bed temperature, initial layer, ° | 60 | 60 | 100 | 100 | 60 | 60 |

| Printing bed temperature, ° | 60 | 60 | 110 | 110 | 60 | 60 |

| PLA | R_PLA | ABS | R_ABS | PET-G | R_PET-G | |

|---|---|---|---|---|---|---|

| Tensile strength (max), MPa | 50.29 | 36.26 | 32.77 | 31.20 | 52.10 | 43.42 |

| Standard deviation, MPa | 1.75 | 0.91 | 0.51 | 2.04 | 0.05 | 0.98 |

| Coefficient of variation (CV), % | 3.48 | 2.55 | 1.49 | 6.54 | 0.09 | 2.26 |

| PLA | R_PLA | ABS | R_ABS | PET-G | R_PET-G | |

|---|---|---|---|---|---|---|

| Elongation at , % | 3.04 | 2.51 | 2.84 | 2.36 | 7.01 | 4.48 |

| Standard deviation, % | 0.07 | 0.06 | 0.04 | 0.82 | 0.02 | 0.21 |

| Coefficient of variation (CV), % | 2.22 | 2.58 | 1.31 | 34.75 | 0.29 | 4.69 |

| Material | Total Energy, J | Energy of Elastic Region, J | Energy of Plastic Region, J |

|---|---|---|---|

| PLA | 4.62 | 2.89 | 1.73 |

| R_PLA | 3.59 | 2.07 | 1.51 |

| ABS | 5.55 | 2.06 | 3.50 |

| R_ABS | 5.27 | 2.55 | 2.73 |

| PET-G | 13.52 | 5.50 | 8.02 |

| R_PET-G | 4.80 | 4.61 | 0.19 |

| PLA | R_PLA | ABS | R_ABS | PET-G | R_PET-G | |

|---|---|---|---|---|---|---|

| Charpy impact strength, kJ/m2 | 5.24 | 4.91 | 9.46 | 4.31 | 7.91 | 3.29 |

| Standard deviation, kJ/m2 | 0.78 | 0.51 | 0.51 | 0.02 | 0.62 | 0.04 |

| Coefficient of variation (CV), % | 14.89 | 10.38 | 5.39 | 6.73 | 7.83 | 1.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janutėnienė, J.; Vasylius, M.; Tadžijevas, A.; Kartašovas, V.; Šapalas, D.; Grigaliūnienė, S. Influence of Recycling and UV Exposure on the Properties of 3D Printing Polymer Materials. Polymers 2024, 16, 3292. https://doi.org/10.3390/polym16233292

Janutėnienė J, Vasylius M, Tadžijevas A, Kartašovas V, Šapalas D, Grigaliūnienė S. Influence of Recycling and UV Exposure on the Properties of 3D Printing Polymer Materials. Polymers. 2024; 16(23):3292. https://doi.org/10.3390/polym16233292

Chicago/Turabian StyleJanutėnienė, Jolanta, Marius Vasylius, Artūras Tadžijevas, Valentinas Kartašovas, Deivydas Šapalas, and Simona Grigaliūnienė. 2024. "Influence of Recycling and UV Exposure on the Properties of 3D Printing Polymer Materials" Polymers 16, no. 23: 3292. https://doi.org/10.3390/polym16233292

APA StyleJanutėnienė, J., Vasylius, M., Tadžijevas, A., Kartašovas, V., Šapalas, D., & Grigaliūnienė, S. (2024). Influence of Recycling and UV Exposure on the Properties of 3D Printing Polymer Materials. Polymers, 16(23), 3292. https://doi.org/10.3390/polym16233292