Saccharomyces pastorianus Residual Biomass Immobilized in a Polymer Matrix as a Biosorbent for Reactive Dye Removal: Investigations in a Dynamic System

Abstract

1. Introduction

- Packed bed systems are one of the most commonly used equipment: The biosorbent is packed into a column, and the contaminated water is passed through the column at a controlled flow rate. The pollutants are adsorbed onto the surface of the biosorbent as the water flows through the column.

- Fluidized bed systems are another type of equipment where the biosorbent is fluidized by passing air or other gas through the column, allowing the use of a high density of particles with good mixing between the phases, and requires low energy.

- Stirred reactors with membranes combine biological treatment and membrane filtration in a single system: the biosorbent is suspended in the wastewater, and a membrane filter is used to separate the clean water from the initial wastewater and biosorbent.

2. Experimental Procedure

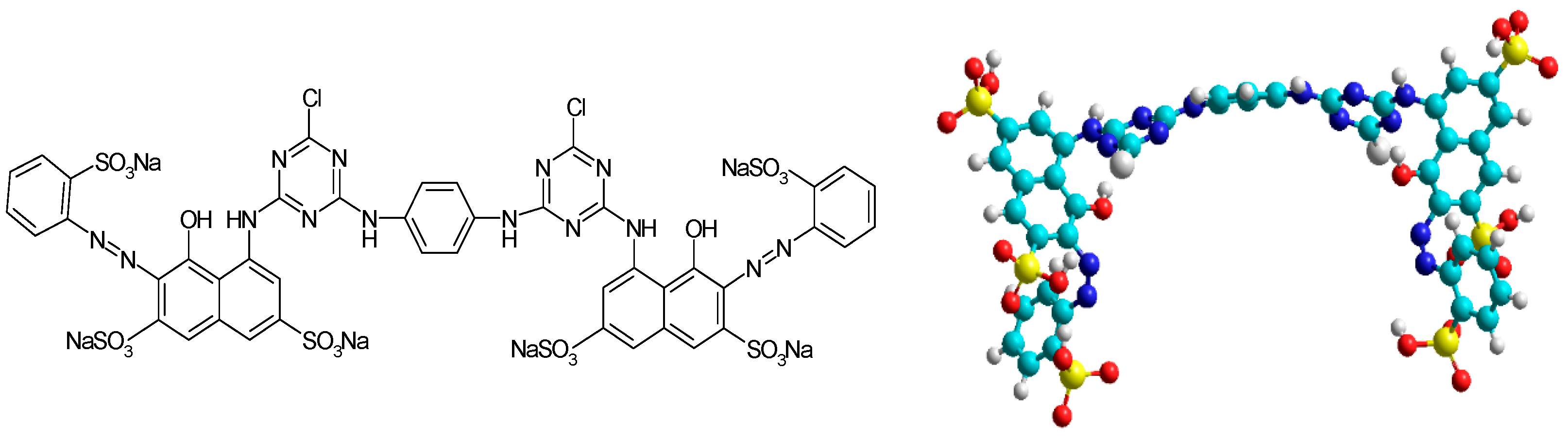

2.1. Materials

2.2. Methods

2.2.1. Quantitative Characterization of the Biosorption Process

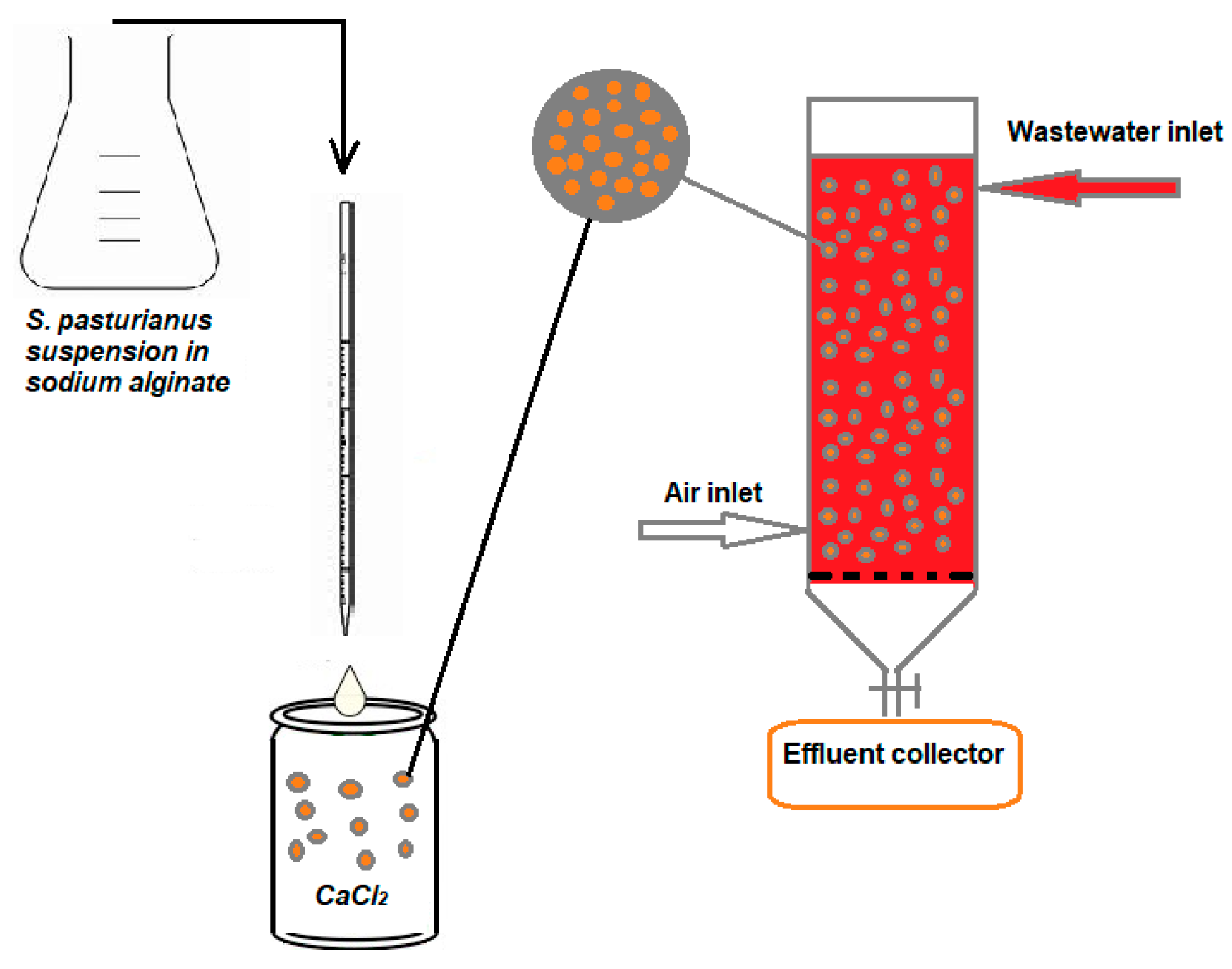

2.2.2. Dynamic Biosorption Procedure

- (1)

- Based on the best outcomes from the batch adsorption investigation, the inlet solution temperature and pH were set at 25 °C and 3, respectively [38];

- (2)

- Two distinct flow rates (Fv1 = 4.0 and Fv2 = 6.1 mL/min) of the dye synthetic solutions with the same dye concentration (51.2 mg/L and 77.84 mg/L, respectively) were passed through the fluidized biosorbent bed in the column, equivalent to a biosorbent mass (m) of 20 g.

- (3)

- Another parameter analyzed was the BRed dye initial concentration. Concentrations of 51.2 mg/L and 77.84 mg/L were selected and tested at a flow rate of 6.1 mL/min and biosorbent dose of 20 g.

- (4)

- The third parameter analyzed was the biosorbent dose. Two doses of 16 and 20 g were tested at a flow rate of 6.1 mL/min and an initial dye concentration of 77.84 mg/L.

