Improving the Elastic Response of Tanned Leather by Treatment with a Carboxylic Elastomer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tanned Leather Elastomer Addition

2.2. Analytical Techniques

2.3. Mechanical Properties

3. Results

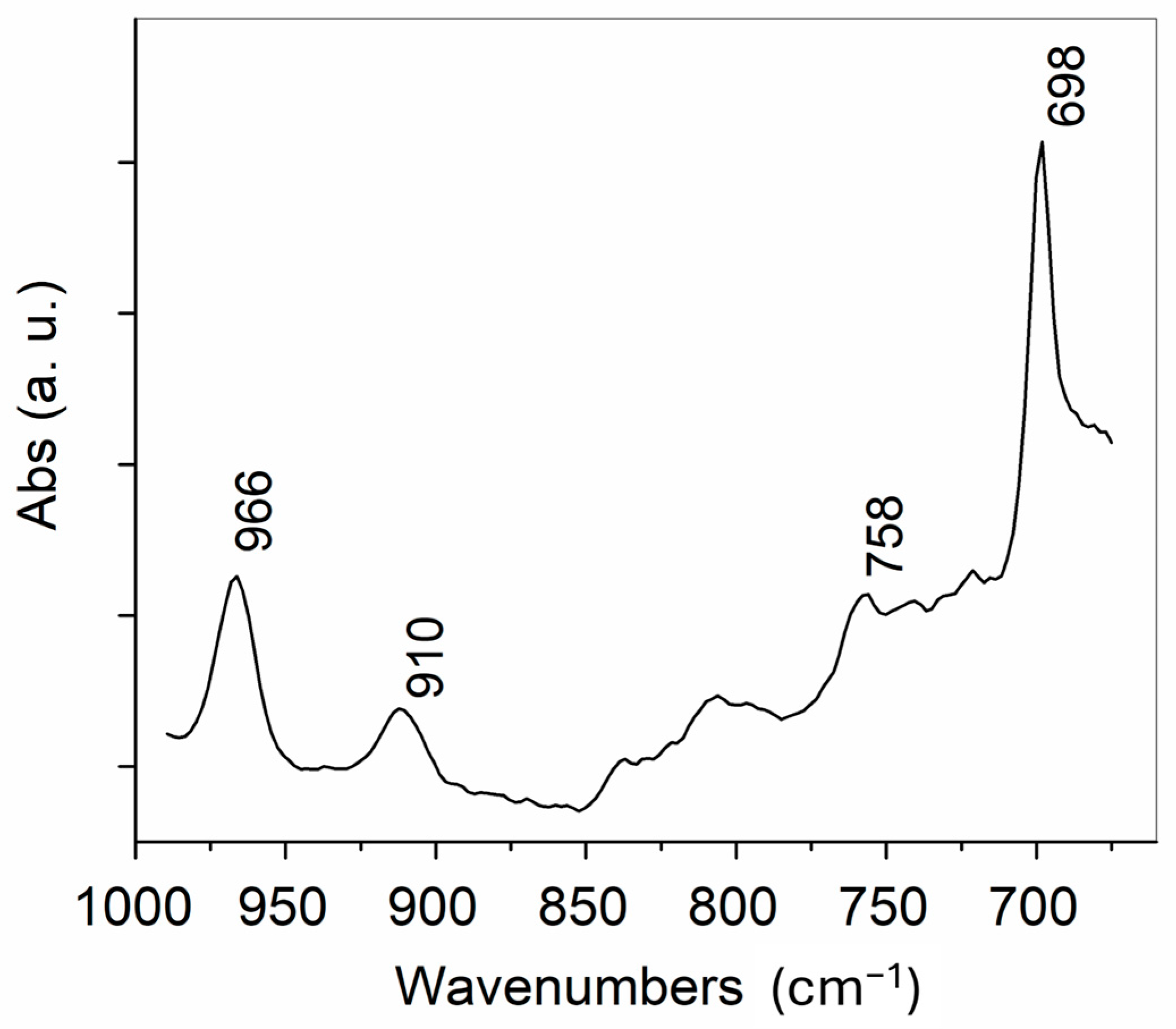

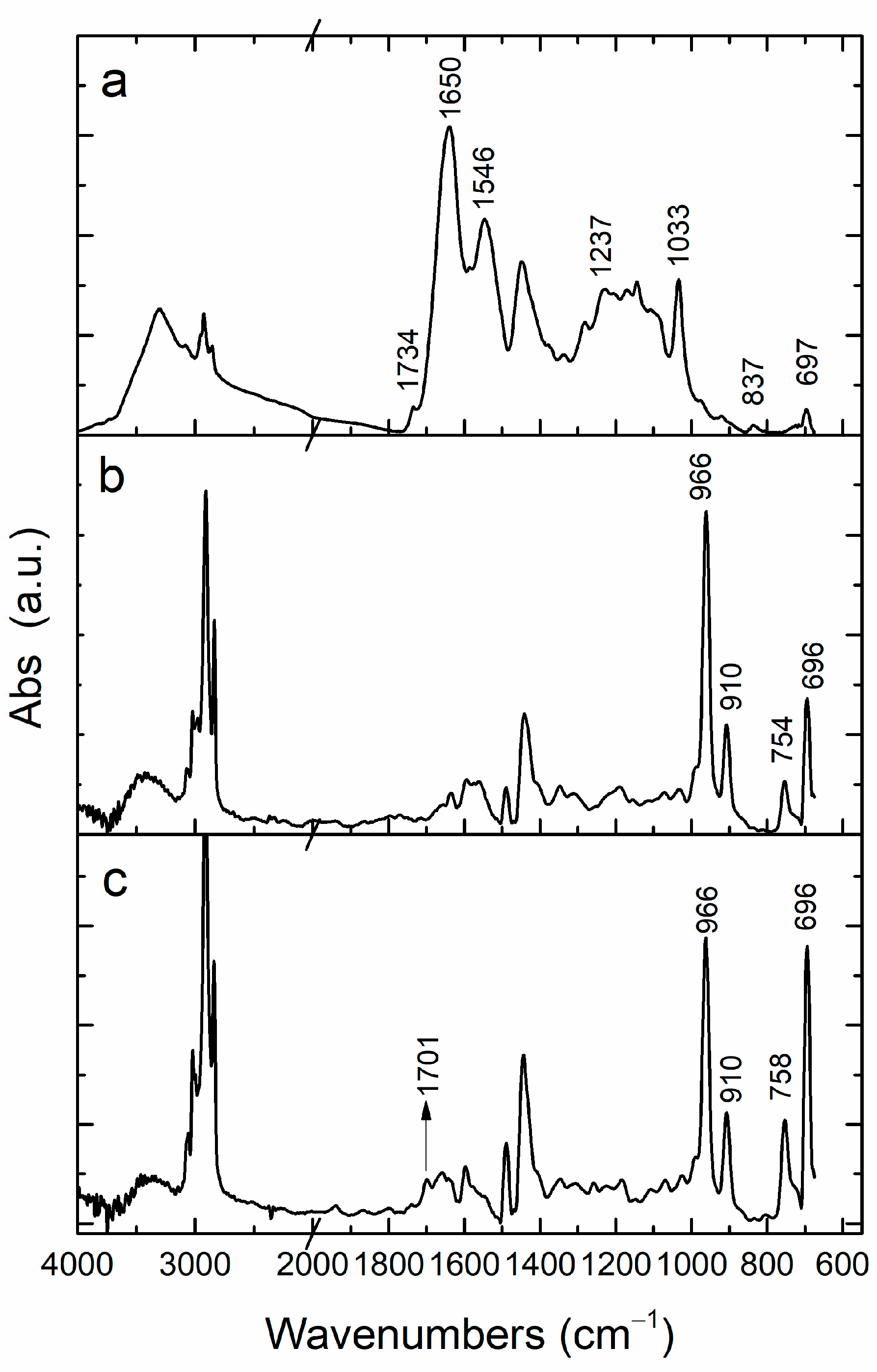

3.1. FTIR Analysis

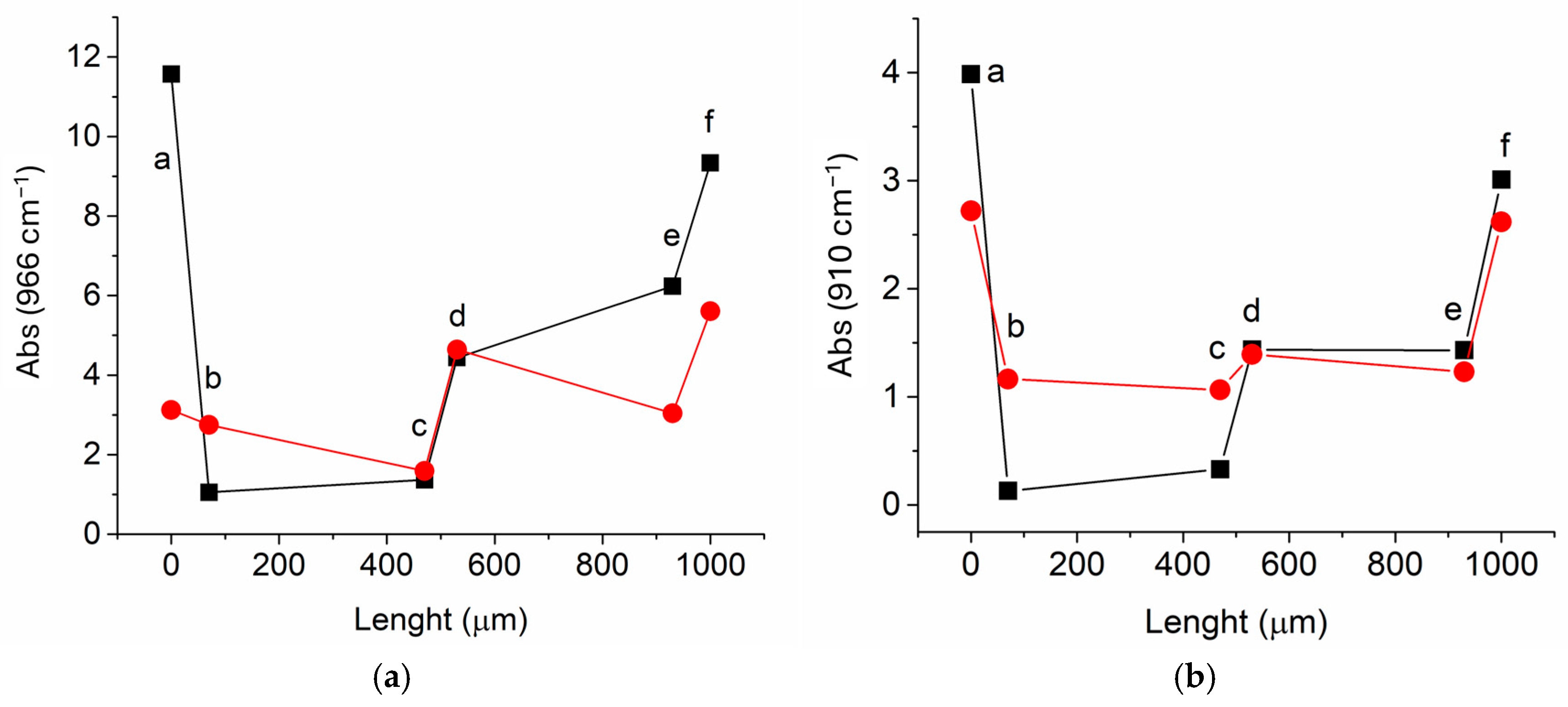

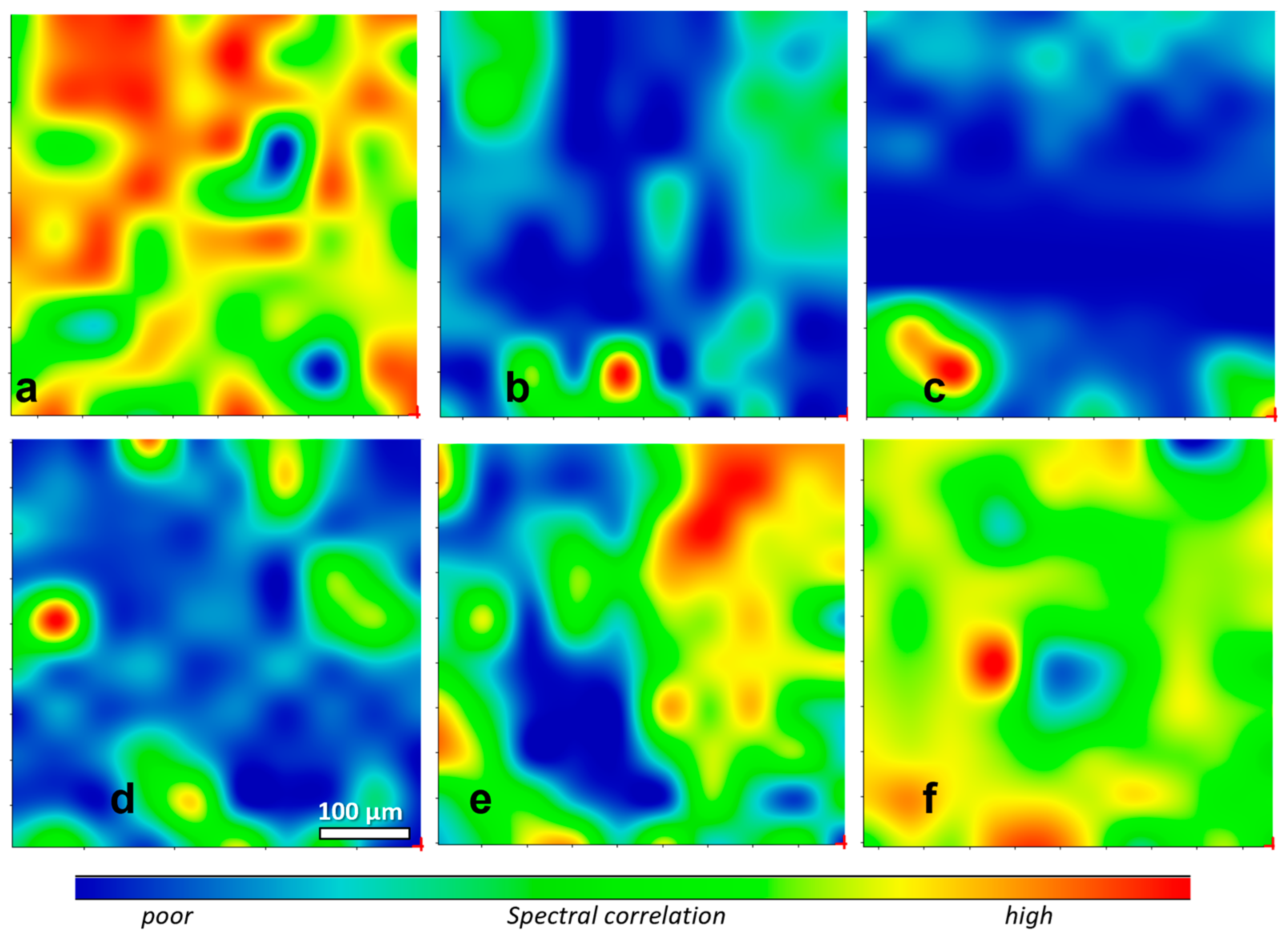

