Machine Learning-Based Process Optimization in Biopolymer Manufacturing: A Review

Abstract

:1. Introduction

2. Overview of Biopolymer Manufacturing

2.1. Feedstock Selection

2.2. Fermentation

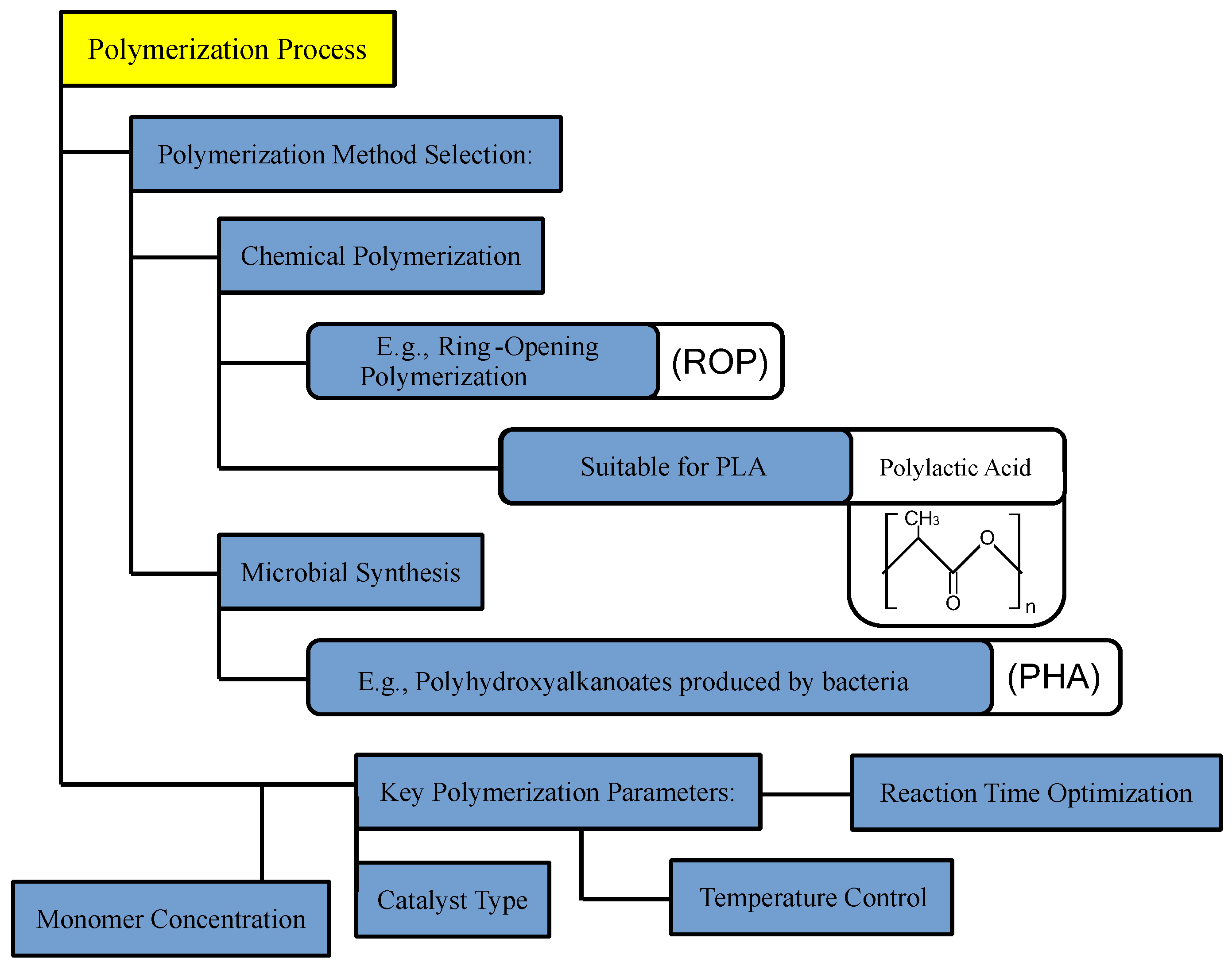

2.3. Polymerization and Extraction

2.4. Quality Control and Post-Processing

3. ML Techniques in Process Optimization

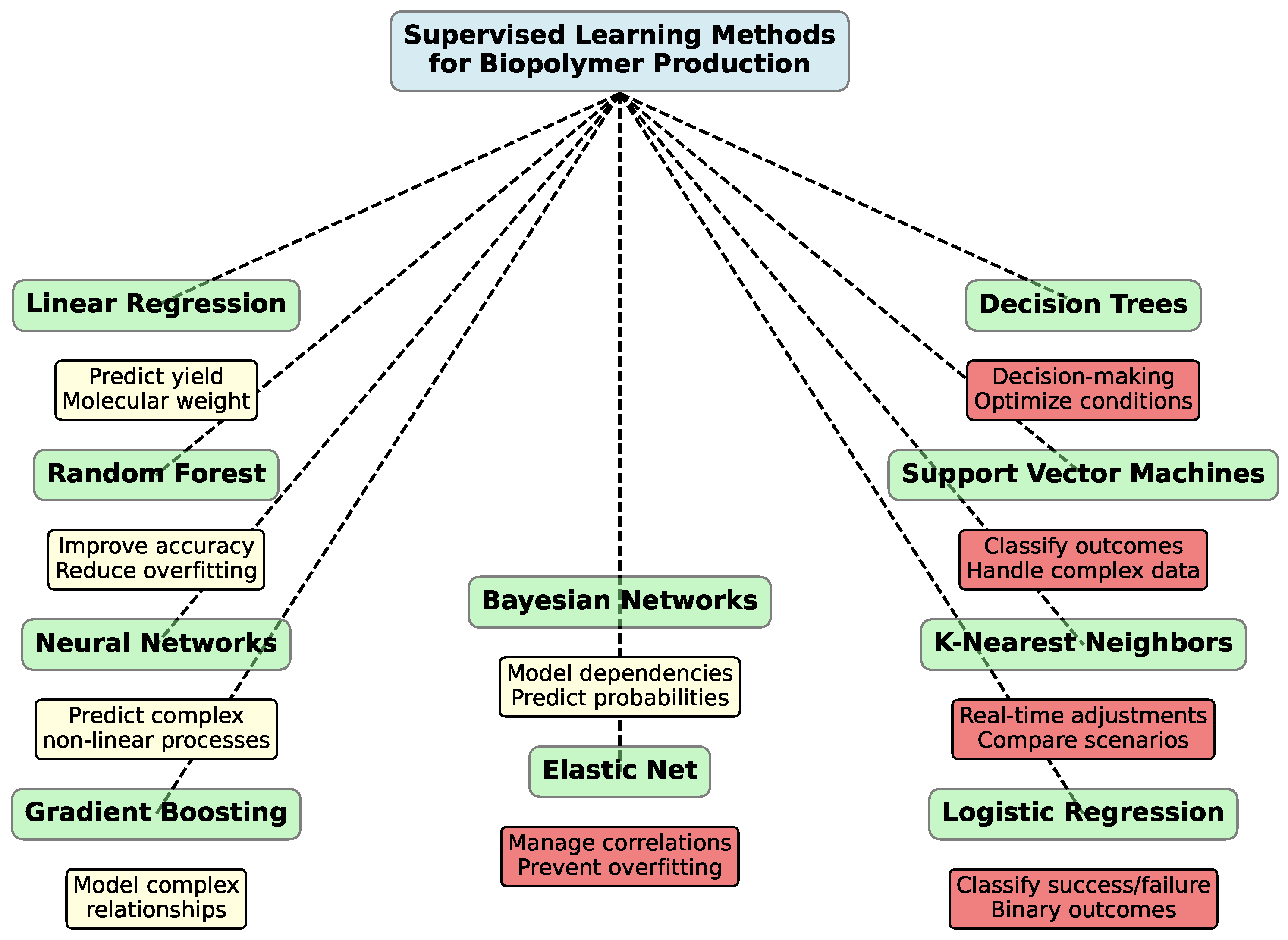

3.1. Supervised Learning

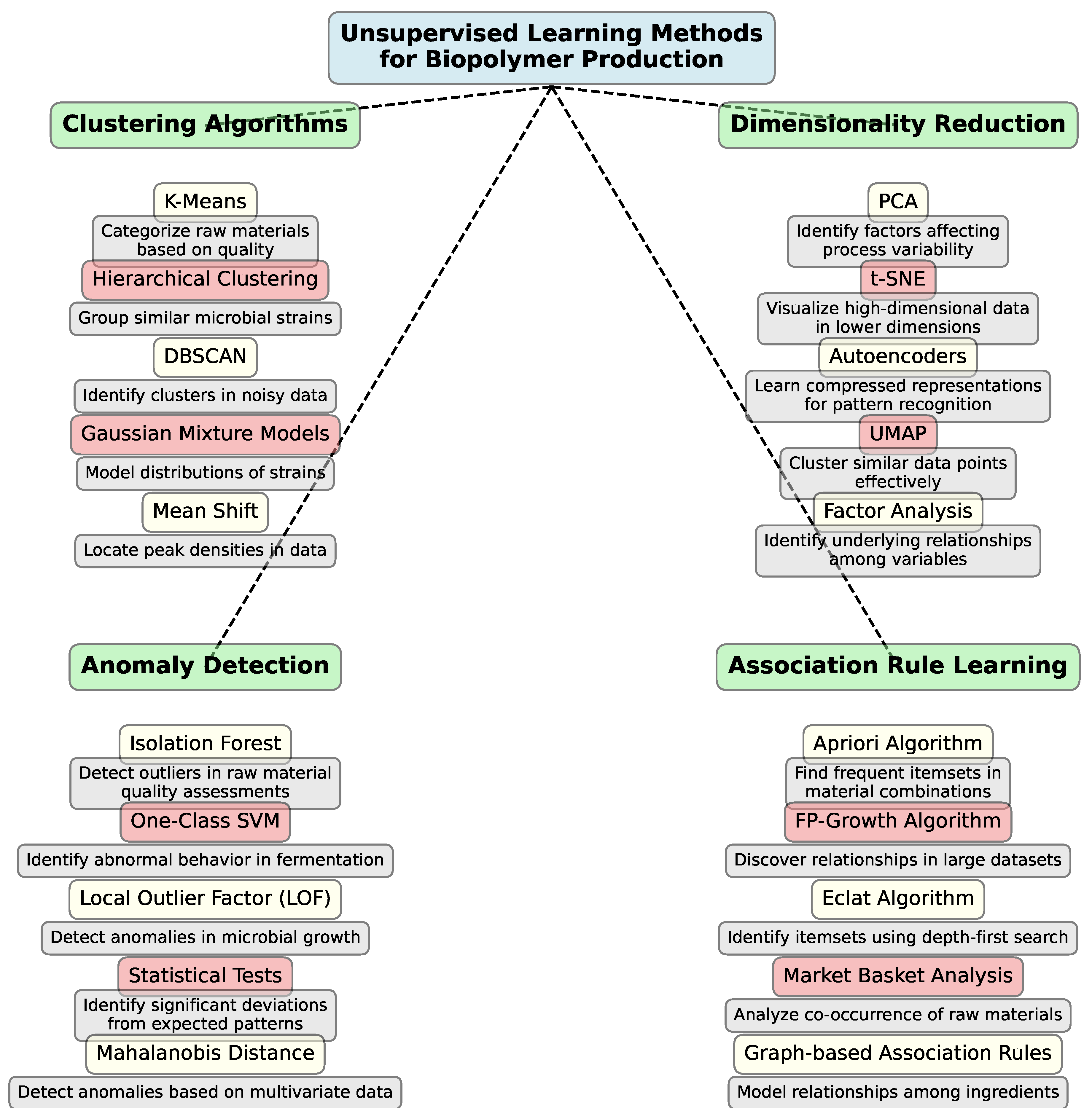

3.2. Unsupervised Learning

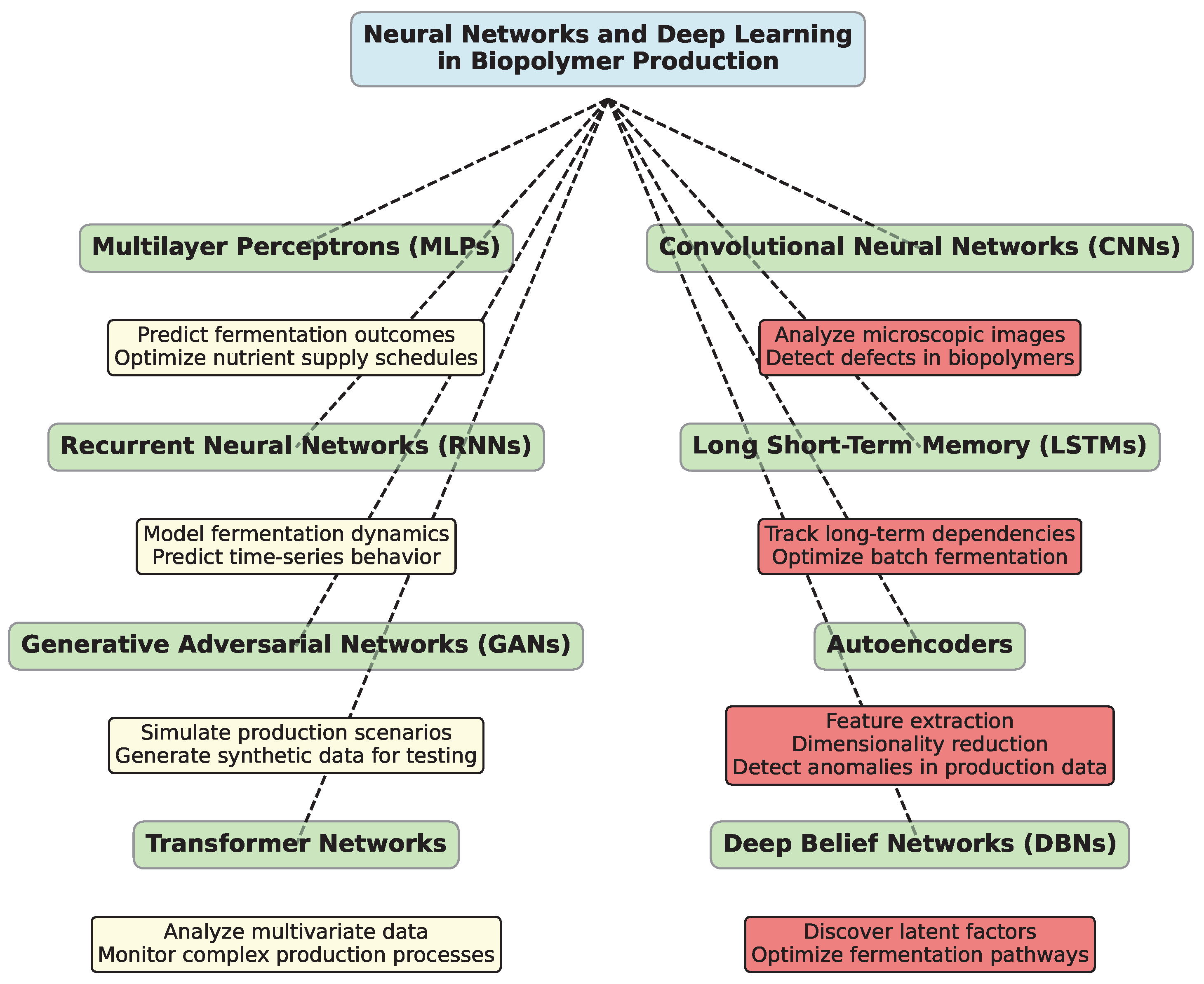

3.3. Neural Networks and Deep Learning

4. Challenges of Integrating ML in Biopolymer Research

- Using variational autoencoders (VAEs) and generative adversarial networks (GANs) to synthesize new data from small experimental datasets can enhance model quality and mitigate the risk of overfitting. This approach has already been proven effective in certain biopolymer studies.

- Applying nonlinear methods such as Random Forests, SVM, and NNs can significantly improve the prediction of biopolymer properties. These algorithms are particularly useful for handling data with complex molecular interactions.

- ML in biopolymer research can benefit from closer integration with traditional computational chemistry methods, like molecular dynamics or quantum chemistry simulations. Combining knowledge from fundamental laws with ML capabilities will enable more accurate predictions.

- Active learning algorithms can efficiently use small datasets by selecting the most informative experiments to prioritize data collection. This strategy can reduce the experimental workload required to train models.

- As demonstrated by the Lignin Structural Dataset (LGS), the creation and publication of unique datasets for different biopolymers is importnant for advancing the field. These databases will support improved simulations, predictive models, and facilitate resource sharing among researchers.

5. Future Directions for Development

- Grishanovich et al. (2024) [333] used Hierarchical Cluster Analysis (HCA) to classify lignin alterations using solid-state NMR spectra, addressing the gap between dissolved and solid lignins. Ireddy et al. (2024) [334] demonstrated that 1D Fourier Transform (FT) achieved high accuracy in classifying polyhydroxyalkanoate (PHA) films using unsupervised machine learning algorithms. Both approaches highlight the effectiveness of unsupervised techniques in classifying complex biopolymers. However, the accuracy of these models is constrained by the limitations of the underlying technologies (solid-state NMR and FT) and may vary with material composition. Future research should focus on integrating more advanced spectroscopic techniques or hybrid models to overcome these limitations and improve generalization across different biopolymer types.

- Mulrennan et al. (2022) [336] combined near-infrared (NIR) and conventional sensor data with Random Forest (RF) and Support Vector Regression (SVR) models to predict the mechanical strength of polylactide (PLA). Similarly, Bejagam et al. (2022) [294] demonstrated that Support Vector Machines (SVMs) excelled in predicting the mechanical properties of wheat straw-filled polypropylene composites. Both studies show the superiority of nonlinear models like RF and SVM over traditional linear methods for material property prediction. However, the complexity of these models and the need for real-time data or specific formulations may limit practical applications. Future work could focus on simplifying these models for broader use and exploring their adaptability to different biopolymer formulations.

- Zhang et al. (2021) [339] used ensemble learning for high-accuracy DNA-binding protein prediction, relying on feature selection with LASSO. Xing et al. (2002) [298] employed an SVM to predict the molecular weight of polycaprolactone (PCL), showing that SVM outperformed Artificial Neural Networks (ANNs) in this context. While these methods provide high accuracy, they require large, high-quality datasets for training and may not generalize well across different protein types or polymers. Future research could explore methods for data augmentation or transfer learning to expand these models’ applicability and robustness.

- Qiao et al. (2001) [341] employed self-organizing maps (SOMs) for visualizing protein molecular surfaces, while Bandyopadhyay et al. (2021) [388] used autoencoders to predict protein dynamics and folding pathways. Both approaches highlight the importance of unsupervised learning in understanding complex biomolecular features. However, the effectiveness of an SOM depends on input feature quality, while autoencoders may struggle with very complex datasets. Future studies could integrate SOMs with deep learning-based feature extraction or enhance autoencoders by incorporating reinforcement learning to better model protein conformational landscapes.

- Sadeghi et al. (2024) [389] used variational autoencoders (VAEs) for multiobjective optimization in the design of DNA-stabilized silver nanoclusters. Satteri et al. (2021) [390] emphasized the potential of data-driven models, such as generative models, for polymer design. Both studies demonstrate the power of data-driven techniques in optimizing material properties, but challenges remain in data quality and model generalizability. Future research should focus on improving model robustness and combining these techniques with traditional methods to achieve more accurate and versatile material design processes.

- Kartal et al. (2023) [398] employed Artificial Neural Networks (ANNs) to predict the thermal degradation of biomass biopolymers with high accuracy, while Khare et al. (2022) [387] demonstrated the potential of small transformer models to predict the thermal stability of collagen triple helices. Both studies underline the importance of accurate prediction of biopolymer degradation, though the complexity of biomass and the limitations of smaller datasets in transformers may pose challenges. Future studies could integrate more advanced models, such as hybrid machine learning techniques, and explore the use of multi-modal datasets to improve prediction accuracy for biopolymer stability and degradation.

