Carbon Based Polymeric Nanocomposite Hydrogel Bioink: A Review

Abstract

:1. Introduction

2. Unique Characteristics of Carbon-Based Polymeric Nanocomposite Hydrogels (NCHs)

2.1. Mechanical and Rheological Properties

2.2. Adjustable Conductivity, Swelling, Optical, and Thermoresponsive Properties

2.3. Biocompatibility

3. Carbon-Laden Materials and Nanocomposite Hydrogel Ink for Bioprinting

3.1. Carbon Quantum Dots

3.2. Graphene-Based Nanomaterials

3.3. Carbon Nanotubes/Nanorods

3.4. Activated Charcoal

4. Challenges and Future Trends

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siwal, S.S.; Zhang, Q.; Devi, N.; Thakur, V.K. Carbon-Based Polymer Nanocomposite for High-Performance Energy Storage Applications. Polymers 2020, 12, 505. [Google Scholar] [CrossRef] [PubMed]

- Moura, D.; Pereira, R.F.; Gonçalves, I.C. Recent advances on Bioprinting of hydrogels containing carbon materials. Mater. Today Chem. 2022, 23, 100617. [Google Scholar] [CrossRef]

- Shahnaz, T.; Hayder, G.; Shah, M.A.; Ramli, M.Z.; Ismail, N.; Hua, C.K.; Zahari, N.M.; Mardi, N.H.; Selamat, F.E.; Kabilmiharbi, N.; et al. Graphene-based nanoarchitecture as a potent cushioning/filler in polymer composites and their applications. J. Mater. Res. Technol. 2024, 28, 2671–2698. Available online: https://www.sciencedirect.com/science/article/pii/S2238785423031721 (accessed on 21 September 2024). [CrossRef]

- Rueda-Gensini, L.; Serna, J.A.; Cifuentes, J.; Cruz, J.C.; Muñoz-Camargo, C. Graphene Oxide-Embedded Extracellular Matrix-Derived Hydrogel as a Multiresponsive Platform for 3D Bioprinting Applications. Int. J. Bioprint. 2021, 7, 353. [Google Scholar] [CrossRef]

- Homem, N.C.; Miranda, C.S.; Teixeira, M.A.; Teixeira, M.O.; Domingues, J.M.; Seibert, D.; Antunes, J.C.; Amorim, M.T.P.; Felgueiras, H.P. Graphene oxide-based platforms for wound dressings and drug delivery systems: A 10 year overview. J. Drug Deliv. Sci. Technol. 2022, 78, 103992. [Google Scholar] [CrossRef]

- Vashist, A.; Kaushik, A.; Vashist, A.; Sagar, V.; Ghosal, A.; Gupta, Y.K.; Ahmad, S.; Nair, M. Advances in Carbon Nanotubes-Hydrogel Hybrids in Nanomedicine for Therapeutics. Adv. Healthc. Mater. 2018, 7, e1701213. [Google Scholar] [CrossRef]

- Sun, X.; Qin, Z.; Ye, L.; Zhang, H.; Yu, Q.; Wu, X.; Li, J.; Yao, F. Carbon nanotubes reinforced hydrogel as flexible strain sensor with high stretchability and mechanically toughness. Chem. Eng. J. 2020, 382, 122832. [Google Scholar] [CrossRef]

- Sachdev, A.; Matai, I.; Gopinath, P. Carbon dots incorporated polymeric hydrogels as multifunctional platform for imaging and induction of apoptosis in lung cancer cells. Colloids Surf. B Biointerfaces 2016, 141, 242–252. [Google Scholar] [CrossRef]

- Ramdhun, Y.; Mohanta, M.; Arunachalam, T.; Gupta, R.; Verma, D. Bromelain-loaded polyvinyl alcohol–activated charcoal-based film for wound dressing applications. Macromol. Res. 2023, 31, 469–488. [Google Scholar] [CrossRef]

- Argenta, D.F.; Santos, T.C.D.; Campos, A.M.; Caon, T. Chapter 3—Hydrogel Nanocomposite Systems: Physico-Chemical Characterization and Application for Drug-Delivery Systems. In Nanocarriers for Drug Delivery; Mohapatra, S.S., Ranjan, S., Dasgupta, N., Mishra, R.K., Thomas, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 81–131. [Google Scholar] [CrossRef]

- Gupta, P.; Lahiri, D. Aligned carbon nanotube containing scaffolds for neural tissue regeneration. Neural Regen. Res. 2016, 11, 1062–1063. Available online: https://pmc.ncbi.nlm.nih.gov/articles/PMC4994439/ (accessed on 18 October 2024).

- Sharma, G.; Thakur, B.; Naushad, M.; Kumar, A.; Stadler, F.J.; Alfadul, S.M.; Mola, G.T. Applications of nanocomposite hydrogels for biomedical engineering and environmental protection. Environ. Chem. Lett. 2018, 16, 113–146. [Google Scholar] [CrossRef]

- Owonubi, S.J.; Malima, N.M.; Revaprasadu, N. Chapter 16—Metal Oxide–Based Nanocomposites as Antimicrobial and Biomedical Agents, In Antibiotic Materials in Healthcare; Kokkarachedu, V., Kanikireddy, V., Sadiku, R., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 287–323. [Google Scholar] [CrossRef]

- Karchoubi, F.; Ghotli, R.A.; Pahlevani, H.; Salehi, M.B. New insights into nanocomposite hydrogels; a review on recent advances in characteristics and applications. Adv. Ind. Eng. Polym. Res. 2024, 7, 54–78. Available online: https://www.sciencedirect.com/science/article/pii/S2542504823000453 (accessed on 21 September 2024). [CrossRef]

- Murphy, S.V.; Atala, A. 3D Bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Dadigala, R.; Bandi, R.; Alle, M.; Gangapuram, B.R.; Lee, S.-H. Graphene-Based Smart Nanomaterials for Photothermal Therapy. In Smart Nanomaterials in Biomedical Applications; Kim, J.-C., Alle, M., Husen, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 125–153. [Google Scholar] [CrossRef]

