Influence of Lignin Type on the Properties of Hemp Fiber-Reinforced Polypropylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Variants

2.3. Composite Materials Manufacturing

2.4. Fourier Transform Infrared Spectroscopy

2.5. Tensile and Bending Testing

2.6. Water Absorbency and Thickness Swelling

2.7. Thermal Analysis

3. Results and Discussions

3.1. FTIR Spectroscopy

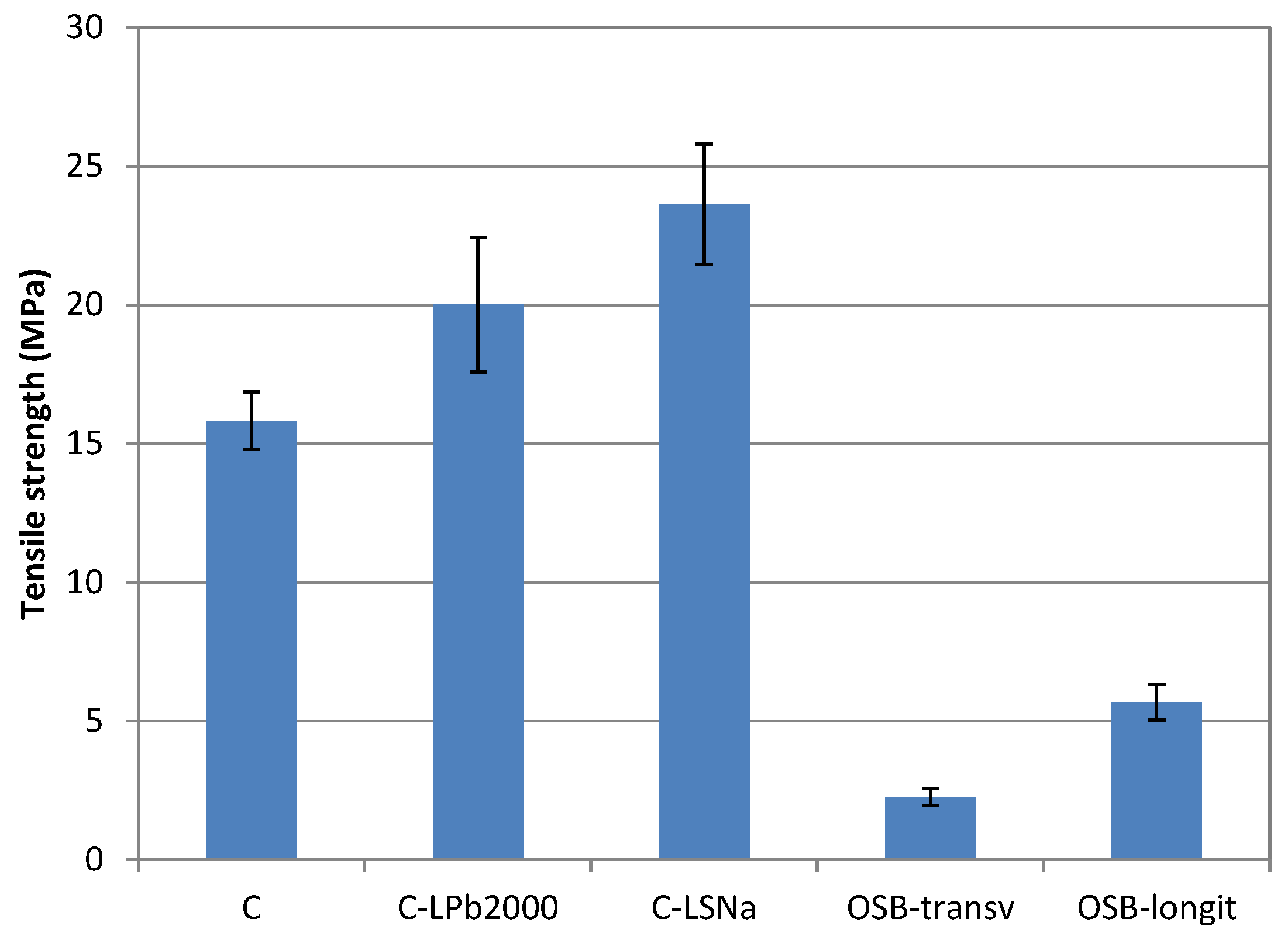

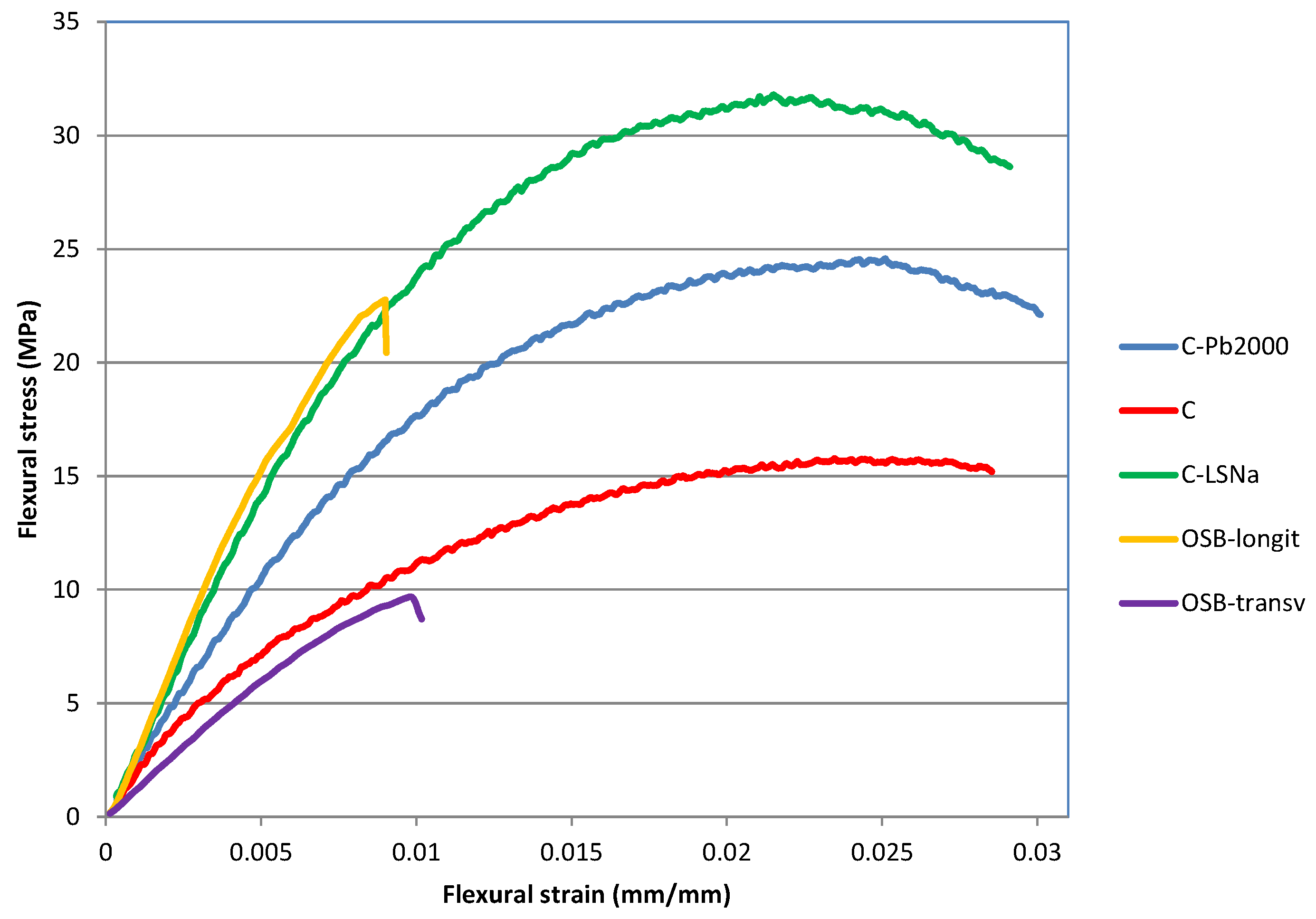

3.2. Mechanical Properties

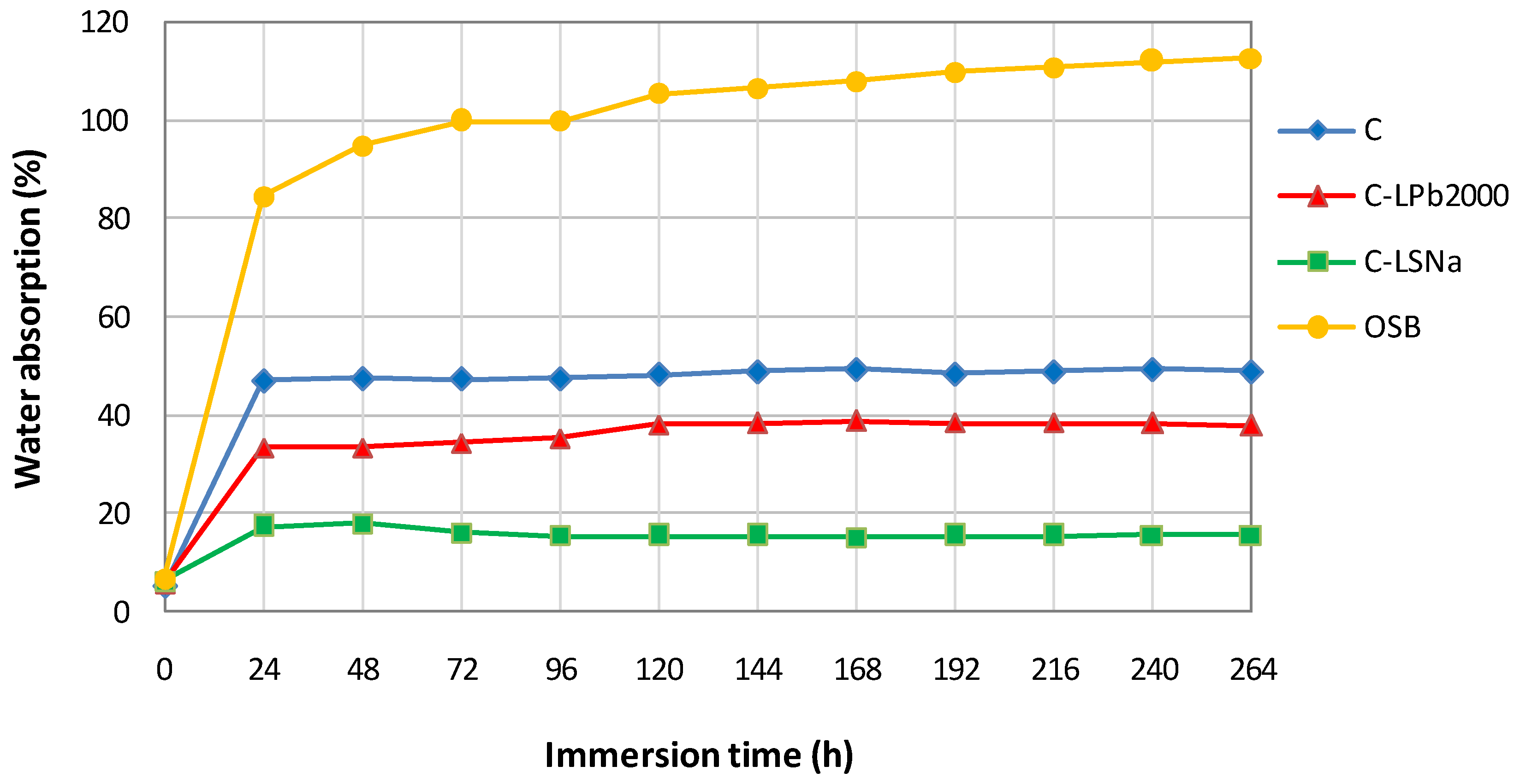

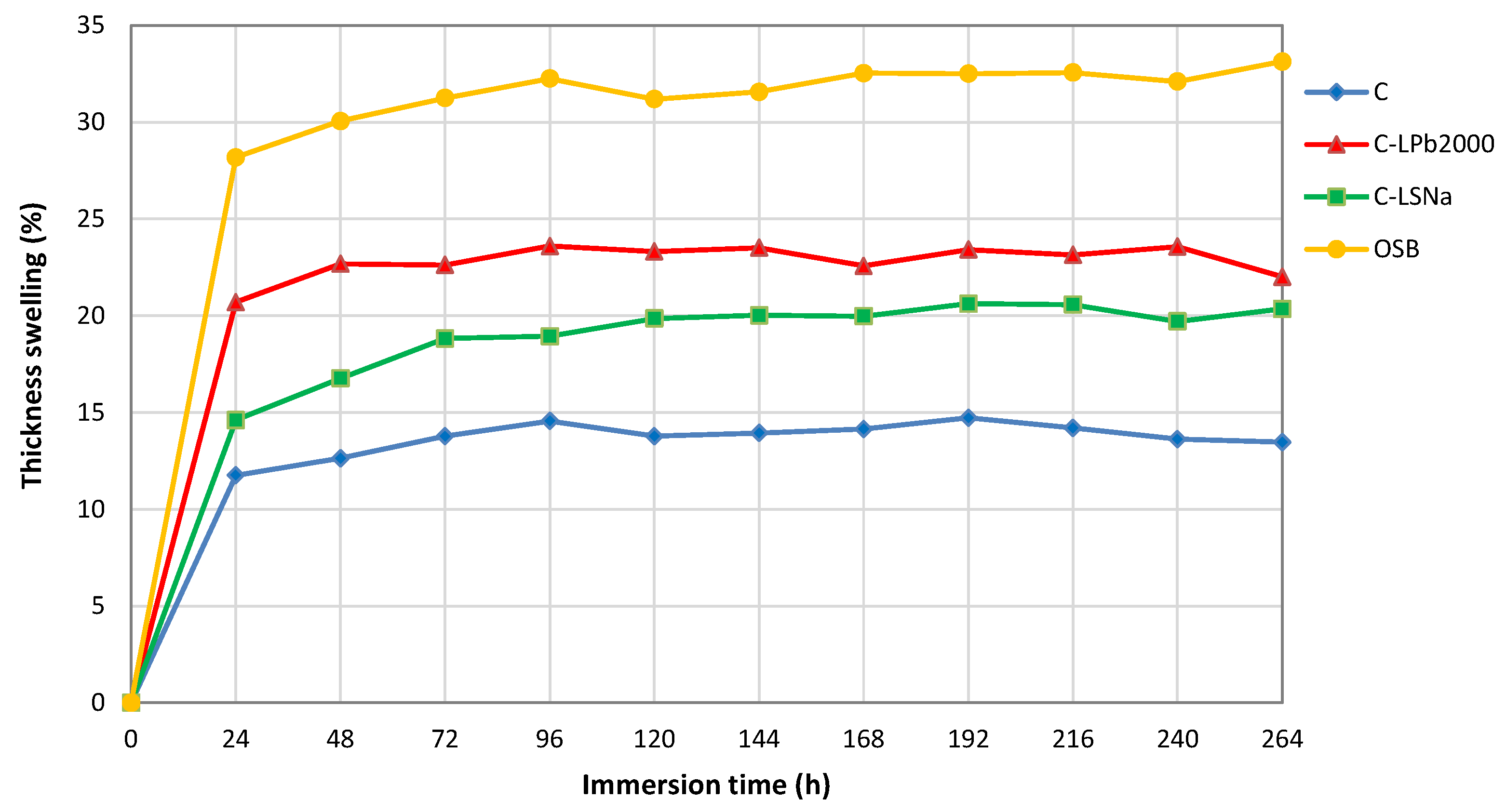

3.3. Water Absorption Behavior

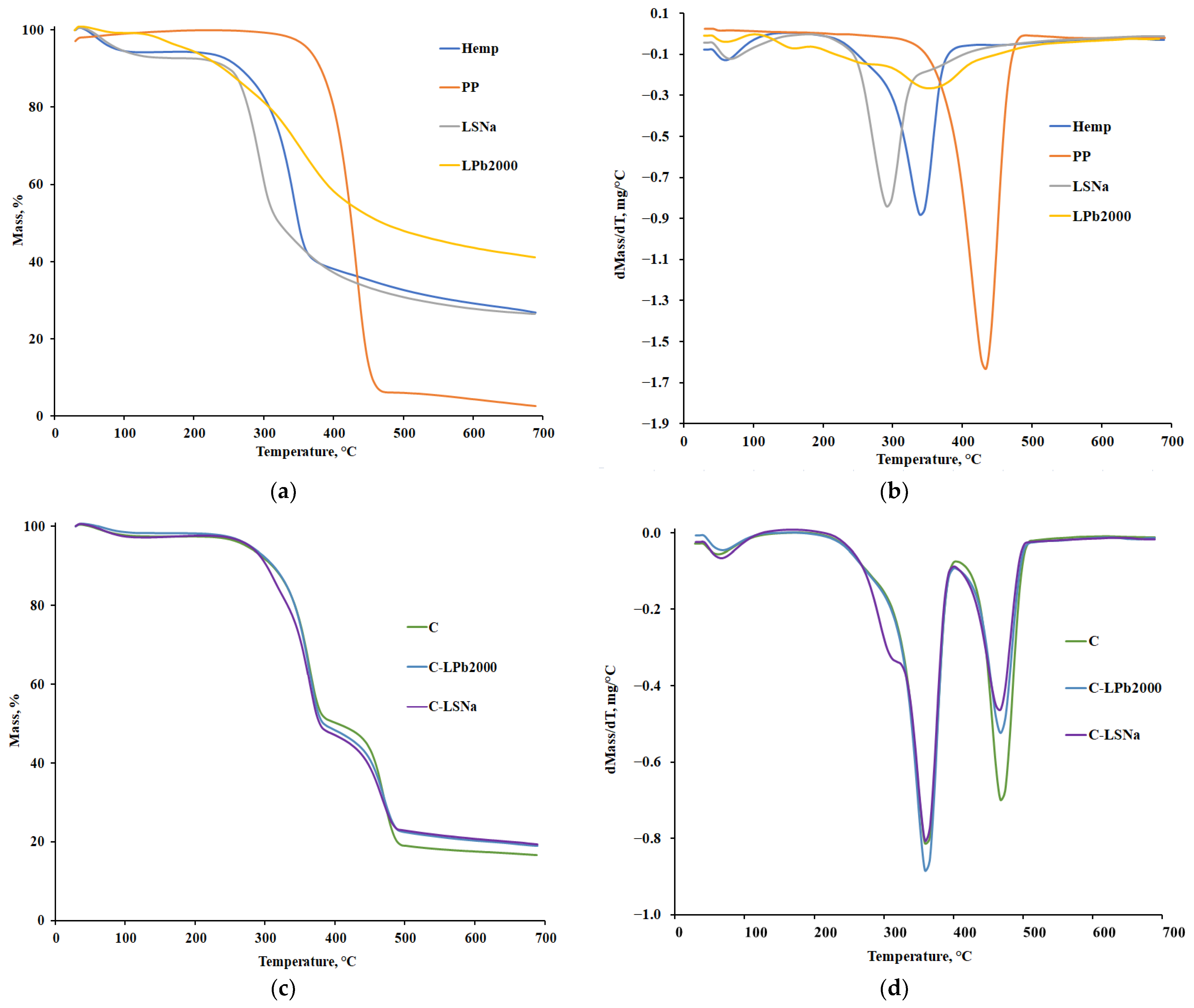

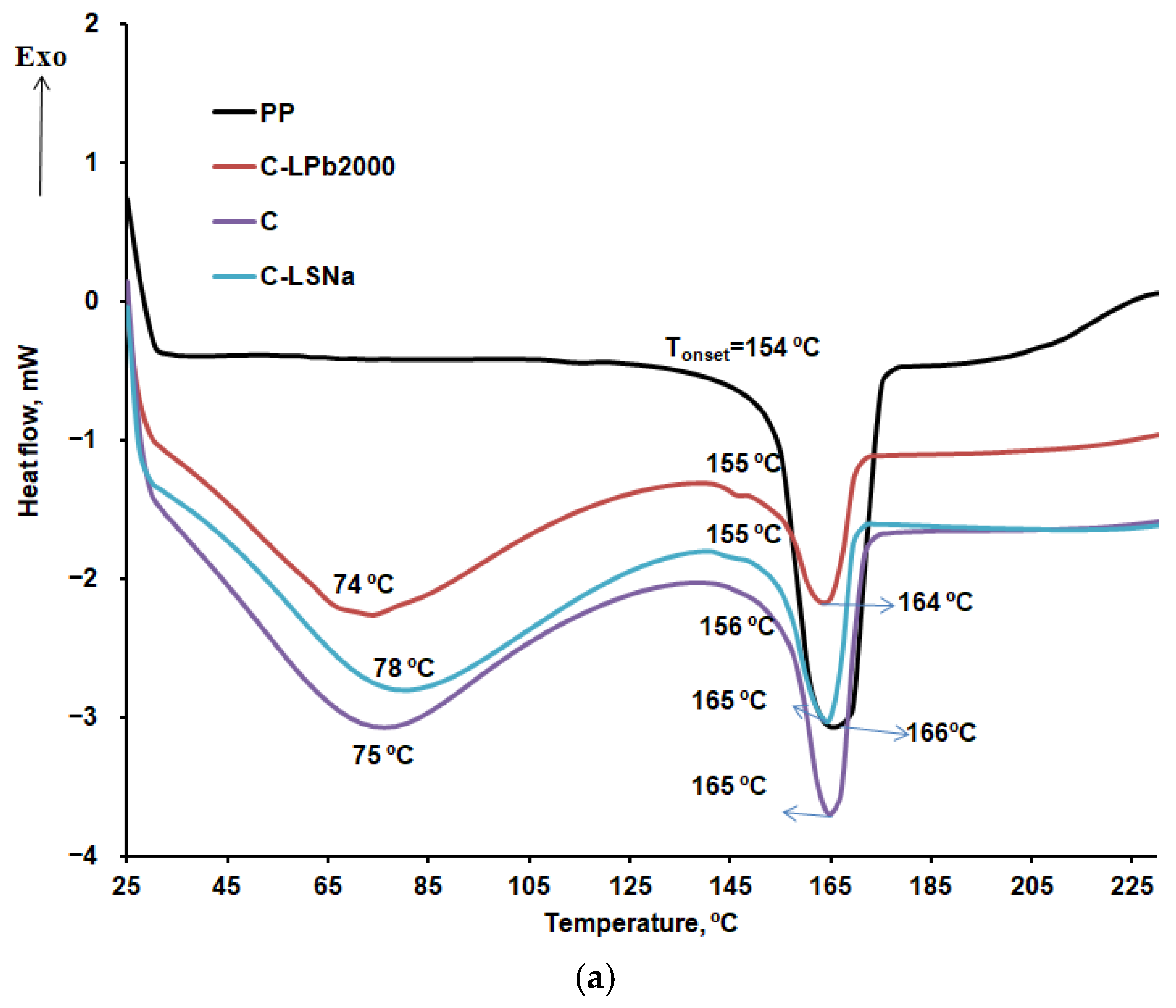

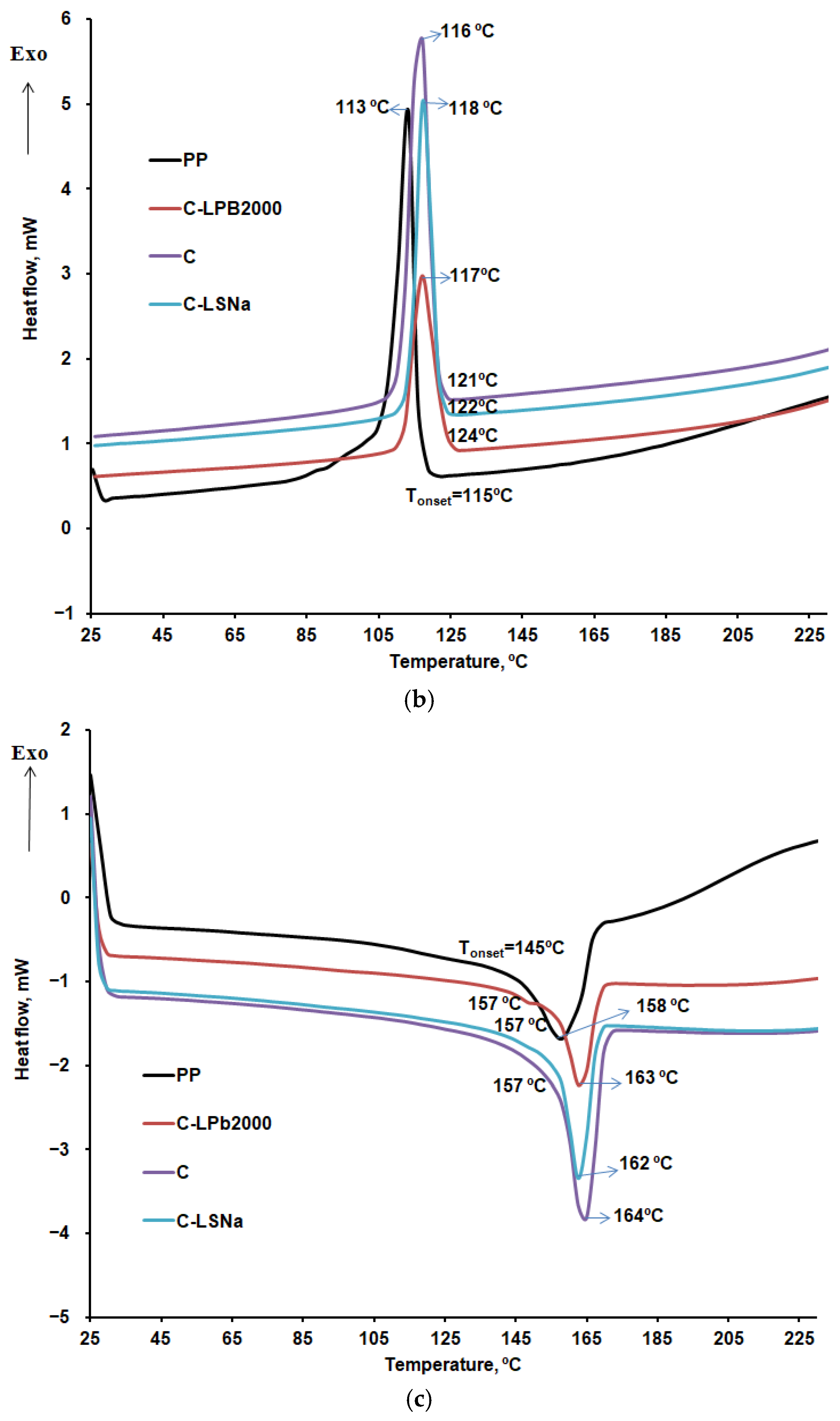

3.4. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vasiliev, V.V.; Morozov, E.V. Introduction. In Advanced Mechanics of Composite Materials, 2nd ed.; Vasiliev, V.V., Morozov, E.V., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 1–30. [Google Scholar]