- Ifran et al. (2020) [331] used Gaussian Process Regression (GPR) for accurate prediction of nutrient release in biopolymer-coated controlled-release fertilizers (CRFs), while Kathuria et al. (2022) [291] applied k-Nearest Neighbor (k-NN) models to optimize biodegradable starch film formulations. Both approaches show promise in predicting biopolymer properties, but their applicability may be limited by specific material conditions or dataset sizes. Future research should explore expanding these models to include a broader range of materials and applications and work towards integrating them with other predictive models for improved generalization.

- Khare et al. (2022) [387] demonstrated that small transformer models can efficiently predict the thermal stability of biopolymer structures like collagen triple helices. These models provide a promising alternative to larger models such as ProtBERT, offering similar accuracy with fewer parameters. Future research could investigate the scalability of transformer models for larger, more complex datasets and explore their application to other biopolymer stability predictions.

- Wei et al. (2022) [348] emphasized the importance of data augmentation in improving machine learning model performance for biopolymerization modeling. By enhancing the dataset, they were able to significantly boost prediction accuracy. Future research could focus on developing more robust data augmentation techniques and incorporating generative models, such as GANs, to handle real-world data variability and improve prediction reliability in biopolymer-related fields.

Funding

Conflicts of Interest

References

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (lactic acid)(PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 11, 17151–17196. [Google Scholar] [CrossRef] [PubMed]

- Pilapitiya, P.N.T.; Ratnayake, A.S. The world of plastic waste: A review. Clean. Mater. 2024, 11, 100220. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Iacovidou, E.; Gerassimidou, S. Plastic waste in a circular economy. In Environmental Materials and Waste; Elsevier: Amsterdam, The Netherlands, 2024; pp. 99–134. [Google Scholar]

- Frąckowiak, P.; Jędrzejczak, E.; Kaspryszyn, F.; Jesionowski, T.; Wysokowski, M. Revolutionizing electrospinning: Sustainable solutions through deep eutectic solvents in biopolymer processing. J. Appl. Polym. Sci. 2024, 141, e55864. [Google Scholar] [CrossRef]

- Gholivand, S.; Tan, T.B.; Yusoff, M.M.; Qoms, M.S.; Wang, Y.; Liu, Y.; Nyam, K.L.; Tan, C.P. Innovative microencapsulation of hemp seed oil using plant-based biopolymers: A comparative analysis of dehydration techniques on core stability, digestibility and release pattern. Food Hydrocoll. 2024, 158, 110683. [Google Scholar] [CrossRef]

- Joshi, J.S.; Langwald, S.V.; Ehrmann, A.; Sabantina, L. Algae-Based Biopolymers for Batteries and Biofuel Applications in Comparison with Bacterial Biopolymers—A Review. Polymers 2024, 16, 610. [Google Scholar] [CrossRef]

- Saharan, B.S.; Kamal, N.; Badoni, P.; Kumar, R.; Saini, M.; Kumar, D.; Sharma, D.; Tyagi, S.; Ranga, P.; Parshad, J.; et al. Biopolymer and polymer precursor production by microorganisms: Applications and future prospects. J. Chem. Technol. Biotechnol. 2024, 99, 17–30. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Nooshkam, M.; Zargar, M.; Garavand, F.; Ghosh, S.; Hadidi, M.; Forough, M. Green synthesis of nanomaterials for smart biopolymer packaging: Challenges and outlooks. J. Nanostruct. Chem. 2024, 14, 113–136. [Google Scholar] [CrossRef]

- Saberi Riseh, R.; Hassanisaadi, M.; Vatankhah, M.; Varma, R.S.; Thakur, V.K. Nano/micro-structural supramolecular biopolymers: Innovative networks with the boundless potential in sustainable agriculture. Nano-Micro Lett. 2024, 16, 147. [Google Scholar] [CrossRef]

- Jineesh, A.; Parameswaranpillai, J.; Chavali, M.; Bahadur, V.; Prasad, V.; Hegde, C.; Bhansali, P.R. Automotive applications of biodegradable polymers. In Biopolymers; Elsevier: Amsterdam, The Netherlands, 2023; pp. 425–445. [Google Scholar]

- Peng, X.; Umer, M.; Pervez, M.N.; Hasan, K.F.; Habib, M.A.; Islam, M.S.; Lin, L.; Xiong, X.; Naddeo, V.; Cai, Y. Biopolymers-based microencapsulation technology for sustainable textiles development: A short review. Case Stud. Chem. Environ. Eng. 2023, 7, 100349. [Google Scholar] [CrossRef]

- Monia, T. Sustainable natural biopolymers for biomedical applications. J. Thermoplast. Compos. Mater. 2024, 37, 2505–2524. [Google Scholar] [CrossRef]

- Mehmood, A.; Raina, N.; Phakeenuya, V.; Wonganu, B.; Cheenkachorn, K. The current status and market trend of polylactic acid as biopolymer: Awareness and needs for sustainable development. Mater. Today Proc. 2023, 72, 3049–3055. [Google Scholar] [CrossRef]

- Westlake, J.R.; Tran, M.W.; Jiang, Y.; Zhang, X.; Burrows, A.D.; Xie, M. Biodegradable biopolymers for active packaging: Demand, development and directions. Sustain. Food Technol. 2023, 1, 50–72. [Google Scholar] [CrossRef]

- Li, F.; Xie, X.; Xu, X.; Zou, X. Water-soluble biopolymers calcium polymalate derived from fermentation broth of Aureobasidium pullulans markedly alleviates osteoporosis and fatigue. Int. J. Biol. Macromol. 2024, 268, 132013. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Zuo, Z.; Zhang, X.; Wang, L. Food biopolymer behaviors in the digestive tract: Implications for nutrient delivery. Crit. Rev. Food Sci. Nutr. 2024, 64, 8709–8727. [Google Scholar] [CrossRef]

- Lackner, M.; Mustakhimov, I.; García Martínez, J.B.; Pflügl, S. Aerobic and anaerobic fermentation of gaseous and liquid one carbon feedstocks to produce food, feed, biopolymers and value-added products. Front. Bioeng. Biotechnol. 2024, 12, 1334864. [Google Scholar] [CrossRef]

- McClements, D.J. Composite hydrogels assembled from food-grade biopolymers: Fabrication, properties, and applications. Adv. Colloid Interface Sci. 2024, 332, 103278. [Google Scholar] [CrossRef]

- Aquinas, N.; Bhat, R.M.; Selvaraj, S. Submerged Fermentation and Kinetics of Newly Isolated Priestia megaterium for the Production of Biopolymer Curdlan. J. Polym. Environ. 2024, 32, 4683–4698. [Google Scholar] [CrossRef]

