Dynamic Thermo-Mechanical Properties of Carbon Nanotube Resin Composite Films

Abstract

:1. Introduction

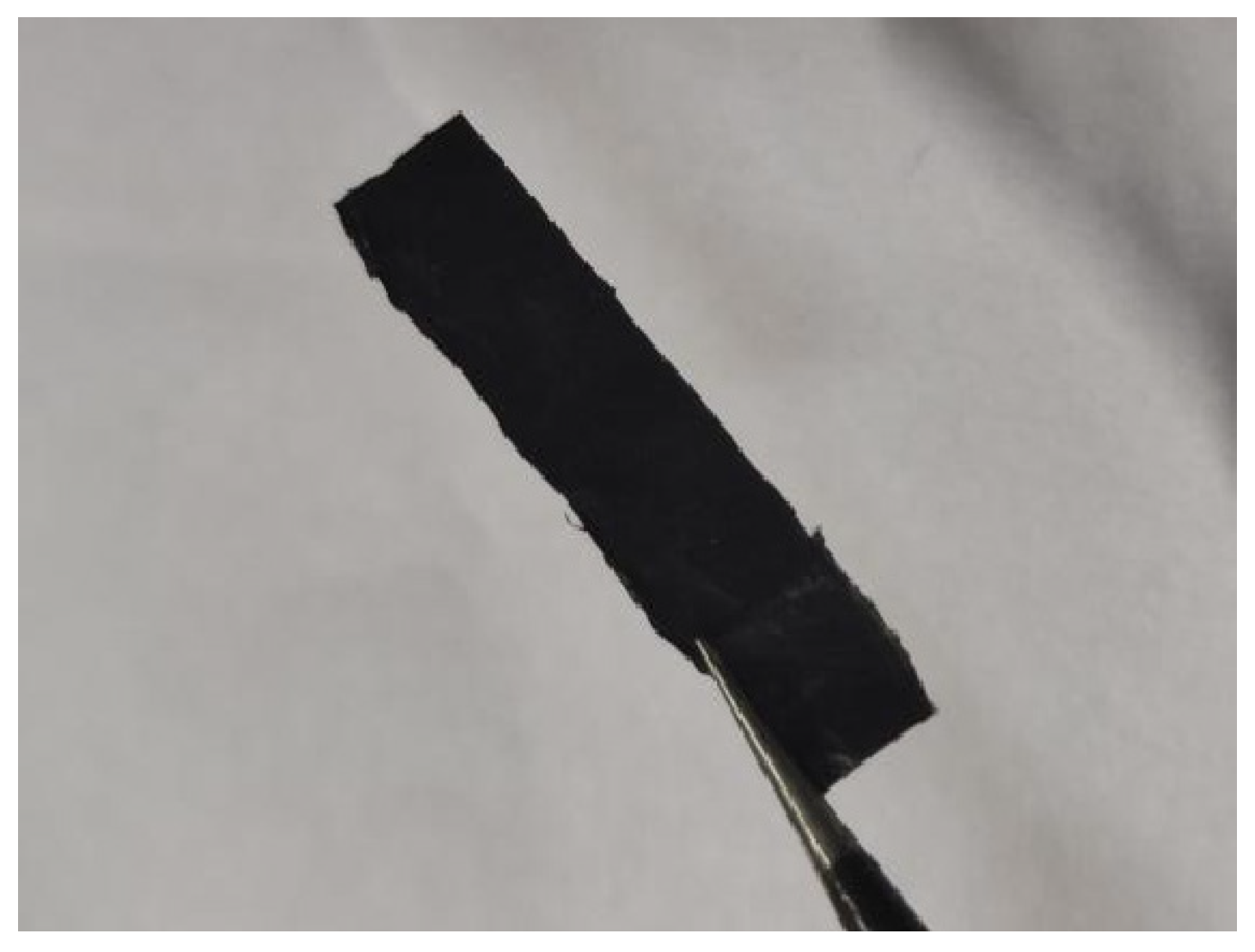

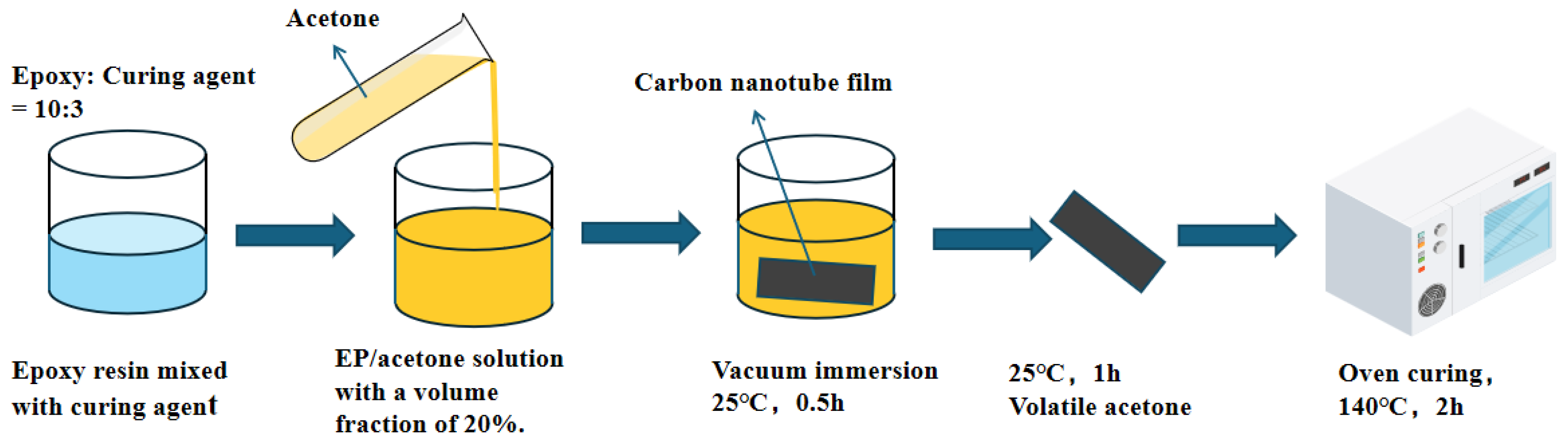

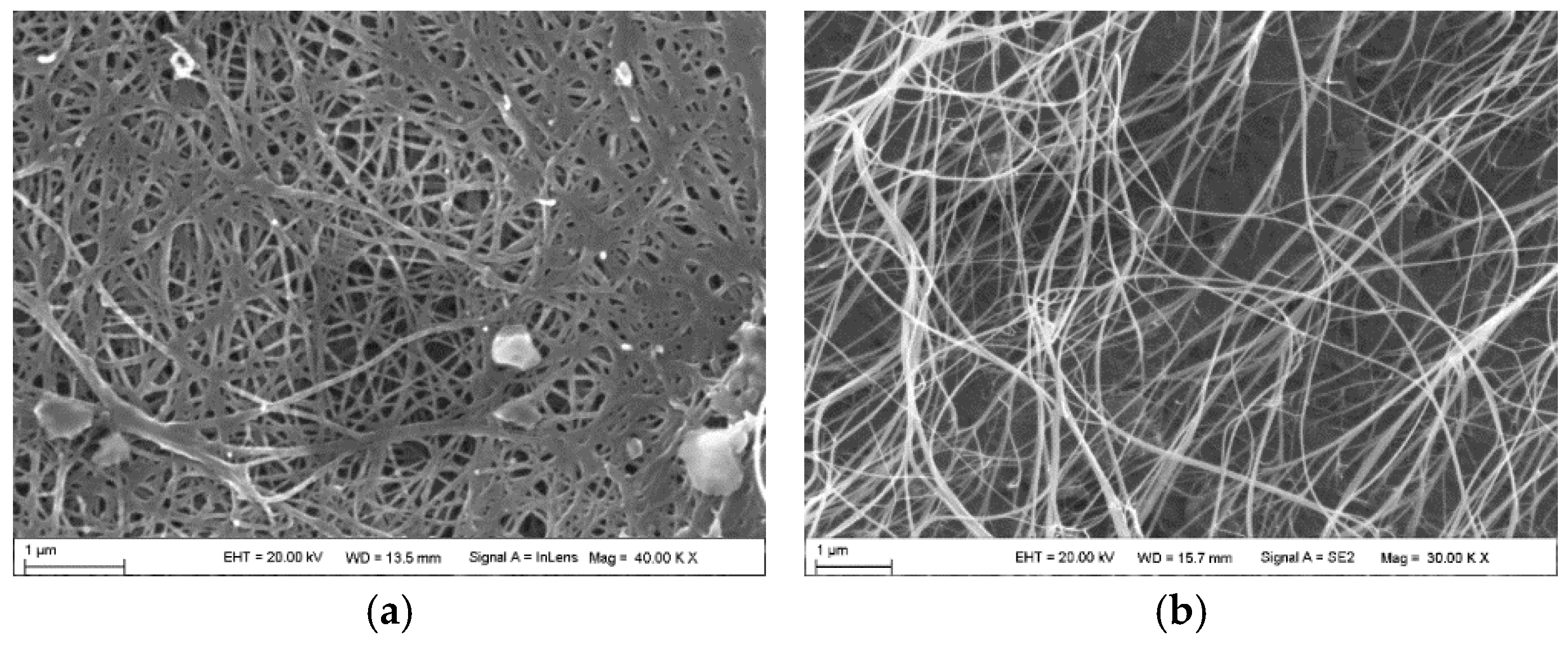

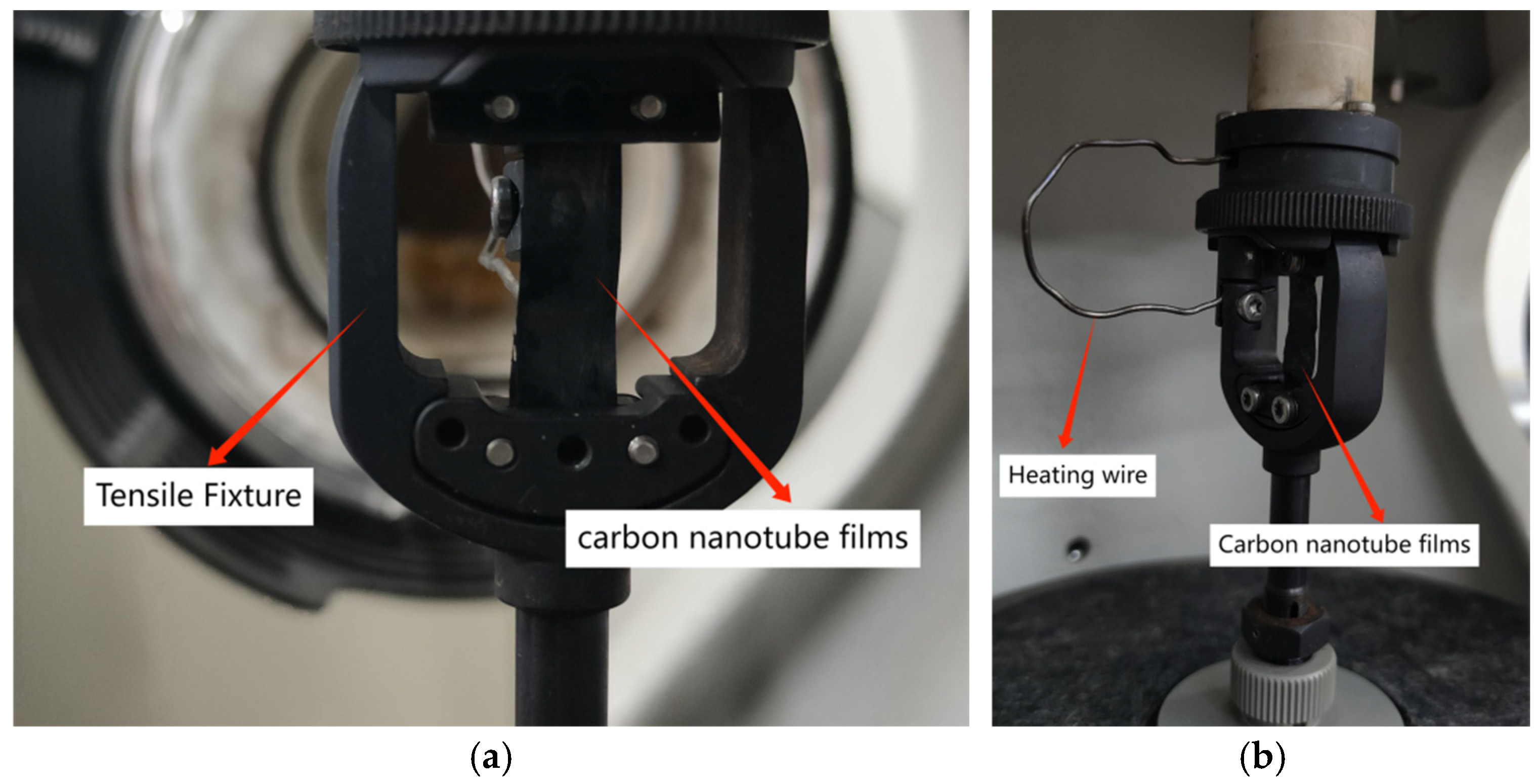

2. Material Preparation and Test Methods

2.1. Experimental Materials

2.2. Experimental Methods

3. Results and Discussion

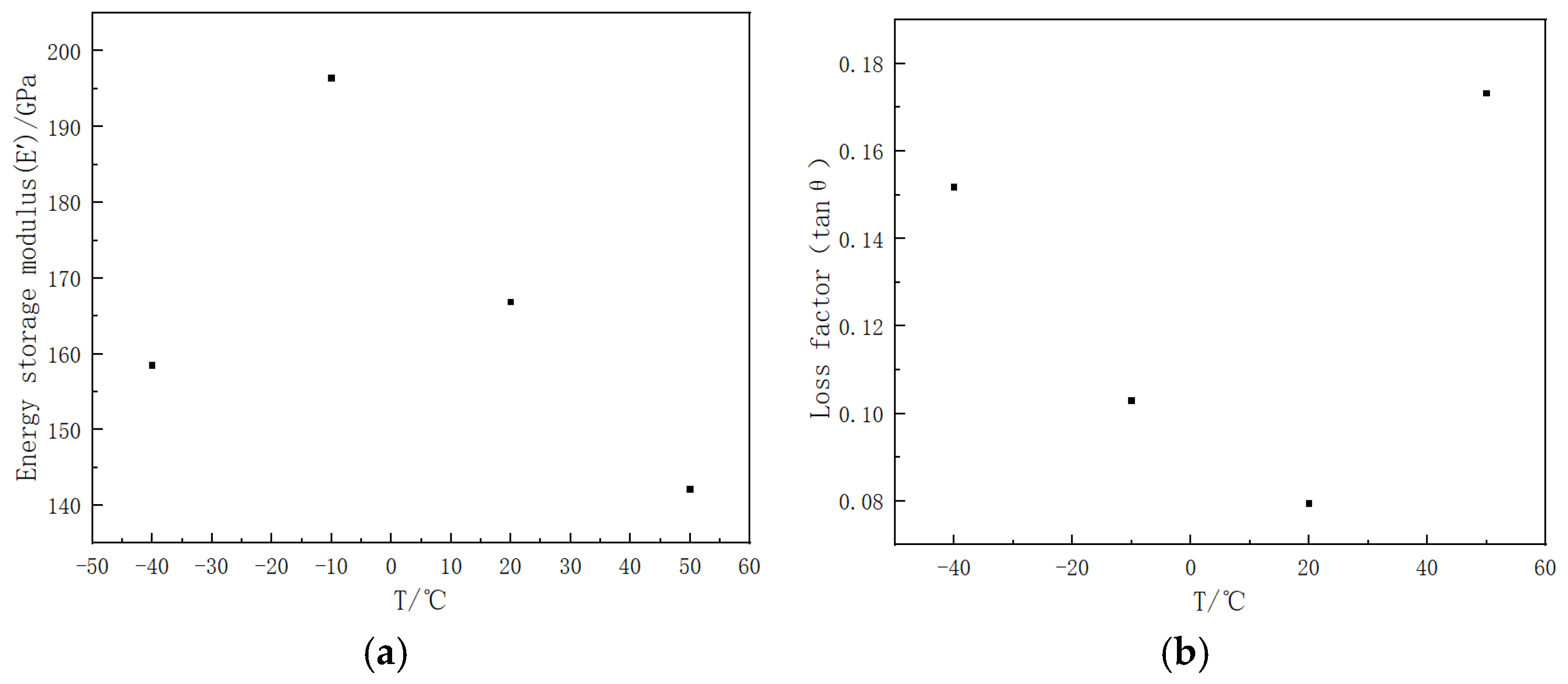

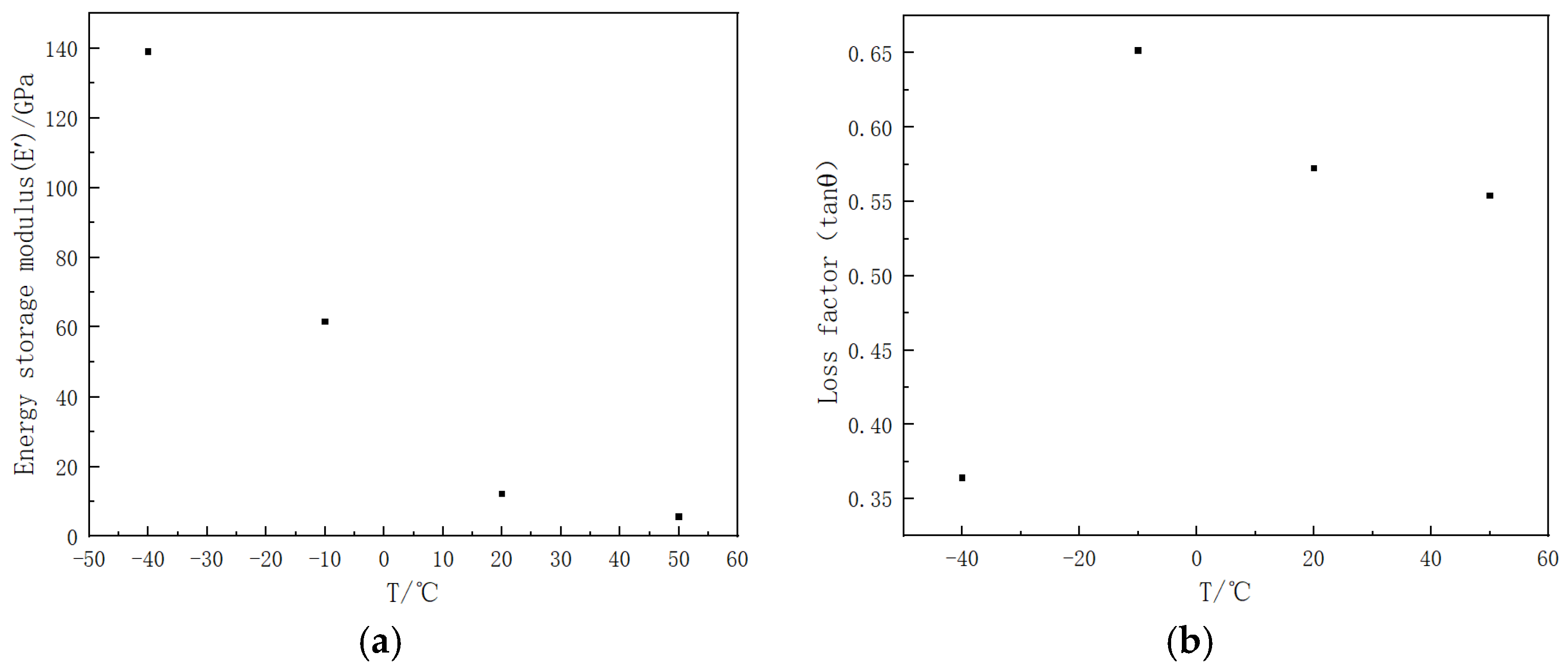

3.1. Effect of Temperature on Material Properties