- Ichim, M.; Muresan, E.I.; Codau, E. Natural-Fiber-Reinforced Polymer Composites for Furniture Applications. Polymers 2024, 16, 3113. [Google Scholar] [CrossRef] [PubMed]

- Sasamori, A.M.; Pires, P.G.P.; de Lemos, A.L.; Santana, R.M.C. Influence of lignin type on the characterization of natural fiber polymer composites. Ciênc. Nat. 2022, 44, e14. [Google Scholar] [CrossRef]

- Baysal, A.; Turkmen, H.S.; Yayla, P. High-velocity impact behavior of nonwoven mats and unidirectional prepreg hemp and flax fibers reinforced hybrid biocomposites. Polym. Compos. 2024, 45, 5399–5415. [Google Scholar] [CrossRef]

- Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer matrix-natural fiber composites: An overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Baysal, A.; Yayla, P.; Turkmen, H.S.; Karaca Ugural, B. Mechanical characterization of hybrid biocomposites reinforced with nonwoven hemp and unidirectional flax fibers. Polym. Compos. 2023, 44, 3555–3566. [Google Scholar] [CrossRef]

- Wood, B.M.; Coles, S.R.; Maggs, S.; Meredith, J.; Kirwan, K. Use of lignin as a compatibiliser in hemp/epoxy composites. Compos. Sci. Technol. 2011, 71, 1804–1810. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Tarrés, Q.; Espinach, F.X.; Vilaseca, F.; Mutjé, P.; Delgado-Aguilar, M. Influence of lignin content on the intrinsic modulus of natural fibers and on the stiffness of composite materials. Int. J. Biol. Macromol. 2020, 155, 81–90. [Google Scholar] [CrossRef] [PubMed]

- Pregi, E.; Faludi, G.; Kun, D.; Móczó, J.; Pukánszky, B. Three-component polypropylene/lignin/flax composites with high natural additive content for structural applications. Ind. Crops Prod. 2022, 182, 114890. [Google Scholar] [CrossRef]