- Nie, L.; Li, J.; Lu, G.; Wei, X.; Deng, Y.; Liu, S.; Zhong, S.; Shi, Q.; Hou, R.; Sun, Y.; et al. Temperature responsive hydrogel for cells encapsulation based on graphene oxide reinforced poly(N-isopropylacrylamide)/hydroxyethyl-chitosan. Mater. Today Commun. 2022, 31, 103697. [Google Scholar] [CrossRef]

- Lima-Sousa, R.; de Melo-Diogo, D.; Alves, C.G.; Cabral, C.S.D.; Miguel, S.P.; Mendonça, A.G.; Correia, I.J. Injectable in situ forming thermo-responsive graphene based hydrogels for cancer chemo-photothermal therapy and NIR light-enhanced antibacterial applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2020, 117, 111294. Available online: https://pubmed.ncbi.nlm.nih.gov/32919655/ (accessed on 18 October 2024). [CrossRef]

- Cui, F.; Xi, L.; Wang, D.; Ren, L.; Tan, X.; Li, X.; Li, J.; Li, T. Advanced in carbon dot-based hydrogels for antibacterial, detection and adsorption. Coord. Chem. Rev. 2023, 497, 215457. [Google Scholar] [CrossRef]

- Hagemann, N.; Spokas, K.; Schmidt, H.-P.; Kägi, R.; Böhler, M.A.; Bucheli, T.D.; Carbon, A. Biochar and Charcoal: Linkages and Synergies across Pyrogenic Carbon’s ABCs. Water 2018, 10, 182. [Google Scholar] [CrossRef]

- Kwon, Y.-K.; Kim, P. Unusually High Thermal Conductivity in Carbon Nanotubes. In High Thermal Conductivity Materials; Shindé, S.L., Goela, J.S., Eds.; Springer: New York, NY, USA, 2006; pp. 227–265. [Google Scholar] [CrossRef]

- Kausar, A.; Ilyas, H.; Siddiq, M. Current Research Status and Application of Polymer/Carbon Nanofiller Buckypaper: A Review. Polym.-Plast. Technol. Eng. 2017, 56, 1780–1800. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Fal, V.I.; Colombo, L.; Gellert, P.R.; Schwab, M.G.; Kim, K. A roadmap for graphene. Nature 2012, 490, 192–200. [Google Scholar] [CrossRef]

- Chen, J.; Yao, B.; Li, C.; Shi, G. An improved Hummers method for eco-friendly synthesis of graphene oxide. Carbon 2013, 64, 225–229. [Google Scholar] [CrossRef]

- Li, L.; Qin, S.; Peng, J.; Chen, A.; Nie, Y.; Liu, T.; Song, K. Engineering gelatin-based alginate/carbon nanotubes blend bioink for direct 3D printing of vessel constructs. Int. J. Biol. Macromol. 2020, 145, 262–271. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, E.; Singh, P.; Meyyappan, M.; Singh, H. A review on graphene-based nanocomposites for electrochemical and fluorescent biosensors. RSC Adv. 2019, 9, 8778–8881. [Google Scholar] [CrossRef]

- Shauloff, N.; Bhattacharya, S.; Jelinek, R. Elastic carbon dot/polymer films for fluorescent tensile sensing and mechano-optical tuning. Carbon 2019, 152, 363–371. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0008622319305998 (accessed on 19 October 2024). [CrossRef]

- Valentin, T.M.; Landauer, A.K.; Morales, L.C.; DuBois, E.M.; Shukla, S.; Liu, M.; Valentin, L.H.S.; Franck, C.; Chen, P.-Y.; Wong, I.Y. Alginate-graphene oxide hydrogels with enhanced ionic tunability and chemomechanical stability for light-directed 3D printing. Carbon 2019, 143, 447–456. [Google Scholar] [CrossRef]

- Basu, A.; Saha, A.; Goodman, C.; Shafranek, R.T.; Nelson, A. Catalytically Initiated Gel-in-Gel Printing of Composite Hydrogels. ACS Appl. Mater. Interfaces 2017, 9, 40898–40904. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Xiong, X.; Jiang, C.; Xie, Q. Broadband transmission properties of graphene-dielectric interfaces. Results Phys. 2019, 14, 102521. [Google Scholar] [CrossRef]

- Czakkel, O.; Berke, B.; László, K. Effect of graphene-derivatives on the responsivity of PNIPAM-based thermosensitive nanocomposites—A review. Eur. Polym. J. 2019, 116, 106–116. [Google Scholar] [CrossRef]

- Liu, S.; Bastola, A.K.; Li, L. A 3D Printable and Mechanically Robust Hydrogel Based on Alginate and Graphene Oxide. ACS Appl. Mater. Interfaces 2017, 9, 41473–41481. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.; Li, L. Rheological study on 3D printability of alginate hydrogel and effect of graphene oxide. Int. J. Bioprint. 2016, 2, 54–66. Available online: https://search.proquest.com/openview/37e2a0b768edad5ba77e57833b1ff45e/1?pq-origsite=gscholar&cbl=5474055&casa_token=bAWRqvFX3EUAAAAA:rpemtu9CDhDH_r_4WbdJIZW7j_IDJODnD2n0xpqOHgVd0riKzPUCiW9z6QykmunYrVs4atua (accessed on 22 September 2024). [CrossRef]

- Adewunmi, A.A.; Ismail, S.; Sultan, A.S. Carbon Nanotubes (CNTs) Nanocomposite Hydrogels Developed for Various Applications: A Critical Review. J. Inorg. Organomet. Polym. Mater. 2016, 26, 717–737. [Google Scholar] [CrossRef]

- Bhattacharya, M. Polymer Nanocomposites—A Comparison between Carbon Nanotubes, Graphene, and Clay as Nanofillers. Materials 2016, 9, 262. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Barber, A.H.; Nuriel, S.; Wagner, H.D. Mechanical Properties of Functionalized Single-Walled Carbon-Nanotube/Poly(vinyl alcohol) Nanocomposites. Adv. Funct. Mater. 2005, 15, 975–980. [Google Scholar] [CrossRef]