2.3. Modeling the Biosorption Experimental Data in a Dynamic Regime

3. Results and Discussion

3.1. Factors That Influence the Biosorption Process in the Dynamic Regime

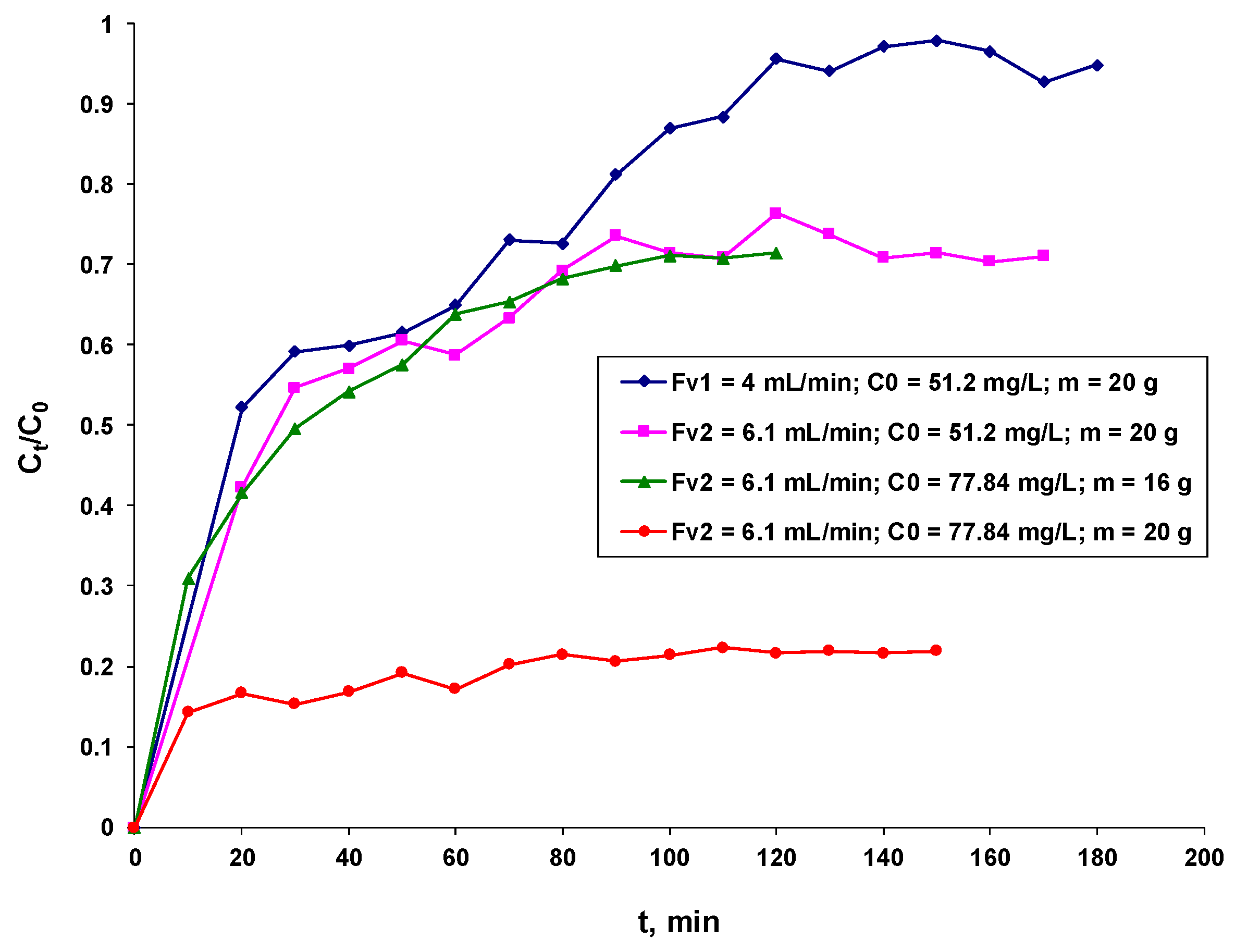

- (i)

- For the same initial dye concentration and the same amount of biosorbent in the fluidized bed, the biosorption capacity (qt, mg/g) is positively influenced by the passage of the solution through the column at a lower flow rate (Fv, mL/min), as this ensures a longer contact between it and the biosorbent layer, which favors a better retention of the high-molecular-weight dye;

- (ii)

- For the same flow rate of the solution (Fv, mL/min) through the column and the same amount of biosorbent in the fluidized layer, it is observed that the retention of the dye is better in the case of the solution with a lower concentration of the dye. This behavior can be explained by the fact that the active centers of the biosorbent become more accessible with a larger amount of dye, since the molecules are more mobile at a lower concentration and can diffuse more easily to the surface of the biosorbent.

- (iii)

- For the same initial concentration of dye and the same flow rate of the solution flowing through the column, an improved biosorption of the dye is observed in the case of a lower biosorbent dose. This behavior can be explained by taking into account the large size of the adsorbate molecules and the possible steric hindrances that may occur during their dissolution. A lower dosage of the biosorbent leads to less compaction of the layer, which facilitates the diffusion of the bulky dye molecules to the active sites.