- Mittal, T.; Kant, R.; Bhalla, Y.; Goel, M.K. Recent Advancement and Emerging Applications of Lignin. Indones. J. Chem. 2024, 24, 303–314. [Google Scholar] [CrossRef]

- Collins, M.N.; Nechifor, M.; Tanasă, F.; Zănoagă, M.; McLoughlin, A.; Stróżyk, M.A.; Culebras, M.; Teaca, C.-A. Valorization of lignin in polymer and composite systems for advanced engineering applications—A review. Int. J. Biol. Macromol. 2019, 131, 828–849. [Google Scholar] [CrossRef]

- Mariana, M.; Alfatah, T.; Abdul Khalil, H.P.S.; Yahya, E.B.; Olaiya, N.G.; Nuryawan, A.; Mistar, E.M.; Abdullah, C.K.; Abdulmadjid, S.N.; Ismail, H. A current advancement on the role of lignin as sustainable reinforcement material in biopolymeric blends. J. Mater. Res. Technol. 2021, 15, 2287–2316. [Google Scholar] [CrossRef]

- Ma, C.; Kim, T.H.; Liu, K.; Ma, M.G.; Choi, S.E.; Si, C. Multifunctional Lignin-Based Composite Materials for Emerging Applications. Front. Bioeng. Biotechnol. 2021, 9, 708976. [Google Scholar] [CrossRef] [PubMed]

