Using the Burning of Polymer Compounds to Determine the Applicability of the Acoustic Method in Fire Extinguishing

Abstract

:1. Introduction

1.1. Features of Fires of Organic Compounds

1.1.1. Features of Combustion of Organic Substances

1.1.2. Consequences of the Combustion of Organic Substances on the Environment

1.2. Features of Extinguishing Fires

1.3. Features of the Application of the Acoustic Method for Detecting and Extinguishing Fires of Organic Substances

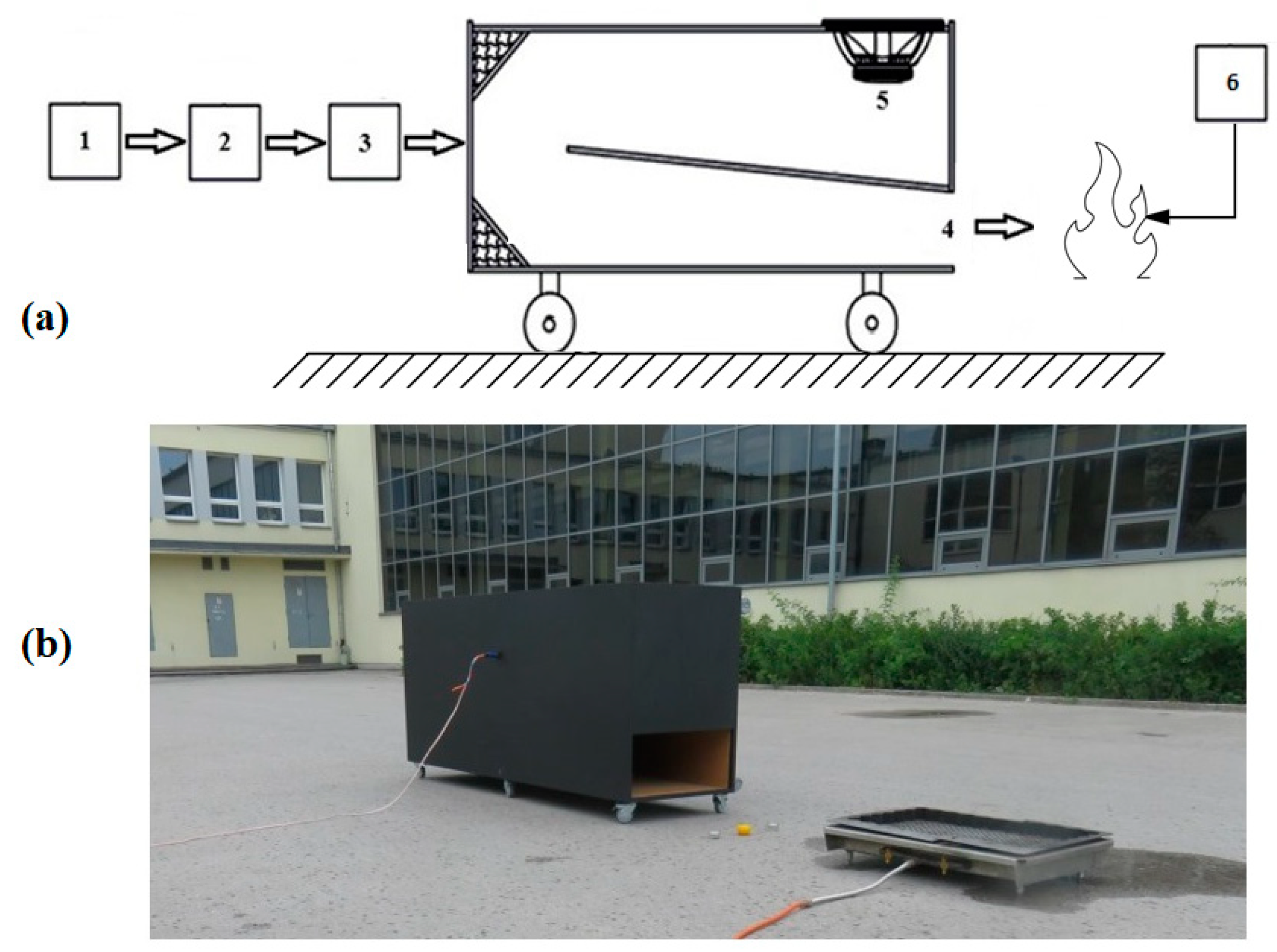

2. Materials and Methods

3. Results and Discussion

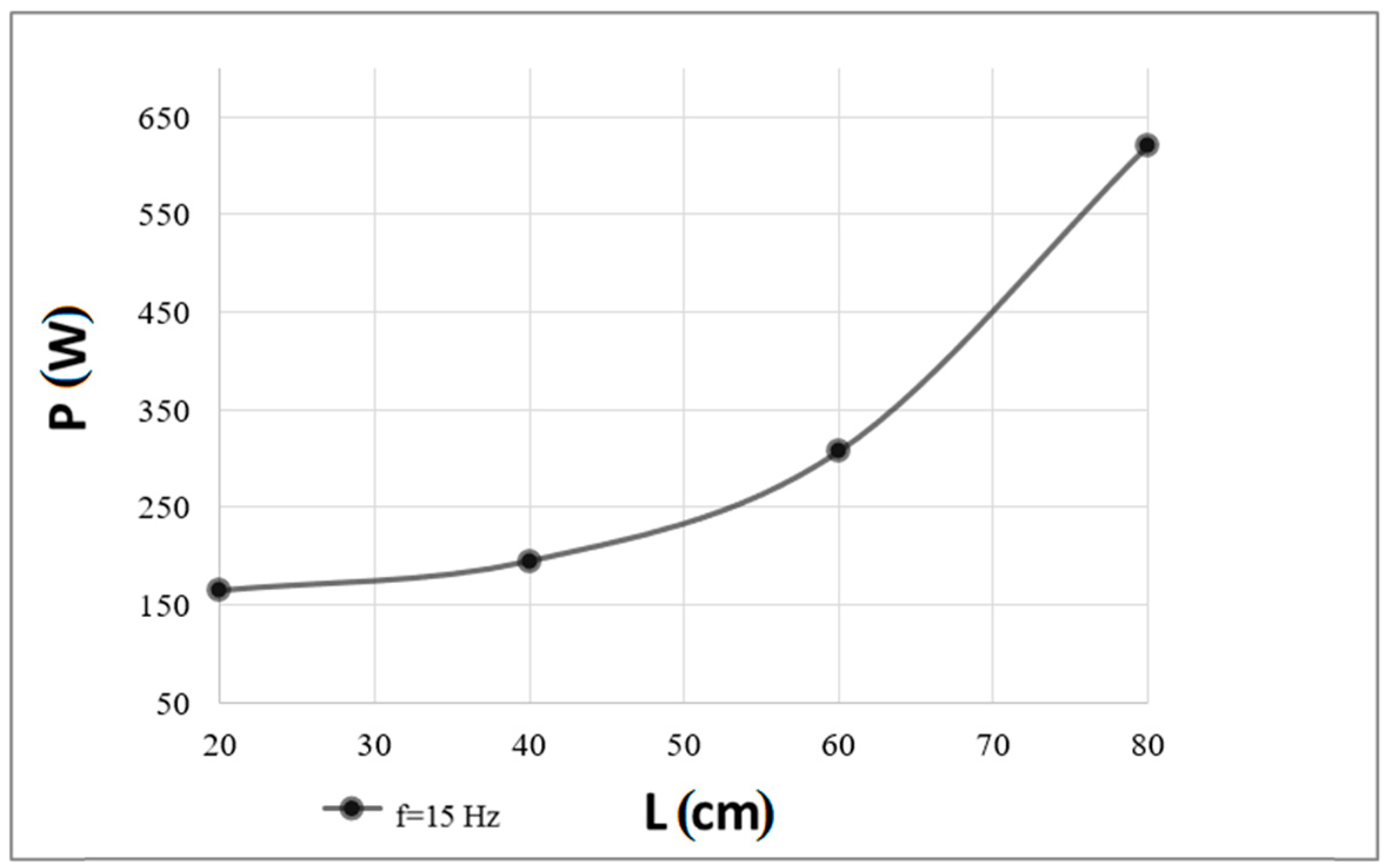

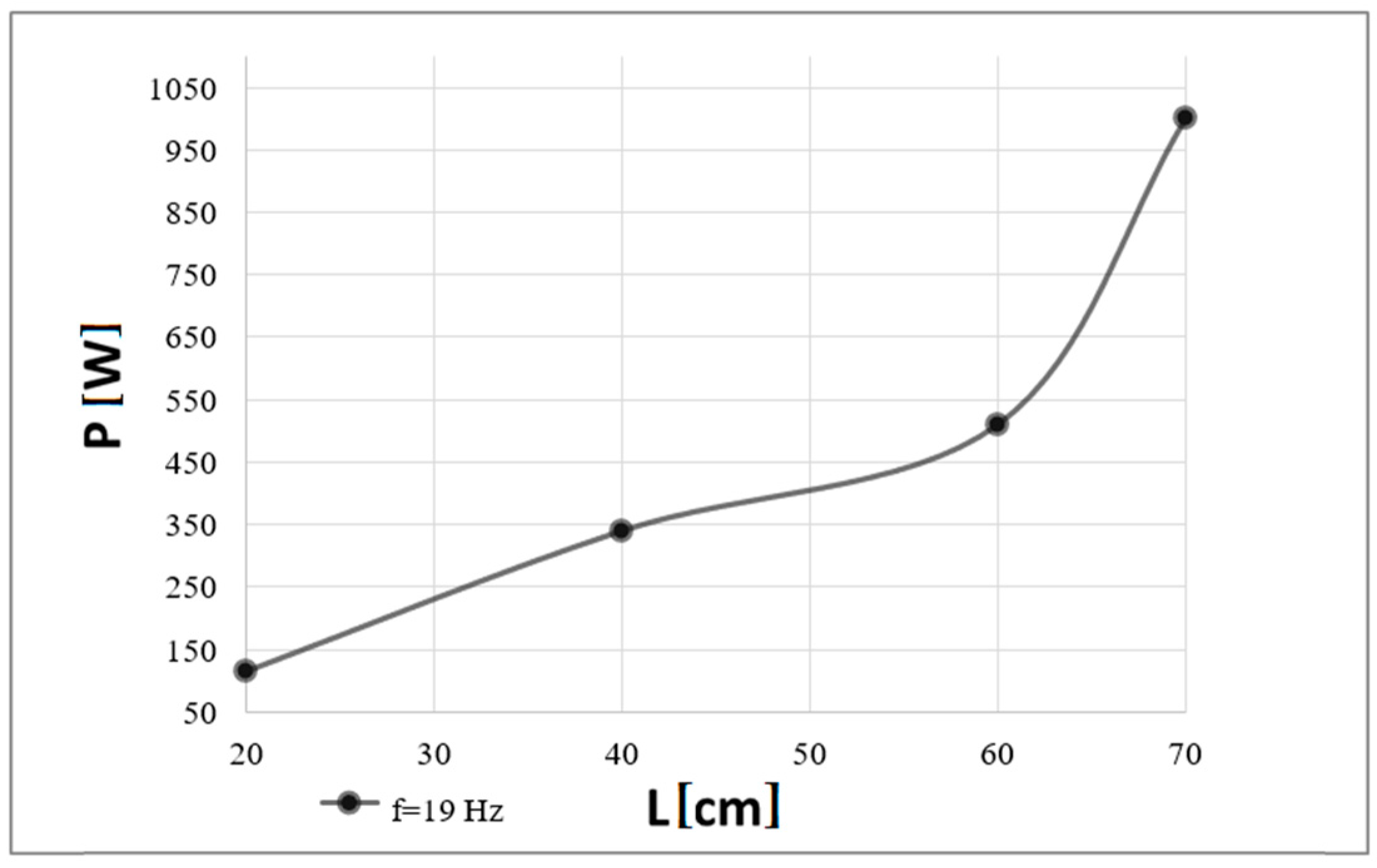

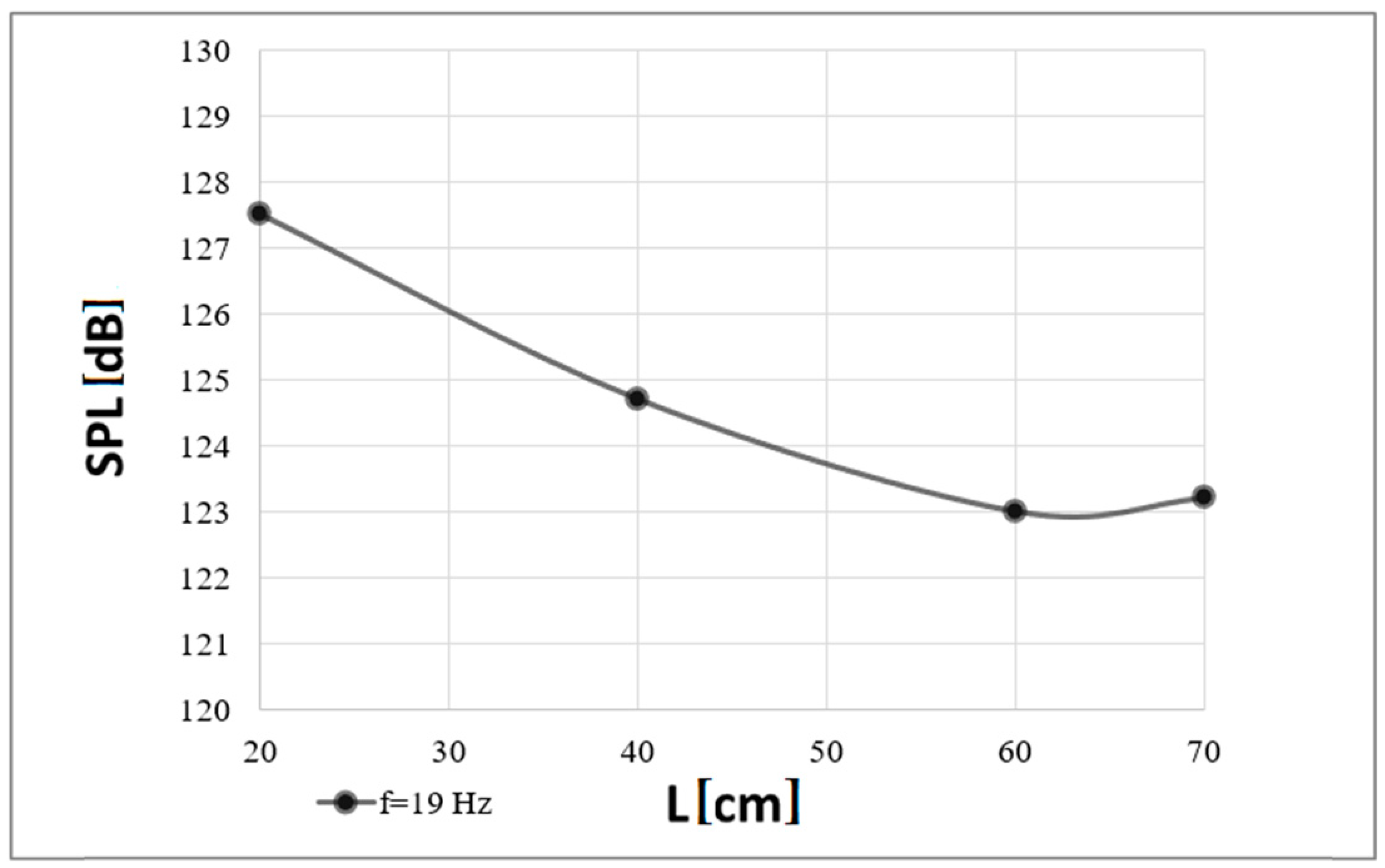

3.1. Study of the Possibilities of the Acoustic Method for Detecting and Extinguishing Fires of Organic Substances

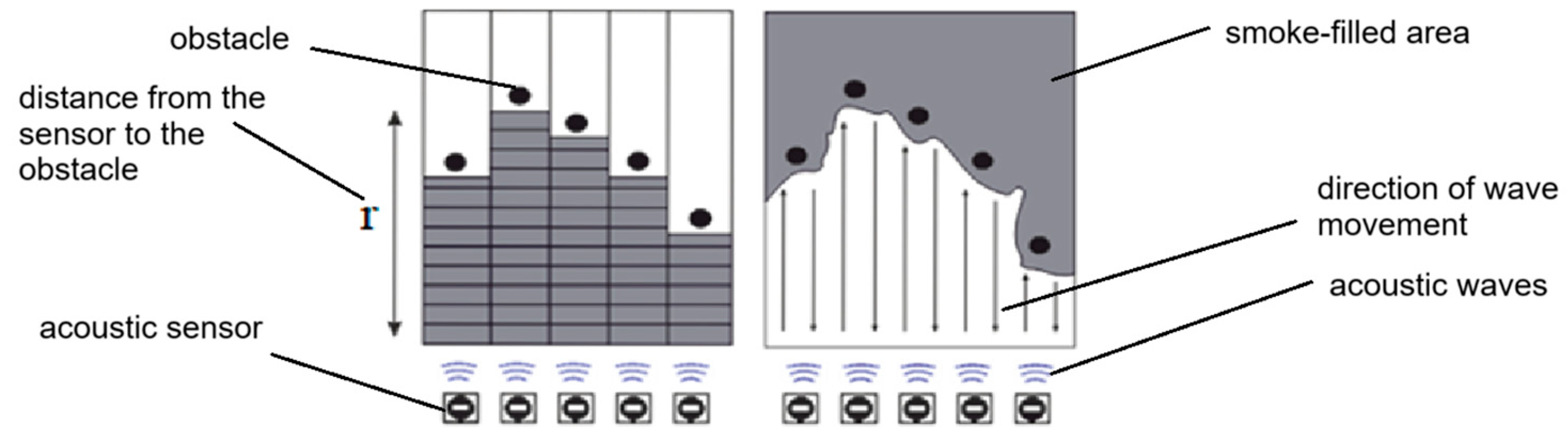

3.2. Justification of the Effect of the Smoke-Filled Rooms Due to the Burning of Various Organic Compounds on Its Acoustic Characteristics