- Khalfallah, R.; Mechmeche, M.; Ksontini, H.; Jmoui, I.; Hamdi, M.; Kachouri, F. Novel Approach Coating by Edible Biopolymers of Sesame Fermented with Lactobacillus plantarum to Improve the Shelf Life of Strawberries and Preserve Their Nutritional Quality During Storage. J. Packag. Technol. Res. 2024, 8, 63–77. [Google Scholar] [CrossRef]

- Hanifah, A.; Arfiathi; Mahardika, M.; Sumirat, R.; Nissa, R.C.; Nurhamiyah, Y. Recent Updates on Biopolymers: Precursors, Process, Properties, Challenge, and Future Perspectives. In Biomass Conversion and Sustainable Biorefinery: Towards Circular Bioeconomy; Springer: Singapore, 2024; pp. 19–42. [Google Scholar]

- Rangel, C.; Lourenço, N.D.; Reis, M.A.; Carvalho, G. Dynamics in the profile of biopolymers produced by mixed microbial cultures from ethanol-rich feedstocks. J. Environ. Chem. Eng. 2024, 12, 112609. [Google Scholar] [CrossRef]

- Sinha, S. An overview of biopolymer-derived packaging material. Polym. Renew. Resour. 2024, 15, 193–209. [Google Scholar] [CrossRef]

- Abou-alfitooh, S.A.; El-Hoshoudy, A. Eco-friendly modified biopolymers for enhancing oil production: A review. J. Polym. Environ. 2024, 32, 2457–2483. [Google Scholar] [CrossRef]

- Khaydukova, I.V.; Ivannikova, V.M.; Zhidkov, D.A.; Belikov, N.V.; Peshkova, M.A.; Timashev, P.S.; Tsiganov, D.I.; Pushkarev, A.V. Current State and Challenges of Tissue and Organ Cryopreservation in Biobanking. Int. J. Mol. Sci. 2024, 25, 11124. [Google Scholar] [CrossRef] [PubMed]

- Pinaeva, L.G.; Noskov, A.S. Biodegradable biopolymers: Real impact to environment pollution. Sci. Total. Environ. 2024, 947, 174445. [Google Scholar] [CrossRef] [PubMed]

- Opriș, O.; Mormile, C.; Lung, I.; Stegarescu, A.; Soran, M.L.; Soran, A. An overview of biopolymers for drug delivery applications. Appl. Sci. 2024, 14, 1383. [Google Scholar] [CrossRef]

- Hou, X.; Lin, L.; Li, K.; Jiang, F.; Qiao, D.; Zhang, B.; Xie, F. Towards superior biopolymer gels by enabling interpenetrating network structures: A review on types, applications, and gelation strategies. Adv. Colloid Interface Sci. 2024, 325, 103113. [Google Scholar] [CrossRef]

- Wahba, M.I. A comprehensive review on genipin: An efficient natural cross-linker for biopolymers. Polym. Bull. 2024, 81, 14251–14305. [Google Scholar] [CrossRef]

- Yang, W.; Yang, W.; Zeng, J.; Chen, Y.; Huang, Y.; Liu, J.; Gan, J.; Li, T.; Zhang, H.; Zhong, L.; et al. Biopolymer-based gel electrolytes for electrochemical energy Storage: Advances and prospects. Prog. Mater. Sci. 2024, 144, 101264. [Google Scholar] [CrossRef]

- Rahman, A.; Hasan, K.; Imran, A.B. Biopolymers for Supercapacitors. In Bio-Based Polymers: Farm to Industry. Volume 3: Emerging Trends and Applications; ACS Publications: Washington, DC, USA, 2024; pp. 57–80. [Google Scholar]

- Mumtaz, M.; Hussain, N.; Ashraf, M.; Azam, H.M.H.; Iftikhar, A. Introduction to Biopolymers, Their Blend, IPN s, Gel, Composites, and Nanocomposites. In Applications of Biopolymers in Science, Biotechnology, and Engineering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2024; pp. 1–29. [Google Scholar]

- Werner, J.; Zgoła-Grześkowiak, A.; Grześkowiak, T.; Frankowski, R. Biopolymers-based sorbents as a future green direction for solid phase (micro) extraction techniques. TrAC Trends Anal. Chem. 2024, 173, 117659. [Google Scholar] [CrossRef]

- Hisham, F.; Akmal, M.M.; Ahmad, F.; Ahmad, K.; Samat, N. Biopolymer chitosan: Potential sources, extraction methods, and emerging applications. Ain Shams Eng. J. 2024, 15, 102424. [Google Scholar] [CrossRef]

- Abate, T.; Amabile, C.; Muñoz, R.; Chianese, S.; Musmarra, D. Polyhydroxyalkanoate recovery overview: Properties, characterizations, and extraction strategies. Chemosphere 2024, 356, 141950. [Google Scholar] [CrossRef]

- Durand, K.; Daassi, R.; Rodrigue, D.; Stevanovic, T. Study of biopolymers and silica recovery from pre-hydrolyzed rice husks. Biomass Convers. Biorefinery 2024, 1–18. [Google Scholar] [CrossRef]

- Ai, J.; Wang, K.; Fu, Q.; Dong, T.; Li, L.; Peng, S.; Wang, D.; Wang, Q.; Zhang, W. Novel insights into the biopolymers transformation under wastewater sludge drying process at different temperatures in relation to drying behavior. Chem. Eng. J. 2024, 486, 150376. [Google Scholar] [CrossRef]

- Ludka, F.R.; Klosowski, A.B.; Camargo, G.A.; Justo, A.S.; Andrade, E.A.; Beltrame, F.L.; Olivato, J.B. Brewers’ spent grain extract as antioxidants in starch-based active biopolymers. Int. J. Food Sci. Technol. 2024, 59, 142–150. [Google Scholar] [CrossRef]

- Sudheshwar, A.; Vogel, K.; Nyström, G.; Malinverno, N.; Arnaudo, M.; Camacho, C.E.G.; Beloin-Saint-Pierre, D.; Hischier, R.; Som, C. Unraveling the climate neutrality of wood derivatives and biopolymers. RSC Sustain. 2024, 2, 1487–1497. [Google Scholar] [CrossRef]

- Garnett, M.T.; Kumar, H.K.S.; Beckingham, B.S.; Alexander, S.L. Extraction of cellulose from restaurant food waste. RSC Sustain. 2024, 2, 170–178. [Google Scholar] [CrossRef]

- Bhat, S.G.; Thivaharan, V.; Divyashree, M. Sustainable Opportunities in the Downstream Processing of the Intracellular Biopolymer Polyhydroxyalkanoate. ChemBioEng Rev. 2024, 11, 79–94. [Google Scholar] [CrossRef]

- List, M.; Maurischat, J. Extraction of Protein-Based Biopolymers from Algae and Food Byproducts. 2024. Available online: https://opus4.kobv.de/opus4-rosenheim/frontdoor/index/index/docId/2739 (accessed on 11 October 2024).

- Dutta, S.; Ghosh, A.; Spakowitz, A.J. Effect of local active fluctuations on structure and dynamics of flexible biopolymers. Soft Matter 2024, 20, 1694–1701. [Google Scholar] [CrossRef]

- Shah, Y.A.; Bhatia, S.; Al-Harrasi, A.; Oz, F.; Khan, M.H.; Roy, S.; Esatbeyoglu, T.; Pratap-Singh, A. Thermal properties of biopolymer films: Insights for sustainable food packaging applications. Food Eng. Rev. 2024, 1–16. [Google Scholar] [CrossRef]

- Abady, M.M.; Shawky, A.M.; Sakr, F.A.; Mohammed, D.M.; Goda, E.S. Recent Advancements in Biosensors Using Biopolymers. In Bio-Based Polymers: Farm to Industry. Volume 2: Current Trends and Applications; ACS Publications: Washington, DC, USA, 2024; pp. 81–112. [Google Scholar]

- Chen, K.; Tian, R.; Jiang, J.; Xiao, M.; Wu, K.; Kuang, Y.; Deng, P.; Zhao, X.; Jiang, F. Moisture loss inhibition with biopolymer films for preservation of fruits and vegetables: A review. Int. J. Biol. Macromol. 2024, 263 Pt 1, 130337. [Google Scholar] [CrossRef]

- Chiu, I.; Yang, T. Biopolymer-based intelligent packaging integrated with natural colourimetric sensors for food safety and sustainability. Anal. Sci. Adv. 2024, 5, e202300065. [Google Scholar] [CrossRef]

- Pawliszak, P.; Beheshti, A.; Møller, A.; Blencowe, A.; Beattie, D.A.; Krasowska, M. Increasing surface hydrophilicity with biopolymers: A combined single bubble collision, QCM-D and AFM study. J. Colloid Interface Sci. 2024, 667, 393–402. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, X.; Gao, N.; Wang, X.; Sun, S. Multivariable analysis of egg white protein-chitosan interaction: Influence of pH, temperature, biopolymers ratio, and ionic concentration. Food Chem. X 2023, 19, 100817. [Google Scholar] [CrossRef] [PubMed]

- Meng, J.P.; Li, S.; Yan, R.; Wei, C. Effect of pH value on effectiveness of biopolymer-based treatment of bauxite mine slurry. Physicochem. Probl. Miner. Process. 2023, 59, 167949. [Google Scholar] [CrossRef]

- Kumar, Y.; Bist, Y.; Thakur, D.; Nagar, M.; Saxena, D.C. A review on the role of pH-sensitive natural pigments in biopolymers based intelligent food packaging films. Int. J. Biol. Macromol. 2024, 276 Pt 1, 133869. [Google Scholar] [CrossRef]

- Vegad, U.; Patel, M.; Khunt, D.; Zupančič, O.; Chauhan, S.; Paudel, A. pH stimuli-responsive hydrogels from non-cellulosic biopolymers for drug delivery. Front. Bioeng. Biotechnol. 2023, 11, 1270364. [Google Scholar] [CrossRef]

- Liu, Y.; Ni, J.; Gu, J.; Liu, S.; Huang, Y.; Sadeghi, H. Influence of biopolymer-vegetation interaction on soil hydro-mechanical properties under climate change: A review. Sci. Total. Environ. 2024, 954, 176535. [Google Scholar] [CrossRef]

- Schniete, J.K.; Brüser, T.; Horn, M.A.; Tschowri, N. Specialized biopolymers: Versatile tools for microbial resilience. Curr. Opin. Microbiol. 2024, 77, 102405. [Google Scholar] [CrossRef]

- Dey, B.; Prabhakar, M.R.; Jayaraman, S.; Gujjala, L.K.S.; Venugopal, A.P.; Balasubramanian, P. Biopolymer-based solutions for enhanced safety and quality assurance: A review. Food Res. Int. 2024, 191, 114723. [Google Scholar] [CrossRef]

- Semenova, M.G.; Aslanova, M.A.; Galimova, A.R.; Fedulova, L.V.; Antipova, A.S.; Martirosova, E.I.; Zelikina, D.V.; Bero, A.L.; Utyanov, D.A. Thermal stability and digestibility of a biopolymer system for the delivery of minor nutrients in enriched meat products. Theory and practice of meat processing 2024, 9, 160–168. [Google Scholar] [CrossRef]

- Gonçalves, E.M.; Silva, M.; Andrade, L.; Pinheiro, J. From Fields to Films: Exploring Starch from Agriculture Raw Materials for Biopolymers in Sustainable Food Packaging. Agriculture 2024, 14, 453. [Google Scholar] [CrossRef]

- da Silva Cazella, P.H.; de Souza, M.V.; Rodrigues, F.R.; da Silva, S.A.M.; Bispo, R.A.; De Araujo, V.A.; Christoforo, A.L. Polyethylene terephthalate (PET) as a recycled raw material for particleboards produced from pinus wood and biopolymer resin. J. Clean. Prod. 2024, 447, 141460. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Zhang, Y.; Shi, M.; Zhang, Y.; Yu, H.; Liu, S.; Li, J.; Tan, S.C.; Chen, W. Biopolymers for hygroscopic material development. Adv. Mater. 2024, 36, 2209479. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zhang, X.; Wei, A.; Li, H.; Zhang, H.; Zheng, L.; Xia, N.; Wang, J. Protein-based active films: Raw materials, functions, and food applications. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13302. [Google Scholar] [CrossRef]

- Wang, K.; Chi, B.Y.; Yang, T.Y.; Ren, W.F.; Gao, X.J.; Wang, K.H.; Sun, R.C. Natural biopolymers derived kinematic and self-healing hydrogel coatings to continuously protect metallic zinc anodes. Electrochim. Acta 2024, 489, 144238. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, Y.; Li, J.; Hao, Y.; Ke, H.; Lv, P.; Wei, Q. Wet Spinning Technology for Aerogel Fiber: Pioneering the Frontier of High-Performance and Multifunctional Materials. Adv. Fiber Mater. 2024, 1–41. [Google Scholar] [CrossRef]

- Sinha, S. Synthesis of biopolymer based superabsorbent: An eco-friendly approach towards future sustainability. In Bio-Based Superabsorbents: Recent Trends, Types, Applications And Recycling; Springer: Singapore, 2023; pp. 29–49. [Google Scholar]

- TG, Y.G.; Ballupete Nagaraju, S.; Puttegowda, M.; Verma, A.; Rangappa, S.M.; Siengchin, S. Biopolymer-based composites: An eco-friendly alternative from agricultural waste biomass. J. Compos. Sci. 2023, 7, 242. [Google Scholar] [CrossRef]

- Sharma, A.; Jha, A. Application of biopolymers in clothing and fashion. Int. J. Pharma Prof. Res. (IJPPR) 2023, 14, 1–21. [Google Scholar] [CrossRef]