- Lievonen, M.; Valle-Delgado, J.J.; Mattinen, M.L.; Hult, E.L.; Lintinen, K.; Kostiainen, M.A.; Paananen, A.; Szilvay, G.R.; Setäläb, H.; Österberg, M. A simple process for lignin nanoparticle preparation. Green Chem. 2016, 18, 1416–1422. [Google Scholar] [CrossRef]

- Parit, M.; Jiang, Z. Towards lignin derived thermoplastic polymers. Int. J. Biol. Macromol. 2020, 165, 3180–3197. [Google Scholar] [CrossRef]

- Kropat, M.; Liao, M.; Park, H.; Salem, K.S.; Johnson, S.; Argyropoulos, D.S. A perspective of lignin processing and utilization technologies for composites and plastics with emphasis on technical and market trends. BioResources 2021, 16, 2084–2115. [Google Scholar] [CrossRef]

- Upton, B.M.; Kasko, A.M. Strategies for the Conversion of Lignin to High-Value Polymeric Materials: Review and Perspective. Chem. Rev. 2016, 116, 2275–2306. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Raghavan, P.; Kessler, M.R. Progress in Green Polymer Composites from Lignin for Multifunctional Applications: A Review. ACS Sustain. Chem. Eng. 2014, 2, 1072–1092. [Google Scholar] [CrossRef]

- Albadarin, A.B.; Al-Muhtaseb, A.H.; Walker, G.M.; Allen, S.J.; Ahmad, M.N.M. Retention of toxic chromium from aqueous phase by H3PO4-activated lignin: Effect of salts and desorption studies. Desalination. 2011, 274, 64–73. [Google Scholar] [CrossRef]

- Wang, T.; Li, H.; Diao, X.; Lu, X.; Ma, D.; Ji, N. Lignin to dispersants, adsorbents, flocculants and adhesives: A critical review on industrial applications of lignin. Ind. Crops Prod. 2023, 199, 116715. [Google Scholar] [CrossRef]

- Yang, J.; Wang, X.; Liu, H. Lignins and Lignin Derivatives as Dispersants for Copper Phthalocyanine Pigment Nanoparticles. ACS Sustain. Chem. Eng. 2023, 11, 8199–8207. [Google Scholar] [CrossRef]

- Chen, J.; Eraghi Kazzaz, A.; Alipoor Mazandarani, N.; Hosseinpour Feizi, Z.; Fatehi, P. Production of Flocculants, Adsorbents, and Dispersants from Lignin. Molecules. 2018, 23, 868. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Chen, F.; He, T. Preparation of lignin-based dye dispersant with favorable heat stability and slight fiber staining. J. Dispers. Sci. Technol. 2022, 43, 2122–2133. [Google Scholar] [CrossRef]

- Kalliola, A.; Kangas, P.; Winberg, I.; Vehmas, T.; Kyllönen, H.; Heikkinen, J.; Poukka, O.; Kemppainen, K.; Sjögård, P.; Pehu-Lehtonen, L. Oxidation process concept to produce lignin dispersants at a kraft pulp mill. Nord. Pulp Paper Res. J. 2022, 37, 394–404. [Google Scholar] [CrossRef]

- Gargulak, J.; Gundersen, S.A.; Bierre, F.; Rolland, P. Lignin-Based Chemicals as Green Dispersants for Liquid Formulation: Better Protection Against Crystal Growth. Pestic. Formul. Deliv. Syst. 2016, 36, 30–41. [Google Scholar] [CrossRef]

- Chen, N.; Liu, W.; Huang, J.; Qiu, X. Preparation of octopus-like lignin-grafted cationic polyacrylamide flocculant and its application for water flocculation. Int. J. Biol. Macromol. 2020, 146, 9–17. [Google Scholar] [CrossRef]

- Moore, C.; Gao, W.; Fatehi, P. Cationic Lignin Polymers as Flocculant for Municipal Wastewater. Polymers 2021, 13, 3871. [Google Scholar] [CrossRef]

- Wu, W.; Qi, J.; Fang, J.; Lyu, G.; Yuan, Z.; Wang, Y.; Li, H. One-pot preparation of lignin-based cationic flocculant and its application in dye wastewater. Colloids Surf. A Physicochem. Eng. Asp. 2022, 654, 130082. [Google Scholar] [CrossRef]

- Wang, S.; Kong, F.; Gao, W.; Fatehi, P. Novel Process for Generating Cationic Lignin Based Flocculant. Ind. Eng. Chem. Res. 2018, 57, 6595–6608. [Google Scholar] [CrossRef]

- Grenda, K.; Gamelas, J.A.F.; Arnold, J.; Cayre, O.J.; Rasteiro, M.G. Evaluation of Anionic and Cationic Pulp-Based Flocculants with Diverse Lignin Contents for Application in Effluent Treatment from the Textile Industry: Flocculation Monitoring. Front. Chem. 2020, 8, 5. [Google Scholar] [CrossRef] [PubMed]

- Tian, W.; Gao, Q.; Qian, W. Interlinked Porous Carbon Nanoflakes Derived from Hydrolyzate Residue during Cellulosic Bioethanol Production for Ultrahigh-Rate Supercapacitors in Nonaqueous Electrolytes. ACS Sustain. Chem. Eng. 2017, 5, 1297–1305. [Google Scholar] [CrossRef]

- Hasan, S.; Sardar, R.I.; Shafin, A.A.; Rahman, S.; Mahmud, H.M. A Brief Review on Applications of Lignin. J. Chem. Rev. 2023, 5, 56–82. [Google Scholar] [CrossRef]

- Rudnitskaya, A.; Evtuguin, D.V.; Costa, L.C.; Graça, M.P.F.; Fernandes, A.J.S.; Correia, M.R.P.; Gomes, M.T.S.R.; Oliveira, J.A.B.P. Potentiometric chemical sensors from lignin–poly(propylene oxide) copolymers doped by carbon nanotubes. Analyst. 2013, 138, 501–508. [Google Scholar] [CrossRef] [PubMed]

- Burrs, S.L.; Jairam, S.; Vanegas, D.C.; Tong, Z.; McLamore, E.S. Lignin and silicate based hydrogels for biosensor applications. In Proceedings SPIE 8719, Smart Biomedical and Physiological Sensor Technology X; Cullum, B.M., McLamore, E.S., Eds.; SPIE Defense, Security, and Sensing: Baltimore, MD, USA, 31 May 2013; p. 87190H. [Google Scholar] [CrossRef]

- Peng, Z.; Zou, Y.; Xu, S.; Zhong, W.; Yang, W. High-Performance Biomass-Based Flexible Solid-State Supercapacitor Constructed of Pressure-Sensitive Lignin-Based and Cellulose Hydrogels. ACS Appl. Mater. Interfaces 2018, 10, 22190–22200. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Su, W.; Fang, J.; Qian, Y.; Li, H. A Degradable Mulch Film with Fertilizer Slow-Release Function Enhanced by Lignin. ACS Appl. Polym. Mater. 2023, 5, 6864–6874. [Google Scholar] [CrossRef]

- Chiappero, L.R.; Bartolomei, S.S.; Estenoz, D.A.; Moura, E.A.B.; Nicolau, V.V. Lignin-Based Polyethylene Films with Enhanced Thermal, Opacity and Biodegradability Properties for Agricultural Mulch Applications. J. Polym. Environ. 2021, 29, 450–459. [Google Scholar] [CrossRef]

- Tian, D.; Zhang, J.; Hu, J.; Huang, M.; Zhao, L.; Lei, Y.; Zou, J.; Zhang, S.; Shen, F. A new water-soluble lignin incorporation enhanced the barrier performance of liquid mulching film. Chem. Eng. J. 2023, 452, 139383. [Google Scholar] [CrossRef]

