Mechanical Testing of Selective-Laser-Sintered Polyamide PA2200 Details: Analysis of Tensile Properties via Finite Element Method and Machine Learning Approaches

Abstract

:1. Introduction

- Aviation and aerospace industry: SLS is used to manufacture critically important parts such as engine components, air and space structures, and for prototyping new designs. This helps to reduce design and development time, as well as to create components with optimal weight and strength characteristics [2].

- Medical industry: In the medical field, SLS is utilized for the production of customized implants, prosthetics, and anatomical models for surgical planning and training [3]. Its ability to create patient-specific solutions contributes to improved patient outcomes and medical advancements.

- Automotive industry: In automotive manufacturing, SLS is utilized for rapid prototyping of parts and functional components [4]. It facilitates the development of innovative designs and allows for the production of complex geometries with high precision, enhancing overall vehicle performance.

- Electronics: SLS technology is employed in the electronics industry for manufacturing housings, casings, and intricate components for electronic devices [5]. It enables the rapid production of prototypes and customized parts, contributing to the development of cutting-edge electronic products.

- Energy industry: Sectors involved in energy equipment production benefit from SLS technology for the fabrication of robust and high-precision components [6]. These components are essential for enhancing the efficiency and reliability of energy systems, including renewable energy technologies.

- Defense industry: SLS is instrumental in the defense sector for producing lightweight, durable, and complex parts for defense systems, including aerospace and ground-based applications [7]. It supports rapid prototyping, testing, and customization of components to meet specific defense requirements.

- Tool and equipment manufacturing: SLS technology is applied in tool and equipment manufacturing for the production of tooling [8], jigs, fixtures, and functional prototypes [9]. Its versatility and ability to create intricate geometries make it a valuable tool for various manufacturing applications.

- PA2200 demonstrates high resistance to oils, fats, various solvents, and other chemical substances, ensuring stability and reliability in different environments [25].

- PA2200 exhibits significant thermal resistance, maintaining stability even at high temperatures [26]. This quality makes it relevant for applications involving elevated temperatures and processes where the material is exposed to high-intensity energy radiation.

- PA2200 combines flexibility and strength, allowing it to withstand deformation and high impact loads without compromising its structural integrity [27].