- Liu, B.; Desai, A.S.; Sun, X.; Ren, J.; Pathan, H.M.; Dabir, V.; Ashok, A.; Hou, H.; Pan, D.; Guo, X.; et al. An overview of sustainable biopolymer composites in sensor manufacturing and smart cities. Adv. Compos. Hybrid Mater. 2024, 7, 146. [Google Scholar] [CrossRef]

- Behrooznia, Z.; Nourmohammadi, J. Polysaccharide-based materials as an eco-friendly alternative in biomedical, environmental, and food packaging. Giant 2024, 19, 100301. [Google Scholar] [CrossRef]

- Biswal, T. Future perspectives of biopolymeric industry. Phys. Sci. Rev. 2024, 9, 2965–2988. [Google Scholar] [CrossRef]

- Rahman, M.Z.; Rahman, M.; Mahbub, T.; Ashiquzzaman, M.; Sagadevan, S.; Hoque, M.E. Advanced biopolymers for automobile and aviation engineering applications. J. Polym. Res. 2023, 30, 106. [Google Scholar] [CrossRef]

- Khandeparkar, A.S.; Paul, R.; Sridhar, A.; Lakshmaiah, V.V.; Nagella, P. Eco-friendly innovations in food packaging: A sustainable revolution. Sustain. Chem. Pharm. 2024, 39, 101579. [Google Scholar] [CrossRef]

- Palaniappan, S.K.; Singh, M.K.; Rangappa, S.M.; Siengchin, S. Eco-friendly Biocomposites: A Step Towards Achieving Sustainable Development Goals. Composites 2023, 7, 7373. [Google Scholar] [CrossRef]

- Dhoundiyal, S.; Alam, M.A.; Kaur, A.; Maqsood, S.; Sharma, S.; Khan, S.A. Biopolymers in Sustainable Textile Dyeing and Printing. In Biopolymers in the Textile Industry: Opportunities and Limitations; Springer: Singapore, 2024; pp. 123–146. [Google Scholar]

- Kanchetti, D.; Munirathnam, R.; Thakkar, D. Integration of Machine Learning Algorithms with Cloud Computing for Real-Time Data Analysis. J. Res. Appl. Sci. Biotechnol. 2024, 3, 301–306. [Google Scholar] [CrossRef]

- Momeni, M.; Afkanpour, M.; Rakhshani, S.; Mehrabian, A.; Tabesh, H. A prediction model based on artificial intelligence techniques for disintegration time and hardness of fast disintegrating tablets in pre-formulation tests. BMC Med. Inform. Decis. Mak. 2024, 24, 88. [Google Scholar] [CrossRef]

- Piras, G.; Muzi, F.; Tiburcio, V.A. Digital Management Methodology for Building Production Optimization through Digital Twin and Artificial Intelligence Integration. Buildings 2024, 14, 2110. [Google Scholar] [CrossRef]

- Ayhan, H.M.; Kır, S. Ml-driven approaches to enhance inventory planning: Inoculant weight application in casting processes. Comput. Ind. Eng. 2024, 193, 110280. [Google Scholar] [CrossRef]

- Strielkowski, W.; Vlasov, A.; Selivanov, K.; Muraviev, K.; Shakhnov, V. Prospects and challenges of the machine learning and data-driven methods for the predictive analysis of power systems: A review. Energies 2023, 16, 4025. [Google Scholar] [CrossRef]

- Mhlanga, D. Artificial intelligence and machine learning for energy consumption and production in emerging markets: A review. Energies 2023, 16, 745. [Google Scholar] [CrossRef]

- Aguiar, M.I.; Sousa, A.F.; Teixeira, G.; Tavares, A.P.; Ferreira, A.M.; Coutinho, J.A. Enhancing plastic waste recycling: Evaluating the impact of additives on the enzymatic polymer degradation. Catal. Today 2024, 429, 114492. [Google Scholar] [CrossRef]

- Nasrin, T.; Pourkamali-Anaraki, F.; Peterson, A.M. Application of machine learning in polymer additive manufacturing: A review. J. Polym. Sci. 2024, 62, 2639–2669. [Google Scholar] [CrossRef]

- Miao, B.H.; Dong, Y.; Wu, Z.Y.; Alemdar, B.N.; Zhang, P.; Kohler, M.D.; Noh, H.Y. Integration of physics-based building model and sensor data to develop an adaptive digital twin. In Proceedings of the 9th ACM International Conference on Systems for Energy-Efficient Buildings, Cities, and Transportation, Boston, MA, USA, 9–10 November 2022; pp. 282–283. [Google Scholar]

- Prateek, S.; Garg, R.; Kumar Saxena, K.; Srivastav, V.; Vasudev, H.; Kumar, N. Data-driven materials science: Application of ML for predicting band gap. Adv. Mater. Process. Technol. 2024, 10, 708–717. [Google Scholar] [CrossRef]

- Chew, A.K.; Sender, M.; Kaplan, Z.; Chandrasekaran, A.; Chief Elk, J.; Browning, A.R.; Kwak, H.S.; Halls, M.D.; Afzal, M.A.F. Advancing material property prediction: Using physics-informed machine learning models for viscosity. J. Cheminform. 2024, 16, 31. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhou, M.; Wu, H.H.; Wang, L.; Zhang, J.; Wu, N.; Pan, K.; Liu, G.; Zhang, Y.; Han, J.; et al. Machine Learning-Assisted Property Prediction of Solid-State Electrolyte. Adv. Energy Mater. 2024, 14, 2304480. [Google Scholar] [CrossRef]

- Cao, Z.; Barati Farimani, O.; Ock, J.; Barati Farimani, A. Machine Learning in Membrane Design: From Property Prediction to AI-Guided Optimization. Nano Lett. 2024, 24, 2953–2960. [Google Scholar] [CrossRef]

- Kazemi-Khasragh, E.; Blázquez, J.P.F.; Gómez, D.G.; González, C.; Haranczyk, M. Facilitating polymer property prediction with machine learning and group interaction modelling methods. Int. J. Solids Struct. 2024, 286, 112547. [Google Scholar] [CrossRef]

- Yu, T.; Wang, C.; Yang, H.; Li, F. Machine learning in metal-ion battery research: Advancing material prediction, characterization, and status evaluation. J. Energy Chem. 2024, 90, 191–204. [Google Scholar] [CrossRef]

- Watpade, A.D.; Thakor, S.; Jain, P.; Mohapatra, P.P.; Vaja, C.R.; Joshi, A.; Shah, D.V.; Islam, M.T. Comparative analysis of machine learning models for predicting dielectric properties in MoS2 nanofiller-reinforced epoxy composites. Ain Shams Eng. J. 2024, 15, 102754. [Google Scholar] [CrossRef]

- Min, Y.; Ming, X.; Peihong, C.; Yang, S.; Zhang, H.; Lingfeng, W.; Liucheng, Z.; Yinghong, L.; Wanlin, G. Machine learning for predicting fatigue properties of additively manufactured materials. Chin. J. Aeronaut. 2024, 37, 1–22. [Google Scholar]

- Kalhor, P.; Jung, N.; Bräse, S.; Wöll, C.; Tsotsalas, M.; Friederich, P. Functional material systems enabled by automated data extraction and machine learning. Adv. Funct. Mater. 2024, 34, 2302630. [Google Scholar] [CrossRef]

- Mi, X.; Dai, L.; Jing, X.; She, J.; Holmedal, B.; Tang, A.; Pan, F. Accelerated design of high-performance Mg-Mn-based magnesium alloys based on novel bayesian optimization. J. Magnes. Alloy. 2024, 12, 750–766. [Google Scholar] [CrossRef]

- Liu, S.; Yang, C. Machine learning design for high-entropy alloys: Models and algorithms. Metals 2024, 14, 235. [Google Scholar] [CrossRef]

- Sharma, V.; Misra, J.P.; Singhal, S. Machine learning algorithms based advanced optimization of wire-EDM parameters: An experimental investigation into titanium alloy. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 2855–2868. [Google Scholar] [CrossRef]

- Padhy, S.P.; Chaudhary, V.; Lim, Y.F.; Zhu, R.; Thway, M.; Hippalgaonkar, K.; Ramanujan, R.V. Experimentally validated inverse design of multi-property Fe-Co-Ni alloys. iScience 2024, 27, 109723. [Google Scholar] [CrossRef]

- Zhou, H.r.; Yang, H.; Li, H.q.; Ma, Y.c.; Yu, S.; Shi, J.; Cheng, J.c.; Gao, P.; Yu, B.; Miao, Z.q.; et al. Advancements in machine learning for material design and process optimization in the field of additive manufacturing. China Foundry 2024, 21, 101–115. [Google Scholar] [CrossRef]

- Zhao, S.; Jiang, B.; Song, K.; Liu, X.; Wang, W.; Si, D.; Zhang, J.; Chen, X.; Zhou, C.; Liu, P.; et al. Machine learning assisted design of high-entropy alloys with ultra-high microhardness and unexpected low density. Mater. Des. 2024, 238, 112634. [Google Scholar] [CrossRef]

- Wu, Y.; Shang, Z.; Lu, T.; Zhou, W.; Li, M.; Lu, W. Target-directed discovery for low melting point alloys via inverse design strategy. J. Alloys Compd. 2024, 971, 172664. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, X.; Lan, S.; Gao, N.; Yin, S.; Guo, W.; Fan, Z.; Wang, K. Machine-learning assisted design of as-cast NiCoFeCrAlTi multi-principal element alloys with tensile yield strength over 1.35 GPa. Intermetallics 2024, 166, 108170. [Google Scholar] [CrossRef]

- Lian, Z.; Ma, Y.; Li, M.; Lu, W.; Zhou, W. Discovery Precision: An effective metric for evaluating performance of machine learning model for explorative materials discovery. Comput. Mater. Sci. 2024, 233, 112738. [Google Scholar] [CrossRef]

- Cheetham, A.K.; Seshadri, R. Artificial intelligence driving materials discovery? perspective on the article: Scaling deep learning for materials discovery. Chem. Mater. 2024, 36, 3490–3495. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, C.F.; Ju, M.G.; Jia, Q.; Zhou, Q.; Lu, S.; Gao, X.; Zhang, Y.; Wang, J. Universal machine learning aided synthesis approach of two-dimensional perovskites in a typical laboratory. Nat. Commun. 2024, 15, 138. [Google Scholar] [CrossRef] [PubMed]

- Talukder, M.J.; Alshami, A.S.; Tayyebi, A.; Ismail, N.; Yu, X. Membrane science meets machine learning: Future and potential use in assisting membrane material design and fabrication. Sep. Purif. Rev. 2024, 53, 216–229. [Google Scholar] [CrossRef]

- Barcin, T.; Yucel, M.A.; Ersan, R.H.; Alagoz, M.A.; Dogen, A.; Burmaoglu, S.; Algul, O. Deep learning approach to the discovery of novel bisbenzazole derivatives for antimicrobial effect. J. Mol. Struct. 2024, 1295, 136668. [Google Scholar] [CrossRef]

- Mican, J.; Da’san MM, J.; Liu, W.; Weber, G.; Mazurenko, S.; Bornscheuer, U.T.; Damborsky, J.; Wei, R.; Bednar, D. Exploring new galaxies: Perspectives on the discovery of novel PET-degrading enzymes. Appl. Catal. B Environ. 2024, 342, 123404. [Google Scholar] [CrossRef]

- Song, J.; Lee, J.; Kim, N.; Min, K. Artificial intelligence in the design of innovative metamaterials: A comprehensive review. Int. J. Precis. Eng. Manuf. 2024, 25, 225–244. [Google Scholar] [CrossRef]

- Zhuang, J.; Midgley, A.C.; Wei, Y.; Liu, Q.; Kong, D.; Huang, X. Machine-Learning-Assisted Nanozyme Design: Lessons from Materials and Engineered Enzymes. Adv. Mater. 2024, 36, 2210848. [Google Scholar] [CrossRef]

- Lu, B.; Xia, Y.; Ren, Y.; Xie, M.; Zhou, L.; Vinai, G.; Morton, S.A.; Wee, A.T.; van der Wiel, W.G.; Zhang, W.; et al. When Machine Learning Meets 2D Materials: A Review. Adv. Sci. 2024, 11, 2305277. [Google Scholar] [CrossRef]

- Yang, J.; Li, F.Z.; Arnold, F.H. Opportunities and challenges for machine learning-assisted enzyme engineering. ACS Cent. Sci. 2024, 10, 226–241. [Google Scholar] [CrossRef]

- Butler, K.T.; Davies, D.W.; Cartwright, H.; Isayev, O.; Walsh, A. Machine learning for molecular and materials science. Nature 2018, 559, 547–555. [Google Scholar] [CrossRef]

- Ibarra-Pérez, D.; Faba, S.; Hernández-Muñoz, V.; Smith, C.; Galotto, M.J.; Garmulewicz, A. Predicting the composition and mechanical properties of seaweed bioplastics from the scientific literature: A machine learning approach for modeling sparse data. Appl. Sci. 2023, 13, 11841. [Google Scholar] [CrossRef]

- Patel, R.A.; Webb, M.A. Data-driven design of polymer-based biomaterials: High-throughput simulation, experimentation, and machine learning. ACS Appl. Bio Mater. 2023, 7, 510–527. [Google Scholar] [CrossRef]

- Ahmed, E.; Mulay, P.; Ramirez, C.; Tirado-Mansilla, G.; Cheong, E.; Gormley, A.J. Mapping biomaterial complexity by machine learning. Tissue Eng. Part A 2024, 30, 662–680. [Google Scholar] [CrossRef]