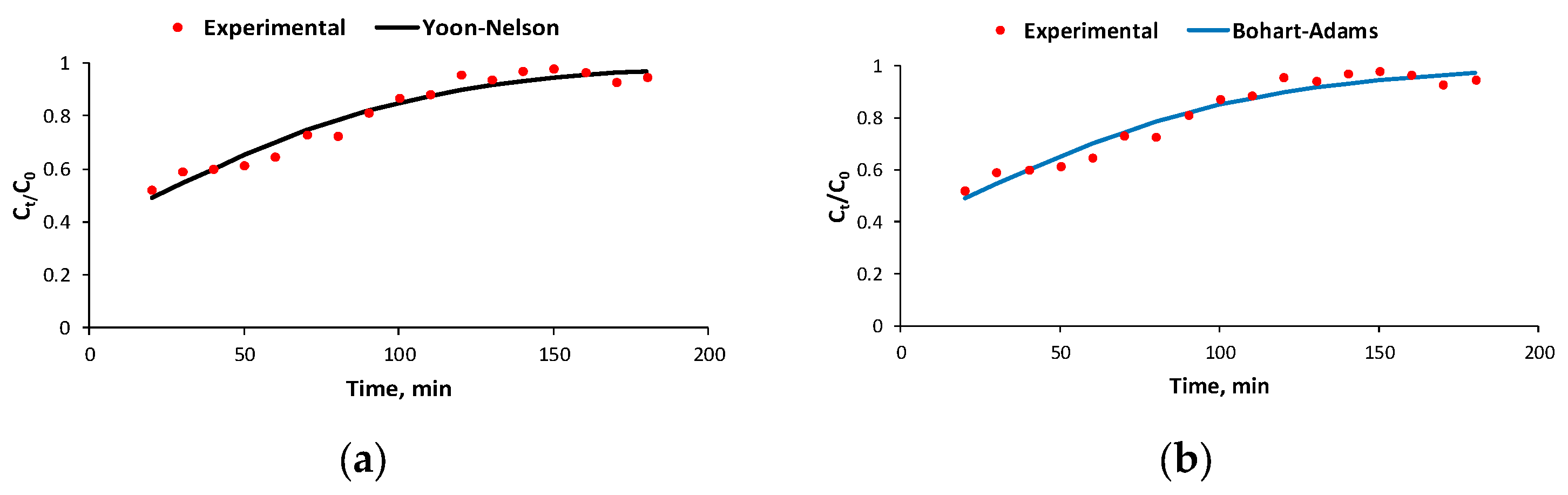

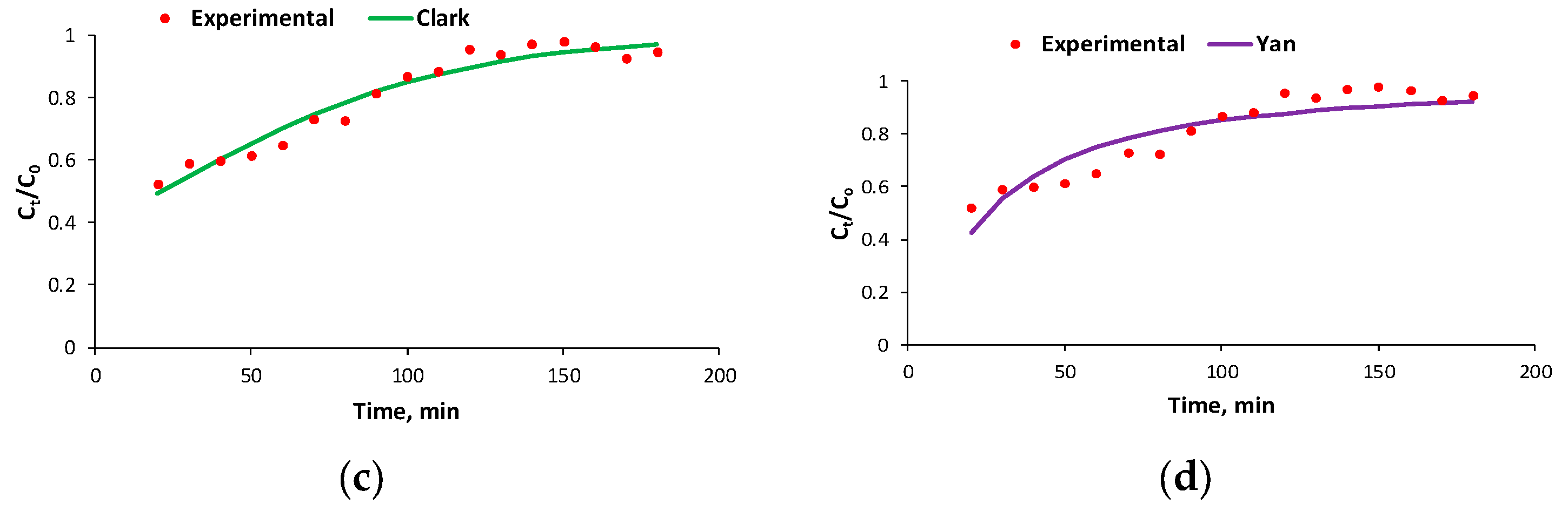

3.2. Breakthrough Curves

3.3. Modeling the Dynamic Biosorption Process

- -

- -

- When the flow rate is 6.1 mL/min, the only matched model is that of Yan with values for R2 in the range of 0.87005–0.992838. The best value for the regression coefficient (0.992838) was obtained for C0 = 77.84 mg/L and biosorbent mass = 16 g (Table 2)

3.4. Dye-Loaded Biosorbent Regeneration Study

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Subbaiah, M.V.; Kim, D.-S. Adsorption of methyl orange from aqueous solution by aminated pumpkin seed powder: Kinetics, isotherms, and thermodynamic studies. Ecotoxicol. Environ. Saf. 2016, 128, 109–117. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, T.K.; Ghosh, G.; Akter, M.N.; Adhikary, K.; Islam, M.S.; Ghosh, P.; Zaman, S.; Habib, A.; Kabir, A.H.M.E. Biosorption of Reactive Red 120 Dye from Aqueous Solutions by using Mahagoni (Swietenia mahagoni) Wood and Bark Charcoal: Equilibrium, and Kinetic Studies. Pollution 2021, 7, 905–921. [Google Scholar] [CrossRef]

- Chandanshive, V.; Kadam, S.; Rane, N.; Jeon, B.-H.; Jadhav, J.; Govindwar, S. In situ textile wastewater treatment in high rate transpiration system furrows planted with aquatic macrophytes and floating phytobeds. Chemosphere 2020, 252, 126513. [Google Scholar] [CrossRef] [PubMed]

- Rápó, E.; Szép, R.; Keresztesi, Á.; Suciu, M.; Tonk, S. Adsorptive removal of cationic and anionic dyes from aqueous solutions by using eggshell household waste as biosorbent. Acta Chim. Slov. 2018, 65, 709–717. [Google Scholar] [CrossRef]

- Subramani, S.E.; Thinakaran, N. Isotherm, kinetic and thermodynamic studies on the adsorption behaviour of textile dyes onto chitosan. Process Saf. Environ. Prot. 2017, 106, 1–10. [Google Scholar] [CrossRef]