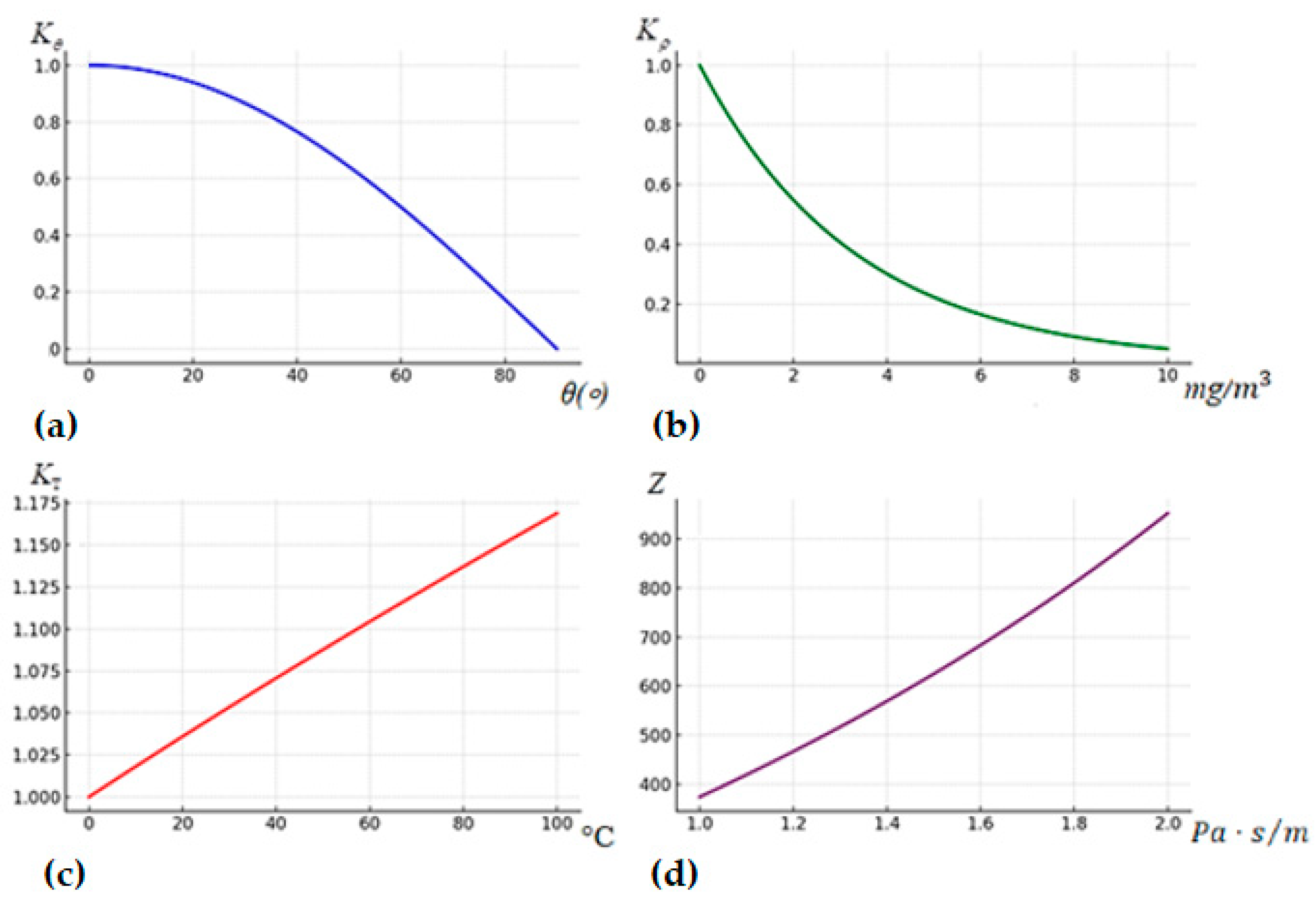

3.2.1. Determination of the Acoustic Characteristics of the Smoke-Filled Environment Due to the Combustion of Organic Substances