- Stuart, S.; Watchorn, J.; Gu, F.X. Sizing up feature descriptors for macromolecular machine learning with polymeric biomaterials. Npj Comput. Mater. 2023, 9, 102. [Google Scholar] [CrossRef]

- Haarlemmer, G.; Matricon, L.; Roubaud, A. Hydrothermal liquefaction data for use in machine learning models. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2024; Volume 53, pp. 3169–3174. [Google Scholar]

- Babatunde, Q.O.; Son, D.G.; Kim, S.Y.; Byun, Y.H. Effect of Curing Condition and Solvent Content on Mechanical Properties of Zein-Biopolymer-Treated Soil. Sustainability 2023, 15, 12048. [Google Scholar] [CrossRef]

- Karkoszka, M.; Rok, J.; Wrześniok, D. Melanin Biopolymers in Pharmacology and Medicine—Skin Pigmentation Disorders, Implications for Drug Action, Adverse Effects and Therapy. Pharmaceuticals 2024, 17, 521. [Google Scholar] [CrossRef]

- Vázquez, V.; Giorgi, V.; Bonfiglio, F.; Menéndez, P.; Gioia, L.; Ovsejevi, K. Lignocellulosic residues from bioethanol production: A novel source of biopolymers for laccase immobilization. RSC Adv. 2023, 13, 13463–13471. [Google Scholar] [CrossRef]

- Garduño-Juárez, R.; Tovar-Anaya, D.O.; Perez-Aguilar, J.M.; Lozano-Aguirre Beltran, L.F.; Zubillaga, R.A.; Alvarez-Perez, M.A.; Villarreal-Ramirez, E. Molecular dynamic simulations for biopolymers with biomedical applications. Polymers 2024, 16, 1864. [Google Scholar] [CrossRef]

- Nasarian, E.; Alizadehsani, R.; Acharya, U.R.; Tsui, K.L. Designing interpretable ML system to enhance trust in healthcare: A systematic review to proposed responsible clinician-AI-collaboration framework. Inf. Fusion 2024, 108, 102412. [Google Scholar] [CrossRef]

- Räz, T. ML interpretability: Simple isn’t easy. Stud. Hist. Philos. Sci. 2024, 103, 159–167. [Google Scholar] [CrossRef]

- Ciobanu-Caraus, O.; Aicher, A.; Kernbach, J.M.; Regli, L.; Serra, C.; Staartjes, V.E. A critical moment in machine learning in medicine: On reproducible and interpretable learning. Acta Neurochir. 2024, 166, 14. [Google Scholar] [CrossRef]

- Khayretdinova, M.; Zakharov, I.; Pshonkovskaya, P.; Adamovich, T.; Kiryasov, A.; Zhdanov, A.; Shovkun, A. Prediction of brain sex from EEG: Using large-scale heterogeneous dataset for developing a highly accurate and interpretable ML model. NeuroImage 2024, 285, 120495. [Google Scholar] [CrossRef]

- Jiang, S.; Sweet, L.b.; Blougouras, G.; Brenning, A.; Li, W.; Reichstein, M.; Denzler, J.; Shangguan, W.; Yu, G.; Huang, F.; et al. How interpretable machine learning can benefit process understanding in the geosciences. Earth’s Futur. 2024, 12, e2024EF004540. [Google Scholar] [CrossRef]

- Antonini, A.S.; Tanzola, J.; Asiain, L.; Ferracutti, G.R.; Castro, S.M.; Bjerg, E.A.; Ganuza, M.L. Machine Learning model interpretability using SHAP values: Application to Igneous Rock Classification task. Appl. Comput. Geosci. 2024, 23, 100178. [Google Scholar] [CrossRef]

- Ma, D.; Bortnik, J.; Ma, Q.; Hua, M.; Chu, X. Machine learning interpretability of outer radiation belt enhancement and depletion events. Geophys. Res. Lett. 2024, 51, e2023GL106049. [Google Scholar] [CrossRef]

- Kobayashi, K.; Alam, S.B. Explainable, interpretable, and trustworthy AI for an intelligent digital twin: A case study on remaining useful life. Eng. Appl. Artif. Intell. 2024, 129, 107620. [Google Scholar] [CrossRef]

- Zheng, J.X.; Li, X.; Zhu, J.; Guan, S.Y.; Zhang, S.X.; Wang, W.M. Interpretable machine learning for predicting chronic kidney disease progression risk. Digit. Health 2024, 10, 20552076231224225. [Google Scholar] [CrossRef]

- Nadizar, G.; Rovito, L.; De Lorenzo, A.; Medvet, E.; Virgolin, M. An analysis of the ingredients for learning interpretable symbolic regression models with human-in-the-loop and genetic programming. ACM Trans. Evol. Learn. Optim. 2024, 4, 1–30. [Google Scholar] [CrossRef]

- Zou, X.; Perlaza, S.M.; Esnaola, I.; Altman, E. Generalization analysis of machine learning algorithms via the worst-case data-generating probability measure. Proc. Aaai Conf. Artif. Intell. 2024, 38, 17271–17279. [Google Scholar] [CrossRef]

- Trivedi, A. Addressing the Fallacy of Generalizing Caste Racism among Hindus: An AI/ML Approach to Deconstructing Misconceptions. Int. J. Multidiscip. Innov. Res. Methodol. 2024, 3, 50–63. [Google Scholar]

- Ispirova, G.; Eftimov, T.; Džeroski, S.; Seljak, B.K. MsGEN: Measuring generalization of nutrient value prediction across different recipe datasets. Expert Syst. Appl. 2024, 237, 121507. [Google Scholar] [CrossRef]

- Gil-Fuster, E.; Eisert, J.; Bravo-Prieto, C. Understanding quantum machine learning also requires rethinking generalization. Nat. Commun. 2024, 15, 2277. [Google Scholar] [CrossRef]

- Anagnostopoulos, S.J.; Toscano, J.D.; Stergiopulos, N.; Karniadakis, G.E. Learning in PINNs: Phase transition, total diffusion, and generalization. arXiv 2024, arXiv:2403.18494. [Google Scholar]

- Wang, Y.; Patel, S.; Ortner, C. A theoretical case study of the generalization of machine-learned potentials. Comput. Methods Appl. Mech. Eng. 2024, 422, 116831. [Google Scholar] [CrossRef]

- Alsaggaf, I.A.; Aloufi, S.F.; Baharith, L.A. A new generalization of the inverse generalized Weibull distribution with different methods of estimation and applications in medicine and engineering. Symmetry 2024, 16, 1002. [Google Scholar] [CrossRef]

- Corso, G.; Deng, A.; Fry, B.; Polizzi, N.; Barzilay, R.; Jaakkola, T. Deep confident steps to new pockets: Strategies for docking generalization. arXiv 2024, arXiv:2402.18396. [Google Scholar]

- Mora, A.; Bujari, A.; Bellavista, P. Enhancing generalization in federated learning with heterogeneous data: A comparative literature review. Futur. Gener. Comput. Syst. 2024, 157, 1–15. [Google Scholar] [CrossRef]

- Ramírez, J.G.C.; Islam, M.M. Navigating the Terrain: Scaling Challenges and Opportunities in AI/ML Infrastructure. J. Artif. Intell. Gen. Sci. (JAIGS) 2024, 2, 241–250. [Google Scholar]

- Singla, A.; Malhotra, T. Challenges and Opportunities in Scaling AI/ML Pipelines. J. Sci. Technol. 2024, 5, 1–21. [Google Scholar]

- Darzi, S.; Yavuz, A.A. PQC meets ML or AI: Exploring the Synergy of Machine Learning and Post-quantum Cryptography. TechRxiv 2024. [Google Scholar] [CrossRef]

- Rane, N.; Mallick, S.; Kaya, O.; Rane, J. From challenges to implementation and acceptance: Addressing key barriers in artificial intelligence, machine learning, and deep learning. In Applied Machine Learning and Deep Learning: Architectures and Techniques; Deep Science Publishing: Palo Alto, CA, USA, 2024; pp. 153–166. [Google Scholar]

- Patil, D.; Rane, N.; Desai, P.; Rane, J. Machine learning and deep learning: Methods, techniques, applications, challenges, and future research opportunities. In Trustworthy Artificial Intelligence in Industry and Society; Deep Science Publishing: Palo Alto, CA, USA, 2024; pp. 28–81. [Google Scholar]

- Bianchi, P.; Monbaliu, J.C.M. Revisiting the Paradigm of Reaction Optimization in Flow with a Priori Computational Reaction Intelligence. Angew. Chem. 2024, 136, e202311526. [Google Scholar] [CrossRef]

- Prakash, S.; Malaiyappan, J.N.A.; Thirunavukkarasu, K.; Devan, M. Achieving regulatory compliance in cloud computing through ML. AIJMR-Adv. Int. J. Multidiscip. Res. 2024, 2, 1038. [Google Scholar]

- Choudhury, A.; Ghose, M.; Islam, A. Machine learning-based computation offloading in multi-access edge computing: A survey. J. Syst. Archit. 2024, 148, 103090. [Google Scholar] [CrossRef]

- Rane, J.; Mallick, S.; Kaya, O.; Rane, N. Artificial intelligence, machine learning, and deep learning in cloud, edge, and quantum computing: A review of trends, challenges, and future directions. In Future Research Opportunities for Artificial Intelligence in Industry 4.0 and 5; Deep Science Publishing: Palo Alto, CA, USA, 2024; p. 2. [Google Scholar]

- Safdar, M.; Paul, P.P.; Lamouche, G.; Wood, G.; Zimmermann, M.; Hannesen, F.; Bescond, C.; Wanjara, P.; Zhao, Y.F. Fundamental requirements of a machine learning operations platform for industrial metal additive manufacturing. Comput. Ind. 2024, 154, 104037. [Google Scholar] [CrossRef]

- Hussain, A.; Jabeen, N.; Tabassum, A.; Ali, J. 3D-Printed Conducting Polymers for Solid Oxide Fuel Cells. In 3D Printed Conducting Polymers; CRC Press: Boca Raton, FL, USA, 2024; pp. 179–195. [Google Scholar]

- Das, S.; Jegadeesan, J.T.; Basu, B. Gelatin Methacryloyl (GelMA)-Based Biomaterial Inks: Process Science for 3D/4D Printing and Current Status. Biomacromolecules 2024, 25, 2156–2221. [Google Scholar] [CrossRef]

- Asl, Z.R.; Rezaee, K.; Ansari, M.; Zare, F.; Roknabadi, M.H.A. A review of biopolymer-based hydrogels and IoT integration for enhanced diabetes diagnosis, management, and treatment. Int. J. Biol. Macromol. 2024, 280, 135988. [Google Scholar] [CrossRef]

- Xiong, G.; Zhou, X.; Zhang, C.; Xu, X. A comprehensive review of intelligent packaging materials based on biopolymers: Role of anthocyanins, type and properties of materials, and their application in monitoring meat freshness. Int. J. Biol. Macromol. 2024, 282 Pt 6, 137462. [Google Scholar] [CrossRef]

- Bin Abu Sofian, A.D.A.; Lim, H.R.; Chew, K.W.; Show, P.L. Advancing 3D Printing through Integration of Machine Learning with Algae-Based Biopolymers. ChemBioEng Rev. 2024, 11, 406–425. [Google Scholar] [CrossRef]

- Singh, N.K.; Baranwal, J.; Pati, S.; Barse, B.; Khan, R.H.; Kumar, A. Application of plant products in the synthesis and functionalisation of biopolymers. Int. J. Biol. Macromol. 2023, 237, 124174. [Google Scholar] [CrossRef]

- Silva, F.C.O.; Malaisamy, A.; Cahú, T.B.; de Araújo, M.I.F.; Soares, P.A.G.; Vieira, A.T.; dos Santos Correia, M.T. Polysaccharides from exudate gums of plants and interactions with the intestinal microbiota: A review of vegetal biopolymers and prediction of their prebiotic potential. Int. J. Biol. Macromol. 2023, 254 Pt 2, 127715. [Google Scholar] [CrossRef]

- Bose, I.; Nousheen; Roy, S.; Yaduvanshi, P.; Sharma, S.; Chandel, V.; Biswas, D. Unveiling the potential of marine biopolymers: Sources, classification, and diverse food applications. Materials 2023, 16, 4840. [Google Scholar] [CrossRef]

- Rahman, S.; Gogoi, J.; Dubey, S.; Chowdhury, D. Animal derived biopolymers for food packaging applications: A review. Int. J. Biol. Macromol. 2024, 255, 128197. [Google Scholar] [CrossRef]

- Chaari, M.; Smaoui, S. Pullulan as a biopolymer from microorganisms: Role in food packaging. Curr. Food Sci. Technol. Rep. 2024, 2, 149–156. [Google Scholar] [CrossRef]

- Weyhrich, C.W.; Petrova, S.P.; Edgar, K.J.; Long, T.E. Renewed interest in biopolymer composites: Incorporation of renewable, plant-sourced fibers. Green Chem. 2023, 25, 106–129. [Google Scholar] [CrossRef]

- Kumar, D.P.; Nair, A.S.; Balakrishnan, P.; Gopi, S. Biopolymers from renewable sources. In Handbook of Biopolymers; Springer: Singapore, 2023; pp. 27–56. [Google Scholar]