- Sirivechphongkul, K.; Chiarasumran, N.; Saisriyoot, M.; Thanapimmetha, A.; Srinophakun, P.; Iamsaard, K.; Lin, Y.-T. Agri-Biodegradable Mulch Films Derived from Lignin in Empty Fruit Bunches. Catalysts. 2022, 12, 1150. [Google Scholar] [CrossRef]

- Tian, D.; Hu, J.; Bao, J.; Chandra, R.P.; Saddler, J.N.; Lu, C. Lignin valorization: Lignin nanoparticles as high-value bio-additive for multifunctional nanocomposites. Biotechnol. Biofuels. 2017, 10, 192. [Google Scholar] [CrossRef]

- Pappa, C.P.; Cailotto, S.; Gigli, M.; Crestini, C.; Triantafyllidis, K.S. Kraft (Nano)Lignin as Reactive Additive in Epoxy Polymer Bio-Composites. Polymers 2024, 16, 553. [Google Scholar] [CrossRef]

- Diógenes, O.B.F.; de Oliveira, D.R.; da Silva, L.R.R.; Pereira, Í.G.; Mazzetto, S.E.; Araujo, W.S.; Lomonaco, D. Development of coal tar-free coatings: Acetylated lignin as a bio-additive for anticorrosive and UV-blocking epoxy resins. Prog. Org. Coat. 2021, 161, 106533. [Google Scholar] [CrossRef]

- Jedrzejczyk, M.A.; Van den Bosch, S.; Van Aelst, J.; Van Aelst, K.; Kouris, P.D.; Moalin, M.; Haenen, G.R.M.M.; Boot, M.D.; Hensen, E.J.M.; Lagrain, B.; et al. Lignin-Based Additives for Improved Thermo-Oxidative Stability of Biolubricants. ACS Sustain. Chem. Eng. 2021, 9, 12548–12559. [Google Scholar] [CrossRef]

- Xie, S.; Li, Q.; Karki, P.; Zhou, F.; Yuan, J.S. Lignin as Renewable and Superior Asphalt Binder Modifier. ACS Sustain. Chem. Eng. 2017, 5, 2817–2823. [Google Scholar] [CrossRef]

- Ghabchi, R. Effect of Lignin Type as an Additive on Rheology and Adhesion Properties of Asphalt Binder. Solids 2022, 3, 603–619. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Klapiszewska, I.; Ślosarczyk, A.; Jesionowski, T. Lignin-Based Hybrid Admixtures and their Role in Cement Composite Fabrication. Molecules 2019, 24, 3544. [Google Scholar] [CrossRef]

- Zahedi, M.; Zarei, A.; Zarei, M. The effect of lignin on mechanical and dynamical properties of asphalt mixtures. SN Appl. Sci. 2020, 2, 1242. [Google Scholar] [CrossRef]

- Mili, M.; Hashmi, S.A.R.; Ather, M.; Hada, V.; Markandeya, N.; Kamble, S.; Mohapatra, M.; Rathore, S.K.S.; Srivastava, A.K.; Verma, S. Novel lignin as natural-biodegradable binder for various sectors—A review. J. Appl. Polym. Sci. 2022, 139, e51951. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Ji, G.; Fan, Z.; Guo, Y.; Gao, W.; Xin, L. Mechanical Performance Characterization of Lignin-Modified Asphalt Mixture. Appl. Sci. 2020, 10, 3324. [Google Scholar] [CrossRef]

- Zhang, E.; Liu, S.; Shan, L.; Wang, Y. Mechanism analysis of Lignin’s effect on Asphalt’s resistance to moisture damage. J. Clean. Prod. 2024, 434, 139425. [Google Scholar] [CrossRef]

- Mulder, W.J.; Gosselink, R.J.A.; Vingerhoeds, M.H.; Harmsen, P.F.H.; Eastham, D. Lignin based controlled release coatings. Ind. Crops Prod. 2011, 34, 915–920. [Google Scholar] [CrossRef]

- Majeed, Z.; Ramli, N.K.; Mansor, N.; Man, Z. Lignin Modified Urea Fertilizer’s Biodegradation and Nitrogen Release under Reduced Soil Condition. Appl. Mech. Mater. 2014, 699, 981–987. [Google Scholar] [CrossRef]

- Kumar, R.; Næss, G.; Sørensen, M. Slow-release fertilizers using lignin: Challenges and future prospects. Biofuels Bioprod. Biorefining 2023, 17, 1368–1381. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.; Zhang, L.; Li, Z.; Xue, Y.; Wang, R.; Fan, X.; Sun, S. Green construction and release mechanism of lignin-based double-layer coated urea. Biotechnol. Biofuels Bioprod. 2023, 16, 97. [Google Scholar] [CrossRef] [PubMed]

- Vafakish, B.; Babaei-Ghazvini, A.; Patel, R.; Acharya, B. Valorization of Lignin by Crosslinking for Slow-Release Urea Fertilizer Systems: A Promising Approach for Agricultural Applications. Can. J. Chem. 2024, e-First. [Google Scholar] [CrossRef]

- Jiao, G.J.; Xu, Q.; Cao, S.L.; Peng, P.; She, D. Controlled-Release Fertilizer with Lignin Used to Trap Urea/Hydroxymethylurea/Urea-Formaldehyde Polymers. Bioresources 2018, 13, 1711–1728. [Google Scholar] [CrossRef]

- Dikshit, P.K.; Jun, H.B.; Kim, B.S. Biological conversion of lignin and its derivatives to fuels and chemicals. Korean J. Chem. Eng. 2020, 37, 387–401. [Google Scholar] [CrossRef]

- Gendron, J.; Stambouli, I.; Bruel, C.; Boumghar, Y.; Montplaisir, D. Characterization of different types of lignin and their potential use in green adhesives. Ind. Crops Prod. 2022, 182, 114893. [Google Scholar] [CrossRef]

- Bergamasco, S.; Zikeli, F.; Vinciguerra, V.; Sobolev, A.P.; Scarnati, L.; Tofani, G.; Scarascia Mugnozza, G.; Romagnoli, M. Extraction and Characterization of Acidolysis Lignin from Turkey Oak (Quercus cerris L.) and Eucalypt (Eucalyptus camaldulensis Dehnh.) Wood from Population Stands in Italy. Polymers 2023, 15, 3591. [Google Scholar] [CrossRef]

- Huang, C.; He, J.; Narron, R.; Wang, Y.; Yong, Q. Characterization of Kraft Lignin Fractions Obtained by Sequential Ultrafiltration and Their Potential Application as a Biobased Component in Blends with Polyethylene. ACS Sustain. Chem. Eng. 2017, 5, 11770–11779. [Google Scholar] [CrossRef]

- Vishtal, A.; Kraslawski, A. Challenges in industrial applications of technical lignins. Bioresources. 2011, 6, 3547–3568. [Google Scholar] [CrossRef]

- Fredheim, G.E.; Braaten, S.M.; Christensen, B.E. Molecular weight determination of lignosulfonates by size-exclusion chromatography and multi-angle laser light scattering. J. Chromatogr. A 2002, 942, 191–199. [Google Scholar] [CrossRef]

- Gaynor, J.G.; Agwuncha, S.C.; Smith, A.; Gaynor, G.; Harrington, M.J.; Lucia, L. Alkaline pretreatment and soda pulping of genetically improved hemp. Ind. Crops Prod. 2024, 211, 118181. [Google Scholar] [CrossRef]