2. Materials and Methods

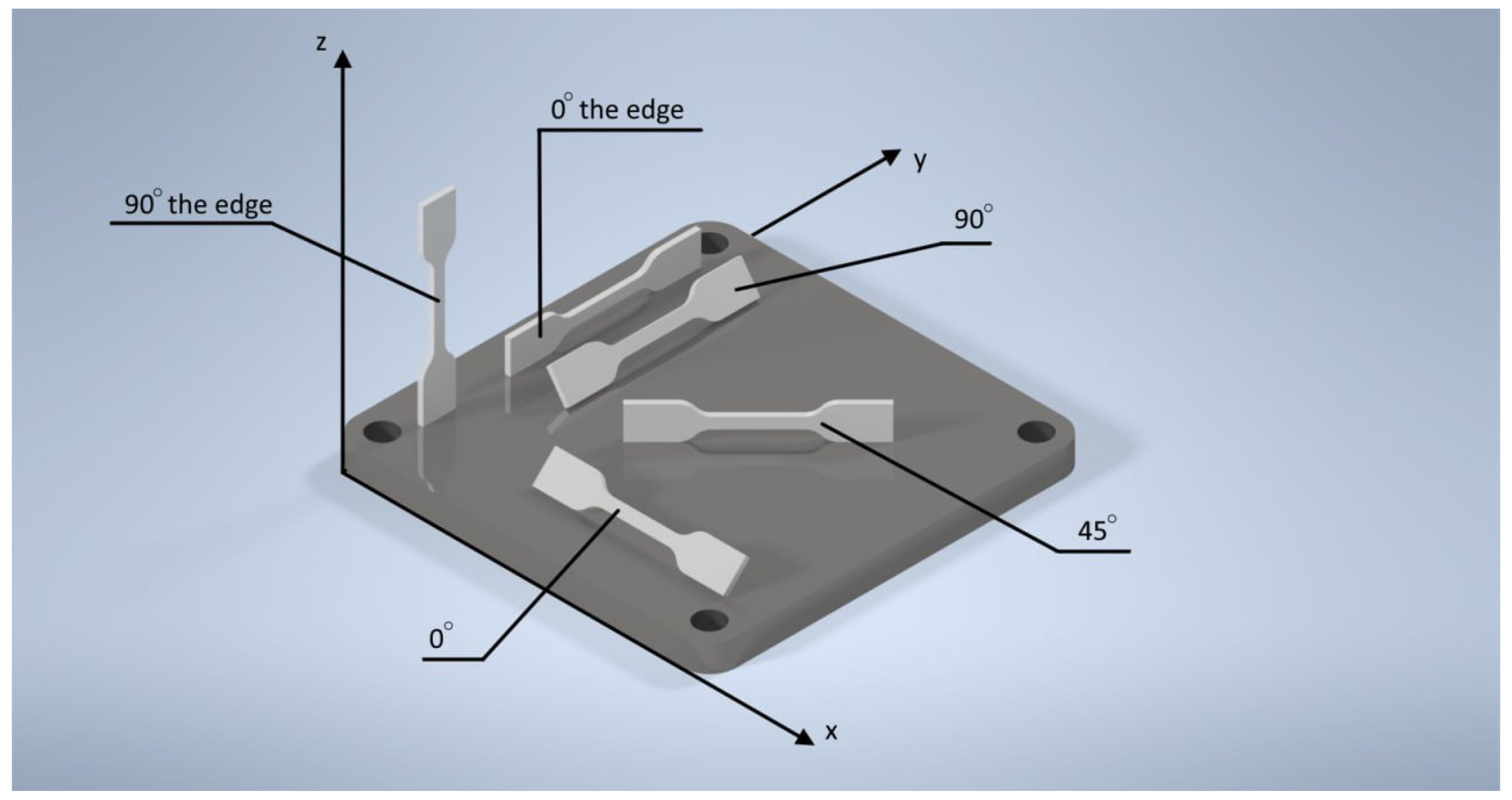

2.1. Fabrication Process

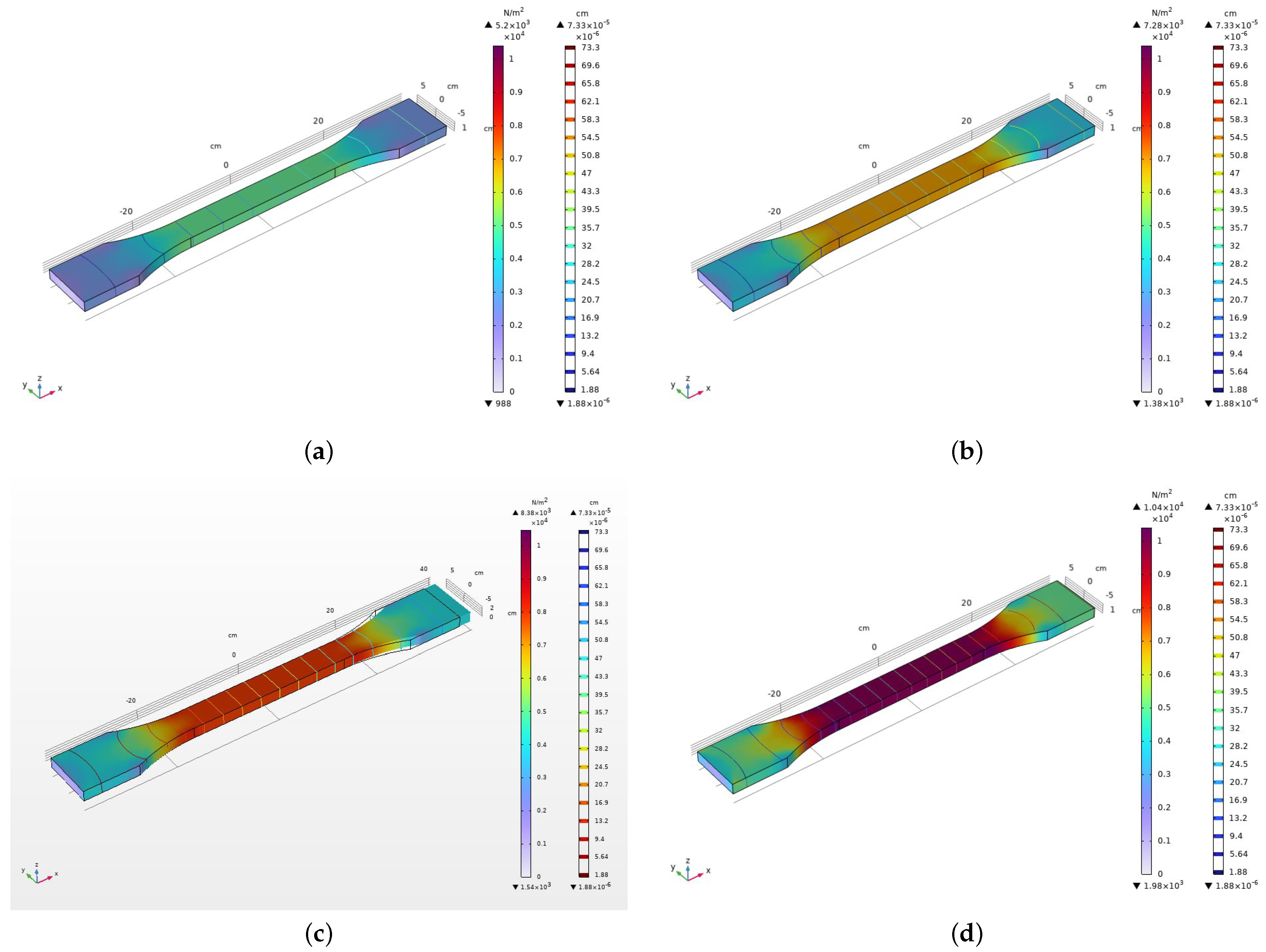

2.2. Finite Element Method Modeling

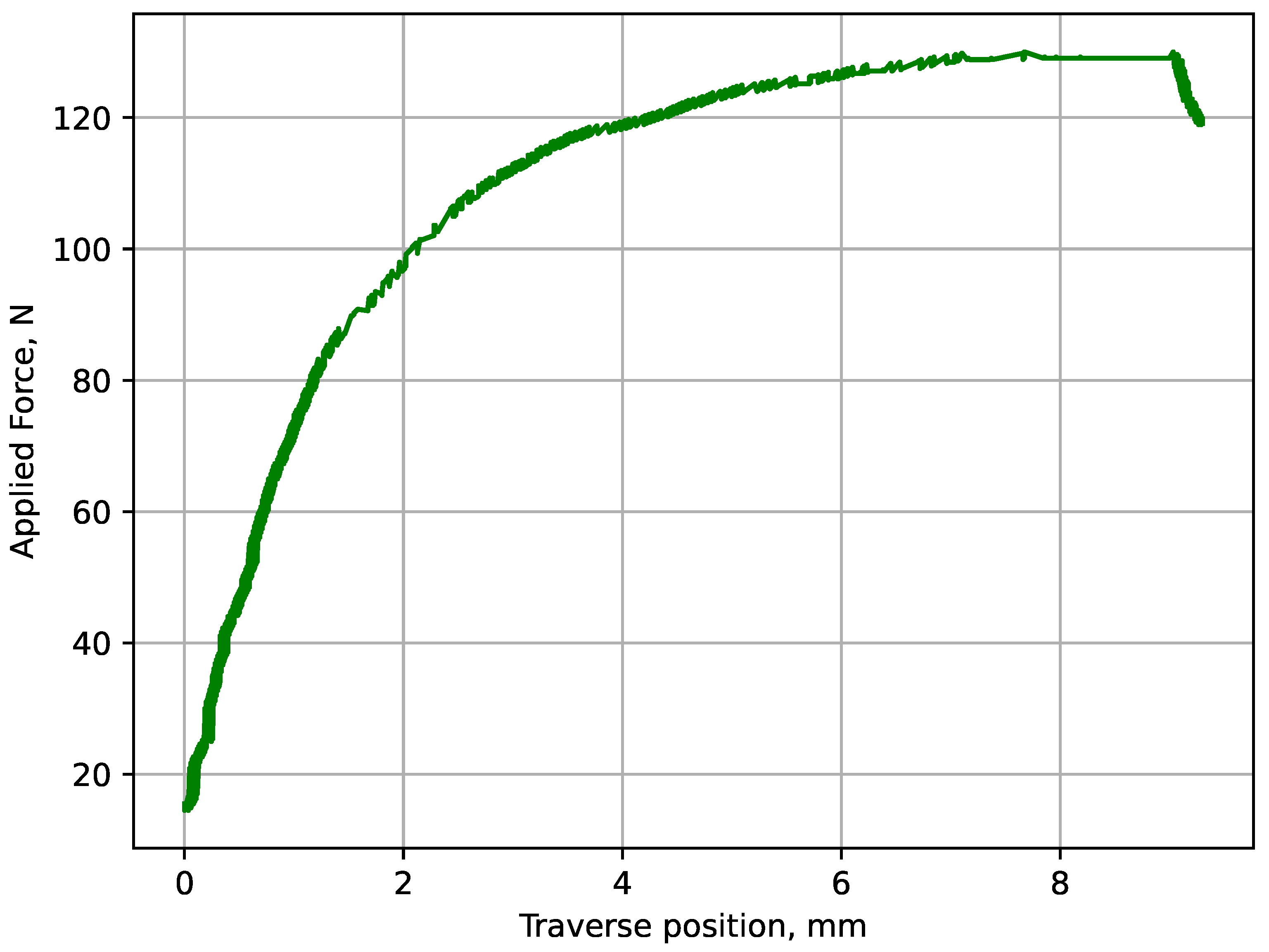

2.3. Experimental Methodology: Conducting Tensile Tests on PA2200 Material Using the QUASAR 50 Universal Testing Machine

3. Results

ML Approach for Predicting Calculated Characteristics

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kruth, J.P.; Wang, X.; Laoui, T.; Froyen, L. Lasers and materials in selective laser sintering. Assem. Autom. 2003, 23, 357–371. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Saffarzadeh, M.; Gillispie, G.J.; Brown, P. Selective Laser Sintering (SLS) rapid protytping technology: A review of medical applications. In Proceedings of the 53rd Annual Rocky Mountain Bioengineering Symposium, RMBS 2016 and 53rd International ISA Biomedical Sciences Instrumentation Symposium, Denver, CO, USA, 8–10 April 2016; pp. 8–10. [Google Scholar]

- Kruf, W.; van de Vorst, B.; Maalderink, H.; Kamperman, N. Design for rapid manufacturing functional SLS parts. In Intelligent Production Machines and Systems; Elsevier: Amsterdam, The Netherlands, 2006; pp. 389–394. [Google Scholar]

- Roy, N.K.; Behera, D.; Dibua, O.G.; Foong, C.S.; Cullinan, M.A. A novel microscale selective laser sintering (μ-SLS) process for the fabrication of microelectronic parts. Microsyst. Nanoeng. 2019, 5, 64. [Google Scholar] [CrossRef] [PubMed]

- Shulunov, V.R. Several advantages of the ultra high-precision additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2016, 85, 1941–1945. [Google Scholar] [CrossRef]

- Mouzakis, D.E. Advanced technologies in manufacturing 3D-layered structures for defense and aerospace. Lamination-Theory Appl. 2018, 74331. [Google Scholar]

- Berry, E.; Brown, J.; Connell, M.; Craven, C.; Efford, N.; Radjenovic, A.; Smith, M. Preliminary experience with medical applications of rapid prototyping by selective laser sintering. Med. Eng. Phys. 1997, 19, 90–96. [Google Scholar] [CrossRef]