- Sayin, F. Insight into Decolorization Characteristics of a Green Biocomposite Sorbent System Prepared by Immobilization of Fungal Cells on Lignocellulosic Matrix: Box-Behnken Design. Water Air Soil Pollut. 2022, 233, 262. [Google Scholar] [CrossRef]

- Pérez-Calderón, J.; Santos, M.V.; Zaritzky, N. Experimental study and modelling of an azo colorant dynamic adsorption onto functional cross-linked chitosan/ceramic particles in a fixed bed column. Can. J. Chem. Eng. 2023, 1, 5941–5955. [Google Scholar] [CrossRef]

- Al-Tohamy, R.; Ali, S.S.; Li, F.; Okasha, K.M.; Mahmoud, Y.A.-G.; Elsamahy, T.; Sun, J. A critical review on the treatment of dye-containing wastewater: Ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicol. Environ. Saf. 2022, 231, 113160. [Google Scholar] [CrossRef]

- Samsami, S.; Mohamadizaniani, M.; Sarrafzadeh, M.-H.; Rene, E.R.; Firoozbahr, M. Recent advances in the treatment of dye-containing wastewater from textile industries: Overview and perspectives. Process Saf. Environ. Prot. 2020, 143, 138–163. [Google Scholar] [CrossRef]

- Ahmad, A.; Mohd-Setapar, S.H.; Chuong, C.S.; Khatoon, A.; Wani, W.A.; Kumar, R.; Rafatullah, M. Recent advances in new generation dye removal technologies: Novel search for approaches to reprocess wastewater. RSC Adv. 2015, 5, 30801–30818. [Google Scholar] [CrossRef]

- Rahmani, A.R.; Mousavi-Tashar, A.; Masoumi, Z.; Azarian, G. Integrated advanced oxidation process, sono-Fenton treatment, for mineralization and volume reduction of activated sludge. Ecotoxicol. Environ. Saf. 2019, 168, 120–126. [Google Scholar] [CrossRef] [PubMed]

- Deniz, F. Application of biorefinery by-product of Nigella sativa L. herb for green treatment of synthetic dye impurity in aquatic environment: A circular economy based approach to water purification. Int. J. Phytoremediation 2023, 25, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Kotabewatta, P.A.; Lim, L.B.L.; Priyantha, N. Biosorption of Cr(III) and Pb(II) from synthetic wastewater under dynamic conditions–diffusion characteristics. Ceylon J. Sci. 2023, 52, 71. [Google Scholar] [CrossRef]

- Dehaghania, A.H.S.; Soleimanib, R.; Mohammadic, A.H. Simulation of chromium(III) ions biosorption from aqueous environment by olive stone biomass in a fixed-bed column and analysis of effective parameters using computational fluid dynamics method. Desalination Water Treat. 2022, 264, 196–204. [Google Scholar] [CrossRef]

- Fomina, M.; Gadd, G.M. Biosorption: Current perspectives on concept, definition and application. Bioresour. Technol. 2014, 160, 3–14. [Google Scholar] [CrossRef] [PubMed]

- Elgarahy, A.M.; Elwakeel, K.Z.; Mohammad, S.H.; Elshoubaky, G.A. A critical review of biosorption of dyes, heavy metals and metalloids from wastewater as an efficient and green process. Clean. Eng. Technol. 2021, 4, 100209. [Google Scholar] [CrossRef]

- Jabli, M. Synthesis, characterization, and assessment of cationic and anionic dye adsorption performance of functionalized silica immobilized chitosan bio-polymer. Int. J. Biol. Macromol. 2020, 153, 305–316. [Google Scholar] [CrossRef]

- Da Fontoura, J.T.; Rolim, G.S.; Mella, B.; Farenzena, M.; Gutterres, M. Defatted microalgal biomass as biosorbent for the removal of Acid Blue 161 dye from tannery effluent. J. Environ. Chem. Eng. 2017, 5, 5076–5084. [Google Scholar] [CrossRef]

- Sarıkaya, A.G.; Kopar, E.E. Biosorption of Sirius Blue azo-dye by Agaricus campestris biomass: Batch and continuous column studies. Mater. Chem. Phys. 2022, 276, 125381. [Google Scholar] [CrossRef]

- Tonato, D.; Drumm, F.C.; Grassi, P.; Georgin, J.; Gerhardt, A.E.; Dotto, G.L.; Mazutti, M.A. Residual biomass of Nigrospora sp. from process of the microbial oil extraction for the biosorption of procion red H–E7B dye. J. Water Process Eng. 2019, 31, 100818. [Google Scholar] [CrossRef]

- Hamad, M.T.M.H. Optimization study of the adsorption of malachite green removal by MgO nano-composite, nano-bentonite and fungal immobilization on active carbon using response surface methodology and kinetic study. Environ. Sci. Eur. 2023, 35, 26. [Google Scholar] [CrossRef]

- Noreen, S.; Bhatti, H.N.; Zuber, M.; Zahid, M.; Asgher, M. Removal of Actacid Orange-RL Dye Using Biocomposites: Modeling Studies. Pol. J. Environ. Stud. 2017, 26, 2125–2134. [Google Scholar] [CrossRef] [PubMed]