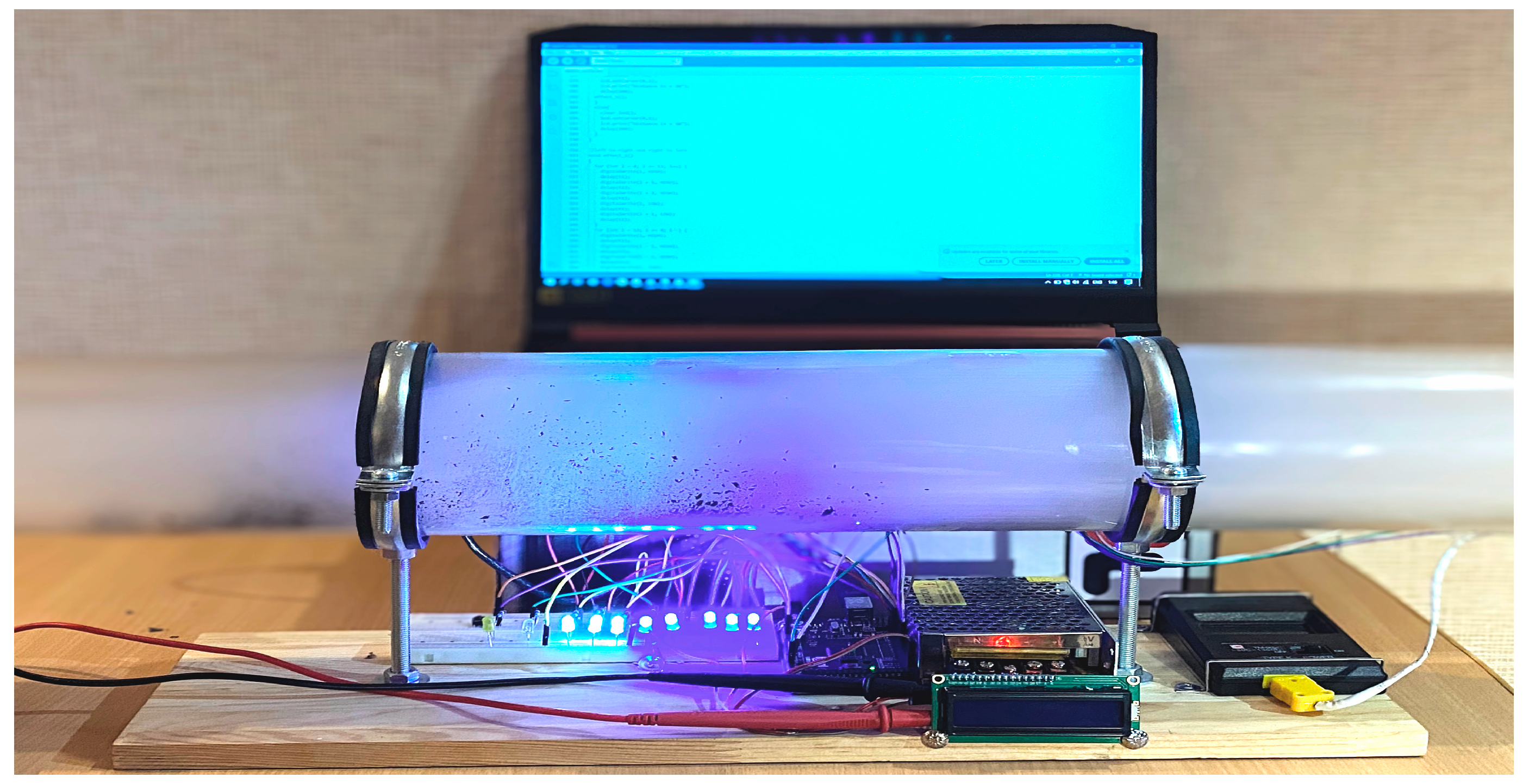

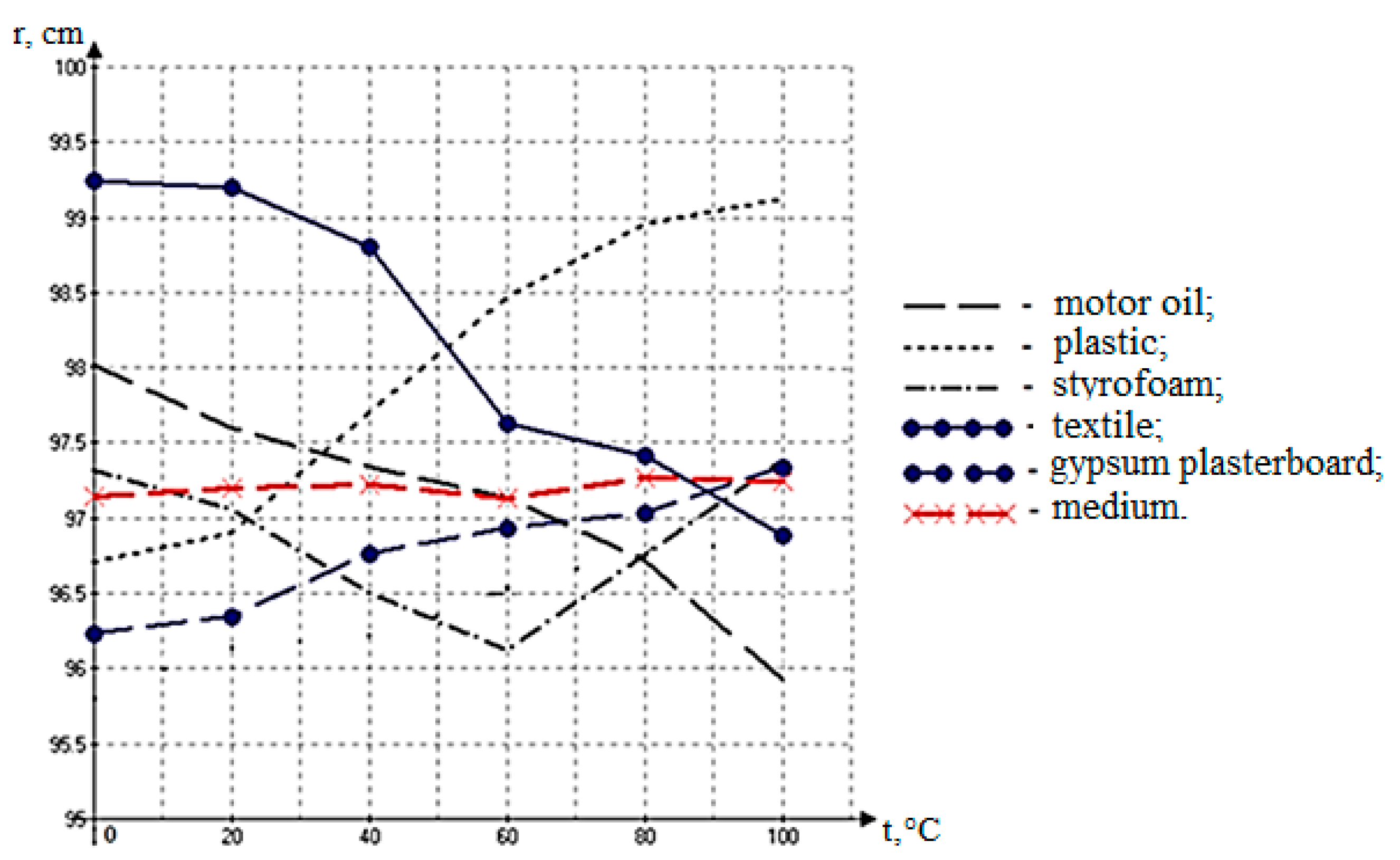

3.2.2. Experimental Determination of the Influence of the Temperature of Combustion Products on the Physical Properties of Acoustic Waves

4. Prospects for Applying the Approach

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- THE 17 GOALS. Sustainable Development—The United Nations. Available online: https://sdgs.un.org/goals (accessed on 1 August 2024).

- Evro, S.; Oni, B.A.; Tomomewo, O.S. Carbon Neutrality and Hydrogen Energy Systems. Int. J. Hydrog. Energy 2024, 78, 1449–1467. [Google Scholar] [CrossRef]

- Loboichenko, V.; Iranzo, A.; Casado-Manzano, M.; Navas, S.J.; Pino, F.J.; Rosa, F. Study of the Use of Biogas as an Energy Vector for Microgrids. Renew. Sustain. Energy Rev. 2024, 200, 114574. [Google Scholar] [CrossRef]

- De Luca Peña, L.V.; Taelman, S.E.; Préat, N.; Boone, L.; Van der Biest, K.; Custódio, M.; Hernandez Lucas, S.; Everaert, G.; Dewulf, J. Towards a Comprehensive Sustainability Methodology to Assess Anthropogenic Impacts on Ecosystems: Review of the Integration of Life Cycle Assessment, Environmental Risk Assessment and Ecosystem Services Assessment. Sci. Total Environ. 2022, 808, 152125. [Google Scholar] [CrossRef] [PubMed]

- Menon, A.; Vinod, A.; Sreeram, P.; Pacheeri, A.; Akhilesh, P.K.; Naiker, V.; Sasidharan, S.P.; Raghavan, P. Environmental Impact and Recycling Technologies of Thermoset Resin, Foams, Aerogels and Hydrogels. In Handbook of Thermosetting Foams, Aerogels, and Hydrogels; Elsevier eBooks; Raghavan, P., Sreekala, M.S., Ravindran, L., Menon, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 43–63. [Google Scholar] [CrossRef]

- Nath, A.; Mishra, A.; Pande, P.P. A Review Natural Polymeric Coagulants in Wastewater Treatment. Mater. Today Proc. 2020, 46, 6113–6117. [Google Scholar] [CrossRef]

- Ding, H.; Hussein, A.M.; Ahmad, I.; Latef, R.; Abbas, J.K.; Ali, A.T.A.; Saeed, S.M.; Abdulwahid, A.S.; Ramadan, M.F.; Rasool, H.A.; et al. Conducting polymers in industry: A comprehensive review on the characterization, synthesis and application. Alex. Eng. J. 2024, 88, 253–267. [Google Scholar] [CrossRef]

- Biron, M. Plastics solutions for practical problems. In Thermoplastics and Thermoplastic Composites, 3rd ed.; Elsevier eBooks; Biron, M., Andrew, W., Eds.; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 883–1038. [Google Scholar] [CrossRef]

- Rungruangkitkrai, N.; Phromphen, P.; Chartvivatpornchai, N.; Srisa, A.; Laorenza, Y.; Wongphan, P.; Harnkarnsujarit, N. Water Repellent Coating in Textile, Paper and Bioplastic Polymers: A Comprehensive Review. Polymers 2024, 16, 2790. [Google Scholar] [CrossRef]

- Getahun, M.J.; Kassie, B.B.; Alemu, T.S. Recent Advances in Biopolymer Synthesis, Properties, & Commercial Applications: A Review. Process Biochem. 2024, 145, 261–287. [Google Scholar] [CrossRef]

- Bano, S.; Aslam, A.A.; Khan, A.; Shabbir, A.; Qayyum, F.; Wahab, N.; Jabar, A.; Islam, I.U.; Ng, S.L. A Mini-Review on Polyhydroxyalkanoates: Synthesis, Extraction, Characterization, and Applications. Process Biochem. 2024, 146, 250–261. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Z.; Liu, X.; Ma, W.; Li, L.; Wang, Y. Protein-Based Grafting Modification in the Food Industry: Technology, Applications and Prospects. Trends Food Sci. Technol. 2024, 153, 104751. [Google Scholar] [CrossRef]

- Kumar, K.; Umapathi, R.; Ghoreishian, S.M.; Tiwari, J.N.; Hwang, S.K.; Huh, Y.S.; Venkatesu, P.; Shetti, N.P.; Aminabhavi, T.M. Microplastics and Biobased Polymers to Combat Plastics Waste. Chemosphere 2023, 341, 140000. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, L.; Zhang, W.; Muhammad, I.; Yin, C.; Zhu, Y.; Li, C.; Zheng, L. Significant Influence of Land Use Types and Anthropogenic Activities on the Distribution of Microplastics in Soil: A Case from a Typical Mining-Agricultural City. J. Hazard. Mater. 2024, 477, 135253. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Jalalah, M.; Alsareii, S.A.; Harraz, F.A.; Thakur, N.; Zheng, Y.; Koutb, M.; Yoon, Y.; Salama, E.S. Plastic Wastes (PWs) and Microplastics (MPs) Formation: Management, Migration, and Environmental Impact. J. Environ. Chem. Eng. 2024, 12, 112926. [Google Scholar] [CrossRef]

- Gilani, I.E.; Sayadi, S.; Zouari, N.; Al-Ghouti, M.A. Plastic Waste Impact and Biotechnology: Exploring Polymer Degradation, Microbial Role, and Sustainable Development Implications. Bioresour. Technol. Rep. 2023, 24, 101606. [Google Scholar] [CrossRef]

- Banaee, M.; Multisanti, C.R.; Impellitteri, F.; Piccione, G.; Faggio, C. Environmental toxicology of microplastic particles on fish: A review. Comp. Biochem. Physiol. Part C Toxicol. Pharmacol. 2024, 287, 110042. [Google Scholar] [CrossRef] [PubMed]

- Tuuri, E.M.; Leterme, S.C. How plastic debris and associated chemicals impact the marine food web: A review. Environ. Pollut. 2023, 321, 121156. [Google Scholar] [CrossRef]

- Côté, W.A. Chemical composition of wood. In Principles of Wood Science and Technology; Springer eBooks; Kollmann, F.F.P., Côté, W.A., Eds.; Springer: Berlin, Germany, 1968; pp. 55–78. [Google Scholar] [CrossRef]

- American Forest & Paper Association. What is Paper Pulp? Available online: https://www.afandpa.org/news/2024/what-paper-pulp (accessed on 25 September 2024).