- Singhal, S.; Jain, P.K.; Pandey, P.M. Adaptive Slicing for SLS Prototyping. Comput.-Aided Des. Appl. 2008, 5, 412–423. [Google Scholar] [CrossRef]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process phenomena and material properties in selective laser sintering of polymers: A review. Materials 2021, 15, 183. [Google Scholar] [CrossRef]

- Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. Selective laser sintering (SLS) 3D printing of medicines. Int. J. Pharm. 2017, 529, 285–293. [Google Scholar] [CrossRef]

- Gueche, Y.A.; Sanchez-Ballester, N.M.; Cailleaux, S.; Bataille, B.; Soulairol, I. Selective laser sintering (SLS), a new chapter in the production of solid oral forms (SOFs) by 3D printing. Pharmaceutics 2021, 13, 1212. [Google Scholar] [CrossRef]

- Pilipović, A.; Brajlih, T.; Drstvenšek, I. Influence of processing parameters on tensile properties of SLS polymer product. Polymers 2018, 10, 1208. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; De Coninck, F.; Moens, D.; Boonen, R.; Sas, P. Microstructural characterization of SLS-PA12 specimens under dynamic tension/compression excitation. Polym. Test. 2010, 29, 319–326. [Google Scholar] [CrossRef]

- Faraj, Z.; Zaki, S.; Aboussaleh, M.; Abouchadi, H. Influence of processing parameters on tensile properties of PA12 parts manufactured by selective laser sintering. Int. J. Adv. Manuf. Technol. 2023, 128, 1115–1125. [Google Scholar] [CrossRef]

- Jevtić, I.; Golubović, Z.; Mladenović, G.; Berto, F.; Sedmak, A.; Milovanović, A.; Milošević, M. Printing orientation influence on tensile strength of PA12 specimens obtained by SLS. J. Mech. Sci. Technol. 2023, 37, 5549–5554. [Google Scholar] [CrossRef]

- Pilipović, A.; Ilinčić, P.; Tujmer, M.; Rujnić Havstad, M. Impact of Part Positioning along Chamber Z-Axis and Processing Parameters in Selective Laser Sintering on Polyamide Properties. Appl. Sci. 2024, 14, 976. [Google Scholar] [CrossRef]

- Razaviye, M.K.; Tafti, R.A.; Khajehmohammadi, M. An investigation on mechanical properties of PA12 parts produced by a SLS 3D printer: An experimental approach. CIRP J. Manuf. Sci. Technol. 2022, 38, 760–768. [Google Scholar] [CrossRef]

- Tomanik, M.; Żmudzińska, M.; Wojtków, M. Mechanical and structural evaluation of the PA12 desktop selective laser sintering printed parts regarding printing strategy. 3D Print. Addit. Manuf. 2021, 8, 271–279. [Google Scholar] [CrossRef]

- Wörz, A.; Wudy, K.; Drummer, D. Understanding the Influence of Energy-Density of the Layer Dependent Part Properties in Laser-Sintering of PA12. In Proceedings of the 2019 International Solid Freeform Fabrication Symposium, University of Texas at Austin, Austin, TX, USA, 12–14 August 2019. [Google Scholar]

- Hofland, E.C.; Baran, I.; Wismeijer, D.A. Correlation of process parameters with mechanical properties of laser sintered PA12 parts. Adv. Mater. Sci. Eng. 2017, 2017, 4953173. [Google Scholar] [CrossRef]

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J. Mater. Process. Technol. 2021, 288, 116882. [Google Scholar] [CrossRef]

- D’Onofrio, S.; Bignotti, F. Surface modification of polyamide 12 angioplasty balloons by photochemical reaction with an aromatic azide. Polym. Adv. Technol. 2019, 30, 51–57. [Google Scholar] [CrossRef]

- Kondo, M.Y.; Montagna, L.S.; Morgado, G.F.d.M.; Castilho, A.L.G.d.; Batista, L.A.P.d.S.; Botelho, E.C.; Costa, M.L.; Passador, F.R.; Rezende, M.C.; Ribeiro, M.V. Recent advances in the use of Polyamide-based materials for the automotive industry. Polímeros 2022, 32, e2022023. [Google Scholar] [CrossRef]