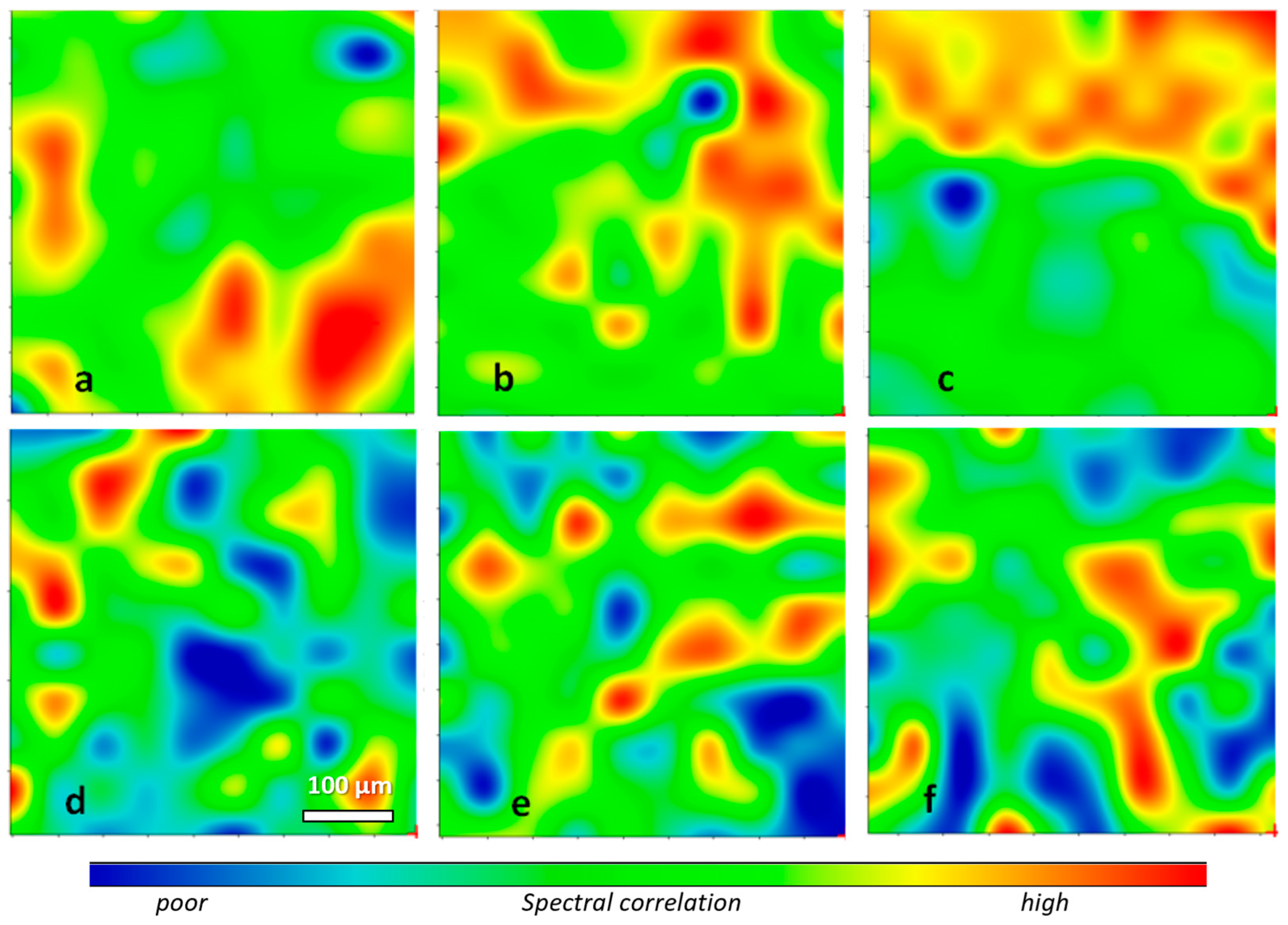

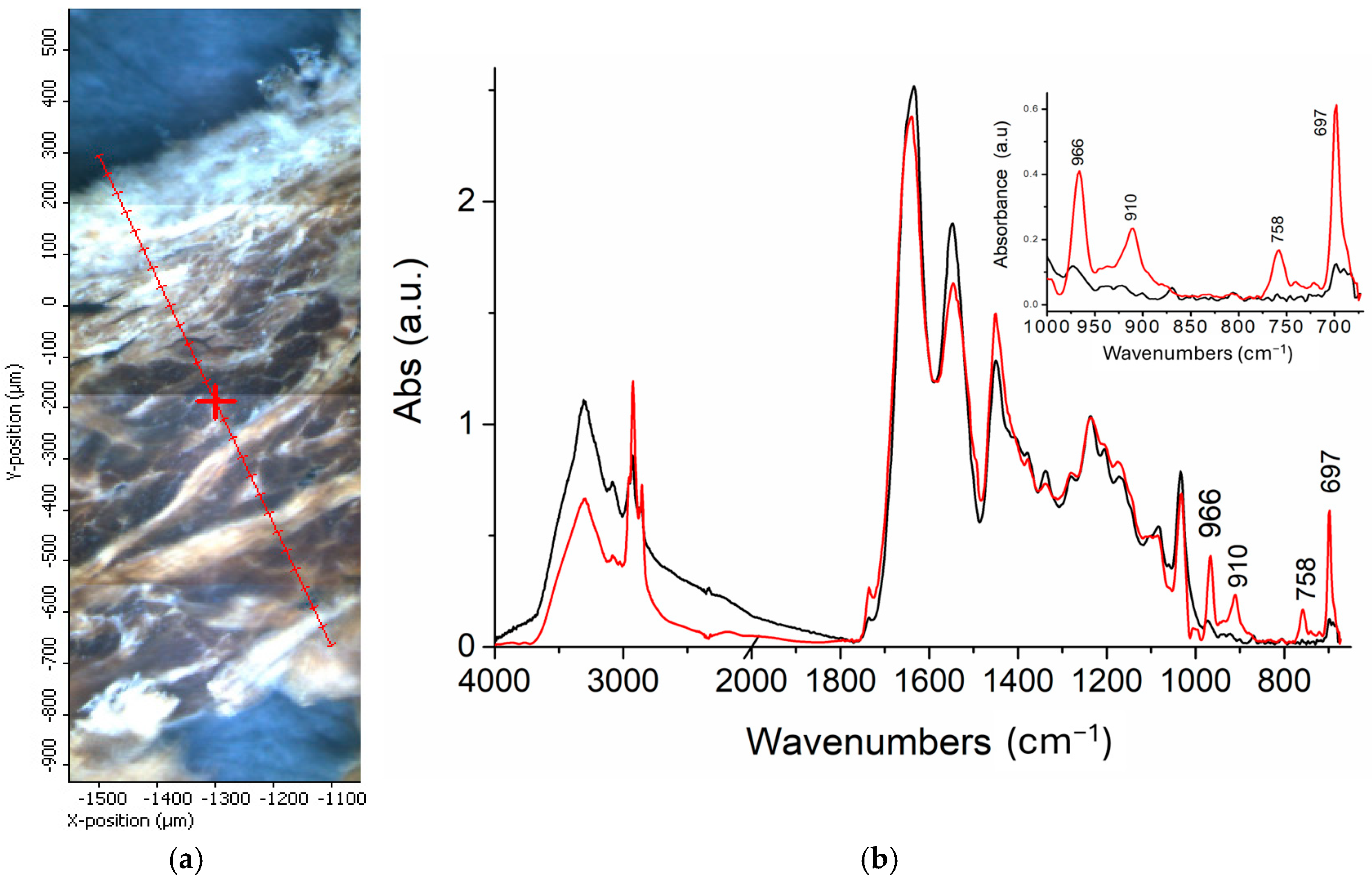

3.2. ATR-FTIR Mapping of Internal Layers of Rubber-Treated Tanned Leather

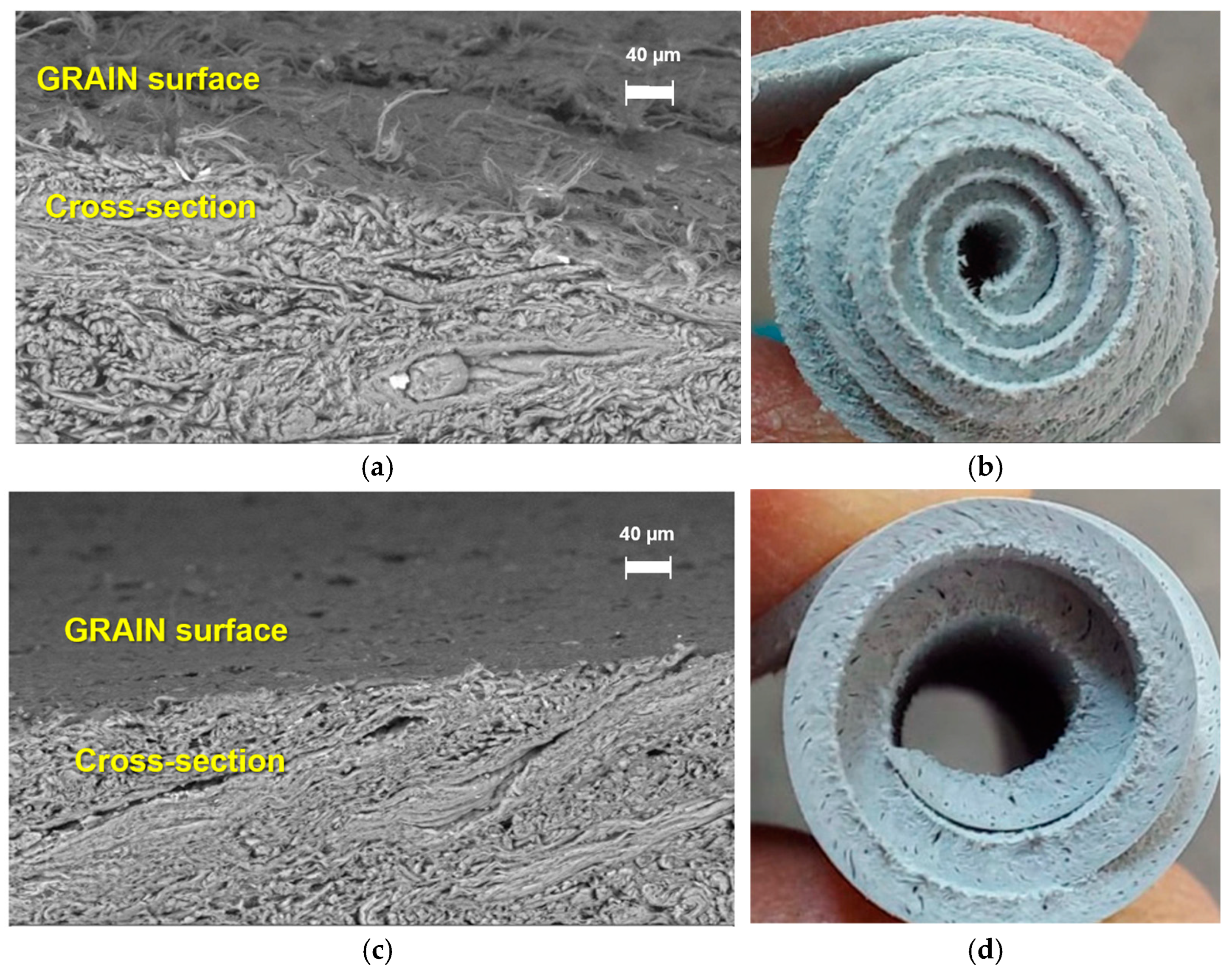

3.3. Distribution of Rubber Within the Tanned Leather Using Micro-ATR-FTIR Depth Profiling

3.4. Mechanical Response of Rubber-Treated Leathers

4. Conclusions

5. Patent

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, B.; Lu, J.; Liu, X.; Jin, H.; He, G.; Guo, X. Synthesis