- Růžičková, J.; Raclavská, H.; Šafář, M.; Kucbel, M.; Švédová, B.; Raclavský, K.; Juchelková, D.; Scala, F.; Kantor, P. Environmental risks related to organic compounds from the combustion of paper briquettes in domestic boilers. J. Hazard. Mater. 2021, 418, 126291. [Google Scholar] [CrossRef]

- McKeen, L.W. Introduction to plastics, polymers, and their properties. In Plastics Design Library. The Effect of Temperature and Other Factors on Plastics and Elastomers, 4th ed.; Elsevier eBooks; Mckeen, L.W., Ed.; William Andrew Publishing: Norwich, NY, USA, 2023; pp. 1–45. [Google Scholar] [CrossRef]

- Calles-Arriaga, C.A.; López-Hernández, J.; Hernández-Ordoñez, M.; Echavarría-Solís, R.A.; Ovando-Medina, V.M. Thermal characterization of microwave assisted foaming of expandable polystyrene. Ing. Investig. Y Tecnol. 2016, 17, 15–21. [Google Scholar] [CrossRef]

- Qin, Y. A brief description of textile fibers. In Medical Textile Materials; Elsevier eBooks; Woodhead Publishing Series in Textiles; Qin, Y., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 23–42. [Google Scholar] [CrossRef]

- Solorzano, J.A.P.; Moinuddin, K.A.M.; Tretsiakova-McNally, S.; Joseph, P. A study of the thermal degradation and combustion characteristics of some materials commonly used in the construction sector. Polymers 2019, 11, 1833. [Google Scholar] [CrossRef]

- Park, H.J.; Jian, H.; Wen, M.; Jo, S.U. Toxic gas and smoke generation and flammability of Flame-Retardant plywood. Polymers 2024, 16, 507. [Google Scholar] [CrossRef]

- Warnatz, H.J.; Dibble, R.; Maas, U. Combustion; Springer Nature: Berlin, Germany, 2006. [Google Scholar] [CrossRef]

- Głowacki, A.; Rybiński, P.; Żelezik, M.; Mirkhodjaev, U.Z. Cage Nanofillers’ Influence on Fire Hazard and Toxic Gases Emitted during Thermal Decomposition of Polyurethane Foam. Polymers 2024, 16, 645. [Google Scholar] [CrossRef]

- Purser, D.A.; Stec, A.A.; Hull, T.R. Effects of the Material and Fire Conditions on Toxic Product Yields. In Fire Toxicity; Elsevier eBooks; Stec, A., Hull, R., Eds.; Woodhead Publishing: Sawston, UK, 2010; pp. 515–540. [Google Scholar] [CrossRef]

- Lemieux, P.M.; Lutes, C.C.; Santoianni, D.A. Emissions of organic air toxics from open burning: A comprehensive review. Prog. Energy Combust. Sci. 2003, 30, 1–32. [Google Scholar] [CrossRef]

- Hull, T.R.; Stec, A.A. Introduction to fire toxicity. In Fire Toxicity; Elsevier eBooks; Stec, A., Hull, R., Eds.; Woodhead Publishing: Sawston, UK, 2010; pp. 3–25. [Google Scholar] [CrossRef]

- Shi, X.; Yang, P.; Peng, X.; Huang, C.; Qian, Q.; Wang, B.; He, J.; Liu, X.; Li, Y.; Kuang, T. Bi-phase fire-resistant polyethylenimine/graphene oxide/melanin coatings using layer by layer assembly technique: Smoke suppression and thermal stability of flexible polyurethane foams. Polymer 2019, 170, 65–75. [Google Scholar] [CrossRef]

- Ma, T.; Wang, W.; Wang, R. Thermal Degradation and Carbonization Mechanism of Fe-Based Metal-Organic Frameworks onto Flame-Retardant Polyethylene Terephthalate. Polymers 2023, 15, 224. [Google Scholar] [CrossRef] [PubMed]

- Jin, X.; Cui, S.; Sun, S.; Sun, J.; Zhang, S. The Preparation and Characterization of Polylactic Acid Composites with Chitin-Based Intumescent Flame Retardants. Polymers 2021, 13, 3513. [Google Scholar] [CrossRef]

- Kapatel, P.M.; Patel, R.H. Green Approach for the Development of Novel Flame Retardant Waterborne Polyurethanes: Synthesis and its Characterizations. Mater. Today Proc. 2020, 23, 389–399. [Google Scholar] [CrossRef]

- Stec, A.A.; Rhodes, J. Smoke and hydrocarbon yields from fire retarded polymer nanocomposites. Polym. Degrad. Stab. 2010, 96, 295–300. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Tran, P.; Ren, X.; Zhang, G.; Mendis, P. Fire performance of maritime composites. In Marine Composites; Elsevier EBooks; Woodhead Publishing Series in Composites Science and Engineering; Pemberton, R., Summerscales, J., Graham-Jones, J., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 115–160. [Google Scholar] [CrossRef]

- Rybiński, P.; Bradło, D.; Żukowski, W.; Syrek, B. Determination of toxic products emissions of polymers thermal decomposition using fluidised bed reactor and FTIR analysis. Polym. Test. 2019, 79, 106040. [Google Scholar] [CrossRef]

- Yılmaz-Atay, H.; Wilk-Jakubowski, J.L. A Review of Environmentally Friendly Approaches in Fire Extinguishing: From Chemical Sciences to Innovations in Electrical Engineering. Polymers 2022, 14, 1224. [Google Scholar] [CrossRef]

- Szydło, Z.A. History of Fire. Chem. Didact. Ecol. Metrol. 2017, 24, 23–43. [Google Scholar] [CrossRef]

- Stec, A.A. Estimation of toxicity during burning of common materials. In Fire Toxicity; Elsevier eBooks; Stec, A., Hull, R., Eds.; Woodhead Publishing: Sawston, UK, 2010; pp. 541–558. [Google Scholar] [CrossRef]

- Gałaj, J.A.; Saleta, D. Toxicity of toxic gases emitted during a fire and ventilation. In Advances in the Toxicity of Construction and Building Material; Elsevier eBooks; Woodhead Publishing Series in Civil and Structural Engineering; Pacheco-Torgal, F., Falkinham, J.O., Gałaj, J.A., Eds.; Elsevier: Sawston, UK, 2022; pp. 81–115. [Google Scholar] [CrossRef]

- Wakefield, J.C. A Toxicological Review of the Products of Combustion; Health Protection Agency; Centre for Radiation, Chemical and Environmental Hazards, Chemical Hazards and Poisons Division: Chilton, UK, 2010; HPA-CHaPD-004. Available online: https://assets.publishing.service.gov.uk/media/5a74afd1ed915d0e8e39a374/HPA-CHaPD-004_for_website.pdf (accessed on 22 November 2024).

- Jakhar, R.; Samek, L.; Styszko, K. A comprehensive study of the impact of waste fires on the environment and health. Sustainability 2023, 15, 14241. [Google Scholar] [CrossRef]

- Manisalidis, I.; Stavropoulou, E.; Stavropoulos, A.; Bezirtzoglou, E. Environmental and Health Impacts of Air Pollution: A review. Front. Public Health 2020, 8, 14. [Google Scholar] [CrossRef] [PubMed]

- Vorkamp, K. An Overlooked Environmental Issue? A Review of the Inadvertent Formation of PCB-11 and Other PCB Congeners and Their Occurrence in Consumer Products and in the Environment. Sci. Total Environ. 2016, 541, 1463–1476. [Google Scholar] [CrossRef] [PubMed]

- David, E.; Niculescu, V.C. Volatile Organic compounds (VOCs) as environmental pollutants: Occurrence and mitigation using nanomaterials. Int. J. Environ. Res. Public Health 2021, 18, 13147. [Google Scholar] [CrossRef]

- Mathew, N.; Somanathan, A.; Tirpude, A.; Arfin, T. The Impact of Short-Lived Climate Pollutants on the Human Health. Environ. Pollut. Manag. 2024, 1, 1–14. [Google Scholar] [CrossRef]

- Gefenienė, A.; Zubrytė, E.; Kaušpėdienė, D.; Ramanauskas, R.; Ragauskas, R. Firefighting wastewater from a tire recycling plant: Chemical characterization and simultaneous removal of multiple pollutants. J. Environ. Chem. Eng. 2024, 12, 112148. [Google Scholar] [CrossRef]

- Shaw, S.D.; Berger, M.L.; Harris, J.H.; Yun, S.H.; Wu, Q.; Liao, C.; Blum, A.; Stefani, A.; Kannan, K. Persistent organic pollutants including polychlorinated and polybrominated dibenzo-p-dioxins and dibenzofurans in firefighters from Northern California. Chemosphere 2013, 91, 1386–1394. [Google Scholar] [CrossRef]