- Huang, Y.; Zheng, Y.; Song, W.; Ma, Y.; Wu, J.; Fan, L. Poly(vinyl pyrrolidone) wrapped multi-walled carbon nanotube/poly(vinyl alcohol) composite hydrogels. Compos. Part Appl. Sci. Manuf. 2011, 42, 1398–1405. [Google Scholar] [CrossRef]

- Nurly, H.; Yan, Q.; Song, B.; Shi, Y. Effect of carbon nanotubes reinforcement on the polyvinyl alcohol—Polyethylene glycol double-network hydrogel composites: A general approach to shape memory and printability. Eur. Polym. J. 2019, 110, 114–122. [Google Scholar] [CrossRef]

- Lee, S.-J.; Zhu, W.; Nowicki, M.; Lee, G.; Heo, D.N.; Kim, J.; Zuo, Y.Y.; Zhang, L.G. 3D printing nano conductive multi-walled carbon nanotube scaffolds for nerve regeneration. J. Neural Eng. 2018, 15, 016018. [Google Scholar] [CrossRef]

- Khabibullin, A.; Alizadehgiashi, M.; Khuu, N.; Prince, E.; Tebbe, M.; Kumacheva, E. Injectable Shear-Thinning Fluorescent Hydrogel Formed by Cellulose Nanocrystals and Graphene Quantum Dots. Langmuir 2017, 33, 12344–12350. [Google Scholar] [CrossRef]

- Alam, A.; Zhang, Y.; Kuan, H.-C.; Lee, S.-H.; Ma, J. Polymer composite hydrogels containing carbon nanomaterials—Morphology and mechanical and functional performance. Prog. Polym. Sci. 2018, 77, 1–18. [Google Scholar] [CrossRef]

- Yi, J.; Choe, G.; Park, J.; Lee, J.Y. Graphene oxide-incorporated hydrogels for biomedical applications. Polym. J. 2020, 52, 823–837. [Google Scholar] [CrossRef]

- Aqcheli, F.; Salehi, M.B.; Taghikhani, V.; Pahlevani, H. Synthesis of a custom-made suspension of preformed particle gel with improved strength properties and its application in the enhancement of oil recovery in a micromodel scale. J. Pet. Sci. Eng. 2021, 207, 109108. [Google Scholar] [CrossRef]

- Aqcheli, F.; Salehi, M.B.; Pahlevani, H.; Taghikhani, V. Rheological properties and the micromodel investigation of nanosilica gel-reinforced preformed particle gels developed for improved oil recovery. J. Pet. Sci. Eng. 2020, 192, 107258. [Google Scholar] [CrossRef]

- Kuzmenko, V.; Karabulut, E.; Pernevik, E.; Enoksson, P.; Gatenholm, P. Tailor-made conductive inks from cellulose nanofibrils for 3D printing of neural guidelines. Carbohydr. Polym. 2018, 189, 22–30. [Google Scholar] [CrossRef] [PubMed]

- Håkansson, K.M.O.; Henriksson, I.C.; de la Peña Vázquez, C.; Kuzmenko, V.; Markstedt, K.; Enoksson, P.; Gatenholm, P. Solidification of 3D Printed Nanofibril Hydrogels into Functional 3D Cellulose Structures. Adv. Mater. Technol. 2016, 1, 1600096. [Google Scholar] [CrossRef]

- Shin, S.R.; Farzad, M.R.; Tamayol, A.; Manoharan, M.V.; Mostafalu, P.; Zhang, Y.S.; Akbari, M.; Jung, S.M.; Kim, D.; Commotto, M.M.; et al. A bioactive carbon nanotube-based ink for printing 2D and 3D flexible electronics. Adv. Mater. 2016, 28, 3280. Available online: https://pmc.ncbi.nlm.nih.gov/articles/PMC4850092/ (accessed on 19 October 2024). [CrossRef]

- Deng, Z.; Hu, T.; Lei, Q.; He, J.; Ma, P.X.; Guo, B. Stimuli-Responsive Conductive Nanocomposite Hydrogels with High Stretchability, Self-Healing, Adhesiveness, and 3D Printability for Human Motion Sensing. ACS Appl. Mater. Interfaces 2019, 11, 6796–6808. [Google Scholar] [CrossRef]

- Wu, Q.; Wei, J.; Xu, B.; Liu, X.; Wang, H.; Wang, W.; Wang, Q.; Liu, W. A robust, highly stretchable supramolecular polymer conductive hydrogel with self-healability and thermo-processability. Sci. Rep. 2017, 7, 41566. [Google Scholar] [CrossRef]

- Bengtson, S.; Kling, K.; Madsen, A.M.; Noergaard, A.W.; Jacobsen, N.R.; Clausen, P.A.; Alonso, B.; Pesquera, A.; Zurutuza, A.; Ramos, R.; et al. No cytotoxicity or genotoxicity of graphene and graphene oxide in murine lung epithelial FE1 cells in vitro. Environ. Mol. Mutagen. 2016, 57, 469–482. [Google Scholar] [CrossRef]

- Chang, Y.; Yang, S.-T.; Liu, J.-H.; Dong, E.; Wang, Y.; Cao, A.; Liu, Y.; Wang, H. In vitro toxicity evaluation of graphene oxide on A549 cells. Toxicol. Lett. 2011, 200, 201–210. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Wang, J.; Li, J.; Lin, Y. Graphene and graphene oxide: Biofunctionalization and applications in biotechnology. Trends Biotechnol. 2011, 29, 205–212. [Google Scholar] [CrossRef]

- Yang, K.; Wan, J.; Zhang, S.; Zhang, Y.; Lee, S.-T.; Liu, Z. In Vivo Pharmacokinetics, Long-Term Biodistribution, and Toxicology of PEGylated Graphene in Mice. ACS Nano 2011, 5, 516–522. [Google Scholar] [CrossRef]