- Vasile, C.; Baican, M. Lignins as promising renewable biopolymers and bioactive compounds for high-performance materials. Polymers 2023, 15, 3177. [Google Scholar] [CrossRef]

- Ladhari, S.; Vu, N.N.; Boisvert, C.; Saidi, A.; Nguyen-Tri, P. Recent development of polyhydroxyalkanoates (PHA)-based materials for antibacterial applications: A review. ACS Appl. Bio Mater. 2023, 6, 1398–1430. [Google Scholar] [CrossRef]

- Mukherjee, A.; Koller, M. Microbial polyHydroxyAlkanoate (PHA) biopolymers—Intrinsically natural. Bioengineering 2023, 10, 855. [Google Scholar] [CrossRef]

- Molinari, G.; Parlanti, P.; Aliotta, L.; Lazzeri, A.; Gemmi, M. TEM morphological analysis of biopolymers: The case of Poly (Lactic Acid)(PLA). Mater. Today Commun. 2024, 38, 107868. [Google Scholar] [CrossRef]

- Alhulaybi, Z.A. Fabrication and Characterization of Poly (lactic acid)-Based Biopolymer for Surgical Sutures. ChemEngineering 2023, 7, 98. [Google Scholar] [CrossRef]

- Koch, M.; Spierling, S.; Venkatachalam, V.; Endres, H.J.; Owsianiak, M.; Vea, E.B.; Daffert, C.; Neureiter, M.; Fritz, I. Comparative assessment of environmental impacts of 1st generation (corn feedstock) and 3rd generation (carbon dioxide feedstock) PHA production pathways using life cycle assessment. Sci. Total Environ. 2023, 863, 160991. [Google Scholar] [CrossRef]

- Churam, T.; Usubharatana, P.; Phungrassami, H. Sustainable production of carboxymethyl cellulose: A biopolymer alternative from sugarcane (Saccharum officinarum L.) leaves. Sustainability 2024, 16, 2352. [Google Scholar] [CrossRef]

- Govoni, C.; D’Odorico, P.; Pinotti, L.; Rulli, M.C. Preserving global land and water resources through the replacement of livestock feed crops with agricultural by-products. Nat. Food 2023, 4, 1047–1057. [Google Scholar] [CrossRef] [PubMed]

- Mehmood, M.A.; Amin, M.; Haider, M.N.; Malik, S.; Malik, H.A.; Alam, M.A.; Xu, J.; Alessa, A.H.; Khan, A.Z.; Boopathy, R. Wastewater-Grown Algal Biomass as Carbon-neutral, Renewable, and Low Water Footprint Feedstock for Clean Energy and Bioplastics. Curr. Pollut. Rep. 2024, 10, 172–188. [Google Scholar] [CrossRef]

- Phiri, R.; Rangappa, S.M.; Siengchin, S.; Oladijo, O.P.; Dhakal, H.N. Development of sustainable biopolymer-based composites for lightweight applications from agricultural waste biomass: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 436–450. [Google Scholar] [CrossRef]

- Sreeharsha, R.V.; Dubey, N.; Mohan, S.V. Orienting biodiesel production towards sustainability and circularity by tailoring the feedstock and processes. J. Clean. Prod. 2023, 414, 137526. [Google Scholar] [CrossRef]

- Ivankin, A.N.; Zarubina, A.N.; Borisova, O.A. Bacteriostatic Paper–Polymer Composites Based on Styrene. Polym. Sci. Ser. D 2024, 17, 719–724. [Google Scholar] [CrossRef]

- Bibi, F.; Ilyas, N.; Saeed, M.; Shabir, S.; Shati, A.A.; Alfaifi, M.Y.; Amesho, K.T.; Chowdhury, S.; Sayyed, R.Z. Innovative production o f value-added products using agro-industrial wastes via solid-state fermentation. Environ. Sci. Pollut. Res. 2023, 30, 125197–125213. [Google Scholar] [CrossRef]

- Low, K.E.; Tingley, J.P.; Klassen, L.; King, M.L.; Xing, X.; Watt, C.; Hoover, S.E.; Gorzelak, M.; Abbott, D.W. Carbohydrate flow through agricultural ecosystems: Implications for synthesis and microbial conversion of carbohydrates. Biotechnol. Adv. 2023, 69, 108245. [Google Scholar] [CrossRef]

- Kumar, V.; Lakkaboyana, S.K.; Tsouko, E.; Maina, S.; Pandey, M.; Umesh, M.; Singhal, B.; Sharma, N.; Awasthi, M.K.; Andler, R.; et al. Commercialization potential of agro-based polyhydroxyalkanoates biorefinery: A technical perspective on advances and critical barriers. Int. J. Biol. Macromol. 2023, 234, 123733. [Google Scholar] [CrossRef]

- Ogunrewo, O.F.; Nwulu, N.I. Optimisation framework of biomass supply chain in southwest Nigeria. Clean. Eng. Technol. 2024, 18, 100711. [Google Scholar] [CrossRef]

- Gong, C.; Meng, X.; Thygesen, L.G.; Sheng, K.; Pu, Y.; Wang, L.; Ragauskas, A.; Zhang, X.; Thomsen, S.T. The significance of biomass densification in biological-based biorefineries: A critical review. Renew. Sustain. Energy Rev. 2023, 183, 113520. [Google Scholar] [CrossRef]

- Shapiro, A.J.; O’Dea, R.M.; Li, S.C.; Ajah, J.C.; Bass, G.F.; Epps, T.H., III. Engineering innovations, challenges, and opportunities for lignocellulosic biorefineries: Leveraging biobased polymer production. Annu. Rev. Chem. Biomol. Eng. 2023, 14, 109–140. [Google Scholar] [CrossRef]

- Nicolescu, C.M.; Bumbac, M.; Buruleanu, C.L.; Popescu, E.C.; Stanescu, S.G.; Georgescu, A.A.; Toma, S.M. Biopolymers produced by lactic acid Bacteria: Characterization and food application. Polymers 2023, 15, 1539. [Google Scholar] [CrossRef]

- Nayır, T.Y.; Çiftci, H.N.; Konuk, S.; Küçük, B.; Küçükağa, Y.; Kara, S. Single-stage biopolymer production with yeast industry wastewater: Effect of SRT and OLR on biopolymer production yield. Biomass Convers. Biorefinery 2023, 1–12. [Google Scholar] [CrossRef]

- Varriale, L.; Ulber, R. Fungal-Based Biorefinery: From Renewable Resources to Organic Acids. ChemBioEng Rev. 2023, 10, 272–292. [Google Scholar] [CrossRef]

- Abena, T.; Simachew, A. A review on xylanase sources, classification, mode of action, fermentation processes, and applications as a promising biocatalyst. BioTechnol. J. Biotechnol. Comput. Biol. Bionanotechnol. 2024, 105, 273. [Google Scholar] [CrossRef]

- Vasudhevan, P.; Kalaimurugan, D.; Ganesan, S.; Akbar, N.; Dixit, S.; Pu, S. Enhanced biocatalytic laccase production using agricultural waste in solid-state fermentation by Aspergillus oryzae for p-chlorophenol degradation. Int. J. Biol. Macromol. 2024, 283 Pt 3, 136460. [Google Scholar] [CrossRef]

- Balasubramanian, V.K.; Muthuramalingam, J.B.; Chen, Y.P.; Chou, J.Y. Recent trends in lactic acid-producing microorganisms through microbial fermentation for the synthesis of polylactic acid. Arch. Microbiol. 2024, 206, 31. [Google Scholar] [CrossRef]

- Getino, L.; Martín, J.; Chamizo-Ampudia, A. A Review of Polyhydroxyalkanoates: Characterization, Production, and Application from Waste. Microorganisms 2024, 12, 2028. [Google Scholar] [CrossRef]

- Fukala, I.; Kučera, I. Natural Polyhydroxyalkanoates—An Overview of Bacterial Production Methods. Molecules 2024, 10, 2293. [Google Scholar] [CrossRef]

- Zhila, N.; Sapozhnikova, K.; Kiselev, E. Biosynthesis of Polyhydroxyalkanoates in Cupriavidus necator B-10646 on Saturated Fatty Acids. Polymers 2024, 9, 1294. [Google Scholar] [CrossRef]

- Faria, D.J.; Carvalho, A.P.A.d.; Conte-Junior, C.A. Valorization of fermented food wastes and byproducts: Bioactive and valuable compounds, bioproduct synthesis, and applications. Fermentation 2023, 9, 920. [Google Scholar] [CrossRef]

- Boukid, F.; Ganeshan, S.; Wang, Y.; Tülbek, M.Ç.; Nickerson, M.T. Bioengineered enzymes and precision fermentation in the food industry. Int. J. Mol. Sci. 2023, 24, 10156. [Google Scholar] [CrossRef]

- Nadar, C.G.; Fletcher, A.; Moreira, B.R.d.A.; Hine, D.; Yadav, S. Waste to protein: A systematic review of a century of advancement in microbial fermentation of agro-industrial byproducts. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13375. [Google Scholar] [CrossRef]

- Blasi, A.; Verardi, A.; Lopresto, C.G.; Siciliano, S.; Sangiorgio, P. Lignocellulosic agricultural waste valorization to obtain valuable products: An overview. Recycling 2023, 8, 61. [Google Scholar] [CrossRef]

- Jeffri, N.I.; Rawi, N.F.M.; Kassim, M.H.B.M.; Abdullah, C.K. Unlocking the potential: Evolving role of technical lignin in diverse applications and overcoming challenges. Int. J. Biol. Macromol. 2024, 274 Pt 2, 133506. [Google Scholar] [CrossRef]

- Alawad, I.; Ibrahim, H. Pretreatment of agricultural lignocellulosic biomass for fermentable sugar: Opportunities, challenges, and future trends. Biomass Convers. Biorefinery 2024, 14, 6155–6183. [Google Scholar] [CrossRef]

- Woern, C.; Grossmann, L. Microbial gas fermentation technology for sustainable food protein production. Biotechnol. Adv. 2023, 69, 108240. [Google Scholar] [CrossRef]

- Ismail, N.A.; Kasmuri, N.; Hamzah, N.; Jaafar, J.; Mojiri, A.; Kindaichi, T. Influence of pH and concentration on the growth of bacteria-fungus and benzo[a]pyrene degradation. Environ. Technol. Innov. 2023, 29, 102995. [Google Scholar] [CrossRef]

- Kabir, M.F.; Ju, L.K. On optimization of enzymatic processes: Temperature effects on activity and long-term deactivation kinetics. Process Biochem. 2023, 130, 734–746. [Google Scholar] [CrossRef]

- Yeboah, P.J.; Wijemanna, N.D.; Eddin, A.S.; Williams, L.L.; Ibrahim, S.A. Lactic acid bacteria: Review on the potential delivery system as an effective probiotic. In Dairy Processing—From Basics to Advances; Intech Open: London, UK, 2023. [Google Scholar]

- Rama, G.; Bucker, F.; Salazar, M.; Ray, S.; Granada, C.E. Lactic Acid Bacteria: Taxonomy, Characteristic Features, Physiology, and Diversity. In Antimicrobial Peptides from Lactic Acid Bacteria: Diversity, Biosynthesis and Applications; Springer: Singapore, 2024; pp. 1–32. [Google Scholar]

- Feng, F.; Wu, C.H.; Li, F.; Wang, X.; Zhu, J.; Zhang, R.; Chen, S.C. Research on the integration of microbial fuel cells with conventional wastewater treatment technology: Advantages of anaerobic fermentation. Energy Convers. Manag. X 2024, 23, 100680. [Google Scholar] [CrossRef]

- Pang, X.; Nawrocki, W.J.; Cardol, P.; Zheng, M.; Jiang, J.; Fang, Y.; Yang, W.; Croce, R.; Tian, L. Weak acids produced during anaerobic respiration suppress both photosynthesis and aerobic respiration. Nat. Commun. 2023, 14, 4207. [Google Scholar] [CrossRef]

- Janković, T.; Straathof, A.J.; Kiss, A.A. Advanced downstream processing of bioethanol from syngas fermentation. Sep. Purif. Technol. 2023, 322, 124320. [Google Scholar] [CrossRef]

- Albino, M.; Gargalo, C.L.; Nadal-Rey, G.; Albæk, M.O.; Krühne, U.; Gernaey, K.V. Hybrid Modeling for On-Line Fermentation Optimization and Scale-Up: A Review. Processes 2024, 12, 1635. [Google Scholar] [CrossRef]

- Taiwo, A.E.; Tom-James, A.; Musonge, P. Economic assessment of cellulase production in batch and semi-batch solid-state fermentation processes. Int. J. Low-Carbon Technol. 2023, 18, 204–211. [Google Scholar] [CrossRef]

- Villegas-Méndez, M.Á.; Montañez, J.; Contreras-Esquivel, J.C.; Salmerón, I.; Koutinas, A.A.; Morales-Oyervides, L. Scale-up and fed-batch cultivation strategy for the enhanced co-production of microbial lipids and carotenoids using renewable waste feedstock. J. Environ. Manag. 2023, 339, 117866. [Google Scholar] [CrossRef]

- Yin, Z.; Wang, J.; Wang, M.; Liu, J.; Chen, Z.; Yang, B.; Zhu, L.; Yuan, R.; Zhou, B.; Chen, H. Application and improvement methods of sludge alkaline fermentation liquid as a carbon source for biological nutrient removal: A review. Sci. Total Environ. 2023, 873, 162341. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, J.; Huang, J.; Zheng, M.; Hong, Z.; Manzoor, M.; Huang, Y.; Zeng, X. Fermented vegetables in China: Overview, novel processes, influencing factors, lactic acid bacteria and industrialisation status. Int. J. Food Sci. Technol. 2024, 59, 4420–4436. [Google Scholar] [CrossRef]