- Yimlamai, P.; Ardsamang, T.; Puthson, P.; Somboon, P.; Puangsin, B. Soda pulping of sunn hemp (Crotalaria juncea L.) and its usage in molded pulp packaging. J.Bioresour.Bioprod. 2023, 8, 280–291. [Google Scholar] [CrossRef]

- Rabelo, S.C.; Nakasu, P.Y.S.; Scopel, E.; Araújo, M.F.; Cardoso, L.H.; da Costa, A.C. Organosolv pretreatment for biorefineries: Current status, perspectives, and challenges. Bioresour. Technol. 2023, 369, 128331. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Li, M.; Zheng, Y. Lignin biorefinery: Lignin source, isolation, characterization, and bioconversion. In Advances in Bioenergy; Li, Y., Zhou, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; Volume 7, pp. 211–270. [Google Scholar] [CrossRef]

- Liu, B.; Abu-Omar, M.M. Lignin extraction and valorization using heterogeneous transition metal catalysts. In Advances in Inorganic Chemistry; Ford, P.C., van Eldik, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 77, pp. 137–174. [Google Scholar] [CrossRef]

- Mastrolitti, S.; Borsella, E.; Giuliano, A.; Petrone, M.T.; De Bari, I.; Gosselink, R.; van Erven, G.; Annevelink, E.; Triantafyllidis, K.S.; Stichnothe, H. Sustainable Lignin Valorization. Technical Lignin, Processes and Market Development, IEA Bioenergy. 2021. Available online: https://www.ieabioenergy.com/wp-content/uploads/2022/01/Sustainable-Lignin-Valorization_rev26-01-2022.pdf (accessed on 25 November 2024).

- Zhao, Y.; Tagami, A.; Dobele, G.; Lindström, M.E.; Sevastyanova, O. The Impact of Lignin Structural Diversity on Performance of Cellulose Nanofiber (CNF)-Starch Composite Films. Polymers 2019, 11, 538. [Google Scholar] [CrossRef] [PubMed]

- Lang, J.M.; Shrestha, U.M.; Dadmun, M. The Effect of Plant Source on the Properties of Lignin-Based Polyurethanes. Front. Energy Res. 2018, 6, 4. [Google Scholar] [CrossRef]

- Mimini, V.; Sykacek, E.; Syed Hashim, S.N.A.; Holzweber, J.; Hettegger, H.; Fackler, K.; Potthast, A.; Mundigler, N.; Rosenau, T. Compatibility of Kraft Lignin, Organosolv Lignin and Lignosulfonate with PLA in 3D Printing. J. Wood Chem. Technol. 2019, 39, 14–30. [Google Scholar] [CrossRef]

- Hargitai, H.; Rácz, I.; Anandjiwala, R.D. Development of Hemp Fiber Reinforced Polypropylene Composites. J. Thermoplast. Compos. Mater. 2008, 21, 165–174. [Google Scholar] [CrossRef]

- Ichim, M.; Stelea, L.; Filip, I.; Lisa, G.; Muresan, E.I. Thermal and Mechanical Characterization of Coir Fibre–Reinforced Polypropylene Biocomposites. Crystals 2022, 12, 1249. [Google Scholar] [CrossRef]

- Ciupan, C.; Ciupan, M. Designing a line for the continuous thermoforming of boards made of composite materials. Acta Tech. Napoc. Ser.-Appl. Math. Mech. Eng. 2024, 67, 413–420, WOS:001328942700052. [Google Scholar]

- Sameni, J.K. Physico-Chemical Characterization of Lignin Isolated from Industrial Sources for Advanced Applications. Ph.D Thesis, University of Toronto, Toronto, ON, Canada, 2015. [Google Scholar]

- Sameni, J.; Jaffer, S.A.; Sain, M. Thermal and mechanical properties of soda lignin/HDPE blends. Compos. A Appl. Sci. Manuf. 2018, 115, 104–111. [Google Scholar] [CrossRef]

- Abdelaziz, O.Y.; Meier, S.; Prothmann, J.; Turner, C.; Riisager, A.; Hulteberg, C.P. Oxidative Depolymerisation of Lignosulphonate Lignin into Low-Molecular-Weight Products with Cu–Mn/δ-Al2O3. Top. Catal. 2019, 62, 639–648. [Google Scholar] [CrossRef]

- Pylypchuk, I.; Sipponen, M.H. Organic solvent-free production of colloidally stable spherical lignin nanoparticles at high mass concentrations. Green Chem. 2022, 24, 8705–8715. [Google Scholar] [CrossRef]

- Cionca, I.; Ciupan, E.; Ciupan, M.; Ciupan, C. New Ecological Composite Materials for the Upholstered Furniture Industry. Acta Tech. Napoc. Ser.-Appl. Math. Mech. Eng. 2023, 66, 67–72. [Google Scholar]

- ISO 527-4; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. International Organisation for Standardization: Geneva, Switzerland, 2021.

- ISO 527-4:2023; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-reinforced Plastic Composites. International Organisation for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/standard/85809.html (accessed on 11 November 2024).

- ISO 14125; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. International Organisation for Standardization: Geneva, Switzerland, 1998. Available online: https://www.iso.org/standard/23637.html#amendment (accessed on 11 November 2024).

- SIST EN 310; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. Slovenian Institute for Standardization: Ljubljana, Slovenia, 1996. Available online: https://standards.iteh.ai/catalog/standards/sist/32eb8102-345a-4166-8b47-02e92418a30c/sist-en-310-1996?srsltid=AfmBOorxAlHWGW1Hb9_DtZYDxgCTvLndPVN5zib2N1ETF6J4-uLKHPBp (accessed on 11 November 2024).

- Sanjeevi, S.; Shanmugam, V.; Kumar, S.; Ganesan, V.; Sas, G.; Johnson, D.J.; Shanmugam, M.; Ayyanar, A.; Naresh, K.; Neisiany, R.E.; et al. Effects of water absorption on the mechanical properties of hybrid natural fibre/phenol formaldehyde composites. Sci. Rep. 2021, 11, 13385. [Google Scholar] [CrossRef]

- ISO 11357-1:2023; Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General Principles. International Organisation for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/obp/ui/#iso:std:iso:11357:-1:ed-4:v1:en (accessed on 11 November 2024).

- ISO 11358-1:2022; Plastics—Thermogravimetry (TG) of Polymers—Part 1: General Principles. International Organisation for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/79999.html (accessed on 11 November 2024).

- Liu, Q.; Zhou, S.J.; Xiong, S.J.; Yu, S.; Yuan, T.Q. Fractionated lignin as a green compatibilizer to improve the compatibility of poly (butylene adipate-co-terephthalate)/polylactic acid composites. Int. J. Biol. Macromol. 2024, 265 Pt 1, 130834. [Google Scholar] [CrossRef]

- Hamdan, M.H.M.; Siregar, J.P.; Cionita, T.; Jaafar, J.; Efriyohadi, A.; Junid, R.; Kholil, A. Water absorption behaviour on the mechanical properties of woven hybrid reinforced polyester composites. Int. J. Adv. Manuf. Technol. 2019, 104, 1075–1086. [Google Scholar] [CrossRef]

- Saw, S.K.; Akhtar, K.; Yadav, N.; Singh, A.K. Hybrid Composites Made from Jute/Coir Fibers: Water Absorption, Thickness Swelling, Density, Morphology, and Mechanical Properties. J. Nat. Fibers. 2014, 11, 39–53. [Google Scholar] [CrossRef]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose, and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Jakab, E.; Faix, O.; Till, F. Thermal decomposition of milled wood lignins studied by thermogravimetry/mass spectrometry. J. Anal. Appl. Pyrolysis 1997, 40–41, 171e86. [Google Scholar] [CrossRef]