- Boakye-Yiadom, K.O.; Kesse, S.; Opoku-Damoah, Y.; Filli, M.S.; Aquib, M.; Joelle, M.M.B.; Farooq, M.A.; Mavlyanova, R.; Raza, F.; Bavi, R.; et al. Carbon dots: Applications in bioimaging and theranostics. Int. J. Pharm. 2019, 564, 308–317. [Google Scholar] [CrossRef] [PubMed]

- Wagner, W.R.; Sakiyama-Elbert, S.E.; Zhang, G.; Yaszemski, M.J. Biomaterials Science: An Introduction to Materials in Medicine; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Zhu, K.; Shin, S.R.; van Kempen, T.; Li, Y.-C.; Ponraj, V.; Nasajpour, A.; Mandla, S.; Hu, N.; Liu, X.; Leijten, J.; et al. Gold Nanocomposite Bioink for Printing 3D Cardiac Constructs. Adv. Funct. Mater. 2017, 27, 1605352. [Google Scholar] [CrossRef] [PubMed]

- Holmannova, D.; Borsky, P.; Svadlakova, T.; Borska, L.; Fiala, Z. Carbon Nanoparticles and Their Biomedical Applications. Appl. Sci. 2022, 12, 7865. Available online: https://www.mdpi.com/2076-3417/12/15/7865 (accessed on 21 September 2024). [CrossRef]

- Ali, A.; Hasan, A.; Negi, Y.S. Effect of carbon based fillers on xylan/chitosan/nano-HAp composite matrix for bone tissue engineering application. Int. J. Biol. Macromol. 2022, 197, 1–11. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, C.; Liu, Z.; Ko, J.; Chen, L.; Zhang, T.; Xiong, Z.; Zhang, L.; Sun, W. 3D Printed Conductive Multiscale Nerve Guidance Conduit with Hierarchical Fibers for Peripheral Nerve Regeneration. Adv. Sci. 2023, 10, 2205744. [Google Scholar] [CrossRef]

- Wang, J.; Huang, D.; Ren, H.; Shang, L. Biomimic Trained Immunity-MSCs Delivery Microcarriers for Acute Liver Failure Regeneration. Small 2022, 18, e2200858. [Google Scholar] [CrossRef]

- Mahmud, Z.; Nasrin, A.; Hassan, M.; Gomes, V.G. 3D-printed polymer nanocomposites with carbon quantum dots for enhanced properties and in situ monitoring of cardiovascular stents. Polym. Adv. Technol. 2022, 33, 980–990. [Google Scholar] [CrossRef]

- Lee, K.K.; Raja, N.; Yun, H.-S.; Lee, S.C.; Lee, C.-S. Multifunctional bone substitute using carbon dot and 3D printed calcium-deficient hydroxyapatite scaffolds for osteoclast inhibition and fluorescence imaging. Acta Biomater. 2023, 159, 382–393. [Google Scholar] [CrossRef]

- Fuchs, S.; Shariati, K.; Ma, M. Specialty Tough Hydrogels and their Biomedical Applications. Adv. Healthc. Mater. 2020, 9, e1901396. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, B.; Zhang, D.; Yang, M.; Huang, X.; Han, L.; Chen, K.; Li, X.; Pang, R.; Shang, Y.; et al. Conductive hydrogels incorporating carbon nanoparticles: A review of synthesis, performance and applications. Particuology 2023, 83, 212–231. [Google Scholar] [CrossRef]

- Wahid, F.; Zhao, X.-J.; Jia, S.-R.; Bai, H.; Zhong, C. Nanocomposite hydrogels as multifunctional systems for biomedical applications: Current state and perspectives. Compos. Part B Eng. 2020, 200, 108208. [Google Scholar] [CrossRef]

- Bhardwaj, D.; Singhmar, R.; Garg, M.; Gupta, D.; Dhiman, A.; Han, S.S.; Agrawal, G. Designing advanced hydrogel inks with direct ink writing based 3D printability for engineered biostructures. Eur. Polym. J. 2024, 205, 112736. [Google Scholar] [CrossRef]

- Qiao, L.; Zhou, M.; Shi, G.; Cui, Z.; Zhang, X.; Fu, P.; Liu, M.; Qiao, X.; He, Y.; Pang, X. Ultrafast Visible-Light-Induced ATRP in Aqueous Media with Carbon Quantum Dots as the Catalyst and Its Application for 3D Printing. J. Am. Chem. Soc. 2022, 144, 9817–9826. [Google Scholar] [CrossRef] [PubMed]