of controllable carboxylated polystyrene microspheres by two-step dispersion polymerization with hydrocarbon alcohols. Int. J. Polym. Sci. 2018, 2018, 8702597. [Google Scholar] [CrossRef]

- Ahn, D.; Shull, K.R. Effects of methylation and neutralization of carboxylated poly(n-butyl acrylate) on the interfacial and bulk contributions to adhesion. Langmuir 1998, 14, 3637–3645. [Google Scholar] [CrossRef]

- Alarifi, I.M. A comprehensive review on advancements of elastomers for engineering applications. Adv. Ind. Eng. Polym. Res. 2023, 6, 451–464. [Google Scholar] [CrossRef]

- Alimardani, M.; Abbassi-Sourki, F. New and emerging applications of carboxylated styrene butadiene rubber latex in polymer composites and blends: Review from structure to future prospective. J. Compos. Mater. 2015, 49, 1267–1282. [Google Scholar] [CrossRef]

- Rocha Ferreira, S.; Sena Neto, A.R.; de Andrade Silva, F.; Gomes de Souza, F.; Toledo Filho, R.D. The influence of carboxylated styrene butadiene rubber coating on the mechanical performance of vegetable fibers and on their interface with a cement matrix. Constr. Build. Mater. 2020, 262, 120770. [Google Scholar] [CrossRef]

- Lattime, R.; Laurich, J.; Handley, G. Carpet Latex Compound. U.S. Patent 2004/0191468 A1, 30 September 2004. now abandoned. [Google Scholar]

- Taneja, A.; Sekaran, K.C. A Glove Made from a Blend of Chloroprene Rubber and a Carboxylated Synthetic Butadiene Rubber. PCT Patent WO2000029478A1, 25 May 2000. [Google Scholar]

- Jubete, E.; Liauw, C.M.; Allen, N.S. Water uptake and tensile properties of carboxylated styrene butadiene rubber based water born paints: Models for water uptake prediction. Prog. Org. Coat. 2007, 59, 126–133. [Google Scholar] [CrossRef]