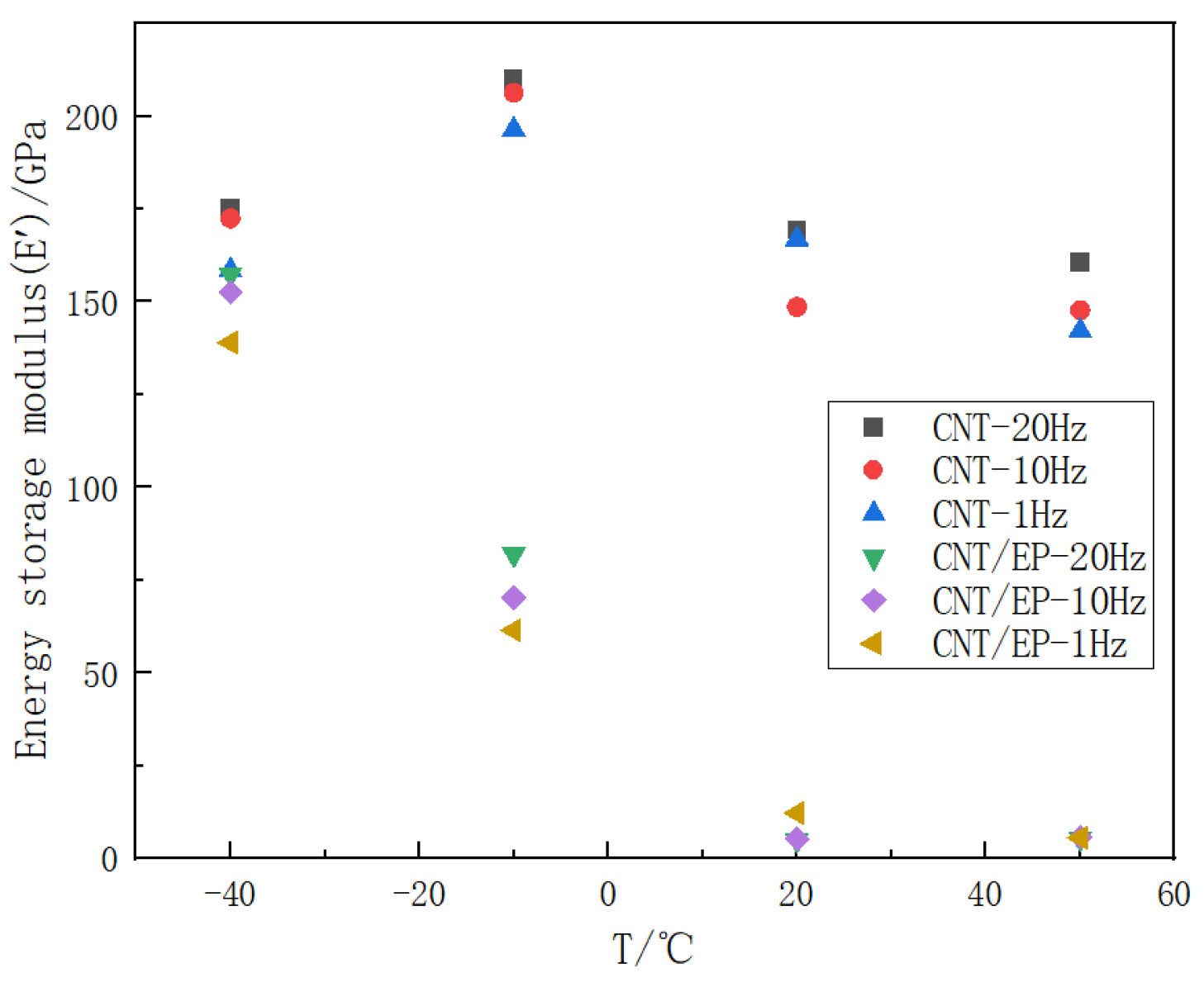

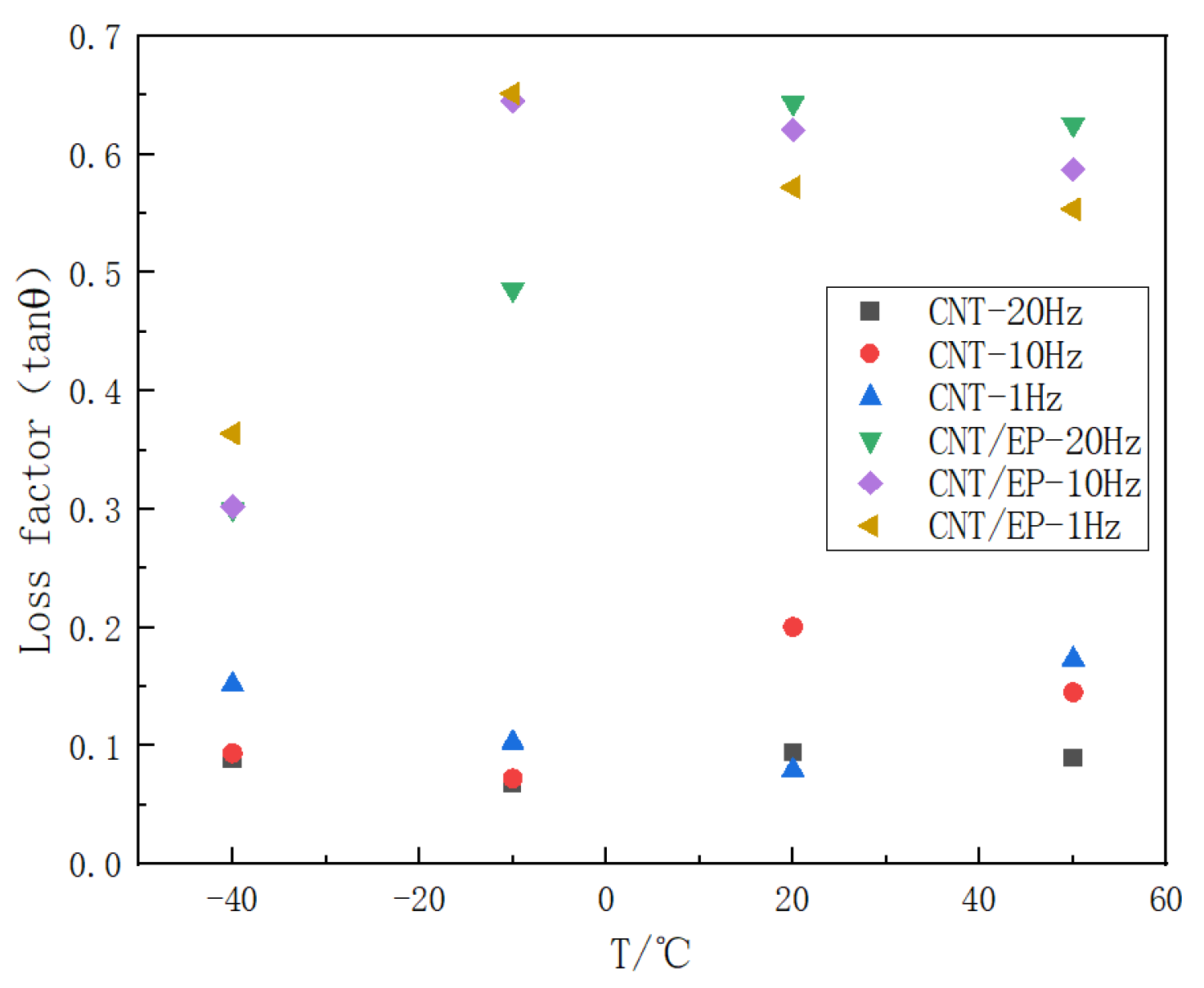

3.2. Effect of Frequency on Material Properties

3.3. Effect of the Presence of Epoxy Resin on the Material Properties

4. Conclusions

- (1)

- The material properties of pure carbon nanotube films and carbon nanotube epoxy resin films are significantly affected by ambient temperature. At temperatures of −40 °C, −10 °C, 20 °C, and 50 °C, the energy storage modulus of pure carbon nanotubes reaches its peak value of approximately 196 GPa at −10 °C, where the material demonstrates optimal elastic deformation. As the temperature rises, the energy storage modulus of pure carbon nanotube films decreases by approximately 15%. In contrast, carbon nanotube epoxy resin films exhibit a marked reduction in energy storage modulus with increasing ambient temperatures. At lower temperatures, the energy storage modulus is roughly twice that observed at elevated temperatures, suggesting that the elastic deformation capacity of the composite material diminishes as ambient temperature increases.

- (2)

- The material properties of pure carbon nanotube (CNT) films and CNT epoxy resin films are affected by variations in frequency. Specifically, at frequencies of 1 Hz, 10 Hz, and 20 Hz, an increase in frequency leads to a corresponding rise in the energy storage modulus of both the pure CNT film and the CNT epoxy resin film, with increases ranging from approximately 1% to 15%. In contrast, the loss factor exhibits a decrease to varying degrees as frequency increases.

- (3)

- A comparative analysis of the material properties of pure carbon nanotube (CNT) film and CNT-epoxy composite film across varying temperatures indicates that the incorporation of epoxy resin has a significant impact on the film’s material properties. Specifically, this addition leads to a marked reduction in the energy storage modulus and an increase in the loss factor of the composite material. The energy storage modulus of pure CNT film is approximately 13 times greater than that of the composite material, whereas the loss factor of the composite is approximately 25 times higher than that of pure epoxy resin and 7 times higher than that of pure CNT film. The introduction of epoxy resin into the CNT film serves to fill the voids between the carbon nanotubes, thereby reducing the material’s capacity for elastic deformation during dynamic tensile testing. This filling process decreases the internal porosity of the material and introduces relative friction between the carbon nanotubes and the epoxy resin during tensile stretching, ultimately enhancing the damping performance of the material.