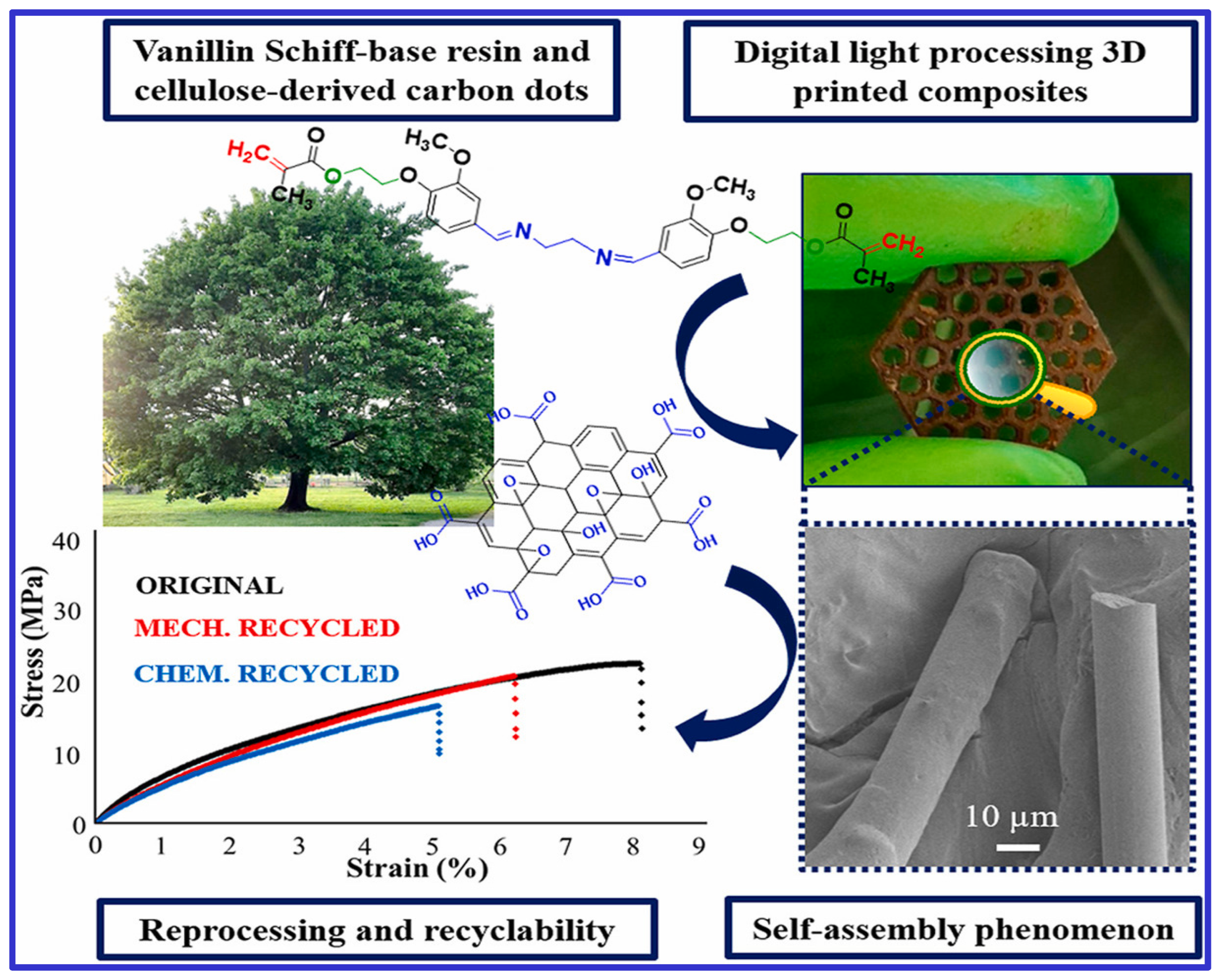

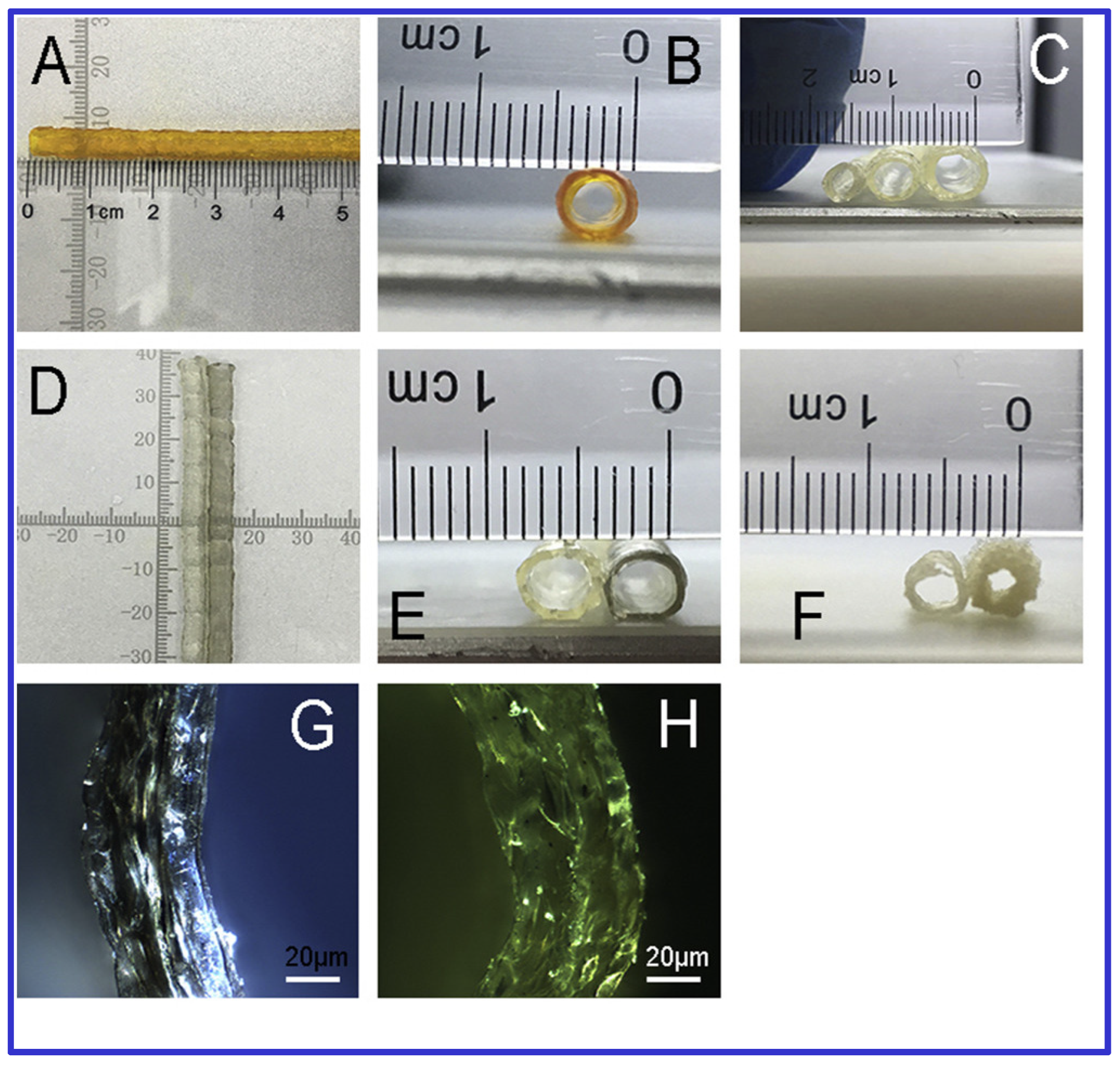

- Liguori, A.; Gonzalez, K.; Hakkarainen, M. Unexpected self-assembly of carbon dots during digital light processing 3D printing of vanillin Schiff-base resin. Polymer 2023, 283, 126252. [Google Scholar] [CrossRef]