- Mayer, A.C.; Fent, K.W.; Wilkinson, A.; Chen, I.C.; Kerber, S.; Smith, D.L.; Kesler, R.M.; Horn, G.P. Characterizing exposure to benzene, toluene, and naphthalene in firefighters wearing different types of new or laundered PPE. Int. J. Hyg. Environ. Health 2021, 240, 113900. [Google Scholar] [CrossRef]

- Chua, M.H.; Zhou, H.; Xu, J. Polymer-POSS hybrid materials as fire retardants. In Polyhedral Oligomeric Silsesquioxane (POSS) Polymer Nanocomposites; Elsevier eBooks; Thomas, S., Somasekharan, L., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 305–332. [Google Scholar] [CrossRef]

- Mu, X.; Zhou, X.; Wang, W.; Xiao, Y.; Liao, C.; Longfei, H.; Kan, Y.; Song, L. Design of compressible flame retardant grafted porous organic polymer based separator with high fire safety and good electrochemical properties. Chem. Eng. J. 2020, 405, 126946. [Google Scholar] [CrossRef]

- Wang, X.; Guo, W.; Cai, W.; Wang, J.; Song, L.; Hu, Y. Recent advances in construction of hybrid nano-structures for flame retardant polymers application. Appl. Mater. Today 2020, 20, 100762. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C.D. Polymers on fire. In Polymer Green Flame Retardants; Elsevier eBooks; Papaspyrides, C.D., Kiliaris, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–43. [Google Scholar] [CrossRef]

- Fu, T.; Guo, D.M.; Chen, L.; Wu, W.S.; Wang, X.L.; Wang, Y.Z. Fire hazards management for polymeric materials via synergy effects of pyrolysates-fixation and aromatized-charring. J. Hazard. Mater. 2020, 389, 122040. [Google Scholar] [CrossRef]

- Purser, D.A. Fire Safety Performance of Flame Retardants Compared with Toxic and Environmental Hazards. In Polymer Green Flame Retardants; Elsevier eBooks; Papaspyrides, C.D., Kiliaris, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 45–86. [Google Scholar] [CrossRef]

- Lv, H.; Gu, Y.; Zhou, R.; Pei, P.; Cai, Z. An integrated quantitative method of risk analysis and decision making for safety manipulation of a forest firefighting aircraft by using physical models of Multi-Hazard factors. Heliyon 2024, 10, e38341. [Google Scholar] [CrossRef]

- Park, S.Y.; Ahn, K.I. Evaluation of an accident management strategy of emergency water injection using fire engines in a typical pressurized water reactor. Nucl. Eng. Technol. 2015, 47, 719–728. [Google Scholar] [CrossRef]

- Yazir, D. Application of IF-TOPSIS method on fixed fire fighting systems for cargo hold fires on the dry/bulk cargo ships. Ocean. Eng. 2022, 260, 111891. [Google Scholar] [CrossRef]

- Zhang, S.; Yao, J.; Wang, R.; Liu, Z.; Ma, C.; Wang, Y.; Zhao, Y. Design of intelligent fire-fighting robot based on multi-sensor fusion and experimental study on fire scene patrol. Robot. Auton. Syst. 2022, 154, 104122. [Google Scholar] [CrossRef]

- Oliinyk, V.; Basmanov, O.; Romanyuk, I.; Rashkevich, O.; Malovyk, I. Building a model of heating an oil tank under the thermal influence of a spill fire. East. -Eur. J. Enterp. Technol. 2024, 4, 21–28. [Google Scholar] [CrossRef]

- Karabyn, O.; Smotr, O.; Kuzyk, A.; Malets, I.; Karabyn, V. Mathematical and Computer Model of the Tree Crown Ignition Process from a Mobile Grassroots Fire. In Lecture Notes in Data Engineering, Computational Intelligence, and Decision Making. ISDMCI 2022. Lecture Notes on Data Engineering and Communications Technologies; Babichev, S., Lytvynenko, V., Eds.; Springer: Cham, Switzerland, 2022; Volume 149, pp. 148–159. [Google Scholar] [CrossRef]

- Huang, P.; Chen, M.; Chen, K.; Zhang, H.; Yu, L.; Liu, C. A combined real-time intelligent fire detection and forecasting approach through cameras based on computer vision method. Process Saf. Environ. Prot. 2022, 164, 629–638. [Google Scholar] [CrossRef]

- Xu, L.; Zheng, W. Numerical simulation on the influence of low air pressure upon smoke spread and fire alarm process. Case Stud. Therm. Eng. 2021, 26, 101004. [Google Scholar] [CrossRef]

- Kolomiiets, V.; Abramov, Y.; Basmanov, O.; Sobyna, V.; Sokolov, D. Determining the dynamic characteristics of a class B fire in the case of extinguishing by water spray. East.-Eur. J. Enterp. Technol. 2023, 6, 50–57. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Zhang, X.; Fan, C.; Gong, J. Performance evaluation of water mist fire suppression: A clean and sustainable fire-fighting technique in mechanically-ventilated place. J. Clean. Prod. 2018, 209, 1319–1331. [Google Scholar] [CrossRef]

- Koshiba, Y.; Yamamoto, Y.; Ohtani, H. Fire suppression efficiency of water mists containing organic solvents. J. Loss Prev. Process Ind. 2019, 62, 103973. [Google Scholar] [CrossRef]

- Shcherbak, O.; Loboichenko, V.; Skorobahatko, T.; Shevchenko, R.; Levterov, A.; Pruskyi, A.; Khrystych, V.; Khmyrova, A.; Fedorchuk-Moroz, V.; Bondarenko, S. Study of Organic Carbon-Containing Additives to water used in fire fighting, in terms of their environmental friendliness. Fire Technol. 2024, 60, 3739–3765. [Google Scholar] [CrossRef]

- Shevchenko, R.I.; Strelets, V.M.; Loboichenko, V.M.; Pruskyi, A.V.; Myroshnyk, O.N.; Kamyshentsev, G.V. Review of Up-To-Date Approaches for Extinguishing Oil and Petroleum Products. SOCAR Proc. 2021, SI1, 169–174. [Google Scholar] [CrossRef]

- Høisæter, Å.; Breedveld, G.D. Leaching potential of per- and polyfluoroalkyl substances from source zones with historic contamination of aqueous film forming foam—A surfactant mixture problem. Environ. Adv. 2022, 8, 100222. [Google Scholar] [CrossRef]

- Strelets, V.V.; Loboichenko, V.M.; Leonova, N.A.; Strelets, V.M.; Pruskyi, A.V.; Avramenko, O.V. Comparative Assessment of Environmental Parameters of Foaming Agents Based on Synthetic Hydrocarbon Used for Extinguishing the Fires of Oil and Petroleum Products. SOCAR Proc. 2021, SI2, 1–10. [Google Scholar] [CrossRef]

- Gurbanova, M.; Loboichenko, V.; Leonova, N.; Strelets, V. Effect of Inorganic Components of Fire Foaming Agents on the Aquatic Environment. J. Turk. Chem. Soc. Sect. A Chem. 2020, 7, 833–844. [Google Scholar] [CrossRef]

- Gurbanova, М.; Loboichenko, V.; Leonova, N.; Strelets, V.; Shevchenko, R. Comparative Assessment of the Ecological Characteristics of Auxiliary Organic Compounds in the Composition of Foaming Agents Used for Fire Fighting. Bull. Georgian Natl. Acad. Sci. 2020, 14, 58–66. [Google Scholar]

- Kireev, A.A.; Kirichenko, I.K.; Petukhov, R.A.; Sharshanov, A.Y.; Yarkho, T.A. Modeling the Insulating Properties of Multicomponent Solid Foam-like Material Based on Gel-Forming Systems. Funct. Mater. 2021, 28, 549–555. [Google Scholar] [CrossRef]

- Dadashov, I.F.; Loboichenko, V.M.; Strelets, V.M. About the Environmental Characteristics of Fire Extinguishing Substances Used in Extinguishing Oil and Petroleum Products. SOCAR Proc. 2020, 1, 79–84. [Google Scholar] [CrossRef]

- Ananth, R.; Hinnant, K.M.; Giles, S.L.; Snow, A.W.; Farley, J.P. Environmentally-Friendly Surfactants for Foams with Low Fuel Permeability Needed for Effective Pool Fire Suppression; Naval Research Laboratory: Washington, DC, USA, 2020; DC 20375-5320, NRL/MR/6180--20-10,145; Available online: https://apps.dtic.mil/sti/pdfs/AD1111148.pdf (accessed on 10 September 2024).