- (4)

- The performance characteristics of carbon nanotubes (CNTs) and carbon nanotube epoxy resin composites at varying temperatures and frequencies provide a fundamental understanding of the operational mechanisms of CNT films. This understanding is essential when CNTs are utilized as reinforcing phase materials for interlayer toughening and the enhancement of impact resistance. Additionally, it establishes a theoretical framework for examining the performance variations in aircraft components that are predominantly composed of carbon nanotube epoxy resin composites under diverse temperature and operational conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, L.; Wang, H.; Leng, D.; Fang, S.; Yang, Y.; Du, Y. Machine Learning Applications in Nanomaterials: Recent Advances and Future Perspectives. Chem. Eng. J. 2024, 500, 156687. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, H.; Zhang, F.; Zou, M.; Li, J.-C.; Zhang, L.; Hou, P.-X.; Shi, C.; Zhang, L.; Cheng, H.-M.; et al. Green and Efficient Electrolysis of Seawater Using Carbon Nanotube-Based Hybrid Films. Nano Energy 2024, 123, 109356. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, L.; Ai, Z.; Wang, B.; Mansoor, A.; Zhang, Y.; Sun, W. Application of Zro2 and Ni Modified Carbon Nanotube Composites as Bifunctional Water Electrolysis Catalysts. Diam. Relat. Mater. 2024, 150, 111731. [Google Scholar] [CrossRef]

- Xie, W. Research Progress of Carbon Nanotubes for Aviation Functional Applications. Aeronaut. Manuf. 2023, 66, 112–118. [Google Scholar]

- Wei, R.; Huo, Q.; Liu, K.; Elnaggar, A.Y.; El-Bahy, S.M.; El-Bahy, Z.M.; Ren, J.; Wang, L.; Wu, Z. Distributing Fluorinated Carbon Nanotube on Pore Walls of Polyarylene Ether Nitrile Porous Films for Advanced Electromagnetic Interference Shielding. Adv. Compos. Hybrid Mater. 2024, 7, 196. [Google Scholar] [CrossRef]

- Li, Y.H. Preparation of Carbon Nanotube Composite Films and Their Dynamic Tensile Properties; Suzhou University: Suzhou, China, 2023. [Google Scholar]

- Kaushal, A.; Alexander, R.; Prakash, J.; Dasgupta, K. Engineering Challenges and Innovations in Controlled Synthesis of Cnt Fiber and Fabrics in Floating Catalyst Chemical Vapor Deposition (Fc-Cvd) Process. Diam. Relat. Mater. 2024, 148, 111474. [Google Scholar] [CrossRef]

- Tan, W.; Stallard, J.C.; Smail, F.R.; Boies, A.M.; Fleck, N.A. The Mechanical and Electrical Properties of Direct-Spun Carbon Nanotube Mat-Epoxy Composites. Carbon 2019, 150, 489–504. [Google Scholar] [CrossRef]

- Xia, Q.; Mei, H.; Zhang, Z.; Liu, Y.; Liu, Y.; Leng, J. Fabrication of the Silver Modified Carbon Nanotube Film/Carbon Fiber Reinforced Polymer Composite for the Lightning Strike Protection Application. Compos. Part B Eng. 2020, 180, 107563. [Google Scholar] [CrossRef]

- Qu, S.X.; Gong, W.B.; Sun, X.Z.; Zhang, D.X.; Liang, Z.Q.; Gao, L.M.; Lv, W.B. On Line Damage Monitoring of Composites Based on Ca Rbon Nanotube Fi Lms. Acta Aeronaut. Astronaut. Si Nica 2022, 43, 424949. [Google Scholar]

- Rogozhkin, G.V.; Gordeev, N.E.; Butt, H.A.; Kondrashov, V.A.; Goldt, A.E.; Dmitrieva, V.A.; Vildanova, A.R.; Konev, S.D.; Sergeichev, I.V.; Wang, Z.; et al. Mechanically Neutral and Facile Monitoring of Thermoset Matrices with Ultrathin and Highly Porous Carbon Nanotube Films. Carbon 2024, 230, 119603. [Google Scholar] [CrossRef]

- Sun, W.; Gao DE, D. Synergistic Toughening of Epoxy Resin by Block Ionomers and Carbon Nanofibers. Eng. Fract. Mech. 2024, 311, 110584. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Chai, J.; Ni, Z.; Yan, Y. Cryogenic Mechanical Performance and Gas-Barrier Property of Epoxy Resins Modified with Multiwalled Carbon Nanotubes. Int. J. Hydrogen. Energy 2024, 89, 738–745. [Google Scholar] [CrossRef]

- Mongya, W.; Peng, L. Acoustic Emission Study of Carbon Nanotube-Modified Epoxy Composites. Sci. Technol. Innov. 2021, 178–179. [Google Scholar]

- Kordzangeneh, D.; Khoramishad, H.; Fatolahi, A.R. Post-Creep Residual Tensile Properties of Multiwalled Carbon Nanotube/Epoxy Nanocomposites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 238, 2131–2141. [Google Scholar]

- Zhu, X.; Lu, G.; Ma, S.; Zhou, H.; Zhang, H. Comparison of Mechanical Properties Between Cnt Reinforced Resin and Metal Based Materials. J. Beijing Inst. Technol. 2023, 43, 1187–1196. [Google Scholar]

- Li, Z.; Liu, H.; Ren, T.; Liu, X.; Wang, H. Study on Transverse High-Speed Impact Resistance of Carbon Nanotube Resin Composite Films. J. Acta Aeronautica Astronautica Sinica 2024, 1–18. [Google Scholar] [CrossRef]

- Xiao, K.; Lei, X.; Chen, Y.; An, Q.; Hu, D.; Wang, C.; Wu, X.; Huang, C. Extraordinary Impact Resistance of Carbon Nanotube Film with Cross-links Under Micro-Ballistic Impact. Carbon 2021, 175, 478–489. [Google Scholar] [CrossRef]