- Yildiz, A.P.Z.; Darici, H.; Yavuz, B.; Abamor, E.S.; Ozdemir, C.; Yasin, M.E.; Bagirova, M.; Allahverdiyev, A.; Karaoz, E. Preparation and Characterization of Graphene-Based 3D Biohybrid Hydrogel Bioink for Peripheral Neuroengineering. J. Vis. Exp. JoVE 2022, 183, e63622. [Google Scholar] [CrossRef]

- Lai, J.; Chen, X.; Lu, H.H.; Wang, M. 3D Bioprinting of Graphene Oxide-Incorporated Hydrogels for Neural Tissue Regeneration. 3D Print Addit. Manuf. 2023. [Google Scholar] [CrossRef]

- Zhang, J.; Griesbach, J.; Ganeyev, M.; Zehnder, A.-K.; Zeng, P.; Schädli, G.N.; de Leeuw, A.; Lai, Y.; Rubert, M.; Müller, R. Long-term mechanical loading is required for the formation of 3D bioprinted functional osteocyte bone organoids. Biofabrication 2022, 14, 035018. [Google Scholar] [CrossRef]

- Zhou, B.; Jiang, X.; Zhou, X.; Tan, W.; Luo, H.; Lei, S.; Yang, Y. GelMA-based bioactive hydrogel scaffolds with multiple bone defect repair functions: Therapeutic strategies and recent advances. Biomater. Res. 2023, 27, 86. Available online: https://spj.science.org/doi/full/10.1186/s40824-023-00422-6 (accessed on 19 October 2024). [CrossRef]

- Li, J.; Liu, X.; Crook, J.M.; Wallace, G.G. Development of 3D printable graphene oxide based bio-ink for cell support and tissue engineering. Front. Bioeng. Biotechnol. 2022, 10, 994776. [Google Scholar] [CrossRef]

- Dorishetty, P.; Balu, R.; Gelmi, A.; Mata, J.P.; Quigley, A.; Dutta, N.K.; Choudhury, N.R. Microporosity engineered printable silk/graphene hydrogels and their cytocompatibility evaluations. Mater. Today Adv. 2022, 14, 100233. [Google Scholar] [CrossRef]

- Cao, Y.; Cheng, Y.; Zhao, G. Near-Infrared Light-, Magneto-, and pH-Responsive GO–Fe3O4/Poly(N-isopropylacrylamide)/alginate Nanocomposite Hydrogel Microcapsules for Controlled Drug Release. Langmuir 2021, 37, 5522–5530. [Google Scholar] [CrossRef] [PubMed]

- Dai, W.; Guo, H.; Gao, B.; Ruan, M.; Xu, L.; Wu, J.; Kirk, T.B.; Xu, J.; Ma, D.; Xue, W. Double network shape memory hydrogels activated by near-infrared with high mechanical toughness, nontoxicity, and 3D printability. Chem. Eng. J. 2019, 356, 934–949. Available online: https://www.sciencedirect.com/science/article/pii/S1385894718317947?casa_token=HBdt1HMQQ-0AAAAA:nWNmjkztCm0BfceIFU_52HvAMmAOLErdC0TVjBLCBsuibBOnk_b5Z7LchzUDR7GW91VM3txe (accessed on 22 September 2024). [CrossRef]

- Cheng, Z.; Landish, B.; Chi, Z.; Nannan, C.; Jingyu, D.; Sen, L.; Xiangjin, L. 3D printing hydrogel with graphene oxide is functional in cartilage protection by influencing the signal pathway of Rank/Rankl/OPG. Mater. Sci. Eng. C Mater. Biol. Appl. 2018, 82, 244–252. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Nowicki, M.; Cui, H.; Zhu, W.; Fang, X.; Miao, S.; Lee, S.-J.; Keidar, M.; Zhang, L.G. 3D bioprinted graphene oxide-incorporated matrix for promoting chondrogenic differentiation of human bone marrow mesenchymal stem cells. Carbon 2017, 116, 615–624. [Google Scholar] [CrossRef]