- Liu, C.; Zhu, G.; Chen, C.; Guo, X.; An, C.; Ding, J. Research on the fire-extinguishing effectiveness of a new nano-scale aerogel fire-extinguishing agent. Therm. Sci. Eng. Prog. 2022, 37, 101625. [Google Scholar] [CrossRef]

- Dubocq, F.; Bjurlid, F.; Ydstål, D.; Titaley, I.A.; Reiner, E.; Wang, T.; Almirall, X.O.; Kärrman, A. Organic contaminants formed during fire extinguishing using different firefighting methods assessed by nontarget analysis. Environ. Pollut. 2020, 265, 114834. [Google Scholar] [CrossRef]

- Levterov, A.A. Acoustic research method for burning flammable substances. Acoust. Phys. 2019, 65, 444–449. [Google Scholar] [CrossRef]

- Loboichenko, V.; Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Harabin, R.; Shevchenko, R.; Strelets, V.; Levterov, A.; Soshinskiy, A.; Tregub, N.; Antoshkin, O. The use of acoustic effects for the prevention and elimination of fires as an element of modern environmental technologies. Environ. Clim. Technol. 2022, 26, 319–330. [Google Scholar] [CrossRef]

- Loboichenko, V.; Wilk-Jakubowski, G.; Wilk-Jakubowski, J.L.; Ciosmak, J. Application of Low-Frequency acoustic waves to extinguish flames on the basis of selected experimental attempts. Appl. Sci. 2024, 14, 8872. [Google Scholar] [CrossRef]

- Vovchuk, T.S.; Wilk-Jakubowski, J.L.; Telelim, V.M.; Loboichenko, V.M.; Shevchenko, R.I.; Shevchenko, O.S.; Tregub, N.S. Investigation of the use of the acoustic effect in extinguishing fires of oil and petroleum products. SOCAR Proc. 2021, 2, 24–31. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.; Stawczyk, P.; Ivanov, S.; Stankov, S. The using of Deep Neural Networks and natural mechanisms of acoustic waves propagation for extinguishing flames. Int. J. Comput. Vis. Robot. 2022, 12, 101–119. [Google Scholar] [CrossRef]

- Ivanov, S.; Stankov, S. Acoustic Extinguishing of Flames Detected by Deep Neural Networks in Embedded Systems. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2021, 46, 307–312. [Google Scholar] [CrossRef]

- Ivanov, S.; Stankov, S. The Artificial Intelligence Platform with the Use of DNN to Detect Flames: A Case of Acoustic Extinguisher. Lect. Notes Netw. Systems. Intell. Comput. Optim. 2021, 371, 24–34. [Google Scholar] [CrossRef]

- Martinsson, J.; Runefors, M.; Frantzich, H.; Glebe, D.; McNamee, M.; Mogren, O. A Novel Method for Smart Fire Detection Using Acoustic Measurements and Machine Learning: Proof of Concept. Fire Technol. 2022, 58, 3385–3403. [Google Scholar] [CrossRef]

- Levterov, A. Acoustic engineering-technical method for preventing emergencies arising as a result of a fire inside a potentially hazardous object. Probl. Fire Saf. 2019, 46, 94–102. [Google Scholar]

- Levterov, A. Identification of a technogenic emergency on the acoustic radiation of a hazard zone. Munic. Econ. Cities 2019, 5, 100–106. [Google Scholar]

- Martínez-de Dios, J.R.; Merino, L.; Caballero, F.; Ollero, A. Automatic forest-fire measuring using ground stations and Unmanned Aerial Systems. Sensors 2011, 11, 6328–6353. [Google Scholar] [CrossRef] [PubMed]

- Wilk-Jakubowski, J.; Stawczyk, P.; Ivanov, S.; Stankov, S. Control of acoustic extinguisher with Deep Neural Networks for fire detection. Elektron. Ir Elektrotechnika 2022, 28, 52–59. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.; Stawczyk, P.; Ivanov, S.; Stankov, S. High-power acoustic fire extinguisher with artificial intelligence platform. Int. J. Comput. Vis. Robot. 2022, 12, 236–249. [Google Scholar] [CrossRef]

- Gelfert, S. Novel Mobile Robot Concept for Human Detection in Fire Smoke Indoor Environments using Deep Learning. In Proceedings of the 8th International Conference on Robotics and Artificial Intelligence (ICRAI 2022), Singapore, 18–20 November 2022. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, G.; Harabin, R.; Ivanov, S. Robotics in crisis management: A review. Technol. Soc. 2022, 68, 101935. [Google Scholar] [CrossRef]

- Digiesi, S.; Laurieri, N.; Lucchese, A.; Piccininno, G. A Novel Integrated Fire Monitoring and Extinguishing System for Trucks. Procedia Comput. Sci. 2024, 232, 2468–2477. [Google Scholar] [CrossRef]

- Szczesniak, A.; Szczesniak, Z. Fast Designing Ladder Diagram of Programmable Logic Controller for a Technological Process. Int. J. Electron. Telecommun. 2022, 68, 709–714. [Google Scholar] [CrossRef]

- Stawczyk, P.; Wilk-Jakubowski, J. Non-invasive attempts to extinguish flames with the use of high-power acoustic extinguisher. Open Eng. 2021, 11, 349–355. [Google Scholar] [CrossRef]

- Friedman, A.N.; Stoliarov, S.I. Acoustic extinction of laminar line-flames. Fire Saf. J. 2017, 93, 102–113. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Predicting Satellite System Signal Degradation due to Rain in the Frequency Range of 1 to 25 GHz. Pol. J. Environ. Stud. 2018, 27, 391–396. [Google Scholar] [CrossRef]

- Azarenko, O.; Honcharenko, Y.; Divizinyuk, M.; Mirnenko, V.; Strilets, V.; Wilk-Jakubowski, J.L. Influence of anthropogenic factors on the solution of applied problems of recording language information in the open area. Soc. Dev. Secur. 2022, 12, 135–143. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Total Signal Degradation of Polish 26-50 GHz Satellite Systems Due to Rain. Pol. J. Environ. Stud. 2018, 27, 397–402. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Overview of broadband information systems architecture for crisis management. Inform. Control. Meas. Econ. Environ. Prot. 2021, 11, 56–60. [Google Scholar] [CrossRef]

- Azarenko, O.; Honcharenko, Y.; Divizinyuk, M.; Mirnenko, V.; Strilets, V.; Wilk-Jakubowski, J.L. The influence of air environment properties on the solution of applied problems of capturing speech information in the open terrain. Soc. Dev. Secur. 2022, 12, 64–77. [Google Scholar] [CrossRef]

- Sturtevant, B.T.; Pantea, C.; Sinha, D.N. Measured sound speeds and acoustic nonlinearity parameter in liquid water up to 523 K and 14 MPa. AIP Adv. 2016, 6, 075310. [Google Scholar] [CrossRef]

- Qiu, W.; Joergensen, J.H.; Corato, E.; Bruus, H.; Augustsson, P. Fast microscale acoustic streaming driven by a Temperature-Gradient-Induced nondissipative acoustic body force. Phys. Rev. Lett. 2021, 127, 064501. [Google Scholar] [CrossRef]

- Acharya, V.S.; Bothien, M.R.; Lieuwen, T.C. Non-linear dynamics of thermoacoustic eigen-mode interactions. Combust. Flame 2018, 194, 309–321. [Google Scholar] [CrossRef]

- Guan, Y.; He, W.; Murugesan, M.; Li, Q.; Liu, P.; Li, L.K.B. Control of self-excited thermoacoustic oscillations using transient forcing, hysteresis and mode switching. Combust. Flame 2019, 202, 262–275. [Google Scholar] [CrossRef]

- OECD. The Global Portal to Information on Chemical Substances. Available online: https://www.echemportal.org/echemportal/substance-search (accessed on 20 September 2024).

- Keerthan, P.; Mahendran, M. Numerical studies of gypsum plasterboard panels under standard fire conditions. Fire Saf. J. 2012, 53, 105–119. [Google Scholar] [CrossRef]

- Rivero, A.J.; Sathre, R.; Navarro, J.G. Life cycle energy and material flow implications of gypsum plasterboard recycling in the European Union. Resour. Conserv. Recycl. 2016, 108, 171–181. [Google Scholar] [CrossRef]

- Abdelbary, K. Chemical analysis of engine oils as an indicator to estimate the rate of wear. Egypt. J. Chem. 2018, 61, 581–590. [Google Scholar] [CrossRef]

- PŚk. Urządzenie do Gaszenia Płomieni Falami Akustycznymi. Ośrodek Transferu Technologii PŚk. Available online: http://ott.tu.kielce.pl/wp-content/uploads/2018/08/Oferta-Technologiczna-ga%C5%9Bnica.pdf (accessed on 5 October 2024).