- De Chiricoa, A.; Armaninia, M.; Chinib, P.; Cioccolob, G.; Provasolia, F.; Audisio, G. Flame retardants for polypropylene based on lignin. Polym. Degrad. Stab. 2003, 79, 139–145. [Google Scholar] [CrossRef]

- Canetti, M.; Bertini, F.; De Chirico, A.; Audisio, G. Thermal degradation behaviour of isotactic polypropylene blended with lignin. Polym. Degrad. Stab. 2006, 91, 494–498. [Google Scholar] [CrossRef]

- Yu, Y.; Fu, S.; Song, P.; Luo, X.; Jin, Y.; Lu, F.; Wu, Q.; Ye, J. Functionalized lignin by grafting phosphorus-nitrogen improves the thermal stability and flame retardancy of polypropylene. Polym. Degrad. Stab. 2012, 97, 541–546. [Google Scholar] [CrossRef]

- Wladyka-Przybylak, M.; Wesolek, D.; Rojewski, S.; Gasiorowski, R.; Gieparda, W.; Bujnowicz, K.; Maciejewski, H.; Wojcik, R.; Nowicki, M. Synergistic Effect of Modified Natural Fibres with Halogen-Free Fire Retardants in Reducing Flammability of Composites. J. Biobased Mater. Bioenergy 2015, 9, 115–127. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Fierascu, R.C.; Gabor, A.R.; Nicolae, C.A. Effect of hemp fiber length on the mechanical and thermal properties of polypropylene/SEBS/hemp fiber composites. J. Mater. Res. Technol. 2020, 9, 10768–10781. [Google Scholar] [CrossRef]

- Prambauer, M.; Paulik, C.; Burgstaller, C. Influence of Paper Content and Matrix Selection on the Porosity, Crystallinity and Water Uptake of Thermoplastic Paper Composites. J. Polym. Environ. 2018, 26, 2007–2017. [Google Scholar] [CrossRef]

- Lanyi, F.; Wenzke, N.; Kaschta, J.; Schubert, D.W. On the Determination of the Enthalpy of Fusion of α-Crystalline Isotactic Polypropylene Using Differential Scanning Calorimetry, X-Ray Diffraction, and Fourier-Transform Infrared Spectroscopy: An Old Story Revisited. Adv. Eng. Mater. 2020, 22, 1900796. [Google Scholar] [CrossRef]

- Pengfei, N.; Xiaojun, W.; Baoying, L.; Shengru, L.; Jie, Y. Melting and nonisothermal crystallization behavior of polypropylene/hemp fiber composites. J. Compos. Mater. 2011, 46, 203–210. [Google Scholar] [CrossRef]

| Characteristics | Values |

|---|---|

| Solids, % | 95 |

| Ash, % | 1.3 |

| pH (10% dispersion) | 4.8 |

| Density, g/mL | ~0.6 |

| Aromatic OH, mmole/g | 1.6–1.8 |

| COOH, mmole/g | 2.1–2.3 |

| T softening, °C | ~130 |

| Solubility in aqueous alkali, % | 95 |

| Properties | Value |

|---|---|

| Dry solids, % w/w | >95% |

| pH (10% solution) | 6 ± 1 |

| Analytical data | Typical value (as % w/w of total dry solids) |

| Sodium, Na | 9 |

| Sulfur, S | 8.5 |

| Calcium, Ca | 0.12 |

| Chlorine, Cl | 0.01 |

| Insolubles | <0.1 |

| Sulfate (as sulfate ions) | 7.5 |

| Total free sugars (determined by HPLC) | 2.0 |

| Composite Code | Components Ratio | Composition |

|---|---|---|

| C | Hemp/PP = 4:1 | 80% hemp + 20% PP |

| C-LPb2000 | Hemp/PP/Soda Lignin = 4:1:1 | 66.7% hemp + 16.65% PP + 16.65% Soda Lignin |

| C-LSNa | Hemp/PP/Lignosulfonate = 4:1:1 | 66.7% hemp + 16.65% PP + 16.65% Lignosulfonate |

| Material | Thickness (mm) | Density (g/cm3) |

|---|---|---|

| C | 4.87 ± 0.12 | 0.73 ± 0.03 |

| C-LPb2000 | 4.53 ± 0.15 | 1.10 ± 0.04 |

| C-LSNa | 4.47 ± 0.06 | 1.09 ± 0.02 |

| OSB | 8.1 ± 0.1 | 0.67 ± 0.06 |

| Sample | Stage | Tonset, [°C] | Tmax, [°C] | Tendset, [°C] | Mass Loss, [%] |

|---|---|---|---|---|---|

| Hemp | I | 47.41 | 60.21 | 97.77 | 6.27 |

| II | 290.67 | 341.59 | 360.09 | 51.14 | |

| III | 360.09 | 467.95 | 562.66 | 16.51 | |

| PP | I | 380.39 | 431.69 | 462.29 | 99.99 |

| LSNa | I | 50.95 | 65.94 | 116.47 | 7.89 |

| II | 258.24 | 292.99 | 310.13 | 38.91 | |

| III | 310.13 | 358.27 | 485.30 | 27.39 | |

| LPb 2000 | I | 50.61 | 59.17 | 75.96 | 1.67 |

| II | 129.90 | 158.86 | 214.95 | 6.29 | |

| III | 214.95 | 261.50 | 319.18 | 15.17 | |

| IV | 319.18 | 352.10 | 544.83 | 36.82 | |

| C | I | 48.49 | 61.72 | 113.07 | 3.00 |

| II | 304.55 | 362.55 | 381.08 | 48.02 | |

| III | 446.70 | 469.91 | 488.62 | 32.74 | |

| C-LPb2000 | I | 44.84 | 69.33 | 101.86 | 3.63 |

| II | 284.30 | 310.98 | 343.70 | 26.34 | |

| III | 343.70 | 361.89 | 378.72 | 28.64 | |

| IV | 449.97 | 470.89 | 486.17 | 25.23 | |

| C-LSNa | I | 48.45 | 69.33 | 101.86 | 3.63 |

| II | 284.30 | 310.98 | 343.70 | 26.34 | |

| III | 343.70 | 361.89 | 378.72 | 28.64 | |

| IV | 449.97 | 470.89 | 486.17 | 25.23 |

| Sample | First Heating | Second Heating | ||

|---|---|---|---|---|

| (J/g) | Xc (%) | Xc (%) | ||

| PP | 82.28 | 39.74 | 68.73 | 33.18 |

| C-LPb2000 | 13.62 | 32.89 | 11.88 | 28.69 |

| C | 24.07 | 58.14 | 25.89 | 62.53 |

| C-LSNa | 15.94 | 38.50 | 15.09 | 36.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciolacu, F.; Măluțan, T.; Lisa, G.; Ichim, M. Influence of Lignin Type on the Properties of Hemp Fiber-Reinforced Polypropylene Composites. Polymers 2024, 16, 3442. https://doi.org/10.3390/polym16233442

Ciolacu F, Măluțan T, Lisa G, Ichim M. Influence of Lignin Type on the Properties of Hemp Fiber-Reinforced Polypropylene Composites. Polymers. 2024; 16(23):3442. https://doi.org/10.3390/polym16233442

Chicago/Turabian StyleCiolacu, Florin, Teodor Măluțan, Gabriela Lisa, and Mariana Ichim. 2024. "Influence of Lignin Type on the Properties of Hemp Fiber-Reinforced Polypropylene Composites" Polymers 16, no. 23: 3442. https://doi.org/10.3390/polym16233442

APA StyleCiolacu, F., Măluțan, T., Lisa, G., & Ichim, M. (2024). Influence of Lignin Type on the Properties of Hemp Fiber-Reinforced Polypropylene Composites. Polymers, 16(23), 3442. https://doi.org/10.3390/polym16233442