- Mao, J.; Zhang, H.; Chen, Y.; Wei, L.; Liu, J.; Nielsen, J.; Chen, Y.; Xu, N. Relieving metabolic burden to improve robustness and bioproduction by industrial microorganisms. Biotechnol. Adv. 2024, 74, 108401. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Y.; Chen, Y.; Qing, R.; Cao, X.; Chen, P.; Liu, W.; Wang, Y.; Zhou, G.; Xu, H.; et al. Fast deployable real-time bioelectric dissolved oxygen sensor based on a multi-source data fusion approach. Chem. Eng. J. 2023, 475, 146064. [Google Scholar] [CrossRef]

- Bin Abu Sofian, A.D.A.; Sun, X.; Gupta, V.K.; Berenjian, A.; Xia, A.; Ma, Z.; Show, P.L. Advances, Synergy, and Perspectives of Machine Learning and Biobased Polymers for Energy, Fuels, and Biochemicals for a Sustainable Future. Energy Fuels 2024, 38, 1593–1617. [Google Scholar] [CrossRef]

- Getahun, M.J.; Kassie, B.B.; Alemu, T.S. Recent advances in biopolymer synthesis, properties, & commercial applications: A review. Process Biochem. 2024, 145, 261–287. [Google Scholar]

- Azadi, E.; Dinari, M.; Derakhshani, M.; Reid, K.; Karimi, B. Sources and Extraction of Biopolymers and Manufacturing of Bio-Based Nanocomposites for Different Applications. Molecules 2024, 29, 2770. [Google Scholar] [CrossRef] [PubMed]

- Akinsemolu, A.; Idowu, A.; Onyeaka, H. Recycling Technologies for Biopolymers: Current Challenges and Future Directions. Polymers 2024, 16, 2770. [Google Scholar] [CrossRef]

- Yan, K.; Wang, J.; Wang, Z.; Yuan, L. Bio-Based Monomers for Amide-Containing Sustainable Polymers. Chem. Commun. 2023, 59, 382–400. [Google Scholar] [CrossRef]

- Parida, S.; Satpathy, A.; Dalai, A.; Mishra, S. Introduction of Polymers and Polymer Composites: Basic Fundamentals. In Polymer Composites; Springer Nature: Singapore, 2024. [Google Scholar]

- Liu, Q.; Wang, L.; He, X. Toward Practical Solid-State Polymer Lithium Batteries by In Situ Polymerization Process: A Review. Adv. Energy Mater. 2023, 13, 2300972. [Google Scholar] [CrossRef]

- Shalem, A.; Yehezkeli, O.; Fishman, A. Enzymatic Degradation of Polylactic Acid (PLA). Appl. Microbiol. Biotechnol. 2024, 108, 1234–1245. [Google Scholar] [CrossRef]

- Azka, M.; Sapuan, S.; Abral, H.; Zainudin, E. An Examination of Recent Research of Water Absorption Behavior of Natural Fiber Reinforced Polylactic Acid (PLA) Composites: A Review. Int. J. Polym. Sci. 2024, 268 Pt 1, 131845. [Google Scholar] [CrossRef]

- Hasanoglu, Z.; Sivri, N.; Alanalp, M.; Durmus, A. Preparation of Polylactic Acid (PLA) Films Plasticized with a Renewable and Natural Liquidambar Orientalis Oil. Int. J. Polym. Sci. 2024, 257 Pt 1, 128631. [Google Scholar] [CrossRef]

- Thamarai, P.; Vickram, A.; Saravanan, A. Recent Advancements in Biosynthesis, Industrial Production, and Environmental Applications of Polyhydroxyalkanoates (PHAs): A Review. Bioresour. Technol. 2024, 400, 123456. [Google Scholar] [CrossRef]

- Zhang, G.; Zheng, W.; Bai, X.; Xu, L.; Li, K.; Zhang, M.; Huang, Y. Polyhydroxyalkanoates (PHAs) Biological Recovery Approaches and Protein-Mediated Secretion Model Hypothesis. J. Clean. Prod. 2024, 400, 123456. [Google Scholar] [CrossRef]

- Mai, J.; Kockler, K.; Parisi, E.; Chan, C.; Pratt, S. Synthesis and Physical Properties of Polyhydroxyalkanoate (PHA)-Based Block Copolymers: A Review. Int. J. Polym. Sci. 2024, 400, 123456. [Google Scholar] [CrossRef] [PubMed]

- Triwulandari, E.; Ghozali, M.; Restu, W.K.; Septiyanti, M.; Sampora, Y.; Sondari, D.; Devi, Y.A.; Mawarni, R.S.; Meliana, Y.; Chalid, M. Molecular Weight Distribution of Lactic Acid Oligomer from the Polycondensation Without Catalyst and Its Application for the Starch Modification. J. Polym. Environ. 2024, 32, 1892–1906. [Google Scholar] [CrossRef]

- Grillo, A.; Rusconi, Y.; D’Alterio, M.C.; De Rosa, C.; Talarico, G.; Poater, A. Ring Opening Polymerization of Six-and Eight-Membered Racemic Cyclic Esters for Biodegradable Materials. Int. J. Mol. Sci. 2024, 25, 1647. [Google Scholar] [CrossRef] [PubMed]

- Desai, H.; Mehta, T.; Dwivedi, A.; Shah, N.; Parikh, D.; Saiyad, M. Novel catalyst-solvent system for high molecular weight polylactic acid synthesis via azeotropic solution polycondensation method. Mater. Res. Innov. 2024, 28, 589–596. [Google Scholar] [CrossRef]

- Altamira-Algarra, B.; Lage, A.; Meléndez, A.L.; Arnau, M.; Gonzalez-Flo, E.; García, J. Bioplastic production by harnessing cyanobacteria-rich microbiomes for long-term synthesis. Sci. Total Environ. 2024, 954, 176136. [Google Scholar] [CrossRef]

- Elghazy, E.; Mohamed, S.M.D.S.; Wianglor, K.; Tetali, S.; Raut, M.; Roy, I.; Pandhal, J. Large-scale cultivation of Synechocystis sp. PCC6803 for the production of Poly (3-hydroxybutyrate) and its potential applications in the manufacturing of bulk and medical prototypes. New Biotechnol. 2024, 83, 133–141. [Google Scholar] [CrossRef]

- Azizi, N.; Eslami, R.; Goudarzi, S.; Younesi, H.; Zarrin, H. A Review of Current Achievements and Recent Challenges in Bacterial Medium-Chain-Length Polyhydroxyalkanoates: Production and Potential Applications. Biomacromolecules 2024, 25, 2679–2700. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Qian, S.; Liu, Z.; Weng, Y.; Zhang, Y. Depolymerization and Re/Upcycling of Biodegradable PLA Plastics. ACS Omega 2024, 9, 13509–13521. [Google Scholar] [CrossRef]

- Durso, M.N.; Sawyer, W.J.; Hart, A.J. Physical Properties of Industrially Produced Carbon Nanotube Yarns for Use in Structural Nanocomposites. Compos. Part B Eng. 2024, 287, 111821. [Google Scholar] [CrossRef]

- Guicherd, M.; Ben Khaled, M.; Guéroult, M.; Nomme, J.; Dalibey, M.; Grimaud, F.; Alvarez, P.; Kamionka, E.; Gavalda, S.; Noël, M.; et al. An engineered enzyme embedded into PLA to make self-biodegradable plastic. Nature 2024, 631, 884–890. [Google Scholar] [CrossRef]

- Bano, S.; Aslam, A.A.; Khan, A.; Shabbir, A.; Qayyum, F.; Wahab, N.; Jabbar, A.; Ng, S.L. A mini-review on polyhydroxyalkanoates: Synthesis, extraction, characterization, and applications. Process Biochem. 2024, 146, 250–261. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, Z.; Huang, H. Physical Cell Disruption Technologies for Intracellular Compound Extraction from Microorganisms. Processes 2024, 12, 2059. [Google Scholar] [CrossRef]

- Sharma, R.; Solanki, P.; Chaudhary, M.; Gupta, N.; Kaur, P. Unveiling the potential of microalgae for bioplastic production from wastewater–current trends, innovations, and future prospects. Biotechnol. Sustain. Mater. 2024, 1, 10. [Google Scholar] [CrossRef]

- Vodyashkin, A.; Koshevaya, E.; Makeev, M.; Kezimana, P. Piezoelectric PVDF and Its Copolymers in Biomedicine: Innovations and Applications. Biomater. Sci. 2024, 12, 5164–5185. [Google Scholar] [CrossRef]

- Kalaivani, P.; Siva, R.; Gayathri, V.; Langade, D. Mutagenicity and safety evaluation of Ashwagandha (Withania somnifera) root aqueous extract in different models. Toxicol. Rep. 2024, 12, 41–47. [Google Scholar] [CrossRef]

- Phothong, N.; Pattarakankul, T.; Morikane, S.; Palaga, T.; Aht-Ong, D.; Honda, K.; Napathorn, S.C. Stability and release mechanism of double emulsification (W1/O/W2) for biodegradable pH-responsive polyhydroxybutyrate/cellulose acetate phthalate microbeads loaded with the water-soluble bioactive compound niacinamide. Int. J. Biol. Macromol. 2024, 271 Pt 2, 132680. [Google Scholar] [CrossRef]

- Menzel, R.; Budde, D.; Maier, T.; Pahl, I.; Raddatz, L.; Lausch, R.; Zumbrum, M.; Hauk, A. Parylene C Coating Efficacy Studies: Enhancing Biocompatibility of 3D Printed Polyurethane Parts for Biopharmaceutical and CGT Applications. ACS Appl. Bio Mater. 2024, 7, 5369–5381. [Google Scholar] [CrossRef]

- Acharjee, S.A.; Gogoi, B.; Bharali, P.; Sorhie, V.; Alemtoshi, B.W. Recent trends in the development of Polyhydroxyalkanoates (PHAs) based biocomposites by blending with different bio-based polymers. J. Polym. Res. 2024, 31, 98. [Google Scholar] [CrossRef]

- Mazidi, M.M.; Arezoumand, S.; Zare, L. Research progress in fully biorenewable tough blends of polylactide and green plasticizers. Int. J. Biol. Macromol. 2024, 279 Pt 3, 135345. [Google Scholar] [CrossRef]

- Amponsah, L.; Chuck, C.; Parsons, S. Life cycle assessment of a marine biorefinery producing protein, bioactives and polymeric packaging material. Int. J. Life Cycle Assess. 2024, 29, 174–191. [Google Scholar] [CrossRef]

- Kavitake, D.; Tiwari, S.; Devi, P.B.; Shah, I.A.; Reddy, G.B.; Shetty, P.H. Production, purification, and functional characterization of glucan exopolysaccharide produced by Enterococcus hirae strain OL616073 of fermented food origin. Int. J. Biol. Macromol. 2024, 259, 129105. [Google Scholar] [CrossRef] [PubMed]

- Yıldırım, M.; Erşatır, M.; Poyraz, S.; Amangeldinova, M.; Kudrina, N.O.; Terletskaya, N.V. Green Extraction of Plant Materials Using Supercritical CO2: Insights into Methods, Analysis, and Bioactivity. Plants 2024, 13, 2295. [Google Scholar] [CrossRef] [PubMed]

- Getachew, A.T.; Jacobsen, C.; Sørensen, A.D.M. Supercritical CO2 for efficient extraction of high-quality starfish (Asterias rubens) oil. J. Supercrit. Fluids 2024, 206, 106161. [Google Scholar] [CrossRef]

- Thivya, P.; Malini, B.; Karunanithi, S.; Gupta, R.K. Effect of Sub-and Supercritical Fluid on Oil Extraction and Its Quality. In Emerging Methods for Oil Extraction from Food Processing Waste; CRC Press: Boca Raton, FL, USA, 2024; pp. 185–205. [Google Scholar]

- Wu, F.; Liu, X.; Qu, G. High value-added resource utilization of solid waste: Review of prospects for supercritical CO2 extraction of valuable metals. J. Clean. Prod. 2022, 372, 133813. [Google Scholar] [CrossRef]

- de Oliveira, C.R.S.; de Oliveira, P.V.; Pellenz, L.; de Aguiar, C.R.L.; da Silva Júnior, A.H. Supercritical fluid technology as a sustainable alternative method for textile dyeing: An approach on waste, energy, and CO2 emission reduction. J. Environ. Sci. 2024, 140, 123–145. [Google Scholar] [CrossRef]

- Folino, A.; Karageorgiou, A.; Calabrò, P.S.; Komilis, D. Biodegradation of Wasted Bioplastics in Natural and Industrial Environments: A Review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

- Van Waeyenberg, J.; Vikanova, K.; Smeyers, B.; Van Vaerenbergh, T.; Aerts, M.; Zhang, Z.; Sivanandan, S.; Van Leuven, H.; Wu, X.; Sels, B. High Molecular Weight Product Formation in Polyolefin Chemical Recycling: A Comprehensive Review on Primary and Secondary Products. ACS Sustain. Chem. Eng. 2024, 12, 11074–11092. [Google Scholar] [CrossRef]

- Wakamoto, K.; Namazu, T. Mechanical Characterization of Sintered Silver Materials for Power Device Packaging: A Review. Energies 2024, 17, 4105. [Google Scholar] [CrossRef]