- Stephen, R.; Ranganathaiah, C.; Varghese, S.; Joseph, K.; Thomas, S. Gas transport through nano and micro composites of natural rubber (NR) and their blends with carboxylated styrene butadiene rubber (XSBR) latex membranes. Polymer 2006, 47, 858–870. [Google Scholar] [CrossRef]

- Baueregger, S.; Perello, M.; Plank, J. Influence of carboxylated styrene-butadiene latex copolymer on Portland cement hydration. Cem. Concr. Compos. 2015, 63, 42–50. [Google Scholar] [CrossRef]

- Nair, S.S.; Hurley, D.C.; Wang, S.; Young, T.M. Nanoscale characterization of interphase properties in maleated polypropylene-treated natural fiber-reinforced polymer composites. Polym. Eng. Sci. 2013, 54, 888–896. [Google Scholar] [CrossRef]

- Stephen, R.; Thomas, S.; Raju, K.V.S.N.; Varghese, S.; Joseph, K.; Oommen, Z. Dynamic mechanical and dielectric properties of nanocomposites of natural rubber (nr), carboxylated styrene butadiene rubber (XSBR) latices and their blends. Rubber Chem. Technol. 2007, 80, 672–689. [Google Scholar] [CrossRef]

- Alimardani, M.; Abbassi-Sourki, F.; Bakhshandeh, G.R. Preparation and characterization of carboxylated styrene butadiene rubber (XSBR)/multiwall carbon nanotubes (MWCNTs) nanocomposites. Iran Polym. J. 2012, 21, 809–820. [Google Scholar] [CrossRef]

- Lin, M.; Zheng, Z.; Yang, L.; Luo, M.; Fu, L.; Lin, B.; Xu, C. A high-performance, sensitive, wearable multifunctional sensor based on rubber/CNT for human motion and skin temperature detection. Adv. Mater. 2022, 34, 2107309. [Google Scholar] [CrossRef] [PubMed]

- Du, M.; Guo, B.; Lei, Y.; Liu, M.; Jia, D. Carboxylated butadiene-styrene rubber/halloysite nanotube nanocomposites: Interfacial interaction and performance. Polymer 2008, 49, 4871–4876. [Google Scholar] [CrossRef]

- Dhanorkar, R.J.; Mohanty, S.; Gupta, V.K. Synthesis of functionalized styrene butadiene rubber and its applications in SBR−silica composites for high performance tire applications. Ind. Eng. Chem. Res. 2021, 60, 4517–4535. [Google Scholar] [CrossRef]

- Cao, X.; Xu, C.; Liu, Y.; Chen, Y. Preparation and properties of carboxylated styrene-butadiene rubber/cellulose nanocrystals composites. Carbohydr. Polym. 2013, 92, 69–76. [Google Scholar] [CrossRef]

- Florjańczyk, Z.; Dębowski, M.; Wolak, A.; Malesa, M.; Płecha, J. Dispersions of organically modified boehmite particles and a carboxylated styrene-butadiene latix: A simple way to nanocomposites. J. Appl. Polym. Sci. 2007, 105, 80–88. [Google Scholar] [CrossRef]

- Abdollahi, M.; Rahmatpour, A.; Khanli, H.H. Structure and Mechanical Properties of Carboxylated Styrene-Butadiene Rubber (XSBR)/Pristine Clay Nanocomposites. e-Polymers 2007, 7, 151. [Google Scholar] [CrossRef]

- Xu, C.; Wu, W.; Nie, J.; Fu, L.; Lin, B. Preparation of carboxylic styrene butadiene rubber/chitosan composites with dense supramolecular network via solution mixing process. Compos. Part A Appl. Sci. Manuf. 2019, 117, 116–124. [Google Scholar] [CrossRef]

- Liu, M.; Peng, Q.; Luo, B.; Zhou, C. The improvement of mechanical performance and water-response of carboxylated SBR by chitin nanocrystals. Eur. Polym. J. 2015, 68, 190–206. [Google Scholar] [CrossRef]

- Xu, C.; Nie, J.; Wu, W.; Fu, L.; Lin, B. Design of self-healable supramolecular hybrid network based on carboxylated styrene butadiene rubber and nano-chitosan. Carbohydr. Poly. 2019, 205, 410–419. [Google Scholar] [CrossRef]

- Stadler, R.; de Lucca Freitas, L. Thermoplastic elastomers by hydrogen bonding 1. Rheological properties of modified polybutadiene. Colloid Polym. Sci. 1986, 264, 773–778. [Google Scholar] [CrossRef]

- Marinai, D. Tanning Process for Producing Leather with High Elastic Properties and Leather Obtained. European Patent EP3041962, 5 June 2019. [Google Scholar]

- Dickinson, E.; High, K.E. The use of infrared spectroscopy and chemometrics to investigate deterioration in vegetable tanned leather: Potential applications in heritage science. Herit. Sci 2022, 10, 65. [Google Scholar] [CrossRef]

- ISO 2419; IULTCS/IUP 3 Leather—Physical and Mechanical Tests—Specimen and Test Piece Conditioning. ISO: Cham, Switzerland, 2024.