- Vairavel, P.; Murty, V.R. Optimization of batch process parameters for Congo red color removal by Neurospora crassa live fungal biomass with wheat bran dual adsorbent using response surface methodology. Desalination Water Treat. 2018, 103, 84–101. [Google Scholar] [CrossRef]

- Tofan, L.; Suteu, D. Renewable Resource Biosorbents for Pollutant Removal from Aqueous Effluents in Column Mode. Separations 2023, 10, 143. [Google Scholar] [CrossRef]

- Horciu, L.I.; Zaharia, C.; Blaga, A.C.; Rusu, L.; Suteu, D. Brilliant Red HE-3B Dye Biosorption by Immobilized Residual Consortium Bacillus sp. Biomass: Fixed-Bed Column Studies. Appl. Sci. 2021, 11, 4498. [Google Scholar] [CrossRef]

- Ksnv, P.; Veluru, S.D.; Rao, P.; Pamu, S.H. Biosorption of dyes onto low cost adsorbent in a fixed bed column. Mater. Today Proc. 2022, 66, 1932–1937. [Google Scholar] [CrossRef]

- Boutaleb, Y.; Zerdoum, R.; Bensid, N.; Abumousa, R.A.; Hattab, Z.; Bououdina, M. Adsorption of Cr(VI) by Mesoporous Pomegranate Peel Biowaste from Synthetic Wastewater under Dynamic Mode. Water 2022, 14, 3885. [Google Scholar] [CrossRef]

- Costa, F.M.A.S.; Seolatto, A.A.; Fontoura, R.S.; Freitas, F.F. Use of brewery spent grains as a biosorbent for reactive blue 5G dye removal: Batch and continuous flow studies. Chem. Eng. Commun. 2023, 210, 147–164. [Google Scholar] [CrossRef]

- Juchen, P.T.; Veit, M.T.; Gonçalves, G.D.C.; Palácio, S.M.; Honório, J.F.; Suzaki, P.Y.R. Biosorption of Dye by Malt Bagasse in a Fixed-Bed Column: Experimental and Theoretical Breakthrough Curves. Water Air Soil Pollut. 2021, 232, 128. [Google Scholar] [CrossRef]

- López-Cervantes, J.; Sánchez-Machado, D.I.; Sánchez-Duarte, R.G.; Correa-Murrieta, M.A. Study of a fixed-bed column in the adsorption of an azo dye from an aqueous medium using a chitosan–glutaraldehyde biosorbent. Adsorpt. Sci. Technol. 2017, 36, 215–232. [Google Scholar] [CrossRef]

- Abrouki, Y.; Mabrouki, J.; Anouzla, A.; Rifi, S.K.; Zahiri, Y.; Nehhal, S.; Souabi, S. Optimization and modeling of a fixed-bed biosorption of textile dye using agricultural biomass from the Moroccan Sahara. Desalination Water Treat. 2021, 240, 144–151. [Google Scholar] [CrossRef]

- Kanamarlapudi, S.L.R.K.; Chintalpudi, V.K.; Muddada, S. Application of Biosorption for Removal of Heavy Metals from Wastewater. Biosorption 2018, 18, 69. [Google Scholar] [CrossRef]

- Parimelazhagan, V.; Jeppu, G.; Rampal, N. Continuous fixed-bed column studies on congo red dye adsorption-desorption using free and immobilized Nelumbo nucifera leaf adsorbent. Polymers 2021, 14, 54. [Google Scholar] [CrossRef]

- Vairavel, P.; Murty, V.R. Continuous fixed-bed adsorption of Congo red dye by dual adsorbent (Neurospora crassa dead fungal biomass and wheat bran): Experimental and theoretical breakthrough curves, immobilization and reusability studies. Desalin. Water Treat 2017, 98, 276–293. [Google Scholar] [CrossRef]

- Conway, J. Beer Production Worldwide from 1998 to 2020 (in Billion Hectoliters). Available online: https://www.statista.com/statistics/270275/worldwide-beer-production/ (accessed on 7 February 2024).

- Kordialik-Bogacka, E. Saccharomyces pastorianus immobilized on brewer’s spent grain in continuous system for lead ion biosorption. Int. Biodeterior. Biodegrad. 2014, 96, 191–197. [Google Scholar] [CrossRef]

- Rusu, L.; Grigoraș, C.-G.; Simion, A.-I.; Suceveanu, E.-M.; Botezatu, A.V.D.; Harja, M. Biosorptive Removal of Ethacridine Lactate from Aqueous Solutions by Saccharomyces pastorianus Residual Biomass/Calcium Alginate Composite Beads: Fixed-Bed Column Study. Materials 2022, 15, 4657. [Google Scholar] [CrossRef] [PubMed]

- Suteu, D.; Blaga, A.C.; Cimpoesu, R.; Puiţel, A.C.; Tataru-Farmus, R.-E. Composites Based on Natural Polymers and Microbial Biomass for Biosorption of Brilliant Red HE-3B Reactive Dye from Aqueous Solutions. Polymers 2021, 13, 4314. [Google Scholar] [CrossRef]