- Ladkau, N.; Assmann, M.; Schrewe, M.; Julsing, M.K.; Schmid, A.; Bühler, B. Efficient production of the Nylon 12 monomer ω-aminododecanoic acid methyl ester from renewable dodecanoic acid methyl ester with engineered Escherichia coli. Metab. Eng. 2016, 36, 1–9. [Google Scholar] [CrossRef]

- Mwania, F.M.; Maringa, M.; Van der Walt, K. A review of methods used to reduce the effects of high temperature associated with polyamide 12 and polypropylene laser sintering. Adv. Polym. Technol. 2020, 2020, 9497158. [Google Scholar] [CrossRef]

- McCardle, J.R.; Bunyan, J. Observation of impact energy absorption performance on idealised trabecular forms in laser sintered nylon. Rapid Prototyp. J. 2016, 22, 895–900. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, T.; Ju, W.; Shi, S. Materials discovery and design using machine learning. J. Mater. 2017, 3, 159–177. [Google Scholar] [CrossRef]

- Wegner, A.; Mielicki, C.; Grimm, T.; Gronhoff, B.; Witt, G.; Wortberg, J. Determination of robust material qualities and processing conditions for laser sintering of polyamide 12. Polym. Eng. Sci. 2014, 54, 1540–1554. [Google Scholar] [CrossRef]

- Vygodskii, Y.S.; Lozinskaya, E.I.; Shaplov, A.S. Ionic Liquids as Novel Reaction Media for the Synthesis of Con densation Polymers. Macromol. Rapid Commun. 2002, 23, 676–680. [Google Scholar] [CrossRef]

- Griehl, W.; Ruestem, D. Nylon-12-preparation, properties, and applications. Ind. Eng. Chem. 1970, 62, 16–22. [Google Scholar] [CrossRef]

- David Müzel, S.; Bonhin, E.P.; Guimarães, N.M.; Guidi, E.S. Application of the finite element method in the analysis of composite materials: A review. Polymers 2020, 12, 818. [Google Scholar] [CrossRef]

- Jagota, V.; Sethi, A.; Kumar, D.K. Finite Element Method: An Overview. Walailak J. Sci. Technol. 2013, 10, 1–8. [Google Scholar]

- Safronov, Y.V.; Nosko, A. Experimental evaluation of the load capacity of the rollers of gravity conveyors for pallets. Izv. MGTU MAMI 2020, 14, 59–64. [Google Scholar] [CrossRef]

- Tan, J.; Yang, J.; Wu, S.; Chen, G.; Zhao, J. A critical look at the current train/test split in machine learning. arXiv 2021, arXiv:2106.04525. [Google Scholar]

- Köksoy, O. Multiresponse robust design: Mean square error (MSE) criterion. Appl. Math. Comput. 2006, 175, 1716–1729. [Google Scholar] [CrossRef]

- Luo, H.; Cheng, F.; Yu, H.; Yi, Y. SDTR: Soft decision tree regressor for tabular data. IEEE Access 2021, 9, 55999–56011. [Google Scholar] [CrossRef]

- El Mrabet, Z.; Sugunaraj, N.; Ranganathan, P.; Abhyankar, S. Random forest regressor-based approach for detecting fault location and duration in power systems. Sensors 2022, 22, 458. [Google Scholar] [CrossRef]

- Keprate, A.; Ratnayake, R.C. Using gradient boosting regressor to predict stress intensity factor of a crack propagating in small bore piping. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 1331–1336. [Google Scholar]

- Terrault, N.A.; Hassanein, T.I. Management of the patient with SVR. J. Hepatol. 2016, 65, S120–S129. [Google Scholar] [CrossRef]

- Yao, B. Walmart sales prediction based on decision tree, random forest, and K neighbors regressor. Simulation 2023, 5, 330–335. [Google Scholar] [CrossRef]

- Radulović, D.; Negovanović, D. Gait speed prediction based on walking parameters using MLPRegressor. Ri-STEM-2021 2021, 13. Available online: https://www.researchgate.net/profile/Sandi-Baressi-Segota/publication/352311675_Ri-STEM-2021_Conference_Proceedings/links/60c31657299bf1949f49a4f6/Ri-STEM-2021-Conference-Proceedings.pdf#page=20 (accessed on 25 June 2021).