- ISO 3379:2015; IULTCS/IUP 9 Leather—Determination of Distension and Strength of Surface (Ball Burst Method), 2nd ed. ISO: Cham, Switzerland, 2015.

- ISO 3377-1:2011; IULTCS/IUP 40 Leather—Physical and Mechanical Tests—Determination of Tear Load Part 1: Single Edge Tear, 2nd ed. ISO: Cham, Switzerland, 2011.

- ISO 3377-2:2016; IULTCS/IUP 8 Leather—Physical and Mechanical Tests—Determination of Tear Load Part 2: Double Edge Tear, 2nd ed. ISO: Cham, Switzerland, 2016.

- ISO 3376; IULTCS/IUP 6 Leather—Physical and Mechanical Tests—Determination of Tensile Strength and Percentage Extension. ISO: Cham, Switzerland, 2011.

- Falcão, L.; Araújo, M.E.M. Application of ATR-FTIR Spectroscopy to the Analysis of Tannins in Historic Leathers: The Case Study of the Upholstery from the 19th Century Portuguese Royal Train. Vibrat. Spectrosc. 2014, 74, 98–103. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Sahu, P.; Bhajiwala, H.; Mohanty, S.; Gupta, V.; Bhowmick, A.K. Synthesis, characterization and properties of selfhealable ionomeric carboxylated styrene-butadiene polymer. J. Mater. Sci. 2019, 54, 14986–14999. [Google Scholar] [CrossRef]

- Wibowo, H.B.; Dharmawan, W.; Saeri, C.; Wibowo, R.S.M.; Yulianto, A. Rapid Analysis of HTPB (Hydroxyl Terminated Polybutadiene) Properties with Infrared Spectroscopy and Gel Chromatography. AIP Conf. Proc. 2020, 2226, 040012. [Google Scholar] [CrossRef]

| Sample | Retanned Leather, mm | Retanned Leather + XSBR, mm |

|---|---|---|

| 1 | 6.32 | 9.93 |

| 2 | 8.25 | 10.11 |

| 3 | 7.25 | 10.08 |

| Average ± St. Dev. | 7.27 ± 0.97 | 10.04 ± 0.11 |

| Sample | Tear Load: Single-Edge Tear 1 (N) | Tear Load: Double-Edge Tear 2 (N) | ||

|---|---|---|---|---|

| Retanned Leather | Retanned Leather + XSBR | Retanned Leather | Retanned Leather + XSBR | |

| Parallel | 29.8 | 36.7 | 68.3 | 116.2 |

| Parallel | 36.4 | 55.3 | 60.2 | 104.0 |

| Perpendicular | 31.2 | 37.2 | 62.2 | 112.3 |

| Perpendicular | 34.3 | 43.5 | 61.8 | 110.8 |

| Average ± St. Dev. | 32.9 ± 3.0 | 43.2 ± 8.7 | 63.1 ± 3.6 | 110.8 ± 5.1 |

| Sample | Thickness (mm) | Tensile Strength ± St. Dev. (N/mm2) | Elongation at Break ± St. Dev. (%) |

|---|---|---|---|

| Retanned leather (RL) | 1.38 | 13.4 ± 2.5 | 47.4 ± 7.4 |

| RL with XSBR | 1.42 | 17.0 ± 1.8 | 65.7 ± 6.7 |

| RL with SBR | 1.35 | 17.9 ± 2.7 | 55.7 ± 10.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marinai, D.; Borchi, C.; Marinai, L.; Defeo, G.A.; Manariti, A.; Minei, P.; Castelvetro, V.; Ciardelli, F. Improving the Elastic Response of Tanned Leather by Treatment with a Carboxylic Elastomer. Polymers 2024, 16, 3411. https://doi.org/10.3390/polym16233411

Marinai D, Borchi C, Marinai L, Defeo GA, Manariti A, Minei P, Castelvetro V, Ciardelli F. Improving the Elastic Response of Tanned Leather by Treatment with a Carboxylic Elastomer. Polymers. 2024; 16(23):3411. https://doi.org/10.3390/polym16233411

Chicago/Turabian StyleMarinai, Daniele, Cristiana Borchi, Lorenzo Marinai, Gustavo Adrián Defeo, Antonella Manariti, Pierpaolo Minei, Valter Castelvetro, and Francesco Ciardelli. 2024. "Improving the Elastic Response of Tanned Leather by Treatment with a Carboxylic Elastomer" Polymers 16, no. 23: 3411. https://doi.org/10.3390/polym16233411

APA StyleMarinai, D., Borchi, C., Marinai, L., Defeo, G. A., Manariti, A., Minei, P., Castelvetro, V., & Ciardelli, F. (2024). Improving the Elastic Response of Tanned Leather by Treatment with a Carboxylic Elastomer. Polymers, 16(23), 3411. https://doi.org/10.3390/polym16233411