- Hasanin, M.S.; El-Hadek, M.A.; Abdel-Hamid, S.; Al-Qahtani, W.H.; Toderaș, M.; Bassyouni, M. Studies on Fracture Mechanics of Self-Healing Epoxy Nanocomposite-Based Carbon Nanotube and Glass Fibers. Int. J. Adv. Manuf. Technol. 2024, 134, 5855–5864. [Google Scholar] [CrossRef]

- Wang, Y.; Zhai, W.; Li, J.; Liu, H.; Li, C.; Li, J. Friction Behavior of Biodegradable Electrospun Polyester Nanofibrous Membranes. Tribol. Int. 2023, 188, 108891. [Google Scholar] [CrossRef]

- Miao, Y. Research on Mechanical Behavior and Reinforcement Mechanism of Resin-Based Nanocomposites; Northwestern Polytechnical University: Xi’an, China, 2017. [Google Scholar]

- Duan, P.; Zhang, Y.; He, B.; Li, M.M.; Wang, Y.; Bai, R.Y. Effect of Carbon Nanotube Modification on Mechanical Properties of Epoxy Resin. Gansu Sci. Technol. 2023, 39, 35–38. [Google Scholar]

- Han, J.d.; Gao, Y.q. Study on Damping Properties of Carbon Nanotube Reinforced Epoxy Composites. Mater. Her. 2011, 25, 12–15, 24. [Google Scholar]

- Pan, S.; Dai, Q.; Safaei, B.; Qin, Z.; Chu, F. Damping Characteristics of Carbon Nanotube Reinforced Epoxy Nanocomposite Beams. Thin-Walled Struct. 2021, 166, 108127. [Google Scholar] [CrossRef]

- Han, B. Preparation and Property Optimization of Carbon Nanotube Fibers by Floating Catalytic Chemical Vapor Deposition; Harbin Institute of Technology: Harbin, China, 2019. [Google Scholar]

- Sun, L.; Yang, J.; Shi, Y.; Zhong, M.Q. Analysis of Dynamic Mechanical Properties and Reinforcement Mechanism of Pa6/Cnt Composites. Plast. Ind. 2007, 247–249. [Google Scholar]

- Cai, J. Mechanism of Carbon Nanotubes Interaction with Epoxy Resin and Effect on Glass Transition Temperature and Toughness; National University of Defense Technology: Changsha, China, 2019. [Google Scholar]

- Ma, Q.L.; Zhang, C.X.; Wang, H.; Jiang, J.; Lv, W.B. Effect of Temperature on the Shear Strength of Carbon Nanotube Fiber/Epoxy Resin Interface. J. Shanghai Univ. 2018, 24, 961–967. [Google Scholar]

- Li, J.; Chen, S.; Zhang, J.; Wang, J.L. Dynamic Viscoelastic Properties of Non-Aqueous Reactive Polymer Materials Based on Dynamic Thermomechanical Analysis. J. Build. Mater. 2020, 23, 1398–1409. [Google Scholar]

- Wang, G.J.; Xu, C.Y.; Xu, Z.Y.; Xiong, X.P. Analysis of Dynamic Thermo-Mechanical Properties of Graphene Oxide/Nanocellulose Composite Films. Sci. Technol. Dev. 2015, 29, 86–89. [Google Scholar]

- Cao, J.; Li, W.; Zhang, X.; Li, Z.; Song, L.; Yang, L.; Wang, N. Effects of Carbon Nanotubes and Graphene on the Structure and Properties of Nbr/Eug Composites. Spec. Rubber Prod. 2024, 45, 27–32. [Google Scholar]

- Liu, S.; Lyu, M.; Yang, C.; Jiang, M.; Wang, C. Study of Viscoelastic Properties of Graphene Foams Using Dynamic Mechanical Analysis and Coarse-Grained Molecular Dynamics Simulations. Materials 2023, 16, 2457. [Google Scholar] [CrossRef]

- Zhang, C. Characterization of the Damping and Mechanical Properties of a Novel (Znsno3/Pvdf)@Ppy Nanofibers/Ep Composite. Rsc. Adv. 2017, 7, 37130–37138. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Li, Z.; Liu, Y.; Pei, P. Dynamic Thermo-Mechanical Properties of Carbon Nanotube Resin Composite Films. Polymers 2024, 16, 3307. https://doi.org/10.3390/polym16233307

Wang Y, Li Z, Liu Y, Pei P. Dynamic Thermo-Mechanical Properties of Carbon Nanotube Resin Composite Films. Polymers. 2024; 16(23):3307. https://doi.org/10.3390/polym16233307

Chicago/Turabian StyleWang, Ying, Zhouyi Li, Yan Liu, and Penghao Pei. 2024. "Dynamic Thermo-Mechanical Properties of Carbon Nanotube Resin Composite Films" Polymers 16, no. 23: 3307. https://doi.org/10.3390/polym16233307

APA StyleWang, Y., Li, Z., Liu, Y., & Pei, P. (2024). Dynamic Thermo-Mechanical Properties of Carbon Nanotube Resin Composite Films. Polymers, 16(23), 3307. https://doi.org/10.3390/polym16233307