- McDonald, G.C. Ridge regression. Wiley Interdiscip. Rev. Comput. Stat. 2009, 1, 93–100. [Google Scholar] [CrossRef]

- Osborne, M.R.; Presnell, B.; Turlach, B.A. On the lasso and its dual. J. Comput. Graph. Stat. 2000, 9, 319–337. [Google Scholar]

- Lekurwale, S.; Karanwad, T.; Banerjee, S. Selective laser sintering (SLS) of 3D printlets using a 3D printer comprised of IR/red-diode laser. Ann. 3D Print. Med. 2022, 6, 100054. [Google Scholar] [CrossRef]

- Calignano, F.; Giuffrida, F.; Galati, M. Effect of the build orientation on the mechanical performance of polymeric parts produced by multi jet fusion and selective laser sintering. J. Manuf. Process. 2021, 65, 271–282. [Google Scholar] [CrossRef]

- Pant, P.; Sjöström, S.; Simonsson, K.; Moverare, J.; Proper, S.; Hosseini, S.; Luzin, V.; Peng, R. A simplified layer-by-layer model for prediction of residual stress distribution in additively manufactured parts. Metals 2021, 11, 861. [Google Scholar] [CrossRef]

- Borzan, C.; Dudescu, M.; Elghany, K.; Ceclan, V.; Berce, P. Analysis of Mechanical Proprieties of Selective Laser Sintered Polyamide Parts Obtained on Different Equipment. Mater. Plast. 2015, 52, 39. [Google Scholar]

- Lozhkin, D.; Maksimov, P. Topological optimization of a part taking into account technological constraints. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1100, 012036. [Google Scholar] [CrossRef]

| № | H, cm | B, cm | , | , MPa | , N | , MPa | , N | , MPa | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 0.64 | 10.1 | 6.46 | 44 | 6.8 | 68 | 10.5 | 131 | 20.3 | 14 |

| 2 | 0.63 | 10 | 6.3 | 46 | 7.3 | 67.3 | 10.7 | 128 | 20.4 | 13.6 | |

| 3 | 0.63 | 10 | 6.3 | 44.5 | 7.06 | 61.3 | 9.7 | 127.5 | 20.3 | 14 | |

| 45 | 1 | 0.64 | 10 | 6.4 | 46.6 | 7.28 | 72.3 | 11.3 | 142.6 | 22.3 | 14.6 |

| 2 | 0.61 | 10 | 6.1 | 45.7 | 7.5 | 73.8 | 12.01 | 137.6 | 22.6 | 14.6 | |

| 3 | 0.63 | 10 | 6.3 | 50 | 7.93 | 77.7 | 12.3 | 142 | 22.6 | 13.4 | |

| 4 | 0.63 | 10 | 6.3 | 46.6 | 7.4 | 62.7 | 9.95 | 134.8 | 21.2 | 12.8 | |

| 90 | 1 | 0.71 | 10 | 7.1 | 48.7 | 6.86 | 73.3 | 10.32 | 143.2 | 20.17 | 13.4 |

| 2 | 0.64 | 10 | 6.4 | 45 | 7.03 | 68.4 | 10.69 | 129.4 | 20.22 | 13.4 | |

| 3 | 0.62 | 10 | 6.2 | 49.4 | 7.97 | 68.4 | 11.03 | 135.7 | 21.89 | 14 | |

| 4 | 0.64 | 10 | 6.4 | 47.2 | 7.38 | 69 | 10.78 | 129.6 | 20.25 | 13.7 |

| № | H, cm | B, cm | , | , MPa | , N | , MPa | , N | , MPa | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 0.57 | 10.25 | 5.84 | 28 | 4.79 | 42.8 | 7.33 | 78.4 | 13.42 | 8.8 |