- Wilk-Jakubowski, J. Experimental Investigation of Amplitude-Modulated Waves for Flame Extinguishing: A Case of Acoustic Environmentally Friendly Technology. Environ. Clim. Technol. 2023, 27, 627–638. [Google Scholar] [CrossRef]

- Niegodajew, P.; Gruszka, K.; Gnatowska, R.; Šofer, M. Application of acoustic oscillations in flame extinction in a presence of obstacle. In Proceedings of the XXIII Fluid Mechanics Conference (KKMP 2018), Zawiercie, Poland, 9–12 September 2018. [Google Scholar] [CrossRef]

- Callanan, J.; Adlakha, R.; Mousa, M.; Nouh, M. Traveling wave thermoacoustic refrigeration with variable phase-coordinated boundary conditions. J. Acoust. Soc. Am. 2023, 154, 3943–3954. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Thakur, S. Acoustic Wave Propagation at Boundaries: Reflection, Absorption, and Transmission. In Handbook of Vibroacoustics, Noise and Harshness; Garg, N., Gautam, C., Rab, S., Wan, M., Agarwal, R., Yadav, S., Eds.; Springer: Singapore, 2024; pp. 1–18. [Google Scholar] [CrossRef]

- Bansod, P.V.; Mohanty, A.R. Inverse acoustical characterization of natural jute sound absorbing material by the particle swarm optimization method. Appl. Acoust. 2016, 112, 41–52. [Google Scholar] [CrossRef]

- Howard, C.; Cazzolato, B. Acoustic Analyses Using MatLab and Ansys, 1st ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Kinsler, L.E.; Frey, A.R.; Coppens, A.B.; Sanders, J.V. Fundamentals of Acoustics, 4th ed.; John Wiley and Sons Inc.: Hoboken, NJ, USA, 2000. [Google Scholar]

- Levterov, A.; Tyutyunik, V.; Kalugin, V. Identification methods of combustion process cellulose materials on the basis of acoustic emission effect. Probl. Fire Saf. 2017, 42, 72–84. [Google Scholar]

- Çengel, Y.A.; Boles, M.A.; Kanoğlu, M. Thermodynamics: An Engineering Approach, 9th ed.; McGraw-Hill Education: New York, NY, USA, 2019. [Google Scholar]

- Future Content. Fire Retardant Material—A History. Available online: https://specialistworkclothing.wordpress.com/2014/03/05/fire-retardant-material-a-history (accessed on 20 October 2024).

- LeVan, S.L. Chemistry of Fire Retardancy; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1984; pp. 531–574. [Google Scholar]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Wilk-Jakubowski, G.; Yılmaz-Atay, H.; Harabin, R.; Ciosmak, J.; Ivanov, S.; Stankov, S. Acoustic Firefighting Method on the Basis of European Research: A Review: Acoustic Firefighting Method. Akustika 2023, 46, 31–45. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Analysis of Flame Suppression Capabilities Using Low-Frequency Acoustic Waves and Frequency Sweeping Techniques. Symmetry 2021, 13, 1299. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Loboichenko, V. Experimental Attempts of Using Modulated and Unmodulated Waves in Low-Frequency Acoustic Wave Flame Extinguishing Technology: A Review of Selected Cases. Stroj. Vestn.—J. Mech. Eng. 2024, 70, 270–281. [Google Scholar] [CrossRef]

- Rabajczyk, A.; Zielecka, M.; Gniazdowska, J. Application of Nanotechnology in Extinguishing Agents. Materials 2022, 15, 8876. [Google Scholar] [CrossRef]

- Yilmaz Atay, G.; Loboichenko, V.; Wilk-Jakubowski, J.Ł. Investigation of calcite and huntite/hydromagnesite mineral in co-presence regarding flame retardant and mechanical properties of wood composites. Cem. Lime Concr. 2024, 29, 40–53. [Google Scholar] [CrossRef]

- Bras, M.L.; Wilkie, C.A.; Bourbigot, S. Fire Retardancy of Polymers-New Applications of Mineral Fillers; The Royal Society of Chemistry: Sawston, UK, 2005; pp. 4–6. [Google Scholar]

- Wicklein, B.; Kocjan, D.; Carosio, F.; Camino, G.; Bergström, L. Tuning the nanocellulose–borate interaction to achieve highly flame retardant hybrid materials. Chem. Mater. 2016, 28, 1985–1989. [Google Scholar] [CrossRef]

| Combustion Product | Impact | References |

|---|---|---|

| Carbon monoxide (CO) | Causes shortness of breath, nausea, vomiting, dizziness, headache in humans, death is possible | [42] |

| Carbon dioxide (CO2) | Causes nausea, dizziness, blurred vision, loss of consciousness, respiratory acidosis | [43] |

| Ammonia ((NH3) | Irritates mucous membranes, causes coughing, lacrimation and cell necrosis, pulmonary edema, and death | [43] |

| Polycyclic aromatic hydrocarbons (PAH)(phenols, aldehydes, ketones, etc.) | Causes cancer in humans, genotoxicity | [44] |

| Hydrogen cyanide (HCN) | Paralyzes the respiratory system, causing tissue respiration disorders | [42] |

| Hydrogen chloride (HCl) | Causes acid rain. Causes irritation and inflammation of mucous membranes in humans | [42,44] |

| Phosphine (HF) | Causes irritation of mucous membranes and damage to the human nervous system, very toxic | [42] |

| Nitrogen oxide (NO) | Causes coughing, vomiting, shortness of breath, cyanosis, cardiovascular failure in humans | [42,44] |

| Sulfur dioxide (SO2) | Causes acid rain, negatively affects plants and animals. In humans, it causes spasm and swelling of the larynx | [44,45] |

| Nitrogen dioxide (NO2) | Causes acid rain. Irritates mucous membranes, causes respiratory diseases, coughing, wheezing, shortness of breath, pulmonary edema | [44,45] |

| Polychlorinated biphenyls (PCBs) | They are neurotoxicants, immunosuppressants, and carcinogens, affecting the thyroid gland and human reproductive functions | [46] |

| Volatile organic compounds (toluene, benzene, ethylbenzene and xylene, formaldehyde, etc.) | Cause irritation of human mucous membranes, contribute to the development of cancer. Toxic to the environment, contribute to global warming | [45,47] |

| Dioxins | They cause pigmentation and skin lesions, disorders of the immune, nervous, reproductive, and endocrine systems, and contribute to the development of cancer | [45] |

| Particulate matters | They irritate the mucous membranes and contribute to the development of respiratory diseases | [43,45] |

| Methane (CH4) | Does not cause direct harm to human health when inhaled, but is a major source of air pollution on a global scale | [48] |

| Material | Time to Reach Critical Concentration, s | Concentration of Combustion Products, mg/L | K | Loss of Velocity, % | Ambient Temperature, °C |

|---|---|---|---|---|---|

| Plastic | 20 | 50 | 1.029 | 15 | 25 |

| Styrofoam | 11.2 | 50 | 1.035 | 20 | |

| Textile | 26.2 | 50 | 1.029 | 12 | |

| Gypsum plasterboard | 78.5 | 50 | 1.018 | 8 | |

| Wood | 32.7 | 50 | 1.03 | 25 | |

| Paper | 21.8 | 50 | 1.02 | 13 | |

| Motor oil | 15.7 | 50 | 1.04 | 25 |

| № | Material | The Indicator of the Distance from the Device to the Obstacle at Different Temperatures, m | The Average Error Rate of Device Readings | Average Value of the Adjusting Parameter, m | |||||

|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 40 °C | 60 °C | 80 °C | 100 °C | Δ, m | Ϭ, % | |||

| 1 | Motor oil | 0.976 | 0.973 | 0.971 | 0.967 | 0.959 | 0.061 | 0.612 | 0.03 |

| 2. | Plastic | 0.969 | 0.977 | 0.985 | 0.989 | 0.991 | 0.06 | 0.61 | 0.019 |

| 3 | Styrofoam | 0.971 | 0.965 | 0.961 | 0.968 | 0.982 | 0.07 | 0.745 | 0.035 |

| 4. | Textile | 0.992 | 0.988 | 0.976 | 0.971 | 0.968 | 0.011 | 1.15 | 0.015 |

| 5. | Paper | 0.963 | 0.968 | 0.969 | 0.971 | 0.973 | 0.03 | 0.27 | 0.034 |

| 6. | Gypsum plasterboard | 0.979 | 0.981 | 0.983 | 0.985 | 0.988 | 0.1.72 | 1.74 | 0.017 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Loboichenko, V.; Wilk-Jakubowski, J.L.; Levterov, A.; Wilk-Jakubowski, G.; Statyvka, Y.; Shevchenko, O. Using the Burning of Polymer Compounds to Determine the Applicability of the Acoustic Method in Fire Extinguishing. Polymers 2024, 16, 3413. https://doi.org/10.3390/polym16233413

Loboichenko V, Wilk-Jakubowski JL, Levterov A, Wilk-Jakubowski G, Statyvka Y, Shevchenko O. Using the Burning of Polymer Compounds to Determine the Applicability of the Acoustic Method in Fire Extinguishing. Polymers. 2024; 16(23):3413. https://doi.org/10.3390/polym16233413

Chicago/Turabian StyleLoboichenko, Valentyna, Jacek Lukasz Wilk-Jakubowski, Alexander Levterov, Grzegorz Wilk-Jakubowski, Yevhenii Statyvka, and Olga Shevchenko. 2024. "Using the Burning of Polymer Compounds to Determine the Applicability of the Acoustic Method in Fire Extinguishing" Polymers 16, no. 23: 3413. https://doi.org/10.3390/polym16233413

APA StyleLoboichenko, V., Wilk-Jakubowski, J. L., Levterov, A., Wilk-Jakubowski, G., Statyvka, Y., & Shevchenko, O. (2024). Using the Burning of Polymer Compounds to Determine the Applicability of the Acoustic Method in Fire Extinguishing. Polymers, 16(23), 3413. https://doi.org/10.3390/polym16233413