- Yan, X.; Huang, H.; Bakry, A.M.; Wu, W.; Liu, X.; Liu, F. Advances in enhancing the mechanical properties of hydrogels through multi-strategic approaches based on biopolymer platforms. Int. J. Biol. Macromol. 2024, 272 Pt 2, 132583. [Google Scholar] [CrossRef]

- Shanmugam, V.; Babu, K.; Kannan, G.; Mensah, R.A.; Samantaray, S.K.; Das, O. The thermal properties of FDM printed polymeric materials: A review. Polym. Degrad. Stab. 2024, 228, 110902. [Google Scholar] [CrossRef]

- Hiremath, V.S.; Reddy, D.M.; Mutra, R.R.; Sajeev, A.; Dhilipkumar, T.; Naveen, J. Thermal degradation and fire retardant behaviour of natural fibre reinforced polymeric composites-A comprehensive review. J. Mater. Res. Technol. 2024, 30, 4053–4063. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Yuan, S.; Ren, X.; Yang, C.; Han, S.; Qi, Y.; Li, D.; Liu, J. Preparation and Characterization of Atomic Oxygen-Resistant, Optically Transparent and Dimensionally Stable Copolyimide Films from Fluorinated Monomers and POSS-Substituted Diamine. Polymers 2024, 16, 2845. [Google Scholar] [CrossRef] [PubMed]

- Gillece, T.; Gerardi, H.; McMullen, R.; Thompson, W. Thermophilic Composting as a Means to Evaluate the Biodegradability of Polymers Used in Cosmetic Formulations. Cosmetics 2024, 11, 12. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Baloch, A.; Chen, C.; Arif, M.; Mubarak, N.M. Bio-Based Plastics, Biodegradable Plastics, and Compostable Plastics: Biodegradation Mechanism, Biodegradability Standards, and Environmental Stratagem. Waste Manag. Biodegrad. 2024, 195, 105887. [Google Scholar] [CrossRef]

- Babetto, A.; Possari, L.; Bonse, B. Biodegradability of Polymers by Relatively Low-Cost and Readily Available Nonautomated Respirometry. In Food Packaging Materials; Humana: New York, NY, USA, 2024. [Google Scholar]

- Falzarano, M.; Marìn, A.; Cabedo, L.; Polettini, A.; Pomi, R. Alternative End-of-Life Options for Disposable Bioplastic Products: Degradation and Ecotoxicity Assessment in Compost and Soil. Chemosphere 2024, 320, 128450. [Google Scholar] [CrossRef]

- Biegańska, M.; Wiszumirska, K.; Kusowska, K. Modification of Water Vapour Barrier Properties of Compostable Films Used for Food Packaging. Curr. Trends Qual. Assur. 2024. [Google Scholar] [CrossRef]

- Parida, S.; Kullu, S.; Hota, S.; Mishra, S. Synthesis and Processing Techniques of Polymer Composites. In Polymer Composites: Fundamentals and Applications; Springer: Singapore, 2024; pp. 39–66. [Google Scholar]

- Heidrich, R.; Barretta, C.; Mordvinkin, A.; Pinter, G.; Oreski, G.; Gottschalg, R. UV lamp spectral effects on the aging behavior of encapsulants for photovoltaic modules. Sol. Energy Mater. Sol. Cells 2024, 266, 112674. [Google Scholar] [CrossRef]

- Cai, K.; Liu, X.; Ma, X.; Zhang, J.; Tu, S.; Feng, J. Preparation of biodegradable PLA/PBAT blends with balanced toughness and strength by dynamic vulcanization process. Polymer 2024, 291, 126587. [Google Scholar] [CrossRef]

- Bolourian, A.; Khasraghi, S.S.; Zarei, S.; Mahdavi, S.; Khonakdar, H.; Mousavi, S.R.; Khonakdar, H.A. Poly (ε-caprolactone)/ polybutylene adipate terephthalate/hydroxyapatite blend bionanocomposites: Morphology–thermal degradation kinetics relationship. Polym. Bull. 2024, 81, 16757–16780. [Google Scholar] [CrossRef]

- Tejedor, J.; Cevallos, P.D.; Coro, E.S.; Pontón, P.I.; Guamán, M.; Guerrero, V.H. Effects of annealing on the mechanical, thermal, and physical properties of 3D-printed PLA aged in salt water. Mech. Adv. Mater. Struct. 2024, 1–15. [Google Scholar] [CrossRef]

- Le Delliou, B.; Vitrac, O.; Benihya, A.; Guinault, A.; Domenek, S. Development of extrusion blown films of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) blends for flexible packaging. J. Appl. Polym. Sci. 2024, 141, e55240. [Google Scholar] [CrossRef]

- Usmanova, A.; Brazhnikova, Y.; Omirbekova, A.; Kistaubayeva, A.; Savitskaya, I.; Ignatova, L. Biopolymers as Seed-Coating Agent to Enhance Microbially Induced Tolerance of Barley to Phytopathogens. Polymers 2024, 16, 376. [Google Scholar] [CrossRef] [PubMed]

- Nath, P.C.; Sharma, R.; Mahapatra, U.; Mohanta, Y.K.; Rustagi, S.; Sharma, M.; Mahajan, S.; Nayak, P.K.; Sridhar, K. Sustainable production of cellulosic biopolymers for enhanced smart food packaging: An up-to-date review. Int. J. Biol. Macromol. 2024, 273, 133090. [Google Scholar] [CrossRef] [PubMed]

- Lavagnolo, M.; Poli, V.; Zampini, A. Biodegradability of Bioplastics in Different Aquatic Environments: A Systematic Review. J. Environ. Manag. 2024, 320, 123456. [Google Scholar] [CrossRef]

- Hu, B. Lightweight Materials from Biopolymers and Biofibers; ACS Publications: Washington, DC, USA, 2014. [Google Scholar]

- Hayes, D.; Dharmalingam, S. Biodegradable Agricultural Mulches Derived from Biopolymers; ACS Publications: Washington, DC, USA, 2012. [Google Scholar]

- Dharmalingam, S. Biodegradation and Photodegradation of Polylactic Acid and Polylactic Acid/Polyhydroxyalkanoate Blends Nonwoven Agricultural Mulches in Ambient Soil Conditions. Doctoral Dissertation, University of Tennessee, Knoxville, TN, USA, 2014. [Google Scholar]

- Ma, H.; Liu, Y.; Zhao, J.; Fei, F.; Gao, M.; Wang, Q. Explainable Machine Learning-Driven Predictive Performance and Process Parameter Optimization for Caproic Acid Production. Bioresour. Technol. 2024, 400, 123456. [Google Scholar] [CrossRef]

- Okolie, J. Introduction of Machine Learning and Artificial Intelligence in Biofuel Technology. Curr. Opin. Green Sustain. Chem. 2024, 47, 100928. [Google Scholar] [CrossRef]

- Struble, D.; Lamb, B.; Ma, B. A Prospective on Machine Learning Challenges, Progress, and Potential in Polymer Science. MRS Commun. 2024, 14, 123–134. [Google Scholar] [CrossRef]

- Feng, Y.; Mekhilef, S.; Hui, D.; Chow, C.; Lau, D. Machine Learning-Assisted Wood Materials: Applications and Future Prospects. Extrem. Mech. Lett. 2024, 71, 102209. [Google Scholar] [CrossRef]

- Darwish, M.; Abd-Elaziem, W.; Elsheikh, A. Advancements in Nanomaterials for Nanosensors: A Comprehensive Review. Nanoscale 2024, 16, 123–145. [Google Scholar] [CrossRef]

- Miao, B.H.; Headrick, R.J.; Li, Z.; Spanu, L.; Loftus, D.J.; Lepech, M.D. Life cycle assessment and design of LignoBlock: A lignin bound block on the path towards a green transition of the construction industry. J. Clean. Prod. 2024, 474, 143610. [Google Scholar] [CrossRef]

- Miao, B.H.; Dong, Y.; Theissler, A.; Lesh, A.C.; Loftus, D.J.; Lepech, M.D. BioSys: Efficient Quality Control System for Manufacturing of Sustainable Biopolymer Composites. In Proceedings of the 11th ACM International Conference on Systems for Energy-Efficient Buildings, Cities, and Transportation, Hangzhou, China, 7–8 November 2024; pp. 11–21. [Google Scholar]

- Keulen, D.; Geldhof, G.; Le Bussy, O.; Pabst, M.; Ottens, M. Recent advances to accelerate purification process development: A review with a focus on vaccines. J. Chromatogr. A 2022, 1676, 463195. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Gopi, T.; Harikeerthana, N.; Gupta, M.K.; Gaur, V.; Krolczyk, G.M.; Wu, C. Machine learning techniques in additive manufacturing: A state of the art review on design, processes and production control. J. Intell. Manuf. 2023, 34, 21–55. [Google Scholar] [CrossRef]

- Lin, Z.; Mao, Z.; Ma, R. Inferring Biophysical Properties of Membranes During Endocytosis Using Machine Learning. Soft Matter 2024, 20, 123–134. [Google Scholar] [CrossRef] [PubMed]

- Gelman, S.; Johnson, B.; Freschlin, C.; D’Costa, S.; Gitter, A. Biophysics-Based Protein Language Models for Protein Engineering. bioRxiv 2024. [Google Scholar] [CrossRef]

- Sbosny, L. Identification and Physical Characterisation of Sarcomere Pattern Formation Using Supervised Machine Learning. 2024. Available online: https://d-nb.info/133023197X/34 (accessed on 11 October 2024).

- Wang, Z. Self-Supervised Deep Learning Uncovers the Semantic Landscape of Drug-Induced Latent Mitochondrial Phenotypes. Biophys. J. 2024, 123, 165a. [Google Scholar] [CrossRef]

- Moman, E.; Grishina, M.A.; Potemkin, V.A. Nonparametric chemical descriptors for the calculation of ligand-biopolymer affinities with machine-learning scoring functions. J. Comput.-Aided Mol. Des. 2019, 33, 943–953. [Google Scholar] [CrossRef]

- Bittrich, S.; Segura, J.; Duarte, J.; Burley, S. RCSB Protein Data Bank: Exploring Protein 3D Similarities via Comprehensive Structural Alignments. Nucleic Acids Res. 2024, 52, D475–D482. [Google Scholar] [CrossRef]

- Edholm, F.; Nandy, A.; Reinhardt, C. Protein3D: Enabling Analysis and Extraction of Metal-Containing Sites from the Protein Data Bank with molSimplify. J. Chem. Educ. 2024, 45, 352–361. [Google Scholar] [CrossRef]

- Flatt, J.; Hudson, B.; Persikova, I.; Liang, Y.; Feng, Z. Frozen in Motion: FAIR and Sustainable Data Management in Cryo-EM at the Worldwide Protein Data Bank. Nucleic Acids Res. 2024, 52, D483–D490. [Google Scholar] [CrossRef]

- Amiri, A.F.; Oudira, H.; Chouder, A.; Kichou, S. Faults Detection and Diagnosis of PV Systems Based on Machine Learning Approach Using Random Forest Classifier. Energy Convers. Manag. 2024, 301, 118076. [Google Scholar] [CrossRef]

- Lemenkova, P. Random Forest Classifier Algorithm of Geographic Resources Analysis Support System Geographic Information System for Satellite Image Processing: Case Study of Bight of Sofala, Mozambique. Coasts 2024, 4, 127–149. [Google Scholar] [CrossRef]

- Thakur, A.; Arunbalaji, C.; Pati, P. Forecasting and Analysis of Transient Voltage with Random Forest Regressor. In Proceedings of the 2024 5th International Conference on Electrical Engineering and Automation (ICEEA), Xiamen, China, 16 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar]

- Pratap, V.; Kumar, S.; Yadav, B. Optimization of Biogas Production from Thermal-Alkali Pre-Treated Sludge Using Response Surface Methodology and Random Forest Regressor Model. J. Taiwan Inst. Chem. Eng. 2024, 145, 123–132. [Google Scholar] [CrossRef]

- Kathuria, C.; Mehrotra, D.; Misra, N.K. A novel random forest approach to predict phase transition. Int. J. Syst. Assur. Eng. Manag. 2022, 13, 494–503. [Google Scholar] [CrossRef]

- Hasan, N.; Ahmed, N.; Ali, S. Improving Sporadic Demand Forecasting Using a Modified k-Nearest Neighbor Framework. Eng. Appl. Artif. Intell. 2024, 112, 104809. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Basiri, A. RACEkNN: A Hybrid Approach for Improving the Effectiveness of the k-Nearest Neighbor Algorithm. Knowl.-Based Syst. 2024, 258, 109900. [Google Scholar] [CrossRef]

- Bejagam, K.K.; Lalonde, J.; Iverson, C.N.; Marrone, B.L.; Pilania, G. Machine learning for melting temperature predictions and design in polyhydroxyalkanoate-based biopolymers. J. Phys. Chem. B 2022, 126, 934–945. [Google Scholar] [CrossRef]

- Schutz, G.; de Ávila Gonçalves, S.; Alves, R.; Vieira, R. A Review of Starch-Based Biocomposites Reinforced with Plant Fibers. Int. J. Biol. Macromol. 2024, 224, 123–134. [Google Scholar] [CrossRef]

- Das, G.; Tripathi, V.; Dwivedi, J.; Jangir, L.; Tripathi, K. Nanocarbon-Based Sensors for the Structural Health Monitoring of Smart Biocomposites. Nanoscale 2024, 16, 456–467. [Google Scholar] [CrossRef]