- Suteu, D.; Blaga, A.; Diaconu, M.; Malutan, T. Biosorption of reactive dye from aqueous media using Saccharomyces cerevisiae biomass. Equilibrium and kinetic study. Cent. Eur. J. Chem. 2013, 11, 2048–2057. [Google Scholar] [CrossRef]

- Zaharia, C.; Suteu, D. Textile organic dyes–characteristics, polluting effects, and separation/elimination procedures from industrial effluents. A critical overview. In Organic Pollutants Ten Years after the Stockholm Convention-Environmental and Analytical Update; Puzyn, T., Mostrag-Szlichtyng, A., Eds.; INTECH Publisher: Rijeka, Croatia, 2012; pp. 57–86. ISBN 978-953-307-924-0. [Google Scholar]

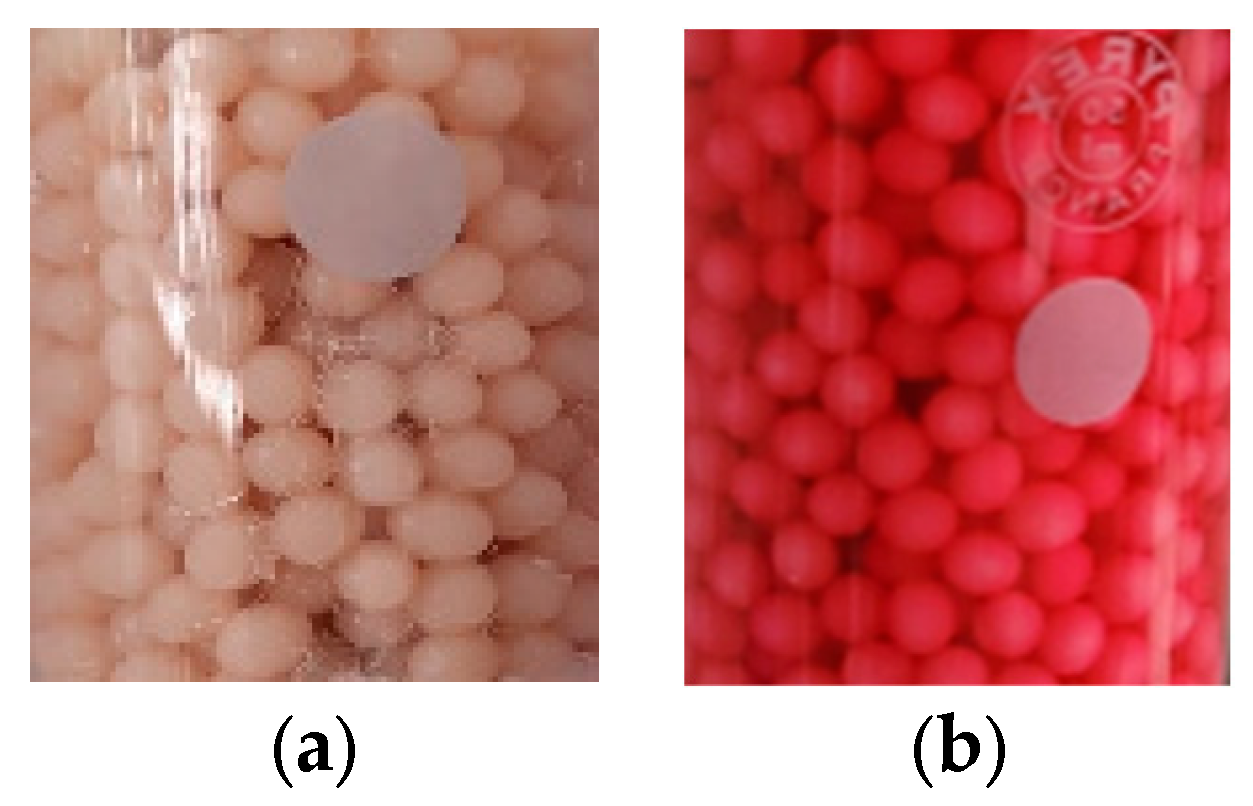

- Blaga, A.C.; Zaharia, C.; Suteu, D. Polysaccharides as Support for Microbial Biomass-Based Adsorbents with Applications in Removal of Heavy Metals and Dyes. Polymers 2021, 13, 2893. [Google Scholar] [CrossRef]

- Han, R.; Wang, Y.; Zhao, X.; Wang, Y.; Xie, F.; Cheng, J.; Tang, M. Adsorption of methylene blue by phoenix tree leaf powder in a fixed-bed column: Experiments and prediction of breakthrough curves. Desalination 2009, 245, 284–297. [Google Scholar] [CrossRef]

- Rouf, S.; Nagapadma, M. Modeling of Fixed Bed Column Studies for Adsorption of Azo Dye on Chitosan Impregnated with a Cationic Surfactant. Int. J. Sci. Eng. Res. 2015, 6, 124–132. [Google Scholar] [CrossRef]