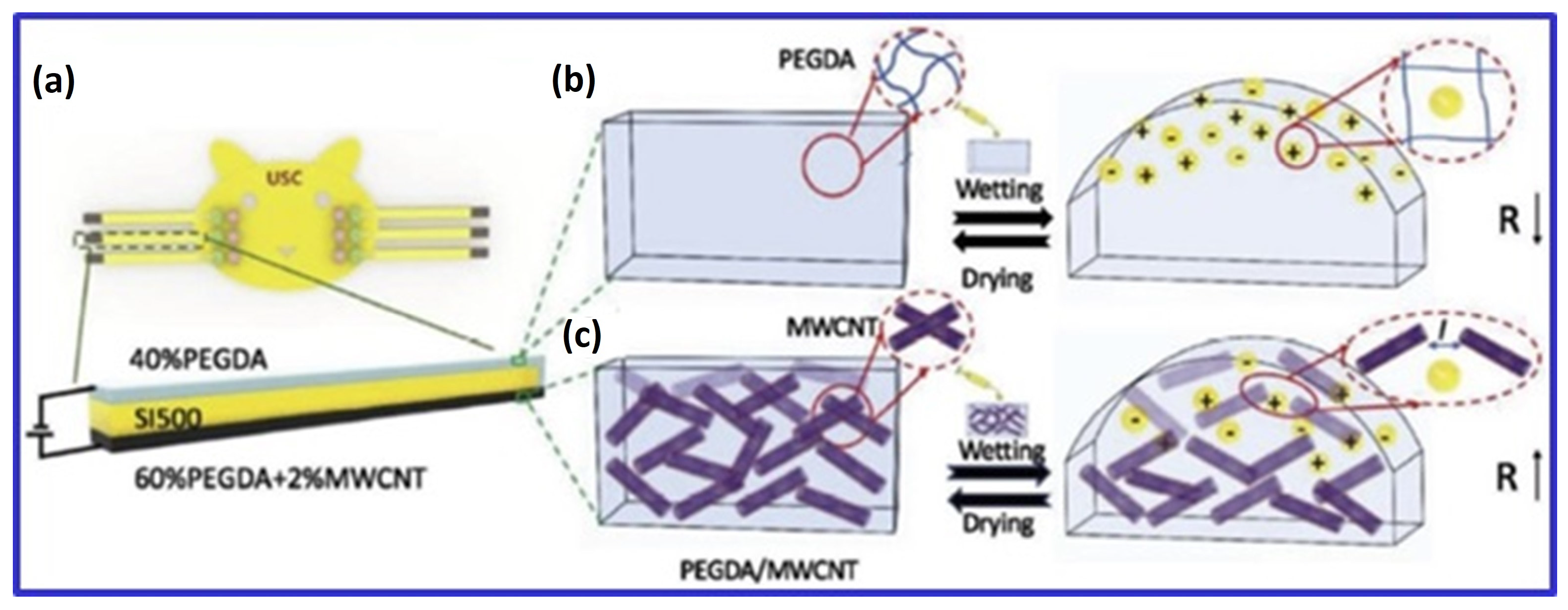

- Li, X.; Yang, Y.; Xie, B.; Chu, M.; Sun, H.; Hao, S.; Chen, Y.; Chen, Y. 3D Printing of Flexible Liquid Sensor Based on Swelling Behavior of Hydrogel with Carbon Nanotubes. Adv. Mater. Technol. 2019, 4, 1800476. [Google Scholar] [CrossRef]

- Cui, H.; Yu, Y.; Li, X.; Sun, Z.; Ruan, J.; Wu, Z.; Qian, J.; Yin, J. Direct 3D printing of a tough hydrogel incorporated with carbon nanotubes for bone regeneration. J. Mater. Chem. B 2019, 7, 7207–7217. [Google Scholar] [CrossRef]

- Szymański, T.; Semba, J.A.; Mieloch, A.A.; Cywoniuk, P.; Kempa, M.; Rybka, J.D. Hyaluronic acid and multi-walled carbon nanotubes as bioink additives for cartilage tissue engineering. Sci. Rep. 2023, 13, 646. [Google Scholar] [CrossRef]

- Rebane, I.; Priks, H.; Levin, K.J.; Sarigül, İ.; Mäeorg, U.; Johanson, U.; Piirimägi, P.; Tenson, T.; Tamm, T. Microbial growth and adhesion of Escherichia coli in elastomeric silicone foams with commonly used additives. Sci. Rep. 2023, 13, 8541. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, B.; Liu, Y.; Suo, X.; Li, H. Influence of surface topography on bacterial adhesion: A review. Biointerphases 2018, 13, 060801. Available online: https://pubs.aip.org/avs/bip/article/13/6/060801/238808/Influence-of-surface-topography-on-bacterial (accessed on 3 November 2024). [CrossRef]

- Fontecha-Umaña, F.; Ríos-Castillo, A.G.; Ripolles-Avila, C.; Rodríguez-Jerez, J.J. Antimicrobial Activity and Prevention of Bacterial Biofilm Formation of Silver and Zinc Oxide Nanoparticle-Containing Polyester Surfaces at Various Concentrations for Use. Foods 2020, 9, 442. [Google Scholar] [CrossRef]

- Dungani, R.; Munawar, S.S.; Karliati, T.; Malik, J.; Aditiawati, P. SULISTYONO, Study of Characterization of Activated Carbon from Coconut Shells on Various Particle Scales as Filler Agent in Composite Materials. J. Korean Wood Sci. Technol. 2022, 50, 256–271. [Google Scholar] [CrossRef]

- Ali, R.; Aslam, Z.; Shawabkeh, R.A.; Asghar, A.; Hussein, I.A. BET, FTIR, and RAMAN characterizations of activated carbon from waste oil fly ash. Turk. J. Chem. 2020, 44, 279. [Google Scholar] [CrossRef] [PubMed]

- Cooke, M.E.; Rosenzweig, D.H. The rheology of direct and suspended extrusion bioprinting. APL Bioeng. 2021, 5, 011502. [Google Scholar] [CrossRef]

- Kim, S.W.; Kim, D.Y.; Roh, H.H.; Kim, H.S.; Lee, J.W.; Lee, K.Y. Three-Dimensional Bioprinting of Cell-Laden Constructs Using Polysaccharide-Based Self-Healing Hydrogels. Biomacromolecules 2019, 20, 1860–1866. [Google Scholar] [CrossRef]

- Ozbolat, I.T.; Hospodiuk, M. Current advances and future perspectives in extrusion-based Bioprinting. Biomaterials 2016, 76, 321–343. [Google Scholar] [CrossRef]

- Saunders, R.E.; Derby, B. Inkjet printing biomaterials for tissue engineering: Bioprinting. Int. Mater. Rev. 2014, 59, 430–448. [Google Scholar] [CrossRef]

- Mandrycky, C.; Wang, Z.; Kim, K.; Kim, D.-H. 3D Bioprinting for engineering complex tissues. Biotechnol. Adv. 2016, 34, 422–434. [Google Scholar] [CrossRef]

- Duan, B.; Hockaday, L.A.; Kang, K.H.; Butcher, J.T. 3D Bioprinting of heterogeneous aortic valve conduits with alginate/gelatin hydrogels. J. Biomed. Mater. Res. A 2013, 101A, 1255–1264. [Google Scholar] [CrossRef]