| 2 | 0.57 | 10.3 | 5.87 | 30.5 | 5.20 | 43.4 | 7.39 | 73.3 | 12.49 | 7.1 | |

| 3 | 0.57 | 10.25 | 5.84 | 26.4 | 4.52 | 43.1 | 7.38 | 73.6 | 12.60 | 5.9 | |

| 4 | 0.57 | 10.25 | 5.84 | 33.1 | 5.67 | 47.8 | 8.18 | 84.5 | 14.46 | 7.7 | |

| 90 | 1 | 0.56 | 10.25 | 5.74 | 27.5 | 4.79 | 38.9 | 6.78 | 72.4 | 12.61 | 7.3 |

| 2 | 0.53 | 10.25 | 5.43 | 23.2 | 4.27 | 34.4 | 6.33 | 61.6 | 11.34 | 7.3 | |

| 3 | 0.53 | 10.25 | 5.43 | 22.9 | 4.22 | 36.5 | 6.72 | 65.7 | 12.09 | 7.4 |

| Regressor | , MPa | , N | , MPa | , N | , MPa | ||

|---|---|---|---|---|---|---|---|

| LinearRegression [29] | 0.10 | 0.00 | 0.23 | 0.01 | 0.93 | 0.02 | 2.38 |

| DecisionTreeRegressor [37] | 18.09 | 0.24 | 13.41 | 1.35 | 15.52 | 0.16 | 1.08 |

| RandomForestRegressor [38] | 9.06 | 0.28 | 11.93 | 0.58 | 9.84 | 0.62 | 0.31 |

| GradientBoostingRegressor [39] | 10.26 | 0.28 | 15.21 | 0.53 | 7.31 | 0.94 | 0.52 |

| SVR [40] | 7.69 | 0.38 | 29.94 | 0.90 | 35.35 | 2.24 | 0.12 |

| KNeighborsRegressor [41] | 6.80 | 0.41 | 19.10 | 0.72 | 9.79 | 1.27 | 0.12 |

| MLPRegressor [42] | 69.33 | 0.62 | 86.87 | 2.26 | 12.54 | 90.99 | 3.01 |

| Ridge [43] | 6.32 | 0.04 | 8.36 | 0.03 | 21.84 | 0.71 | 0.63 |

| Lasso [44] | 5.99 | 0.43 | 10.83 | 0.35 | 20.17 | 1.03 | 0.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malashin, I.; Martysyuk, D.; Tynchenko, V.; Nelyub, V.; Borodulin, A.; Galinovsky, A. Mechanical Testing of Selective-Laser-Sintered Polyamide PA2200 Details: Analysis of Tensile Properties via Finite Element Method and Machine Learning Approaches. Polymers 2024, 16, 737. https://doi.org/10.3390/polym16060737

Malashin I, Martysyuk D, Tynchenko V, Nelyub V, Borodulin A, Galinovsky A. Mechanical Testing of Selective-Laser-Sintered Polyamide PA2200 Details: Analysis of Tensile Properties via Finite Element Method and Machine Learning Approaches. Polymers. 2024; 16(6):737. https://doi.org/10.3390/polym16060737

Chicago/Turabian StyleMalashin, Ivan, Dmitriy Martysyuk, Vadim Tynchenko, Vladimir Nelyub, Aleksei Borodulin, and Andrey Galinovsky. 2024. "Mechanical Testing of Selective-Laser-Sintered Polyamide PA2200 Details: Analysis of Tensile Properties via Finite Element Method and Machine Learning Approaches" Polymers 16, no. 6: 737. https://doi.org/10.3390/polym16060737

APA StyleMalashin, I., Martysyuk, D., Tynchenko, V., Nelyub, V., Borodulin, A., & Galinovsky, A. (2024). Mechanical Testing of Selective-Laser-Sintered Polyamide PA2200 Details: Analysis of Tensile Properties via Finite Element Method and Machine Learning Approaches. Polymers, 16(6), 737. https://doi.org/10.3390/polym16060737