- Alardhi, S.M.; Albayati, T.M.; Alrubaye, J.M. Adsorption of the methyl green dye pollutant from aqueous solution using mesoporous materials MCM-41 in a fixed-bed column. Heliyon 2020, 6, e03253. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Arenas, D.; Macías-Quiroga, I.F.; Dávila-Arias, M.T.; Vélez-Upegui, J.J.; Sanabria-González, N.R. Adsorption of Acid Yellow 23 Dye on Organobentonite/Alginate Hydrogel Beads in a Fixed-Bed Column. J. Compos. Sci. 2023, 7, 362. [Google Scholar] [CrossRef]

- Das, L.; Das, P.; Bhowal, A. Synthesis and application of alginate-nanocellulose composite beads for defluoridation process in a batch and fluidized bed reactor. J. Environ. Manag. 2023, 344, 118569. [Google Scholar] [CrossRef] [PubMed]

- Caesario, B.A.D.; Ali, M.D.R.; Puspitasari, D.; Arnanda, H.K.; Ni’mah, H.; Kurniawansyah, F.; Ningrum, E.O. Cellulose-Based beads for cationic dye removal in continuous adsorption. Mater. Today Proc. 2022, 63, S354–S358. [Google Scholar] [CrossRef]

- Hu, Q.; Xie, Y.; Feng, C.; Zhang, Z. Fractal-like kinetics of adsorption on heterogeneous surfaces in the fixed-bed column. Chem. Eng. J. 2019, 358, 1471–1478. [Google Scholar] [CrossRef]

- De Oliveira, J.T.; de Carvalho Costa, L.R.; Agnol, G.D.; Féris, L.A. Experimental design and data prediction by Bayesian statistics for adsorption of tetracycline in a GAC fixed-bed column. Sep. Purif. Technol. 2023, 319, 124097. [Google Scholar] [CrossRef]

- Amador, I.C.B.; Nunes, K.G.P.; de Franco, M.A.E.; Viegas, B.M.; Macêdo, E.N.; Féris, L.A.; Estumano, D.C. Application of Approximate Bayesian Computational technique to characterize the breakthrough of paracetamol adsorption in fixed bed column. Int. Commun. Heat Mass Transf. 2022, 132, 105917. [Google Scholar] [CrossRef]

- Chojnackaa, K.; Moustakasb, K.; Witek-Krowiakca, A. Bio-based fertilizers: A practical approach towards circular economy. Bioresour. Technol. 2020, 295, 122223. [Google Scholar] [CrossRef]

- Tătaru-Farmuș, R.E.; Zaharia, C.; Șuteu, D.; Blaga, A.C. Biomass-Based Soil in Ecological Agriculture: Characteristics and Wheat Grains Development Trends. J. Appl. Life Sci. Environ. 2021, 187, 273–288. [Google Scholar] [CrossRef]

| Model | kBA | NBA | kYN | τ | rck | Ack | kY | qY | R2 |

|---|---|---|---|---|---|---|---|---|---|

| Bohart–Adams | 0.430281 | −0.65857 | - | - | - | - | - | - | 0.952256 |

| Yoon–Nelson | - | - | 0.02203 | 21.51073 | - | - | - | - | 0.952257 |

| Clark | - | - | - | - | 0.02203 | 1.606224 | - | - | 0.952257 |

| Yan | - | - | - | - | - | - | 1.263763 | 0.258917 | 0.842638 |

| Model | kBA | NBA | kYN | τ | rck | Ack | kY | qY | R2 |

|---|---|---|---|---|---|---|---|---|---|

| Bohart–Adams | 0.19403 | −1.29097 | 0.889542 | ||||||

| Yoon–Nelson | 0.015103 | 36.98367 | 0.889542 | ||||||

| Clark | 0.015103 | 1.74818 | 0.889542 | ||||||

| Yan | 0.736814 | 0.908448 | 0.992838 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suteu, D.; Blaga, A.C.; Rusu, L.; Tanasa, A.M. Saccharomyces pastorianus Residual Biomass Immobilized in a Polymer Matrix as a Biosorbent for Reactive Dye Removal: Investigations in a Dynamic System. Polymers 2024, 16, 491. https://doi.org/10.3390/polym16040491

Suteu D, Blaga AC, Rusu L, Tanasa AM. Saccharomyces pastorianus Residual Biomass Immobilized in a Polymer Matrix as a Biosorbent for Reactive Dye Removal: Investigations in a Dynamic System. Polymers. 2024; 16(4):491. https://doi.org/10.3390/polym16040491

Chicago/Turabian StyleSuteu, Daniela, Alexandra Cristina Blaga, Lacramioara Rusu, and Alexandra Maria Tanasa. 2024. "Saccharomyces pastorianus Residual Biomass Immobilized in a Polymer Matrix as a Biosorbent for Reactive Dye Removal: Investigations in a Dynamic System" Polymers 16, no. 4: 491. https://doi.org/10.3390/polym16040491

APA StyleSuteu, D., Blaga, A. C., Rusu, L., & Tanasa, A. M. (2024). Saccharomyces pastorianus Residual Biomass Immobilized in a Polymer Matrix as a Biosorbent for Reactive Dye Removal: Investigations in a Dynamic System. Polymers, 16(4), 491. https://doi.org/10.3390/polym16040491