- Ouyang, L.; Highley, C.B.; Sun, W.; Burdick, J.A. A Generalizable Strategy for the 3D Bioprinting of Hydrogels from Nonviscous Photo-crosslinkable Inks. Adv. Mater. 2017, 29, 1604983. [Google Scholar] [CrossRef]

- Taormina, G.; Sciancalepore, C.; Messori, M.; Bondioli, F. 3D printing processes for photocurable polymeric materials: Technologies, materials, and future trends. J. Appl. Biomater. Funct. Mater. 2018, 16, 151–160. [Google Scholar] [CrossRef]

- Sarig-Nadir, O.; Livnat, N.; Zajdman, R.; Shoham, S.; Seliktar, D. Laser Photoablation of Guidance Microchannels into Hydrogels Directs Cell Growth in Three Dimensions. Biophys. J. 2009, 96, 4743–4752. [Google Scholar] [CrossRef] [PubMed]

- Guillemot, F.; Souquet, A.; Catros, S.; Guillotin, B.; Lopez, J.; Faucon, M.; Pippenger, B.; Bareille, R.; Rémy, M.; Bellance, S.; et al. High-throughput laser printing of cells and biomaterials for tissue engineering. Acta Biomater. 2010, 6, 2494–2500. [Google Scholar] [CrossRef] [PubMed]

- Pereira, R.F.; Bártolo, P.J. 3D Bioprinting of photocrosslinkable hydrogel constructs. J. Appl. Polym. Sci. 2015, 132, 42458. [Google Scholar] [CrossRef]

- Krkobabić, M.; Medarević, D.; Pešić, N.; Vasiljević, D.; Ivković, B.; Ibrić, S. Digital Light Processing (DLP) 3D Printing of Atomoxetine Hydrochloride Tablets Using Photoreactive Suspensions. Pharmaceutics 2020, 12, 833. [Google Scholar] [CrossRef]

- Gudapati, H.; Dey, M.; Ozbolat, I. A comprehensive review on droplet-based Bioprinting: Past, present and future. Biomaterials 2016, 102, 20–42. [Google Scholar] [CrossRef]

| Material | Dimensions | Elastic Modulus (TPa) | Electrical Conductivity (Sm−1) | Thermal Conductivity (Wm−1K−1) | Reference |

|---|---|---|---|---|---|

| Carbon nanotubes | |||||

| Single-walled carbon nanotubes (SWCNTs) | Ø = 1–2 nm (Length in µm to mm) | 1 | ~1 × 104 | ~6 × 103 | [2,21] |

| Multi-walled carbon nanotubes (MWCNTs) | Ø = 5–20 nm (Length in µm to mm) | 1.2 | ~1 × 104 | ~6 × 103 | [22] |

| Graphene | Thickness = 0.34 nm Lateral size = >100 nm Surface area = 2630 m2/g | 1 | 6 × 105 | 5.1 × 103 | [23] |

| Graphene oxide | Thickness = 0.4–1.7 nm Lateral size = >100 nm Surface area = 2391 m2/g | 0.22 | 1 × 10−1 | 2 × 103 | [24] |

| Carbon dots | Size < 20 nm | 0.1 to 0.3 | ~43 | ~0.605 | [25,26,27] |

| Optical Property | Results | Reference |

|---|---|---|

| Fluorescence Emission | Measured fluorescence and quantum yield of carbon quantum dots (CDs) as photocatalysts in 3D printing. They reported high monomer conversion and efficient photoluminescence under visible light, essential for rapid 3D polymerization. | [68] |

| Fluorescence Emission | In vivo imaging of scaffolds implanted in mouse models, showing the CDs maintained fluorescence and enabled real-time visualization without inducing inflammation. | [63] |

| Fluorescence Emission, Rheological Characteristics. | CDs in hydrogels demonstrated fluorescence emission when excited at 365 nm. This property is beneficial for diagnostic applications, combining bioimaging with mechanical stability in hydrogels. | [41] |

| Fluorescence Emission | high photoluminescence with tunable emission properties, which were effectively used in bioimaging applications, enhancing imaging contrast and specificity in medical diagnostics | [55] |

| Excitation-Dependent Emission | exhibited significant excitation-dependent emission, with fluorescence intensity varying markedly across different excitation wavelengths, demonstrating enhanced brightness and stability under optimal excitation conditions. | [41] |

| Category | Bioprinting Techniques | Key Advantages | Key Limitations | Ref. |

|---|---|---|---|---|

| Cost-Effective Techniques | Inkjet-based, Extrusion-based |

|

| [90,91,92,93,94] |

| High-Speed Printing | Laser-based, Stereolithography, Digital Light Processing |

|

| [92,93,94,95,96,97,98] |

| Resolution-Focused | Inkjet-based, Laser-based, Stereolithography, Digital Light Processing |

|

| [90,91,92,95,96,97,99,100] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madhusudhan, A.; Suhagia, T.A.; Sharma, C.; Jaganathan, S.K.; Purohit, S.D. Carbon Based Polymeric Nanocomposite Hydrogel Bioink: A Review. Polymers 2024, 16, 3318. https://doi.org/10.3390/polym16233318

Madhusudhan A, Suhagia TA, Sharma C, Jaganathan SK, Purohit SD. Carbon Based Polymeric Nanocomposite Hydrogel Bioink: A Review. Polymers. 2024; 16(23):3318. https://doi.org/10.3390/polym16233318

Chicago/Turabian StyleMadhusudhan, Alle, Tejaskumar A. Suhagia, Chhavi Sharma, Saravana Kumar Jaganathan, and Shiv Dutt Purohit. 2024. "Carbon Based Polymeric Nanocomposite Hydrogel Bioink: A Review" Polymers 16, no. 23: 3318. https://doi.org/10.3390/polym16233318

APA StyleMadhusudhan, A., Suhagia, T. A., Sharma, C., Jaganathan, S. K., & Purohit, S. D. (2024). Carbon Based Polymeric Nanocomposite Hydrogel Bioink: A Review. Polymers, 16(23), 3318. https://doi.org/10.3390/polym16233318